Page 1

VESTEL WATER HEATER SERVICE MANUAL

VESTEL WATER

HEATER SERVICE

MANUAL

COVERS ALL BATH STOVES IN THE FIELD MANUFACTURED IN VESTEL

FACTORIES

Page 2

VESTEL WATER HEATER SERVICE MANUAL

VESTEL BEYAZ EŞYA A.Ş. (Air Conditioning Quality Assurance Department) Page 1

Page 3

VESTEL WATER HEATER SERVICE MANUAL

VESTEL BEYAZ EŞYA A.Ş. (Air Conditioning Quality Assurance Department) Page 2

1- GENERAL INFORMATION ABOUT WATER HEATERS

Safety: Each part of the water heater is checked carefully to provide excellent operation durability. Electrical circuit is

completely insulated from the water circuit. All models are equipped with at least 3 safety equipments.

Ease of use: All models can easily be mounted at any place.

Low heat loss: It is preferred to position water heaters that can be installed anywhere as close to the hot water source

as possible to keep the heat loss in the piping minimum.

Small amount of hot water: In order to avoid unnecessary energy consumption, models with different capacities are

designed for spaces such as kitchen or service room where small amounts yet continuously running hot water is

needed.

2- PROPERTIES OF THE WATER HEATER

2-1 Efficient insulation, low energy consumption

High density, thick polyurethane foam layer offer excellent insulation in all electrical heaters and reduces energy

consumption significantly.

2-2 Drum with long service life

Special process of enameling that protects the tank against corrosive (abrasive) effects of the water and water-soluble

substances. It provides longevity and reliability for the mentioned protection drums.

2-3 Magnesium anode.

By using more magnesium anodes in the products, an electro-chemical anti-corrosive system that prolongs the service

life of the drum is used. In addition, it is positioned to allow easy access to anode drum for control and part

replacement when required.

2-4 High quality heating elements.

Heating coils are manufactured using first-class material to ensure long service life.

2-5 Water temperature control

Products are equipped with a temperature control button that helps to maintain the temperature between 35°C and

85°C. Thanks to this button, every user can select the appropriate water temperature according to requirements and

hence achieve energy savings.

2-6 Thermostat.

Hot water heaters are equipped whit thermostats which guarantee high performance and maximum safety. The

electronic card assumes the function of the thermostat in electronic models.

2-7 Limit thermostat.

Hot water heaters are equipped with "maximum temperature" thermostat. This safety device deactivates the main

thermostat and heating coils in case of a failure.

Page 4

VESTEL WATER HEATER SERVICE MANUAL

VESTEL BEYAZ EŞYA A.Ş. (Air Conditioning Quality Assurance Department) Page 3

2-8 Pressure safety.

Water heaters are equipped with a certified safety valve in terms of pressure values standards. Without the need to

remove discharge pipe, a check-valve is used to drain the unit when required.

2-9 Freezing Safety.

When water temperature in your water heater falls below 5°C, heating resistance is automatically activated and heats

the water up to 16°C. In the meantime, lamps with anti ice and heating coil signs illuminate and indicate the

temperature of the water. The anti-freeze safety system activates while the water heater is in stand-by. Install the

water heater in a location safe from risk of freezing. “This safety system is only available in electronically controlled

models.”

2-10 Bacteria Prevention System.

Researches show that when the water is kept under below 60°C for a long time it will become suitable for bacteria

growth. While the device in stand-by, to prevent bacteria from growing the water is heated at least once a week above

65°C and kept at this level for 1 hour. “This safety system is only available in electronically controlled models.”

2-11 Dry Operation Safety.

If your device is operating without water for any reason whatsoever, the system will be activated automatically and

generate E3 error code in the display. In this case disconnect the device using V-automated switch and ensure that the

water heater is filled with water. After ensuring that it is filled with water reconnect to the mains supply, the water

heater will commence its normal operation. “This safety system is only available in electronically controlled models.”

2-12 Low Voltage Protection.

If voltage is dropped to a level harmful for the device due to mains fluctuations, then the low voltage safety system is

activated and E2 error code is displayed. After the voltage is restored to desired level E2 error will disappear and the

water heater will commence its normal operation. “This safety system is only available in electronically controlled

models.”

