Page 1

AKG/S 337 / 397

GB Instructions for use

DE Bedienungsanleitung

FR Mode d’emploi

Page 2

GB

Warning

As the appliance contains a ammable refrigerant, it is essential to

ensure that the refrigerant pipes

are not damaged.

The quantity and type of the

refrigerant used in your appliance is indicated on the rating

plate.

Standard EN378 species that

the room in which you install your

appliance must have a volume of

1m³ per 8 g of hydrocarbon refrigerant used in the appliances.

This is to avoid the formation of

ammable gas/air mixtures in

the room where the appliance is

located in the event of a leak in

the refrigerant circuit.

WARNING:

Keep ventilation openings in the

appliance’s cabinet or in the builtin structure clear of obstruction.

WARNING:

Do not use other mechanical

devices or other means to accelerate the defrosting process

than those recommended by the

manufacturer.

WARNING:

Do not damage the refrigerant

system.

WARNING:

Do not use electrical appliances inside the refrigerated stor-

age compartment, unless they

are of a type recommended by

the manufacturer.

WARNING:

Do not expose the appliance to

rain, and secure not splashing

water when cleaning the oor.

WARNING:

This appliance is not intended

for use by children or inrm

persons unless they have been

adequately supervised by a

responsible person to ensure

that they can use the appliance

safely. Children should be supervised to ensure that they do not

play with the appliance.

WARNING:

Do not store explosives, such

as aerosol cans with ammable

propellants in the unit.

WARNING:

Danger risk of re or explosion if

ammable refrigerant are used.

To be repaired only by trained

personnel.

2

Page 3

WARNING:

When positioning the appliance,

ensure the power cord is not

trapped or damaged.

WARNING:

Do not locate multiple portable

socket-outlets or portable power

supplies at the rear of the appliance.

WARNING:

Sharp edges on cabinet, compressor compartment, evaporator, ventilation cover and on

internal equipment can occur.

Please be aware to avoid injury.

WARNING:

The condenser on the back of

the appliance will in some cases

have a hot surface. Please be

aware to avoid injury.

WARNING:

The appliance must be connected to power minimum 12

hours before using it for storage

of medicine.

GB

● Always keep the keys in a separate place

and out of reach of children.

● Do not step on the lower panel to reach

medicine in the top of the appliance.

● Before servicing or cleaning the appli-

ance, unplug the appliance from the

mains or disconnect the electrical power

supply.

● If the supply cord is damaged, it must be

replaced by the manufacturer, its service

agent, or similarly qualied persons in

order to avoid a hazard.

● Relevant for Australia: Supply cord

tted with a plug complies with AS/NZS

3112.

● Frost formation on the interior evaporator

wall and upper parts is a natural phenomenon. Therefore, the appliance should

be defrosted during normal cleaning or

maintenance.

● Please note that changes to the appli-

ance construction will cancel all warranty

and product liability.

● This device is intended to be

used exclusively for medical

products.

● If medicine is spilled in the appliance

or the defrost water canal is has to be

cleaned immediately to avoid the medicine to evaporate to the surroundings.

● If the instructions is lost please contact

your supplier of the appliance to have a

new instruction for use.

● If service needed to this device, please

be aware of only using service personnel with education in handling medical

devices.

3

Page 4

GB

Contents

Warning ......................................................2

About ........................................................5

Get to know your refrigerator ......................6

Before use ..................................................7

Electrical connection ...................................7

Installation and start-up ..............................8

Placement and installation ..........................9

Levelling the appliance ............................. 11

Probe bottle .............................................12

Interior tting .............................................13

Mounting of drawer dividing system ........14

Ordinary use .............................................15

Porthole ....................................................15

Voltage free contact .................................16

Safety Thermostat ....................................17

Reversing the door ...................................21

Defrosting, cleaning and maintenance .....24

Fault nding ..............................................25

Warranty, spare parts and service ............26

Disposal ....................................................27

4

Page 5

About

Dear Customer. Congratulations with

your new AKG/S 337/397. This pharmacy

refrigerator is meant for reliable storage of

medication and other products needed to

be stored at a stabile temperature between

2-8 degrees C. The parameters are as following.

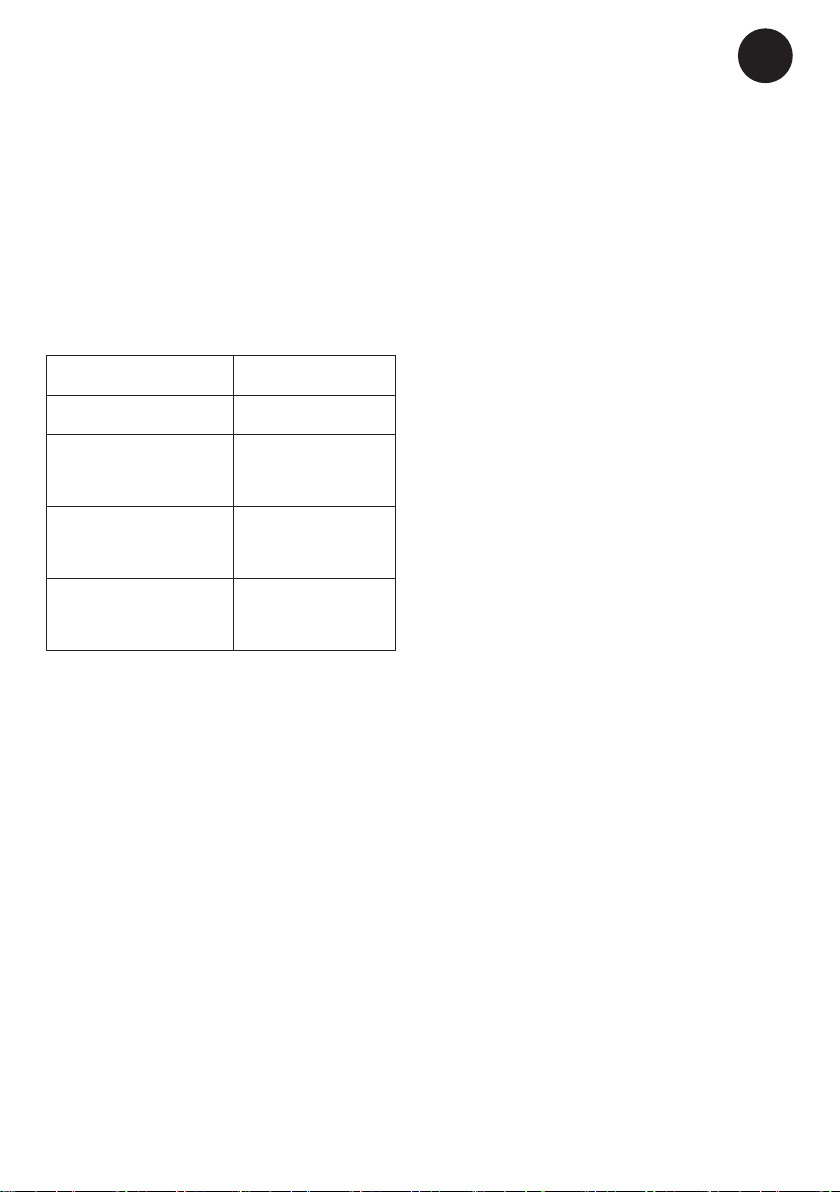

Temperature range 2 °C – 8 °C

Fabric Set Point 4

Ambient Temperature 15 – 30 °C

(35 ° C for solid

doors)

Relative humidity 70 %

(75 % for solid

doors)

Number of probes 3 – 5 depending

on equipment of

the device

GB

As standard, the device is equipped with

3 sensors. One to control the compressor,

one to control the defrost function and one

in the top for information about temperature

at loading limit.

Some model has a reference probe bottle

installed with a fourth probe and a fth

probe for a safety thermostat.

The climate class can be seen at the rating

plate.

5

Page 6

GB

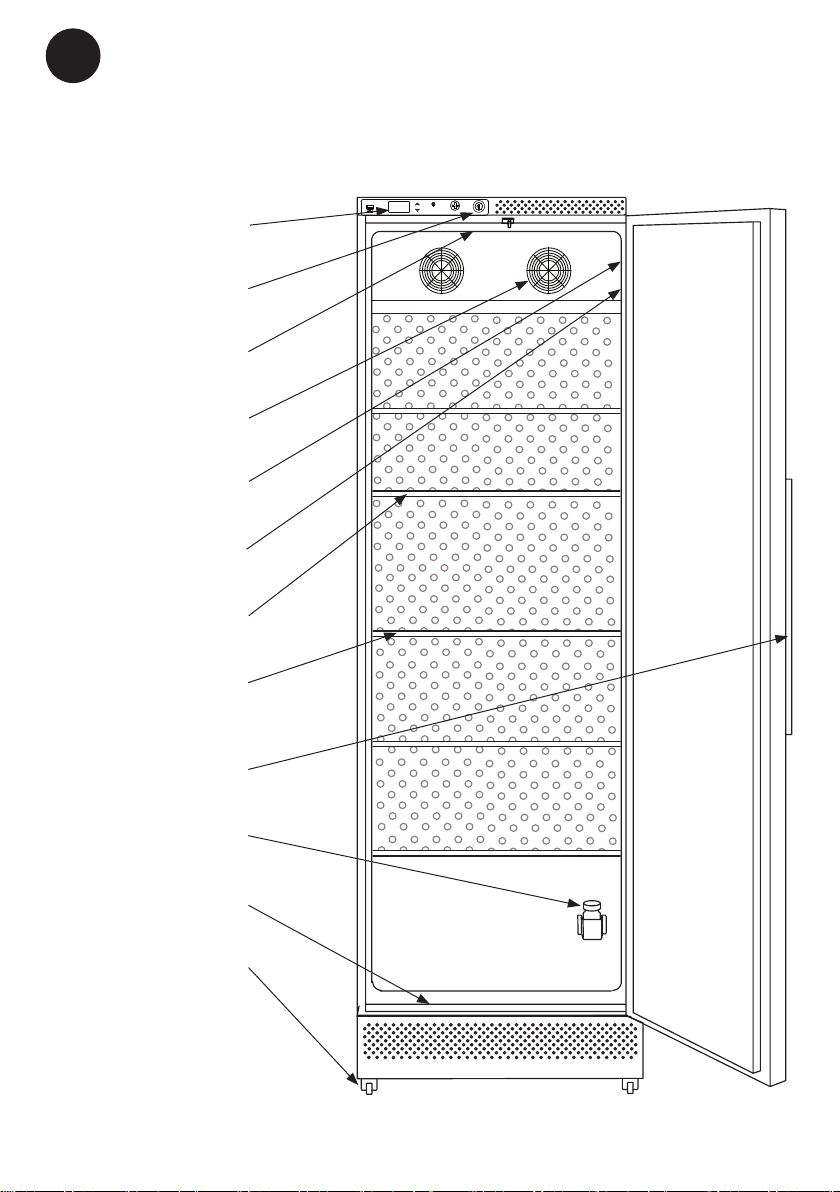

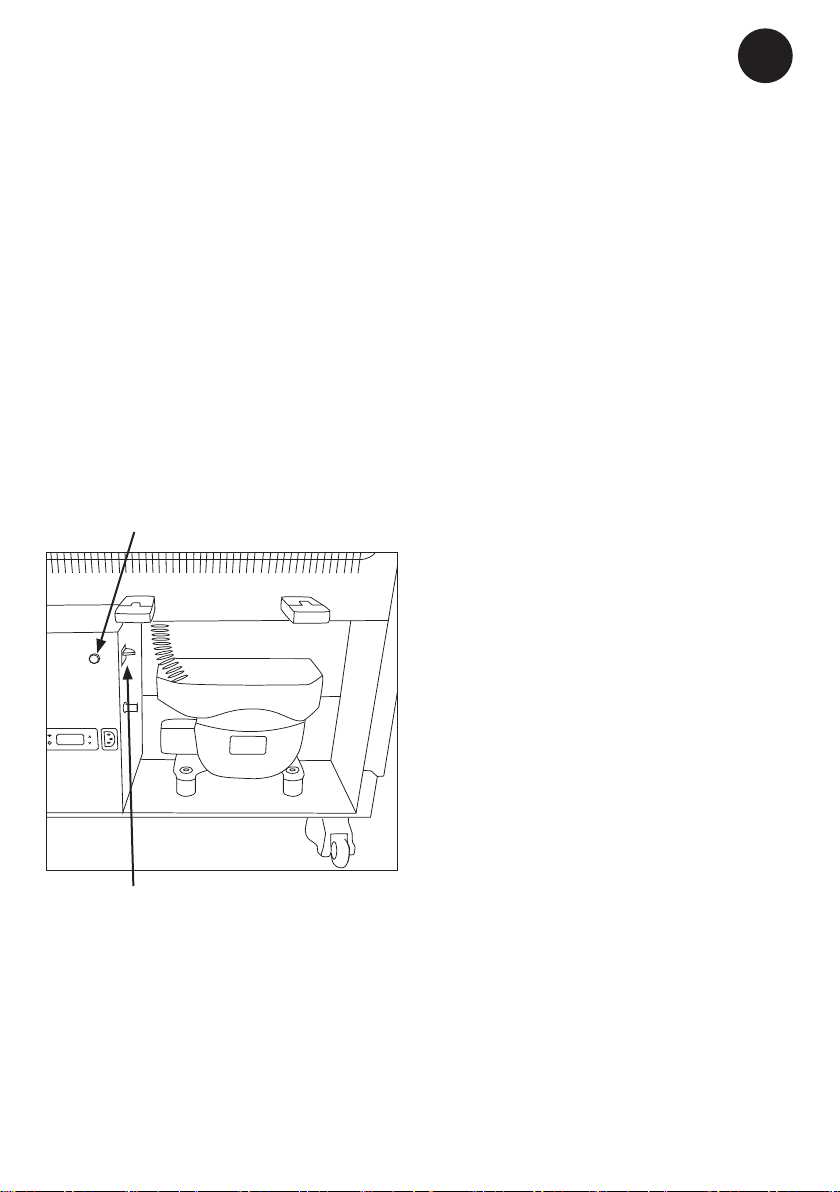

Get to know your refrigerator

SET

DATAREC

Display/Keyboard

Lock

LED Light

Fans (on the rear wall)

Rating plate

Stacking mark

Adjustable shelf

PHARMA

Adjustable drawer

(optional)

Door handle

Probe bottle

Bottom shelf

Wheel or feet

g. 1

6

Page 7

GB

Before use

Before turning on the appliance, please

read the following instructions carefully as

they contain important information regarding safety, installation, operation and

maintenance. Please keep the instructions

for future reference.

On receipt, please check the appliance to

ensure it has not been damaged during

transportations. Damage from transportation should be reported to the distributor. Do

not use the appliance before all commercial

issues have been claried.

The foil on the shelves must be removed

before cleaning and using the unit. Clean

the inside of the cabinet using warm water

with a mild detergent. Rinse with clean

water and dry thoroughly (see cleaning

instructions). Use a soft cloth.

If the appliance has been laid down during

transportation, or if it has been stored in

cold surroundings (colder than +5°C), it has

to stabilize in an upright position for at least

an hour at normal conditions before being

switched on.

Note: If it is necessary to lay down the

appliance, the door must face upwards

and the appliance must be enclosed in the

original packaging.

Electrical connection

Wiring and connections in power supply

systems must be in accordance with all

applicable (local and national) electrical

codes. Consult these codes lengths and

sizes prior to cabinet installation.

This appliance complies with relevant EU

directives including Low Voltage Directive

2014/35/EU and Electromagnetic Compatibility Directive 2014/30/EU.

The socket should be freely accessible.

Connect the appliance only to 220/240 V

/ 50Hz alternating current via a correctly

installed earthed socket.

