Page 1

VESTIL MANUFACTURING CORPORATION

2999 North Wayne St. • Angola, IN 46703

Phone (260) 665-7586 • Fax (260) 665-1339

E-mail: sales@vestil.com • www.vestil.com

Contents

Warnings and Safety Instructions ....................... 1

Receiving Instructions ........................................ 1

Loading Instructions ........................................... 2

Operating Instructions ........................................ 2

Rack Specifications............................................ 3

Periodic Maintenance Instructions ..................... 4

Operation............................................................ 5

Hydraulic Schematic .......................................... 6

Air Bleed Procedure ........................................... 6

Revised 0708

A company dedicated to solving ergonomic

and material handling problems since 1953

.

OWNER'S

MANUAL

HYDRAULIC DRUM STACKER

MODEL HDC-450-60 / 72 / 84 / 96

Foot Pump Troubleshooting Guide ............. 7

Hydraulic Drum Stacker/Boom

Exploded Parts Drawing .............................8

Parts List .....................................................9

Cradle Assembly

Exploded Parts Drawing ...........................10

Parts List ...................................................11

Warning Label Identifications ....................12

Limited Warranty .......................................12

WARNINGS & SAFETY INSTRUCTIONS

Read owner's manual completely before operating unit!

* Remove drum & disconnect power before working on unit.

* Do not stand below any part of a raised drum stacker or

drum when unit is running.

* Stand clear of drum while operating the hand crank or

chain crank.

* Use only maintenance parts supplied or approved by the

manufacturer.

* Do not change pressure relief valve setting.

* Never operate stacker/rotator unless you are watching it.

* Never exceed maximum capacity of 800 pounds for FULL

drum: or 500 pounds for HALF-FULL drum.

* Load drum at the center of the cradle.

* Consult factory for uneven loading.

* Do not continue to pump on the foot pump pedal if the

cradle is not raising.

* Do not use brake fluids or jack oils. Use AW-32 hydraulic

oil or equivalent.

* Consult factory if adding or performing any modifications

to the original equipment.

* Make sure all operator safety labels are in place (p.14).

RECEIVING INSTRUCTIONS

Every unit is thoroughly tested and inspected prior

to shipment. However, it is possible that the unit may incur

damage during transit. If you see damage when unloading

make a note of it on the SHIPPER RECEIVER.

Remove all packing and strapping material, inspect

for damage. IF DAMAGE IS EVIDENT, FILE A CLAIM

WITH THE CARRIER IMMEDIATELY! Also, check the unit

size, type of power unit, etc., to ensure the unit is correct for

the intended application.

HYDRAULIC DRUM STACKER

HDC-450 SERIES

1

Page 2

LOADING INSTRUCTIONS

The load capacity rating as inscribed on the

nameplate of your unit designates the net capacity,

assuming the cradle is aligned at the center of the

drum. This capacity must never be exceeded, as

permanent damage or injury may result.

