Vestil HBD-2-36, HBD-2-48, HBD-2-60, HBD-4-48, HBD-4-60 User Manual

...

03/10/03 3/3/2017 HBD, MANUAL

Vestil Manufacturing Corp.

2999 North Wayne Street, P.O. Box 507, Angola, IN 46703

Telephone: (260) 665-7586 -or- Toll Free (800) 348-0868

Fax: (260) 665-1339

Url: www.vestilmfg.com Email: sales@vestil.com

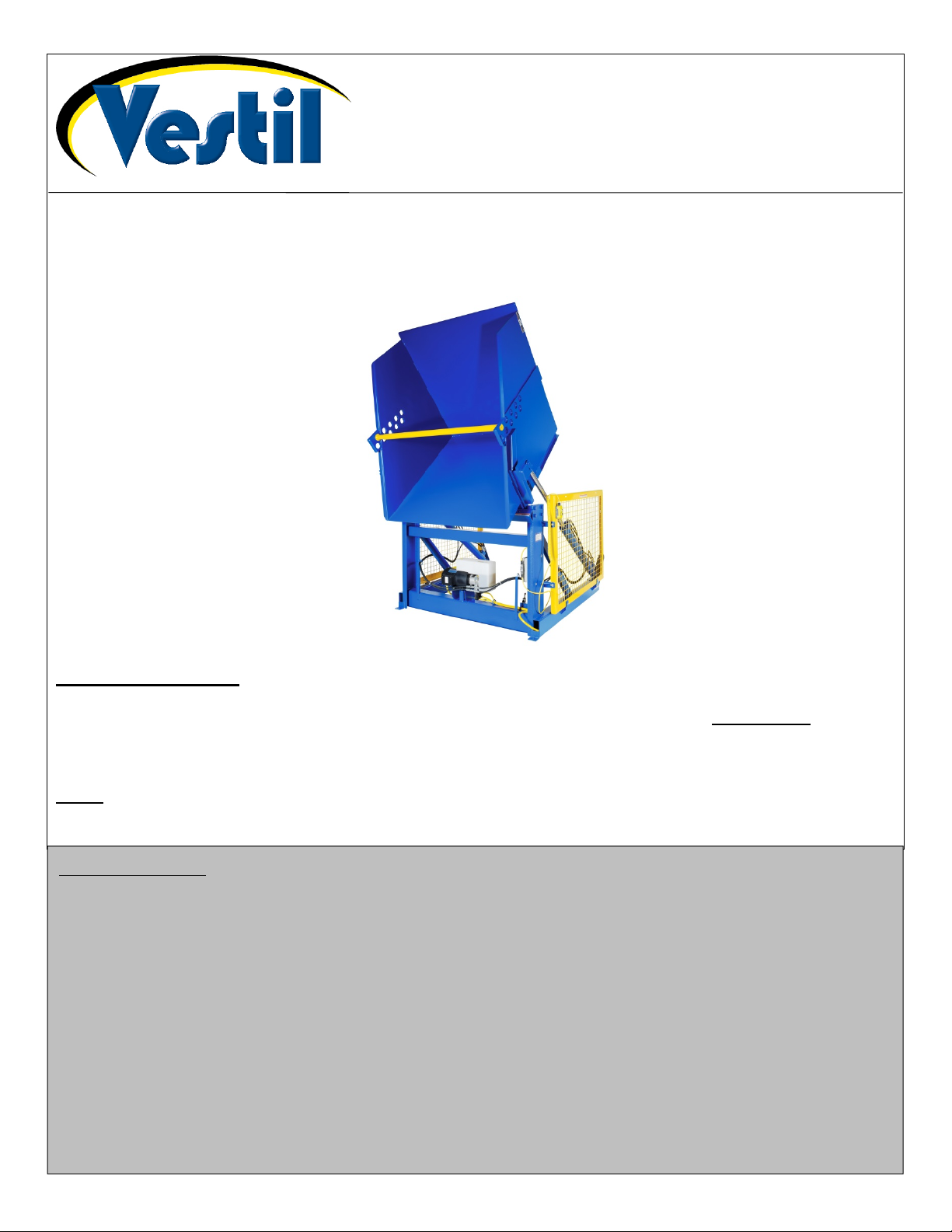

HBD-Series Hydraulic Box Dumpers

Instruction Manual

Receiving instructions:

After delivery, remove the packaging from the product. Inspect the product closely to determine whether it

sustained damage during transport. If damage is discovered during the inspection, immediately record a

complete description of the damage on the bill of lading. If the product is undamaged, discard the

packaging.

NOTE:

The end-user is solely responsible for confirming that product design, installation, use, and maintenance

comply with laws, regulations, codes, and mandatory standards applied where the product is used.

