Page 1

GB Instructions for use

DE Bedienungsanleitung

DK Brugsanvisning

WFG 185 / 155

Page 2

2

GB

As the appliance contains a

ammable refrigerant, it is essential to ensure that the refrigerant pipes are not damaged.

The quantity and type of the

refrigerant used in your appliance is indicated on the rating

plate.

Standard EN378 species that

the room in which you install

your appliance must have a

volume of 1m³ per 8 g of hydrocarbon refrigerant used in the

appliances. This is to avoid the

formation of ammable gas/air

mixtures in the room where the

appliance is located in the event

of a leak in the refrigerant circuit.

WARNING:

Keep ventilation openings in

the appliance’s cabinet or in the

built-in structure clear of obstruc-

tion

WARNING:

Do not use other mechanical

devices or other means to ac-

celerate the defrosting process

than those recommended by the

manufacturer

WARNING:

Do not damage the refrigerant

system

WARNING:

Do not use electrical appli-

ances inside the refrigerated

storage compartment, unless

they are of a type recommended

by the manufacturer

WARNING:

Do not expose the appliance to

rain

WARNING:

This appliance is not intended

for use by children and above

and persons with reduced physical, sensory or mental capabilities or lack of experience and

knowledge if they have been

given supervision or instruction

concerning use of the appliance

in a safe way and understand

the hazards involved

WARNING:

Do not store explosives, such

as aerosol cans with ammable

propellants in the unit.

Warning

Page 3

3

GB

WARNING:

Cleaning and user maintenance

shall not be made by children

without supervision

● Always keep the keys in a sep-

arate place and out of reach of

children

● Before servicing or clean-

ing the appliance, unplug the

appliance from the mains or

disconnect the electrical power

supply

● If the supply cord is damaged,

it must be replaced by the

manufacturer, its service agent,

or similarly qualied persons in

order to avoid a hazard

● Relevant for Australia: Sup-

ply cord tted with a plug complies with AS/NZS 3112.

● Frost formation on the interior

evaporator wall and upper

parts is a natural phenomenon. Therefore, the appliance

should be defrosted during

normal cleaning or maintenance.

● Please note that changes to

the appliance construction will

cancel all warranty and product

liability

● This appliance is intended to

be used exclusively for the

storage of wine

Page 4

4

GB

Warning ..................................................2

Saving energy.........................................4

Befor use ................................................5

Get to know your wine cooler. ................6

Installation and start-up ..........................7

Electrical connection...............................7

Reversible door ....................................10

Operation and function .........................18

Defrosting, cleaning and

maintenance .........................................20

Fault nding ..........................................21

Warranty, spare parts and service ........22

Disposal ................................................23

Contents

The energy consumption reduces ..

1)..the lower the ambient temperature is.

2)..the warmer thermostat set point is.

3)..the lower the number and the shorter

the length of the door openings is.

Savings in energy consumption in the use

Page 5

5

GB

On receipt, check to ensure that the appliance has not been damaged during

transport. Transport damage should be

reported to the local distributor before the

wine cooler is put to use.

Remove the packaging. Clean the inside of

the cabinet using warm water with a mild

detergent. Rinse with clean water and dry

thoroughly (see cleaning instructions). Use

a soft cloth.

If during transport the appliance has been

laid down, or if it has been stored in cold

surroundings (colder than + 5°C), it must be

allowed to stabilise in an upright position for

at least an hour before being switched on.

Before use

Page 6

6

GB

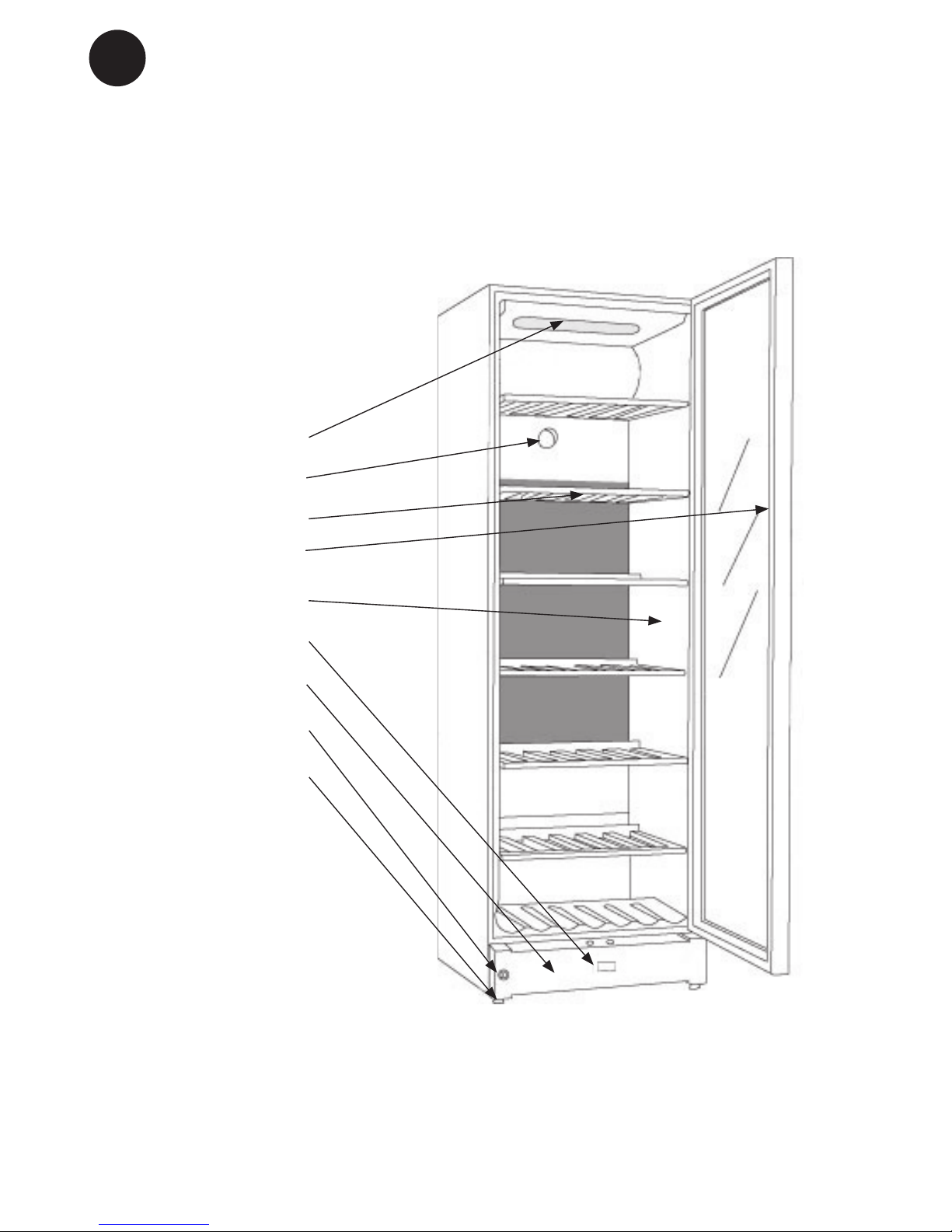

Lighting

Charcoal lter

Wooden shelf

Sealing strip

Name plate

Control panel

Kick plate

Lock

Adjustable feet

Get to know your wine cooler

g.1

Page 7

7

GB

Placement

For safety and operational reasons, the appliance must not be installed outdoors.

The appliance should be placed on a level

surface in a dry, well ventilated room (max.

75% relative air humidity). Never place the

appliance clo se to sources of heat such as

cookers or radiators, and avoid placing it in

direct sunlight.

Ambient temperature

The climate class is stated on the name

plate. This species the optimum ambient

temperature. Wine coolers with winter position, however, function at ambient temperatures as low as 5ºC.

Room temperature

The climate class is stated on the nameplate. This species the optimum room

temperature.

Note that the appliance operates best at

room temperatures from 10°C to 32°C.

Installation and start-up

Wiring and connections in power supply

systems must been all applicable (local and

national) electrical codes. Consult these

codes lengths and sizes prior to cabinet

installation.

This device complies with relevant EU

directives including Low Voltage Directive

2014/35/EU and Electromagnetic Compatibility Directive 2014/30/EU

The socket should be freely accessible.

Connect the appliance only to 220/240 V

/ 50Hz alternating current via a correctly

installed earthed socket.

The socket must be fused with a 10-13 A

fuse.

If the appliance is to be operated in a nonEuropean country, check on the rating plate

whether the indicated voltage and current

type correspond to the values of your mains

supply.

Information regarding voltage, current or

power are given on the rating plate

The power cord may be replaced by a technician only.

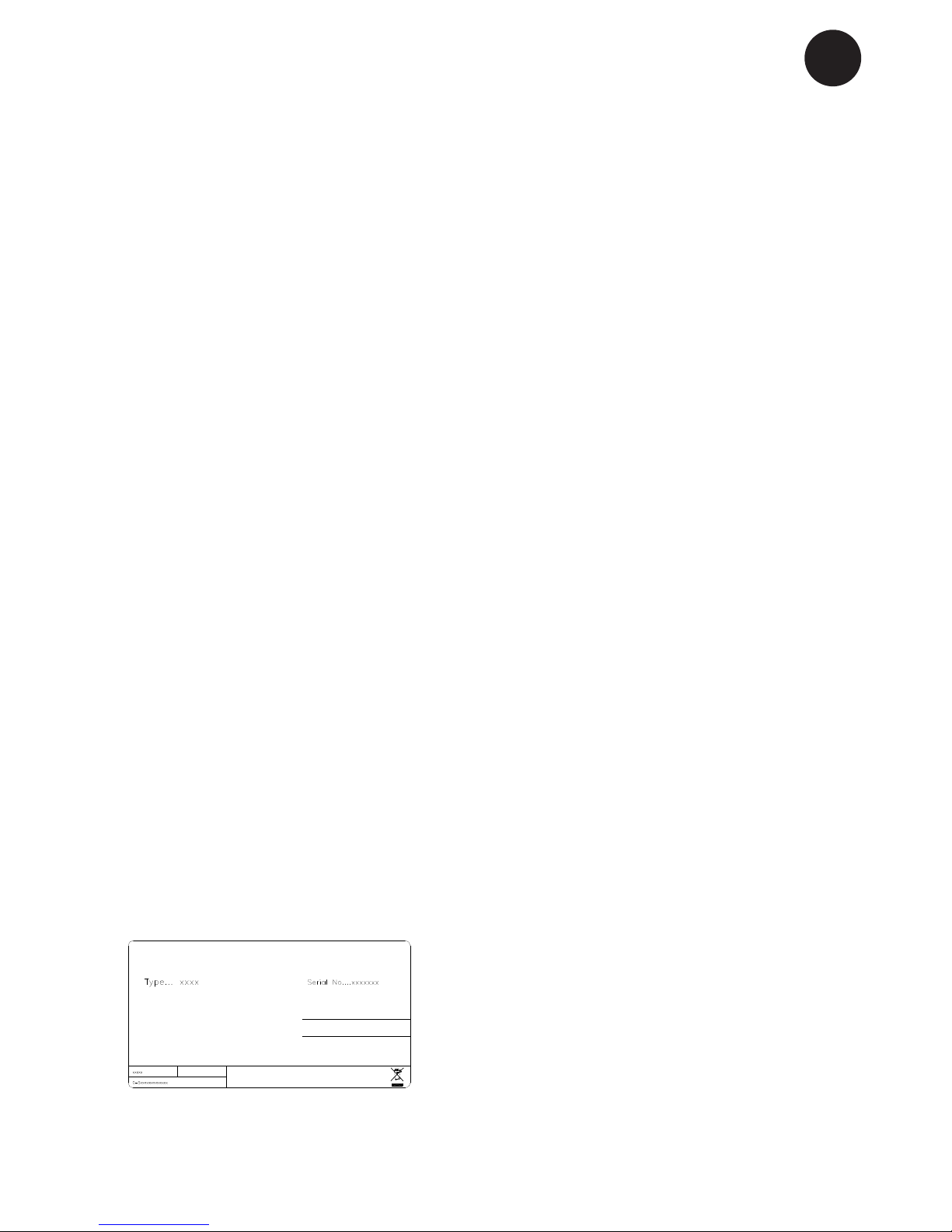

The rating plate provides various technical information as well as type and serial

number.