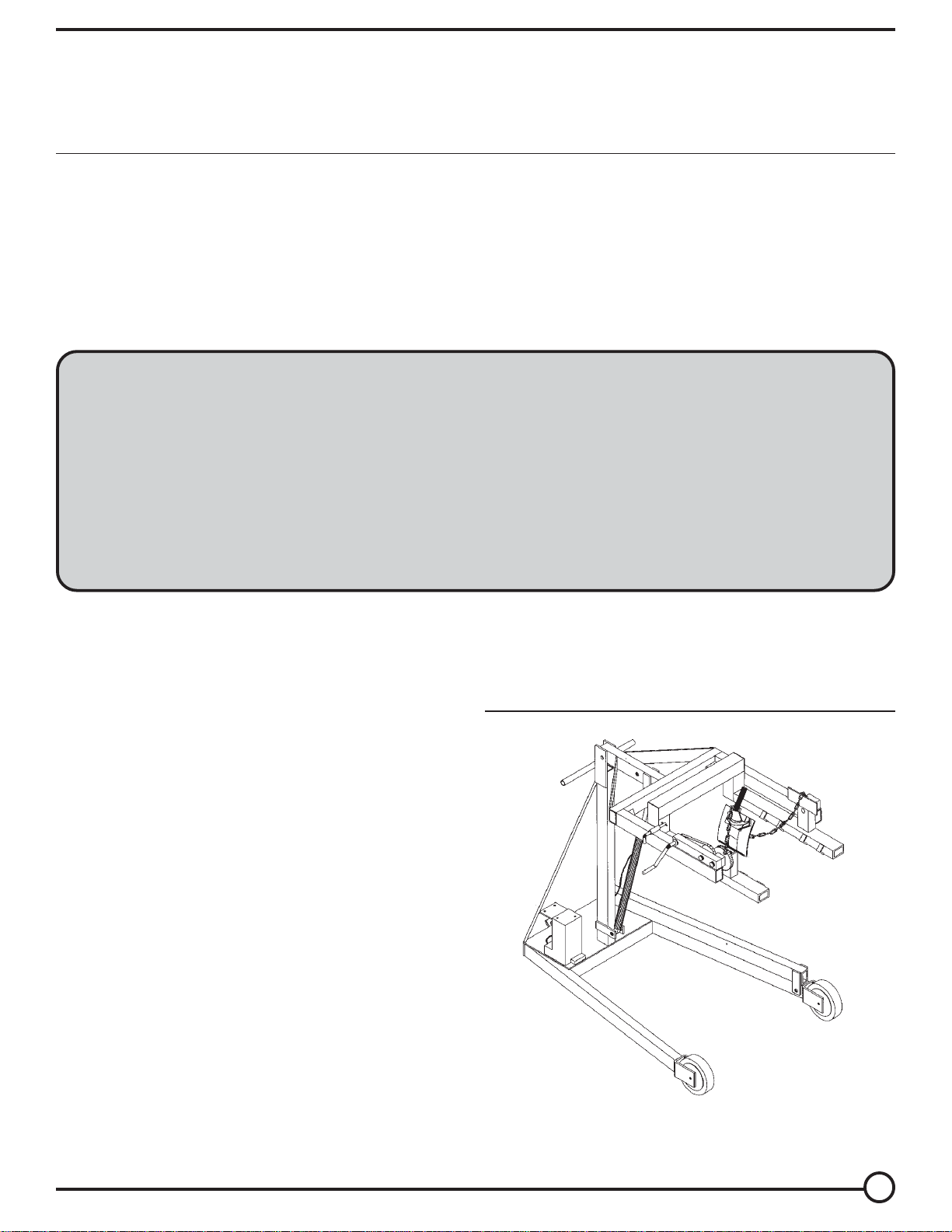

OPERATING INSTRUCTIONS

DRUM STACKER

Remove Hydraulic Drum Stacker (HDC-

450), from the crate. Check carefully for damage

and report any damage immediately. When using

the Hydraulic Drum Stacker, you can either lift up

the drum horizontally or vertically.

