Page 1

Page 2

Do not change pressure relief valve setting on manifold.

Page 3

OPERATING INSTRUCTIONS

The HDC-900 is equipped with a momentary contact control. This relieves the operator from having

to hold the "Start" button while the unit cycles.

Sequence of Operation:

In order to operate, the crusher must be prepared as follows: 1) place a drum insid e the crusher; 2)

close the door; 3) lock the door latch handle; 4) turn the key switch to the appropriate mode; 5) select

“CRUSH” or “COMPACT”; 6) pull out the Emergency Stop button; 7) momentary press the cycle “START”

button to activate the crush/compact cycle.

The direction of the platen's travel wi ll be determined by its starting position -- if it is fully raised to the

top of the cabinet, the platen will move down to crush a drum; otherwise, the cylinder will raise the platen

until it finally is all the way up and in its starting ("home") position, at which point the power unit will turn off.

Pressing the cycle start button again will cause the platen to move downward. The operator must hold the

button for a few seconds to latch the circuit.

When the crusher is in its "home" position and th e cycle start button is pressed, the cylinder pu shes

the platen down onto (or into) the drum. In ord er to achi eve a short cycle time, both sections of the pum p

in the power unit drive oil to the cylinder until the cylinder pressure reaches approximately 1000 PSI. At that

time, the higher-displacement sec tion recycles oil to the reservoir while the low-displacement, high-pressur e

section continues to pump oil to the cylinder, i.e. a typi cal High-Low circuit.

As the platen crushes or compacts the drum to a height of about 6 inches, the cylinder pressure

increases until it reaches the set-point of the appropriate pressure switch. The valve shifts to center and a

timer activates to control the period of decompression. Once the period ends the directional valve shifts

and reverses the direction of oil flow to the cylinder. Reversing the flow of oil raises the platen to its starting,

or "home" position. When the cylinder returns the platen a ll the way to the top of the cabi net, the power

unit turns off. At this point, the cabinet door can be opened to remove the drum.

If the unit needs to be stopped at any point during its cycle, the operator can depress the red

emergency stop button located on the control panel. This stops the motor and prevents the unit from

cycling any further. To return the platen to its starting ("home") position, pull the emergency stop button out

to release it and depress the cycle start button again. This will cause the platen to ascend back to the

starting position. To cycle the unit again, simply depress the cycle start button.

RESPONSIBILITIES OF OWNERS/USERS

It is the responsibility of the owner/user for the following:

1.) Inspected and maintain this product according to the guidelines in this manual.

2.) Any unit not in normal operating condition should immediately be removed from service and remain

out-of-service until it is returned to normal operating condition.

Unsafe conditions include, but are not limited to, the following: excessive hydraulic or air leakage, missing

pins, or fasteners, any cracked or deformed structural members, cut or frayed hydraulic, electric or air lines,

and damaged controls or safety devices. All repairs and maintenance must be performed by qualified

personnel.

3.) Unit should only be used by authorized personnel. All operators must read and understand all operating

procedures and safety guidelines in this manual prior to using the crusher for the first time.

4.) Operator should verify that all safety features function properly before each use.

5.) Any modifications to the unit must be approved in writing by the manufacturer.

Ordering Replacement & Spare Parts

Our company takes pride in using the finest available parts for our equipment. We are not responsible for

equipment failure resulting from the use of unapproved replacement parts. To order parts for your

equipment, contact Customer Service at the factory. In any correspondence with the factory please

include the Serial Number which is inscribed on the nameplate of the piece of equi pment. Use only the part

numbers provided in this Owner's Manual. When ordering parts for AC power units please indicate the

motor phase and voltage that the equipment is operating on. Ordering Replacement or Extra Parts.

Page 4

INSTALLATION INSTRUCTIONS

Read the entire manual before installing the crusher.

For installation you will need the following:

1.) A fork truck.

2.) Lag bolts, masonry drill, masonry bit, and wrench for lag bolt, grout, and steel shims.

3.) A power circuit with the specified voltage, including fuses and disconnect or circuit

breakers. (See p. 8-9). Reference NEC 70.

4.) Minimize voltage drop by using adequate wire size. Reference NEC 70.

Position the crusher with a fork truck by lifting the crusher via the fork tubes on the frame.

Read all warning labels on the unit and b e sure every label shown on page 12 is on the unit.

Anchor the crusher to the floor before using it for the first time.

Connect the power source as shown in electrical section.

Cycle the unit a few times; then check the oil and add more oil, if necessary. (See oil

specification on page 5).