Table of Contents

Specifications………………………………................................................................................................................... 2

Signal Words……….……………….............................................................................................................................. 3

Hazards of Improper Use………….............................................................................................................................. 3

Installation instructions………………………................................................................................................................ 4

Operation instructions………………………................................................................................................................. 4

Inspections……………………………………................................................................................................................ 5

Power unit operation………………………................................................................................................................... 5 – 6

Figs. 1-3 Electrical circuit diagrams ….………………………………………………………………………………………. 7 – 9

Fig. 4 Motor & transformer connection diagrams….……………………………………………………………………… ... 10

Figs. 5A-5C Electrical circuit diagrams…………..…..………………………………………………………………………. 11 – 13

Figs. 6A-6B Hydraulic circuit diagrams………............................................................................................................. 14

Figs. 7A-7C Exploded parts diagrams…………….…………………………………………………………………………. 15 - 17

Installing option HBD-GATE……………………………………………………………………………………………………18

Troubleshooting guide…………………………………………………………………………………………………………. 19

Limited warranty……………………………................................................................................................................... 20

Labeling diagram……………….……………................................................................................................................. 21

Copyright 2017 Vestil Manufacturing Co. Page 1 of 21

03/10/03 3/3/2017 HBD, MANUAL

eight with

usable

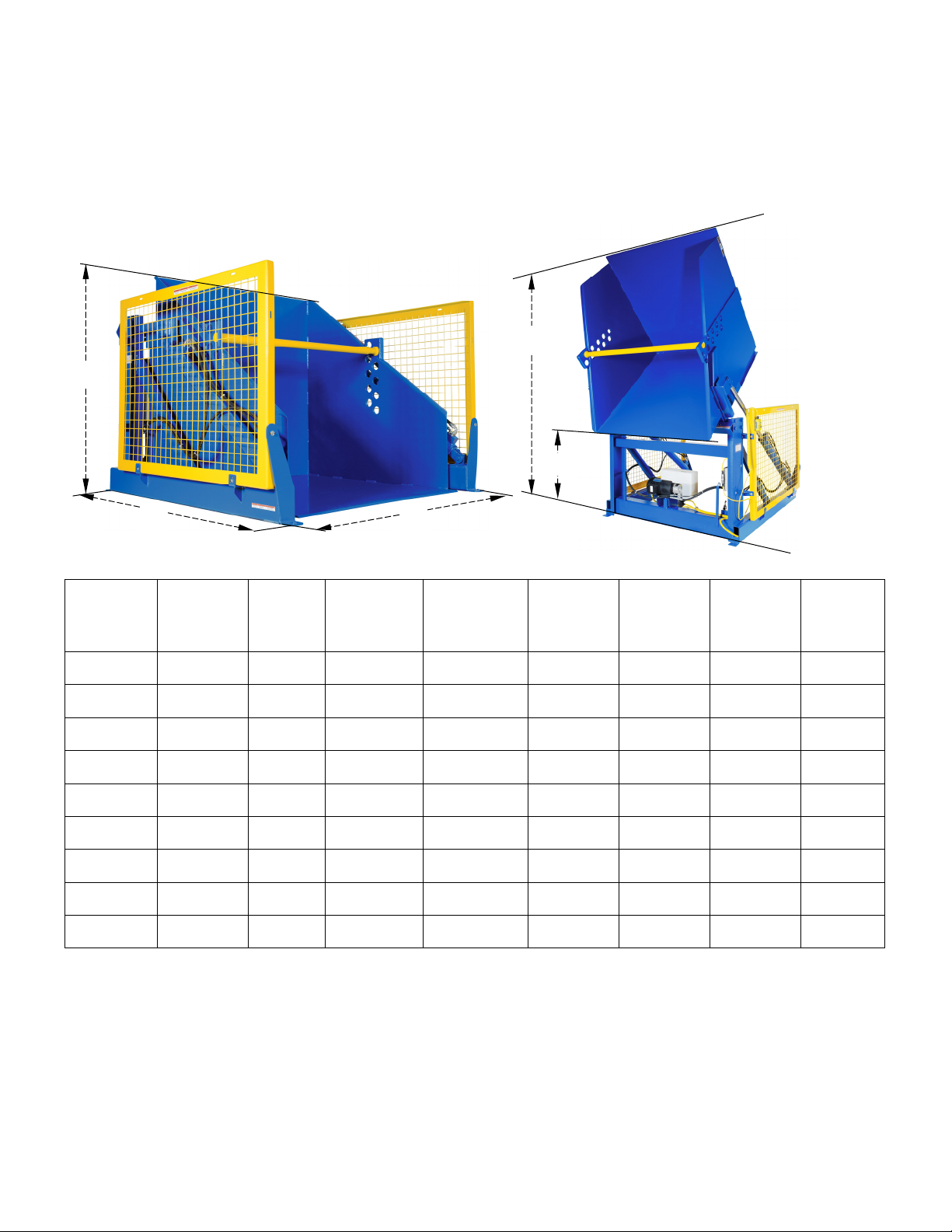

Specifications:

Our dumpers are durable, high-quality products that are rigorously engineered to provide safety-enhancing features

while preserving simplicity. Standard design features include: 2HP, 3-phase motor; cast iron pump that integrates

pressure relief, check, down solenoid, and pressure compensated flow control valves; expanded metal machine sideguards; hydraulic actuators with internal brass velocity fuse and stainless steel spring; and 24V fused control circuit.