The socket must be fused with a 10 A or

13 A fuse.

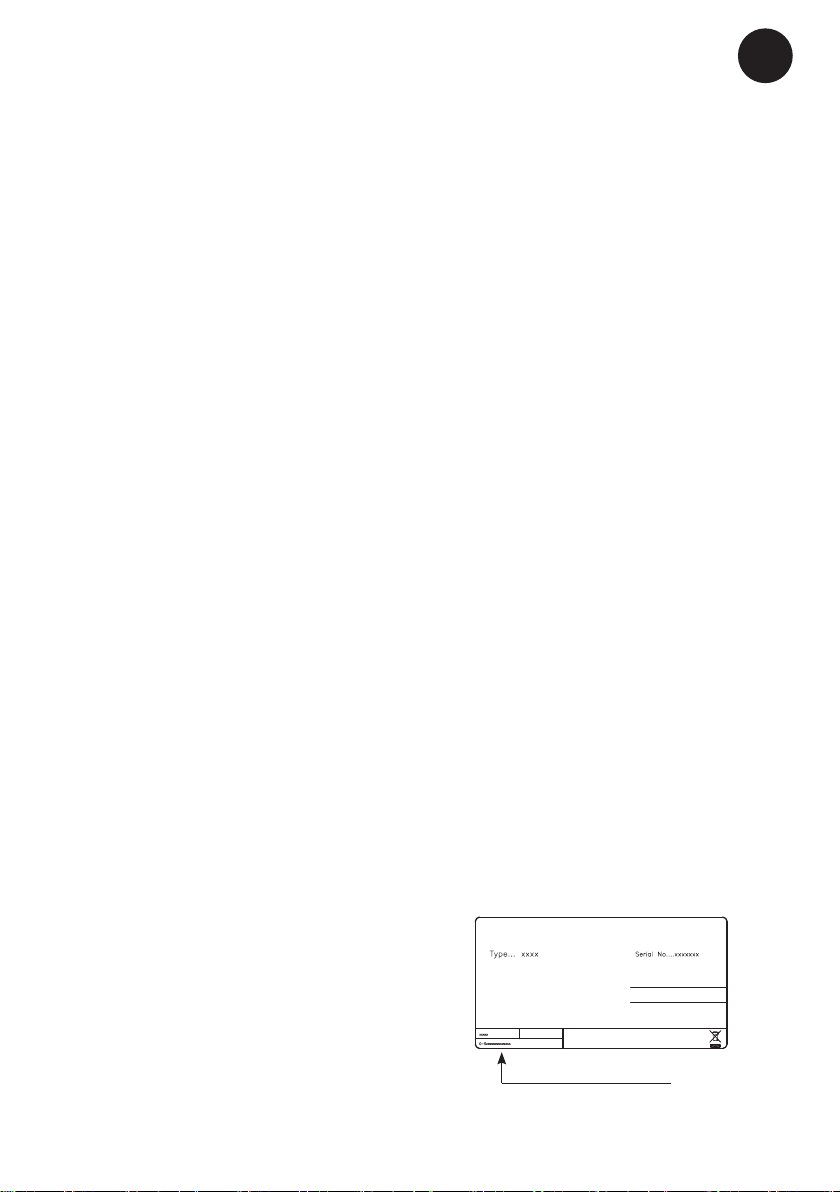

If the appliance is to be operated in a

non-European country, check on the rating

plate whether the indicated voltage and

current type correspond to the values of

your main supply.

Data regarding voltage and absorbed

power / current are given on the rating

plate.

The power cord may be replaced by a

technician only.

The rating plate provides various technical information as well as type and serial

number.

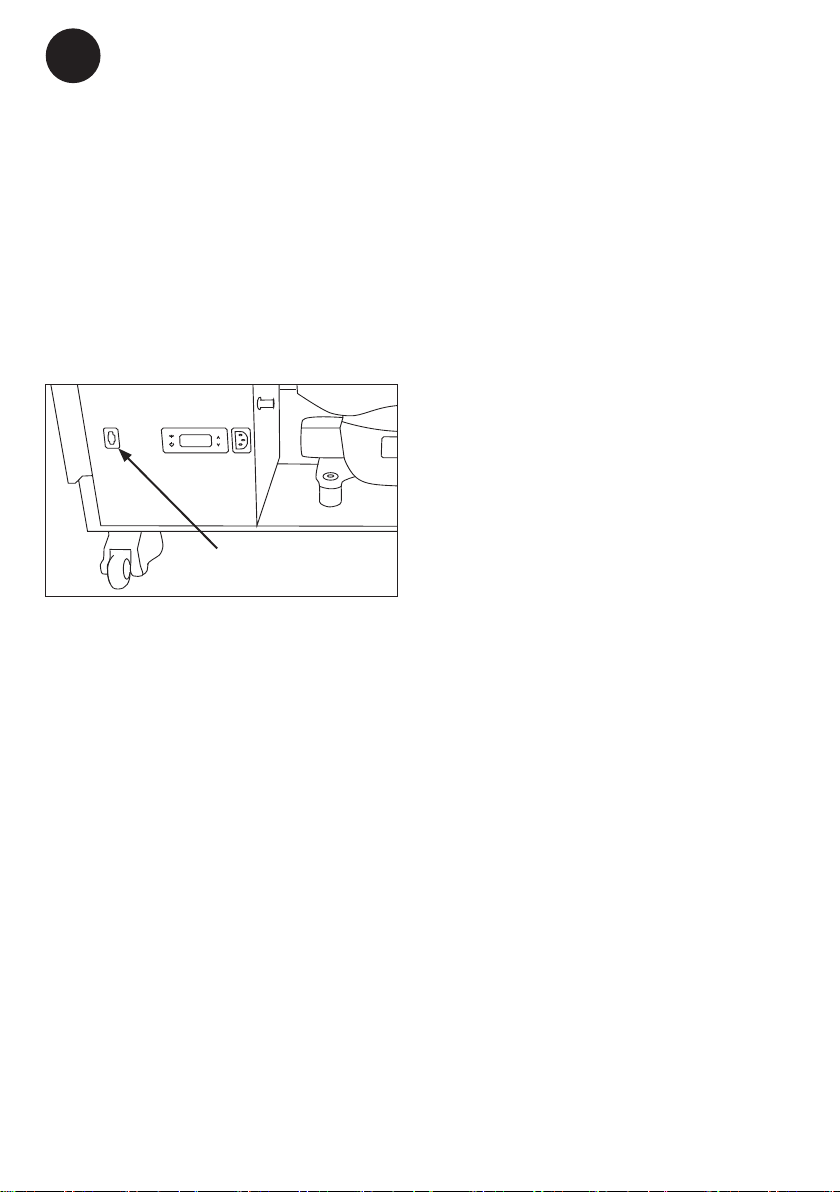

Product number

g. 2

7

Page 8

GB

Installation and start-up

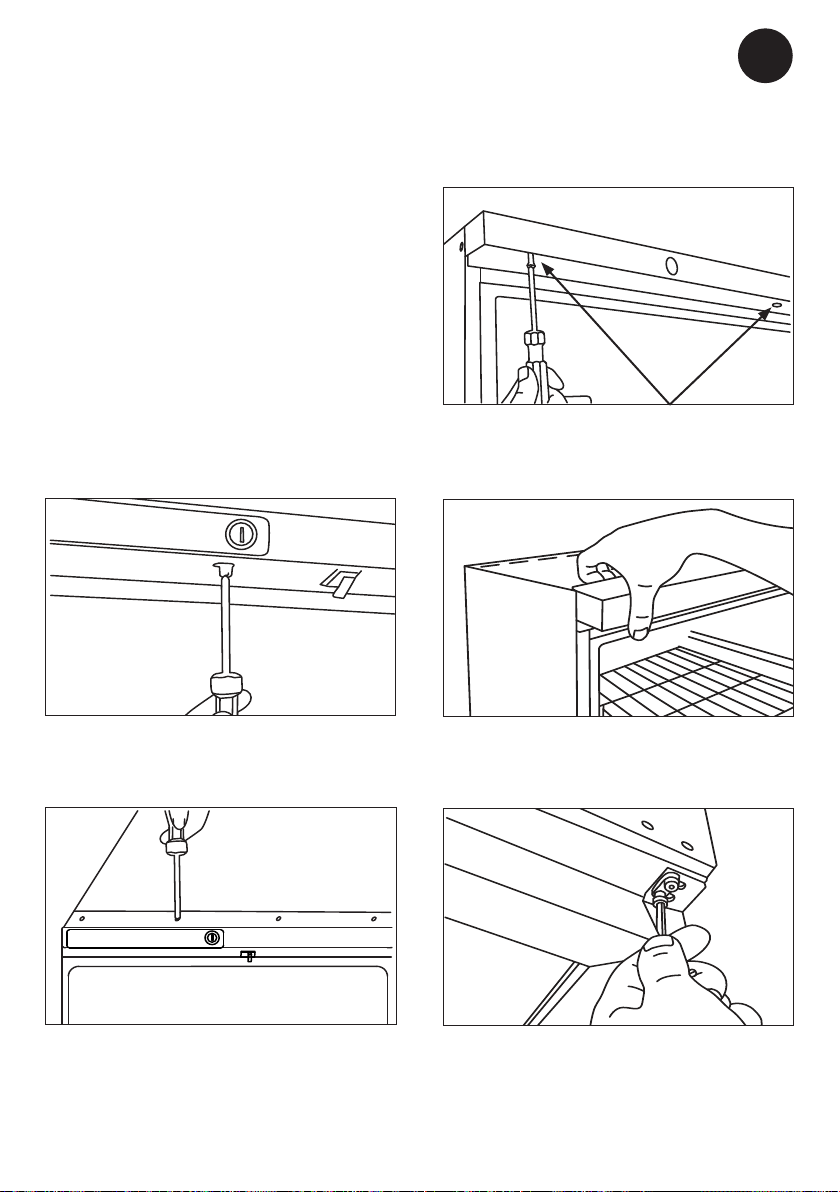

Battery backup

This appliance is equipped with a battery

back up system. Please activate the battery

backup before nal placement A fuse is

placed in the bag with helping materials.

Take this fuse and insert is as illustrated on

the picture.

Fuse

g. 3

NOTE! The battery backup system does

not supply the cooling system

with power. When starting up the

appliance for the rst time it is

necessary to switch on the battery

backup system.

Battery backup function

The battery backup system supplies the

controller and keyboard with power at

power failure. This makes it possible to

supervise the temperatures in the unit during the power failure. The battery backup

system makes it possible to supervise the

temperatures for 48 hours.

After a power failure and at the rst start

up the battery needs to be recharged. To

regain the full capacity the battery will be

reloading for 10 days.

NOTE! The battery for back up should be

changed every third year to secure

48 hours of back up. Please put

this change in the maintenance

schedule for every third year.

8

Page 9

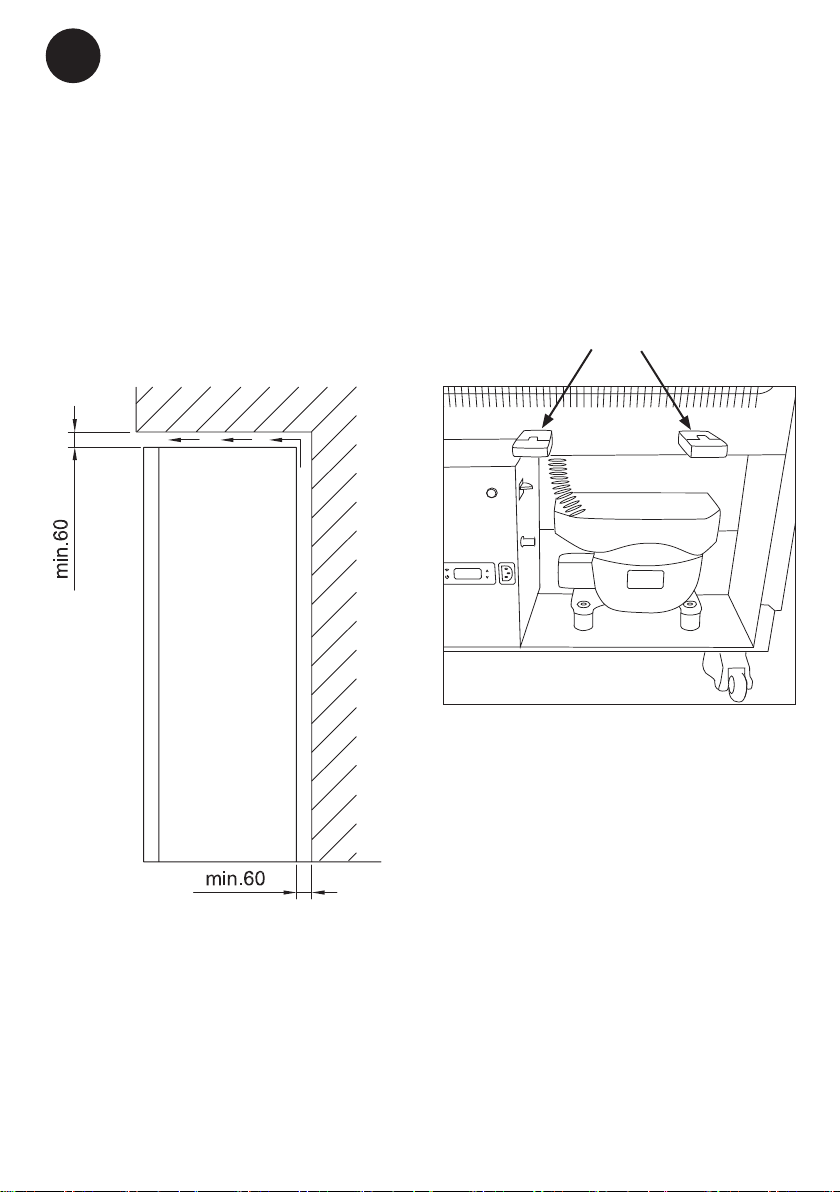

Placement and installation

GB

The appliance viewed from

above

If the appliance is placed beside a wall,

there must be sucient room for its door to

be opened wide enough to allow the shelf to

be pulled out (g. 4)

g. 4

Side by side

In side-by-side arrangements there must be

at least 60 mm between each unit on each

side of the cabinets, to ensure the doors

can be opened freely (See g. 5)

Setting up

It is important that the appliance is absolutely level. It can be levelled by screwing

the adjustable feet of the appliance up or

down.

Use a spirit level to check that the appliance

is absolutely level sideways.

If the appliance is placed on a soft sur-

face, e.g. oorboards or a carpet you must

recheck whether the appliance is still level

after a period of time as the underlying

surface may yield under the weight of the

appliance.

g. 5

9

Page 10

GB

Ventilation

It is important that the appliance is well

ventilated and that air can circulate freely

above, below and around it.

The gurs (g. 4-7) illustrate how the necessary air circulation around the appliance is

ensured.

Ventilation guard

The guards on the rear of the appliance

ensure sucient air circulation. The guards

must be tilted down when the cabinet is

installed.

Guards tilted down

g. 7

g. 6

10

Page 11

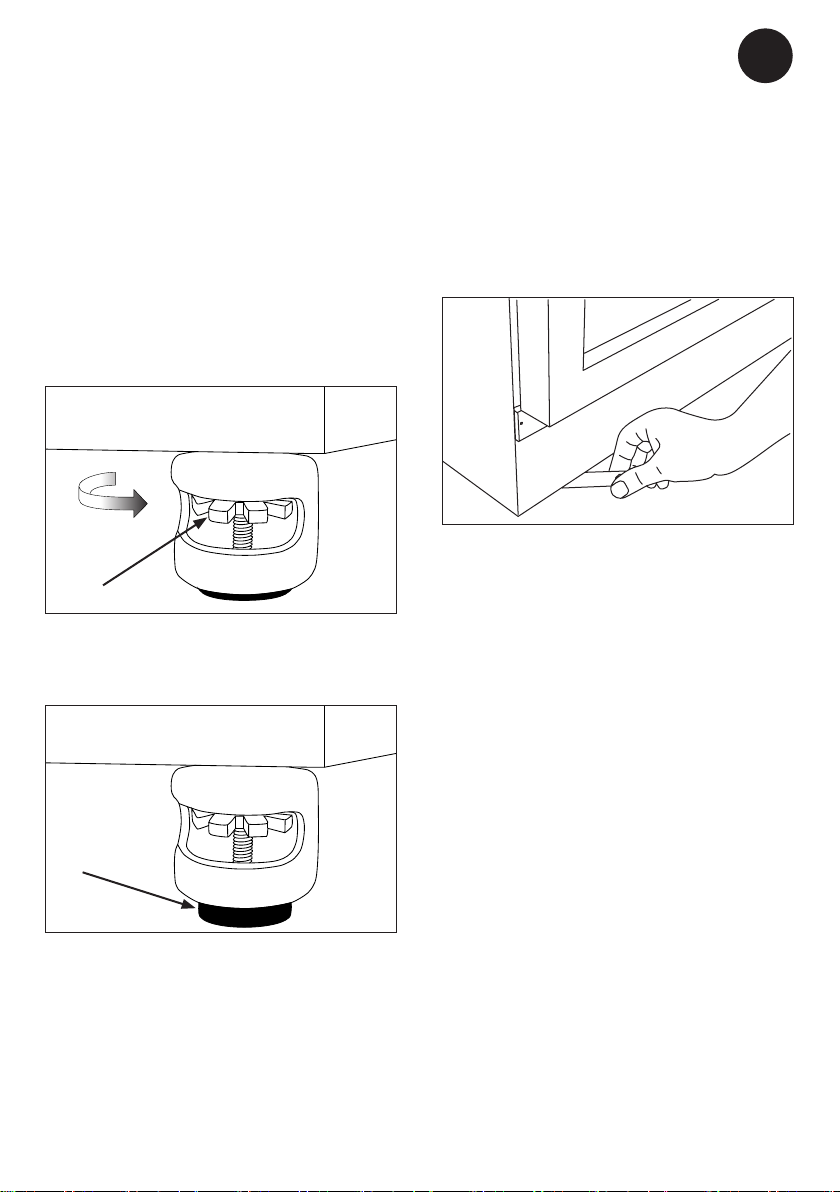

Levelling the appliance

GB

Depending on the equipment of the appliance, the device is either installer with 4

wheels that can be levelled, or with two feet

installed in front of the cabinet.

