Ves INDA56P, INDA564L, INDA484L, INDA364L User Manual

Operating Instructions & Parts Manual

IMPORTANT: READ AND SAVE THESE INSTRUCTIONS. Read carefully before attempting to assemble, install, operate or maintain the product described. Protect yourself and others by observing all safety information. Failure to comply with instructions could result in

personal injury and/or property damage! Retain instructions for future reference.

Commercial Ceiling Fans

Description

The VES commercial ceiling fans are a high efficiency, commercial ceiling fan. It is designed to create air velocity and a cooling effect on high speed. The lower speeds can be used for reduced velocity or heat de-stratification. The low speed gently de-stratifies the air giving a constant room temperature. Models are UL & cUL Certified.

Unpacking

1.After opening carton, look for concealed damage.

2.If concealed damage is found, immediately file claim with carrier. E249273

Specifications

Model |

Size |

Volts |

Hertz |

Amps |

Watts |

RPM |

INDA364L |

36˝ |

120 |

60 |

0.35 |

40 |

360 |

INDA484L |

48˝ |

120 |

60 |

0.50 |

50 |

320 |

INDA564L |

56˝ |

120 |

60 |

0.55 |

65 |

280 |

INDA56P |

56˝ |

120 |

60 |

0.55 |

65 |

280 |

General Safety Information |

2. Do not mount in an area which will |

||||

|

|

|

Disconnect power |

allow the ceiling fan to come in |

|

|

|

|

|||

|

|

|

|||

|

|

|

supply before wiring |

contact with moisture. |

|

|

|

|

|||

connections are made to prevent possible |

3. Make certain the entire installation |

||||

electric shock or damage to equipment. |

is grounded as a precaution against |

||||

|

|

|

|

||

|

|

|

Read and follow |

possible electrical shock. |

|

|

|

|

|||

|

|

|

4. Do not exceed maximum |

||

|

|

|

instructions carefully. |

||

|

|

|

|||

|

|

|

|||

Failure to comply with instructions could |

amperage rating of the ceiling fan |

||||

result in fire, electric shock, injury to |

as overloading can result in |

||||

persons and/or damage to equipment. |

damage to ceiling fan and control. |

||||

|

|

|

|

||

|

|

|

Follow all |

5. When wiring an electrical |

|

|

|

|

|||

|

|

|

appliance or device follow all elec- |

||

|

|

|

maintenance |

||

|

|

|

|||

procedures enclosed. |

trical and safety codes, as well as |

||||

|

|

|

Failure to properly |

the most recent NEC, CEC and local |

|

|

|

|

regulations and the Occupational |

||

|

|

|

ground unit could |

||

|

|

|

Safety and Health Act (OSHA). |

||

result in severe electrical shock or death. |

|||||

6. Suitable for use with a VES solid |

|||||

|

|

|

|

||

1. All wiring should conform to the |

state speed control. |

||||

|

|||||

National Electrical Code ANSI/NFPA |

|

||||

70-1999 (NEC) in the United States, |

|

||||

CEC and local regulations. |

|

||||

Assembly

1.Remove all ceiling fan parts from the box.

2.Tools and supplies needed – Flat and Phillips screwdriver – 9/16” and 3/8” open wrench or adjustable wrench, 2-3 wire nuts.

3.Install a junction box to accept the wiring of the fan. In many cases, a qualified electrician will be required to install the outlet box keeping with local electrical codes or to meet the NEC, CEC and local regulations.

4.For installation to open web steel joist – use threaded J-hook as supplied. For wood joist construction – use J-hook with lag threads (not supplied. For attachment in concrete, drill concrete anchors into the concretes as per specification applicable to NEC, CEC and local regulations.