Dimensions and other specifications appear in the diagrams and table.

C

A

B

D

E

Model

HBD-2-36

HBD-2-48

HBD-2-60

HBD-4-36

HBD-4-48

HBD-4-60

HBD-6-36

HBD-6-48

HBD-6-60

A: Max.

h

chute

retracted

531/2”

cm

65”

165 cm

77”

196 cm

531/2”

cm

65”

165cm

77”

196cm

531/2”

cm

65”

165cm

77”

196cm

B:

Dump

height

36”

91 cm

48”

122 cm

60”

152 cm

36”

91 cm

48”

(122cm

60”

(152)

36”

91 cm

48”

(122cm

60”

(152)

C: Max.

height with

chute

extended

111”

282 cm

1291/2”

329 cm

1491/2”

380 cm

111”

282 cm

1291/2”

329 cm

1491/2”

380 cm

111”

282 cm

1291/2”

329 cm

1491/2”

380 cm

Chute

dimensions

[W x L]

52” x 50”

(132 x 127)cm

52” x 50”

(132 x 127)cm

52” x 50”

(132 x 127)cm

52” x 50”

(132 x 127)cm

52” x 50”

(132 x 127)cm

52” x 50”

(132 x 127)cm

52” x 50”

(132 x 127)cm

52” x 50”

(132 x 127)cm

52” x 50”

(132 x 127)cm

D: Overall

length

681/2”

174 cm

681/2”

174 cm

681/2”

174 cm

681/2”

174 cm

681/2”

174 cm

681/2”

174 cm

681/2”

174 cm

681/2”

174 cm

681/2”

174 cm

E: Overall

width

69”

176 cm

69”

176 cm

69”

176 cm

69”

176 cm

69”

176 cm

69”

176 cm

69”

176 cm

69”

176 cm

69”

176 cm

Capacity

2,000 lb.

909 kg

2,000 lb.

909 kg

2,000 lb.

909 kg

4,000 lb.

1,818 kg

4,000 lb.

1,818 kg

4,000 lb.

1,818 kg

6,000 lb.

2727 kg

6,000 lb.

2727 kg

6,000 lb.

2727 kg

Net

weight

1631 lb.

741.2 kg

1787 lb.

812.2 kg

1948 lb.

885.5 kg

1655 lb.

752.1 kg

1859 lb.

844.8 kg

2020 lb.

918 kg

1808 lb.

795kg

1988 lb.

903.3 kg

2021 lb.

919kg

Copyright 2017 Vestil Manufacturing Co. Page 2 of 21

03/10/03 3/3/2017 HBD, MANUAL

Signal Words:

This manual uses SIGNAL WORDS to identify situations likely to result in personal injury or property damage.

These words also indicate the seriousness of those injuries. Signal words used in this manual appear below along

with their definitions.

Identifies a hazardous situation which, if not avoided, WILL result in DEATH or

SERIOUS INJURY. Use of this signal word is limited to the most extreme situations.

Identifies a hazardous situation which, if not avoided, COULD result in DEATH or

SERIOUS INJURY.

Indicates a hazardous situation which, if not avoided, COULD result in MINOR or

MODERATE injury.

Identifies practices likely to result in product/property damage, such as operation that

might damage the product.

Hazards of Improper Use:

Vestil diligently strives to identify foreseeable hazards associated with the use of its products. However,

material handling is inherently dangerous and no manual can address every conceivable risk. The enduser ultimately is responsible for exercising sound judgment at all times.

Electrocution might result if any part of the dumper contacts electrified wires. Reduce the likelihood

that platform occupants or bystanders might be electrocuted by applying common sense:

DO NOT contact electrified wires with any part of the dumper;

DO NOT install the HBD in an area where contact with electrified wires is likely;

DO NOT use the dumper close to electrified wires or other sources of electricity;

Before using the dumper, always inspect the usage area for unusual conditions that require special precautions.

Material handling is dangerous. Improper or careless operation might result in serious personal

injuries sustained by the operator(s) and/or bystanders. Work platform users should conform to the following:

ONLY use the box dumper as a means for mechanically emptying appropriately sized (see “Load the dumper” on

p. 4-5) boxes, crates and other containers. ALWAYS properly load the dumper according to the directions on p. 4-5.

DO NOT use a damaged dumper. Examples of structural damage include: broken container restraining tube,

broken fork pockets, and holes caused by rust or corrosion. Inspect the dumper before each use according to the

inspection instructions on p. 5. DO NOT use the HBD unless it passes every element of the inspection, or until

authorized maintenance personnel approve the dumper for service.