Page 5

VESTEL WATER HEATER SERVICE MANUAL

VESTEL BEYAZ EŞYA A.Ş. (Air Conditioning Quality Assurance Department) Page 4

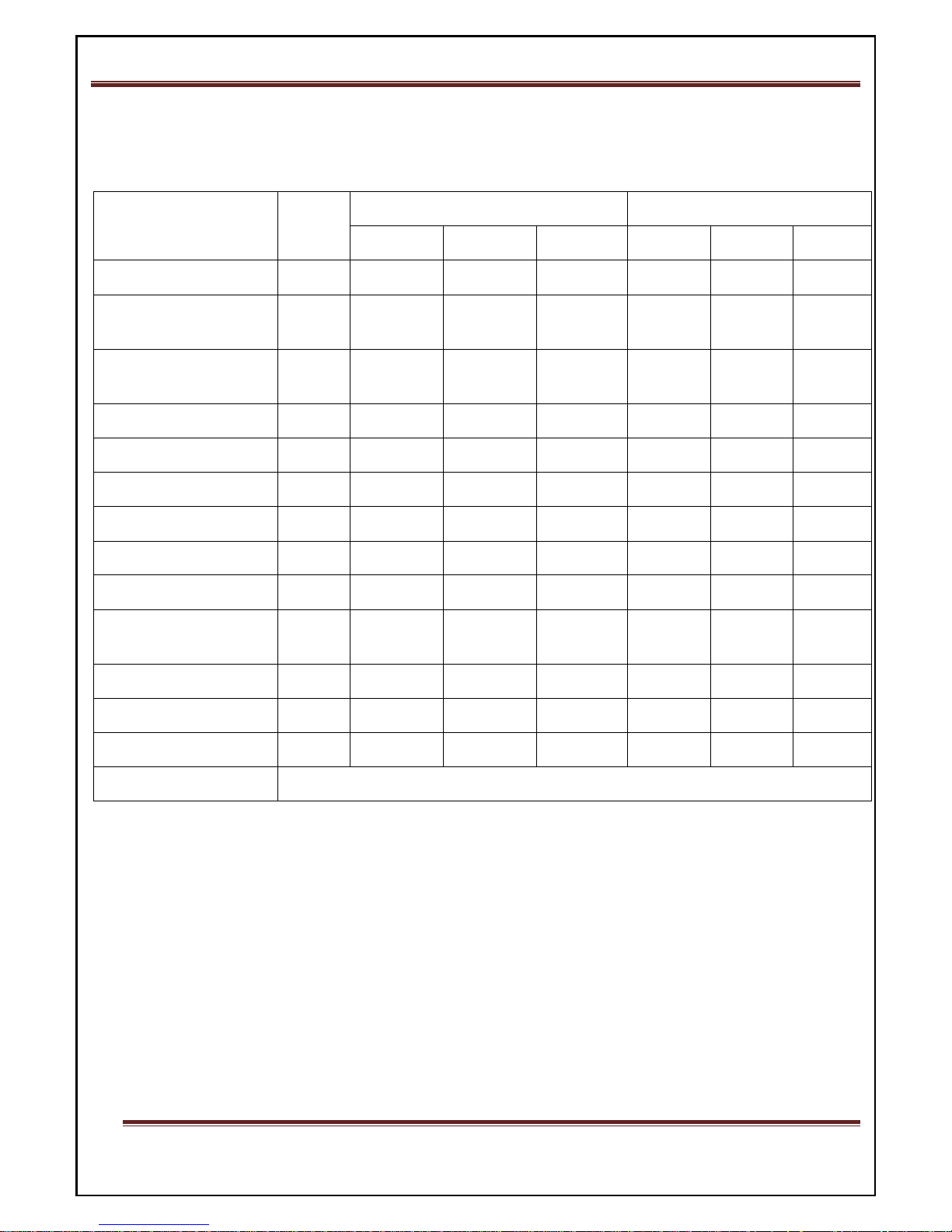

3- TECHNICAL SPECIFICATIONS TABLE

MODEL

UNIT

STANDARD

DIGITAL

TRV 50

TRV 65

TRV 80

TRV 50 E

TRV 65 E

TRV 80 E

CAPACITY

Lt

50

65

80

50

65

80

CONTROL PANEL

-

Thermostat

led

Thermostat

led

Thermostat

led

Digital

Digital

Digital

WATER TEMPERATURE

SETTING RANGE

°C

35-85

35-85

35-85

35-85

35-85

35-85

VOLTAGE

V

230

230

230

230

230

230

CURRENT

A 9 9 9 9 9 9

RESISTANCE POWER

W

1980

1980

1980

1980

1980

1980

OPERATING PRESSURE

Bar/Mpa

8/0,8

8/0,8

8/0,8

8/0,8

8/0,8

8/0,8

SAFETY VALVE MAX.

