Page 1

03/10/03 9/7/2017 HDD, MANUAL

Vestil Manufacturing Corp.

2999 North Wayne Street, P.O. Box 507, Angola, IN 46703

Telephone: (260) 665-7586 -or- Toll Free (800) 348-0868

Fax: (260) 665-1339

Web: www.vestilmfg.com e-mail: info@vestil.com

HDD-Series Hydraulic Drum Dumpers

Instruction Manual

Receiving instructions:

After delivery, remove the packaging from the product. Inspect the product closely to determine whether it

sustained damage during transport. If damage is discovered, record a complete description of it on the bill of

lading. If the product is undamaged, discard the packaging.

NOTE:

The end-user is solely responsible for confirming that product design, installation, use, and maintenance

comply with laws, regulations, codes, and mandatory standards applied where the product is used.

Table of Contents Table of Figures

Product Specifications……………………........... 2-3 FIG. 1: HDD-36-S exploded parts diagram……………….. 5

Signal Words……….………………..................... 4 FIG. 2: HDD-48-S exploded parts diagram……………….. 5

Safe Use Recommendations……...................... 4 FIG. 3: HDD-60-S exploded parts diagram……………….. 6

Installation Instructions…………………………... 11 FIG. 4: HDD-72-S exploded parts diagram……………….. 6

Loading the Dumper……………………………… 11 FIG. 5: HDD-36-P exploded parts diagram..………..…….. 7

Inspections………………………………………… 11-12 FIG. 6: HDD-48-P exploded parts diagram……………...... 8

Power unit operation……………………….......... 12-13 FIG. 7: HDD-60-P exploded parts diagram……………...... 9

Troubleshooting guide…………………………… 23 FIG. 8: HDD-72-S exploded parts diagram……………..... . 10

Labeling Diagram…….…………………………… 24 FIG. 9: Hydraulic Circuit Diagram………………………..... . 13

Limited warranty………………………………….. 25 FIGS. 10A-10F: Electrical Circuit Diagrams……………….. 14-19

FIG. 11: Motor Lead Diagrams & Transformer diagram…. 20

FIGS. 12A-12B: Modular Power Unit parts diagram…….. . 21-22

Copyright 2017 Vestil Manufacturing Co. 1 of 25

Page 2

03/10/03 9/7/2017 HDD, MANUAL

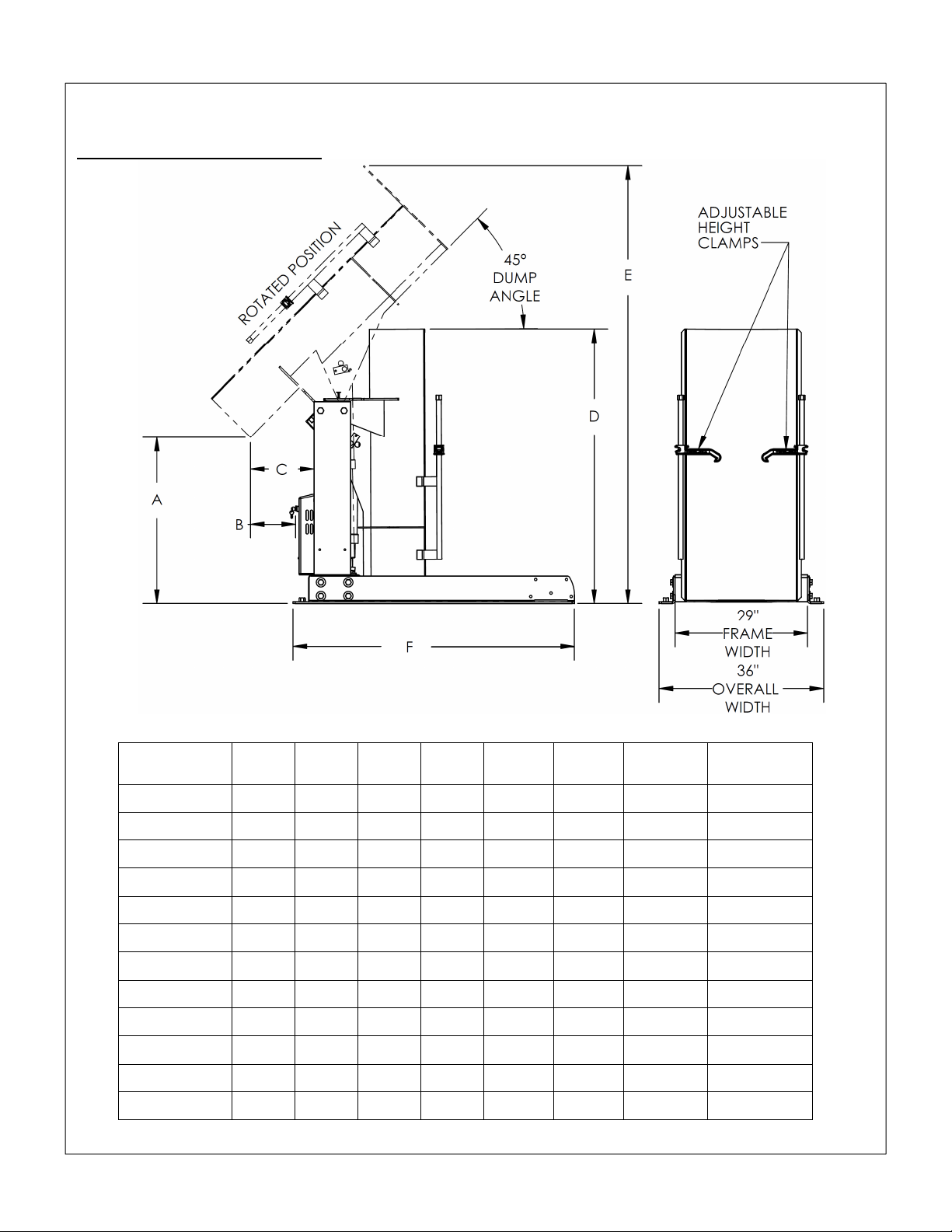

Product Specifications:

Dimensions and other product attributes appear in the diagrams and table below:

Stationary (bolt-down) HDD models

Model A B C D E F Capacity Net weight

HDD-36-7-S 36” 93/4” 14” 60” 953/4” 611/2 750 lb. 709 lb.

HDD-36-10-S 36” 93/4” 14” 60” 953/4” 611/2 1,000 lb. 727 lb.

HDD-36-15-S 36” 93/4” 14” 60” 953/4” 611/2 1,500 lb. 786 lb.

HDD-48-7-S 48” 93/4” 14” 72” 116” 711/2 750 lb. 800 lb.

HDD-48-10-S 48” 93/4” 14” 72” 116” 711/2 1,000 lb. 792 lb.

HDD-48-15-S 48” 93/4” 14” 72” 116” 711/2 1,500 lb. 814 lb.

HDD-60-7-S 60” 93/4” 14” 84” 1363/4” 80” 750 lb. 988 lb.

HDD-60-10-S 60” 93/4” 14” 84” 1363/4” 80” 1,000 lb. 942 lb.

HDD-60-15-S 60” 93/4” 14” 84” 1363/4” 80” 1,500 lb. 937 lb.

HDD-72-7-S 72” 91/2” 131/2” 951/4” 1571/4” 92” 750 lb. 1,113 lb.

HDD-72-10-S 72” 91/2” 131/2” 951/4” 1571/4” 92” 1,000 lb. 1,055 lb.

HDD-72-15-S 72” 91/2” 131/2” 951/2” 1571/4” 92” 1,500 lb. 1,036 lb.