Inspect the unit before each use according to the inspection instructions on p. 5.

DO NOT stand beneath or travel under the dumper chute while it is elevated or allow others to do so.

DO NOT use UNLESS each label shown in Fig. 8 on p. 14 is affixed to the dumper, undamaged and readable.

DO NOT exceed the maximum rated load (capacity) of the dumper. The weight of the container to be dumped

plus the weight of its contents must not exceed the maximum rated load of the dumper.

DO NOT modify the box dumper in any way UNLESS you first obtain express, written approval from Vestil.

Unauthorized modifications might make the dumper unsafe to use, and could result in operator and/or bystander

injury.

DO NOT fill the hydraulic system with brake fluid or jack oils. Only fill the hydraulic system with

either anti-wear hydraulic oil, viscosity grade 150 SUS at 100°F (ISO 32cSt at 40°C) or Dexron transmission fluid.

Copyright 2017 Vestil Manufacturing Co. Page 3 of 21

03/10/03 3/3/2017 HBD, MANUAL

: Run the dumper through several

complete cycles. Press the “UP” button of

the hand controller until the chute raises

as far as it can, and then lower it

letely. Repeat the cycle a few more

times to confirm that the product operates

: Check the oil level in the reservoir.

ully raise the chute (to the 45°) “dumping

position,” and then observe the level of oil

of the oil

the fill

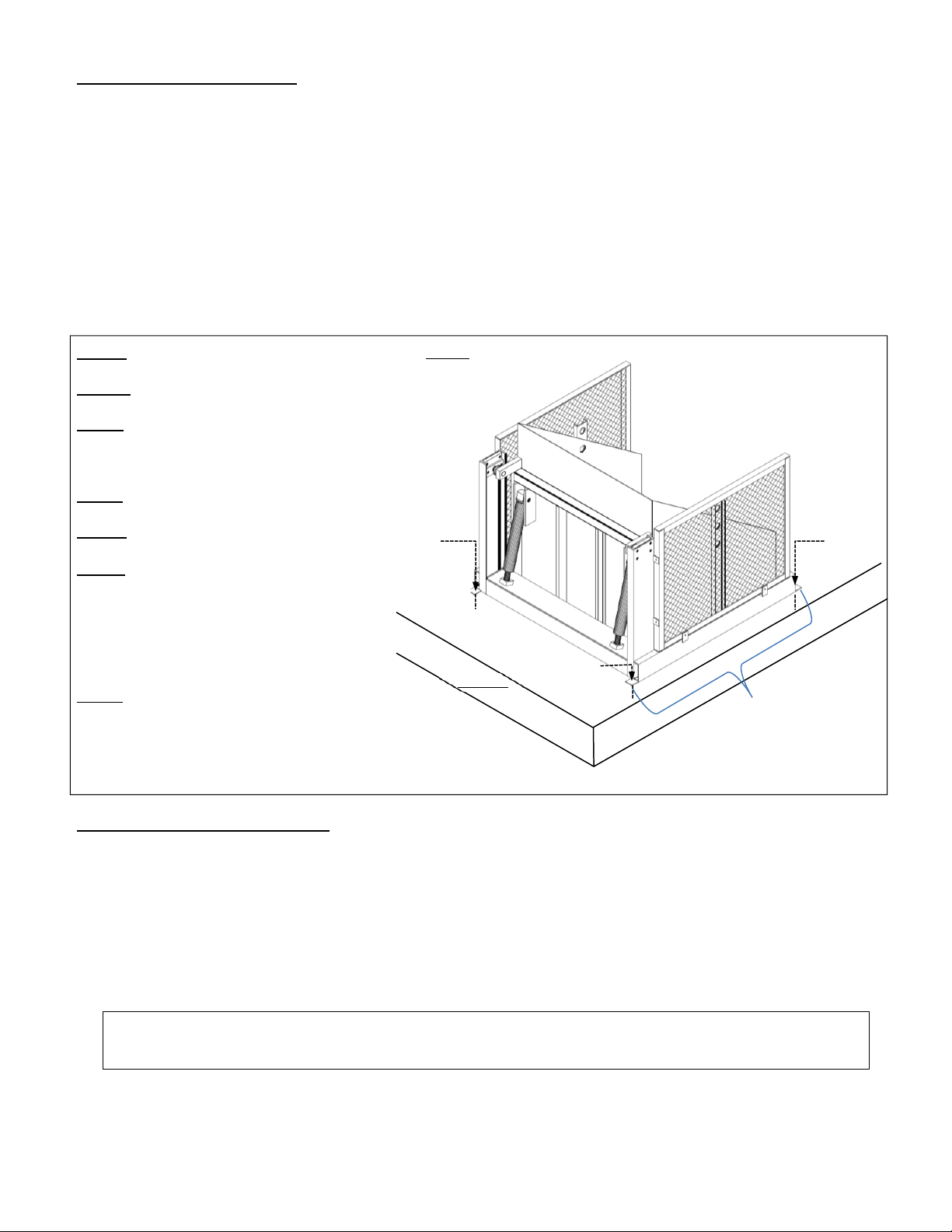

Installation instructions:

Responsibility for compliance will local building code(s) requirements, municipal/county ordinances, etc. rests

exclusively with the end-user. The instructions that appear below are recommendations about essential, minimum

steps necessary for safe installation. If law enforced where the dumper is used requires you to depart from these

directions, Vestil is not responsible for any consequential damages sustained as a result of the installation.

Installation requires at least:

Forklift rated for loads equal to the net weight of your HBD model (see Table on p. 2);

Lag bolts: ½ in. by at least 4in. (length) [approximately equivalent to 1.3cm by at least 10.2cm]

Masonry drill and ½ in. masonry drill bit

Wrench: ½ in.

Grout and steel shims

Power supply circuit: matched to motor voltage and current requirements (see Label 250 in “Labeling Diagram”

on p. 21).

NOTE: End-user responsible for providing overcurrent and short circuit protection.

Step 1: Position the dumper as desired

Installation diagram

with a forklift.

Step 2: Drill holes approximately 4in.

(10cm) deep.

Left side

Step 3: Secure the dumper to the floor by

inserting the lag bolts through the (5/8 in.)

bolt holes in the anchor brackets (dotted

Right side

lines in diagram.

Step 4: Shim and/or grout the sides of the

frame.

Step 5: Connect the power cord to the

power supply.

Step 6

Lag

bolt

Lag bolt

comp

properly.

Step 7

F

in the reservoir. The surface

should be 1 to 1½ inches below

hole.

Concrete

Lag bolt

Shim or grout

entire length

(and under left

side)

Operating the box dumper

Load the dumper:

1. Use only properly sizes waste containers: HBD’s are designed to dump open-top containers. Container width

should be at least ½ the width of the chute, and container height should be at least ¾ the height of the chute.

2. Place the container inside the chute: the back of the container should rest against the back of the chute.

3. Insert retaining tube: to prevent the container from sliding out of the chute along with the trash, install the

container-retaining tube through the sockets that are most closely matched to the height of the container. The

top of the container should not be more than 5 inches (~12½ cm) below the tube.

4. Dump the container: press the “UP” button on the pendant controller to raise the chute to the dumping position.

The cylinders will extend, which raises the chute, only while the operator presses the “UP” button. When the

operator releases the UP button, the chute will maintain its position as of the instant the button is released.

NOTE: If the net weight of the container and its contents exceeds the maximum rated load of the dumper, a

relief valve (incorporated into the hydraulic system) will open. While the relief valve is open, the hydraulic

cylinders will not extend, and therefore the chute will not raise/dump.

5. Return the chute to the loading position: press the “DOWN” button on the controller—the cylinders will retract,

which pulls the chute toward the ground. If the DOWN button is released before the chute is completely retracted,

it will maintain its position. Always completely lower the chute.

Models rated for up to 6,000 pounds (2,727kg) include a lower limit switch that prevents the cylinders from

retracting more than necessary to lower the chute to the loading position.

Copyright 2017 Vestil Manufacturing Co. Page 4 of 21

03/10/03 3/3/2017 HBD, MANUAL

Inspections

Before each use, inspect the listed components:

1. Wires: look for frays;

2. Hydraulic system: check lines for chafes, pinches or leaks, and

the reservoir for punctures or leaks;

3. Container-restraining tube (and the openings in the chute that

receive each end of the tube): damage deformation, looseness

of fit;

4. Frame: check the cylinder brackets, vertical and horizontal

frame members, horizontal cross-member, and angle cross

member, hinge blocks, and pivot shaft and spacer assemblies

for cracking, deformation and corrosion;

5. Limit switches: verify normal function. The chute should not

rotate beyond approximately 45 degrees or below 0 degrees.