Form IS1100 |

Version 1 |

VES001 |

|

01/2017 |

01/2017 |

|

|

624 |

Operating Instructions & Parts Manual

Commercial Ceiling Fans

|

2 |

|

8 |

1 |

|

4 |

5 |

17 |

|

6 |

|

7 |

|

Figure #1 |

|

30 |

20 |

22 |

|

31 |

29 |

12 |

28 |

|

|

|

27 |

|

|

10 |

3 |

11 |

|

9 |

|

|

14 |

||

|

|

13 |

|

|

|

|

|

|

|

16 |

|

|

|

|

15 |

19 |

|

|

|

Figure #2 |

|

1 |

18 |

|

|

||

|

25 |

23 |

26 |

|

24 |

Figure #3 |

|

11 |

Safety |

Cable |

Figure #4 |

Installation

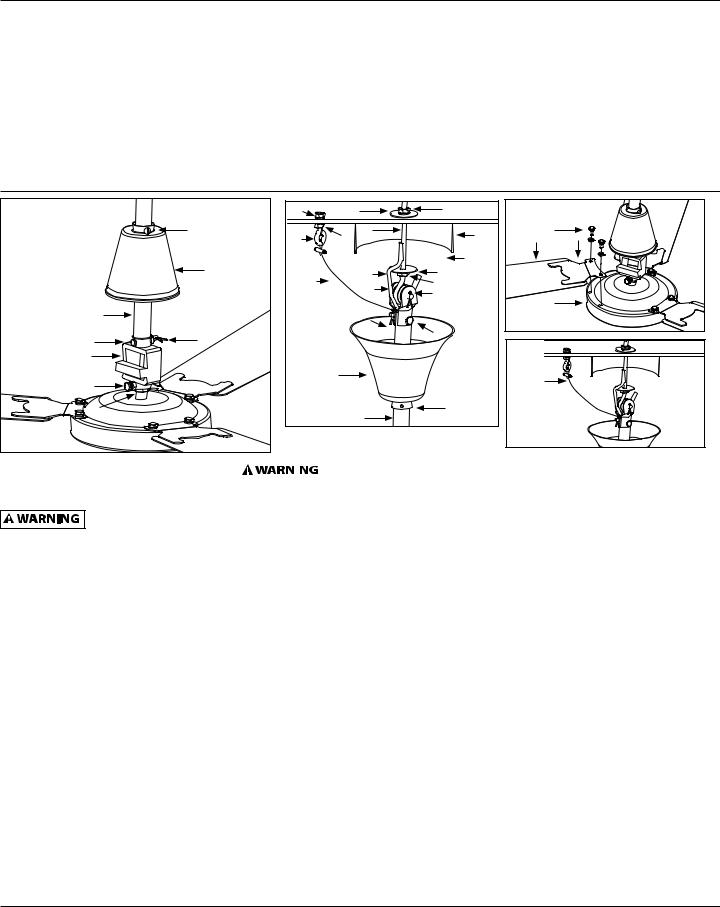

Safety Product Inspection of Fan Prior to Installation (Figure #1 and #2)

To reduce the risk of personal injury, do not

bend the blade brackets when installing the brackets, balancing the blades or cleaning the fan. Do not insert foreign objects in between rotating fan blades.

1.Make certain set screw (4) is tight to ascertain wobble free operation.

2.Make certain cotter pin (5) is in place and secure.

3.Make certain lock-nut (7) is tight and set screw (6) is in place and secure.

4.Slide lower canopy (8) down over rubber gasket (21) to create a tight seal.

5.Make certain lower canopy set screws (2) are tight on downrod (1).

6.Make certain cotter pin (13) is in place and secure.

7.Make certain bolt, cotter pin and nut (16) are tight.

Hanging of Fan (Figure #1 and #2)

. Wind one nut (9) down to bottom of J hook (12) towards the curve. Add a lock washer and then flat washer (3) on top of the nut (9).

