Professional Mixing Controller

VESTAX CORPORATION

1-18-6 Wakabayashi, Setagaya-ku, Tokyo 154-0023 Japan

Phone:03-3412-7011 Fax:03-3412-7013

Web:www.vestax.jp

VESTAX America (west Corst)

15320 Valley View Rord Unit 9 La Mirada, CA 90638

Phone:(562)623-9881 Fax:(562)483-7304

Web:www.vestaxdj.com

VESTAX(Europe)Ltd.

Unit 5 Riverwey Industrial Park Alton, Hampshire GU34 2QL England, U.K

Phone:(0)1420-83000 Fax:(0)1420-80040

Web:www.vestax.co.uk

Vestax Technical Center of America

8489 W.Third Street Ste.1044 Los Angeles CA 90048

Phone:1-323-801-2111 Fax:1-323-801-2112

Vestax Europe Technical Support

Rheinstr.213 D-53332 Bornheim Germany

Phone:49(0)2222-95-23-72 Fax:49(0)2222-95-23-74

OWNER'S MANUAL

1

CONGRATULATIONS

!

The lightning flash with arrowhead symbol,within an equilateral triangle,is intended to

alert the user to the presence of uninsulateddangerous voltagewithin the product's

enclosure that may be of sufficient magnitude to consitute a risk of electric shock to persons.

The exclamation point within an equilateral triangle is intended to alert the user to the presence

of important operating and maintenance(servicing)instructions in the literature accompanying

the appliance.

T0 REDUCE THE RISK 0F FIRE 0R ELECTRlC SHOCK,DO NOT

EXPOSE THIS APPLIANCE T0 RAIN 0R M0ISTURE.

CAUTl0N: TO REDUCE THE RlSK OF ELECTRlC SHOCK

DO NOT REMOVE COVER( OR BACK)

NO USER-SERVICEABLE PARTS INSIDE

REFER SERVlCING T0 QUALIFIED SERVlCE PERSONNEL

CAUTION

RISK OF ELECTRIC SHOCK DO NOT OPEN

CONTENTS

CAUTION

1

IMPORTANT SAFEGUARDS

2

FEATURES

3

FUNCTIONS

4

PROGRAM SECTION

4

MASTER SECTION

5

MICROPHONE SECTION

5

MONITORSECTION

6

REAR PANEL SECTION

6

CONNECTION(EXAMPLE)

7

HOW TO CHANGE THE FADER UNIT

8

HOW TO CHANGE THE JACK P ANEL POSITION

9

BLOCK DIAGRAM 10

SPECIFICATIONS 11

Thank you for purchasing the VESTAX PMC-250, Professional Mixing Controller. Please read

this owner's manual carefully before you start to use your mixer, so that you will fully understand

all of the special features and enjoy the full use of the product.

2

1. Read instructions-All the safety and operating

instructions should be read before the appliance

is operated.

2. Retain instructions-The safety and operating

instructions should be retained for future

reference.

3. Heed Warnings-All warnings on the appliance

and in the operating instructions should be

adhered to.

4. Follow Instructions-All operating and use

instructions should be followed.

5. Cleaning-Do not use liquid cleaners or aerosol

cleaners. Use a damp cloth for cleaning.

6. Attachments-Do not use attachments not

recommended by the product manufacturer as

they may cause hazards.

7. Water and Moisture-Do not use this product near

water-for example, near a bath tub, wash bowl,

kitchen sink, or laundry tub, in a wet basement,

or near a swimming pool, and the like.

8. Accessories-Do not place this product on an

unstable cart, stand, tripod, or table. The product

may fall, causing serious injury to a child or

adult, and serious damage to the appliance. Use

only with a cart,. stand, tripod, bracket, or table

recommended by the manufacturer, or sold with

product. Any mounting of the appliance should

follow the manufacturer's instructions, and

should use a mounting accessory recommended

by the manufacturer.

9. This product should never be placed near or over

a radiator or heat register. This product should

not be placed in a built-in installation such as a

bookcase or rack unless proper ventilation is

provided or the manufacturer's instructions have

been adhered to.