Bar 9 9 9 9 9 9

WATER CONNECTION

inch

1/2

1/2

1/2

1/2

1/2

1/2

ANTI-BACTERIAL

PROTECTION

- - - - √ √ √

DRY OPERATION SAFETY

- - - - √ √ √

FREEZING CONTROL

- - - - √ √ √

PROTECTION CLASS

-

IPx4

IPx4

IPx4

IPx4

IPx4

IPx4

ANTI-CORROSIVE SYSTEM

Enameled interior drum and magnesium anode

Page 6

VESTEL WATER HEATER SERVICE MANUAL

VESTEL BEYAZ EŞYA A.Ş. (Air Conditioning Quality Assurance Department) Page 5

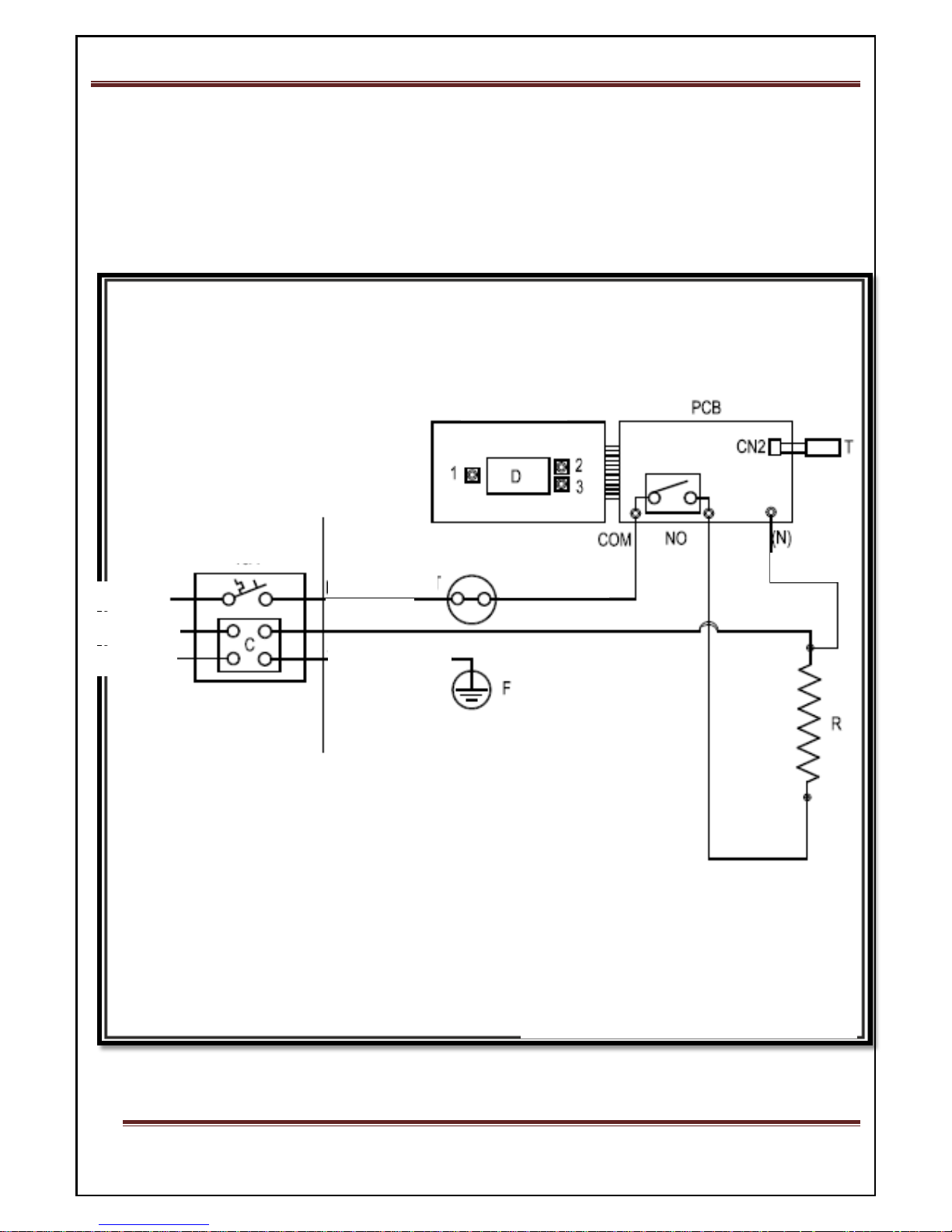

4- BATCH STOVE ELECTRIC GRAPHICS

4-1 FOR DIGITAL MODELS (SQUARE)

C : KLEMENS

LT : LIMIT THERMOSTAT

T : THERMISTOR

R: HEATING COIL

D: DISPLAY

F : FLANGE

1 : ON / OFF BUTTON

2 : "+" INCREASE BUTTON

3 : "-" DECREASE BUTTON

SOIL

NEUTRAL

FUSE 16A

PHASE

BROWN

BROWN

BLUE

YELLOW/GREEN

BLUE

DISPLAY

GREY

20708417 – ELECTRICAL DIAGRAM (TRM-DIGITAL)

Page 7

VESTEL WATER HEATER SERVICE MANUAL

VESTEL BEYAZ EŞYA A.Ş. (Air Conditioning Quality Assurance Department) Page 6

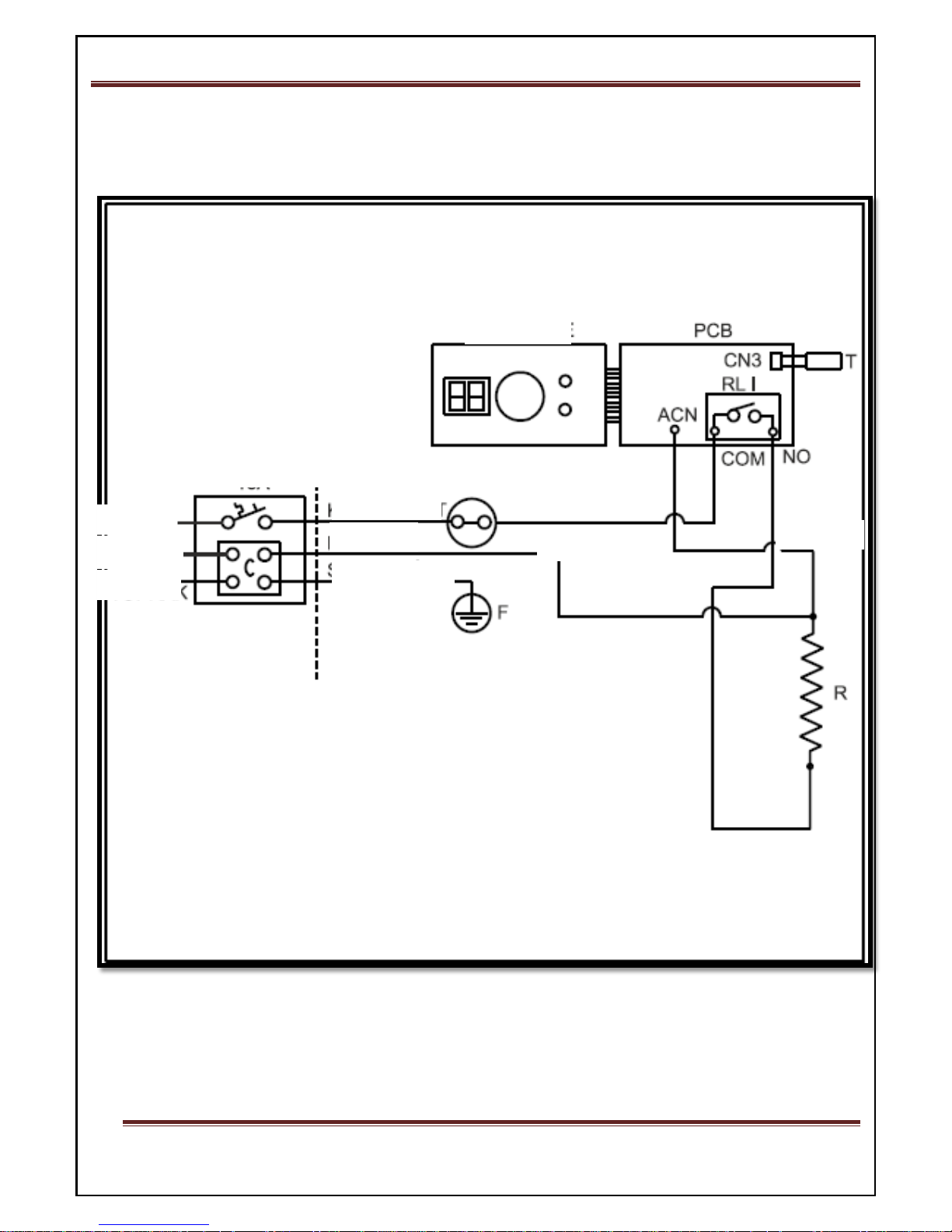

4-2 FOR DIGITAL MODELS (CYLINDER)