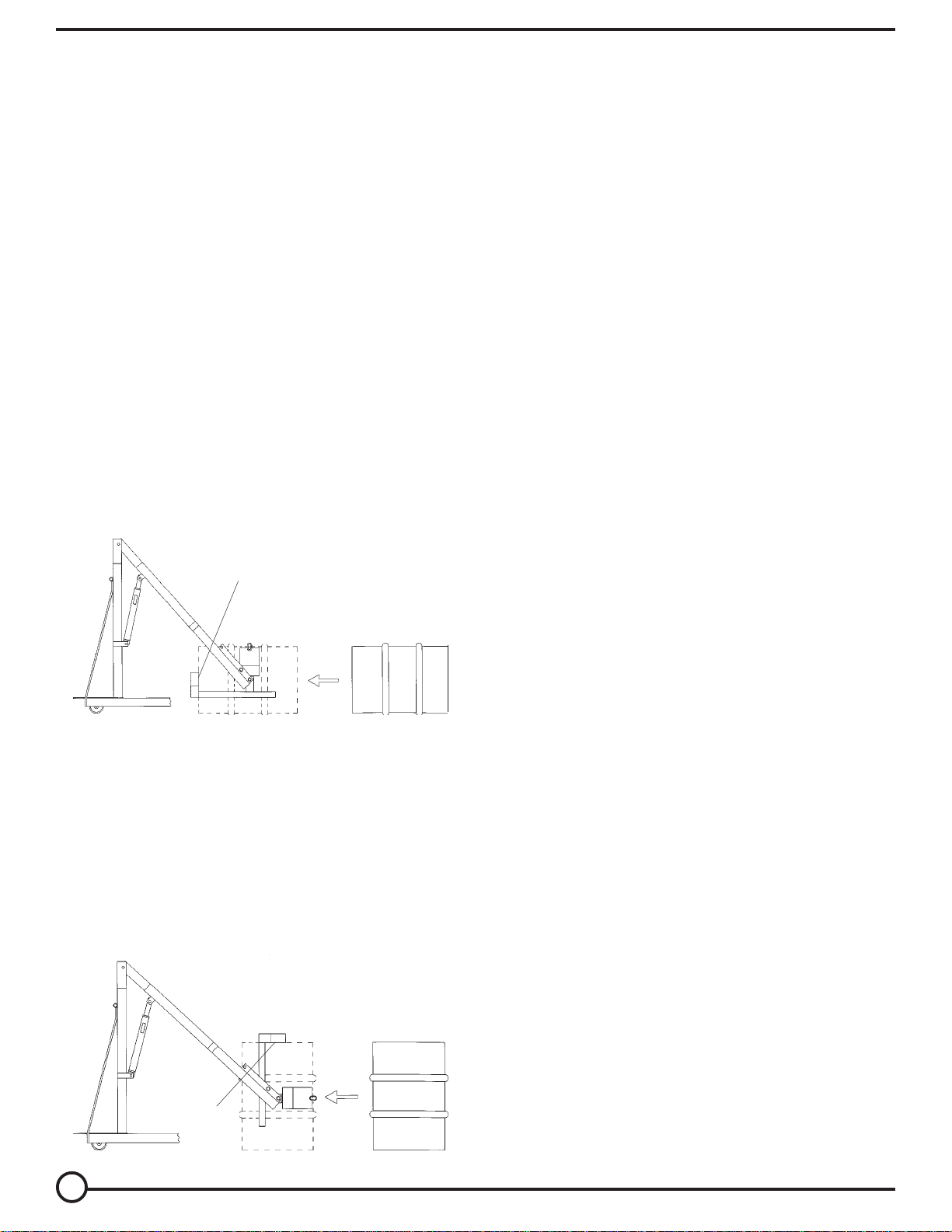

HORIZONTAL DRUM POSITION

For horizontal drum position, lower the

cradle near floor position until you can slide in the

cradle along the side of the drum. Open carrier

cradle full width and hook cradle chain on stud.

Move the unit in until the end of the cradle touch

the end of the drum. Lock drum in place by clinching chain with ratchet tightener.

In both situations, raise the cradle until the

drum is 3 - 4 inches above the ground before

moving. It is recommended, but not required, the

drum to be moved in a VERTICAL position.

Remove control chain from box and place end of

loop near operator. When stacking, rotate drum

to the HORIZONTAL position.

Always stay clear of moving parts. The

cradle will rise as the foot pedal is pumped.

Depressing the release lever will lower the cradle

at a control rate of descent.

In the event the unit is overloaded, the

relief valve will open because of excessive pressure build up, and oil will bypass into the reservoir.