10. Power sources-This product should be operated

only from the type of power source indicated on

the marking label. If you are not sure of the type

of power supply to your home, consult your

appliance dealer or local power company.

11. Lightning-For added protection of this product

during a lightning storm, or when it is left

unattended and unused for long periods of time,

unplug it from the wall outlet. This will prevent

damage to the product due to lightning and

power-line surges.

12. Overloading-Do not overload wall outlets and

extension cords as this can result in a risk of fire

or electric shock.

13. Object and Liquid Entry-Never push objects of

any kind into this product through openings as

they may touch dangerous voltage points or

short-out parts that could result in a fire or

electric shock. Never spill liquid of any kind on

the product.

14. Servicing-Do not attempt to service product

yourself as opening or removing covers may

expose you to dangerous voltage or other

hazards. Refer all servicing to qualified

personnel.

IMPORTANT SAFEGUARDS

READ BEFORE OPERATING EQUIPMENT

This product was designed and manufactured to meet

strict quality and safety standards. There are, however,

some installation and operation precautions which you

should be particularly aware of.

3

15. Damage Requiring Service-Unplug this product

from the wall outlet and refer servicing to

qualified service personnel under the following

conditions:

a. When the power-supply cord or plug is

damaged.

b. If liquid has been spilled or objects have fallen

into the product.

c. If the product has been exposed to rain or

water.

d. If the product dose not operate normally by

following the operating instructions. Adjust

only those controls that are coverd by the

operating instructions as an improper

adjustment of other, controls may result in

damage and will often require extensive work

by a qualified technician to restore the product

to its normal operation.

e. If the product has been dropped or cabinet has

been damaged.

f. When the product exhibits a distinct change in

performance this indicates need for service.

16. Replacement Parts-When replacement parts are

required, be sure the service technician has used

replacement parts specified by the manufacturer

or have the same characteristics as the original

parts. Unauthorized substitutions may result in

fire, electric shock or other hazards.

17. Safety Check-Upon completion of any service or

repairs to product, ask the service technician to

perform safety checks to determine that the

product is in proper operating condition.

18. Carts and Stands-The appliance should be used

only with a cart stand that is recommended by

manufacturer.

19. An appliance and cart combination should be

moved with care. Quick stops, excessive force,

and uneven surfaces may cause the appliance

and cart combination to overturn.

FEATURES

1. Three-band frequency isolators are provided

on PGM1 and PGM2. This allows DJs to

boost / cut and eliminate individual frequency

ranges for active mixing.

2. The worlds first fader-type kill switch enables

smooth and dynamic frequency cut-off without

clicking noise.

3. The I/O panel can be placed on either the rear or

top side. This feature enables the PMC-250 to be

used on the table or in a rack without any extra

space for the leads.

4. Both the input faders(60 mm)and cross fader

(45 mm)are user replaceable. The input fader can

be replaced with a rotary control for House

applications.

5. One Phono and two Line inputs are provided on

each program channel(PGM1, PGM2). Each

input channel has a trim control for adjusting

input level. A Phono / Line selectable AUX input

and a Mic input are also provided.