Electrical connection

g.2

Page 8

8

GB

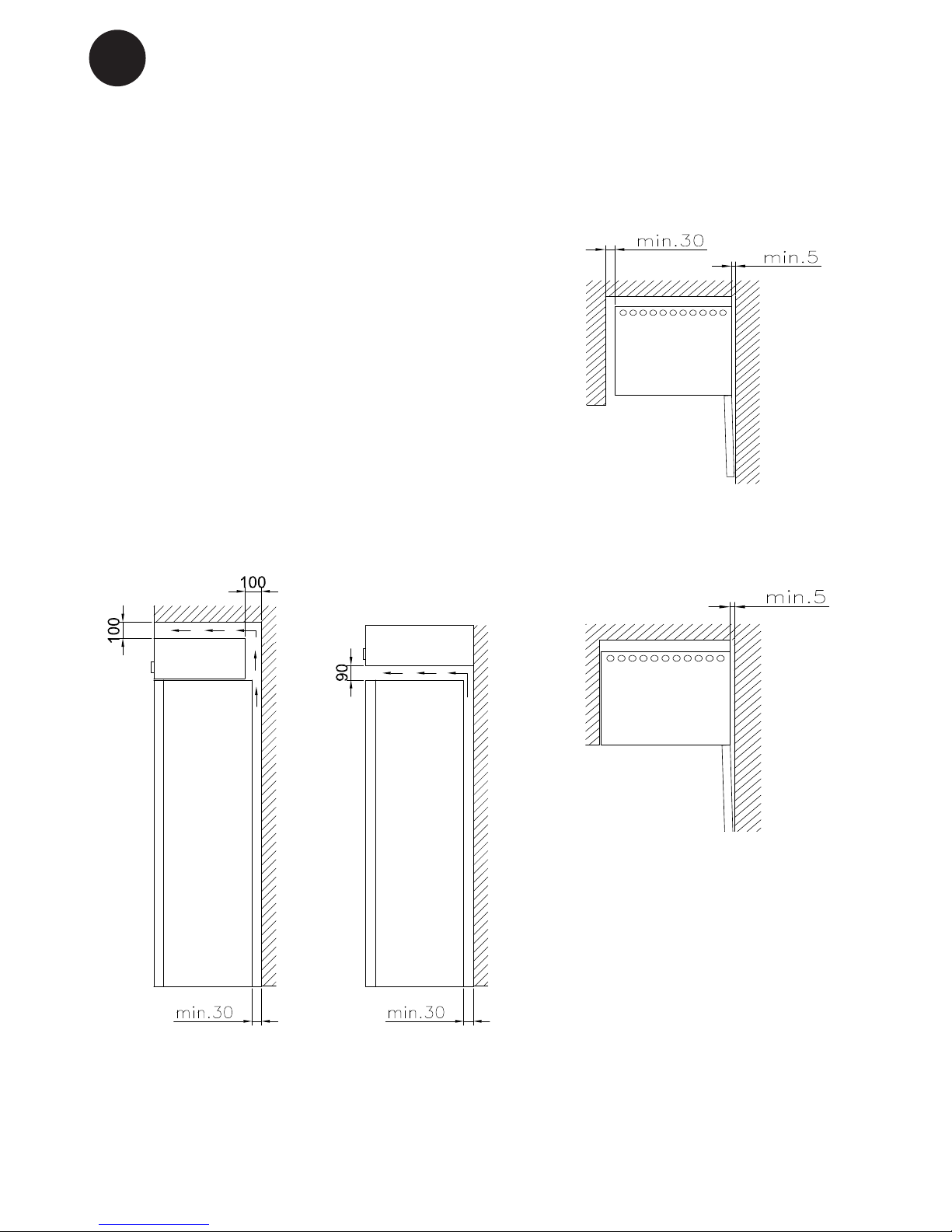

The surface on which the appliance is to be

placed must be level. Do not use a frame or

similar.

The appliance can be installed as a freestanding unit against a wall, built into a

closet or lined up with other appliances.

It is important that the appliance be well

ventilated and that air can circulate unhindered above, below and around it.

The gures below illustrate how the necessary air circulation around the appliance

can be ensured (gs 3).

g. 3

g. 5

g. 4

Installation

Page 9

9

GB

The distance pieces on the rear of the appliance ensure sucient air circulation. Fit

the two caps supplied with the appliance as

shown in g. 7.

g. 7

g. 8

It is important that the appliance be absolutely level. It can be levelled by screwing

the adjustable feet at the front of the appliance up or down (g 8).

Use a spirit level to check that the appliance

is absolutely level sideways.

Setting up

Max. 85 kg.

g. 6

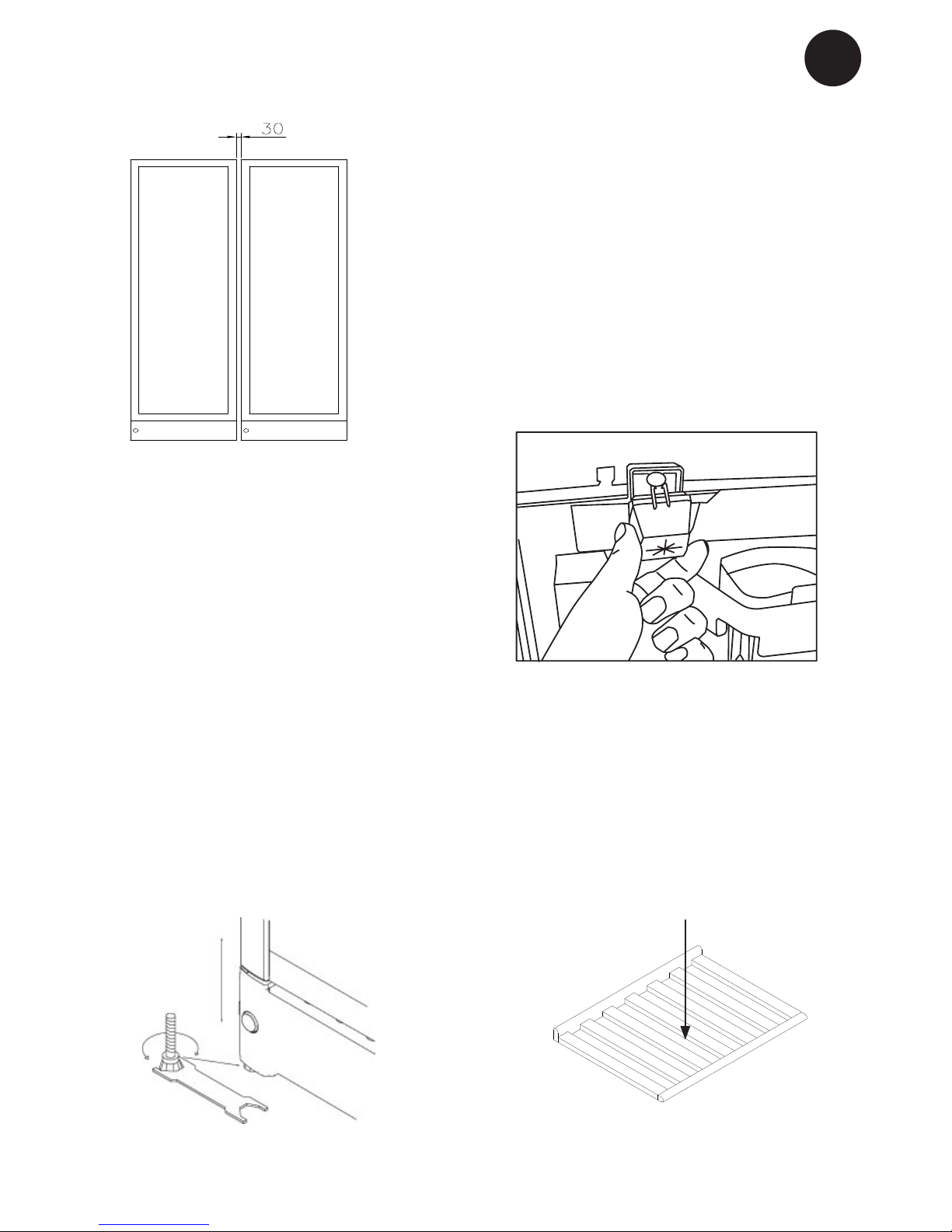

(g 6) A “Side by Side” kit can be ordered

Page 10

10

GB

Reversible door

Follow the instructions carefully

NOTE: Before you start the unit needs to be disconnected from the main grid.

We recommend that the change of door is done by a technician (we recommend two persons)

Helping material:

4 mm Allen key;