Wheels

Install unit and rotate nut clockwise to move

foot to oor. See g 8-10

g. 8

Feet

1. Level the appliance sideways by screwing the adjustable feet up or down using

the accompanying spanner. se g 10

g. 10

2. Check that the appliance is absolutely

level.

If the appliance is to be placed on a soft

surface, e.g. oorboards or a carpet, it is

best to recheck whether the appliance is

still level after a period of time as the underlying surface may give under the weight of

the appliance.

g. 9

11

Page 12

GB

PHARMA

DATAREC

SET

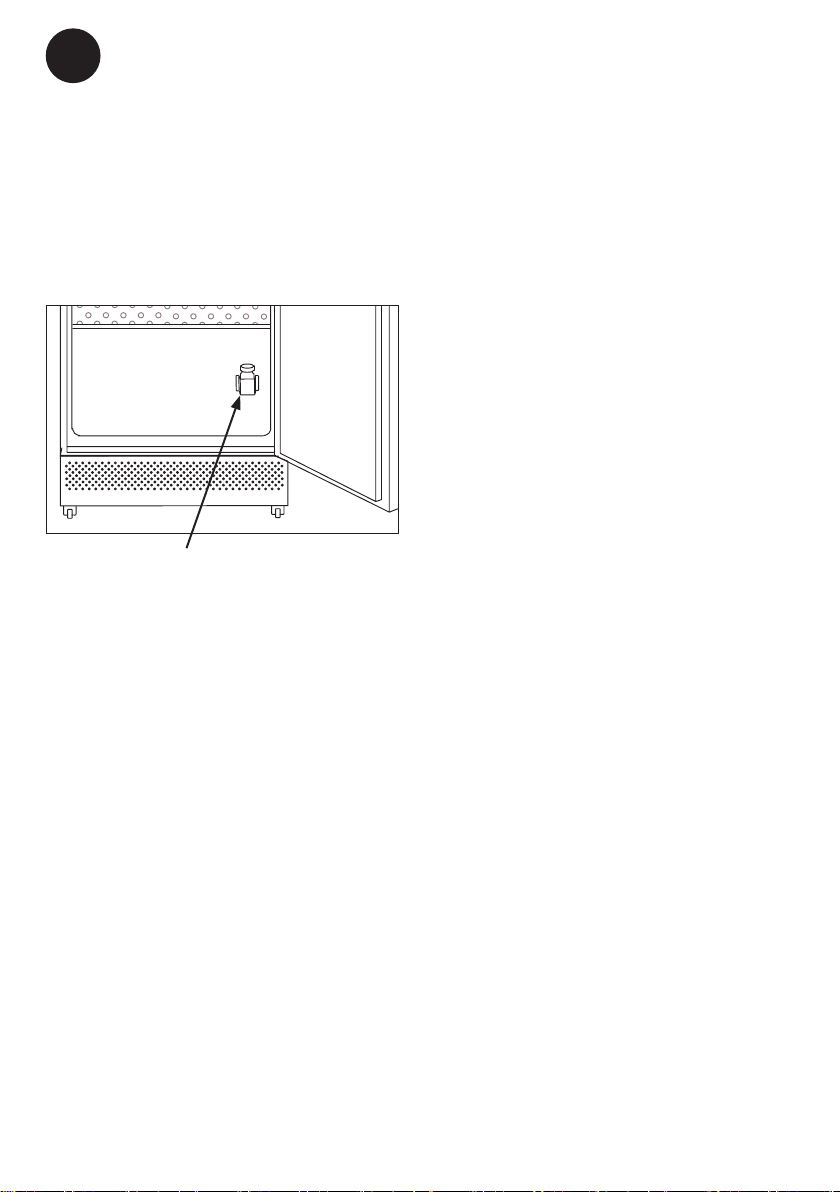

Probe bottle

Some models have a probe bottle installed.

Before starting up the appliance, ll the

probe bottle with a mixture of 50% water

and 50% ethanol.

Probe bottle

g. 11

12

Page 13

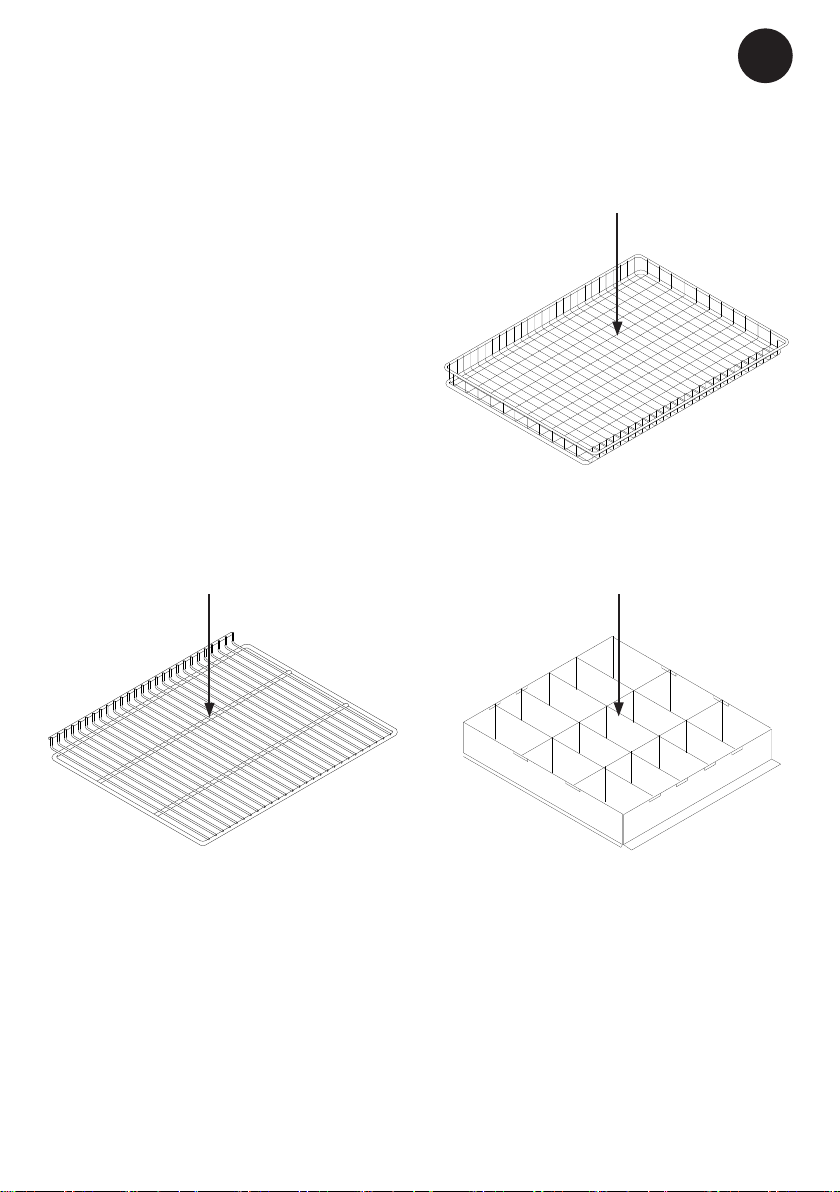

Interior tting

GB

As a standard, the device is equipped with

wire shelfs. The possible equipments is

shown at gure 12-14.

Max. 36 kg

Max. 36 kg

g. 13

Max. 10 kg

g. 12

OBS: Max. 7 drawers in a cabinet.

g. 14

13

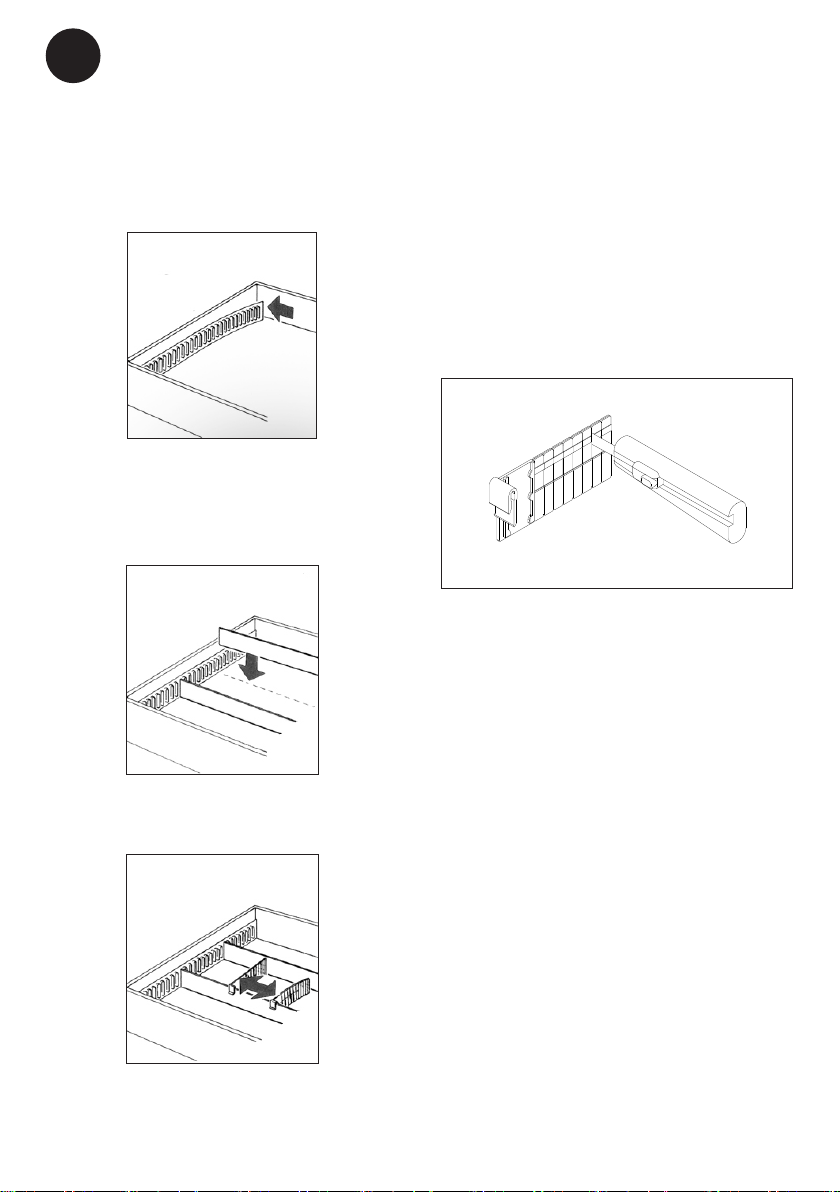

Page 14

GB

Mounting of drawer dividing system

Drawers are optional.

1. The Rail Holder with double adhesive

tape is mounted inside the rear and front

of the drawer.

Adjustment of dividing parts

Integrated breakpoints allows storage of

individual products. Adjust the dividing part

as follows.

(See g 15) Cut into the appropriate seam

and break of the excess part.

g. 15

2. Put in the rails.

3. Snap on the dividers and slide it.

14

Page 15

GB

Ordinary use

Inside the cabinet. Avoid keeping the door

open for long periods unnecessarily.

The appliance is not designed to be used

for cooling warm products. Placing such

items in the cabinet may cause the temperature of products already in the cabinet to

rise. Important: Note that the door opening

frequency will inuence the temperature.

Medicine may not be placed higher than

the red and white stacking mark in the

top of the appliance, because it will

prevent air to circulate and keep the appliance cold. Further more medicine at

the bottom shelf may not touch the sides

of the interior. Both things will prevent

an even temperature in the appliance.

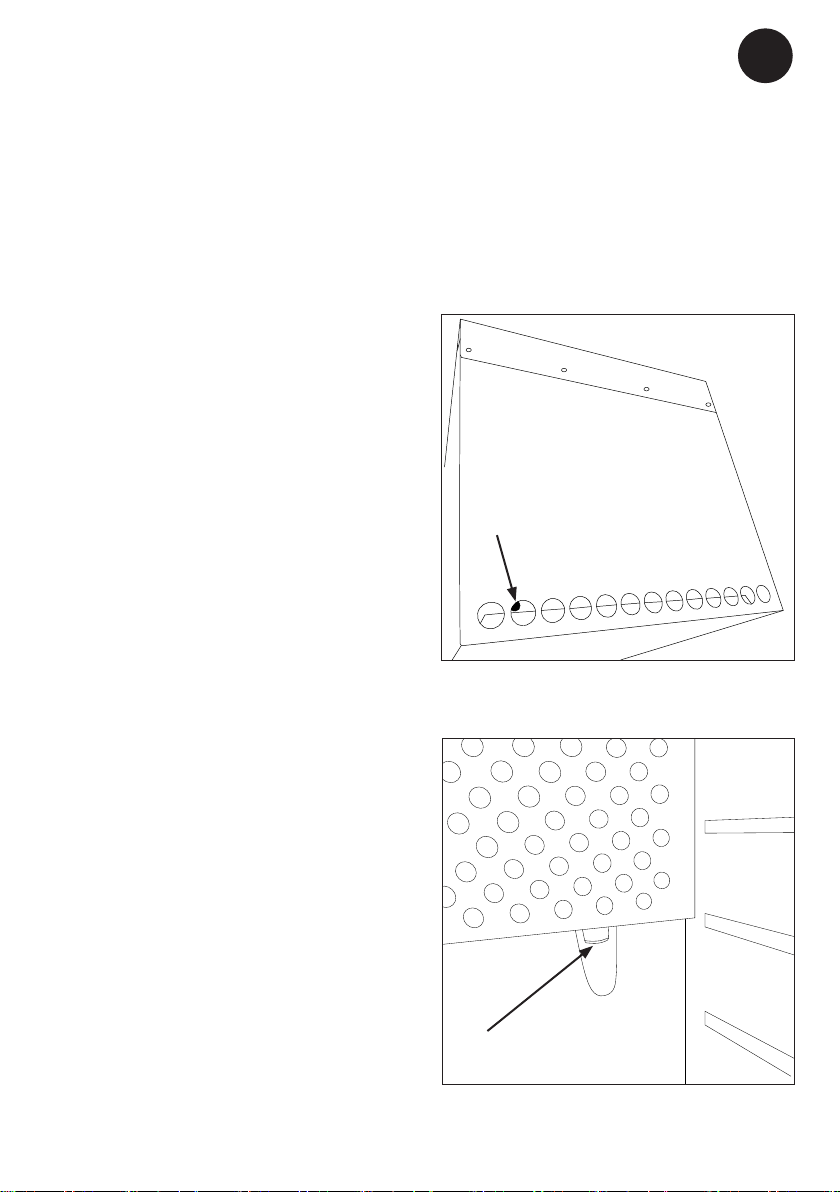

Porthole

The device is equipped with a porthole. Just

put in the probe in the top as illustrated and

it will appear inside the refrigerator below

the cover plate for the evaporator as show

on the next gure.