4

FUNCTIONS

PROGRAM SECTION

21

MAXMIN

MAXMINMAXMIN

MAXMIN

MAX

MIN

MAXMIN

PRO FESSIONAL MIXING CONTROLLER

LEVEL

INPUT FILTER

LOW MID HI

MIC

IN

CUT

ISOLATOR

ISOLATOR

ISOLATOR

ISOLATOR

PEAK

PHONO 1 LINE 2

LINE 1

INPUT

PHONO 2 LINE 4

LINE 3

INPUTTRIM

MAXMIN

MAXMIN

TRIM

PGM 1 LEVEL PGM 2 LEVEL

AUX

MASTER BOOTH OUT

METER SELECT

MASTER

+6 +3 +2 +1 0 -1 -2 -4 -7 -10 -20 -30

-30

POWER

-20 -10 -7 -4 -2 -1 0 +1 +2 +3 +6

CUE SELECTOR

STEREO CUE

LEVEL

PHONES

ON

OFF

12

AUX

PGM 1 PGM 2

0

1

2

3

4

5

6

7

8

9

10

0

1

2

3

4

5

6

7

8

9

10

IN

CUT

IN

CUT

PEAK PEAK

+4dB

-

∞

+4dB

-

∞

+4dB

-

∞

+4dB

000 000

-

∞

+4dB

-

∞

+4dB

-

∞

LOW MID HI

IN

CUT

PEAK

IN

CUT

IN

CUT

PEAK PEAK

MONITOR

PGM

PGM 2

Rch

PGM 1

Lch

MONITOR SECTION

MIC SECTION

PROGRAM SECTION

MASTER SECTION

q INPUT SELECT (Input Select Switch)

Used to select input to be sent to each PGM

channel.

w TRIM (Trim Control Volume)

Adjusts the Input level of each channel. For

proper adjustment, please set the INPUT

FADER to Maximum position then adjust TRIM

so that the INPUT LEVEL METER shows

around 0 dB at nominal level.

e PEAK

Turns on when the signal of HI, MID, LOW

range hits the peak.

r HI (Isolator HI)

Cuts and boosts the high frequency range. The

level is flat when this knob is set at 12 o'clock.

High frequency range is boosted up to +4dB

when this knob is rotated clockwise. When the

knob is rotated counter-clockwise, high

frequency range is cut off up to infinity level. For

example, it can be used to emphasise or cut off

the cymbals or high hats.

t MID (Isolator MID)

Cuts and boosts the mid frequency range. The

level is flat when this knob is set at 12 o'clock.

Mid frequency range is boosted up to +4dB

when this knob is rotated clockwise. When the

knob is rotated counter-clockwise, mid

frequency range is cut off up to infinity level. For

example, it can be used to emphasise or cut off

the vocals or guitars.

y LOW (Isolator LOW)

Cuts and boosts the low frequency range. The

level is flat when this knob is set at 12 o'clock.

Low frequency range is boosted up to +4dB

when this knob is rotated clockwise. When the

knob is rotated counter-clockwise, low

frequency range is cut off up to infinity level. For

example, it can be used to emphasise or cut off

the bass.

MAXMIN

LOW MID HI

IN

CUT

ISOLATOR

ISOLATOR

PEAK

PHONO 1 LINE 2

LINE 1

INPUT TRIM

PGM 1 LEVEL

PGM 1

0

1

2

3

4

5

6

7

8

9

10

IN

CUT

IN

CUT

PEAK PEAK

+4dB

-

∞

+4dB

-

∞

+4dB

000

-

∞

6

5

4

9

3

1

2

10

8

7

u HI CUT (Fader type cut switch HI)

When this volume is set to bottom position, high

frequency range is cut of completely regardless

of the position of the HI level control. The HI

level control knob becomes active when this

volume is set to maximum(top)position.

i MID CUT (Fader type cut switch MID)

When this volume is set to bottom position, mid

frequency range is cut of completely regardless

of the position of the MID level control. The MID

level control knob becomes active when this

volume is set to maximum(top)position.

o LOW CUT (Fader type cut switch LOW)

When this volume is set to bottom position, low

frequency range is cut of completely regardless

of the position of the LOW level control. The

LOW level control knob becomes active when

this volume is set to maximum(top)position.

!0 INPUT FADER

Used to adjust the input level of each program.

Please replace with IF-250 when it is worn out,

or with the optional rotary fader unit.

5

MASTER SECTION

!1 POWER INDICATOR

The LED light when the power is on.

!2 LED LEVEL METER

The bar graph level meters indicate the master

output level(L channel and R channel)or input

level of each program(program 1 and 2).

!3 METER SELECT

When this switch is set to MASTER, the bargraph meter indicates the master output level(L

channel and R channel). When it is set to

PGM, the left meter shows the input level of

PGM1 and the right meter shows the input level

of PGM2.