Copyright 2017 Vestil Manufacturing Co. 2 of 25

Page 3

03/10/03 9/7/2017 HDD, MANUAL

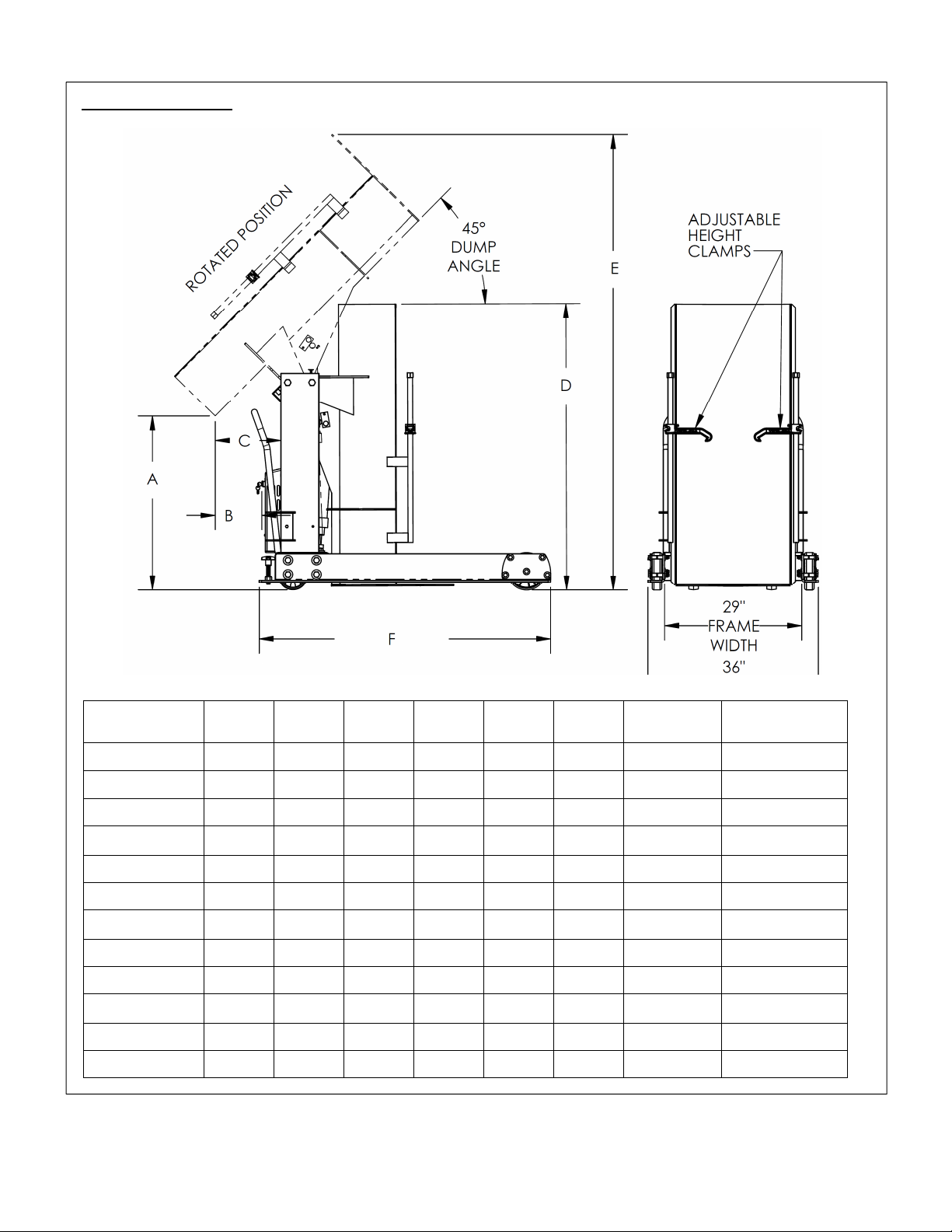

Portable HDD models

Model A B C D E F Capacity Net weight

HDD-36-7-P 36” 93/4” 14” 633/4” 96” 611/2” 750 lb. 788 lb.

HDD-36-10-P 36” 93/4” 14” 633/4” 96” 611/2” 1,000 lb. 763 lb.

HDD-36-15-P 36” 93/4” 14” 633/4” 96” 611/2” 1,500 lb. 776 lb.

HDD-48-7-P 48” 93/4” 14” 721/2” 1163/4” 711/2” 750 lb. 864 lb.

HDD-48-10-P 48” 93/4” 14” 721/2” 1163/4” 711/2” 1,000 lb. 862 lb.

HDD-48-15-P 48” 93/4” 14” 721/2” 1163/4” 711/2” 1,500 lb. 880 lb.

HDD-60-7-P 60” 93/4” 14” 841/2” 1371/4” 80” 750 lb. 1,019 lb.

HDD-60-10-P 60” 93/4” 14” 841/2” 1371/4” 80” 1,000 lb. 1,042 lb.

HDD-60-15-P 60” 93/4” 14” 841/2” 1371/4” 80” 1,500 lb. 1,026 lb.

HDD-72-7-P 72” 91/4” 131/2” 96” 1571/2” 92” 750 lb. 1,034 lb.

HDD-72-10-P 72” 91/4” 131/2” 96” 1571/2” 92” 1,000 lb. 1,100 lb.

HDD-72-15-P 72” 91/4” 131/2” 96” 1571/2” 92” 1,500 lb. 1,115 lb.

Copyright 2017 Vestil Manufacturing Co. 3 of 25

Page 4

03/10/03 9/7/2017 HDD, MANUAL

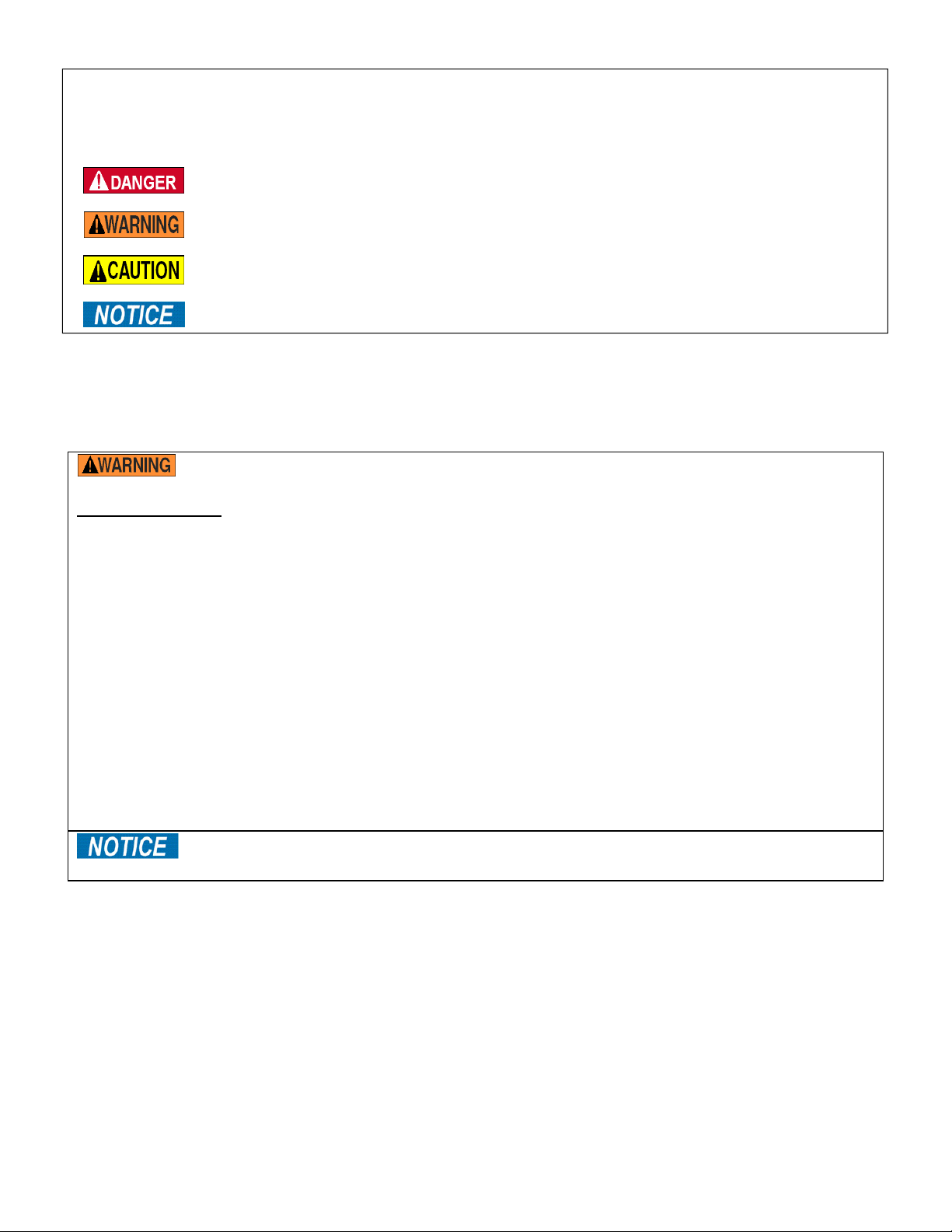

Signal Words:

This manual uses SIGNAL WORDS to indicate the likelihood of personal injuries, as well as the probable seriousness

of those injuries, if the product is misused in the ways described. Other signal words call attention to uses of the

product likely cause property damage. The signal words used appear below along with the meaning of each word:

Identifies a hazardous situation which, if not avoided, WILL result in DEATH or SERIOUS

INJURY. Use of this signal word is limited to the most extreme situations.

Identifies a hazardous situation which, if not avoided, COULD result in DEATH or SERIOUS

INJURY.

Indicates a hazardous situation which, if not avoided, COULD result in MINOR or

MODERATE injury

.

Identifies practices likely to result in product/property damage, such as operation that might

damage the product.

Safe Use Recommendations:

We strive to identify all hazards associated with the use of our products. However, material handling is dangerous and

no manual can address every risk. Ultimately, the most effective way to avoid injury is to exercise sound judgment

whenever using this product.

Improper or careless operation of this drum dumper might result in serious personal injuries.

Failure to read and understand the entire manual before assembling, using or servicing the product

constitutes misuse. Read the manual whenever necessary to refresh your understanding of proper use and

maintenance procedures.

ONLY use the dumper as a means for mechanically emptying drum. ALWAYS properly load the dumper

according to the directions on p. 11.

DO NOT use a damaged dumper. Examples of structural damage include: broken container restraining tube,

broken fork pockets, and holes caused by rust or corrosion. Inspect the dumper before each use according to the

inspection instructions on p. 11-12. DO NOT use the HBD unless it passes every element of the inspection, or until

authorized maintenance personnel approve the dumper for service.

Inspect the unit before each use according to the inspection instructions on p. 11-12.