TO ROTATE DRUM:

Pull on chain, rotating drum to horizontal

position for stacking. For best control of drum

rotating angle, pay out one side of the loop while

pulling in the other.

END OF CRADLE

Figure 1

VERTICAL DRUM POSITION

For vertical drum position, rotate the cradle

to vertical position and lower the cradle until the

end of the cradle is the same height as the top of

the drum. Open carrier cradle full width and hook

cradle chain on stud. Move the unit in until the

side of the drum touches the cradle. Once again,

lock drum in place by clinching chain with ratchet

tightener.

** For model HDC-450-60, the drum is rotated

using a hand crank instead of chain crank.

** When elevation is not required, transport

the drum in the lowered position.

BOOM

The HDC-450 series may also be used as

a hoist using the boom supplied with unit. The

boom is stored conveniently on one of the lower

straddle legs. Simply remove the 3/4" diameter

pin from carriage and position boom on top of

carriage, align holes and replace pin and clip.

Lifting capacity for boom at hook position is 800

pounds. This capacity and load center must never

be exceeded.

END OF CRADLE

2

Figure 2

Page 3

SAFETY INSTRUCTIONS FOR THE OPERATOR

1.) The HDC-450 series has a MAXIMUM CAPACITY RATING of 800 pounds FULL, and 500 pounds

HALF-FULL, and is intended for lifting, moving, and stacking 55 GALLON steel drums. Do not exceed

these ratings as the unsafe condition that may result could cause damage or excessive wear, or make

the unit awkward to handle.

2.) Always load the unit properly. Make sure the end/top of the drum is touching the end of the cradle.

3.) When operating, loading, unloading, or maintaining your drum stacker, always use care and good

judgement, have good footing and a firm hold. Keep hands and loose clothing etc., away from all

moving parts. Never allow anyone to be below any part of a raised drum stacker, drum, or boom. Please

read all instruction THOROUGHLY before attempting to operate your new drum stacker.

4.) Do not allow drum to impact on floor, ground, or dumping station etc., or there may be damage.

5.) Never use the unit if the cradle is in need of repairs or in the case of a malfunction.

6.) Notify your maintenance personnel or supervisor in case you notice anything out of the ordinary, such

as binding, odd noises, appearance of oil, etc.

7.) Do not continue to pump on the foot pedal if the cradle is not raising. The foot pump may be

permanently damaged. Relieve system pressure by depressing the release lever.

8.) It is recommended, but not required, the drum to be moved in a VERTICAL position. When

stacking, rotate the drum to HORIZONTAL position.