C : CONNECTOR

RLI: RELAY

LT : LIMIT THERMOSTAT

T : THERMISTOR

R : HEATING COIL

BF : BOYNER FLANGE

20812533 – ELECTRICAL DIAGRAM (TRM-ELC. YUV VELK

SOIL

NEUTRAL

FUSE 16A

PHASE

BROWN

BROWN

BLUE

YELLOW/GREEN

BLUE

DISPLAY

GREY

Page 8

VESTEL WATER HEATER SERVICE MANUAL

VESTEL BEYAZ EŞYA A.Ş. (Air Conditioning Quality Assurance Department) Page 7

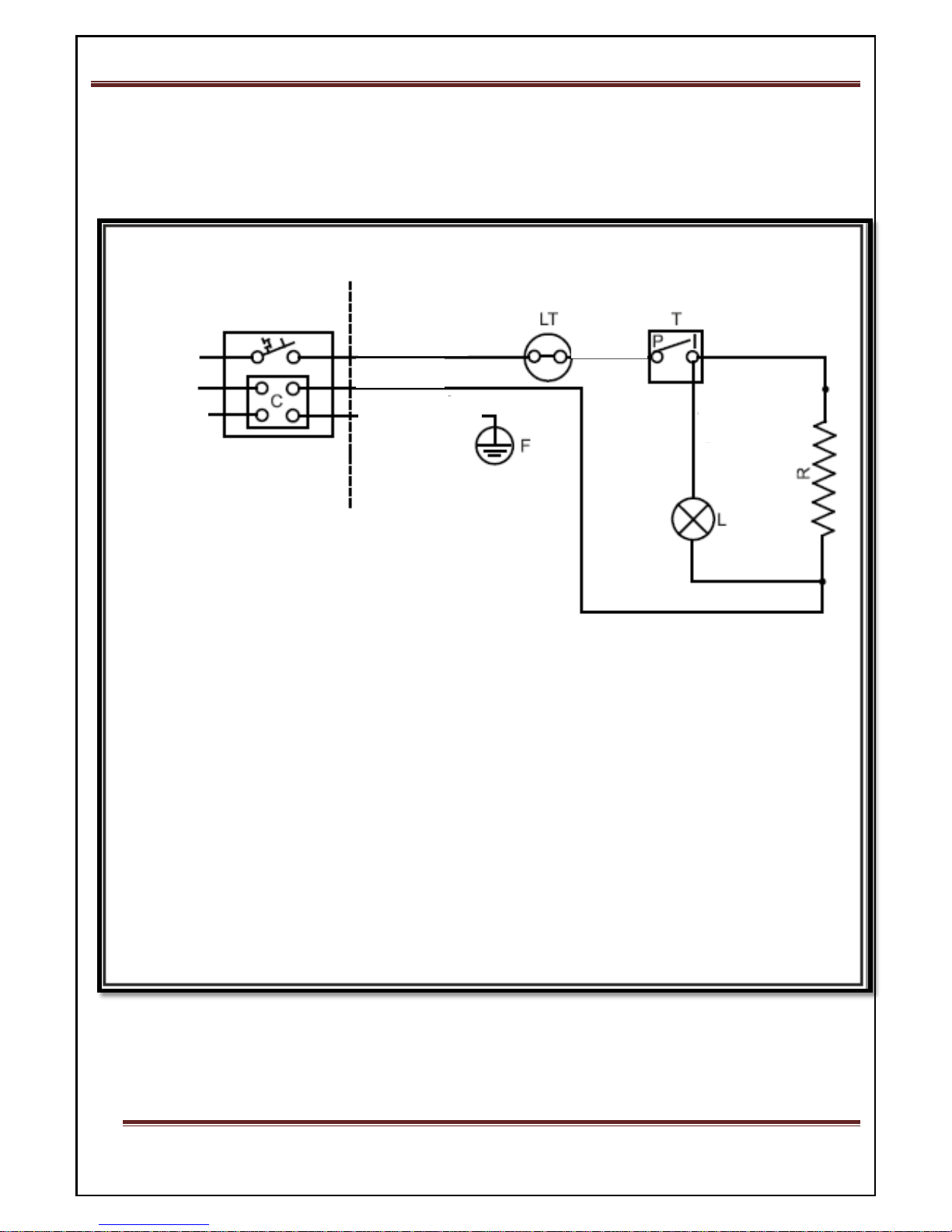

4-3 FOR MECHANICAL (ANALOG) MODELS

SOIL

NEUTRAL

FUSE 16A

PHASE

BROWN

BROWN

BLUE

YELLOW/GREEN

BLUE

GREY

GREY

C : KLEMENS

LT : LIMIT THERMOSTAT

T : THERMOSTAT

R: HEATING COIL

L : SIGNAL LAMP

F : FLANGE

20850064 – ELECTRICAL DIAGRAM ANALOG TYPE

Page 9

VESTEL WATER HEATER SERVICE MANUAL

VESTEL BEYAZ EŞYA A.Ş. (Air Conditioning Quality Assurance Department) Page 8

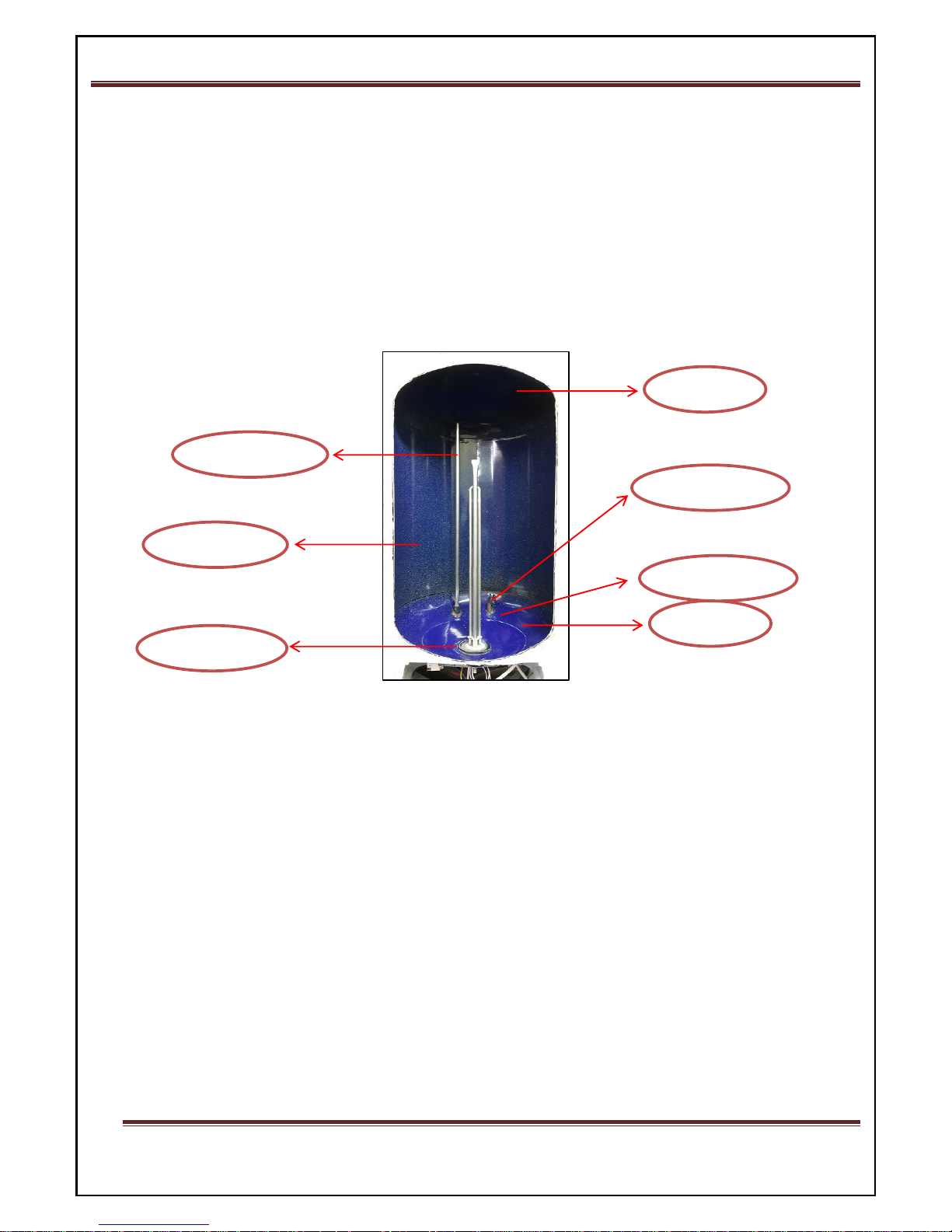

5- WATER HEATER COMPONENTS

5-1 DRUM

Water heater is manufactured from steel sheet suitable for enameling. Interior is coated with enamel with waterresistant titanium enamel up to 850°C.

(1) Top dome

(2) Hot water outlet pipe. Depending on the model, different lengths of pipes can be used for hot water outlet. Hot

water always is always received at the top of the tank.

(3) Lower dome

(4) Drum flange

(5) Cold water inlet pipe

(6) Input diffuser. Prevents turbulence and provides cold water inlet from the bottom of the tank.

(7) Drum

TOP DOME

HOT WATER PIPE

LOWER DOME

DRUM FLANGE

COLD WATER PIPE

INPUT DIFFUSER

HOT WATER PIPE

Page 10

VESTEL WATER HEATER SERVICE MANUAL

VESTEL BEYAZ EŞYA A.Ş. (Air Conditioning Quality Assurance Department) Page 9

5-2 OUTER BODY

Water heater outer body is manufactured from sheet with cataphoresis and electrostatic oven-drying and lower and

upper cover parts are manufactured from heat-resistant plastic material.

5-3 INSULATION

Gap between drum and outer body is filled with polyurethane foam with the most suitable density and pressure for

heat insulation.

5-4 HEATING COIL

Outer part of the heating coil is made of stainless steel and inner part is made of heating coil wire and magnesium

oxide insulation. Heating coil flange includes heating coil, thermocouple pipe and anode bar mounting bracket. It can