DO NOT stand beneath or travel under the dumper chute while it is elevated.

DO NOT use this dumper UNLESS every label shown in the “Labeling diagram” on p. 24 is in place, undamaged,

and easily readable.

DO NOT exceed the capacity of the dumper. The capacity of each model appears in the tables on pp. 2-3 as well

as on label 287 (see “Labeling diagram” on p. 24). The weight of the container to be dumped plus the weight of its

contents must not exceed the capacity.

DO NOT modify the dumper in any way UNLESS you first obtain written approval from Vestil. Modifying the

dumper without first receiving approval automatically voids the limited warranty and might make the dumper unsafe

to use.

DO NOT fill the hydraulic system with brake fluid or jack oils. Only fill the hydraulic system with

either anti-wear hydraulic oil, viscosity grade 150 SUS at 100°F (ISO 32cSt at 40°C) or Dexron transmission fluid.

Copyright 2017 Vestil Manufacturing Co. 4 of 25

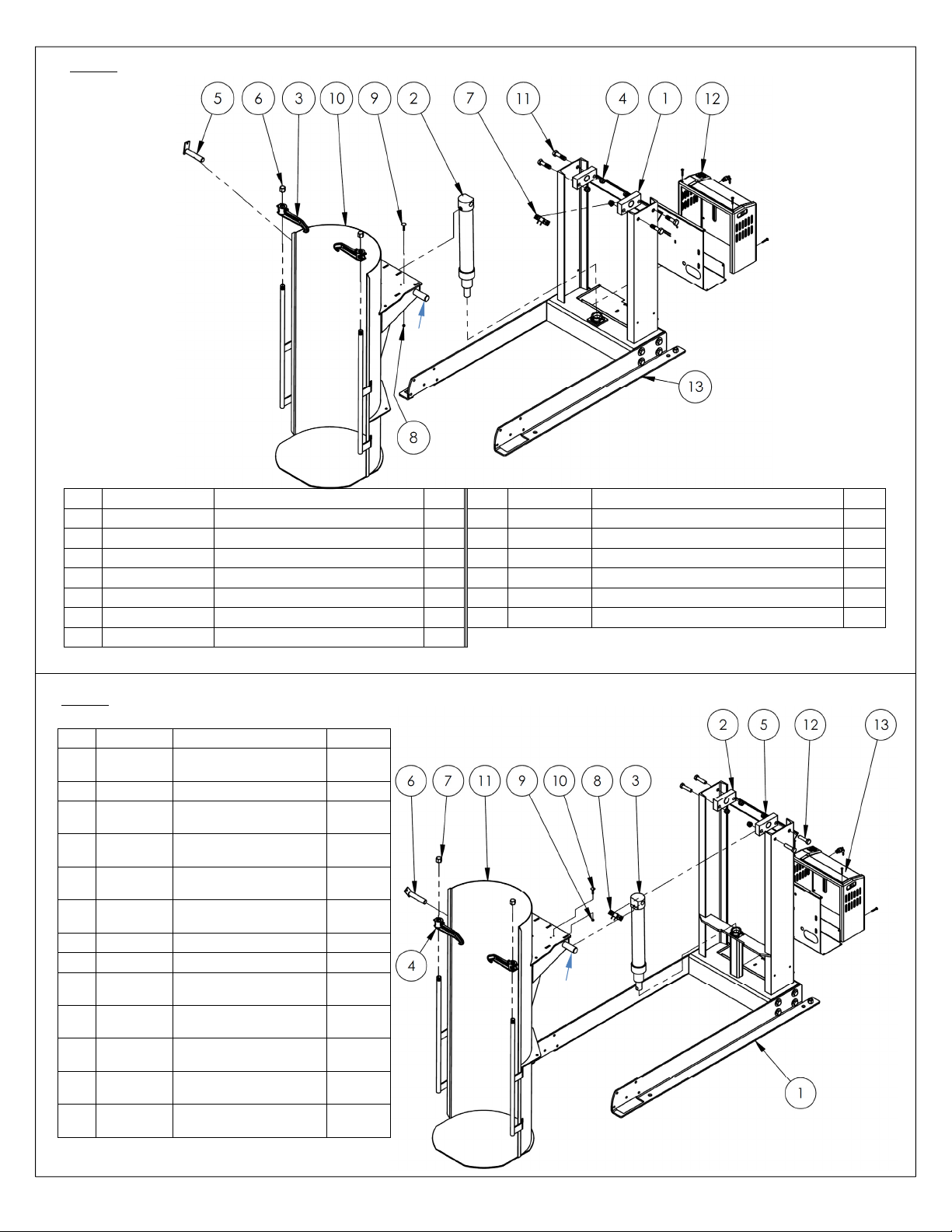

Page 5

03/10/03 9/7/2017 HDD, MANUAL

shaft

shaft

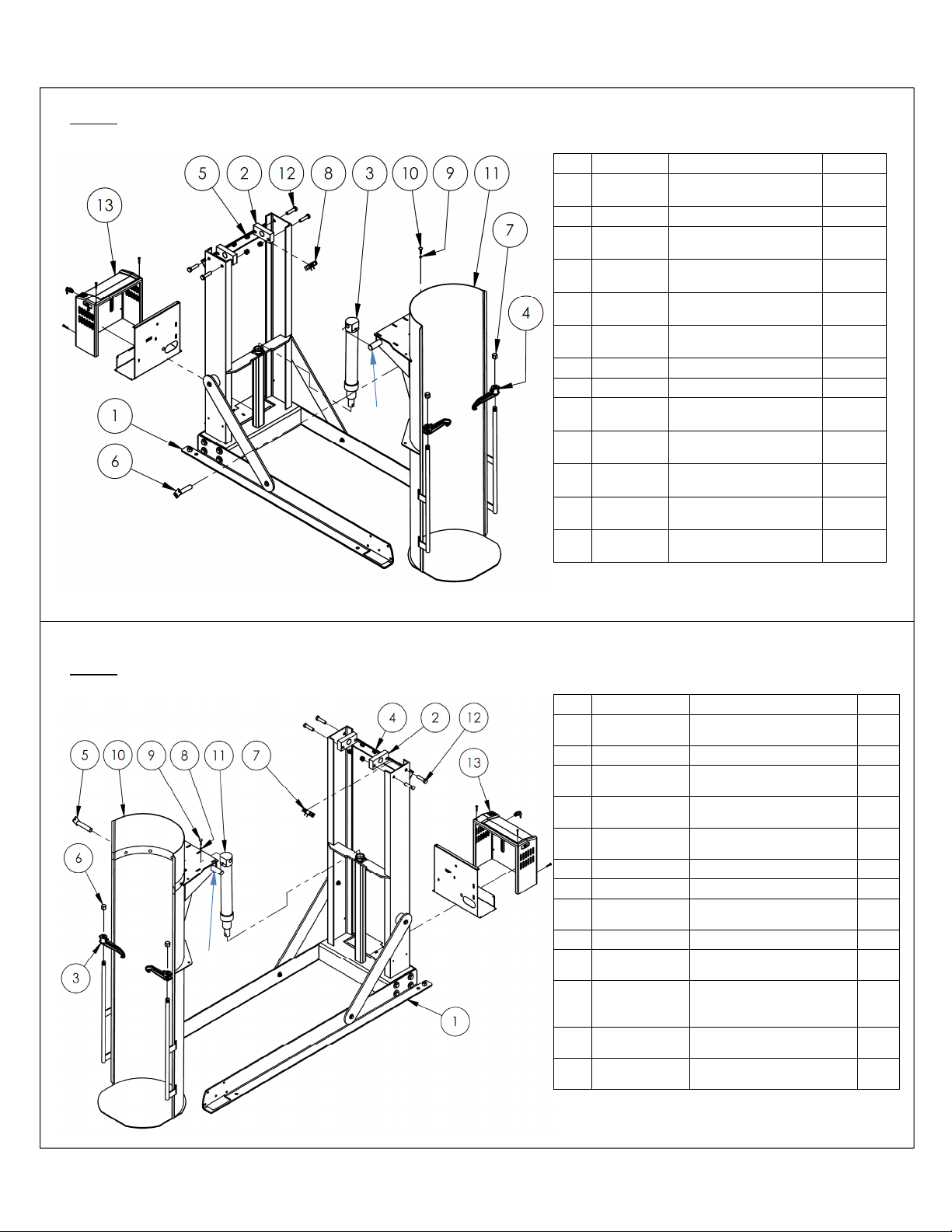

FIG. 1: HDD-36-S series stationary dumpers exploded parts diagram and bill of materials

Pivot

Item

1 09-512-001 Hinge block assembly 2 8 36102 Hex nut, grade A, zinc-plated, 1/4” - 20 1

2 99-021-909-001 Hydraulic cylinder, 21/2” x 18” 1 9 22805 Elevator bolt, limit switch 1

3 09-537-013 Assembly, drum clamp, casting 2 10 09-545-028 Weldment, subassembly, chute 1

4 37039 Nylock nut, zinc-plated, 3/4” – 10 4 11 12365 3/4” – 10UNC x 3” zinc-plated #5 bolt 4

5 24-612-003 Pin assembly, cylinder 1 12 99-158-008 Modular power unit, no push buttons 1

6 09-145-020 Threaded pipe cap 2 13 09-514-131 Weldment, frame, stationary 1

7 01-022-021 Switch, limit, roller arm 1

Part no. Description Qty.