Flat-headed screwdriver

Torx 20 (TX20) screwdriver

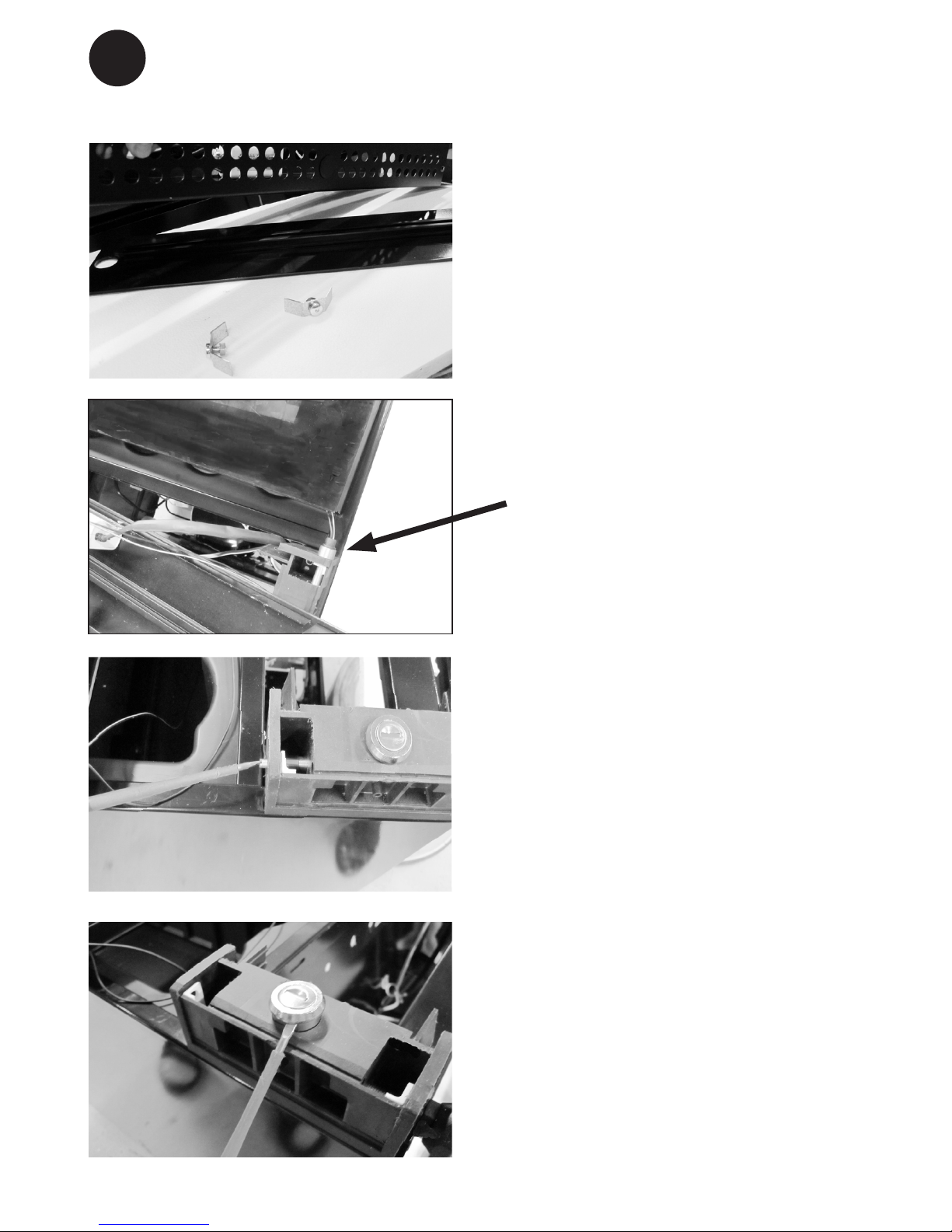

2. Place the appliance on its back (preferably on a soft foundation)

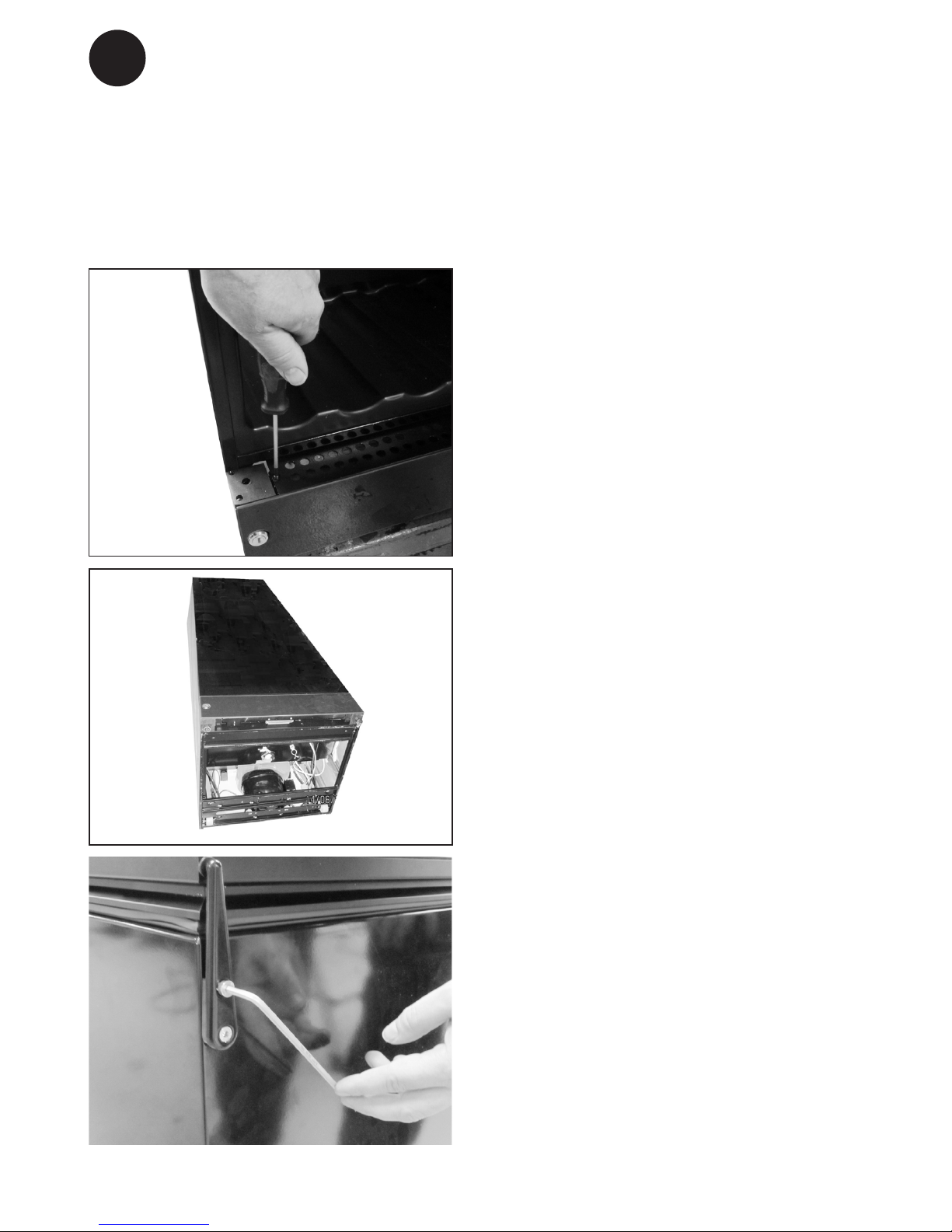

1. Open the door, unscrew the two screws

xing the bottom cover (Torx20). Do not

remove the cover yet.

3. Loosen the upper hinge and remove it ( 4

mm Allen key)

Page 11

11

GB

4. Dismount the bottom cover (the buildin snap function in each side can be

unsnapped with the at-headed screwdriver).

5. Place the bottom cover with glass front

down, on an additional support, so the

wires are not stretched.

6. The door LED wires have to be dismounted from the connector on the

bottom cover (pure black & black / white

stripe wires). Push the top release down

to free the wire ends. (Note: the pure

black wire is + and corresponds to the

red wire on opposite side. The black /

white stripe wire is 0 (neutral) and corresponds to the black wire on the opposite

side – this is important when the wires

are to be mounted later)

7. To reverse the bottom glass, the brackets

need to be removed. Loosen the screw

and the bracket incl. screw and bolt

slides of the plastic prole.

NOTE: Now the glass is loose.

Page 12

12

GB

10.Unscrew the lock pin (using the at-headed screwdriver) and remove it.

8. Lift the bottom sheet metal part and turn

the glass so the lock hole ts the other

ends round Ø hole concentric. Place the

sheet metal part on the glass again, and

mount the brackets onto the plastic prole in each end again. Don’t over tighten

the screws.

Note: The nut has to t into the centre

groove.

11.Pull up the lock cylinder and ret both

lock cylinder and lock pin in opposite

side.

9. The door has to be moved up from the

hinge.

Page 13

13

GB

13.Dismount the bottom hinge pin and t it

on the opposite side.

Note: The bush must also be moved.

12. Pull the LED wires gently out of the bot-

tom hinge pin.

14.Turn the door, so the glass side is down

(Note: Place something between the

glass and the other surface (cabinet) so

scratch are minimized).

Then loosen the gasket on the low end of

the door by pulling.

15. Pull the LED wires up and out.

Page 14

14

GB

16.Replace the wires into the plastic groove

and lead them to the other side.

17.Push the wires through the oblong hole

and through the new hinge hole.This can

be a bit tricky so try to mount only one

wire rst

18.Then tape the second wire end to the

rst wire and pull them both fully through

(remove tape subsequently).

Page 15

15

GB

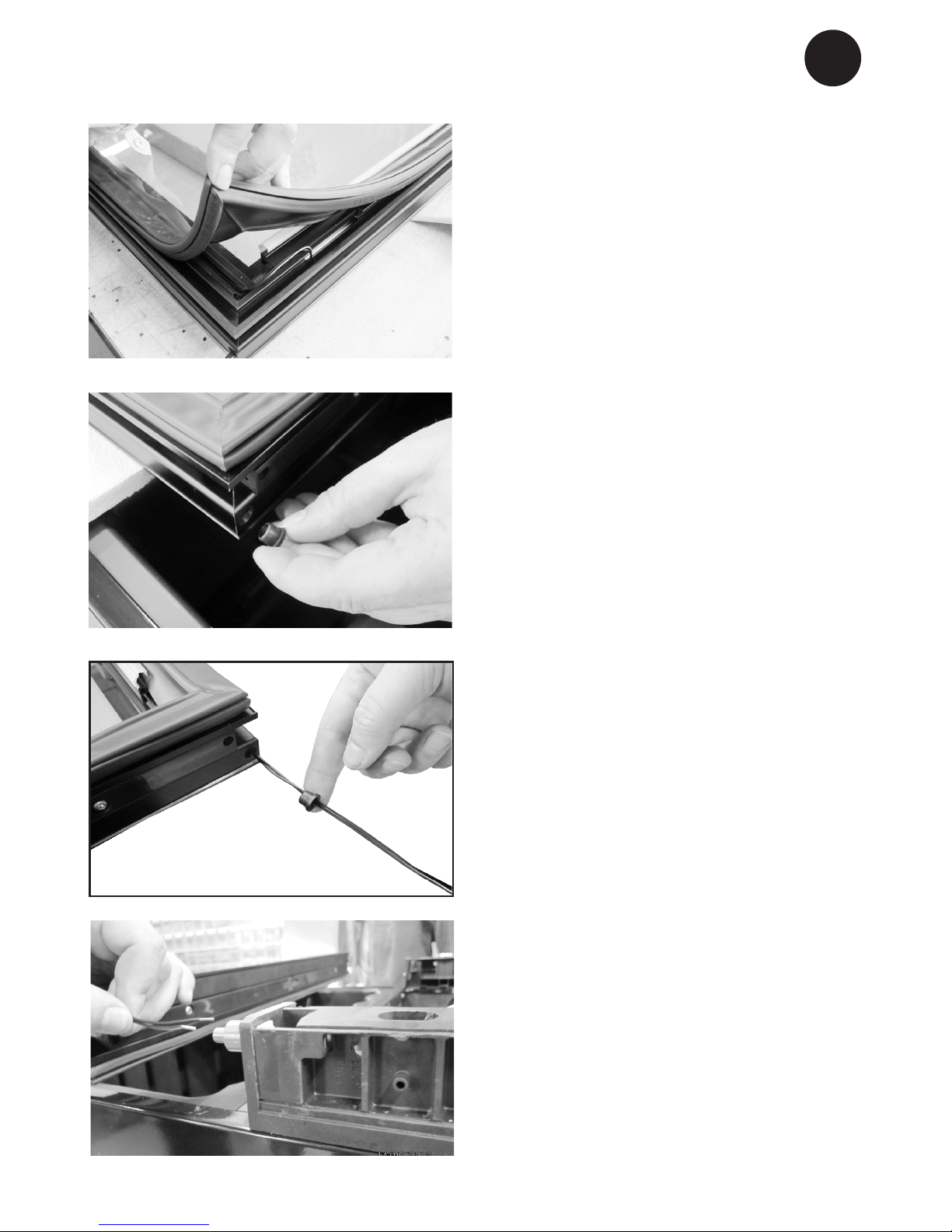

19.Make sure the wires are tted into the

plastic groove and mount the gasket. It’s

important to check that the sealing strip

provides a tight seal all the way round.

If it does not, carefully heat the strip all

the way round using a hair dryer. Then

ease the strip slightly outwards so that it

forms a tight seal against the cabinet. Be

careful not to heat the strip so much that

it melts!

21.Pull the wire through the bushing before

mounting it into the door hinge hole.

20.Dismount the door hinge bushing and

mount it on opposide side.

22.Reverse the door again and displace it

a little on the cabinet proportion to the

botton hinge.

Page 16

16

GB

23.Pull the two wires through the bottom

hinge pin....

24.… and through the wire hole in the plastic column.

25.Remount the wires (se under # 6) and

make sure that they are rmly secured.

26.Pusch the door back in place over the

hinge pin and pull the wires simultaneously so the wire do not get stuck.

Page 17

17

GB

27.Dismount the top door bushing and

mount it on opposite side.

28.Dismount the plastic caps on the top of

the cabinet and mount them on opposite

side.

29.Make sure that the door is aligned with

the cabinet before mounting the top

hinge.

30. Remount the bottom front cover. Place

the unit vertically again and mount the

tow screws (see under # 1).

Note: Important: Wait approx. ½ hour

before connecting the unit to the main

grid.

Note: If the door LEDs don’t give out light

but the top LED in the cabinet is shining, it’s most likely that the wires are not

mounted correctly into the connector.

(See under # 6 & 25)

Page 18

18

GB

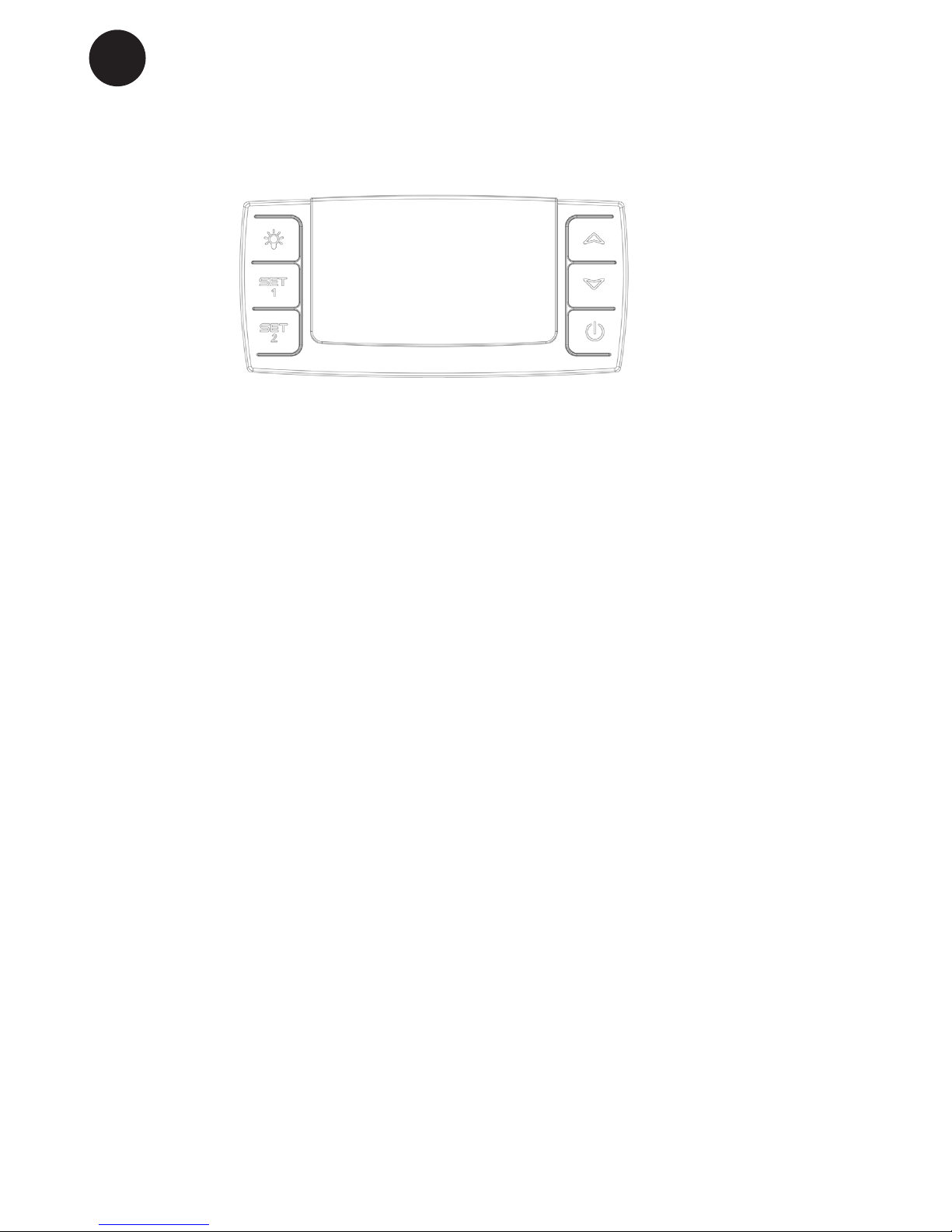

Operation and function

g. 8

Electronic control

The electronic control ensures that the

temperatures set at the top and at the bottom of the appliance are maintained. This is

achieved by means of an advanced control

of the refrigeration system, the heating element, and the fan. The set temperature will

be stored in the event of power failure.