!4 AUX (AUX level volume)

Used to adjust the Input level of AUX IN.

21

MAXMIN

MAX

MIN

MAXMIN

PRO FESSIONAL MIXING CONTROLLER

PGM 2 LEVEL

AUX

MASTER BOOTH OUT

METER SELECT

MASTER

+6 +3 +2 +1 0 -1 -2 -4 -7 -10 -20 -30

-30

POWER

-20 -10 -7 -4 -2 -1 0 +1 +2 +3 +6

PGM

PGM 2

Rch

PGM 1

Lch

16

17

13

14

15

12

11

!5 MASTER (MASTER level volume)

Adjusts the output level of LINE OUT and PA

OUT.

!6 BOOTH OUT

Adjusts the output level of BOOTH OUT.

!7 CROSS FADER

The signal from PGM1 is output when the cross

fader is set to the left side. The signal from

PGM2 is heard when the cross fader is set to

the right side. When the cross fader is set at

centre position, both programs will be mixed

and output at the same time. Please replace it

with the CF-PCV when it is worn out.

MAXMINMAXMIN

LEVEL

INPUT FILTER

MIC

18

19

20

MICROPHONE SECTION

!8 MIC INPUT (Mic Input Jack)

Input jack for the microphone.

!9 MIC LEVEL (Mic Level Volume)

Adjusts the input level of the microphone.

@0 MIC FILTER (Mic Filter Volume)

Adjusts the cut off frequency of the microphone

input. It is used to prevent low frequency noise

such as breathing, vibration, etc.

6

MONITOR SECTION

MAXMIN

CUE SELECTOR

STEREO CUE

LEVEL

PHONES

ON

OFF

12AUX

MONITOR

21

22

23

24

@1 CUE SELECTOR

Used to select the cue signal to be monitored by

headphones from PGM1, PGM2 or AUX.

@2

STEREO CUE (Stereo Cue ON/OFF Switch)

When this switch is set to ON, the input signal

selected by CUE SELECTOR can be monitored

in stereo through headphones. When this switch

is set to OFF, the master signal can be

monitored through the right side of the

headphone all the time, the CUE signal selected

by CUE SELECTOR will be heard from the left

side. This feature allows DJs to monitor current

and next source simultaneously.

@3 LEVEL (Headphone Level)

Adjust the monitor level of the headphones.

@4 PHONES (Headphone Jack)

Used to connect the headphones. Headphones

with impedance from 8-600 can be used.

REAR PANEL SECTION

28

30

26

25 32

33

34 35

29

31 28 28

26 25 29

27

@5 PHONO 1,2 [RCA PIN JACK]

Connect turntables equipped with MM (Moving

Magnet type) cartridge. The signal from the

turntable is fed to the PGM channels when Phono

input is selected.

@6 LINE 1,2,3,4 [RCA PIN JACK]

Connect the equipment with line level output

(-10dB, 0dB, +6dB), such as CD players, tape

decks, DATs, MDs etc. The signal from line

level equipment is fed to the PGM channels

when Line input is selected.

@7

AUX IN (LINE 5, PHONO 3) [RCA PIN JACK]

Input jack for turntable and line level equipment.

The signal from these jacks are fed to AUX input

channel.

@8 INPUT LEVEL[+6/0/-10dB]

Used to select the input level.

@9 GND (Ground Terminal)

Connect the ground lead from the turntable.

Failure to connect a ground lead produces

noise on Phono input signal.

#0

PA OUT (Balanced Output) [XLR MALE, 2 PIN HOT]

Main output jacks. Connect to the input of the

power amplifier or the master console with XLR

3 pin cable.

#1

P A OUT LEVEL (Balanced Output Level Select Switch) [-10dB/0dB]

Used to select the output level of the PA OUT

from -10dB or 0dB. Please select the level

according to the input sensitivity of the power

amplifier or the master console.

#2 LINE OUT

(Unbalanced Output) [1/4" PHONE JACK]

Unbalanced LINE output. Connect to the input

of the power amplifier or the master console with

1/4" phone cable. PA OUT LEVEL (

#1

) does not

effect this output.