Porthole

g. 16

15

Porthole

g. 17

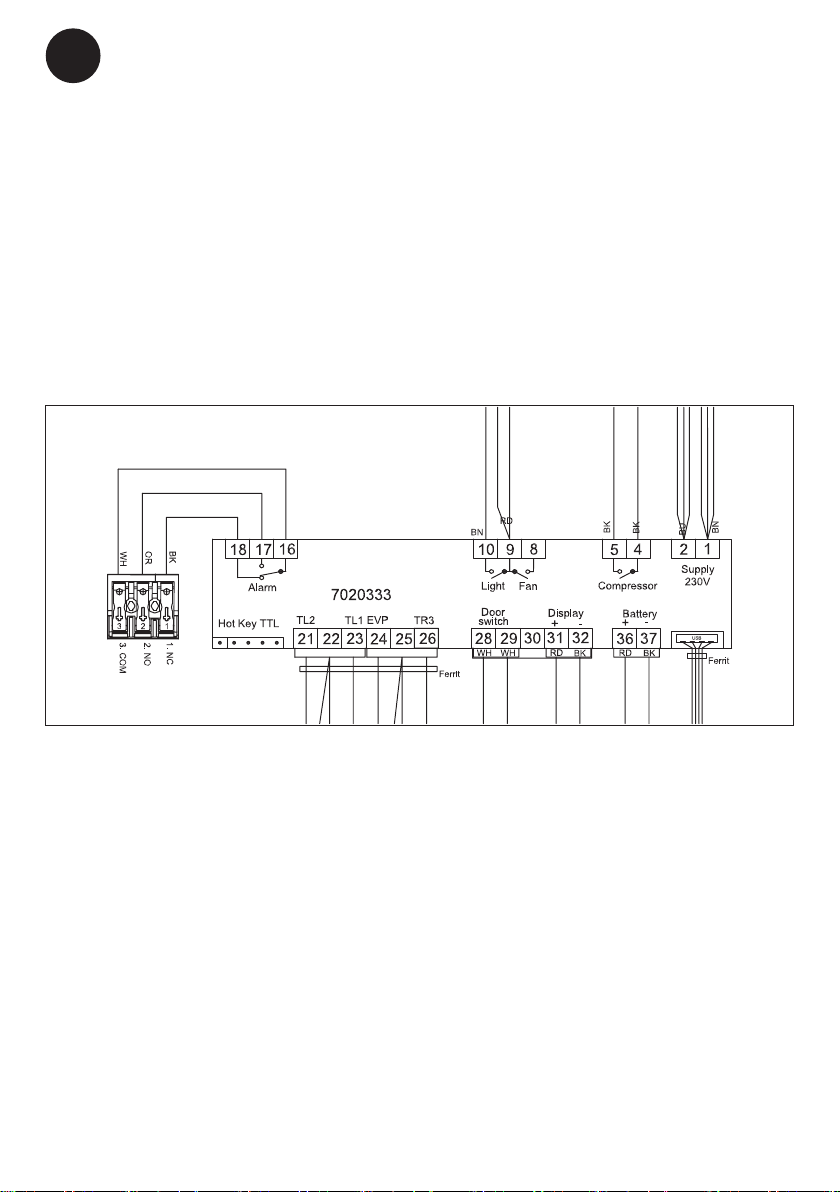

Page 16

GB

Voltage free contact

Your device is equipped with an EXTERNAL ALARM connection. The connection is

executed as DRY Contact.

The 3-pole connection has an NC (pin

1-3) and a NO connection (pin 1-2) and is

used to connect a customer-specic alarm

system.

XW737K

16

g. 18

Page 17

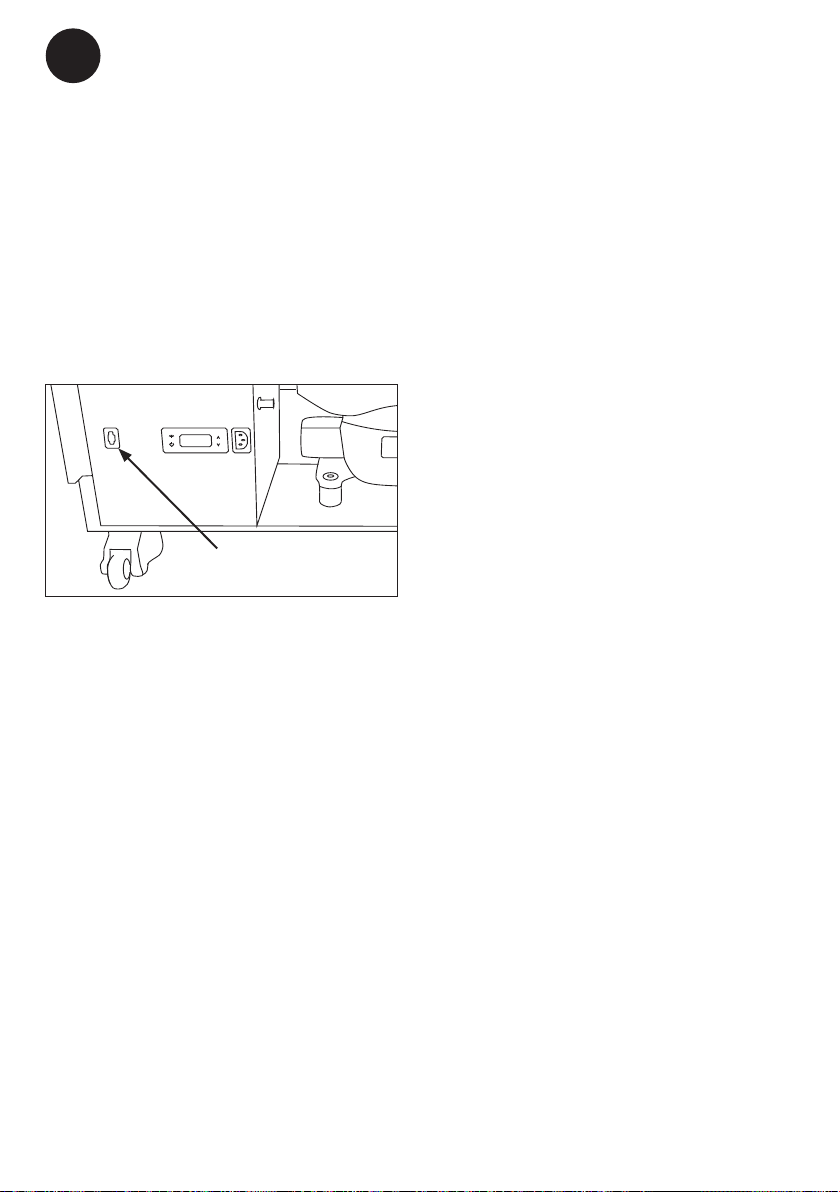

Safety Thermostat

The device contains a safety thermostat

which ensures control of the compressor if

the refrigerator for a reason should become

too cold. It is recommended to test the

safety thermostat at least once a year.

In the engine room, there is a contact

for test of the safety thermostat (see the

picture). When the compressor is running,

push this button. In 10 seconds, the compressor will stop and the green light in the

indicator lamp will be turned o.

Indicator for test of safety thermostat

GB

Contact for test of

safety thermostat

g. 19

17

Page 18

GB

!

DATAREC

SET

PHARMA

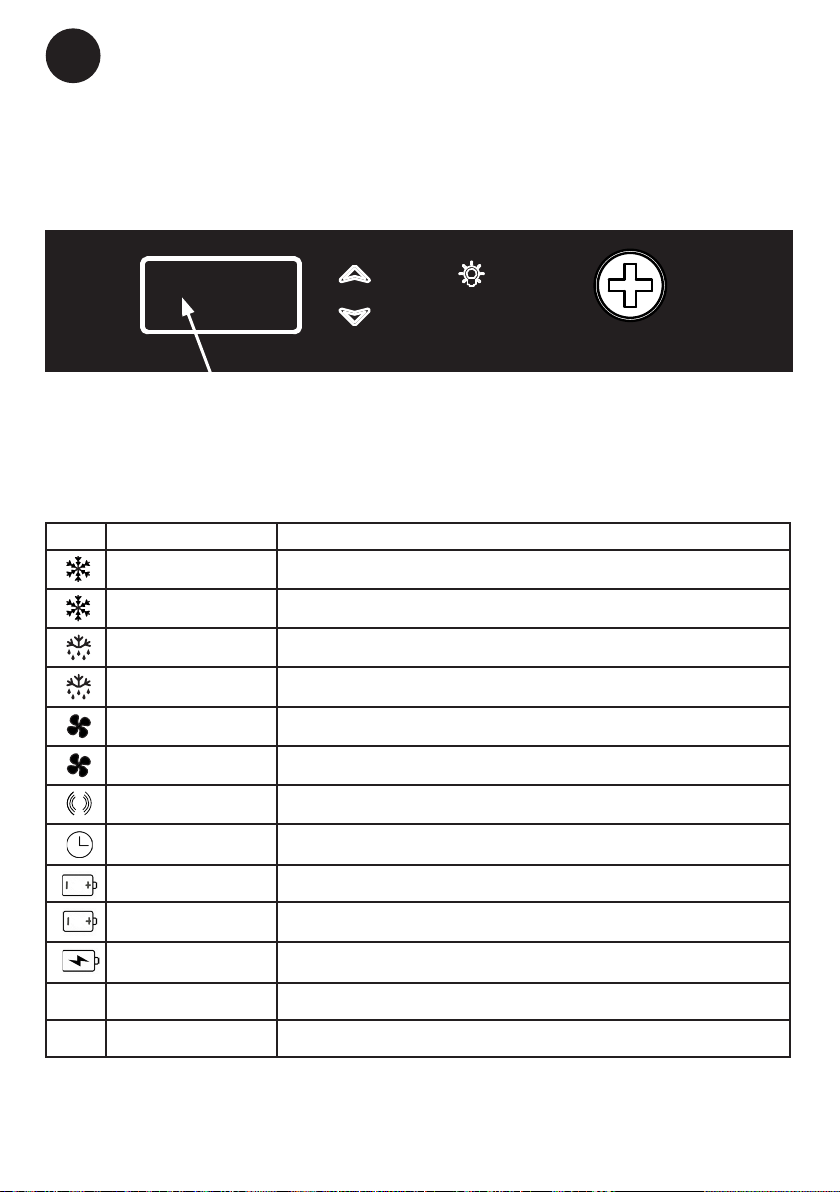

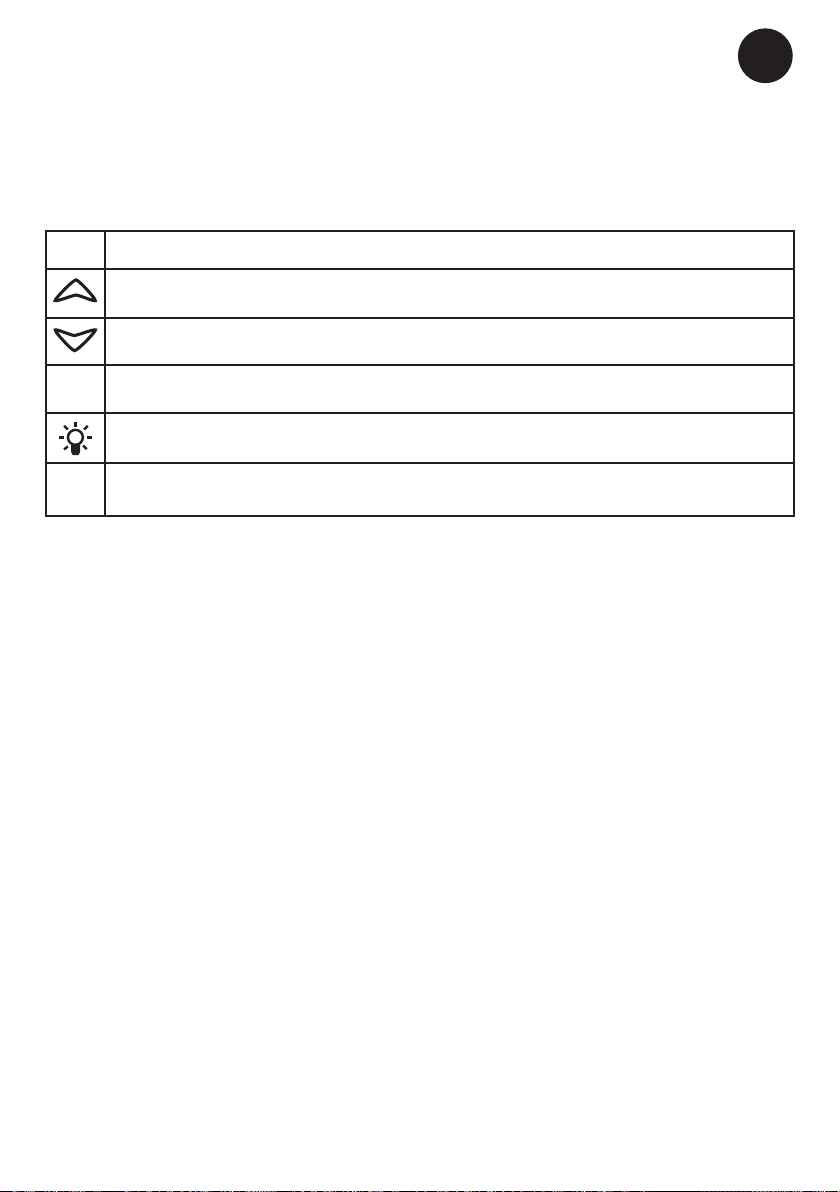

Controller. Operation and function

User interface

Display

LEDS

Each LED function is described in the following table.

LED MODE Function

ON Compressor enabled

Flashing Anti-short cycle delay enabled

ON Defrost enabled

Flashing Drip time in progress

ON Fans enabled

Flashing Fans delay after defrost in progress

ON An alarm is occurring

ON Recording activated

ON Battery is fully charged

Flashing Battery is beeing charged

Flashing Charging problem or battery failure

g. 20

°C/°F ON Measurement unit

°C/°F Flashing Programming phase

18

Page 19

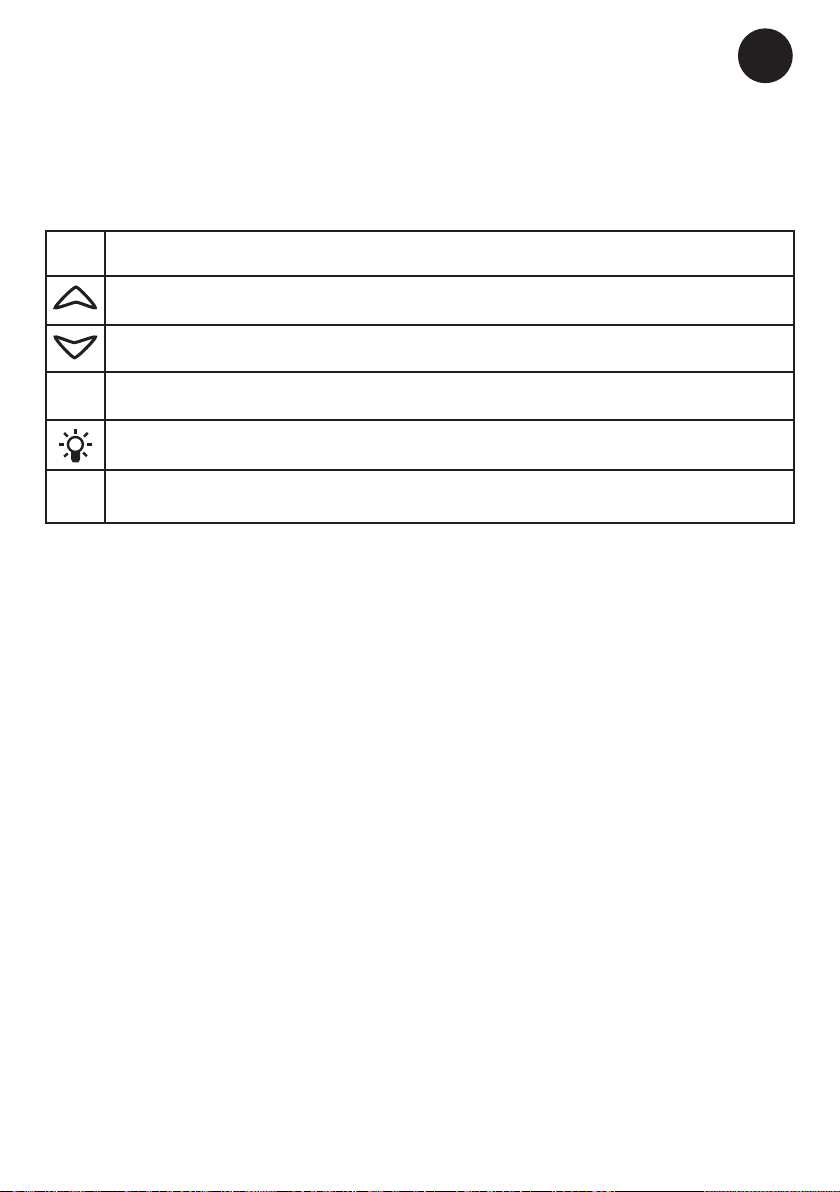

Bottons

To display target set point; in programming mode it selects a parameter or conrm an opera-

SET

tion.

To enter fast access menu In programming mode it browses the parameter codes or increases

the displayed value. (DOWN); n programming mode

In programming mode it browses the parameter codes or decreases the displayed value. Push

it for 3s to start a manual defrost

Export data from button

DATA

To switch o the light in the door (only models with light in the door

Log activation and deactivation from button (Password protected)

REC

GB

How to see and modify the

setpoint

How to: See the Set point

1. Push and immediately release the SET

key: the display will show the Set point

value.

2. Push and immediately release the SET

key or wait for 60 sec to display the temperature in the unit.