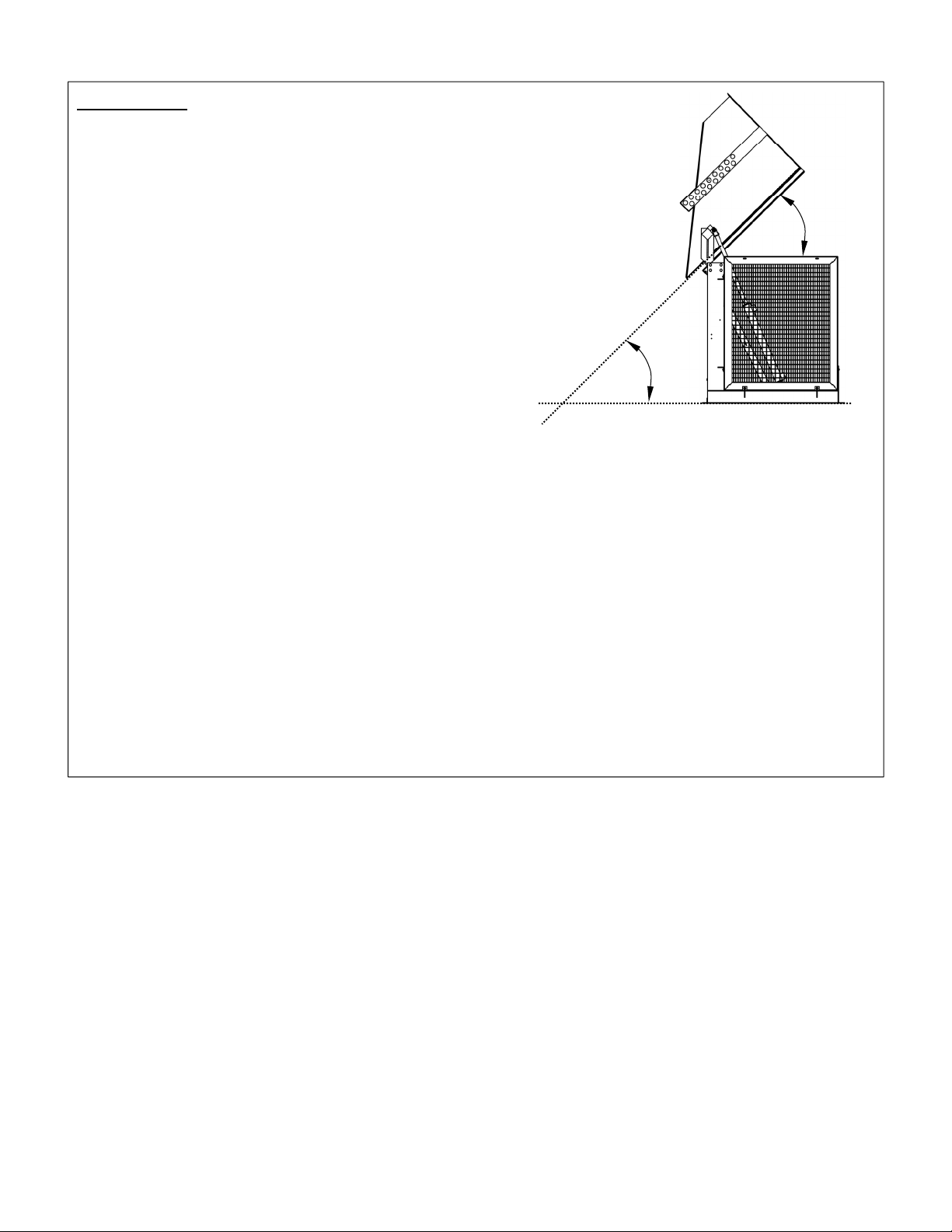

(See FIG. 1).

Also listen for unusual sounds that might indicate binding or

45°

grinding during operation and watch for erratic movement(s).

Contact maintenance personnel if you observe any unusual

sound or movement and do not use the dumper until approved for

service.

At least once per month, inspect the dumper as follows:

1. Oil level: fully raise the chute (to the 45°) “dumping position,” and then observe the level of oil in the reservoir. The

surface of the oil should be 1 to 1½ inches below the fill hole.;

2. Pivot points: check the dumper for excessive wear at the pivot points between hydraulic cylinders and cylinder

brackets, and between pivot shafts and hinge blocks;

3. Floor connection points: anchor bolts should prevent the frame from lifting off of the ground during chute

operation. Concrete around each anchor bolt should be intact—no cracking or flaking;

4. Fasteners: check each fastener connection. Tighten any loose connection;

5. Hoses and wires: check each wire and hose for damage (fraying, binding, etc.);

6. Labels: labels should be easily readable and undamaged, affixed to the dumper in the locations as shown in FIG.

8 on p. 14.

7. Container-restraining tube (and the openings in the chute that receive each end of the tube): inspect the tube for

damage deformation, looseness of fit.

At least once per year, change the hydraulic oil if it becomes gritty or looks milky (water present in the oil). With

the chute in the fully lowered position, drain the oil and replace it with either Dexron transmission fluid or anti-wear

hydraulic oil, viscosity grade 150 SUS at 100°F (ISO 32 cSt at 40°C.

Dumping

position:

Chute

raised

45°

Power unit operation

The box dumper utilizes an electric motor directly coupled to a gear pump to pressurize the hydraulic fluid. Fluid

pressure moves the cylinders up or down, and this movement performs the work required to raise and lower the

chute. A hydraulic manifold bolted directly onto the gear pump houses the hydraulic control components; each

component is rated for 3,000psi working pressure.