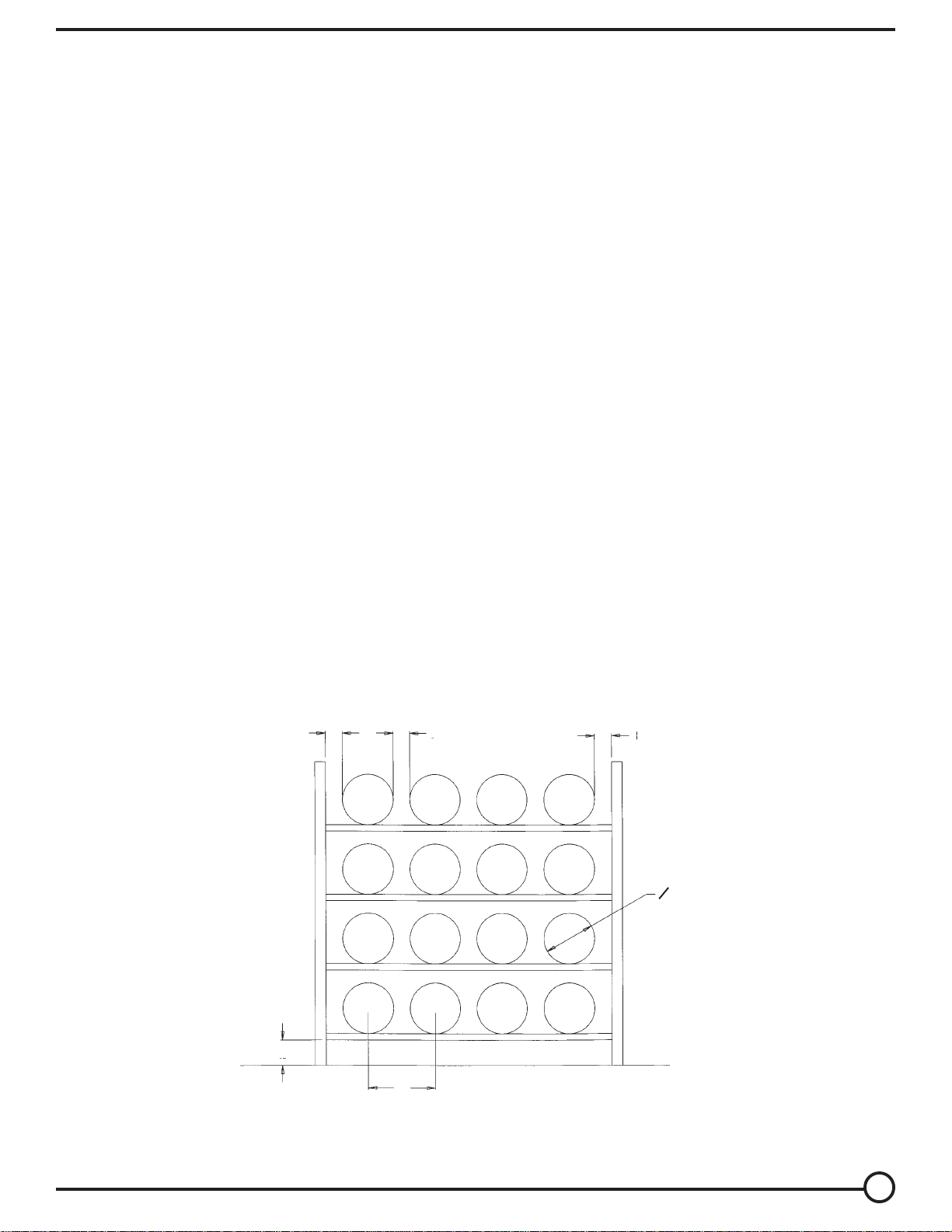

RACK SPECIFICATIONS FOR THE HORIZONTAL DRUM STACKER (HDC-450 SERIES)

8

8

1/4

O 24

12

FLOOR

32

3

Page 4

PERIODIC MAINTENANCE INSTRUCTIONS

BE SURE ALL POWER IS OFF BEFORE ATTEMPTING TO WORK ON THIS EQUIPMENT!

CAUTION: SERVICE WORK SHOULD BE PERFORMED ONLY BY TRAINED & QUALIFIED PERSONNEL

(A) Before Each Use Check For The Following

1.) Oil leaks.

2.) Worn or damaged hose.

3.) Structural deformation of cradle or frame.

4.) Unusual noise or binding.

5.) Check casters for proper operation.

Do not use if there are any of the above!

(B) Monthly Inspections

1.) Check oil level. Oil should be 1" to 1 1/2" below the top of the tank with the

cradle in the fully lowered position. Add as necessary.

2.) Check for oil leaks.

3.) Check for worn or damaged hose.

4.) Check clevis and pivot points for wear.

5.) Periodically inspect all moving parts, framework, and contact areas for sign

of wears, fatigue or loosening.

Tighten, adjust or replace parts as necessary to prevent failure and

maintain proper function.

6.) Check oil cradle hinges, ratchet, pawl, chain and other moving parts

periodically.

7.) Lubricate gear-train once a month with a good grade lubricant.

There are three grease fittings on the gear block, and one grease fitting in

the idler bearing block.

8.) Check for unusual noise.