The electronic control has the following

functions:

● On/o switch

● Light switch*

● Temperature setting

● Temperature indication

● Alarm for too high and too low tempera-

tures

● Door alarm

* The light may either be turned on

constantly or only when the door is open.

Temperature indication

The display shows the actual temperature.

The upper digits of the display indicate the

temperature at the top of the appliance, and

the lower digits of the display indicate the

temperature at the bottom of the appliance.

The temperature indicator is equipped with

a built-in lter which simulates the actual

temperature in the bottles. Consequently,

the indicator does not react on short-term

uctuations of the air temperature

Temperature setting

The thermostat is equipped with a child lock

device. This device is activated by pushing

the “up and down” buttons simultaneously.

After approx. 3 seconds “Pof” ashes in the

display. Then the actual temperatures are

shown as usual. In addition, the set temperatures can be shown by pushing SET1

and SET2, respectively.

The child lock device is cancelled by pushing the “up and down” buttons simultaneously. After approx. 3 seconds “Pon” ashes

in the display, and the temperature can be

set.

Temperature setting at the top

of the appliance

Push SET1. Then the temperature at the

top of the appliance can be adjusted up and

down by means of the “up and down” buttons. The temperature can be adjusted from

8 to 22°C, however so that the temperature

cannot be set at a lower temperature than

the actual set point for the bottom temperature sensor.

Page 19

19

GB

Two-zone setting for serving

temperature

Typical serving temperature settings for the

top and bottom sections are 16°C and 6°C

respectively. With these settings, a suitable

temperature gradient will be achieved in

the cabinet for the storage of various types

of wine distributed from top to bottom as

follows:

● heavy red wines +16 to +19°C

● rosé and light red wines +12 to +16°C

● white wines +10 to +12°C

● champagne and sparkling wines +6 to

+8°C

It is recommended that wine be served at a

temperature which is a couple of degrees

lower than the desired drinking temperature

as the wine will be warmed slightly when it

is poured into the glass.

Single-zone setting for longterm storage

For long-term wine storage, the top and bottom sections should both be set at 12°C.

With identical settings for the top and bottom sections, the controls will maintain an

even temperature throughout the cabinet.

However, the temperature in the room will

gradually aect the temperature in the

cabinet through its door and sides, creating

a slight temperature gradient from top to

Temperature setting at the bottom of the appliance

Push SET2. Then the temperature at the

bottom of the appliance can be adjusted up

and down by means of the “up and down”

buttons. The temperature can be adjusted

from 5 to 22°C, however so that the temperature cannot be set at a higher temperature than the actual set point for the upper

temperature sensor.

Alarm devices

There is a sub-alarm for the low-temperature sensor and an excess-alarm for the

high-temperature sensor.

The alarm consists of a beeper and a warning on the display.

Alarm for high temperature: beep sound

+ alternating display of “HtA” and actual

temperature

Alarm for low temperature: beep sound

+ alternating display of “LtA” and actual

temperature

The alarm temperature depends on the set

points.

The beep sound can be cancelled by pushing a random thermostat button. Push the

on/o button to erase the display alarm,

rst for cancelling the alarm, then again for

restarting the compressor.

Door alarm

When the door has been open for more

than 2 minutes the door alarm is activated.

Light

To turn o the lights, press once

Permanent lighting

For presentation purposes of your wine,

you can turn the lights permanently. Please

press the light switch image twice. To

switch o the lights press on again.

Page 20

20

GB

Automatic defrosting.

The wine cooler is defrosted automatically.

Defrost water runs through a pipe and is

collected in a tray above the compressor

where the heat generated by the compressor causes it to evaporate. The defrost

water tray should be cleaned at intervals.

Cleaning.

Before cleaning the appliance, unplug it

from the main supply. The cabinet is best

cleaned using warm water (max. 65°C) with

a little mild detergent. Never use cleaning

agents that scour. Use a soft cloth. Rinse

with clean water and dry thoroughly. The

defrost water channel, in which condensation from the evaporator runs, is located

at the bottom of the rear inside wall of the

cabinet and must be kept clean. Add a few

drops of disinfectant, e.g. Rodalon, to the

defrost water drain a couple of times a year,

and clean the drain using a pipe cleaner or

similar. Never use sharp or pointed implements.

The sealing strip around the door must be

cleaned regularly to prevent discolouration

and prolong service life. Use clean water.

After cleaning the sealing strip, check that it

continues to provide a tight seal.

Dust collecting on the condenser on the

rear of the cabinet, the compressor and

in the compressor compartment is best

removed using a vacuum cleaner.

Defrosting, cleaning

and maintenance.

bottom. The controls will maintain the set

temperature at the bottom of the cabinet,

and any deviation from the setting will

therefore occur at the top.

The dierence will vary from 0 to 3°C, depending on the ambient temperature.

Page 21

21

GB

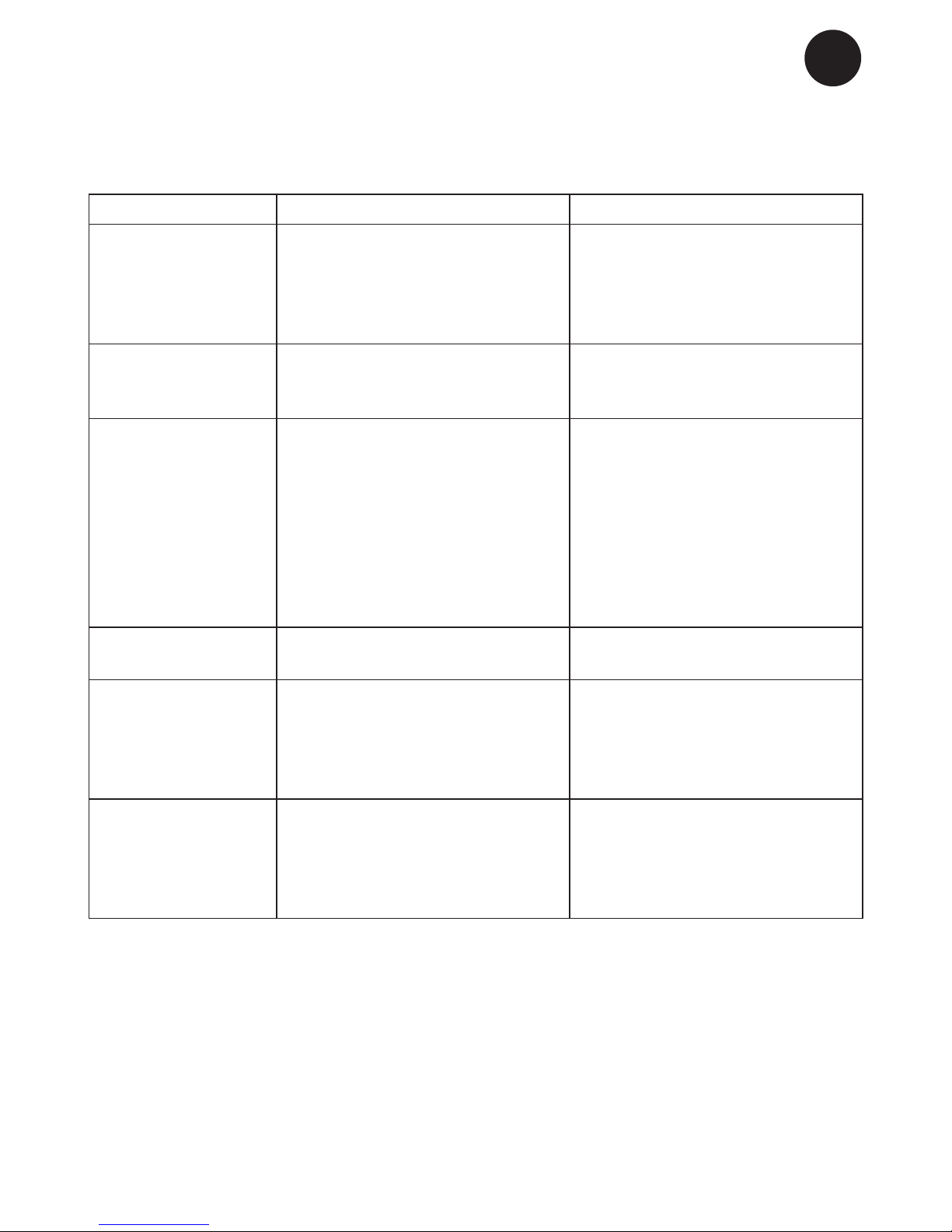

Fault nding

Fault Possible cause Remedy

The appliance is not

working.

The appliance is switched o.

Power failure; the fuse is blown;

the appliance is not plugged in

correctly.

Press the on/o switch.

Check that power is connected.

Reset the fuse.

Water collects in

the bottom of the

cabinet.

The defrost water pipe is

blocked.

Clean the defrost water channel

and the drain hole on the rear

wall of the cabinet.

Vibration or

bothersome noise.

The appliance is not level.

The appliance is resting against

other kitchen elements.

Containers or bottles inside the

cabinet are rattling against one

another.

Level the appliance using a spirit

level.

Move the appliance away from

the kitchen elements or appliances it is in contact with.

Move containers and/or bottles

apart.

Compressor runs

continuously.

High room temperature. Ensure adequate ventilation.

P1 is shown on the

display.

The upper sensor is disconnected or short-circuited.

Call for service. The temperature

within the entire cabinet is maintained at the higher of the two

setpoints until the fault has been

corrected.

P2 is shown on the

display.

The lower sensor is disconnected

or short-circuited.

Call for service. The temperature

within the entire cabinet is maintained at the higher of the two

setpoints until the fault has been

corrected.

Page 22

22

GB

Warranty, spare parts and service.

Warranty disclaimer

Faults and damage caused directly or

indirectly by incorrect operation, misuse,

insucient maintenance, incorrect building,

installation or mains connection. Fire, accident, lightening, voltage variation or other

electrical interference, including defective

fuses or faults in mains installations.

Repairs performed by others than approved

service centres and any other faults and

damage that the manufacturer can substantiate are caused by reasons other than

manufacturing or material faults are not

covered by the warranty.

Please note that changes to the construction of the appliance or changes to the

component equipment of the appliance will

invalidate warranty and product liability, and

the appliance cannot be used lawfully. The

approval stated on rating plate will also be

invalidated.

Transport damage discovered by the buyer

is primarily a matter to be settled between

the buyer and the distributor, i.e. the distributor must ensure that such complaints

are resolved to the buyer’s satisfaction.

Before calling for technical assistance,

please check whether you are able to

rectify the fault yourself. If your request for

assistance is unwarranted, e.g. if the appliance has failed as a result of a blown fuse

or incorrect operation, you will be charged

the costs incurred by your call for technical

assistance.

Spare parts

When ordering spare parts, please state

the type, serial and product numbers of

your appliance. This information is given on

the rating plate. The rating plate contains

various technical information, including type

and serial numbers.

Product numbers

Page 23

23

GB

Disposal

Information for Users on Collection

and Disposal of Old Equipment and

used Batteries

These symbols on the products,

packaging, and/or accompanying

documents mean that used electrical and electronic products and

batteries should not be mixed with

general household waste. For proper

treatment, recovery and recycling

of old products and used batteries,

please take them to applicable collection points, in accordance with your

national legislation and the Directives

2002/96/EC and 2006/66/EC.

By disposing of these products and

batteries correctly, you will help to

save valuable resources and prevent

any potential negative eects on

human health and the environment

which could otherwise arise from

inappropriate waste handling.

For more information about collection and recycling of old products and

batteries, please contact your local

municipality, your waste disposal

service or the point of sale where you

purchased the items.

Penalties may be applicable for incorrect disposal of this waste, in accordance with national legislation.

For business users in the European Union.

If you wish to discard electrical and

electronic equipment, please contact

your dealer or supplier for further

information.