Important components of the power unit include:

Electric motor: when ordered, the owner of this box dumper selected either a single-phase or three-phase AC

motor. Regardless of phase capabilities, every motor is dual-voltage capable.

Gear pump: shaft coupled directly to the shaft of the electric motor. Several displacements are available are

correspond to the horsepower of the motor selected.

Check valve (HBD-2-## and HBD-4-## models): prevents backflow of fluid through the pump and thereby allows

the chute maintain a given position indefinitely.

Pressure relief valve: opens a path for fluid to flow back to the reservoir if fluid pressure exceeds 3,000psi.

Lowering solenoid valve: electrically-operated cartridge valve with an integral screen to keep contaminants from

entering the valve.

Counterbalance valves (6,000lb. rated load models only): allow smooth motion in double-acting hydraulic circuits.

Pressure compensated flow control spool (2,000lb. & 4,000lb. rated load models only): located beneath the

lowering valve, and regulates the fluid flow to the reservoir. This component allows the table to lower at the

constant rate independent of the weight of the dumper and contents. Several sizes are available.

Copyright 2017 Vestil Manufacturing Co. Page 5 of 21

03/10/03 3/3/2017 HBD, MANUAL

Hydraulic cylinders: 2,00lb. and 4,00lb. rated load models utilize displacement style cylinders. Each cylinder

includes a bleeder valve (located at top end) for removing air from the hydraulic system.

6,000lb. HBD models use double action cylinders.

Velocity fuse: a safety device installed in the hose port of each cylinder. If a hose is punctured while the HBD is in

use, the velocity fuse closes automatically. The chute remains stationary until pressure is reapplied to the system.

Hydraulic fluid: HO150 hydraulic fluid. To replenish the fluid, add anti-wear hydraulic fluid with a viscosity grade

of 150 SUS at 100°F (ISO 32 @ 40°C) like AW-32 or Dexron transmission fluid.

Sequence of operation:

To tilt the chute, press the “UP” button. The motor turns and spins the gear pump. Oil flows out of the reservoir,

through the suction filter and into the pump.

2k & 4k rated load models: pump propels oil through the check valve to the lift cylinders.

6k rated load models: pressurized oil flows through the energized directional valve RT and into the blind end of

the lift cylinders; then oil is pressed out of the rod end and through a counterbalance valve 2CB. Counterbalance

valves prevent jerky movement as the chute reaches peak elevation (45° with horizontal).

Releasing the UP button during operation will immediately halt all chute movement.

Additionally, an upper travel limit switch automatically turns off the motor when the chute reaches a preset 45° tilt

angle.

To lower the chute, press the “DOWN” button.

2k & 4k max. rated load models: lowering valve opens which bypasses the check valve and allows oil in the

cylinders to flow to the reservoir (through return hoses).

6k max. rated load models: The motor turns and the pump pushes the pressurized oil through the energized

directional valve LT and into the rod end of the lift cylinders. Oil flows from the blind ends of the cylinders and

through counterbalance valve 1CB, which regulates lowering speed and smoothness. A lower limit switch turns off

the motor when the chute is fully lowered.

Releasing the DOWN button during operation causes all chute movement to stop. The chute will remain in the

same position until you press the DOWN button again and allow it to lower completely.

If the chute slowly loses elevation without pressing the DOWN button, remove, inspect, and clean the lowering

cartridge valve as follows:

1. Lower the chute completely and unplug the AC cord.

2. If loaded, remove the container from the chute.

3. Remove the nut that fastens the solenoid coil to the valve stem, remove the coil, and then unscrew the

valve from the manifold.

4. Inspect the valve for blockage(s).

5. Inspect o-rings and back-up washers for cuts, tears, etc.

6. Submerge the valve in mineral spirits or kerosene and use a thin tool, such as a small screwdriver or a

hex wrench, to push the poppet in and out several times from the bottom end of the valve. The valve

should move freely, about 1/16” between the closed and open positions. If the poppet sticks, the valve

stem might be bent. Replace the poppet if it doesn’t free up after cleaning.

7. Remove mineral oil from the valve with compressed air.

8. Move the poppet in and out.

9. Inspect the bottom of the valve cavity in the manifold for foreign matter.

10. With the thin tool, press the middle of the flow control spool, which is located in the bottom of the

cavity. It should move down and up smoothly.

11. Reinstall the valve (in the manifold) and tighten the valve with 20 lb-ft of torque.

If the chute lowers extremely slowly, air in the cylinders might be the culprit. Air closes the velocity fuse, which

prevents oil from flowing out of the cylinders. To bleed the air from the system:

Fully lower the chute;

If loaded, remove the container from the chute.

Locate the bleeder valve located at the top of each cylinder (it looks like a grease zirk). Bleed one (1) cylinder at

a time. Hold a rag over the valve and open it about 1/2 turn with a 3/8” or 5/16” wrench. Oil and air will sputter

from the valve. Jog the motor by pressing the UP button for just a second. If air continues to escape from the

bleeder valve, jog the motor several more times. Wait at least 5 seconds between successive jogs.