|

|

Make certain crimp on |

of the threaded part of the mount- |

|

|

|

|||

|

|

safety loop is secure (See |

ing screw should be secured into |

|

|

|

|||

Figure #4). Make certain safety cable is |

a structural joist to provide secure |

|||

attached properly to hook or structural |

||||

mounting. |

||||

member. Failure to comply with instruc- |

||||

4. Loosen set screw (18) on top canopy |

||||

tions could result in personal injury and/ |

||||

or property damage. |

(19) on fan downrod (1) and lower |

|||

2. Drill a 5/32” pilot hole for safety |

the canopy to make room to place |

|||

hook (31) within a 12” radius of J |

rubber grommet (14) onto |

|||

hook (12) support for fan. Wind one |

mounting hook. |

|||

nut down (29) to bottom of safety |

5. Tighten top nut (22) on J hook to |

|||

hook towards the loop. Add a lock |

raise fan into proper installation |

|||

washer (29) and slide safety hook |

position. |

|||

through pilot hole. Slide lock washer |

6. Ensure power to outlet box is off be- |

|||

(30)on top side of the safety hook |

fore hooking up wiring (10) (except |

|||

and add nut (30). Tighten so lock |

INDA56P see note below). Wire the |

|||

washer on top and bottom of the |

fan according to NEC, CEC and local |

|||

structure are secure. |

electrical codes (see Figure #5 or 6). |

|||

3. Drill a 1/2” pilot hole for J hook. Put |

After making the wire connections |

|||

J hook (12) through pilot hole in |

as outlined in Figure #5 or 6, the |

|||

joist. Add flat washer and then lock |

wires should be spread apart with |

|||

washer (20) and nut (22). Do not |

the grounded conductor and the |

|||

tighten completely until fan is put in |

equipment-grounding conductor on |

|||

place on J hook. A lubricant should |

one side of the outlet box and the |

|||

not be used on the single mount- |

ungrounded conductor on the other |

|||

ing screw; and the pilot hole should |

side of the outlet box. Splices should |

|||

be drilled no larger than the minor |

be turned upward and pushed care- |

|||

diameter of the mounting screw |

fully up into the outlet box. |

|||

threads, and at least 38 mm (1-1/2”) |

|

|||

2

Operating Instructions & Parts Manual

Commercial Ceiling Fans

|

Figure #5 - Wiring diagram for Forward/ |

Top of Rubber |

Reverse. |

|

|

Grommet |

120V |

|

|

|

Optional F/R Switch |

Figure #6 - Wiring diagram for optional #ICFCFR5 control.

18” |

CEILING |

|

FAN |

Flat surface |

ICFCFR5 |

|

|

blades attach. |

|

Length of downrod is |

|

measured as shown above. |

|

Note: Model INDA56P already has a 3 |

IMPORTANT: |

|

prong plug wired for 120V. Cord |

The standard downrod installed properly |

|

must be plugged into a properly |

be mounted a minimum 10’ above the floor |

|

level. It is critical that the “J” hook and nut |

||

wired 120V grounded outlet. |

||

adjustment is done so that the blades will |

||

7. Raise top canopy (19) up the |

||

be a minimum 12” from the ceiling. If your |

||

downrod to cover hook. Leave 1/8” |

ceiling is less that 12’ than the hook and |

|

gap between top canopy (19) and |

downrod must be recessed into the ceiling |

|

hanging surface (so downrod does |

so that the blades are mounted 10’ above |

|

the floor level to meet OSHA standards. |

||

not move off center which could |

||

|

make fan wobble or vibrate and |

Operation |

|

transmit motor noise to ceiling |

For optimum fan performance, use the |

|

surface). Tighten set screw (18). |

||

VES model ICFCFR5 control to adjust |

||

8. Attach blades (23) to motor (24) |

||

speed and direction of your fan (see |

||

with blade bolts (25). (Figure #3) |

||

figure #6 for wiring). Follow the in- |

||

The blade (24) should be positioned |

||

structions included with the control for |

||

below the blade arm bracket (26) |

||

minimum speed setting and operation. |

||

when attaching to the motor to get |

||

The forward/reverse control will allow |

||

proper air flow and direction. |

||

you to adjust the speed and direction of |

||

|

||

|

the fan. The forward/downdraft direc- |

|

|

tion blows air down on high speed for |

|

|

cooling or low speed for heat de-strat- |

|

|

ification. The reverse direction is idle |

|

|

for heat de-stratification or creating air |

|

|

movement without direct air flow. |

3

Loading...

Loading...