[Information on Disposal in other

Countries outside the European

Union]

These symbols are only valid in the

European Union. If you wish to discard this product, please contact your

local authorities or dealer and ask for

the correct method of disposal.

Note for the battery symbol:

This symbol might be used in combination with a chemical symbol. In this

case it complies with the requirement

set by the Directive for the chemical

involved.

Page 24

2

DE

Warnung

WARNUNG:

Verwenden Sie keine anderen

mechanischen Geräte oder Hilfsmittel, um den Abtauprozess zu

beschleunigen, als diejenigen,

die vom Hersteller empfohlen

sind.

WARNUNG:

Beschädigen Sie nicht den Kühlkreislauf.

WARNUNG:

Verwenden Sie keine elektrischen Geräte im Gerät, es sei

denn, dass die Geräte vom Hersteller empfohlen sind.

WARNUNG:

Das Gerät nicht dem Regen

aussetzen.

WARNUNG:

Dieses Gerät ist nicht zur Verwendung durch Personen

(einschließlich Kinder) mit eingeschränkten physischen, sensorischen oder geistigen Fähigkeiten oder fehlender Erfahrung

und Wissen bestimmt, es sei

denn, eine angemessene Aufsicht oder Anleitung zur Benut-

Da ein brennbares Gas als Kältemittel in diesem Gerät dient, ist

es wichtig sicherzustellen, dass

kein Teil des Kühlkreislaufs oder

der Rohre beschädigt ist.

Die Menge und Art von Kältemittel im Gerät ist auf dem

Typenschild angegeben.

Der Standard EN378 speziziert,

dass der Raum, in dem das Gerät installiert wird, ein Volumen

von 1m³ pro 8 g Kohlenwassersto-Kältemittel, das im Gerät

verwendet ist, haben soll. Dies

ist zu beachten, um die Bildung

von leicht entzündlichen Gasgemischen in dem Raum, wo das

Gerät installiert ist, zu vermeiden, falls eine Undichtigkeit des

Kuhlkreislaufs entsteht.

WARNUNG:

Bitte beachten Sie bei der Platzierung der Waren im Gerät,

dass die Luftzirkulation durch

Verstellen der Luftaus- trittsönungen des Lüfters nicht behindert wird.

Page 25

3

DE

zung des Geräts durch eine für

ihre Sicherheit zuständige Person ist gegeben. Kinder sollten

beaufsichtigt werden um sicherzustellen, dass sie nicht mit dem

Gerät spielen

WARNUNG:

Keine Produkte mit brennbaren

Treibgasen (z. B. Spraydosen)

und keine explosiven Stoe lagern. Explosionsgefahr

WARNUNG:

Gefahr von Feuer oder Explosion wenn brennbares Kältemittel ist verwendet. Darf nur von

Fachpersonal repariert werden

● Vor Reparatur oder Reinigung

des Gerätes den Netzstecker

aus der Steckdose ziehen.

● Wenn die Anschlussleitung

beschädigt ist, darf sie nur von

einem autorisierten Kundendienst ausgewechselt werden,

um Gefahr zu vermeiden.

● Beachten Sie bitte, dass Ände-

rungen der Konstruktion dieses

Gerätes zur Folge haben, dass

Gewährleistung und Produkthaftung erlöschen.

● Dieses Gerät eignet sich ins-

besondere zur Lagerung von

Getränken in Flaschen oder

Dosen.

● Before servicing or cleaning

the appliance, unplug the

appliance from the mains or

disconnect the electrical power

supply

● ldung von Reif auf der inne-

ren Verdampferplatte und den

obersten Teilen ist normal. In

Verbindung mit Reinigung oder

Wartung muss das Gerät deshalb entfrostet werden.

● Dieses Gerät ist ausschließlich

zur Lagerung von Wein bestimmt

● Nur im Innenbereich anwen-

den

Beleuchtung: Klasse 1, LED Produkt

Page 26

4

DE

Warnung .................................................2

Vor dem Gebrauch. ................................5

Lernen Sie .............................................6

Elektrischer Anschluss. ..........................7

Inbetriebnahme und Installation .............7

Wendbare Tür .........................................9

Bedienung und Funktion.......................18

Abtauen, Reinigung und Wartung

Fehlersuche .......................................... 20

Fehlersuche .......................................... 21

Ersatzteile und Service ......................... 22

Entsorgung ...........................................23

Inhalt

Der Energieverbrauch ist geringer…

1) ..je niedriger die Umgebungstemperatur

ist

2) ..je wärmer der Thermostatsollwert eingestellt ist

3) ..je weniger man die Tür önet und umso

kürzer die Türönungszeit ist.

Energieeinsparung während des Gebrauchs

Page 27

5

DE

Kontrollieren Sie das Gerät sofort bei

Lieferung auf eventuelle Beschädigungen.

Transportschäden sind dem Händler zu

melden, bevor das Gerät in Gebrauch

genommen wird.

Verpackung entfernen. Das Schrankinnere

mit lauwarmem Wasser und etwas mildem

Spülmittel reinigen. Mit klarem Wasser

nachwischen und gründlich trocknen (siehe

“Reinigung”). Verwenden Sie ein weiches

Tuch.

Falls das Gerät liegend transportiert wurde

oder einer Temperatur von weniger als +5

°C ausgesetzt war, muss es vor dem Einschalten mindestens eine Stunde lang bei

höherer Außentemperatur aufrecht stehen.

Vor dem Gebrauch

Page 28

6

DE

Abb.1

Beleuchtung

Kohlelter

Holzfach

Dichtleiste

Typenschild

Sockelblende

Bedienungselemente

Schloss

Einstellbare Füße

Lernen Sie Ihren Weinschrank zu kennen

Page 29

7

DE

Aufstellort.

Aus Sicherheits- und betriebstechnischen

Gründen darf das Gerät nicht im Freien

aufgestellt werden.

Stellen Sie den Schrank auf einen ebenen

Untergrund in einem trockenen, gut belüfteten Raum (max. 75 % relative Luftfeuchtigkeit). Stellen Sie den Schrank nicht in

unmittelbarer Nähe von Wärmequellen wie

Herden oder Heizkörpern auf, und vermeiden Sie direkte Sonneneinstrahlung oder

Wärme von anderen Wärmequellen .

Umgebungstemperatur

Die Klimaklasse nden Sie auf dem Typenschild. Sie gibt an, innerhalb welcher Umgebungstemperatur bereiche der Kühlschrank

optimal arbeitet. Weinschränke mit Winterposition fungieren bis zu einer Umgebungstemperatur von 5 °C.

Beachte: Das Gerät arbeitet am besten bei

Raumtemperaturen von 10 ° bis 32 ° C

Inbetriebnahme und

Installation

Elektrischer Anschluss

Verkabelung und Anschlüsse in Stromversorgungssystemen müssen allen (örtlichen

und nationalen) Elektrovorschriften entsprechen. Machen Sie sich vor dem Einbau mit

den Angaben in diesen Vorschriften vertraut

Dieses Gerät entspricht den einschlägigen

EU-Richtlinien einschließlich:

Niederspannungsrichtinie 2014/35/EU.

Elektromagnetische Kompatibilitätsrichtlinie

2014/30/EU

Die Steckdose sollte frei zugänglich sein.

Das Gerät an (220/240 V / 50Hz) Wechselstrom über eine vorschriftsmäßig installierte

Steckdose anschließen.

Die Steckdose muss mit einer 10A - 13A

Sicherung abgesichert sein.

Bei Geräten, die in nicht-europäischen Ländern betrieben werden, ist auf dem Typenschild zu überprüfen, ob die angegebene

Spannung und Stromart mit den Werten

Ihres Stromnetzes übereinstimmt.

Informationen über Spannung und Leistungsaufnahme / Strom sind auf dem

Typenschild.

Das Typenschild, das sich im Gerät bendet, enthält verschiedene technische

Angaben sowie Typen- und Seriennummer.

Ein eventuell notwendiger Austausch der

Netzanschlussleitung darf nur durch einen

Fachmann erfolgen

Abb..2

Page 30

8

DE

Installation

Die Unterlage zum Aufstellen des Schranks

muss eben sein. Verwenden Sie keinen

Rahmen o.ä.

Der Schrank kann frei an einer Wand

stehen, in ein Schrank eingebaut werden

oder neben anderen Schränken aufgestellt

werden

Der Schrank muss ausreichend belüftet

sein, und die Luftzirkulation über und unter

ihm sowie seitlich vom Schrank darf nicht

behindert sein.

Wird der Schrank an einer Wand aufgestellt, ist darauf zu achten, soviel Platz zu

lassen, dass die Tür genug geönet werden

kann.

g. 3

g. 5

g. 4

Page 31

9

DE

Der Schrank muss waagerecht stehen. Der

Schrank kann durch Drehen der einstellbaren Füße ausgerichtet werden

(siehe Abb. 7).

Prüfen Sie mit einer Wasserwaage nach, ob

der Schrank waagerecht steht.

Aufstellung

g. 6

g. 7

Max. 85 kg.

Die Abstandsstücke auf der Rückseite des

Schranks sichern die erforderliche Luftzirkulation. Die beiden Abdeckungen montieren,

die zusammen mit dem Schrank mitgeliefert

werden (siehe Abb. 6)

(Zwei verschiedene Modelle)

Belüftung

g. 6

(g.6)

A “Seite an Seite” Kit kann bestellt werden

Page 32

10

DE

Wendbare Tür

Folgen Sie sorgfältig der Anleitung

Hinweis: Bevor Sie starten das Gerät vom Stromnetz trennen.

Wir empfehlen den Wechsel des Türanschlages vom einem Techniker ausführen zu lassen (wir

empfehlen zwei Personen)

Hilfsmaterial:

4 mm Inbusschlüssel

Schlitzschrauben dreher

Torx 20 (TX20) Schraubendreher

2. Legen Sie das Gerät auf die Rückseite

(am besten auf einer weichen Unterlage)

1.Tür önen und die beiden Schrauben für

die untere Blende entfernen. (Torx 20)

Die Blende jetzt noch nicht entfernen.

3. Lösen und entfernen Sie das obere

Scharnier (4 mm Inbus)

Page 33

11

DE

4. Entfernen Sie die untere Blende

(Die beiden Rastfunktionen an den Sei-

ten können mit einem Schlitzschraubendreher entrastet werden.)

5. Legen Sie die Blende mit der Glasseite

nach unten auf eine Unterlage, damit

das Glas keine Kratzer bekommt und die

Kabel nicht gespannt sind.

6. Lösen Sie das Kabel zum LED-Türlicht

am Verbinder (schwarzes und schwarz/

weißes Kabel, drücken Sie auf die jeweilige Wippe).

(Hinweis: das schwarze Kabel ist +12V

und ist verbunden mit dem roten Kabel

vom Trafo auf der gegenüberliegenden

Seite. Das schwarz/ weiße Kabel vom

LED-Licht ist verbunden mit dem schwarzen Kabel vom Trafo. – wichtig wenn die

Kabel später wieder verbunden werden

müssen.)

7. Um die Glasscheibe zu drehen müssen

beide Halterungen am Plastikprol gelöst

werden und können dann zur Seite entfernt werden.

Hinweis: Nun ist die Scheibe lose

Page 34

12

DE

10.Sicherungsstift mit dem Flachschrau

bendreher entfernen.

8. Heben Sie die Blende und drehen die

Glasscheibe, das Loch für das Schloss

muss konzentrisch zum Loch in der

Blende liegen. Montieren Sie die beiden

Halterungen am Plastikprol.

Nicht die Schrauben überdrehen.

11.Ziehen Sie den Schließzylinder heraus

und montieren Sie Zylinder und Stift auf

der gegenüberliegenden Seite.

9. Die Tür aus dem Gelenk heben.

Page 35

13

DE

13. Demontieren Sie den unteren Scharni-

erstift und setzen ihn auf der gegenüberliegenden Seite wieder ein.

Hinweis: Die Buchse muss auch bewegt

werden.

12. Ziehen Sie die LED-Kabel vorsichtig

aus dem Scharnier.

14.Drehen Sie die Tür, das Glas zeigt nun

nach unten.

Hinweis:Legen Sie etwas Weiches zwi-

schen Glas und Gerät um die Gefahr von

Kratzern zu vermeiden.

Ziehen Sie die Türdichtung am unteren

Ende ab.

15. Ziehen Sie die LED-Kabel herausziehen.

Page 36

14

DE

16.Die beiden Kabel werden nun im Plastikkanal zur anderen Seite geführt.

17.Die Kabel müssen nun in das Langloch

eingeführt werden und kommen aus dem

neuen Scharnierloch wieder heraus.

Dies ist ein wenig kompliziert. Versuchen

Sie es deshalb zuerst nur mit einem

Kabel.