LOADING INSTRUCTIONS

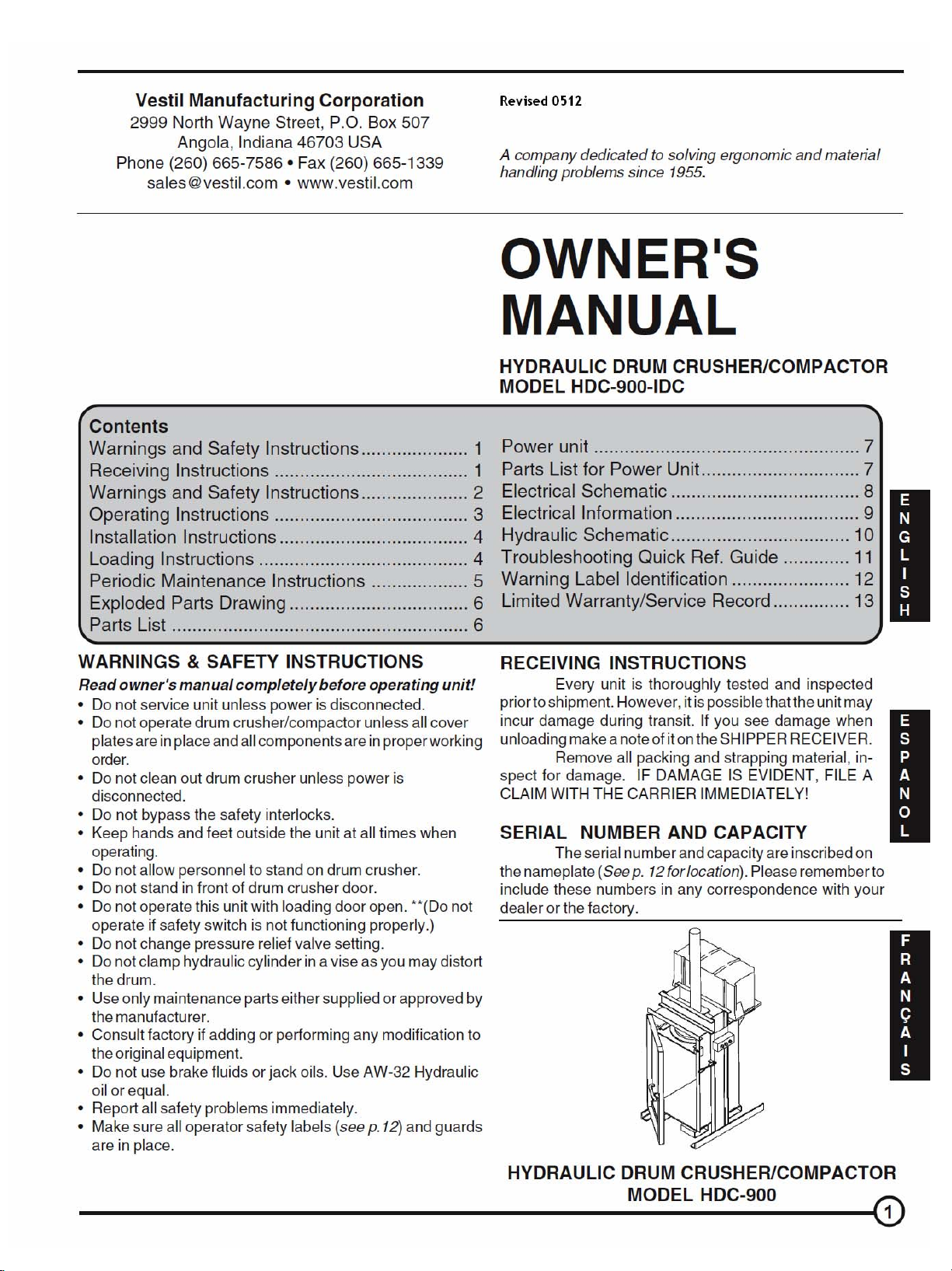

The Hydraulic Drum Crusher/Compactor (HDC-900) is designed to crush standard ribbed steel

drums of 55 gallon size or smaller. DO NOT use the crusher to compact smooth -walled drums,

i.e. drums that lack ribs. The crusher can be used to compact (standard ribbed) steel drums

that contain soft materials.

When loading the crusher, always apply these suggestions:

1.) Before using the crusher, confirm that the platen is properly installed;

2.) Carefully center the material/item to be crushed under the platen, because an offset or

uneven load might damage the cylinder rod;

3.) DO NOT fill drums with scrap metal, paint cans, etc. which w ill exceed the crushing

capacity of the unit and significantly damage the crusher.