Item

Part no. Description Qty

FIG. 2: HDD-48-S series stationary dumpers exploded parts diagram and bill of materials

Item Part no. Description Quantity

1 09-514-129 Weldment, frame,

2 09-512-001 Hinge block assembly 2

3 99-021-

909-001

4 09-537-013 Assembly, drum clamp,

5 37039 Nylock nut, zinc-plated,

6 24-612-003 Pin assembly, cylinder,

7 09-145-020 Threaded pipe cap 2

8 01-022-021 Switch, limit, roller arm 1

9 36102 Hex nut, grade A, zinc-

10 22805 Elevator bolt, limit

11 09-545-030 Weldment,

12 13365 3/4” – 10 UNC x 3” zinc-

13 99-158-008 Modular power unit

stationary

Hydraulic cylinder, 21/2”

x 18”

casting

3

/4” – 10

box dumper

1

plated,

switch

subassembly, chute

plated #5 bolt

w/out push buttons

/4” - 20

1

1

2

4

1

1

1

1

4

1

Pivot

Copyright 2017 Vestil Manufacturing Co. 5 of 25

Page 6

03/10/03 9/7/2017 HDD, MANUAL

shaft

shaft

FIG. 3: HDD-60-S series stationary dumpers exploded parts diagram and bill of materials

Pivot

Item Part no. Description Quantity

1 09-514-127 Weldment, frame,

stationary

2 09-512-001 Hinge block assembly 2

3 99-021-

909-001

4 09-537-013 Assembly, drum clamp,

5 37039 Nylock nut, zinc-plated,

6 24-612-003 Pin assembly, cylinder,

7 09-145-020 Threaded pipe cap 2

8 01-022-021 Switch, limit, roller arm 1

9 36102 Hex nut, grade A, zinc-

10 22805 Elevator bolt, limit

11 09-545-031 Weldment,

12 13365 3/4” – 10 UNC x 3” zinc-

13 99-158-008 Modular power unit

Hydraulic cylinder, 21/2”

x 18”

casting

3

/4” – 10

box dumper

plated, 1/4” - 20

switch

subassembly, chute

plated #5 bolt

w/out push buttons

FIG. 4: HDD-72-S series stationary dumpers exploded parts diagram and bill of materials

Pivot

Item Part no. Description Qty.

1 09-514-125 Weldment, frame,

2 09-512-001 Hinge block assembly 2

3 09-537-013 Assembly, drum clamp,

4 37039 Nylock nut, zinc-plated, 3/4”

5 24-612-003 Pin assembly, cylinder, box

6 09-145-020 Threaded pipe cap 2

7 01-022-021 Switch, limit, roller arm 1

8 36102 Hex nut, grade A, zinc-

9 22805 Elevator bolt, limit switch 1

10 09-545-032 Weldment, subassembly,

11

99-021-909-001

09-021-018

12 13365 3/4” – 10 UNC x 3” zinc-

13 99-158-008 Modular power unit w/out

stationary

casting

– 10

dumper

1

plated,

chute

Hydraulic cylinder:

2

3” x 18” (HDD-72-15-S)

plated #5 bolt

push buttons

1

/2” x 18”

/4” - 20

1

1

2

4

1

1

1

1

4

1

1

2

4

1

1

1

1

1

4

1

Copyright 2017 Vestil Manufacturing Co. 6 of 25

Page 7

03/10/03 9/7/2017 HDD, MANUAL

3

shaft

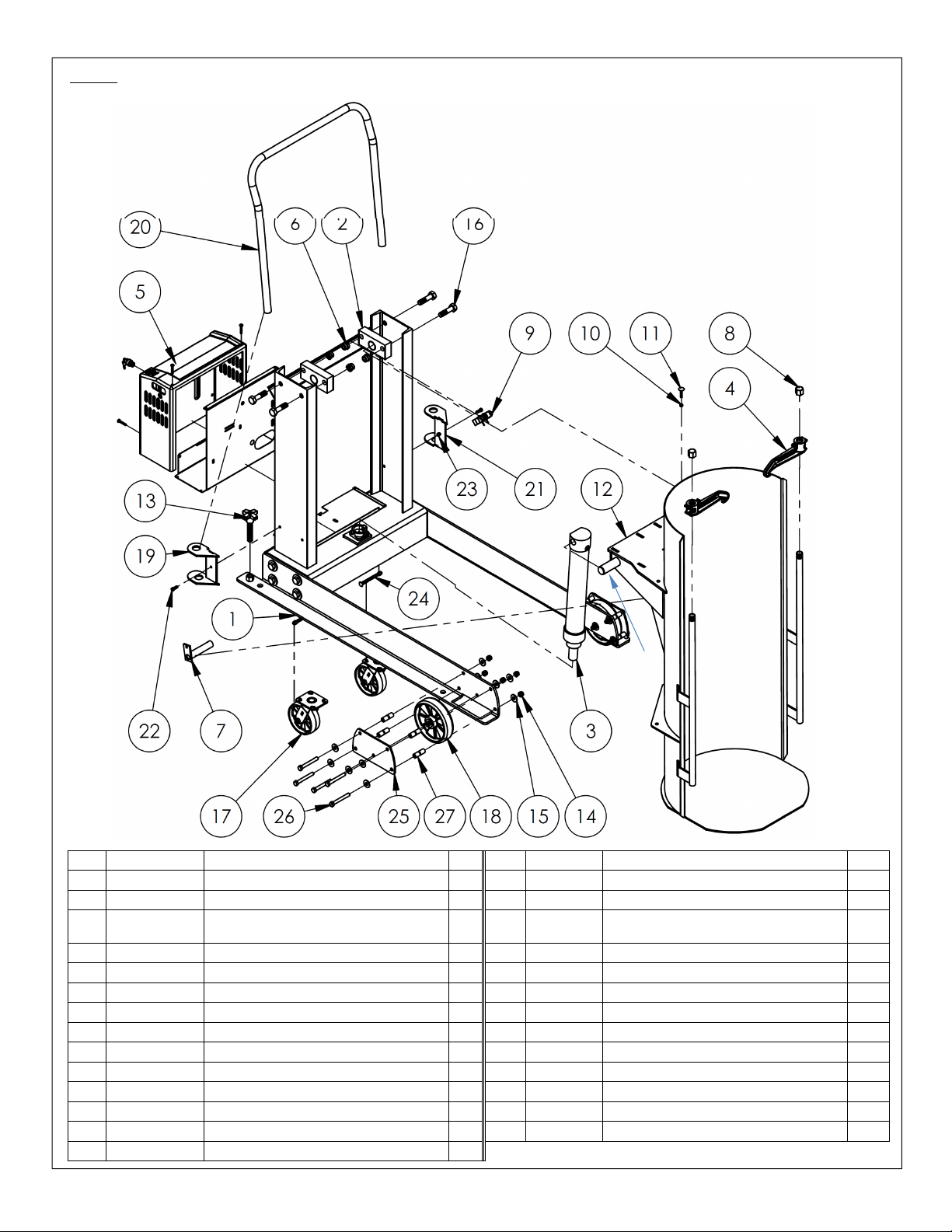

FIG. 5: HDD-36-P series portable dumpers exploded parts diagram and bill of materials

Pivot

Item Part no. Description Qty. Item Part no. Description Qty.

1 09-514-131 Weldment, frame, stationary 1 15 33012 1/2” flat washer, low carbon, zinc finish 20

2 09-512-001 Hinge block assembly 2 16 12365 3/4” – 10 x 3” HHCS #5 plain bolt 4

3 99-021-909-

001

4 09-537-013 Assembly, drum clamp, casting 2 18 16-132-216 Caster, 8”, glass filled nylon 2

5 99-158-008 Modular power unit, no push buttons 1 19 09-525-009 Weldment, handle bracket, right 1

6 37039 Nylock nut, zinc-plated, 3/4” – 10 4 20 16-025-028 Handle, push handles, chromed 1

7 24-612-003 Pin assembly, cylinder 1 21 09-525-008 Weldment, handle bracket, left 1

8 09-145-020 Threaded pipe cap 2 22 11055 5/16”–18 x 1” HHCS #2 zinc-plated bolt 2

9 01-022-021 Switch, limit, roller arm 1 23 36104 5/16”–18 grade A zinc-plated hex nut 2

10 36102 Hex nut, grade A, zinc-plated, 1/4” - 20 1 24 99-612-001

11 22805 Elevator bolt, limit switch 1 25 09-016-169 Bracket, wheel 2

12 09-545-028 Weldment, subassembly, chute 1 26 11219 1/2”–13 x 4” hex head bolt 10

13 08-025-008 4-handle bolt, 4” 2 27 16-111-003 Sleeve bearing for 2” wheel 8

14 37030 1/2” – 13 nylon insert lock nut 10

Copyright 2017 Vestil Manufacturing Co. 7 of 25

Hydraulic cylinder, 21/2” x 18” 1 17 16-132-262 6” x 2” glass filled nylon swivel caster 2