How to: Change the Set point

1. Push the SET key more than 2 sec to

change the Set point value.

2. The value of the set point will be displayed and the “°C” LED will start blinking.

3. To change the Set value push the UP or

DOWN arrows within 60 sec.

4. To save the new set point value, push the

SET key again and wait for 3 sec.

NOTE: To exit without making any change

to the set point, push the SET key or

wait 60 sec.

Clock settings and RTC alarm

reset

1. Push the UP key once, to acces the

menu.

2. The display shows H∩, then push SET.

3. The parameters for setting time and date

occurs. To set the parameter push SET,

push the UP or DOWN button to change

the parameter. Conrm by pushing SET.

The time and date parameters:

Hur: hour

∩in: minutes

Udy: weekday

dAy: date

∩on: month

yEA: year

To exit: Press SET + UP keys for about 10

sec. or wait 60 sec.

19

Page 20

GB

How to export data and alarms

to USB

1. Insert the USB key

2. Push the DATA key for more than 3 sec.

3. Controller starts uploading data to USB

4. At the end the following message will be

displayed:

a.“End” if everything is ok

b.“Err” if exporting has not taken place.

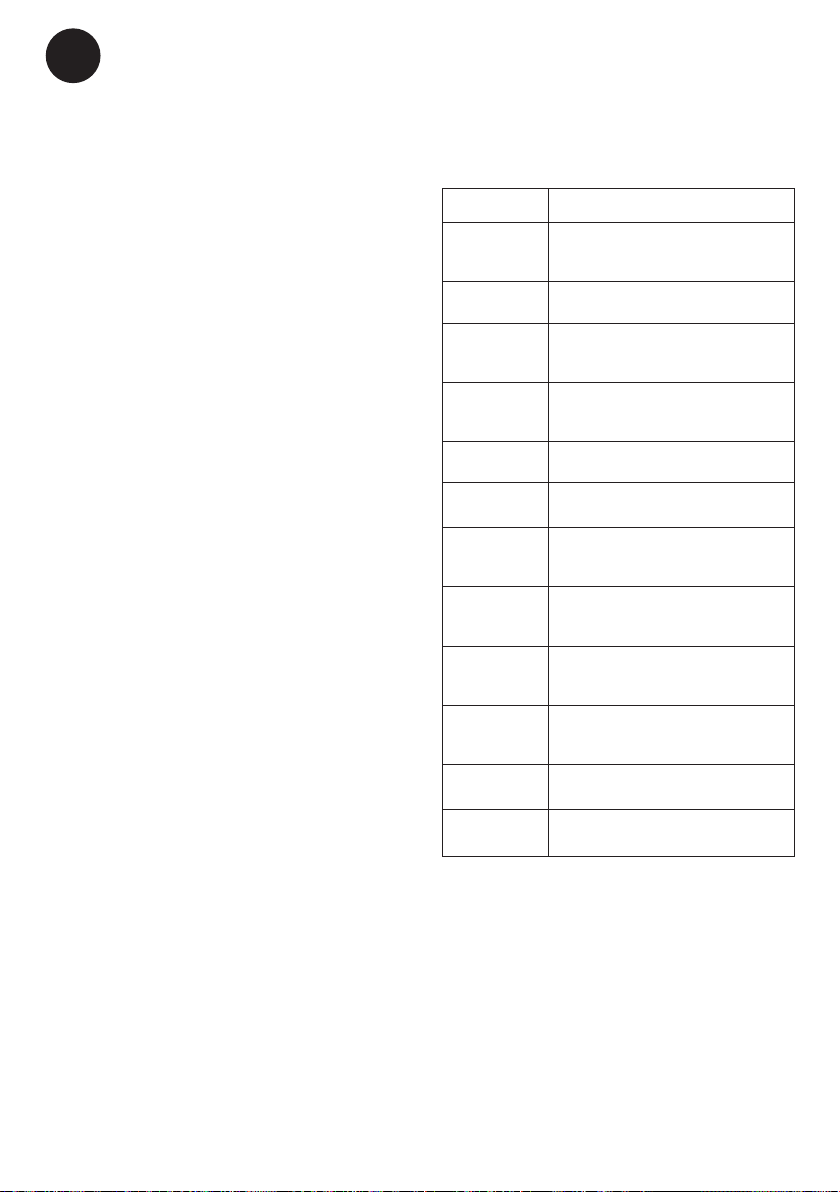

Alarms

The controller memorizes the last 100

alarms happened, together with their start

and nish time. It’s possible to export the

alarms as described in the previous chapter.

Active alarm

Controller will show active alarm alternated

with the temperature inside the unit.

Alarm signals

The alarm message is displayed until the

alarm condition is recovered.

All the alarm messages are showed alternating with the temperature in the unit.

Except for the “PF1” which is ashing.

Alarms at start up

When the unit is started up the rst time

the alarm will sound/show until the unit has

reached the upper temperature alarm limit.

This can take several hours.

It is possible to mute the alarm for 30 min-

utes. See below explanation.

Message Cause

“PF1” Regulating probe TR3

failure

“PF2” EVP Probe Failure

“PF3” Logging probe TL1

failure

“PF4” Logging probe TL2

failure

“HA1” TR3 High Alarm

“LA1” TR3 Low Alarm

”HA3” High temperature

alarm probe TL1

”LA3” Low temperature

alarm probe TL1

”HA4” High temperature

alarm probe TL2

”LA4” Low temperature

alarm probe TL2

“dA” Door Open Alarm

“CA” Serious Alarm

Muting the alarm

When an alarm occurs any button on the

display can be pushed to mute the alarm for

30 minutes. The alarm will still be visible at

the display and the red LED will continue to

ash.

20

Page 21

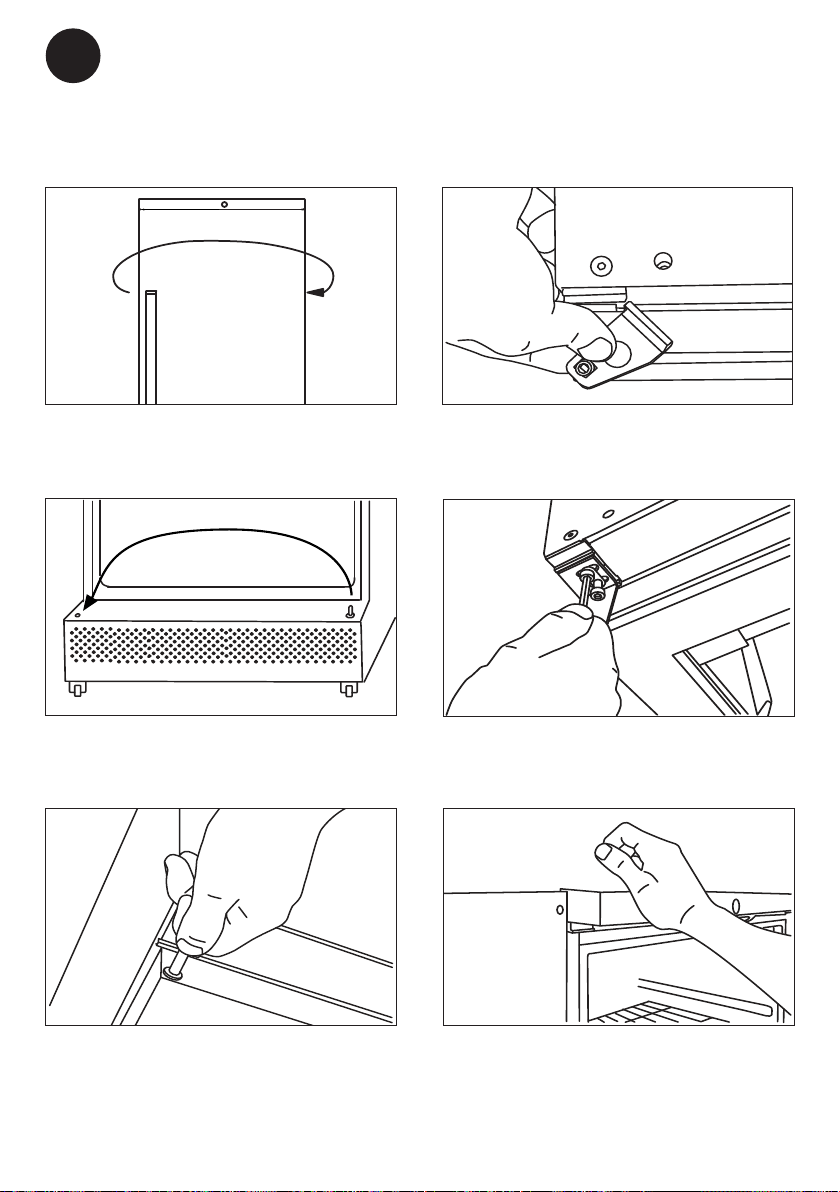

Reversing the door

Remember to unplug the unit.

Note:

the unit may not be placed on its back.

OBS:

Left-side top hinge is required for reversing

the door. Request a spare parts list

GB

3. Remove the 2 screws below the panel.

1. Remove the lock pin using a at-headed

screwdriver.

2. Remove the top panel. Remove the 4

screws at the top op the panel.

4. Tilt the top panel forwards to remove it

Place the panel upside down on top of

the unit).

5. Remove upper hinge (use hex key to the

2 screws) and the torsion spring.

21

Page 22

GB

6. Move the door handle to the opposite

side.

7. Move the hinge pin to the opposite side

of the bottom hinge.

9. Fit the left-side top hinge (required

spare part)

10. Secure the top hinge in position.

9. Insert the hinge pin and the torsion

spring into the the top of the door on the

opposite side.

11. Bring the top panel into place.

22

Page 23

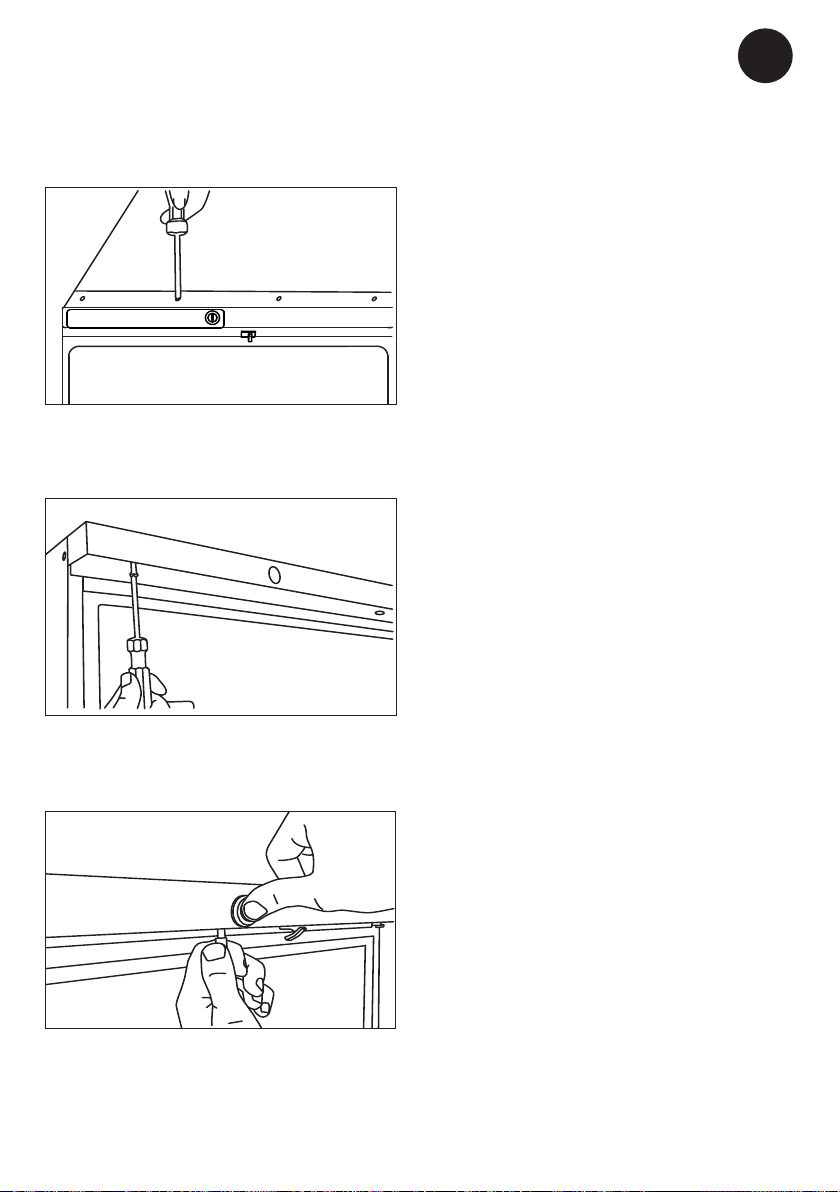

12. Remount the top panel with 4 screws at

the top op the panel...

GB

15. After reversing the door, it is important

to check that the sealing strip provides

a tight seal all the way round. If it does

not, carefully heat the strip all the way

round using a hair dryer. Then ease the

strip outwards slightly so that it forms a

tight seal against the cabinet. Be careful not to heat the strip so much that it

melts!

13. .. and the 2 screws below the panel.

14. Ret the lock housing and lock pin.

23

Page 24

GB

Defrosting, cleaning and maintenance

Automatic defrosting.

The refrigerator is defrosted automatically.

Defrost water runs through a pipe and is

collected in a tray above the compressor

where the heat generated by the compressor causes it to evaporate. Defrost water

can be collected from behind, where there

is a container to collect it. The container

should be emptied regularly.The defrost

water tray should be cleaned when needed

or at least once a year.

Cleaning and maintenance

Before cleaning, disconnect the power sup-

ply and remove all loose ttings.

The appliance is best cleaned using warm

water (max. 65°C) with a little mild, perfume-free detergent. Never use cleaning

agents that scour. Use a soft cloth. Rinse

with clean water and dry thoroughly. It is

important to prevent water from entering the

control panel.

Add a few drops of disinfectant to the

defrost water drain a couple of times a year,

and clean the drain using a pipe cleaner or

similar. Never use sharp or pointed implements.

When disinfecting the appliance always

consult professional persons to ensure that

the disinfectant used is approved in your

country, and to ensure right method is used.

For use in this appliance, we recommend

the following base of disinfectant: alcohols

and aldehydes. Chlorine and peracids can

also be used, but please be aware that

chlorine and peracids based products can

inect on the surface of materials, there for

a careful washing o with clear water and

wiping o, after disinfecting, is very impor-

tant.

The sealing strip around the door must be

cleaned regularly, at least twice a year. to

prevent discolouration and prolong service life. Use clean water. After cleaning

the sealing strip, check that it continues to

provide a tight seal.

It is recommended that the wire and tubular

condensers on the rear of the appliance are

cleaned.

Dust collecting on the condenser on the

rear of the cabinet, the compressor and in

the compressor compartment is best removed using a vacuum cleaner. This must

be done regularly, at least four times a year

OBS: If the appliance is not to be used for

any length of time, switch it o, disconnect

the power supply, empty it, clean the inside

and leave the door open to allow air circulation and prevent smells.

WARNING: Secure not splashing water

when cleaning the oor.

24

Page 25

Fault nding

Fault Possible cause Remedy

Screen of keybord is

not lit.

Power failure; the fuse is blown;

the appliance is not plugged in

correctly, the power is cut.

Check that power is connected.

Reset the fuse

GB

Temperature in refrigerator too high

Temperature in refrigerator too low.

Vibration or bothersome noise

Compressor runs

continuously.

Display or alarm log

shows ”RTC” error

The ventilation grille is blocked.

The door is not closed properly.

The quantity of items placed in

the freezer at a time is greater

than the capacity of the appliance.

The temperature setting is too

high

The temperature setting is too

low

The appliance is not level. Level the appliance (For model

The temperature setting is too

low.

Too high room temperature.

The date and time is not set. Please set the date and time.

Ensure unhindered air circulation

Close the door and wait 15 min.

Wait 15min

Lower the temperature setting.

Raise the temperature setting

with adjustable feet: use a spirit

level)

Raise the temperature setting.

Ensure adequate ventilation

25

Page 26

GB

Warranty, spare parts and service

Warranty disclaimer

Faults and damage caused directly or

indirectly by incorrect operation, misuse,

insucient maintenance, incorrect building,

installation or mains connection. Fire, accident, lightening, voltage variation or other

electrical interference, including defective

fuses or faults in mains installations.

Repairs performed by others than approved

service centres and any other faults and

damage that the manufacturer can substantiate are caused by reasons other than

manufacturing or material faults are not

covered by the warranty.