18.Mit Klebeband befestigen Sie das zweite

Kabel am ersten und ziehen dann beide

ganz hindurch. (Klebeband wieder entfernen)

Page 37

15

DE

19.Vergewissern Sie sich, dass die Kabel

richtig im Plastikprol liegen und montieren Sie die Türdichtung wieder.

Überprüfen Sie ob die Türdichtung

rundherum richtig schließt.

Falls nicht erwärmen Sie die Türdichtung

vorsichtig mit einem Haarfön und ziehen

Sie die Dichtung leicht nach außen.

Seien Sie vorsichtig beim Erwärmen,

damit die Dichtung nicht schmilzt.

21.… nach Durchfädelung der Kabel durch

die Buchse einsetzen.

20.Die Türanschlagbuchse demontieren

und auf der gegenüberliegenden Seite

wieder…….

22.Die Tür wird zurückgedreht und ein

wenig oberhalb zum unteren Scharnier

plaziert.

Page 38

16

DE

23.Die beiden Kabel werden durch den

Scharnierstift ……

24.… und durch das Loch der Plastiksäule

gezogen.

25.Die beiden Kabel werden wieder montiert (siehe unter # 6)

26.Die Tür wird nun auf den Scharnierstift geschoben, gleichzeitig wird an

den Kabeln gezogen, damit diese nicht

eingeklemmt werden.

Page 39

17

DE

27.Die obere Türbuchse wird demontiert

und auf der gegenüberliegenden Seite

wieder eingesetzt.

28.Die Kunststokappen oben am Gerät

werden an der gegenüberliegenden Seite

montiert

29.Bevor Sie das obere Scharnier wieder montieren richten Sie die Tür zum

Schrank richtig aus,

30. Die untere Blende wird wieder montiert..

Das Gerät wird aufgestellt und die beiden

Schrauben in der Blende montiert

(siehe unter # 1)

Hinweis: Wichtig: Warten Sie ca. eine

halbe Stunde bevor Sie das Gerät wieder

einschalten.

Hinweis: Wenn das Türlicht nicht funk-

tioniert, das Licht im Schrank jedoch,

überprüfen Sie bitte die Verbindungen

(siehe unter # 6 & 25)

Page 40

18

DE

Elektronische Steuerung.

Die elektronische Steuerung sorgt dafür

dass die eingestellten Temperaturen oben

und unten im Gerät gehalten werden. Dies

wird mit der fortschrittlichen Steuerung im

Zusammenspiel von Kühlsystem, Wärmeleitung und Ventilator erreicht.

Nach einem evt. Stromausfall kehrt das

System automatisch zu den eingestellten

Temperaturwerten zurück.

Die elektronische Steuerung

hat folgende Funktionen:

● Ein/Aus Schalter

● Lichtschalter*

● Temperatureinstellung

● Temperaturanzeige

● Automatisches Abtauen

● Alarmanzeige bei zu hoher oder niedriger

Temperatur

● Türalarm

* Das Licht kann entweder generell oder nur

bei geöneter Tür brennen.

Bedienung und Funktion.

Abb. 8

Temperaturanzege.

Das Display zeigt die aktuelle Temperatur.

Die obere Zahl im Display zeigt die Temperatur oben im Gerät, die untere Zahl die

Temperatur unten im Gerät. Die Temperaturanzeige hat ein eingebautes Filter

mit dem die Temperatur in den Flaschen

simuliert wird. Deshalb reagiert die Anzeige

nicht auf kurzzeitige Änderungen der Lufttemperatur z.B nach dem Önen der Tür

Temperatureinstellung.

Der Termostat hat eine Kindersicherung.

Sie wird durch gleichzeitiges drücken der

Tasten „hoch und runter“ von ca. 3 sek. eingeschaltet. Im Display blinkt ”Pof”. Danach

wird wieder die aktuelle Temperatur angezeigt. Ausserdem kann man durch Drücken

von SET1 und SET2 die eingestellten

Temperaturen sehen.

Die Kindersicherung wird durch gleichzeitiges Drücken von „hoch und runter“ von ca.

3 sek. wieder ausgeschaltet und im Display

blinkt „Pon“. Danach können Temperaturen

eingestellt werden.

Page 41

19

DE

Mehrzoneneinstellung für

Serviertemperierung.

Typisch für diese Anwendung ist eine

Oberteil-/Boden-Einstellung von 16/6 °C.

Mit dieser Einstellung verteilen sich die

Temperaturen durch den Schrank zur

Aufbewahrung verschiedener Weintypen

gemäß folgender von oben nach unten

gehender Reihenfolge:

● schwere Rotweine +16 bis +19 °C

● Rosé und leichte Rotweine +12 bis

+16°C

● Weißwein +10 bis +12 °C

● Champagner und Schaumweine +6 bis

+8°C

Es empehlt sich, die Weine ein paar

Grade kälter als die gewünschte Trinktemperatur zu servieren, da sich der Wein

beim Einschenken ins Glas rasch etwas

erwärmt.

Einzoneneinstellung für

Langzeitlagerung.

Zur Langzeitlagerung von Weinen empehlt sich eine Oberteil-/Boden-Einstellung

von 12/12 °C.

Mit der gleichen Einstellung im Oberteil

und Boden sorgt das Kühlsystem für

Temperatureinstellung oben.

Drücke auf SET1. Danach kann die Temperatur oben im Gerät mit den Tasten „rauf

und runter“ gewählt werden. Der Einstellbereich geht von 8 bis 22*C, jedoch kann

kein Wert kleiner als der Temperaturwert für

unten gewählt werden.

Temperatureinstellung unten.

Drücke auf SET2. Danach kann die Temperatur unten im Gerät mit den Tasten „rauf

und runter“ gewählt werden. Der Einstellbereich geht von 5 bis 22*C, jedoch kann kein

Wert höher als der Temperaturwert für oben

gewählt werden.

Alarmfunktion.

Der Alarm wird durch einen Piepton und

eine Anzeige im Display signalisiert.

Alarm bei zu hoher Temperatur: Piepton

und die Anzeige blinkt zwischen „HtA“ und

aktueller Temperatur.

Alarm bei zu tiefer Temperatur: Piepton

und die Anzeige blinkt zwischen „LtA“ und

aktueller Temperatur.

Die Alarmtemperaturen sind abhängig von

den eingestellten Temperaturwerten.

Der Piepton kann durch Drücken einer

beliebigen Taste abgeschaltet werden.

Um die Alarmanzeige abzuschalten muss

die on/o Taste 2mal gedrückt werden,

zuerst um den Alarm zurückzusetzen und

danach noch einmal um das Gerät neu zu

starten.

Türalarm

Wenn die Tür länger als 2 min oen steht

wird der Türalarm aktiviert.

Beleuchtung.

So schalten Sie das Licht, drücken Sie

einmal

Zu Präsentationszwecken ihres Weines

können sie die Beleuchtung auch dauerhaft

einschalten. Dazu Lichtschalter zweimal

drücken. Zum Abschalten der Beleuchtung

Lichtschalter erneut drücken.

Page 42

20

DE

Automatisches Abtauen des

Kühlschranks.

Der Kühlschrank wird automatisch abgetaut, das Tauwasser läuft durch ein

Rohr in die Tauwasserschale, die sich auf

dem Kompressor bendet. Das Wasser

verdampft durch die Betriebswärme des

Kompressors. Die Tauwasserschale ist

gelegentlich zu reinigen.

Reinigung.

Zum Reinigen des Schrankinnern den

Schrank am Ein-/Ausschalter ausschalten. Eine Mischung aus warmem Wasser

und Spülmittel (max. 65 °C) ist dazu am

besten geeignet). Verwenden Sie keine

Reinigungsmittel, die Kratzer verursachen

können. Verwenden Sie ein weiches Tuch.

Mit klarem Wasser nachwischen und gut

abtrocknen. Die Tauwasserrinne, durch die

das Kondenswasser vom Verdampfer herab

läuft, bendet sich innen an der Schrankrückwand. Sie ist stets sauber zu halten.

Tropfen Sie mehrmals jährlich ein Desinfektionsmittel in den Tauwasserabuss. Mit

einem Pfeifenreiniger o.ä. reinigen. Niemals

scharfkantige oder spitze Gegenstände

verwenden.

Die Türdichtleiste muss regelmäßig gereinigt werden, um Verfärbungen zu vermeiden und lange Haltbarkeit zu gewährleisten. Klares Wasser verwenden. Nach der

Reinigung der Türdichtleiste prüfen, ob sie

dicht schließt.

Vom Rückwandverüssiger, Kompressor

und Kompressorraum den Staub am besten

mit einem Staubsauger entfernen.

Abtauen, Reinigung

und Wartung

eine gleichmäßige Temperatur im ganzen

Schrank.

Jedoch drängt die Umgebungstemperatur

langsam durch die Tür und Seiten des

Schranks ein und verursacht einen kleinen

Temperaturunterschied zwischen Oberteil

und Boden. Der Schrank wird am Boden

nach der eingestellten Temperatur gesteuert, weshalb Abweichungen im Oberteil

auftreten.

Der Unterschied liegt zwischen 0–3 °C,

abhängig von der Umgebungstemperatur.

Page 43

21

DE

Fehlersuche

Fehler Mögliche Ursache Abhilfe

Der Schrank reagiert nicht.

Der Schrank ist abgeschaltet

Stromausfall; Sicherung hat

angesprochen; Netzstecker nicht

richtig eingesteckt.

Ein-/Ausschalter betätigen.

Prüfen, ob der Strom angeschlossen ist. Die Sicherung

muss intakt/eingeschaltet sein.

Es läuft Wasser

auf den Boden des

Kühlschranks.

Das Tauwasserabussrohr ist

verstopft.

Tauwasserrinne und Abussloch

in der Rückwand reinigen.

Vibrationen

oder störende

Geräusche.

Der Schrank steht schief.

Der Schrank berührt andere

Küchenelemente.

Behälter oder Flaschen im

Schrank berühren sich.

Schrank mit einer Wasserwaage

ausrichten.

Schrank von den Küchenelementen oder Geräten abrücken, die

er berührt.

Für Abstände zwischen Flaschen

und/oder Behältern sorgen.

Der Kompressor

läuft ständig.

Hohe Raumtemperatur. Für gute Belüftung sorgen.

Steuerung zeigt P1 anOberer Fühler ist unterbrochen

oder kurzgeschlossen

Rufen Sie den Kundendienst.

Der gesamte Schrank wird

gemäß dem wärmsten Sollwert

gesteuert, bis die Störung behoben ist.

Steuerung zeigt P2 anUnterer Fühler ist unterbrochen

oder kurzgeschlossen.

Rufen Sie den Kundendienst.

Der gesamte Schrank wird

gemäß dem wärmsten Sollwert

gesteuert, bis die Störung behoben ist.

Page 44

22

DE

Ersatzteile

Bitte bei der Ersatzteilbestellung Typ- und

Seriennummer sowie Produktnummer angeben. Diese Angaben nden Sie auf dem

Typenschild an der Geräterückseite.

Das Typenschild enthält verschiedene

technische Angaben, u.a. auch Typ- und

Seriennummer. Denken Sie daran! Stets

nur autorisierte Handwerker zu beauftragen, wenn ein Teil repariert oder ausgewechselt werden muss!

Der Lieferant haftet nicht für Fehler oder

Schäden, die direkt oder indirekt durch

Fehlbedienung, Missbrauch, mangelhafte

Wartung, fehlerhaften Einbau, fehlerhafte

Aufstellung oder fehlerhaften Anschluss

sowie Feuer, Unfall, Blitzschlag, Spannungsänderungen oder andere elektrische

Störungen – wie z.B. defekte Sicherungen

oder Fehler in der Netzinstallation – sowie

von anderen als den von dem Lieferanten

vorgeschriebenen Reparaturbetrieben

ausgeführten Reparaturen verursacht

wurden, und allgemein nicht für Fehler und

Schäden, die der Lieferant nachweislich

auf andere Ursachen als Fabrikations- und

Materialfehler zurückführen kann. Diese

Fehler oder Schäden fallen nicht unter das

Reklamationsrecht.

Transportschäden, die der Anwender feststellt, sind primär eine Sache zwischen ihm

und dem Händler, d.h. der Händler hat den

Anwender zufrieden zu stellen.

Bevor Sie den Kundendienst rufen, prüfen

Sie bitte, ob Sie den Fehler selbst beheben

können (siehe Fehlersuche). Ist Ihr Hilfverlangen unberechtigt, beispielsweise weil

das Versagen des Geräts auf eine defekte

Sicherung oder Fehlbedienung zurück zu

führen ist, gehen die Kosten für den Service

besuch zu Ihren Lasten.

Reklamation, Ersatzteile und Service.

Product number.

Page 45

23

DE

Entsorgung.

Benutzerinformation zur Sammlung und

Entsorgung von veralteten Geräten und

benutzten Batterien.