9.) Clean off dirt and debris.

10.) Make sure all warning labels are in place and in good condition (p.14).

(C) Yearly Inspection

4

Hydraulic oil should be changed at least once a year, or sooner if the oil

darkens or becomes gritty. Flush reservoir before refilling. Presence of

water is indicated if the oil turns milky. Recommended oil: AW-32

Hydraulic fluid or equal.

All maintenance work must be performed by qualified personnel with

training in the repair of electrical and hydraulic components

Page 5

OPERATION

Warning:

Keep all personnel clear of the machine when it is in operation. Be certain no part of any

person or object is under any part of the platform before lowering the unit.

Caution:

Always carefully watch cradle and any load on it when it is in operation.

Do not exceed a rate of two feet per second when transporting a load with the drum stacker.

• The standard manually-powered stacker is furnished with a two-speed foot pump. Under empty or

low load conditions, the pump pushes a higher volume of fluid to the cylinder and thus lifts the platform

with fewer foot strokes. With a moderate to full load, the pump will automatically reduce its output in

order to generate the required hydraulic pressure.

• To lift the platform, simply repeatedly press the foot pump's foot treadle. To lower the platform, press

the small lever at the left corner of the pump with your toe. The unt will hold its position when the

lowering lever is released.

VELOCITY FUSE OPERATION

There is a brass velocity fuse with a stainless steel spring in the base of each cylinder. In the

event of a hydraulic hose or fitting failure, the cradle starts to lower at a fast rate. As soon as the descent speed exceeds the fuse's preset speed, the velocity fuse will shut off the oil flow and the cradle

will remain nearly stationary until pressure is reapplied (after repairs are done). This safety feature

reduces the possibility of accidental personal injury or damage to the unit or its loads. If air is introduced into the system, the velocity fuse can lock up even though no failure has occurred. To reset the

velocity fuse just activate pump by depressing the "UP" button. Remove the load and follow the

cylinder air bleed procedures on page 6.

5

Page 6

AIR BLEED PROCEDURE

If your unit descends very slowly or will not descend at all, air could be trapped in the hydraulic

circuit and must be "bled" from the system. The Hydraulic Drum Stacker (HDC-450 Series) utilizes a

"bleeder" fitting at the end of the cylinder near the cross tube. If you experience the above, follow

these directions.

1.) Remove the drum from the cradle.

2.) Raise the unit.

3.) If available, place a 1/4" plastic hose over the cylinder bleeder screw.

4.) Loosen the bleeder screw at the top of the cylinder approximately 1/4 to 1/2 turn to allow

trapped air to escape.

5.) When the cylinder is free of air, tighten the bleeder screw and remove the plastic hose.

Air can also become trapped in the foot pump.

Please refer to page 8 for the foot pump air bleed procedure.