be in different shapes and powers depending on the model. Mechanical thermostat, electronic thermostat and limit

thermostat thermocouples installed in thermocouple pipe must be secured to the deepest section and a rubber plug

must be mounted at the end to prevent them from falling.

Heating coil measurement method;

Move the level of your measurement device to Ω (ohm) position and measure the resistance. If you can read the

circuit as illustrated, then you need to check if there is any leakage to the body. Contact one of the probes to one

of the ends and other probe to flange gasket. If the value is shown, it is defective, if not it is intact.

Page 11

VESTEL WATER HEATER SERVICE MANUAL

VESTEL BEYAZ EŞYA A.Ş. (Air Conditioning Quality Assurance Department) Page 10

5-5 FLANGE GASKET

Sealing and electrical insulation between tank flange and flange of the heating element is provided by a gasket. In

cases where flange is removed, for example, when thermostat drum scale is cleaned, it must afterwards be replaced.

5-6 THERMOSTAT

Mechanical thermostat is used to set water temperature in desired level. Thermostat is mounted on front display

panel. For the thermostat to detect water temperature, it is placed in the steel pipe in capillary pipe thermocouple

heating coil flange. Thermocouple must be installed in the steel pipe such a way that it is secured to the bottom part.

Signal lamp is lit red while water is heated to temperature that thermostat is set. Signal lamp lights up green when

water reaches the desired temperature.

Page 12

VESTEL WATER HEATER SERVICE MANUAL

VESTEL BEYAZ EŞYA A.Ş. (Air Conditioning Quality Assurance Department) Page 11

Thermostat.

Mechanical thermostat stability control;

Temperature is set in mechanical thermostats by expanding the gas in the bulb and it has an adjustment button.

This button is used to set the temperature value. If the temperature of the water in the water heater is lower than

the set temperature, contact is opened to allow heating coil to start. It has two ends with phases in both. Line is

turned on or off manually or with heat change.