/8”–16 x 5” bolt and nut combo. 2

Page 8

03/10/03 9/7/2017 HDD, MANUAL

shaft

3

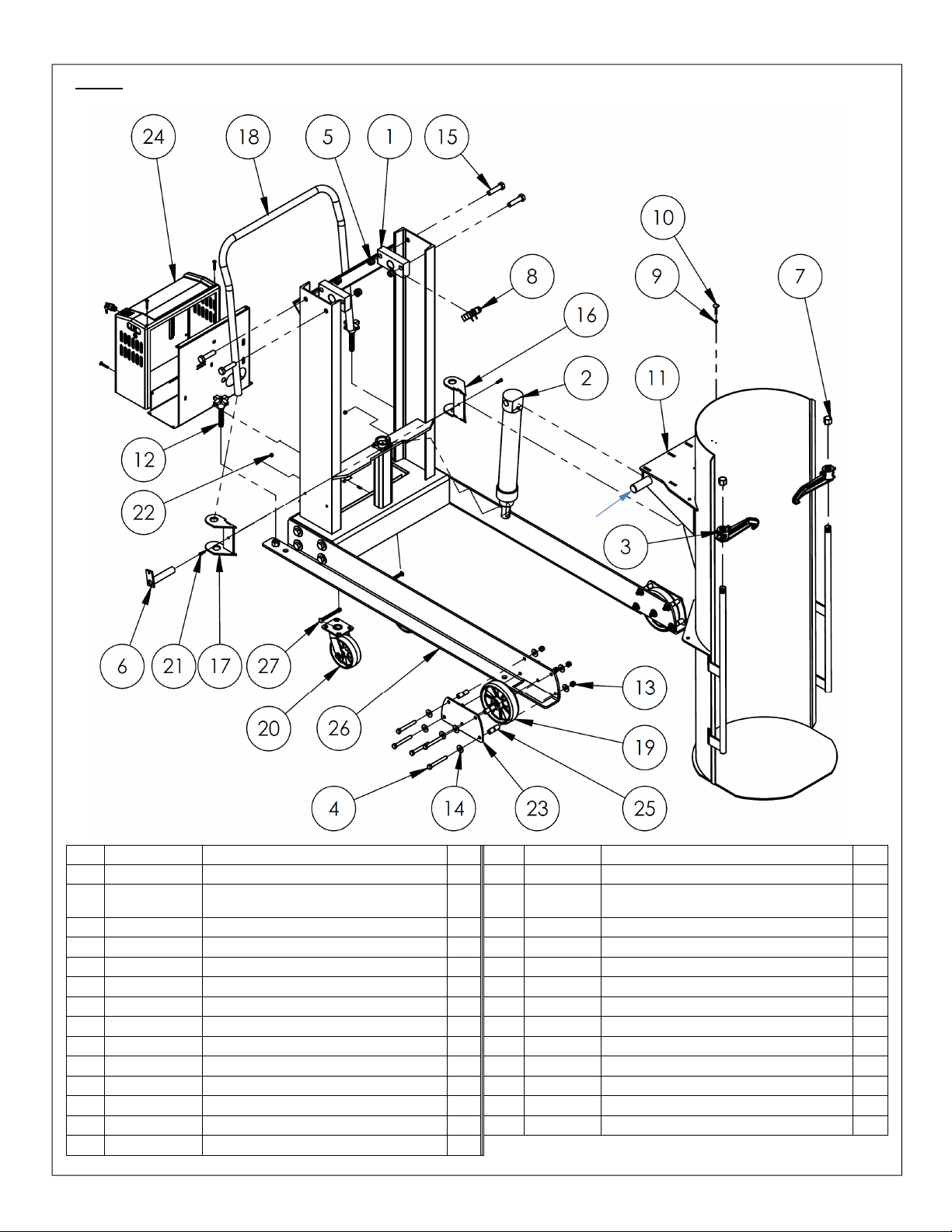

FIG. 6: HDD-48-P series portable dumpers exploded parts diagram and bill of materials

Pivot

Item Part no. Description Qty. Item Part no. Description Qty.

1 09-512-001 Hinge block assembly 2 15 13365 3/4” – 10 x 3” HHCS #5 plain bolt 4

2 99-021-909-

001

3 09-537-013 Assembly, drum clamp, casting 2 17 09-525-009 Weldment, handle bracket, right 1

4 11219 1/2”–13 x 4” hex head bolt 10 18 16-025-028 Handle, push handles, chromed 1

5 37039 Nylock nut, zinc-plated, 3/4” – 10 4 19 16-132-216 Caster, 8”, glass filled nylon 2

6 24-612-003 Pin assembly, cylinder 1 20 16-132-262 6” x 2” glass filled nylon swivel caster 2

7 09-145-020 Threaded pipe cap 25 21 11005 1/4”–20 x 1” HHCS #2 zinc-plated bolt 2

8 01-022-021 Switch, limit, roller arm 1 22 36104 5/16”–18 grade A zinc-plated hex nut 2

9 36102 Hex nut, grade A, zinc-plated, 1/4” - 20 1 23 09-016-169 Bracket, wheel 2

10 22805 Elevator bolt, limit switch 1 24 99-158-008 Modular power unit, no push buttons 1

11 09-545-030 Weldment, subassembly, chute 1 25 16-111-003 Sleeve bearing for 2” wheel 8

12 08-025-008 4-handle bolt, 4” 2 26 09-514-131 Weldment, frame, stationary 1

13 37030 1/2” – 13 nylon insert lock nut 10 27 99-612-001

14 33012 1/2” flat washer, low carbon, zinc finish 20

Hydraulic cylinder, 21/2” x 18” 1 16 09-525-008 Weldment, handle bracket, left 1

/8”–16 x 5” bolt and nut combo. 2

Copyright 2017 Vestil Manufacturing Co. 8 of 25

Page 9

03/10/03 9/7/2017 HDD, MANUAL

shaft

3

FIG. 7: HDD-60-P series portable dumpers exploded parts diagram and bill of materials

Pivot

Item Part no. Description Qty. Item Part no. Description Qty.

1 09-512-001 Hinge block assembly 2 15 13365 3/4” – 10 x 3” HHCS #5 plain bolt 4

2 99-021-909-

001

3 09-537-013 Assembly, drum clamp, casting 2 17 09-525-009 Weldment, handle bracket, right 1

4 99-158-008 Modular power unit, no push buttons 1 18 16-025-028 Handle, push handles, chromed 1

5 37039 Nylock nut, zinc-plated, 3/4” – 10 4 19 16-132-216 Caster, 8”, glass filled nylon 2

6 24-612-003 Pin assembly, cylinder 1 20 16-132-262 6” x 2” glass filled nylon swivel caster 2

7 09-145-020 Threaded pipe cap 2 21 11005 1/4”–20 x 1” HHCS #2 zinc-plated bolt 2

8 01-022-021 Switch, limit, roller arm 1 22 36104 5/16”–18 grade A zinc-plated hex nut 2

9 36102 Hex nut, grade A, zinc-plated, 1/4” - 20 1 23 09-016-169 Bracket, wheel 2

10 22805 Elevator bolt, limit switch 1 24 16-111-003 Sleeve bearing for 2” wheel 8

11 09-545-031 Weldment, subassembly, chute 1 25 11219 1/2”–13 x 4” hex head bolt 10

12 08-025-008 4-handle bolt, 4” 2 26 09-514-127 Weldment, frame, stationary 1

13 37030 1/2” – 13 nylon insert lock nut 10 27 99-612-001

14 33012 1/2” flat washer, low carbon, zinc finish 20

Copyright 2017 Vestil Manufacturing Co. 9 of 25

Hydraulic cylinder, 21/2” x 18” 1 16 09-525-008 Weldment, handle bracket, left 1

/8”–16 x 5” bolt and nut combo. 2

Page 10

03/10/03 9/7/2017 HDD, MANUAL

shaft

3

FIG. 8: HDD-72-P series portable dumpers exploded parts diagram and bill of materials

Pivot

Item Part no. Description Qty. Item Part no. Description Qty.

1 09-512-001 Hinge block assembly 2 15 09-525-008 Weldment, handle bracket, left 1

2 09-537-013 Assembly, drum clamp, casting 2 16 09-525-009 Weldment, handle bracket, right 1

3 99-158-008 Modular power unit, no push buttons 1 17 11005 1/4”–20 x 1” HHCS #2 zinc-plated bolt 2

4 37039 Nylock nut, zinc-plated, 3/4” – 10 4 18 16-025-028 Handle, push handles, chromed 1

5 24-612-003 Pin assembly, cylinder 1 19 16-132-216 Caster, 8”, glass filled nylon 2

6 09-145-020 Threaded pipe cap 2 20 16-132-262 6” x 2” glass filled nylon swivel caster 2

7 01-022-021 Switch, limit, roller arm 1 21 36104 5/16”–18 grade A zinc-plated hex nut 2

8 22805 Elevator bolt, limit switch 1 22 99-612-001

9 09-545-032 Weldment, subassembly, chute 1 23 36102 Hex nut, grade A, zinc-plated, 1/4” - 20 1

10 08-025-008 4-handle bolt, 4” 2 24 09-016-169 Bracket, wheel 2

11 37030 1/2” – 13 nylon insert lock nut 10 25 16-111-003 Sleeve bearing for 2” wheel 8

12 33012 1/2” flat washer, low carbon, zinc finish 20 26 11219 1/2”–13 x 4” hex head bolt 10

13

14 13365 3/4” – 10 x 3” HHCS #5 plain bolt 4

99-021-909-

001

09-021-018

Hydraulic cylinder:

1

2

/2” x 18”

3” x 18” (HDD-72-15-P)

1

27 09-514-125

/8”–16 x 5” bolt and nut combo. 2

Weldment, frame, stationary 1

Copyright 2017 Vestil Manufacturing Co. 10 of 25

Page 11

03/10/03 9/7/2017 HDD, MANUAL

3

3

inside wall of drum

Installation instructions (stationary units):

Step 1: Position the dumper where

desired with a forklift.