HYDRAULIC SCHEMATIC

1.5" x 18" DISPLACEMENT CYLINDER

WITH INTERNAL VELOCITY FUSE

6

Page 7

Trouble shooting Guide for Single and Two-speed Hydraulic Foot Pump

1.) Cradle does not raise

2.) Foot pedal goes down hard but

cradle does not raise

3.) Unit will pump under no load or

when rapidly stroked, or pedal will

stroke without pumping

4.) Cradle raises when the pump is

stroked but lowers on return stroke

5.) Cradle raises but takes too much

effort

6.) Cradle raises but is too slow

7.) Spongy or jerky operation

Possible Cause

a. Excessive load

b. Oil is low

c. Pinched hose

d. Relief valve set too low

a. Particle of dirt under the pressure

relief valve

b. Particle of dirt under inlet check valve

a. Pump is air locked

b. Inlet check valve has foreign material on

seat

c. Relief setting is out of adjustment

d. Foreign material on relief valve seat

a. Outlet check is leaking

a. Change pump displacement speed

a. Change pump displacement speed

b. Intake filter clogged

c. Foreign material stuck under pressure relief

valve or under inlet check valve

a. Check for foreign material stuck in clevis or

pivot points or frame rails

b. Oil is low

RemedyObservation

a. Remove part of the load

b. Fill oil to within one inch of the top of the

reservoir

c. Correct as necessary

d. Increase only as necessary

a. Lower cradle - Disassemble, clean and re

assemble pressure relief valve*

b. Lower cradle - Disassemble, clean and re

assemble inlet check valve*

a. Bleed air from system inlet

b. Remove and clean inlet ball and seat

c. Adjust relief setting higher

d. Lowering valve has foreign material on the

seat or is stuck in the open position

a. Clean foreign material from ball and seat

a. Slide locking collar back

a. Slide locking collar forward

b. Lower cradle - drain reservoir, clean and

flush debris, refill with clean oil

c. Lower cradle - Disassemble, clean and re

assemble pressure relief valve*

a. Correct as necessary

b. Fill oil to within one inch of the top of the

reservoir

*Refer to exploded view

8.) Cradle lowers too slow

9.) Cradle lowers too fast

10.) Cradle raises but does not lower

a. Pinched hose

b. Intake filter clogged

c. Foreign material lodged in velocity fuse

d. Foreign material lodged in pressure

compensated flow control valve

a. Foreign material lodged in pressure

compensated flow control valve

a. Foreign material lodged in pressure

compensated flow control valve

b. Release pin bent or missing

c. Foreign object blocking roller travel

d. Velocity fuse is locked

a. Correct as necessary

b. Correct as necessary

c. Lower cradle - Disassemble, clean and re

assemble

d. Lower cradle - Disassemble, clean and re

assemble pressure relief valve*

a. Lower cradle - Disassemble, clean and re

assemble pressure relief valve*

a. Lower cradle - Disassemble, clean and re

assemble pressure relief valve*

b. Replace as necessary

c. Correct as necessary

d. Remove air from hydraulic system, to un

lock, repressurize system

7

Page 8

HDC-450 SERIES HYDRAULIC DRUM CARRIER/ROTATOR

7

6

17

7

6

16

1

14

10

13

12

7

6

15

2

7

6

8

4

9

3

5

8

Page 9

PARTS IDENTIFICATION

HDC-450 SERIES HYDRAULIC DRUM CARRIER/ROTATOR

ITEM NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

DESCRIPTION

HDC cradle ass'y (see pages 6 & 7)

Hydraulic cyl., 1-1/2" dia. x 18" [HDC-450-60/72/84]

Hydraulic cyl., 1-1/2" dia. x 18" [HDC-450-96 only]

Wheel, caster

Locking hex nut, 1/2"-20

Hex head cap screw, 1/2"-20 x 3-1/2"

Clevis pin, 3/4" dia. x 3-3/8"

Hitch pin clip, # 11 (Fastenal)

Floor brake

Hex nut, 3/8"-16

Reservoir

Two-speed hydraulic foot pump (not shown)

Handle grip

Hex head cap screw, 3/8"-16 x 1"

PART NO.

09538005

09021004

09021004

16132036

A/L

A/L

09112006

45285

16132080

A/L

15023001

250550

AL

A/L

QTY

1

1

2

2

2

2

4

4

1

4

1

1

2

4

14

15

16

17

A/L

Available at local hardware store

Reservoir hose

Hydraulic hose (HDC-450-60)

Hydraulic hose (HDC-450-72)

Hydraulic hose (HDC-450-84)

Hydraulic hose (HDC-450-96)

Spring pin, 3/16" x 1-1/2" (HDC-305-60 only)

Boom

09623001

09623002

09623003

09623004

09623005

A/L

09514031

1

1

1

1

1

1

1

9

Page 10

31

28

HDC-450 SERIES

PARTS DIAGRAM FOR CRADLE ASSEMBLY (DRUM CARRIER/ROTATOR

29

30

10

Page 11

PARTS DIAGRAM FOR CRADLE ASSEMBLY (DRUM CARRIER/ROTATOR

HDC-450 SERIES

ITEM

NUMBER

1a

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

DESCRIPTION

Hand wheel ( HDC-450-60 only)