NOTE: The crusher is designed to compact standard, ribbed steel drums. However, the crusher

might not compact a particular drum. It is also possible that the crusher might sustain minor

damage during the compaction process.

Page 5

PERIODIC INSPECTIONS & MAINTENANCE INSTRUCTIONS

ALWAYS EMPTY THE CRUSHER BEFORE INSPECTING OR PERFORMING MAINTENANCE ON IT.

(A) Before each use, inspect the crusher and remove it from service if any of the following

issues are observed:

1.) Frayed wires;

2.) Oil leaks;

3.) Pinched or chafed hoses, loose fittings;

4.) Structural deformation of frame;

5.) Unusual noise or binding

(B) Monthly Inspections

1.) Check oil level. Oil should be 2" to 2½" below the top of the tank with the

cylinder in the fully retracted position. Add as necessary.

2.) Check for oil leaks.

3.) Check for worn or damaged hydraulic hoses, elect rical wires, and cords.

Repair as necessary.

4.) Cycle the crusher and listen for unusual noise.

5.) Make sure all warning labels are readable and in plac e according to the

diagram on p. 12.

6.) Remove dirt and debris.

(C) Yearly Inspection

Change the hydraulic oil at least once per year. However, because the oil

should be changed as soon as it darkens, looks milky, or becomes gritty, oil

changes might be required more frequently than every 12 months.

After draining the oil from the reservoir, flush the reservoir before refilling it.

If the oil looks milky, water is present and the oil should be changed

immediately.

Recommended hydraulic oil

: Purity ISO AW-32 Hydraulic fluid or equal.

Page 6

HYDRAULIC DRUM CRUSHER Model HDC-900

8

PARTS IDENTIFICATION FOR HYDRAULIC DRUM CRUSHER/COMPACTOR (Model HDC-900)

KIT NO. ITEM NO.

A 5 Plunger switch 01-022-021 HDC9-PS 1

A 8 Roller switch 01-022-001 HDC9-PU 1

B 9 Hydraulic hose, bottom 22-623-008 HDC9-RS 1

B 10 Hydraulic hose, top 22-623-009 HDC9-HHB 1

1 Hydraulic cylinder (2-1/2" dia. x 36") 22-021-001 HDC9-CYL 1

2 Weather cover 04-024-001 HDC9-WC 1

3 Drum crushing platen 22-514-005 HDC9-DCP 1

4 Drum compacting head 22-514-004 HDC9-DCH 1

6 Control box 22-529-001 HDC9-CB 1

7 Power unit SEE PAGE 7 SEE PAGE 7 1

11 Weather cover, power unit (not shown) 04-024-001 HDC9-HHT 1

A Switch Kit (includes 5 & 8) 22-154-002 HDC9-KITA 1

B Hose Kit (incl udes 9 & 10) 22-154-003 HDC9-KITB 1

DESCRIPTION PART NO. QTY.

ENGINEER

NO.

Page 7

Page 8

Shipped 2011 to Present

Page 9

Shipped 2011

to Present

Page 10

Page 11

Shipped 2011 to Present

Hydraulic System Diagram

Page 12

Page 13

Rev. 01/2011

LIMITED WARRANTY

Vestil Manufacturing Corporation (“Vestil”) warrants this HDC-900 (excluding “Washdown” model HDC-900-WD,

which is covered by a separate warranty) to be free of defects in material and workmanship during the warranty

period. Our warranty obligation is to provide a

warranty, after we receive a proper request from the warrantee (you) for warranty service.

replacement for a defective original part if the part is covered by the

Who may request service?

Only a warrantee may request service. You are a warrantee if you purchased the product from Vestil or from an

authorized distributor AND Vestil has been fully paid.

What is an “original part”?

An original part is a part used to make the product as shipped

to the warrantee.

What is a “proper request”?

A request for warranty service is pr oper if Vestil receives: 1) a photocopy of the Customer Invoice

shipping date; AND 2) a written request

by any of the following methods:

for warranty service including your name and phone number. Send requests

that displays the

Mail Fax Email

Vestil Manufacturing Corporation (260) 665-1339 sales@vestil.com

2999 North Wayne Street, PO Box 507 Phone

Angola, IN 46703 (260) 665-7586

In the written request, list the parts believed to be defective and include the address where replacements should be

delivered.

What is covered under the warranty?