Diese Symbole auf den Produkten,

Verpackungen und/oder Begleitdokumenten bedeuten, dass benutzte

elektrische und elektronische Produkte

und Batterien nicht in den allgemeinen

Hausmüll gegeben werden sollen.

Bitte bringen Sie diese alten Produkte

und Batterien zur Behandlung, Aufarbeitung bzw. zum Recycling gemäß

Ihrer Landesgesetzgebung und den

Richtlinien 2002/96/EG und 2006/66/

EG zu Ihren zuständigen Sammelpunkten.

Indem Sie diese Produkte und Batterien ordnungsgemäß entsorgen, helfen

Sie dabei, wertvolle Ressourcen zu

schützen und eventuelle negative

Auswirkungen auf die menschliche

Gesundheit und die Umwelt zu vermeiden, die anderenfalls durch eine

unsachgemäße Abfallbehandlung

auftreten können.

Wenn Sie ausführlichere Informationen zur Sammlung und zum Recycling

alter Produkte und Batterien wünschen, wenden Sie sich bitte an Ihre

örtlichen Verwaltungsbehörden, Ihren

Abfallentsorgungsdienstleister oder an

die Verkaufseinrichtung, in der Sie die

Gegenstände gekauft haben.

Gemäß Landesvorschriften können wegen nicht ordnungsgemäßer

Entsorgung dieses Abfalls Strafgelder

verhängt werden.

Für geschäftliche Nutzer in der

Europäischen Union.

Wenn Sie elektrische oder elektronische Geräte entsorgen möchten,

wenden Sie sich wegen genauerer

Informationen bitte an Ihren Händler

oder Lieferanten.

Informationen zur Entsorgung in

Ländern außerhalb der Europäischen Union

Diese Symbole gelten nur innerhalb

der Europäischen Union. Bitte treten

Sie mit Ihrer Gemeindeverwaltung

oder Ihrem Händler in Kontakt,

wenn Sie dieses Produkt entsorgen

möchten, und fragen Sie nach einer

Entsorgungsmöglichkeit.

Hinweis zum Batteriesymbol:

Dieses Symbol kann in Kombination mit einem chemischen symbol

verwendet werden. In diesem Fall

erfüllt es die Anforderungen derjenigen Richtlinie, die für die betreende

Chemikalie erlassen wurde.

Page 46

2

DK

Advarsel

Da kølemidlet, som anvendes

i apparatet, er en brændbar

gasart, er det vigtigt at sikre, at

kølekredsløb og rør ikke er beskadigede.

Mængde og type af kølemiddel

i apparatet er angivet på typeskiltet.

Standard EN378 angiver, at rummet hvor apparatet installeres

skal have en volumen på 1 m³

pr. 8 g kulbrinte kølemiddel, der

er brugt i apparatet. Dette er for

at undgå dannelse af brandfarlige gas-/luftblandinger i rummet,

hvis der skulle opstå en utæthed

i kølekredsløbet.

ADVARSEL:

Lad ventilationsåbninger, i apparatets kabinet og i eventuelt

indbygningsmodul, være utildækkede.

ADVARSEL:

Anvend ikke mekaniske apparater eller andre hjælpemidler til at

fremskynde afrimningsprocessen, udover dem som er anbefalet af fabrikanten.

ADVARSEL:

Undgå at beskadige kølemiddelsystemet

ADVARSEL:

Anvend ikke elektriske apparater

inde i apparatet, medmindre de

er af en type som er anbefalet af

fabrikanten.

ADVARSEL:

Apparatet må ikke udsættes for

regn.

ADVARSEL:

Dette apparat er ikke beregnet til

at blive anvendt af børn, medmindre det er blevet tilstrækkeligt kontrolleret af en ansvarlig

person, sådan at apparatet kan

anvendes forsvarligt. Børn skal

være under opsyn for at sikre at

de ikke leger med apparatet.

ADVARSEL:

Opbevar ikke eksplosive stoffer såsom spraydåser med en

brændbar drivgas i dette apparat.

Page 47

3

DK

ADVARSEL:

Fare og risiko for brand eller

eksplosion da kølemidlet er

brændbart. Apparatet må kun repareres af uddannet personale.

● Opbevar altid nøgler et separat

sted utilgængeligt for børn.

● Træk stikket ud af stikkontak-

ten før reparation eller rengøring af apparatet.

● Hvis netledningen er beskadi-

get, skal den udskiftes af producenten, producentens serviceagent eller anden fagmand

for at undgå fare.

● Dannelse af rim på den ind-

vendige fordamperplade og de

øverste dele er normalt. Apparatet skal derfor afrimes i forbindelse med almindelig rengøring eller vedligeholdelse.

● Vær opmærksom på at æn-

dringer i apparatets konstruktion vil medføre, at al garanti

og produktansvar bortfalder.

● Apparatet er udelukkende be-

regnet til opbevaring af vin.

CLASS 1 LED PRODUCT

Page 48

4

DK

Indhold

Advarsel..................................................2

Lær vinskabet at kende. .........................5

Inden brug. .............................................6

Energispare forslag. ...............................6

Tekniske data. ........................................7

Ibrugtagning og installation.....................7

Vendbar dør ..........................................10

Betjening og funktion ............................12

Afrimning rengøring og vedligeholdelse 20

Fejlndingsliste .....................................21

Reklamation, reservedele og service ...22

Bortskaelse .........................................23

Energiforbruget reduceres ..

1) .. jo lavere den omgivende temperatur

er.

2) .. jo varmere termostat indstillingen er.

3) .. jo færre antal gange, døren bliver åbnet og jo kortede tid, døren står åben

Energispare forslag

Page 49

5

DK

Kontroller at skabet ikke er beskadiget ved

modtagelsen. Transportskader skal anmeldes til forhandleren inden køleskabet tages

i brug.

Fjern emballagen. Rengør skabet indvendigt med lunken vand tilsat et mildt opvaskemiddel. Afvask med rent vand og tør

grundigt af (se rengøring). Brug en blød

klud.

Hvis skabet har ligget ned under transport

eller det er blevet opbevaret i kolde omgivelser (koldere end +5 ºC) skal apparatet

stå op i minimum en time inden ibrugtagning.

Inden brug

Page 50

6

DK

Belysning

Kullter

Træhylde

Tætningsliste

Typeskilt

Kontrolpanel

Fodspark

Lås

Justerbare fødder

g.1

Lær vinskabet at kende

Page 51

7

DK

Tekniske data

Denne enhed overholder de relevante EUdirektiver, herunder Lavspændingsdirektivet

2014/35/EU - Elektromagnetisk kompatibilitet direktiv 2014/30/EU

Typeskiltet, g. 2, som er placeret inde i

apparatet, indeholder forskellige tekniske

opIysninger samt type- og serienummer.

Kabelføring og forbindelser til strøm forsynings systemer skal overholde alle (lokale

og nationale) standarder.

Stikkontakten skal være let tilgængelig.

Tilslut apparatet til 220-240 V / 50 Hz vekselstrøm via en korrekt installeret stikkontakt med jordforbindelse. Stikkontakten skal

være sikret med en 10 -13 A sikring.

For udstyr, der anvendes i ikke-europæiske

lande, tjekkes på typeskiltet om strømforsyningen har den korrekte angivne spænding

og strømstyrke

Spænding og strøm / energi er angivet

på typeskiltet

Hvis netledningen er beskadiget, skal den

udskiftes af producenten, producentens

serviceagent eller anden fagmand for at

undgå fare.

Ibrugtagning og

installation

Placering

Af sikkerhedsmæssige og driftsmæssige

grunde må apparatet ikke placeres udendørs.

Stil skabet på et plant underlag i et tørt

og godt ventileret rum (max. 75% relativ

luftfugtighed). Anbring ikke skabet tæt på

varmekilder såsom komfur eller radiator og

undgå at det udsættes for direkte sollys eller varme fra anden varmkilde.

Omgivende temperatur

Klimaklassen står på typeskiltet. Den angiver indenfor hvilke omgivende temperaturer

kølekabet kører optimalt. Vinskabene med

vinterposition fungerer dog ned til 5º C.

Bemærk: Skabet fungerer bedst ved e omgivende temperaturer på 10 ° til 32 ° C

g.2

Page 52

8

DK

Underlaget hvorpå skabet opstilles skal

være plant. Brug ikke en ramme eller

lignende.

Skabet kan stå frit op ad en væg, bygges

ind i et køkkenelement eller stå side om

side med andre skabe.

Ventilation

Det er vigtigt, at skabet får tilstrækkelig

ventilation og at der er uhindret

luftcirkulation over, under og omkring det.

Figurene nedenfor viser, hvordan du sikrer

den nødvendige cirkulation omkring skabet

g. 3

g. 5

g. 4

Installation

Page 53

9

DK

Afstandsstykkerne på skabets bagside sikrer den nødvendige luftcirkulation. Monter

de to afdækninger som følger med skabet

(se g. 7)

g. 7

g. 8

Opstilling

Det er vigtigt, at skabet står helt lige.

Man kan justere skabet ved at dreje de stilbare fødder i front op eller ned (se gur 8).

Kontroller med et vaterpas, at skabet står

lige sideværts.

Max. 85 kg.

g. 6

(g 6)

Et “Side by Side” kit kan bestilles.

Page 54

10

DK

Vendbar dør

Følg anvisningen omhyggelig

OBS: Før du begynder skal du sikre dig at skabet ikke er tilsluttet strøm.

Vi anbefaler at man er to personer til opgaven.

Hjælpemateriale :

4 mm 6kant nøgle

Fladhovedet skruetrækker

Torx 20 (TX20) skruetrækker

2. Læg skabet ned på ryggen på et blødt

underlag for at undgå skader.

1. Åbn døren og afmonter de to skruer, som

fastholder fodsparket (TX20)

(Vent med at afmonter fodsparket)

3. Øverste dørhængsel fjernes.

( 4 mm nøgle)

Page 55

11

DK

4. Afmonter fodsparket (den indbyggede

snap funktion i hver side kan løsnes ved

hjælp af den adhovedede skruetrækker).

5. Læg fodsparket med glasfronten nedad

på et blødt underlag,

OBS:Der må ikke trækkes i ledningerne.

6. Dørens LED ledninger afmonteres fra

stikket på fodsparket (sort & sort / hvid

stribet ledninger). Tryk den øverste lås

ned for at frigøre ledningsenderne.

Bemærk: sort ledning er + og svarer til den

røde ledning på den modsatte side

Den sort / hvid stribede ledning er 0

(neutral) og svarer til sorte ledning på

den modsatte side - dette er vigtigt, når

ledningerne skal monteres senere.

7. For at vende glasset på fodsparket skal

beslagene fjernes. Skruen løsnes og

beslaget incl. skrue og bolt fjernes fra

beslaget.

OBS: Glasset er nu løst!

Page 56

12

DK

10.Fjern låsepinden ved hjælp af den ad-

hovede skruetrækker.

11.Træk låsecylinderen op og monter den

og låsepinden igen i den modsatte side.

9. Træk døren lidt op fra hængslet.

8. Løft fodsparket og drej glasset, så

låsehulllet passer med hullet i den

anden side. Placer fodsparket på

glasset igen, og monter beslagene

på plastprolet i begge ender igen.

Skruerne må ikke overspændes.

Bemærk: Møtrikken skal passe ind i

den midterste rille.

Page 57

13

DK

13.Flyt hængselstappen over i den mod-

satte side.

OBS: Bøsningen skal også yttes med.

12. Træk LED ledningen forsigtigt op igen-

nem hængselstappen.

15. Træk LED ledningen op og ud.

14. Vend døren, så glassiden er nedad

Bemærk: Anbring noget blødt mellem

glasset og skabet for at undgå ridser.

Tætningslisten trækkes af i den neder-

ste ende af døren.

Page 58

14

DK

16.Læg ledningen ned i plastprolet og før

den over til den anden side.

17. Skub ledningerne gennem det aange

hul, og gennem hængselshullet. Dette

kan være en svært at gøre. Så derfor

montere kun én ledning ad gangen

18. Først føres den ene ledning igennem,

og derefter tapes den anden ledning

fast på den første og de trækkes igennem på én gang. Husk at fjerne tapen

igen.

Page 59

15

DK

21.Træk ledningerne igennem bøsningen

inden de monteres i hullet til dørtappen.

20. Fjern dørhængselsbøsning fra den

anden side.

22.Vend døren igen og anbring den i en kort

afstand fra og overfor dørtappen.

19.Vær opmærksom på at ledningen ligger

pænt nede i prolet, og monter derefter

tætningslisten igen.

Det er vigtigt at kontrollere, at tætningsli-

sten sidder tæt til hele vejen rundt.

Hvis ikke, kan du opvarme listen meget

forsigtigt ved hjælp af en hårtørrer og

derefter trykke den ned, så den danner en

tæt forsegling mod kabinettet. Vær omhyggelig med ikke at opvarme listen så meget,

at den smelter!