#3 BOOTH OUT

(Output for Monitor System) [1/4" PHONE JA CK]

Connect to the input of the power amplifier of

the DJ booth monitor system.

#4 POWER (Power Switch)

#5 AC IN

Connect the AC-12A AC Adapter. (12V AC,

1000mA)

CAUTION

When the line level equipment is connected to

LINE 5 input jack, the input signal from PHONO

3 is disconnected and only the signal from line

level equipment is fed to AUX input. Please

disconnect LINE 5 when turntable is used.

7

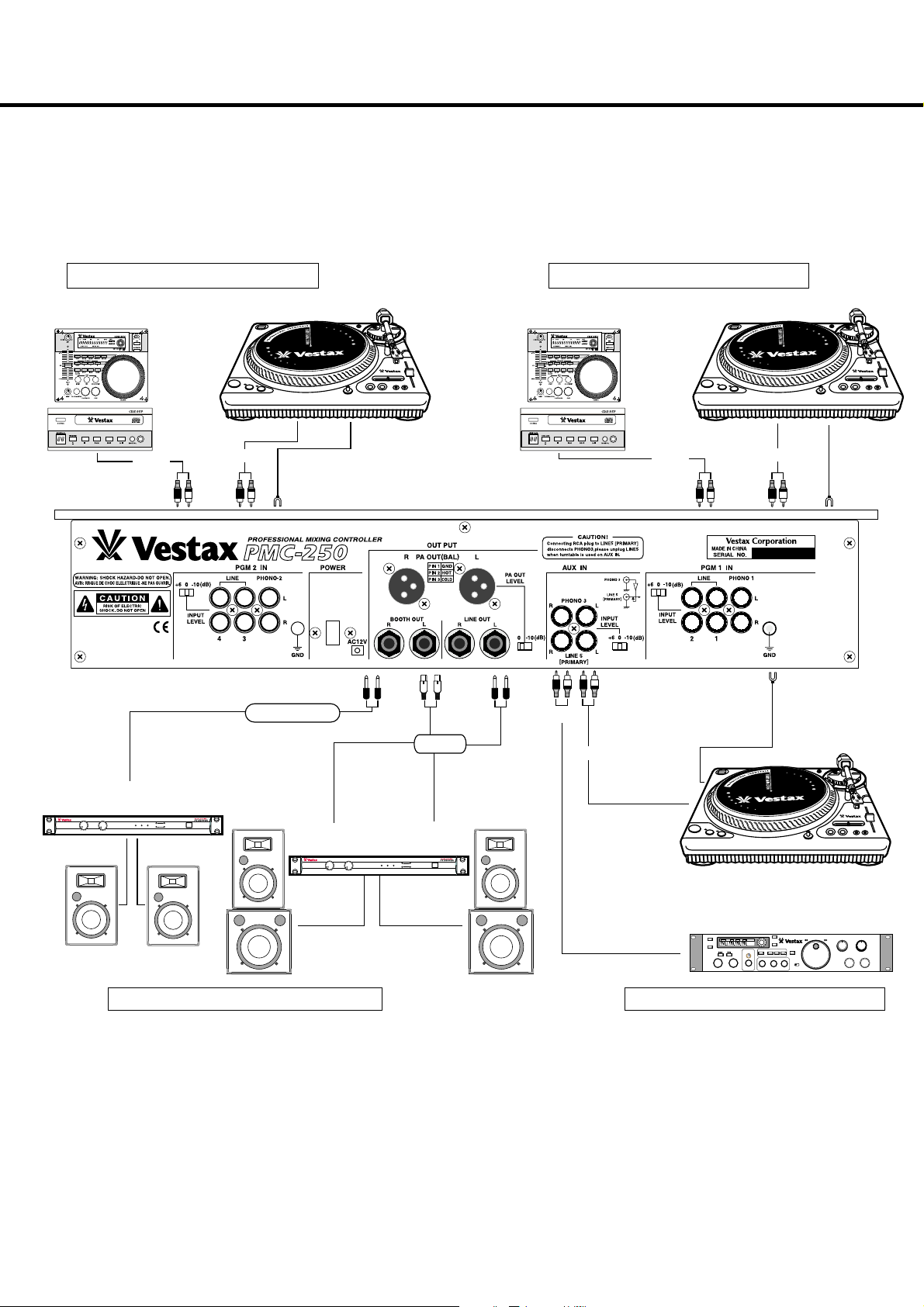

CONNECTION EXAMPLE

PLAY/PAUSE

CUE

PLAY/PAUSE

CUE

KEYPITCH

REVERSE

OPEN/

CLOSE

STOP

DISPLAY

REPEAT

AB

SEARCH

TRACK

MIN SEC FRM

ENTER 123

LOOP

START

END

RELOOP/EXIT

POINT FOCUS

MONITOR

CHANNELACHANNEL

B

MAX MINI MAX MINI

PROTECT B.T.L POWER

POWER

INPUT

PEAK

INPUT ON / OFF

PEAK

CHANNELACHANNEL

B

MAX MINI MAX MINI

PROTECT B.T.L POWER

POWER

INPUT

PEAK

INPUT ON / OFF

PEAK

MONITOR

SPEAKER

MONITOR

SPEAKER

MAIN

SPEAKER

MAIN

SPEAKER

CD,MD PLAYER,DAT,S

CDPLAYER[Vestax CDX-35]

CDPLAYER[Vestax CDX-35]

UNBALANCED INPUT

LINE5

LINE1

or

LINE2

LINE3

or

LINE4

PHONO3

PHONO1

PHONO2

BALANCED INPUT

POWER AMPLIFIER

[Vestax PT-X1000A]

POWER AMPLIFIER

[Vestax PT-X1000A]

OUT PUT

OUT PUT

OUT PUT

OUT PUT

GND TERMINAL

GND TERM

GND TERMINAL

MONITOR SYSTEM

MAIN PA

BOOTH

OUT

PA

OUT

LINE

OUT

GND

GND

GND

Instruments connected to the OUT PUT

Instuments connected

Instruments connected to the PGM 2 Instruments connected to th

TURNTABLE[VESTAX PDX-2000] TURNTABLE[VES

TURNTABLE[VEST

8