/4” anchor bolt

Step 2: Drill holes approximately 4in.

(10cm) deep.

Step 3: Secure the dumper to the floor by

inserting

the bolt holes in the base frame.

3

/4” anchor bolts through

Step 4: Shim and/or grout the sides of the

frame as necessary to achieve

levelness.

Step 5: (AC powered units) Connect the

power cord to the power supply.

/4” anchor bolt

Shim and/or grout

under the frame to

level the dumper

Loading the dumper:

1. Use only properly sized waste containers: HDD-series dumpers are designed to accept 33 gallon and 55 gallon

steel, plastic, and fiber drums.

2. Load the drum onto the chute: Place the drum on the base plate of the chute. The drum should rest against the

back of the chute.

3. Apply the drum retainers (see diagrams in “Inspections” below): to prevent the drum from sliding out of the chute,

move the retainers up or down the rails as necessary and into solid contact with the top of the drum. To move the

retainers, press the rail clamps down. The hook at the end of each retainer must contact the inside wall of the

drum.

4. Dump the drum: press the white (raise) button on the pendant controller to raise the chute to the dumping

position. In response to the input from the controller, the piston extends and raises the bottom end of the chute.

The piston extends only while the operator presses the white button. When the button is released, the cylinder

stops extending and the chute stops moving. The chute maintains whatever position it is in when the button is

released.

NOTE: If the net weight of the drum and its contents exceeds the capacity of the dumper, a relief valve in the

hydraulic system will open. While the relief valve is open, the piston cannot extend. Consequently, the chute

will not move.

5. Return the chute to the loading position: press the black (lower) button on the controller to retract the piston. As

the piston retracts, it pulls the bottom end of the chute towards the ground. If the DOWN button is released before

the chute is completely lowered, the chute will maintain its position.

Inspections: (Refer to FIGS. 1-8, p. 5-10)

Before each use, inspect the listed components:

1. Modular power unit, pendant controller, and wiring: examine

all wires for frays, cuts, tears, etc. (DC-powered units) Check

battery charge status. Cycle the chute all the way up and all

the way down. Recharge the battery, if necessary.

2. Hydraulic system: check the reservoir and all hoses for

pinches, kinks, punctures, and leaks.

3. Drum retainers and clamp rails: examine the retainers for

damage including bends, cracks, and looseness. Each clamp

should maintain position along the rail (i.e. should not slide).

4. Frame: check the hinge blocks, pivot shafts, cylinder brackets

(at each end of cylinder at attachment points to the frame and

the chute), legs, vertical frame, and chute for cracks,

damaged welds, severe wear, and corrosion.

5. Cylinder and limit switches: verify normal function. Cycle the

chute through a complete dumping sequence (fully rotated

and back to the ground).When the chute reaches dumping

height, the power unit should stop running. The piston should

extend and retract smoothly without binding or jerking. Listen

for unusual sounds that might indicate binding or grinding

during operation and watch for unusual movement. If you

observe any unusual sound or movement, do not use the

Chute

Vertical

frame

Modular power unit

Drum retainers:

Rail clamp

Hook of retainer

should contact

Drum retainer

Retainer

rail

Leg

Drum

retainer

Copyright 2017 Vestil Manufacturing Co. 11 of 25

Page 12

03/10/03 9/7/2017 HDD, MANUAL

dumper until it has been restored to normal operating

condition.

At least once per month, inspect the dumper as follows:

1. Oil level: remove the cover from the modular power unit. Then, fully raise the chute (to the 45° “dumping position”)

and observe the level of oil in the reservoir. The surface of the oil should be 1 to 1½ inches below the fill hole. If

oil is needed, add oil as specified below in “Oil specifications”.

2. Pivot points: check the dumper for excessive wear. Pay particular attention to pivot points between hydraulic

cylinders and cylinder brackets, and between pivot shafts and hinge blocks.

3. Floor connection points: anchor bolts should prevent the frame from lifting off of the ground during chute

operation. Concrete around each anchor bolt should be intact, i.e. not cracked or chipped.

4. Fasteners: check each fastener connection (nuts, bolts, pins, etc.). Tighten loose connections. Replace all

damaged hardware.

5. Hydraulic hoses and electrical wires: check each wire and hose for damage (frays, kinks etc.).

6. Labels: labels should be easily readable, undamaged, and be affixed to the dumper as shown in the “Labeling

diagram” on p. 23.

Oil specifications: At least once per year change the hydraulic oil. Change the oil as soon as it becomes gritty or

looks milky (indicating that water is present). With the chute in the fully lowered position, drain the oil and replace it

with either Dexron transmission fluid or anti-wear hydraulic oil viscosity grade 150 SUS at 100°F (ISO 32 cSt at

40°C.

Power unit operation

The drum dumper is powered by an electric motor directly coupled to a gear pump. The pump pressurizes the

hydraulic fluid. Fluid pressure causes the piston of the hydraulic cylinder to extend. Piston extension causes the

bottom of the chute to rotate until it is elevated above the top of the chute. A hydraulic manifold bolted directly onto

the gear pump houses the hydraulic control components. Each component is rated for 3,000psi working pressure.

Important components of the power unit include:

Electric motor: the motor is either AC powered (wall socket) or DC powered (battery). AC-powered motors can be

wired for either single-phase or three-phase operation. Regardless of phase configuration, every motor is dual-

voltage capable.

Gear pump: the pump shaft is directly coupled to the shaft of the electric motor. Several displacements are

available to match the horsepower of the motor selected.

Check valve: prevents backflow of fluid through the pump and to the reservoir. Because fluid can only flow in

response to an electrical signal from the pendant controller, the chute can maintain any position between the

raised and lowered configurations.

Pressure relief valve: opens a path for fluid to flow back to the reservoir if fluid pressure exceeds 3,000psi.

Lowering solenoid valve: electrically-operated cartridge valve with an integral screen to keep contaminants from

entering the valve.

Pressure compensated flow control spool: this feature regulates the flow of hydraulic oil from the cylinder back to

the reservoir. It is located beneath the lowering valve. This component allows the table to lower at a

predetermined constant rate regardless of the weight of the dumper and contents. Several sizes are available.

Displacement style hydraulic cylinder: each cylinder includes a bleeder valve located at top end for removing air

from the hydraulic system.

Velocity fuse: a safety device installed in the hose port of each cylinder. If a hose is punctured while the unit is

operating, the velocity fuse closes automatically. The chute remains stationary until pressure is reapplied to the

system.

Hydraulic fluid: HO150 hydraulic fluid. To replenish the fluid, add anti-wear hydraulic fluid with a viscosity grade

of 150 SUS at 100°F (ISO 32 @ 40°C) like AW-32 or Dexron transmission fluid.

Sequence of operation:

To raise/tilt the chute, press the white (UP) button. In response, the motor turns and rotates the gear pump. As

the pump rotates, oil is drawn from the reservoir, passes through the suction filter, and enters the pump.

The gear pump propels oil through the check valve to the lift cylinder.

Releasing the white button during operation immediately halts chute movement. Additionally, an electrical upper

travel limit switch automatically turns off the motor when the chute reaches a 45° angle to the ground (horizontal).

To lower the chute, press the black (DOWN) button.

Lowering valve opens which bypasses the check valve and allows oil in the cylinder to flow to the reservoir

(through return hoses). Oil flow to the reservoir is regulated by the pressure compensated flow control valve. By

regulating the volume of oil that can flow through the spool, the speed at which the chute lowers is kept constant.

Releasing the DOWN button during operation causes all chute movement to stop. The chute will remain in the

same position until you press either button on the pendant controller.

Copyright 2017 Vestil Manufacturing Co. 12 of 25

Page 13

03/10/03 9/7/2017 HDD, MANUAL

Cleaning lowering solenoid valve: If the chute slowly loses elevation without pressing the DOWN button, lower the

chute completely. Then, remove, inspect, and clean the lowering cartridge valve in the following manner:

1. Lower the chute completely and turn off electrical power to the unit. If your dumper is AC powered,

unplug the electrical cord from the wall socket. If your unit is DC (battery) powered, turn the power

switch to the OFF position.

2. Unload the dumper.

3. Remove the nut that fastens the solenoid coil to the valve stem; then remove the coil and unscrew the

valve from the manifold.

4. Inspect the valve for blockage.

5. Inspect O-rings and back-up washers for cuts, tears, etc.

6. Submerge the valve in mineral spirits or kerosene.

7. Use a thin tool, such as a small screwdriver or a hex wrench, to push the poppet in and out several

times from the bottom end of the valve. The valve should move freely, about 1/16” between the closed

and open positions. If the poppet sticks, the valve stem might be bent. Replace the poppet if it doesn’t

free up after cleaning.