Page 60

16

DK

23.Træk ledningen igennem dørhængslet.

....

24.… og igennem ledningshullet i plastemnet.

25.Monter ledningen igen i stikket (se under

pkt 6) og tjek, at de er fastgjort korrekt.

26. Skub døren ned på plads over bøsnin-

gen samtidig med at der trækkes forsigtig i ledningerne, så de ikke kommer

i klemme.

Page 61

17

DK

27. Flyt bøsningen i toppen af døren over

på den modsatte side (der sidder måske

én i forvejen)

28.Flyt afdækningspropperne i toppen af

skabet over på den modsatte side

29. Vær opmærksom på at døren ligger lige

på kabinettet før tophængslet monteres

igen.

30. Monter fodsparket igen.

Rejs skabet op og skrue de to skruer i

igen (se under pkt. 1).

OBS: VIGTIGT: Vent ca. 1/2 time inden

skabet tilsluttes strøm.

OBS: Hvis LED dørlyset ikke lyser, men

den øverste LED lys i skabet lyser, er

det mest sandsynlige at ledningerne

ikke er monteret korrekt i stikket.

(Tjek pkt. 6 & 25)

Page 62

18

DK

Betjening og funktion

g. 8

Elektronisk styring.

Den elektroniske styring sørger for at

skabet holder de indstillede temperaturer i

top og i bund af skabet. Dette opnås ved en

avanceret styring af kølesystem, varmelegeme og ventilator.

Efter en evt strømafbrydelse huskes den

indstillede temperatur.

Den elektroniske styring har følgende

funktioner:

● Tænd / sluk knap

● Lyskontakt*

● Temperaturindstilling

● Temperatur angivelse

● Automatisk afrimning

● Døralarm

● Alarm ved for høj og for lav temperatur

* Lyset kan enten være tændt hele tiden

eller kun når døren er åben.

Temperatur-udlæsning

Displayet viser den aktuelle temperatur. Tallet øverst i displayet angiver temperaturen i

toppen af skabet og tallet nederst i displayet

angiver temperaturen nederst i skabet.

Temperaturvisningen har et indbygget lter,

som simulerer den aktuelle temperatur i

askerne. Derfor reagerer udvisningen ikke

på kortvarige variationer i lufttemperaturen.

Temperatur-indstilling.

Termostaten har børnesikring. Denne

aktiveres ved at trykke ”op og ned” knapperne samtidig. Efter ca 3 sek blinker ”Pof” i

diplayet. Herefter vises de aktuelle temperaturer som normalt. Desuden kan man se

de indstillede temperaturer ved at trykke

hhv SET1 og SET2.

Børnesikringen annulleres ved at trykke ”op

og ned” knapperne samtidig. Efter ca 3 sek

blinker ”Pon” i diplayet og temperaturen kan

indstilles.

Temperaturindstilling i top.

Tryk på SET1. Herefter kan temperaturen i

toppen af skabet reguleres op og ned med

”op og ned” knapperne. Temperaturen kan

reguleres fra 8 til 22 °C, dog således at

temperaturen ikke kan stilles koldere end

den aktuelle setpunkt for den nederste

temperaturføler.

Page 63

19

DK

Permanent belysning

For præsentation af Deres vin, kan De

vælge at have lyset tændt permanent ved at

trykke på lyssymbolet to gange.

For at slukke for lyset, trykkes igen på .

Fler-zone indstilling for

serverings-temperering.

Typisk indstilling for denne anvendelse er

en top/bund indstilling på 16/6. Med denne

indstilling vil temperaturerne fordele sig ned

igennem skabet, til opbevaring af forskellige

vintyper efter følgende fordeling, fra top

mod bund:

● tunge rødvine +16 til +19 °C

● Rosé og lette rødvine +12 til +16 °C

● hvidvin +10 til +12 °C

● champagne og mousserende vine +6 til

+8 °C

Enkelt-zone indstilling for

langtidslagring.

For langtidsopbevaring af vine anbefales

en top/bund indstilling på 12/12ºC.

Med samme indstilling i top og bund vil

kølesystemet skabe en jævn temperatur i

hele skabet.

Dog vil omgivelsernes temperatur trænge

langsomt ind gennem skabets dør og sider,

og forårsage en lille temperaturforskel

mellem top og bund. Skabet vil styre ind i

bunden efter den indstillede temperatur, og

afvigelsen vil derfor være i toppen.

Forskellen vil ligge mellem 0 – 3 °C, afhængig af omgivelsestemperaturen.

Temperaturindstilling nederst i

skabet.

Tryk på SET2. Herefter kan temperaturen

nederst i skabet reguleres op og ned med

”op og ned” knapperne. Temperaturen

kan reguleres fra 5 til 22 °C, dog således

at temperaturen ikke kan stilles varmere

end den aktuelle setpunkt for den øverste

temperaturføler.

Alarmer.

Der er en underalarm for den kolde temperaturføler og en overalarm for den varme

temperaturføler.

Alarmen består dels af en beeper og af en

advarsel på displayet.

Alarm for høj temperatur: beep lyd + display

skift mellem HtA og aktuel temperatur.

Alarm for lav temperatur: beep lyd + display

skift mellem LtA og aktuel temperatur.

Alarmtemperaturen afhænger af setpunkterne.

Beep-lyden kan annulleres ved et tryk på en

tilfældig termostatknap.

For at fjerne display alarmen skal on/

o knappen trykkes ind. Først for slukke

alarmen. Derefter igen for genopstart af

kompressor.

Døralarm

Når døren har været åbnet mere end 2

minutter aktiveres døralarmen.

Lyset.

For at slukke lyset, trykkes én gang på

Page 64

20

DK

Automatisk afrimning af køleskabet.

Afrimning af køleskabet sker automatisk,

smeltevandet løber gennem et rør ned til

tøvandsskålen der sidder oven på kompressoren. Vandet fordamper på grund af

varmen fra kompressoren. Tøvandsskålen

bør gøres ren engang imellem.

Rengøring.

Før rengøring påbegyndes skal stikproppen

fjernes fra stikkontakten. Skabet rengøres

bedst med en opløsning af lunkent vand

tilsat lidt opvaskemiddel (max. 65 ºC).

Anvend ikke rengøringsmidler der kan

ridse. Brug en blød klud. Vask efter med

rent vand og tør grundigt af. Tøvandsrenden, hvor kondensvandet fra fordamperen

løber ned i, sidder i bunden af bagvæggen

inde i skabet. Sørg for at den er ren. Brug

et desinfektionsmiddel, som f.eks. rodalon,

der skal dryppes i tøvandsaøbet et par

gange om året. Rens med en piberenser

eller lignende.

Brug aldrig skarpe eller spidse genstande.

Tætningslisten rundt ved døren kræver

jævnlig rengøring for at undgå misfarvning

og sikre lang holdbarhed. Brug rent vand.

Efter rengøring af dørens tætningsliste bør

du kontrollere om den fortsat slutter tæt.

På rygkondensator, kompressoren og i

kompressorrummet fjernes støvet bedst

med en støvsuger.

Afrimning, rengøring og vedligeholdelse

Page 65

21

DK

Fejlndningsliste

Fejl Mulig årsag Afhjælpning

Skabet virker ikke. Skabet er slukket.

Strømsvigt; sikringen er slået fra;

netstikket er ikke sat rigtigt i.

Tryk på tænd/sluk knappen.

Kontrollér om strømmen er

tilsluttet. Sikringen skal være

slået til.

Der løber vand i

bunden af køleskabet.

Tøvandsaøbsrøret er tilstoppet. Rens tøvandsrenden og aøbs-

hullet i bagvæggen.

Vibrationer eller

generende støj.

Skabet står skævt.

Skabet hviler op mod andre køkkenelementer.

Beholdere eller asker berøre

hinanden i skabet.

Indstil skabet med et vaterpas.

Ryk skabet væk fra køkkenelementerne eller apparater, som

står umiddelbart op ad skabet.

Sørg for afstand mellem asker

og/eller beholdere.

Kompressor kører

konstant.

Høj rumtemperatur. Sørg for god ventilation.

Styringen viser P1 Topføleren er afbrudt eller kort-

sluttet

Tilkald service. Hele skabet

styrer efter varmeste setpunkt,

indtil fejlen er udbedret.

Styringen viser P2 Bundføleren er afbrudt eller

kortsluttet.

Tilkald service. Hele skabet

styrer efter varmeste setpunkt,

indtil fejlen er udbedret.

Page 66

22

DK

Reklamation, reservedele og service

Reklamationsretten

Såfremt der konstateres fejl ved produktet,

kan De over for leverandøren gøre brug af

reklamationsretten ifølge gældende lovgivning. Producenten skal for egen regning

afhjælpe fabrikations- og materialefejl, der

konstateres ved apparatets normale brug

under forudsætning af, at apparatet er købt

som fabriksnyt i Danmark. For Grønland og

Færøerne gælder særlige bestemmelser.

Såfremt det skønnes nødvendigt at apparatet indsendes til værksted, sker indsendelse

og returnering for producentens regning og

risiko.

Der er ikke dækning for fejl eller skader

direkte eller indirekte opstået ved fejlbetjening, misbrug, mangelfuld vedligeholdelse,

forkert indbygning, opstilling eller tilslutning.

Det samme gælder for brand, ulykke, lynnedslag, spændingsvariationer eller andre

elektriske forstyrrelser som f.eks. defekte

sikringer eller fejl i forsyningsnettets elektriske installationer.

Reparationer udført af andre end de anviste

reparatører, og i det hele taget fejl og

skader, som leverandøren kan godtgøre

skyldes andre årsager end fabrikations- og

materialefejl, er ikke omfattet af reklamationsretten.

Vær opmærksom på, at ved indgreb i

apparatets opbygning, og ved ændring af

apparatets komponentbestykning bortfalder

garanti og produktansvar og apparatet kan

ikke lovligt anvendes. Godkendelse anført

på mærkeskilt er ligeledes ugyldig.

Transportskader, der konstateres hos forbrugeren, er primært en sag mellem forbruger og forhandler, dvs. forhandler må drage

omsorg for, at forbrugeren stilles tilfreds,

inden du tilkalder serviceassistance, bedes

du kontrollere de fejlmuligheder, du selv kan

afhjælpe. (Se brugsanvisningen)

Såfremt dit krav om afhjælpning er uberettiget, eksempelvis hvis apparatets

svigt skyldes en sprunget sikring eller en

fejlbetjening, må du selv betale de omkostninger, der er forbundet med at have tilkaldt

serviceassistance.

Reservedele

Angiv venligst type- og serienummer samt

produkt nummer, når du bestiller reservedele.

Disse oplysninger nder du på typeskiltet.

Typeskiltet indeholder forskellige tekniske

oplysninger, samt type- og serienummer.

Husk altid at bruge autoriserede håndværkere, hvis der er noget der skal repareres

eller udskiftes!

Produkt nr.

Page 67

23

DK

Bortskaelse

Brugerinformation om indsamling og

bortskaelse af elktronikskrot og brugte

batterier

Disse symboler på produkter, emballage og/eller ledsagedokumenter

betyder, at brugte elektriske og

elektroniske produkter og batterier

ikke må smides ud som almindeligt

husholdningsaald. Sådanne gamle

produkter og batterier skal indleveres

til behandling, genvinding resp. recycling i henhold til gældende nationale

bestemmelser samt direktiverne

2002/96/EF og 2006/66/EF.

Ved at bortskae sådanne produkter

og batterier på korrekt vis hjælper

du med til at beskytte værdifulde

ressourcer og imødegå de negative

påvirkninger af det menneskelige

helbred og miljøet, som vil kunne

være følgen af usagkyndig aaldsbehandling.

Ønsker du mere udførlig information

om indsamling og recycling af gamle

produkter og batterier, kan du henvende dig til din kommune, deponeringsselskabet eller stedet, hvor du

har købt produkterne.

Usagkyndig bortskaelse af elektronikskrot og batterier kan eventuelt

udløse bødeforlæg.

For kommercielle brugere i Den

Europæiske Union

Når du ønsker at kassere elektriske

eller elektroniske apparater, bedes du

henvende dig til din forhandler eller

leverandør for nærmere information.

Information om bortskaelse i

lande uden for Den Europæiske

Union

Disse symboler gælder kun inden

for Den Europæiske Union. Hvis du

ønsker at afhænde dette produkt,

skal du rette henvendelse til de lokale

myndigheder eller din forhandler. Her

kan du få oplysninger om, hvordan

du bedst kommer af med produktet.

Information om batterisymbol:

Dette symbol kan optræde sammen

med et kemisk symbol. I så fald opfylder det kravene for det direktiv, som

er blevet fastlagt for det pågældende

kemikalie.

Page 68

9193215 rev 04

GB Reserving the right to alter specications without prior notice.

DE Recht auf Änderungen vorbehalten.

DK Ret til ændringer forbeholdes.

Loading...

Loading...