HOW TO CHANGE THE FADER UNIT

■HOW TO REMOVE THE TOP PANEL

○

1

Remove all slide fader knobs' and screws on

the top panel.

○

2

Remove the top panel.

■HOW TO CHANGE THE FADER UNIT

○

1

Remove the screws on the fader panel.

○

2

Remove the fader unit from position in mixer.

○

3

Carefully remove the multi-cable connector

from fader unit.

○

4

Attach multi-cable connector to new fader unit.

○

5

Position the fader unit carefully and secure

with screws.

PMC CONNECTOR

Set switch to "PMC" position

CF-PCV For

PMC SERIES

( PMC05ProII, PMC06ProA, etc)

Insert the

multi-cable connector

Set switch to "PCV" position.

Note

Use a plus driver fitting screw.

Caution: When you change any parts, do not

loose the screws with marking.

Top panel

Crossfader

unit

Inputfader

unit

9

HOW TO CHANGE THE JACK PANEL POSITION

The I/O jack panel of the PMC-250 can be placed either on the top or back side of the unit. Please

refer to following Fig.

Initially, the I/O panel is placed on the top-side. In case of changing the jack panel position to

TYPE □

B, please use following instructions.

●

Remove 5 pieces of silver screw, which secure

the PANEL ①.

●

Remove 5 pieces of silver screw, which secure

the PANEL ②.

●

Install the PANEL○1to the back side and secure

it with 5 silver screws.

●

Install the PANEL○2to the top side and secure it

with 5 silver screws.

CAUTION

Please ensure use of the proper screwdriver

(3mm Phillips type). Please hold the

screwdriver upright and turn slowly. Do not use

excessive force, or it may damage the screw

head.