As soon as air no longer is observed and only a clear stream of oil flows from the bleeder valve, close the valve.

Check the oil level in the reservoir. If the surface of the oil is lower than 1 to 1½ in. below the fill hole, add oil until

it is between 1 and 1½ inches of the fill hole.

Copyright 2017 Vestil Manufacturing Co. Page 6 of 21

03/10/03 3/3/2017 HBD, MANUAL

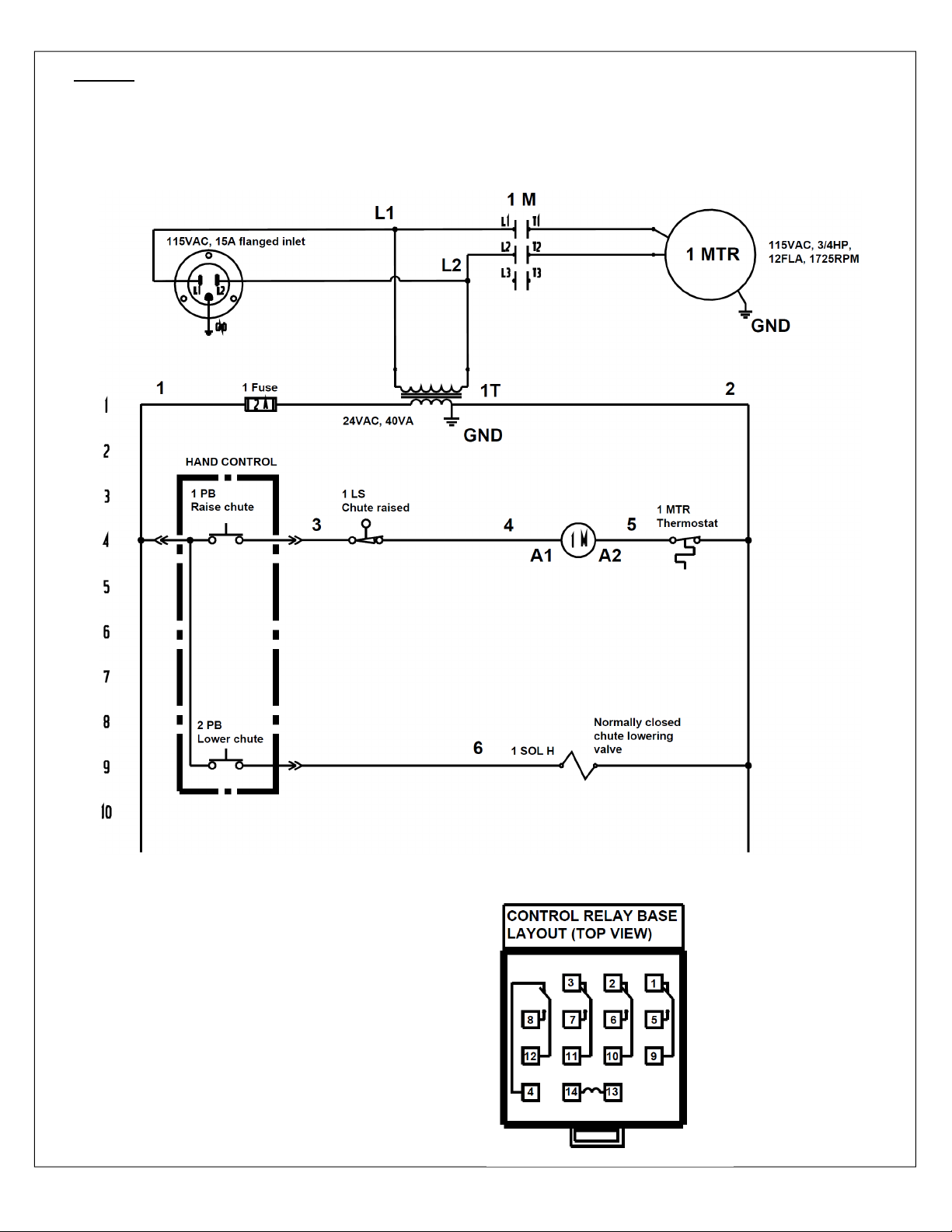

FIG. 1: 115VAC electrical circuit diagram for 2,000 lb. & 4,000 lb. capacity models

(09124017 Rev. D)

NOTE: In this diagram, all components are represented with the chute in “home” location,

i.e. resting, lowered position.

NOTE: Overcurrent and short-

circuit protection should

be provided by the end

user in accordance with

recommendations and

requirements in NEC

(NFPA 70) and local

codes.

Copyright 2017 Vestil Manufacturing Co. Page 7 of 21

Loading...

Loading...