Move the level of your measurement device to Ω (ohm) position and measure the resistance. First, lower the

thermostat adjustment button below the water temperature and contact probes to both ends of the thermostat.

Value must be displayed in the measurement device. If not, it is faulty. When you see the value, measure again by

moving adjustment button above water temperature. The value must disappear. If you see the value, thermostat

is faulty and it must be replaced.

ELECTRONIC THERMOSTAT

Temperature control and some of the safety functions are performed with an electronic card in electronically

controlled water heaters. Electronic card is located on the front panel. To set the temperature, there are two touch

buttons and one on/off touch button. Temperature value, heating coil active, hot water ready, freezing prevention

and bacteria prevention signal leds are located on the display. Electronic thermostat is removed by removing the

screws on both sides in display panel when service cover is removed. The protective lexan film tag in front of the

display must be replaced when it is deformed.

Temperature Adjustment

Button

On-Off signal Lamp

A-MECHANICAL CONTROL

Page 13

VESTEL WATER HEATER SERVICE MANUAL

VESTEL BEYAZ EŞYA A.Ş. (Air Conditioning Quality Assurance Department) Page 12

Water temperature is set to desired value with electronic card. Setting can only be made using the up-down

temperature adjustment keys. At the end of the operation, current temperature in the water heater appears on the

screen. The heating coil active signal lamp on the left side lights up. When water reaches the desired temperature, hot

water ready signal lamp lights up.

Electronic thermostat.

(1) On-Off ButTon

(3) Heating Coil Activation

Lamp

(6) Freezing Safety Lamp

(4) Higher Temperature Setting Button

(5) Lower Temperature Setting Button

(7) Bacteria Prevention Lamp

B-ELECTRONICAL CONTROL

(2) Hot water ready indicator lamp

Page 14

VESTEL WATER HEATER SERVICE MANUAL

VESTEL BEYAZ EŞYA A.Ş. (Air Conditioning Quality Assurance Department) Page 13

Electronic Thermostat Error Codes:

Following codes appear on the electronic card indicator in some error cases.

E1

Thermistor Error

Check the thermistor socket. Replace the

thermistor with a new one.

E2

Low Voltage Warning

When voltage is back to normal, error will

automatically disappear.

E3

Dry operation

When drum is filled with water, and power is

turned off and on, the error will be eliminated.

5-7 LIMIT THERMOSTAT

The limiting thermostat will disable the resistance in case of excessive temperatures in the drum or the failure of

temperature setting thermostat. When limit thermostat trips, check if thermostat is intact. After troubleshooting,

press reset button on limit thermostat to activate again.

Limit thermostat protection values;

1- Circuit cutting temperature is 104 °C.

2- Circuit is cut when gas in the bulb leaks, the product will not operate.

3- When circuit is cut, the red button will come out.

4- When limit thermostat cuts the circuit, water temperature in the drum is decreased to 60°C for reactivation

by pressing the red button.

5- Minimum 30 minutes must pass for limit thermostat to be reactivated.

6- Limit thermostat has a lifespan of 10 trippings.

Page 15

VESTEL WATER HEATER SERVICE MANUAL

VESTEL BEYAZ EŞYA A.Ş. (Air Conditioning Quality Assurance Department) Page 14

Limit thermostat.

Performing controls,

is the most important protection element in the circuit. It allows you to control the increasing pressure depending on

the water temperature. Phase in and phase out and shuts of contacts according to the value measured by the bulb.

Unless water temperature rises to 105°C, it keeps the circuit open at all times. Water must be cooled and minimum

30 minutes must pass for it to be reactivated after tripping. It is checked using measurement device as follows.

Move the level of your measurement device to Ω (ohm) position and measure the resistance.

1- Limit thermostat is constantly active if it is not tripped.

2- If limit thermostat is tripped, red button comes out and breaks the circuit.

Page 16

VESTEL WATER HEATER SERVICE MANUAL

VESTEL BEYAZ EŞYA A.Ş. (Air Conditioning Quality Assurance Department) Page 15

5-8 SAFETY VALVE

Safety valve checks the water pressure in the tank . It provides protection against high pressure and it is activated

when internal pressure exceeds 8 bar. Valve is closed so that it prevents the discharge of thermostat when water

supply is off. Minimum pressure value required to allow valve opening and water inlet is 0,2 bar that is considered to

be equal to 2 m of water height. Safety valve has a latch that opens the valve. This latch can be used for water tank

discharge.

Safety valve is installed on the cold water inlet of the water heater. The following conditions must be observed while

installing and using the safety valve.

1-As water may drip from the drainage tip, this pipe should be left open to the atmosphere. In order to prevent the

dripping waters from causing any harm to the environment, you can connect it to a sewage drain by means of a

discharge hose.

2-The appliance should be operated with intervals pressing the latch in order to prevent caustic lime accumulation

and confirm that it is not blocked.

3-While connecting the safety valve to the appliance, make sure that the drainage tip is downwards.

Methods of protecting the device;

1- Protection 1: Drum pressure is reduced by transferring water to water system if drum pressure exceeds the

system pressure by 0.5-1.

Drain latch safety valve.

2- Protection 2: It is activated when drum pressure exceeds 8 bar. It discharges the water inside through drain

hose to reduce drum pressure.

Pressure rises as water is heated

and water is returned to the

system.

Water received

from the main

Page 17

VESTEL WATER HEATER SERVICE MANUAL

VESTEL BEYAZ EŞYA A.Ş. (Air Conditioning Quality Assurance Department) Page 16

5-9 ANODE STICK

Corrosion is a chemical process that occurs between water heater metal (tank, pipes, heating coils) and water

surrounding it. Corrosion causes punctures in the tank, reduces mechanical resistance of elements and damages

heating element. Reasons that cause corrosion are as follows:

1. Oxygen solution (example: from 5 mg/l at high temperature and up to a maximum of 12 mg/l at low temperature)

2. Salts that harden water.

Magnesium anode is used to prevent tank from punctures.

Corrosion develops in three phases:

1. Water soluble oxygen comes into contact with the inner surface of the drum.

2. Drum iron starts to dissolve (atom loses two electrons and become Fe ++ ion).

3. Iron ion is separated from drum surface and turns into rust by combining with oxygen (FeO). In this case, formation

of punctures start within the tank.