10

BLOCK DIAGRAM

L

R

RIA A

ATT

ATT

RIA A

LINE 1

LINE 3

PHON O 1

PHON O 2

PHON O 3

LINE 2

LINE 4

LINE 5

MIC

MAS TER LEV EL

BOO TH LEVE L

INPUT

SELECTOR

INPUT

SELECTOR

TRI M

TRI M

MIC LE VEL

AUX L EVEL

CUE SE LECT

MON ITOR LEV EL

MET ER SELE CT

PHON ES

LINE O UT

MAST ER OUT

BOOT H OUT

LEV EL METE R

LO PASS

LO PASS

MID PAS S

MID PAS S

HI PASS

HI PASS

ISO LATOR

PEA K LEVEL

CUT

CUT

CUT

CUT

CUT

CUT

PMC-250 BLOCK DIAGRAM

PGM-1

PGM-2

PGM-3 (AU X)

MIC

LO

LO

LO

MID

MID

MID

HI

HI

HI

IF- 1

C.F

L

L

L

L

L

L

L

L (PGM -1)

L

L

L

L

R

R

R

R

R

R

R

R (PGM -2)

R

R

R

R

PHON O 1

PHON O 1

LINE 1

LINE 1

LINE 2

LINE 2

-10d B

+6dB

+6dB

-10d B

-10d B

0dB

0dB

-10d B

-0dB

-0dB

-1

-1

RIA A

RIA A

INPUT

SELECTOR

INPUT

SELECTOR

LO PASS

LO PASS

FILTE R

MID PAS S

MID PAS S

HI PASS

HI PASS

ISO LATOR

PEAK LEVEL

CUT

CUT

CUT

CUT

CUT

CUT

LO

LO

LO

MID

MID

MID

HI

HI

HI

IF- 2

PHON O 2

PHON O 2

LINE 3

LINE 3

LINE 4

LINE 4

-10d B

PGM- 1

SPLI T

PGM- 1

PGM- 2

MAST ER

1

12

3

3

2

MAST ER

SPLI T

STER EO

STER EO

PGM- 2

AUX

+6dB

+6dB

-10d B

-0dB

-0dB

To CUE, LED

RIA A

RIA A

Fro m PGM-1

L

R

ATT

ATT

ATT

ATT

ATT

ATT

ATT

ATT

ATT

ATT

ATT

ATT

ATT

ATT

Vestax Corporation

SPECIFICATIONS

INPUT

SECTION

MIC(1/4' PHONE JACK) -50dBv -20dBv 3.3kΩ

PHONO 1〜3L/R (RCA PIN JACK) -42dBv -22dB v 22kΩ

LINE 1〜5L/R (RCA PIN JACK) -10/0/+6dBv +20dBv 22kΩ

RATED OUTPUT

MAXIMUM OUTPUT

IMPEDANCE

PA OUT L/R

(XLR MALE 2PIN HOT,BALANCE )

0dBv,-10dBv +19dBv 600Ω OVER

LINE L/R

(1/4' PHONE JACK,UNBALANCE )

-10dBv +10dBv 2kΩ OVER

BOOTH OUT L/R

(1/4" PHONE OUT )

-10dBv +14dBv 600Ω OVER

HEAD PHONE(1/4" PHONE JACK ) 130mW 8Ω OVER/47Ω

MIC 30Hz 〜 20kHz ±3dB CROSSFADER CROSSTALK > 100dB

LINE 20Hz 〜 20kHz ±1dB CHANNEL CROSSTALK > 65dB

MIC >60dB POWER SUPPLY

AC12V ADAPTOR

LINE >75dB DIMENSIONS(W×H×D) 482×138×112

>70dB WEIGHT 4kg

OUTPUT

SECTION

FREQUENCY

RESPONSE

S/N RATIO

FADER

ATTENUATION

NOMINAL INPUT

LEVEL

MAXIMUM INPUT

LEVEL

IMPEDANCE

Sep.01 PMC250 E1

Loading...

Loading...