Chain wheel (HDC-450-72/84/96 only)

#1/0 Babbitt lock link chain (20") (HDC-450-72/84/96 only)

Chain wheel shaft w/triangle & bolts (HDC-450-72/84/96 only)

Bolt & nut, 5/16-18 x 1" (HDC-450-72/84/96 only)

Bearing, 3/4" ID x 2-1/2"

Grease fitting Alemite (1608B)

Washer, 3/4" SAE

Sprocket (12T # 35)

Roller chain (# 35-3/8" pitch)

Sprocket (36T # 35)

Pinion gear (7T) w/key

Hinge pine & nuts

Pawl shoulder screw and nut

Pawl spring

Pawl

Snap ring

Ratchet

Handle grip

Pawl & ratchet hinge plate

Binder chain

Chain bolt & nut (3/8"-16 x 2-1/2" HHMS)

Chain hinge plate

Spacer (3/4" ID)

Bearing (Randall SH186)

Bearing block

Collar (3/4" ID)

Washer & nut

Spur gear spacer

Bearing, 1" ID x 2-1/2"

Collar (1" ID)

Cradle assembly for 55 gal. steel drum

PART

NUMBER

1A-P

1-P

2-P

3-P

35-P

01111048

33-P

09113004

09042004

09042006

09042003

09042007

157-P

170-P

169-P

168-P

166-P

165-P

136-P

09516006

180-P

155-P

09516007

20-P

7-P

09113005

09145001

21-P

09113006

01111047

09145003

09538005

QUANTITY

1

1

1

1

3

1

4

5

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

2

1

2

2

2

1

1

1

11

Page 12

WARNING LABEL IDENTIFICATION

MAKE SURE ALL WARNING LABELS ARE IN PLACE!

USE AW-32 HYDRAULIC

OIL OR

EQUIVALENT

1

*Product safety signs or labels should be periodically

inspected and cleaned by the product users as necessary

to maintain good legibility for safe viewing distance ...

ANSI 535.4 (10.21)

Contact manufacturer for replacement labels.

LIMITED WARRANTY

ONE YEAR LIMITED WARRANTY. The manufacturer warrants for the original purchaser against defects

in materials and workmanship under normal use one year after date of purchase. (Not to exceed 15 months after

date of manufacture.) Any part which is determined by the manufacturer to be defective in material or workmanship

and returned to the factory, shipping costs prepaid, will be, as the exclusive remedy, repaired or replaced at our

option. Labor costs for warranty repairs and/or modifications are not covered unless done at manufacturer’s

facilities. Any modifications performed without written approval of the manufacturer may void warranty. This limited

warranty gives purchaser specific legal rights which vary from state to state.

LIMITATION OF LIABILITY. To the extent allowable under applicable law, the manufacturer’s liability for

consequential and incidental damages is expressly disclaimed.

The manufacturer’s liability in any event is limited to, and shall not exceed, the purchase price paid. Misuse or

modification may void warranty.

WARRANTY DISCLAIMER. Our company has made a diligent effort to illustrate and describe the products

shown accurately; however, such illustrations and descriptions are for the sole purpose of identification, and do not

express or imply a warranty that the products are merchantable, or fit for a particular purpose, or that the products

will necessarily conform to the illustrations or descriptions.

The provisions of the warranty shall be construed and enforced in accordance with the UNIFORM

COMMERCIAL CODE and laws as enacted in the State of Indiana.

DISPOSITION. Our company will make a good faith effort for prompt correction or other adjustment with

respect to any product which proves to be defective within the Limited Warranty. Warranty claims must be made

in writing within said year.

12

Loading...

Loading...