4. Grounding connections must certainly be provided during product installation as floating power connections

prevent chemical reactions between anode and drum and cause corrosion and punctures in the drum.

Both iron and magnesium are water soluble; magnesium is more electropositive compared to iron (become mg ++

more easily). Thus, it is the magnesium that becomes a solution.

At this point, magnesium leaves anode and combines with oxygen atoms. Corrosion ends, in other words, while

thermostat stays the same magnesium anode is abraded.

Water received

from the main

Pressure rises as water is heated. Water is

transferred to drain hose when pressure

exceeds 8 bar.

Page 18

VESTEL WATER HEATER SERVICE MANUAL

VESTEL BEYAZ EŞYA A.Ş. (Air Conditioning Quality Assurance Department) Page 17

Service life of the anode depends on water temperature, amount and quality. Anode must be checked and replaced

before it is completely out of service. Recommended duration is to check every two years.

Anode stick

7- OPERATION PRINCIPLE OF WATER HEATER

OPERATION

Tank is always filled with pressurized water. When desired temperature is reached, the control thermostat turns off

the electrical resistance. When hot water is used, cold water intake starts to tank through cold water intake pipe.

Magnesium atom (the

element forming anode)

Magnesium oxide MgO

Page 19

VESTEL WATER HEATER SERVICE MANUAL

VESTEL BEYAZ EŞYA A.Ş. (Air Conditioning Quality Assurance Department) Page 18

Thermostat cools and heating coil is re-activated. Cold water is heated until it reaches the set temperature value in

the thermostat. Water in the tank stays hot and ready for use until more water is drawn.

LAMINATION OF HOT AND COLD WATER LAYERS

Operation principle of a water heater is to create layers that to not mix in different water temperatures.

This principle is extremely simple to explain: water expands when heated and water density is reduced compared to

cold water. In this case, density reduces when water is heated and accumulate at the top of the tank. Water at lower

temperature creates a layer in the lower part.

When hot water is drawn from the top of the tank, this water is replaced by the cold water at the bottom. In this way,

the density balance is provided.

ELECTRICAL WATER HEATER INSTALLATIONS

Service life of a water heater largely depends on the installation to be made correctly. We recommend that installation

must be performed by a professional. The plumber, first of all, must check if water supply, power supply and waste

water connections are in conformity with manufacturer’s recommendations.

Water heater installation and first operation must be performed in accordance with the instructions in the user

manual.

PLACEMENT AND INSTALLATION OF THE UNIT

Attention must be paid to the following issues in the wall-mounting of the stove.

Water heater must be in a position to align with the water connection in the wall.

Dowels and hanger screws should be strong enough. An 80 liter water heater can exceed 100 kg including its

own weight. As this weight will be loaded completely on hanger screws, screws must be strong enough to stay

in the wall.

After hanging, it is ensured that the device is parallel to the wall using the adjustment plastic section at the

bottom of the stove.

There must be no damage on the device that will adversely affect the electrical isolation.

Power cable of the device must be connected to the fuse supplied with the device.

Safety valve is must be mounted to the cold water inlet pipe with blue ring.

Water connection hose sleeves have flexible gaskets. Sleeves must be sufficiently tightened to prevent water

leakage. If extremely tightened, sleeves and gaskets may be damaged. If hose length is not sufficient, different

sizes of hoses recommended by Vestel Service Center must be used.

Water heater must be installed where water inside will not freeze.

6- WATER HEATER MAINTENANCE

CLEANING SCALE ON HEATING COIL

Scale (scaling) can lead to operating problems mentioned below:

Page 20

VESTEL WATER HEATER SERVICE MANUAL

VESTEL BEYAZ EŞYA A.Ş. (Air Conditioning Quality Assurance Department) Page 19

Reduction in the volume of available hot water

Increase in heating coil failure risk

Noisy water heater operation during heating

Thermostat turning on-off frequently

Therefore, water heater cleaning is required in frequency depending on the quality of the water and use of the

appliance. Recommended cleaning period is at least once in two years.

.

Operation:

1. Be sure to disconnect electrical connection before clearing the water heater.

2. Turn off the valve to cut water delivered to the appliance.

3. To eliminate the pressure, turn on hot water tap and then turn off.

4. Disconnect intake pipe water system connections.

5. Remove safety valve and connect a rubber pipe the appropriate length for the discharge.

6. Open hot water tap for the discharge of remaining water in the water heater.

7. Remove the screws that holds the flange (that heating coil is connected).

8. Remove the flange.

9. Clean the scale manually or using a tool (depending on appliance type) carefully.

Page 21

VESTEL WATER HEATER SERVICE MANUAL

VESTEL BEYAZ EŞYA A.Ş. (Air Conditioning Quality Assurance Department) Page 20

10. The magnesium anode stick must be replaced every 2 years.

11. Flange gasket must be replaced every time heating coil is removed from the drum.

FLANGE GASKET

FLANGE

Page 22

VESTEL WATER HEATER SERVICE MANUAL

VESTEL BEYAZ EŞYA A.Ş. (Air Conditioning Quality Assurance Department) Page 21

7- ERROR CODES AND TROUBLESHOOTING

A- ERROR CODES

E1

Thermistor Error

Check the thermistor socket. Replace the

thermistor with a new one.

E2

Low Voltage Warning

When voltage is back to normal, error will

automatically disappear.

E3

Dry operation

When drum is filled with water, and power is

turned off and on, the error will be eliminated.

B- TROUBLESHOOTING

E1 ERROR

This is an error code that occurs only in digital models. It means that temperature sensor is open or there is short

circuit.

Check the sensor and electronic card

sockets, is there looseness or lack of

contact?

Yes

Fix lack of contact in

sockets and start

again

No

Remove sensor and electronic card

and measure resistance values. Is

there open or short circuit?

Yes

Replace Sensor.

Replace electronic

card.