Please note that changes to the construction of the appliance or changes to the

component equipment of the appliance will

invalidate warranty and product liability, and

the appliance cannot be used lawfully. The

approval stated on rating plate will also be

invalidated.

Transport damage discovered by the buyer

is primarily a matter to be settled between

the buyer and the distributor, i.e. the distributor must ensure that such complaints

are resolved to the buyer’s satisfaction.

Before calling for technical assistance,

please check whether you are able to

rectify the fault yourself. If your request for

assistance is unwarranted, e.g. if the appliance has failed as a result of a blown fuse

or incorrect operation, you will be charged

the costs incurred by your call for technical

assistance.

Spare parts

When ordering spare parts, please state the

type, serial and product numbers of your

appliance. This information is given on the

rating plate. The rating plate contains various technical information, including producttype and serial numbers.

Product number

g. 2

26

Page 27

Disposal

GB

Information for Users on Collection

and Disposal of Old Equipment and

used Batteries

These symbols on the products,

packaging, and/or accompanying

documents mean that used electrical and electronic products and

batteries should not be mixed with

general household waste. For proper

treatment, recovery and recycling

of old products and used batteries,

please take them to applicable collection points, in accordance with your

national legislation and the Directives

2002/96/EC and 2006/66/EC.

By disposing of these products and

batteries correctly, you will help to

save valuable resources and prevent

any potential negative eects on

human health and the environment

which could otherwise arise from

inappropriate waste handling.

For more information about collection and recycling of old products and

batteries, please contact your local

municipality, your waste disposal

service or the point of sale where you

purchased the items.

Penalties may be applicable for incorrect disposal of this waste, in accordance with national legislation.

For business users in the European Union.

If you wish to discard electrical and

electronic equipment, please contact

your dealer or supplier for further

information.

Information on Disposal in other

Countries outside the European

Union

These symbols are only valid in the

European Union. If you wish to discard this product, please contact your

local authorities or dealer and ask for

the correct method of disposal.

Note for the battery symbol:

This symbol might be used in combination with a chemical symbol. In this

case it complies with the requirement

set by the Directive for the chemical

involved.

27

Page 28

DE

Warnung

Da ein brennbares Gas als Kältemittel in diesem Gerät dient, ist

es wichtig sicherzustellen, dass

kein Teil des Kühlkreislaufs oder

der Röhren beschädigt ist.

Die Menge von Kältemittel im

Gerät ist auf dem Typenschild

angegeben.

Der Standard EN378 speziziert,

dass der Raum, in dem das Gerät

installiert wird, ein Volumen von

1m³ pro 8 g Kohlenwasser sto-

Kältemittel, das im Gerät verwendet ist, haben soll. Dies ist zu beachten, um die Bildung von leicht

entzündlichen Gasgemischen in

dem Raum, wo das Gerät installiert ist, zu vermeiden, falls eine

Undichtigkeit des Kuhlkreislaufs

entsteht.

WARNUNG:

Decken Sie die Lüftungsönungen im Kabinett am Gerätes oder

am Einbaumodul nicht ab.

WARNUNG:

Verwenden Sie keine anderen

mechanischen Geräte oder Hilfsmittel um den Entfrostungsprozess zu beschleunigen, als die

Geräte, die vom Hersteller empfohlen sind.

WARNUNG:

Beschädigen Sie nicht den Kühlkreislauf.

WARNUNG:

Verwenden Sie keine elektrischen Geräte im Gerät, es sei

denn, dass die Geräte vom Hersteller empfohlen sind.

WARNUNG:

Das Gerät vor Regen schützen,

und bei der Fußbodenreinigung

Spritzwasser vermeiden.

WARNUNG:

Das Gerät ist nicht für den Gebrauch durch Kinder bestimmt,

es sei denn, dass es ausreichend von einer verantwortlichen

Person überprüft ist, dass sie

das Gerät vertretbar verwenden

können. Kleine Kinder müssen

beaufsichtigt werden, um sicherzustellen, dass sie nicht mit dem

Gerät spielen. Der Schlüssel ist

an einer separaten Stelle und

unzugänglich für Kinder aufzubewahren.

WARNUNG:

Wenn ein nicht kompatibler USB

Stick verwendet wird kann dies

zu einem Reset des Kontrollers

führen.

2

Page 29

WARNUNG:

Keine Produkte mit brennbaren

Treibgasen (z. B. Spraydosen)

und keine explosiven Stoe la-

gern. Explosionsgefahr!

WARNUNG:

Gefahr von Feuer oder Explosi-

on wenn brennbares Kältemittel ist verwendet. Darf nur von

Fachpersonal repariert werden.

WARNUNG:

An Gehäuse, Kompressorteil,

Verdampfer, Lüfterverkleidung

und an Innenteilen können

scharfe Kanten vorhanden sein.

Bitte Vorsicht walten lassen, um

Verletzungen zu vermeiden.

DE

WARNUNG:

Achten Sie beim Aufstellen des

Geräts darauf, dass das Netzkabel nicht eingeklemmt oder beschädigt ist.

WARNUNG:

Platzieren Sie keine Verteilersteckdosen, Verlängerungskabel

oder andere Netzteile an der

Rückseite des Gerätes.

● Vor Reparatur oder Reinigung des Gerätes

den Netzstecker von der Steckdose ziehen.

● Wenn die Anschlussleitung beschädigt ist,

muss sie nur vom Hersteller, dem Serviceagent des Herstellers oder einem anderen

Fachmann ausgewechselt werden, um Gefahr zu vermeiden.

● Bildung von Reif auf der inneren Verdampf-

erplatte und den obersten Teile ist normal.

In Verbindung mit Reinigung oder Wartung

muss das Gerät deshalb entfrostet werden.

● Beachten Sie bitte, dass Änderungen der

Konstruktion dieses Gerätes zur Folge haben,

dass die Garantie und Produktenhaftung

erlöschen.

WARNUNG:

Der Verüssiger hinten am Gerät

hat zeitweise eine heiße Oberä-

che. Bitte Vorsicht walten lassen,

um Verletzungen zu vermeiden.

WARNUNG:

Das Gerät muss mindestens 12

Stunden in Betrieb sein bevor

Sie es für die Lagerung von Medizin nutzen.

● Dieses Gerät soll ausschließ-

lich für medizinische Produkte

verwendet werden

● Ist im Gerät Medizin ausgetreten, muss der

Abtauwasserkanal sofort gereinigt werden,

damit die Medizin nicht in die Umgebung

verdampft.

● Bei Verlust der Bedienungsanleitung, be-

schaen Sie sich von Ihrem Händler bitte

Ersatz.

● Wartungsarbeiten sollten ausschließlich von

Personen ausgeführt werden, die im Umgang

mit medizinischen Geräten geschult sind.

3

Page 30

DE

Inhalt

Warnung .....................................................2

Bezüglich des AKG/S 337/397 ...................5

Lernen Sie Ihren Kühlschrank kennen .......6

Vor Gebrauch bitte beachten ......................7

Technische Daten .......................................7

Installation und Inbetriebnahme .................8

Installation und Inbetriebnahme .................9

Nivellieren des Geräts ..............................11

Sensorasche ..........................................12

Inneneinrichtung .......................................13

Montage des Einteilungssystemes in den 14

Schubladen ...............................................14

Normale Nutzung ......................................15

Messloch ..................................................15

Spannungsfreier Kontakt .........................16

Sicherheitsthermostat ...............................17

Steuerung. Bedienung und Funktion ........18

Umschlagbare Tür ....................................21

Abtauen, Reinigung und Wartung.............24

Fehlersuche ..............................................25

Reklamation, Ersatzteile und Service .......26

Entsorgung ...............................................27

4

Page 31

Bezüglich des AKG/S 337/397

Sehr geehrter Kunde, herzlichen Glück-

wunsch zu Ihrem neuen AKG/S 337/397.

Dieser Medikamentenkühlschrank ist für die

zuverlässige Lagerung von Arzneimitteln

und anderen Produkten konzipiert, die bei

konstanten Temperaturen zwischen 2 bis 8

Grad Celsius aufbewahrt werden müssen.

Die Parameter sind folgende.

Temperaturbereich 2 °C bis 8 °C

DE

Werksseitiger

Sollwert

Umgebungstemperatur

Relative Luftfeuchte 70 %

Anzahl der Sensoren 3 bis 5, abhängig

Standardmäßig ist das Gerät mit 3 Sensoren ausgestattet. Ein Sensor zur Steuerung

des Kompressors, einer zur Regelung der

Abtaufunktion und einer im Oberteil, der

Informationen zur Temperatur an der Beladungsgrenze anzeigt.

Einige Modelle verfügen über eine Sensor-

asche, in welcher ein vierter und fünfter

Sensor für ein Sicherheitsthermostat installiert ist.

Die Klimaklasse ist auf dem Typenschild

angegeben.

4

15 – 30 °C

(35 ° C bei Voll

blechtüren)

(75 % bei Vollble

chtüren)

von Ausstattung

des Geräts

-

-

5

Page 32

DE

Lernen Sie Ihren Kühlschrank kennen

SET

DATAREC

Display/Keyboard

Sperren

LED-Beleuchtung

Lüfter (in Rückwand)

Typenschild

Stacking mark

Verstellbarer Regalboden

PHARMA

Verstellbare Schublade

(auf Wunsch)

Türgri

Probe bottle

Unteres Regal

Rad /

Einstellbare Standfüße

Abb. 1

6

Page 33

DE

Vor Gebrauch bitte

beachten

Vor Inbetriebnahme ihres neuen Gerätes

lesen Sie bitte die Bedienungsanleitung

sorgfältig durch. Sie enthält wichtige Informationen zu Sicherheit, Aufstellung, Betrieb

und Wartung. Bewahren Sie die Anleitung

zum späteren Nachschlagen auf.

Nach Erhalt überprüfen Sie ihr Gerät auf

Transportschäden. Transportschäden sind

dem Händler vor Ort vor Inbetriebnahme zu

melden.

Alle kommerziellen Fragen müssen vor der

Inbetriebnahme geklärt werden.

Entfernen sie die Verpackung. Die Folie

auf den Einlegeböden muss vor Inbetriebnahme bzw. Reinigung entfernt werden.

Reinigen Sie das Innere des Gerätes mit

warmen Wasser und einem milden Reinigungsmittel. Mit klarem Wasser nachspülen

und sorgfältig trocknen (siehe Pegehinweise). Verwenden Sie ein weiches Tuch.

Wurde das Gerät liegend transportiert oder

in kalter Umgebung gelagert (kälter als

+5 ° C ) muss das Gerät in aufrechter

Position für mindestens 1 Stunde stabilisiert

werden bevor es eingeschaltet wird.

Hinweis: Wenn Sie das Gerät hinlegen

muss die Tür nach oben zeigen und das

Gerät muss in der Originalverpackung

verbleiben.

Technische Daten

Verkabelung und Anschlüsse in Stromversorgungssystemen müssen allen (örtlichen

und nationalen) Elektrovorschriften entsprechen. Machen Sie sich vor dem Einbau mit

den Angaben in diesen Vorschriften vertraut

Dieses Gerät entspricht den einschlägigen

EU-Richtlinien einschließlich:

Niederspannungsrichtinie 2014/35/EU

Elektromagnetische Kompatibilitätsrichtlinie

2014/30/EU

Die Steckdose muss mit einer 10-A oder

13-A Sicherung abgesichert sein.

Bei Geräten, die in nicht-europäischen Ländern betrieben werden, ist auf dem Typenschild zu überprüfen, ob die angegebene

Spannung und Stromart mit den Werten

Ihres Stromnetzes übereinstimmt.

Daten zur Spannung und Leistungsaufnahme / Strom sind auf dem Typenschild.

Ein eventuell notwendiger Austausch der

Netzanschlussleitung darf nur durch einen

Fachmann erfolgen.

Das Typenschild, das sich im Gerät be-

ndet, enthält verschiedene technische

Angaben sowie Typen- und Seriennummer.

Product number

Abb. 2

7

Page 34

DE

Installation und Inbetriebnahme

Batterie-Backup

Dieses Gerät ist mit einem Batterie-BackupSystem ausgerüstet. Bitte aktivieren Sie

das Batterie-Backup vor der endgültigen

Positionierung. Eine Sicherung bendet

sich im Beutel mit den Zusatzmaterialien.

Nehmen Sie diese Sicherung und setzen

Sie sie wie in der Abbildung dargestellt ein.

Sicherung

Abb. 3

BITTE BEACHTEN! !

Das Batterie-Backup-System ver-

sorgt die Kälteanlage NICHT mit

Energie. Beim ersten Einschalten

des Geräts ist es erforderlich, das

Batterie-Backup-System einzuschalten.

Batterie-Backupfunktion

Das Batterie-Backup-System versorgt bei

Stromausfall Steuerung und Tastatur mit

Energie. So kann die Temperatur im Gerät

während eines Stromausfalls verfolgt werden. Das Batterie-Backup-System ermöglicht die Beobachtung der Temperatur für 48

Stunden.

Nach einem Stromausfall und nach dem

ersten Einschalten muss die Batterie

geladen werden. Um die volle Kapazität zu

erreichen, lädt die Batterie 10 Tage lang.

BITTE BEACHTEN!

Die Batterie des Backupsystems

sollte alle drei Jahre erneuert werden, um 48 Stunden Backup zu

gewährleisten. Bitte nehmen Sie

diesen Batteriewechsel für jedes

dritte Jahr in Ihren Wartungsplan

auf.

8

Page 35

Installation und Inbetriebnahme

DE

Gerät von oben gesehen

Bei Aufstellung neben einer Wand muss

genug Zwischenraum bleiben, damit die Tür

ausreichend weit geönet werden kann, um

die Einlegeböden heraus zu nehmen (Abb.

4).

Abb. 4

Nebeneinander

Nebeneinander aufgestellt müssen mindestens 60 mm zwischen den Geräten an

beiden Seiten des Gehäuses frei bleiben,

damit die Türen unbehindert geönet werden können (Siehe Abb. 5)

Aufstellung

Das Gerät MUSS waagerecht stehen Durch

drehen an den einstellbaren Standfüßen

kann das Gerät ausgerichtet werden-

Mit einer Wasserwaage prüfen, dass das

Gerät seitlich in Waage ist-

Beim Aufstellen auf einem nachgiebigen

Unterboden (Dielen, Teppich) ist nach einer

gewissen Zeit erneut zu prüfen, ob das Gerät in Waage steht, da sich der Untergrund

durch das Gerätegewicht gesetzt haben

könnte

Abb. 5

9

Page 36

DE

Belüftung

Das Gerät muss gut belüftet sein und die

Luft muss frei über, unter und um das Gerät

strömen können.

Die Abb. (4-6) zeigen, wie die erforderliche

Luftzirkulation um das Gerät sichergestellt

wird.

Belüftungsgitter

Das Gitter auf der Geräterückseite sorgt

für ausreichende Luftzirkulation. Die Gitter

müssen beim Aufstellen des Schranks heruntergeklappt werden.

Gitter heruntergeklappt

Abb. 7

Abb. 6

10

Page 37

Nivellieren des Geräts

DE

Je nach Geräteausstattung sind an diesem

entweder 4 Rollen montiert, die nivelliert

werden können, oder zwei Füße auf der

Vorderseite des Schranks.

Rollen

Stellen Sie das Gerät auf und drehen Sie

die Mutter im Uhrzeigersinn, um den Fuß

zum Boden zu schrauben. Siehe Abb. 8-10

Abb. 8

Füße

1.1. Nivellieren Sie das Gerät seitlich, in-

dem Sie die einstellbaren Standfüße mit

dem beiliegenden Schlüssel nach oben

oder unten schrauben, siehe Abb. 10.

Abb.10

2. Überprüfen Sie, dass das Gerät absolut

waagerecht ist.

Beim Aufstellen auf einem nachgiebigen

Boden, z. B. Dielen oder Teppich, muss die

Nivellierung des Geräts nach einer gewis-

sen Zeit erneut geprüft werden, da sich

der Untergrund durch das Gerätegewicht

gesetzt haben könnte.

Abb. 9

11

Page 38

DE

PHARMA

DATAREC

SET

Sensorasche

In einigen Modellen ist eine Sensorasche

installiert. Bevor Sie das Gerät in Betrieb

nehmen, befüllen Sie die Sensorasche mit

einem Gemisch aus 50 % Wasser und 50 %

Ethanol.

Sensorasche

Abb. 11

12

Page 39

Inneneinrichtung

DE

Standardmäßig ist das Gerät mit Drahtfachböden ausgestattet. Die möglichen Kongurationen sind in Abbildung 12-14 dargestellt.

Max. 36 kg

Max. 36 kg

Abb. 13

Max. 10 kg

Abb.12

13

OBS: Max. 7 Schubladen in einem

Schrank.