8. Remove mineral oil from the valve with compressed air.

9. Move the poppet in and out.

10. Inspect the bottom of the valve cavity in the manifold for foreign matter.

11. With the thin tool, press the middle of the flow control spool, which is located in the bottom of the

cavity. It should move down and up smoothly.

12. Reinstall the valve in the manifold and tighten it to 20 lb·ft of torque.

Bleeding air from hydraulic system: If the chute lowers extremely slowly or does not lower, air in the cylinders

might be the culprit. Air in the hydraulic system causes the velocity fuse to close, which traps oil in the cylinder. To

overcome this problem, air must be “bled” from the system.

Completely lower the chute and unload it;

Locate the bleeder valve located at the top of the cylinder (it looks like a grease zerk). Hold a rag over the valve

and open it about a half turn with a 1/4” or 5/16” wrench. Oil and air will sputter from the valve. Jog the motor by

pressing the white (UP) button for just a second. If air continues to escape from the bleeder valve, jog the motor

several more times. Wait at least 5 seconds between successive jogs.

Close the valve once air no longer is heard or seen bubbling out of the valve. At this point, just a clear stream of

oil is seen flowing from the bleeder valve. Close the valve.

Remove the cover from the modular power unit and check the oil level in the reservoir. If the surface of the oil is

lower than 1 to 1½ in. below the fill hole, then add oil until it is between 1 and 1½ inches of the fill hole. Add only

anti-wear hydraulic fluid with a viscosity grade of 150 SUS at 100°F (ISO 32 @ 40°C) like AW-32 or Dexron

transmission fluid.

FIG. 9: Hydraulic circuit diagram

Item Part no. Description Quantity

01-127-010

1

01-135-052 2HP, 3-phase, 1725 RPM motor

2

01-143-908 Gear pump, 0.153 displacement

3

99-021-909

4

99-153-006 Relief valve, 210 bar, size 08

5

99-031-029 Inlet screen, 100 mesh 2” pancake

6

99-153-038

7

01-531-001

8

99-153-015 Valve, cartridge, NC, no coil, w/ nut

9

99-153-011

10

11 99-023-002

Manifold, aluminum, w/o valves

Cylinder, 21/2” x 18” ram style

Flow control, PC, 7/16” - 20, 2gpm

Velocity fuse, adjustable, brass

Check valve, size 08

Reservoir, L-shaped, 1.16 gal., 1.0

gal. nominal

1

1

1

2

1

1

1

2

1

1

1

Copyright 2017 Vestil Manufacturing Co. 13 of 25

Page 14

03/10/03 9/7/2017 HDD, MANUAL

FIG. 10A: 115VAC, Electrical Circuit Diagram (09124017 Rev. D)

NOTE: In this diagram, all components are represented with the chute in “home” location, i.e. resting, lowered position.

115VAC, 3/4 HP

12 FLA, 1725 RPM

NOTE: Overcurrent and short-circuit protection

should be provided by the end user in

accordance with recommendations and

requirements in NEC (NFPA 70) and

local codes.

Copyright 2017 Vestil Manufacturing Co. 14 of 25

Page 15

03/10/03 9/7/2017 HDD, MANUAL

FIG. 10B: 115VAC, Upper & Lower Limit Switches, Electrical Circuit Diagram

NOTE: In this diagram, all components are represented with the chute in “home” location, i.e. resting, lowered

position.

(09124014 Rev. C)

115VAC, 3/4 HP

12 FLA, 1725 RPM

NOTE: Overcurrent and short-circuit protection

should be provided by the end user in

accordance with recommendations and

requirements in NEC (NFPA 70) and

local codes.

Copyright 2017 Vestil Manufacturing Co. 15 of 25

Page 16

03/10/03 9/7/2017 HDD, MANUAL

5.6/2.8 FLA, 3450RPM

FIG. 10C: 208-230VAC, 1-phase, electrical circuit diagram (09124018 Rev. C)

NOTE: In this diagram, all components are represented with the chute in “home” location, i.e. resting, lowered

position.

208-230/460 VAC, 2 HP

7.8-6.2/3.1 FLA, 1725 RPM

-OR-

208-230/460 VAC, 2 HP

Copyright 2017 Vestil Manufacturing Co. 16 of 25

NOTE: Overcurrent and short-

circuit protection should be

provided by the end user

in accordance with

recommendations and

requirements in NEC

(NFPA 70) and local

codes.

Page 17

03/10/03 9/7/2017 HDD, MANUAL

FIG. 10D: 208-230VAC, Upper & Lower Limit Switches, 1-phase electrical circuit

NOTE: In this diagram, all components are represented with the chute in “home” location, i.e. resting, lowered

diagram (09124015 Rev. C)

position.

Indicates wire and/or components

end-user must provide

208-230VAC, 1.5 HP

12 FLA, 1725 RPM

NOTE: Overcurrent and short-

circuit protection should be

provided by the end user

in accordance with

recommendations and

requirements in NEC

(NFPA 70) and local

codes.

Copyright 2017 Vestil Manufacturing Co. 17 of 25

Page 18

03/10/03 9/7/2017 HDD, MANUAL

5.6/2.8 FLA, 3450RPM

FIG. 10E: 3-phase 208-230/460 VAC, electrical circuit diagram (09124019 Rev. C)

NOTE: In this diagram, all components are represented with the chute in “home” location, i.e. resting, lowered

position.

Indicates wire and/or components

end-user must provide

208-230/460 VAC, 2 HP

7.8-6.2/3.1 FLA, 1725 RPM

-OR-

208-230/460 VAC, 2 HP

Copyright 2017 Vestil Manufacturing Co. 18 of 25

NOTE: Overcurrent and short-

circuit protection should be

provided by the end user

in accordance with

recommendations and

requirements in NEC

(NFPA 70) and local

codes.

Page 19

03/10/03 9/7/2017 HDD, MANUAL

5.6/2.8 FLA, 3450RPM

FIG. 10F: 3-phase 208-230/460 VAC, Upper & Lower Limit Switches, electrical

NOTE: In this diagram, all components are represented with the chute in “home” location, i.e. resting, lowered

circuit diagram (09124016 Rev. C)

position.

Indicates wire and/or components

end-user must provide

208-230/460 VAC, 2 HP

7.8-6.2/3.1 FLA, 1725 RPM

-OR-

208-230/460 VAC, 2 HP

Copyright 2017 Vestil Manufacturing Co. 19 of 25

NOTE: Overcurrent and short-circuit

protection should be provided

by the end user in accordance

with recommendations and

requirements in NEC (NFPA

70) and local codes.

Page 20

03/10/03 9/7/2017 HDD, MANUAL

FIG. 11: Motor lead connection diagrams for all 0.5HP, 0.75HP, & 3hp single-

Transformer wiring diagram:

phase motors and for all 2HP, 5.5HP, and 6.5HP three phase motors

Attach thermostat leads to:

1) Grounded side of the transformer secondary; and

2) Motor relay coil.

It does not matter which lead attaches to each location.

Copyright 2017 Vestil Manufacturing Co. 20 of 25

Page 21

03/10/03 9/7/2017 HDD, MANUAL

3

FIG. 12A: DC modular power unit exploded parts diagram and bill of materials

Manifold assembly (24) exploded parts diagram and bill of materials

Item no. Part no. Description Quantity

31 568-015-BN70 O-ring, large 1

32 568-011-BN70 O-ring, small 1

33 99-153-058 Valve, solenoid, zero leak 1

34 99-034-010 Coil w/ weathertight plug 1

35 99-153-006 Valve, pressure relief 1

36 568-334-BN70 O-ring, 25/8”x3”x3/16” 1

37 99-031-029 Screen, inlet, 13/4” diameter 1

38 99-153-038

39 01-127-010 Manifold, LHL standard 1

40

41 99-153-011 3/8”–16x1” socket head bolt 1

6801-06-06-

NWO

Valve, pressure

compensated flow control

Fitting, #6 JIC - #6 O-ring, 90

deg.