No

Page 23

VESTEL WATER HEATER SERVICE MANUAL

VESTEL BEYAZ EŞYA A.Ş. (Air Conditioning Quality Assurance Department) Page 22

E2 ERROR

This is low-high voltage error in digital water heaters. Its protection range is between 165-270V.

E3 ERROR

This is dry operation warning in digital water heaters. If temperature of the water is increased by 1°C in 5 seconds,

it means that water level is low.

Measure supply voltage of the bath

stove, is it out of limits?

Yes

It is a normal process. Card

protection is running, wait for

the voltage to balance.

No

Replace electronic

card.

Open hot water line of bath stove, is

there air release?

No

Increase bath stove thermostat

temperature, does water

temperature rise faster than

normal?

Yes

Bath stove water level is low, fill

it with water and start again.

Yes

No

Replace the control card.

Heating coil is excessively scaled or sensor slot is very

close to the source of heat. Replace the scaled heating

coil or move the sensor slot away from heating coil.

Page 24

VESTEL WATER HEATER SERVICE MANUAL

VESTEL BEYAZ EŞYA A.Ş. (Air Conditioning Quality Assurance Department) Page 23

WATER HEATER NOT WORKING

Turn on V-automate and measure

the voltage. Is there power supply in

No

Yes

V-automate is tripped or broken. Install

again, and replace if it does not work.

Check supply cable. Is it defective?

Yes

Replace supply

cable.

No

Is limit thermostat tripped?

Yes

Cool the water in the drum

and reinstall limit thermostat.

No

No

Check temperature

thermostat. Is output

provided to heating coil?

Yes

Replace thermostat

Check the

heating coil and

replace if

defective.

Check bath stove cable harness. Is

there burning, tearing or lack of

contact?

Yes

Replace cable

harness.

No

Page 25

VESTEL WATER HEATER SERVICE MANUAL

VESTEL BEYAZ EŞYA A.Ş. (Air Conditioning Quality Assurance Department) Page 24

SAFETY VALVE LEAKING WATER

LIMIT THERMOSTAT TRIPS FREQUENTLY

Connect a manometer to water

outlet pipe of the appliance and

measure drum pressure. Is the

No

Yes

Replace the safety valve

Cut 5 cm of chrome hot water pipe

and reinstall. Does the problem

persist?

No

Yes

Fault is fixed. No need for

further actions.

Mains water system pressure is

too high. Recommend pressure

reduction regulators for the

safety of the customer and the

Is the water drawn from the device

over 90°C ?

No

Yes

Remove heating coil

from drum. Does the

sensor slot that limit

thermostat bulb is

inserted contact the

end of heating coil?

Yes

Remove

heating coil

slot from

sensor slot and

reinstall.

No

Replace limit

thermostat.

Remove sensor from control card

and perform measurements. Is there

any deviation in sensor values?

Yes

Replace

Sensor.

Thermostat is faulty, replace it.

No

Page 26

VESTEL WATER HEATER SERVICE MANUAL

VESTEL BEYAZ EŞYA A.Ş. (Air Conditioning Quality Assurance Department) Page 25

WATER HEATER DOES NOT HEAT WATER

Do the display or LEDs illuminate

when on/off button of digital or

mechanical bath stove is pressed?

No

Yes

Check supply, V-Automate,

limit thermostat of the device.

Does thermostat output to

heating coil?

No

Yes

Replace the thermostat.

Check heating coil resistance

values. Are there any broken

cables or short circuit?

Yes

Replace heating coil.

No

Are sensors and bulbs are

correctly fit in their slots?

No

Fix sensors and bulbs and place

them back.

Yes

Hot water pipe is not mounted or

fell inside the appliance. Fix and

start the appliance.

Page 27

VESTEL WATER HEATER SERVICE MANUAL

VESTEL BEYAZ EŞYA A.Ş. (Air Conditioning Quality Assurance Department) Page 26

OTHER MALFUNCTIONS

MALFUNCTION

CAUSE OF MALFUNCTION

TROUBLESHOOTING

Insufficient hot water.

* Hot/cold water pipe connection

may be blocked.

* Connections may be incorrect.

* Connect the pipes correctly.

* Ensure that the system conforms to

the schema.

Formation of excessive hot

water or steam.

* Thermostat setting may be

incorrect or it may be stuck.

* There may be formation of scale

deposits or mud in the tank.

* Adjust the thermostat setting

correctly or replace thermostat.

* Clean scale or mud.

It takes a long time for the

thermostat to start again.

* Thermostat sensor and drum

connection may be irregular.

* Thermostat sensitivity may be

lost.

* Place the thermostat sensor

correctly.

* Replace the thermostat with a new

one.

Heating time is long, energy

consumption is high water

heater cannot reach

maximum temperature.

* There may be leakage in hot

water system.

* Heating coil may be

malfunctioning.

* Detect and repair the leak.

* Replace heating coil.

Hot water drawn from water

heater smells bad.

* Bacteria may have grown in

water heater due to infrequent

use.

* Completely drain and clean the

water in water heater.

Water heater is

enabled/disabled

frequently.

* Thermostat may be faulty.

* Heating coil may be covered

with scale.

* There may be faulty power

input.

* Replace the thermostat.

* Clean heating coil.

* Check the supply voltage.

Page 28

VESTEL WATER HEATER SERVICE MANUAL

VESTEL BEYAZ EŞYA A.Ş. (Air Conditioning Quality Assurance Department) Page 27

MALFUNCTION

CAUSE OF MALFUNCTION

TROUBLESHOOTING

Water heater is making noise

during heating.

* Heating coil may be covered

with scale.

* It may be the boiling sound of

water while heating coil is

heating.

* Clean heating coil.

* It is a normal process. There is no

need for further actions.

There is water leak in heating

coil and flange unit

* Flange or heating coil gaskets

may be damaged.

* Corrosion may have caused

puncture in flange.

* Replace gaskets.

* Replace flange and gaskets (mount

the flange carefully in both cases).

NOTE: Temperature control is electronic in certain models of water heaters. For this reason, thermostat used for

heat control is digital. It detects heat through a sensor.

Loading...

Loading...