After Vestil receives your request for warranty service, an authorized representative will contact you to determine

whether your claim is covered by the warranty. Before providing warranty service, Vestil may require you to send the

entire product, or just the defective part or parts, to its facility in Angola, IN. The warranty covers defects in the

following original dynamic components: motors, hydraulic pumps, electronic controllers, switches and cylinders. It

also covers defects in original parts that wear under normal usage conditions (“wearing parts”): bearings, hoses,

wheels, seals, brushes, batteries, and the battery charger.

How long is the warranty period?

The warranty period for original components is 1 year

. The warranty period begins on the date when Vestil ships the

product to the warrantee. If the product was purchased from an authorized distributor, the period begins when the

distributor ships the product. Vestil may extend the warranty period for products shipped from authorized distributors

by up to 30 days to account for shipping time.

If a defective part is covered by the warranty, what will Vestil do to correct the problem?

Vestil will provide an appropriate replacement for any covered part. An authorized representative of Vestil will contact

you to discuss your claim.

What is not covered by the warranty?

1. Labor;

2. Freight;

3. Occurrence of any of the following, which automatically voids the warranty

:

Product misuse;

Negligent operation or repair;

Corrosion or use in corrosive conditions;

Inadequate or improper maintenance;

Damage sustained during shipping;

Accidents involving the product;

Unauthorized modifications

: DO NOT modify the product IN ANY WAY without first receiving

written authorization from Vestil. Modification(s) might make the product unsafe to use or might

cause excessive and/or abnormal wear.

Do any other warranties apply to the product?

Vestil Manufacturing Corp. makes no other express warranties. All implied warranties are disclaimed to the extent

allowed by law. Any implied warranty not disclaimed is limited in scope to the terms of this Limited Warranty.

Page 13A

Page 14

LIMITED WARRANTY

Vestil Manufacturing Corporation (“Vestil”) warrants this HDC-900-WD drum crusher to be free of defects in material

and workmanship during the warranty period. Our warranty obligation is to provide a

original part if the part is covered by the warranty

warranty service.

, after we receive a proper request from the warrantee (you) for

replacement for a defective

Who may request service?

Only a warrantee may request service. You are a warrantee if you purchased the product from Vestil or from an

authorized distributor AND Vestil has been fully paid.

What is an “original part”?

An original part is a part used to make the product as shipped

to the warrantee.

What is a “proper request”?

A request for warranty service is pr oper if Vestil receives: 1) a photocopy of the Customer Invoice

shipping date; AND 2) a written request

by any of the following methods:

for warranty service including your name and phone number. Send requests

that displays the

Mail Fax Email

Vestil Manufacturing Corporation (260) 665-1339 sales@vestil.com

2999 North Wayne Street, PO Box 507 Phone

Angola, IN 46703 (260) 665-7586

In the written request, list the parts believed to be defective and include the address where replacements should be

delivered.

What is covered under the warranty?

After Vestil receives your request for warranty service, an authorized representative will contact you to determine

whether your claim is covered by the warranty. Before providing warranty service, Vestil may require you to send the

entire product, or just the defective part or parts, to its facility in Angola, IN. The warranty covers defects in the

following original dynamic components: motors, hydraulic pumps, electronic controllers, switches and cylinders. It

also covers defects in original parts that wear under normal usage conditions (“wearing parts”): bearings, hoses,

wheels, seals, brushes, batteries, and the battery charger.

How long is the warranty period?

The warranty period for original components is 30 days

. The warranty period begins on the date when Vestil ships the

product to the warrantee. If the product was purchased from an authorized distributor, the period begins when the

distributor ships the product. Vestil may extend the warranty period for products shipped from authorized distributors

by up to 30 days to account for shipping time.

If a defective part is covered by the warranty, what will Vestil do to correct the problem?

Vestil will provide an appropriate replacement for any covered part. An authorized representative of Vestil will contact

you to discuss your claim.

What is not covered by the warranty?

1. Labor;

2. Freight;

3. Occurrence of any of the following, which automatically voids the warranty

:

Product misuse;

Negligent operation or repair;

Corrosion or use in corrosive conditions;

Inadequate or improper maintenance;

Damage sustained during shipping;

Accidents involving the product;

Unauthorized modifications

: DO NOT modify the product IN ANY WAY without first receiving

written authorization from Vestil. Modification(s) might make the product unsafe to use or might

cause excessive and/or abnormal wear.

Do any other warranties apply to the product?

Vestil Manufacturing Corp. makes no other express warranties. All implied warranties are disclaimed to the extent

allowed by law. Any implied warranty not disclaimed is limited in scope to the terms of this Limited Warranty.

Page 13B

Loading...

Loading...