1

1

Item

no. Part no. Description Quantity

1 99-016-933 Base 1 16 Zb2bz009 Contact block base 2

2 21-034-008 Battery charger 1 17 Zb2be101 Contact block, N.O. 2

3 99-533-008 Adaptor, hand control 1 18 Zb2ba2c

4 37927 Tinnerman clip 4 21 99-024-010 Cover, plastic 1

5 99-023-001 Reservoir 1 22 HS52 Clamp, worm gear hose 1

6 99-034-013 Battery strap 1 23 01-143-906 Pump, hydraulic gear 1

7 99-139-003 Battery 1 *24 01-627-010 Manifold assembly (see p. 16)

8 01-116-003 Breather, vent, brass fitting 1 25 29201 Screw, machine, 1/4”-20x13/4” 2

9 15-533-013 23” black #4 AWG battery cable 1 26 29185 Screw, machine, 1/4”-20x1” 2

10 15-533-014

11

12 99-135-011 Motor 1 29 21-034-025 Flanged inlet w/ locking ring 1

13 15-022-004 Relay, start solenoid 1 30 3MTST3540 1” hook & loop strip 10”

14 HS64 Clamp, worm gear hose 1

15 BG-12V Gauge, battery, charge indicator 1

Copyright 2017 Vestil Manufacturing Co. 21 of 25

23305

33688

33008

23” black #4 AWG battery cable

/8”–16x1” socket head bolt

3

/8” lock washer

3

/8” flat washer

Item

no. Part no. Description Quantity

Operator, black, flush, nonilluminated

1

2

2

2

27 23255

33687

28 152400-03

Bolt, socket head, 5/16”-18x1”

Washer, lock,

Molded cord, charger connect

5

/16”

2

1

4

4

1

Page 22

03/10/03 9/7/2017 HDD, MANUAL

3

5

1

1

1

FIG. 12B: AC modular power unit exploded parts diagram and bill of materials

Detail view of

Manifold (12)

Detail view of Electric Box Assembly (2)

Item

no. Part no. Description Qty

1 99-016-933 MPU base bracket 1 11

2 Electric box assembly 1 12 01-627-010 LHL manifold assembly 1

3 21-034-005 Connector, flanged inlet plug 1 13 01-143-906 Hydraulic gear pump 1

4 37927 U nut 4 14 99-145-061 Worm gear hose clamp 1

5 99-023-001 Reservoir 1 15 99-024-029 Plastic cover (gray) 1

6 Motor brace 1 16 ZB2BZ009 Contact block base 2

23255

7

33687

8 01-116-003

9 29185

10 29201

A 71616 10-32 x 5/8” truss head machine screw 4 F Tb-track 39” rail, din, aluminum 3”

B 01-129-001 Control transformer 1 G 01-029-006 Junction box with screw lid 1

C 132560 Contactor, motor, UL Listed 1 H Ab66jp Plate, enclosure 1

D 27531 10-32 x 1/4” z-plated machine screw 4 I C500 Connector, clamp, NM, Romex 4

E 32028 #8 – 18 x 1/2” self-tapping screw 4

/16” – 18 x 1” socket head bolt

5

/16” lock washer

Breather, vent, brass fitting

/4” – 20 x 1” Phillips head truss

machine screw

/4” – 20 x 13/4” machine screw

Item

no. Part no. Description Qty

23305

33688

33008

4

17 ZB2BE101

4

1 18 ZB2BA2C

2 21 99-135-003

11005

2 22

33004

33618

36102

/8” – 16 x 1” socket head bolt

3

/8” lock washer

3

/8” flat washer

Contact block, n.o.

Operator, black, flush, nonilluminated

Motor, 3/

/4” – 20 - 1” hex head bolt

1

/4” flat washer

1

/4” lock washer

1

/4” – 20 hex nut

4 HP

2

2

2

2

2

1

6

6

6

6

Copyright 2017 Vestil Manufacturing Co. 22 of 25

Page 23

03/10/03 9/7/2017 HDD, MANUAL

binding of the rollers, etc.

Troubleshooting Guide

DO NOT attempt to resolve any issue discussed below UNTIL the chute is fully lowered and the power

supply is disconnected.

Issue:

1. Power unit doesn’t run when white

(UP) button is pressed.

2. Motor runs properly, but chute

doesn’t move. Motor and pump are

quiet.

3. Motor hums, chatters, or buzzes, or

some type of squeal can be heard,

but the chute does not move or only

moves very slowly.

4. Chute elevates, then drifts down. 4. See 3e above. 4. Same as 3e.

5. Chute lowers too slowly. 5a. Flow control spool is stuck.

6. Chute lowers too quickly. 6a. See 3e.

7. Spongy or jerky chute motion. 7. Air in the hydraulic cylinders. 7. Bleed air per procedure described

Possible cause(s): Solution:

1a.Transformer fuse is blown.

b. No supply voltage.

c. Upper-travel limit switch is

engaged or bad.

d. Faulty connection in control

circuit.

e. Bad control transformer.

f. Open motor relay coil.

g. (DC units) Low battery voltage.

1a. Test with meter; replace if bad.

b. Test with meter. Check fuses,

breakers, and overloads to determine

the cause.

c. Inspect and test switch. Replace if

bad.

d. Test all parts of circuit with meter.

e. Check for 24 VAC; replace if bad.

f. Test with meter; replace if bad.

g. Test with meter. Charge battery if

low (is motor relay LED on?)

2a. Incorrect motor rotation.

b. Pump failure.

c. Low hydraulic fluid level.

3a. See 2b above.

b. Excess voltage drop to motor

due to power wire size too small,

wire run too long, or incoming

voltage too low.

c. (3-phase motors) Motor is

“single-phasing”.

d. Pressure relief opening at full

2a. Verify motor shaft rotates

counterclockwise.

b. Consult factory for replacement.

c. Ensure reservoir is filled.

3a. Same as 2b.

b. Check power installation for

adequacy. Check incoming voltage

while motor is running. Correct

problem(s).

c. Determine cause of loss of voltage

on one phase; correct.

d. Check for structural damage or

pressure.

e. Contamination holding open

the lowering valve or the check

Check for chute overload condition.

e. Remove and inspect. Clean the

valve with mineral spirits.

valve.

5a. Remove plug from FC port; push

b. Pinched hose.

c. Velocity fuse locking (chute

only slowly creeps down).

down on the center of the flow spool to

ensure it moves freely.

b. Check pressure, supply, and return

hoses for kinks.

c. Same as 7 (below).

6a. Same as 3e.

b. Flow control spool is stuck.

b. Same as 5a.

on p. 10 of this manual.

Copyright 2017 Vestil Manufacturing Co. 23 of 25

Page 24

03/10/03 9/7/2017 HDD, MANUAL

Labeling diagram:

The drum dumper should always be labeled as shown in the diagram below. Replace labels that are missing,

damaged, faded, or not easily readable.

H

C

A

B

G

F

A: Label 287 (model, capacity, serial no.)

C: Label 824 (both sides of chute; “Keep clear when in use”)

D

C

E

F

B: Label 221 (risk of electric shock)

D: Label 248 or 249 (electrical system

specifications)

E: Label 208 (both sides of frame; “Keep clear of pinch point”)

Label 249

F: Label 204 (both sides; “Secure frame to floor”)

G: Label 206 (on reservoir inside; hydraulic fluid

H: Label 717

specifications)

Copyright 2017 Vestil Manufacturing Co. 24 of 25

Page 25

03/10/03 9/7/2017 HDD, MANUAL

LIMITED WARRANTY

Vestil Manufacturing Corporation (“Vestil”) warrants this product to be free of defects in material and workmanship

during the warranty period. Our warranty obligation is to provide a replacement for a defective original part if the

part is covered by the warranty, after we receive a proper request from the warrantee (you) for warranty service.

Who may request service?

Only a warrantee may request service. You are a warrantee if you purchased the product from Vestil or from an

authorized distributor AND Vestil has been fully paid.

What is an “original part”?

An original part is a part used to make the product as shipped to the warrantee.

What is a “proper request”?

A request for warranty service is proper if Vestil receives: 1) a photocopy of the Customer Invoice that displays the

shipping date; AND 2) a written request for warranty service including your name and phone number. Send

requests by any of the following methods:

Mail Fax Email

Vestil Manufacturing Corporation (260) 665-1339 sales@vestil.com

2999 North Wayne Street, PO Box 507 Phone

Angola, IN 46703 (260) 665-7586

In the written request, list the parts believed to be defective and include the address where replacements should be

delivered.

What is covered under the warranty?

After Vestil receives your request for warranty service, an authorized representative will contact you to determine

whether your claim is covered by the warranty. Before providing warranty service, Vestil may require you to send

the entire product, or just the defective part or parts, to its facility in Angola, IN. The warranty covers defects in the

following original dynamic components: motors, hydraulic pumps, electronic controllers, switches and cylinders. It

also covers defects in original parts that wear under normal usage conditions (“wearing parts”), such as bearings,

hoses, wheels, seals, brushes, and batteries.

How long is the warranty period?

The warranty period for original dynamic components is 1 year. For wearing parts, the warranty period is 90 days.

The warranty periods begin on the date when Vestil ships the product to the warrantee. If the product was

purchased from an authorized distributor, the periods begin when the distributor ships the product. Vestil may, at its

sole discretion, extend the warranty periods for products shipped from authorized distributors by up to 30 days to

account for shipping time.

If a defective part is covered by the warranty, what will Vestil do to correct the problem?

Vestil will provide an appropriate replacement for any covered part. An authorized representative of Vestil will

contact you to discuss your claim.

What is not covered by the warranty?

1. Labor;

2. Freight;

3. Occurrence of any of the following, which automatically voids the warranty:

Product misuse;

Negligent operation or repair;

Corrosion or use in corrosive environments;

Inadequate or improper maintenance;

Damage sustained during shipping;

Collisions or other incidental contacts causing damage to the product;

Unauthorized modifications: DO NOT modify the product IN ANY WAY without first receiving written

authorization from Vestil. Modification(s) might make the product unsafe to use or might cause excessive

and/or abnormal wear.

Do any other warranties apply to the product?

Vestil Manufacturing Corp. makes no other express warranties. All implied warranties are disclaimed to the extent

allowed by law. Any implied warranty not disclaimed is limited in scope to the terms of this Limited Warranty.

Copyright 2017 Vestil Manufacturing Co. 25 of 25

Loading...

Loading...