Abb.14

Page 40

DE

Montage des Einteilungssystemes in den

Schubladen

Schubladen sind Sonderzubehör.

1. The Rail Holder with double adhesive

tape is mounted inside the rear and front

of the drawer.

Anpassung der Teiler

Integrierte Bruchstellen erlauben das Ein-

stellen auf unterschiedliche Produktgröβen.

Kürzen Sie den Teiler wie folgt.

(Siehe Abb.15) Schneiden Sie entlang der

Rille und brechen Sie das überschüssige.

Abb. 15

2. Put in the rails.

3. Snap on the dividers and slide it.

14

Page 41

DE

Normale Nutzung

Im Schrank. Lassen Sie die Tür nicht unnö-

tig oen stehen.

Das Gerät ist nicht zum Abkühlen warmer

Produkte geeignet. Das Einlegen warmer

Produkte in das Gerät kann die Temperatur

bereits darin bendlicher Produkte ansteigen lassen. WICHTIG: Bitte beachten Sie,

dass die Häugkeit des Türönens die

Temperatur beeinusst.

Medikamente dürfen nicht höher als bis

zu den roten und weißen Stapelmarken

oben im Gerät positioniert werden, da

anderenfalls die Luftzirkulation blockiert

wird und das Gerät nicht kühlt. Auch

dürfen die Medikamente auf der unteren

Ablage keine Gerätewände berühren.

Beides würde eine gleichmäßige Temperatur im Gerät verhindern.

Messloch

Das Gerät ist mit einem Messloch ausgestattet. Stecken Sie den Sensor wie abgebildet hinein, sodass dieser im Kühlschrank

unterhalb der Abdeckplatte des Verdampfers erscheint. Siehe Abbildung unten.

Messloch

Abb. 16

15

Messloch

Abb.17

Page 42

DE

Spannungsfreier Kontakt

Ihr Gerät ist mit einem Anschluss für einen

EXTERNEN ALARM ausgestattet. Dieser

Anschluss ist als Schwachstromkontakt

ausgeführt.

Der 3-polige Anschluss hat einen NC- (Pin

1-3) und NO-Anschluss (Pin 1-2) und wird

zum Anschließen eines kundenspezischen

Alarmsystems verwendet.

XW737K

16

Abb. 18

Page 43

Sicherheitsthermostat

Das Gerät umfasst ein Sicherheitsthermostat, das die Kontrolle des Kompressors

sicherstellt, falls der Kühlschrank aus irgendeinem Grund zu kalt werden sollte. Es

wird empfohlen, das Sicherheitsthermostat

mindestens einmal jährlich zu prüfen.

Im Motorfach gibt es einen Kontakt zum

Prüfen des Sicherheitsthermostats (siehe

Abbildung). Wenn der Kompressor läuft,

drücken Sie diese Taste. Der Kompressor

wird innerhalb von 10 Sekunden gestoppt

und die grüne LED in der Kontrollleuchte

erlischt.

Anzeige zum Prüfen des

Sicherheits-thermostats

DE

Kontakt zum Prüfen des

Sicherheitsthermostats

Abb. 19

17

Page 44

DE

!

DATAREC

SET

PHARMA

Steuerung. Bedienung und Funktion

User interface

Display

LED

Alle LED-Funktionen sind in der folgenden Tabelle beschrieben.

LED

ZUSTAND Funktion

EIN Kompressor eingeschaltet

Blinkt Anti-Kurzschluss-Verzögerung eingeschaltet

EIN Abtauen eingeschaltet

Blinkt Abtropfzeit läuft

EIN Lüfter eingeschaltet

Blinkt Lüfterverzögerung nach Abtauen läuft

EIN Alarm läuft ein

EIN Aufzeichnung aktiv

EIN Batterie voll geladen

Blinkt Batterie wird geladen

Blinkt Ladestörung oder Batteriefehler

Abb. 20

°C/°F

°C/°F

EIN Messeinheit

Blinkt Programmierphase

18

Page 45

Tasten

SET

DATA

REC

DE

Zur Anzeige des Zielsollwerts; im Programmierzustand wird ein Parameter gewählt oder eine

Aktion bestätigt.

Zum Schnellzugrismenü Im Programmierzustand werden Parameterkodes durchblättert oder

der angezeigte Wert erhöht- (ABWÄRTS); im Programmierzustand

Im Programmierzustand werden Parameterkodes durchblättert oder der angezeigte Wert

gesenkt. Zum Start eines manuellen Abtauvorgangs 3 Sek. drücken

Datenexport

Schaltet die Türbeleuchtung aus (nur Modelle mit Türbeleuchtung)

Log ein- und ausschalten (passwort geschützt)

Anzeige und Änderung des

Sollwerts

Wie: Sollwert anzeigen

1. SET-Taste drücken und sofort wieder

loslassen: das Display zeigt den Sollwert

an.

2. SET-Taste drücken und sofort wieder

loslassen oder 60 Sek. Warten, um die

Innentemperatur anzuzeigen.

Wie: Sollwert ändern

1. Die SET-Taste länger als 2 Sek. Drücken,

um den Sollwert zu ändern.

2. Der Sollwert wird zusammen mit “°C”

angezeigt. LED beginnt zu blinken.

3. Zum Ändern des Sollwerts die Pfeile

UP oder DOWN innerhalb von 60 Sek.

drücken

4. SET-Taste für 3 Sek. Drücken, um den

neuen Wert zu speichern

ANMERKUNG: Zum Verlassen der Funk-

tion ohne Änderung, die

SET-Taste drücken oder

60 Sek. warten

Uhrzeiteinstellung und RTCAlarm rücksetzen RESET

1. Die taste UP drücken, um ins Menü zu

gelangen.

2. Wenn H∩ in der Anzeige erscheint, SET

drücken.

3. Die Parameter für Uhrzeit- und Datums-

einstellung erscheinen. Zum Einstellen

SET drücken, dann den Parameter mit

UP oder DOWN ändern- Mit SET bestätigen.

Zeit- und Datumsparameter:

Hur: Stunde

∩in: Minuten

Udy: Wochentag

dAy: Datum

∩on: Monat

yEA: Jahr

Zum Verlassen: Tasten SET + UP für ca.

10 Sek. Drücken oder 60 Sek. warten

19

Page 46

DE

Daten- und Alarmexport via

USB

1. Den USB stick einstecken

2. Die taste DATA länger als 3 Sek. drücken

3. Die Steuerung beginnt das Hochladen

der Daten zum USB

4. Zum Abschluss erscheint eine der folgenden Anzeigen:

a.“End” wenn alles in Ordnung ist

b.“Err” wenn der Export nicht stattfand.

Alarme

The controller memorizes the last 100

alarms happened, together with their start

and nish time. It’s possible to export the

alarms as described in the previous chapter.

Active alarm

Die Steuerung speichert die letzten 100

Alarme mit ihren Start- und Endzeitpunkten.

Die Alarme können exportiert werden, wie

im vorherigen Abschnitt beschrieben.

Alarmmeldung

Die Alarmmeldung wird angezeigt, bis der

Alarmzustand behoben ist.

Alle Alarmmeldungen werden abwechselnd

mit der Geräteinnentemperatur angezeigt-

Mit Ausnahme der blinkenden “PF1”.

Alarme bei Inbetriebnahme

Bei der ersten Inbetriebnahme des Geräts

wird bis zum Erreichen der oberen Tempe-

raturalarmgrenze des Schranks akustischer/

visueller Alarm gegeben. Dies kann mehrere

Stunden dauern.

Der Alarm lässt sich für 30 Minuten stummschalten. Siehe nachfolgende Erläuterung.

Stummschalten des Alarms

Wird Alarm ausgelöst, lässt sich durch Betätigen einer beliebigen Taste des Displays

der Alarm für 30 Minuten stummschalten.

Am Display ist der Alarm weiterhin sichtbar

und die rote Leuchte blinkt fortgesetzt.

Message Cause

“PF1” Fehler Fühler TR3

“PF2” EVP Fühlerfehler

“PF3” Fehler Fühler TL1

“PF4” Fehler Fühler TL2

“HA1” Temperatur zu hoch

Fühler TR3

“LA1” Temperatur zu niedrig

Fühler TR3

”HA3” Temperatur zu hoch

Fühler TL1

”LA3” Temperatur zu niedrig

Fühler TL1

”HA4” Temperatur zu hoch

Fühler TL2

”LA4” Temperatur zu niedrig

Fühler TL2

“dA” Tür oen Alarm

“CA” Schwerer Alarm

20

Page 47

Umschlagbare Tür

Denken Sie daran, das Gerät von der

Steckdose zu trennen.

Note:

Das Gerät darf nicht auf seiner Rückseite

abgelegt werden.

OBS:

Das linke obere Scharnier ist ein Ersatzteil

und muss bestellt werden.

DE

3. Die beiden Schrauben aus der oberen

Bedientafel entfernen.

1. Entfernen Sie die Sperre mit einem

Schraubenzieher.

2. Vier Schrauben aus der oberen Bedien-

tafel entfernen.

4. Neigen Sie die Oberseite nach vorne, um

die Gehäuseleiste zu entfernen.

5. Entfernen Sie das untere Scharnier mit

einem Sechskantschlüssel.

21

Page 48

DE

6. Montieren Sie dan Türgri auf der gegenüberliegenden Seite.

7. Die Achse in das andere Loch stecken.

9. Befestigen Sie das linksseitige obere

Scharnier (erhältlich als extra).

10. Das obere Scharnier wieder festschrauben.

9. Stecken Sie den Scharnierstift und die

Torsionsfeder auf der gegenüberliegenden Seite in die obere Seite der Tür.

11. Klicken Sie die obere Gehäuseleiste

wieder ein.

22

Page 49

12. Die vier Schrauben wieder in die obere

Bedientafel eindrehen.

DE

15. Nach dem Umbau der Tür ist es wichtig

zu überprüfen, ob das Dichtband sicher

ringsherum abschliesst. Ist dies nicht

der Fall, bitte das Dichtband mit einem

Haartrocker erwärmen. Dann das

Dichtband leicht nach ziehen, so dass

es wieder einen sicheren Abschluss

zum Gehäuse ergibt. Achten Sie darauf,

nicht zu stark zu erwärmen, sodass der

Dichtruing schmilzt.

13. Die beiden Schrauben für die obere

Gehäuseleiste wieder festziehen.

14. Schlüsselstift und Schloss wieder

einbauen.

23

Page 50

DE

Abtauen, Reinigung und Wartung

Automatisches Abtauen

Der Kühlschrank wird automatisch abgetaut, das Tauwasser läuft durch ein

Rohr in die Tauwasserschale, die sich auf

dem Kompressor bendet. Das Wasser

verdampft durch die Betriebswärme des

Kompressors. Die Tauwasserschale ist

gelegentlich zu reinigen, mindestens einmal

im Jahr.

Reinigung und Pege

Vor der Reinigung Netzstecker ziehen und

alle losen Beschläge entfernen.

Das Gerät lässt sich am besten mit war-

men Wasser (max. 65°C) und ein bisschen

mildem parfümfreien Reinigungsmittel

säubern.Verwenden Sie keine scheuernden Reinigungsmittel. Verwenden Sie ein

weiches Tuch. Mit klarem Wasser nachspülen und sorgfältig trocknen.

Mehrmals im Jahr einige Tropfen Desinfektionsmittel in den Tauwasserablauf träufeln

und den Ablauf mit einem Rohrreiniger o.

ä. reinigen. Niemals scharfe oder spitze

Werkzeuge verwenden!

Bei der Desinfektion des Geräts stets

Fachpersonal zu Rate ziehen, damit ein in

Ihrem Land zugelassenes Mittel in korrekter

Weise eingesetzt wird.

Zur Desinfektion des Geräts empfehlen

wir folgende Ausgangsstoe: Alkohole und

Aldehyde. Chlor und Persäuren dürfen

ebenfalls verwendet werden, können aber

die Oberächen angreifen, sodass gründliches Nachspülen mit Leitungswasser und

nachfolgendes Trockenwischen sehr wichtig

sind.

Die Türdichtung ist regelmäßig zu reinigen,

mindestens zweimal jährlich, um Verfärbungen zu vermeiden und die Nutzungsdauer

zu verlängern.

Dies hat regelmäßig zu geschehen, mindestens viermal jährlich.

Die Dichtungsstreifen rund um die Tür

müssen regelmäßig gereinigt werden,

um Verfärbungen zu verhindern und die

Lebensdauer zu verlängern. Mindestens

zweimal im Jahr .

Verwenden Sie sauberes Wasser. Nach

dem Reinigen prüfen ob die Dichtleiste

korrekt sitzt und weiterhin eine gute Abdichtung gewähr-leistet ist.

Es wird empfohlen den Kondensator auf der

Rückseite des Gerätes zu gereinigen.

Das Lüftungsgitter, der Kondensator, der

Kompressor und das Kompressorfach muss

auch frei von Staub und Schmutz sein.

Reinigen Sie es mit einem Staubsauger

regelmäßig. Mindestens viermal jährlich.

Bitte beachten: Wenn das Gerät für länge-

re Zeit nicht eingesetzt wird, schalten Sie es

aus. Ziehen Sie den Netzstecker. Entleeren

und reinigen Sie den Innenraum und lassen

die Tür oen.

VORSICHT: Bei der Fußbodenreinigung

kein Wasser verspritzen.

24

Page 51

Fehlersuche

Fehler Mögliche Ursache Abhilfe

Anzeige leuchtet

nicht hell

Stromausfall, Sicherung defekt,

Gerät nicht richtig eingesteckt

Stromzufuhr prüfen

Sicherung einschalten

DE

Temperature im

Einheit zu hoch

Temperature im

Einheit zu niedrig

Vibration oder

störende Geräusche

Kompressor läuft

immer

Das Lüftungsgitter ist blockiert

Die Tür ist nicht richtig

geschlossen

Die Menge der eingelagerten

Waren ist größer als die Kapazität des Gerätes

Dicke Schicht von Frost und Eis

Temperatureinstellung zu hoch

Temperatureinstellung zu niedrig Erhöhen Sie die Temperaturein-

Das Gerät steht nicht eben Gerät ausrichten. (Bei Modellen

Die Temperatureinstellung ist zu

niedrig

Zu hohe Raumtemperatur

Stellen Sie ungehinderte Luftzirkulation sicher

Tür schließen und Warten Sie

15 min

Warten Sie 15 min.

Gerät abtauen

Niedrigere Temperatur einstellen

stellung

mit einstellbaren Füßen Füße

einstellen: benutzen Sie eine

Wasserwaage)

Erhöhen Sie die Temperatureinstellung

Sorgen Sie für ausreichende

Belüftung

Display oder Alarmlog zeigt: ”RTC”.

Das Datum und die Zeit sind

nicht gesetzt

25

Bitte stellen Sie das Datum und

die Zeit

Page 52

DE

Reklamation, Ersatzteile und Service

Der Lieferant haftet nicht für Fehler oder

Schäden, die direkt oder indirekt durch

Fehlbedienung, Missbrauch, mangelhafte

Wartung, fehlerhaften Einbau, fehlerhafte

Aufstellung oder fehlerhaften Anschluss

sowie Feuer, Unfall, Blitzschlag, Spannungsänderungen oder andere elektrische

Störungen – wie z.B. defekte Sicherungen

oder Fehler in der Netzinstallation – sowie

von anderen als den von dem Lieferanten

vorgeschriebenen

Reparaturbetrieben ausgeführten Reparaturen verursacht wurden, und allgemein nicht

für Fehler und Schäden, die der Lieferant

nachweislich auf andere Ursachen als

Fabrikations- und Materialfehler zurückführen kann. Diese Fehler oder Schäden fallen

nicht unter das Reklamationsrecht.

Transportschäden, die der Anwender feststellt, sind primär eine Sache zwischen ihm

und dem Händler, d.h. der Händler hat den

Anwender zufrieden zu stellen.

Bevor Sie den Kundendienst rufen, prüfen

Sie bitte, ob Sie den Fehler selbst beheben

können (siehe Fehlersuche). Ist Ihr Hilfeverlangen unberechtigt, beispielsweise weil

das Versagen des Geräts auf eine defekte

Sicherung oder Fehlbedienung zurück zu

führen ist, gehen die Kosten für den Servicebesuch zu Ihren Lasten.

Ersatzteile

Bitte bei der Ersatzteilbestellung Typ- und

Seriennummer sowie Produktnummer an-

geben. Diese Angaben nden Sie auf dem

Typenschild.

Produktnummer

Das Typenschild enthält verschiedene technische Angaben, u.a. auch Typ- und Seriennummer. Denken Sie daran! Stets nur

autorisierte Handwerker zu beauftragen,

wenn ein Teil repariert oder ausgewechselt

werden muss!

26

Page 53

Entsorgung

DE

Benutzerinformation zur Sammlung und

Entsorgung von veralteten Geräten und

benutzten Batterien.

Diese Symbole auf den Produkten,

Verpackungen und/oder Begleitdokumenten bedeuten, dass benutzte

elektrische und elektronische Produkte und Batterien nicht in den allge-

meinen Hausmüll gegeben werden

sollen. Bitte bringen Sie diese alten

Produkte und Batterien zur Behandlung, Aufarbeitung bzw. zum Recycling gemäß Ihrer Landesgesetzge-

bung und den Richtlinien 2002/96/EG

und 2006/66/EG zu Ihren zuständi-

gen Sammelpunkten.

Indem Sie diese Produkte und Batterien ordnungsgemäß entsorgen, helfen Sie dabei, wertvolle Ressourcen

zu schützen und eventuelle negative

Auswirkungen auf die menschliche

Gesundheit und die Umwelt zu vermeiden, die anderenfalls durch eine

unsachgemäße Abfallbehandlung

auftreten können.

Wenn Sie ausführlichere Informationen zur Sammlung und zum Recycling alter Produkte und Batterien

wünschen, wenden Sie sich bitte an

Ihre örtlichen Verwaltungsbehörden,

Ihren Abfallentsorgungsdienstleister

oder an die Verkaufseinrichtung, in

der Sie die Gegenstände gekauft

haben.

Gemäß Landesvorschriften können

wegen nicht ordnungsgemäßer

Entsorgung dieses Abfalls Strafgelder

verhängt werden.

Für geschäftliche Nutzer in der

Europäischen Union.

Wenn Sie elektrische oder elektronische Geräte entsorgen möchten,

wenden Sie sich wegen genauerer

Informationen bitte an Ihren Händler

oder Lieferanten.

Informationen zur Entsorgung in

Ländern außerhalb der Europäischen Union

Diese Symbole gelten nur innerhalb

der Europäischen Union. Bitte treten

Sie mit Ihrer Gemeindeverwaltung

oder Ihrem Händler in Kontakt,

wenn Sie dieses Produkt entsorgen

möchten, und fragen Sie nach einer

Entsorgungsmöglichkeit.

Hinweis zum Batteriesymbol:

Dieses Symbol kann in Kombination mit einem chemischen symbol

verwendet werden. In diesem Fall

erfüllt es die Anforderungen derjeni-

gen Richtlinie, die für die betreende

Chemikalie erlassen wurde.

27

Page 54

FR

Avertissement

Puisque l’appareil contient un

réfrigérant Inammable, il est

essentiel de s’assurer que les

conduits du uide réfrigérant ne

sont pas endommagés.

La quantité et le type de réfrigérant utilisée dans votre

appareil est indiquée sur la

plaque signalétique.

La norme EN378 précise que la

pièce dans laquelle vous installez votre appareil doit posséder

un volume de 1 m³ par 8 g de

réfrigérant avec des hydrocar-

bures utilisés dans l’appareil an

d’éviter la formation de mé-

langes gaz/air inammable dans

la pièce où l’appareil est installé

dans le cas où il y aurait une

fuite dans le circuit réfrigérant.

AVERTISSEMENT:

Gardez les orices de ventilation, situés sur la carrosserie de

l’appareil ou autour de l’appareil,

libres de toute obstruction

AVERTISSEMENT:

Ne pas utiliser d’appareils mécaniques ou autres moyens pour

accélérer la décongélation sauf

ce qui est recommandé par le

fabricant.

AVERTISSEMENT:

Ne pas endommager le système

de réfrigération.

AVERTISSEMENT:

Ne pas utiliser d´appareils électriques à l’intérieur du compartiment de stockage sauf s’ils sont

reconnandés par le fabricant.

AVERTISSEMENT:

Pour des raisons de sécurité et

d’exploitation, l’appareil ne doit

pas être exposé directement à la

pluie et ne doit pas être aspergé

lorsque le sol est nettoyé

AVERTISSEMENT:

Cet appareil n’est pas conçu

pour une utilisation par de

jeunes enfants ou des personnes handicapées sauf si

elles sont sous la surveillance

d’un adulte responsable. Les

enfants ne doivent pas jouer

avec l’appareil.

AVERTISSEMENT:

Ne pas entreposer des explosifs, tels que les aérosols avec

propulseurs inammables dans

l’appareil.

2

Page 55

AVERTISSEMENT:

Danger – risque d’incendie ou

d’explosion si réfrigérant inammable utilisé. L’appareil doit

seulement être réparé par un

personnel qualié.

AVERTISSEMENT:

les bords peuvent être coupants

au niveau de l’encadrement de

l’armoire, du compartiment du

compresseur, de l’évaporateur,

du couvercle de la ventilation et

sur l’équipement interne.

AVERTISSEMENT:

La surface du condensateur si-

tué au dos de l’armoire peut être

chaude. Merci de faire attention

an d’éviter toute blessure.

AVERTISSEMENT:

L’appareil doit être connecté au

moins 12 heures avant de l’utiliser pour le stockage de la médecine.

FR

● Conserver les clés dans un endroit hors

de portée des enfants.

● Avant de faire l’entretien ou le nettoyage

de l’appareil, débranchez-le de son

alimentation.

● Si le câble d’alimentation est endomma-

gé, il doit être remplacé par le fabricant,

des représentants ou des professionnels

agréés an d’éviter les dangers.

● Si le câble d’alimentation est endomma-

gé, il doit être remplacé par le fabricant,

des représentants ou des professionnels

agréés an d’éviter les dangers.

● La formation de givre sur les parois

intérieures de l’évaporateur et les parties

supérieures est un phénomène naturel et

normal. Retirez le givre avec un chion

sec.

● Prenez note que toute modication de

l’appareil annulera toutes les garanties et

la responsabilité du fabricant.

● Ce dispositif est destiné uni-

quement à être utilisé pour des

produits médicaux.

● Si des médicaments sont renversés à l’in-

térieur de l’armoire, le canal de dégivrage

doit être nettoyé immédiatement pour

éviter que la substance médicamenteuse

s’évapore dans l’air ambiant.

● Si vous perdez la notice d’utilisation,

merci de contacter votre fournisseur an

d’obtenir une nouvelle notice d’utilisation.

● Si vous devez entretenir l’armoire médi-

cale, merci de vous adresser à un service

compétent spécialisé dans l’entretien des

armoires médicales.

3

Page 56

FR

Sommaire

Avertissement .............................................2

Concernant AKG/S 337/397 .......................5

Faire connaissance avec son réfrigérateur 6

Avant la mise en service .............................7

Caracteristiques .........................................7

techniques ..................................................7

Installation et mise en marche ....................8

Installation et mise en marche ....................9

Mise à niveau de l’appareil ....................... 11

Bouteille pour sonde ................................12

Ajustement intérieur ..................................13

Montage du système de diviseurs

dans les tiroirs ..........................................14

Utilisation normale ....................................15

Hublot ......................................................15

Contact exempt de potentiel ....................16

Thermostat de sureté ...............................17

Contrôleur. Mise en service et fonctions ...18

Porte réversible .......................................21

Dégivrage, nettoyage et maintenance ......24

Localisation des anomalies ......................25

Garantie, pièces de rechange et service

après-vente ...............................................26

Mise au rebut ............................................27

4

Page 57

Concernant AKG/S 337/397

Cher client. Félicitations pour l’acquisition

de votre nouveau AKG/S 337/397. Ce réfrigérateur pour produits pharmaceutiques est

conçu pour le remisage de médicaments et

autres produits qui doivent demeurer à une

température stable entre 2 et 8 degrés C.

Ses paramètres sont les suivants:

Plage de température 2 °C – 8 °C

FR

Point de consigne

réglé en usine

Température ambi

ante

Humidité relative 70 %

Nombre de sondes 3 - 5 selon

L’appareil est muni de 3 sondes de façon

standard. Une pour le contrôle du compresseur, une pour la fonction de dégivrage et

une dans le haut pour l’information à propos

de la température à la limite de charge.

Certains modèles possèdent une bouteille

pour sonde montée avec une quatrième

sonde et une cinquième sonde pour un

thermostat de sureté.

La classe climatique est indiquée sur la

plaque signalétique.

4

-

15 – 30 °C

(35 °C pour por

tes solides)

(75 % f pour por

tes solides)

l’équipement de

l’appareil

-

-

5

Page 58

FR

Faire connaissance avec son réfrigérateur

SET

DATAREC

Écran/clavier

Serrure

Lumière DEL

Ventilateur (cloison arrière)

Plaque signalétique

Marque d’empilemen

Clayette réglable

PHARMA

Tiroir réglable

(en option)

Poignée de porte

Bouteille pour sonde

Tablette du bas

Pieds réglables

g. 1

6

Page 59

FR

Avant la mise en service

Avant de mettre en service votre nouvel

appareil, veuillez lire attentivement les

instructions suivantes : elles renferment

des informations importantes concernant

la sécurité, l’installation, le fonctionnement

et l’entretien. Conserver ce mode d’emploi

en lieu sûr : vous pourrez en avoir besoin

ultérieurement.

À réception, contrôler que l’appareil n’est

pas endommagé. Les dommages dûs

au transport doivent être notiés à votre

fournisseur avant toute utilisation de votre

réfrigératseur.

Enlever la xation de transport avant utilisation de l’appareil. L’accrocher à une des

clayettes, car elle pourra servir au réajustement de la porte.

Enlever l’emballage.

Nettoyez l’intérieure de l’armoire en suivant

les instructions pour le nettoyage.

Si pendant le transport, l’appareil a été

couché ou s’il a été stocké dans un environnement froid (température inférieure à +5

°C), il doit être placé en position verticale et

rester ainsi au moins une heure avant d’être

mis en service.

Attention : l’appareil doit être exclusivement

couché sur le dos, la porte vers le haut – et

uniquement dans son emballage d’origine.

Caracteristiques

techniques

Le câblage et les raccordements électriques

des systèmes d’alimenta¬tion électrique

doivent respecter les normes électriques

(locales et nationales) en vigueur. Consultez ces normes avant toute installation de

l’appareil.

Ce dispositif est conforme aux directives de

l’U.E. le concernant, y compris la Directive

2014/35/EU sur la Basse Tension et la

Directive 2014/30/EU sur la Compatibilité

Electromagnétique.

La prise de courant doit rester facilement

accessible. Brancher la che mâle de l’appareil dans une prise secteur en 220/240 V

/ 50Hz réglementairement reliée à la terre.

La prise doit être protégée par un fusible/

disjoncteur supportant de 10 A ou 13 A

Sur les appareils destinés aux pays non

européens, vériez si la tension de branchement et le type de courant spéciés sur

la plaque signalétique concordent bien avec

ceux oerts par le secteur du pays oncerné.

Les données relatives à la tension et la

puissance absorbée / courant sont indiquées sur la plaque signalétique.

Si un changement de cordon d’alimentation

électrique s’impose, cette opération est

réservéeà un spécialiste.

La plaque signalétique fournit diverses

informations techniques ainsi que les

numé¬ros de type et de série.

N’utilisez en aucun cas des rallonges de

câble.

g. 2

7

Page 60

FR

Installation et mise en marche

Batterie de secours

Cet appareil est muni d’un système de

secours sur batterie. Activez la batterie de

secours avant la mise en place nale. Il y a

un fusible dans le sac avec des matériels

de secours. Mettez ce fusible en place

comme montrée sur l’image.

Fuse

Abb. 3

REMARQUE!

Le système de batterie de secours

n’alimente pas le système de

refroidissement. Lors du premier

démarrage de l’appareil, il est

nécessaire d’activer le système de

batterie de secours.

Fonction du système de secours sur batterie

Le système de secours sur batterie assure

l’alimentation du contrôleur et du clavier en

cas de panne de l’alimentation électrique.

Ceci rend possible le suivi des températures dans l’appareil pendant une panne de

courant. Le système de secours sur batterie

permet de contrôler la température pendant

48 heures.

Après une panne de courant et au premier

démarrage, la batterie doit être rechargée.

Pour retrouver sa pleine capacité, la batterie se rechargera pendant 10 jours.

REMARQUE!

La batterie de secours devrait

être remplacée toutes les trois

années pour assurer 48 heures

de secours. Veuillez ajouter cette

activité aux trois années dans le

calendrier de maintenance.

8

Page 61

Installation et mise en marche

FR

L’appareil vu du dessus

Si l’appareil est placé près d’un mur, il doit y

avoir susamment d’espace pour permettre

à la porte de s’ouvrir assez pour pouvoir

retirer les clayettes (g. 4)

g. 4

Côte à côte

Dans des arrangements côte à côte, il doit

y avoir un espace d’au moins 60 mm entre

chaque unité, de chaque côté des armoires,

pour assurer que les portes s’ouvrent libre-

ment (voir g. 6)

Montage

Il est important que l’appareil soit parfaitement à niveau. Le niveau peut être ajusté

en vissant ou dévissant les pieds réglables

de l’appareil.

Utilisez un niveau à bulle pour vérier que

l’appareil est latéralement parfaitement à

niveau.

Si l’appareil est placé sur une surface

douce par ex. parquets ou tapis, vous

devez revérier si l’appareil est toujours

à niveau après un certain temps, car la

surface peut s’enfoncer sous le poids de

l’appareil.

g. 6

9

Page 62

FR

Ventilation

Il est important que l’appareil soit bien

ventilé et que l’air puisse circuler librement

au-dessus, au-dessous et autour.

Les gures (g. 4-6) montrent comment

assurer la libre circulation de l’air autour de

l’appareil.

Guide de ventilation

Les guides à l’arrière de l’appareil assurent

une circulation adéquate d’air. Les guides

doivent être inclinés vers le bas quand

l’armoire est installée.

Guides inclinés vers le bas

g. 7

g. 6

10

Page 63

Mise à niveau de l’appareil

FR

Selon l’équipement de l’appareil, ce dernier

sera muni de 4 roulettes qui peuvent ajuster

le niveau ou de deux pieds installés à

l’avant de l’armoire.

Roulettes

Installez l’appareil et faites tourner l’écrou

dans le sens horaire pour amener le pied

au sol. Voir g 8-10

g. 8

Pieds

1. Mettez l’appareil à niveau latéralement

en vissant ou en dévissant les pieds

réglables avec la clé incluse. Voir g 10.

g.10

2. Vériez que l’appareil est bien au niveau.

Si l’appareil est placé sur une surface

douce par ex. parquets ou tapis, vous

devez revérier si l’appareil est toujours

à niveau après un certain temps, car la

surface peut s’enfoncer sous le poids de

l’appareil.

g. 9

11

Page 64

FR

PHARMA

DATAREC

SET

Bouteille pour sonde

Certains modèles incluent une bouteille

pour sonde déjà installée. Avant le démarrage de l’appareil, emplissez la bouteille

avec un mélange de 50 % d’eau et 50 %

d’éthanol.

Bouteille pour sonde

g. 11

12

Page 65

Ajustement intérieur

FR

L’appareil est muni de clayettes en métal de

façon standard. Les équipements possibles

sont montrés à la gure 12-14

Max. 36 kg

Max. 36 kg

g. 13

Max. 10 kg

g. 12

13

OBS : Maximum de 7 tiroirs dans

une armoire.

g. 14

Page 66

FR

Montage du système de diviseurs dans les tiroirs

Réglage des diviseurs

Les points de rupture intégrés permettent le

stockage de produits individuels.

Ajustez les diviseurs comme suit

(voir g. 7). Coupez dans le joint approprié

et enlevez en la cassant la partie

excédentaire.

1. Le rail de support avec ruban adhésif

double-face est monté à l’intérieur de

l’arrière et du devant du tiroir.

g. 15

2. Mettez les rails en place.

3. Fixez les diviseurs et glissez-les.

14

Page 67

FR

Utilisation normale

À l’intérieur de l’armoire. Évitez de laisser la

porte ouverte pendant de longues périodes

si ce n’est pas nécessaire.

L’appareil n’est pas conçu pour refroidir des

produits chauds. Mettre de tels produits

dans l’armoire peut entrainer une hausse

de température des produits déjà dans

l’armoire. Important : Notez que la fré-

quence d’ouverture de la porte inuence la

température.

Il ne faut pas mettre des médicaments

plus haut que la marque d’empilement

rouge et blanc au haut de l’appareil, car

cela empêchera l’air de circuler pour

maintenir l’appareil froid. De plus, les

médicaments sur la clayette du bas ne

doivent pas toucher les côtés intérieurs.

Ces deux situations empêcheront le

maintien d’une température uniforme

dans l’appareil.

Hublot

L’appareil comporte un hublot. Insérez la

sonde dans le haut comme montré et elle