Page 1

Operating Instructions & Parts Manual

IMPORTANT: READ AND SAVE THESE INSTRUCTIONS. Read carefully before attempting to assemble, install, operate or maintain the

product described. Protect yourself and others by observing all safety information. Failure to comply with instructions could result in

personal injury and/or property damage! Retain instructions for future reference.

Commercial Ceiling

Fans

Description

The VES commercial ceiling fans are a high efficiency, commercial ceiling fan. It

is designed to create air velocity and a cooling effect on high speed. The lower

speeds can be used for reduced velocity or heat de-stratification. The low speed

gently de-stratifies the air giving a constant room temperature. Models are UL &

cUL Certified.

Unpacking

1. After opening carton, look for concealed damage.

2. If concealed damage is found, immediately file claim with carrier.

Specifications

Model Size Volts Hertz Amps Watts RPM

INDA364L 36˝ 120 60 0.35 40 360

INDA484L 48˝ 120 60 0.50 50 320

INDA564L 56˝ 120 60 0.55 65 280

INDA56P 56˝ 120 60 0.55 65 280

General Safety Information

Disconnect power

supply before wiring

connections are made to prevent possible

electric shock or damage to equipment.

Read and follow

instructions carefully.

Failure to comply with instructions could

result in fire, electric shock, injury to

persons and/or damage to equipment.

Follow all

maintenance

procedures enclosed.

Failure to properly

ground unit could

result in severe electrical shock or death.

1. All wiring should conform to the

National Electrical Code ANSI/NFPA

70-1999 (NEC) in the United States,

CEC and local regulations.

2. Do not mount in an area which will

allow the ceiling fan to come in

contact with moisture.

3. Make certain the entire installation

is grounded as a precaution against

possible electrical shock.

4. Do not exceed maximum

amperage rating of the ceiling fan

as overloading can result in

damage to ceiling fan and control.

5. When wiring an electrical

appliance or device follow all electrical and safety codes, as well as

the most recent NEC, CEC and local

regulations and the Occupational

Safety and Health Act (OSHA).

6. Suitable for use with a VES solid

state speed control.

E249273

Assembly

1. Remove all ceiling fan parts from

the box.

2. Tools and supplies needed – Flat and

Phillips screwdriver – 9/16” and 3/8”

open wrench or adjustable wrench,

2-3 wire nuts.

3. Install a junction box to accept the

wiring of the fan. In many cases, a

qualified electrician will be required

to install the outlet box keeping

with local electrical codes or to

meet the NEC, CEC and local

regulations.

4. For installation to open web steel

joist – use threaded J-hook as

supplied. For wood joist

construction – use J-hook with lag

threads (not supplied. For attachment in concrete, drill concrete

anchors into the concretes as per

specification applicable to NEC, CEC

and local regulations.

Form IS1100

Version 1

01/2017

VES001

01/2017

624

Page 2

Operating Instructions & Parts Manual

Commercial Ceiling Fans

2

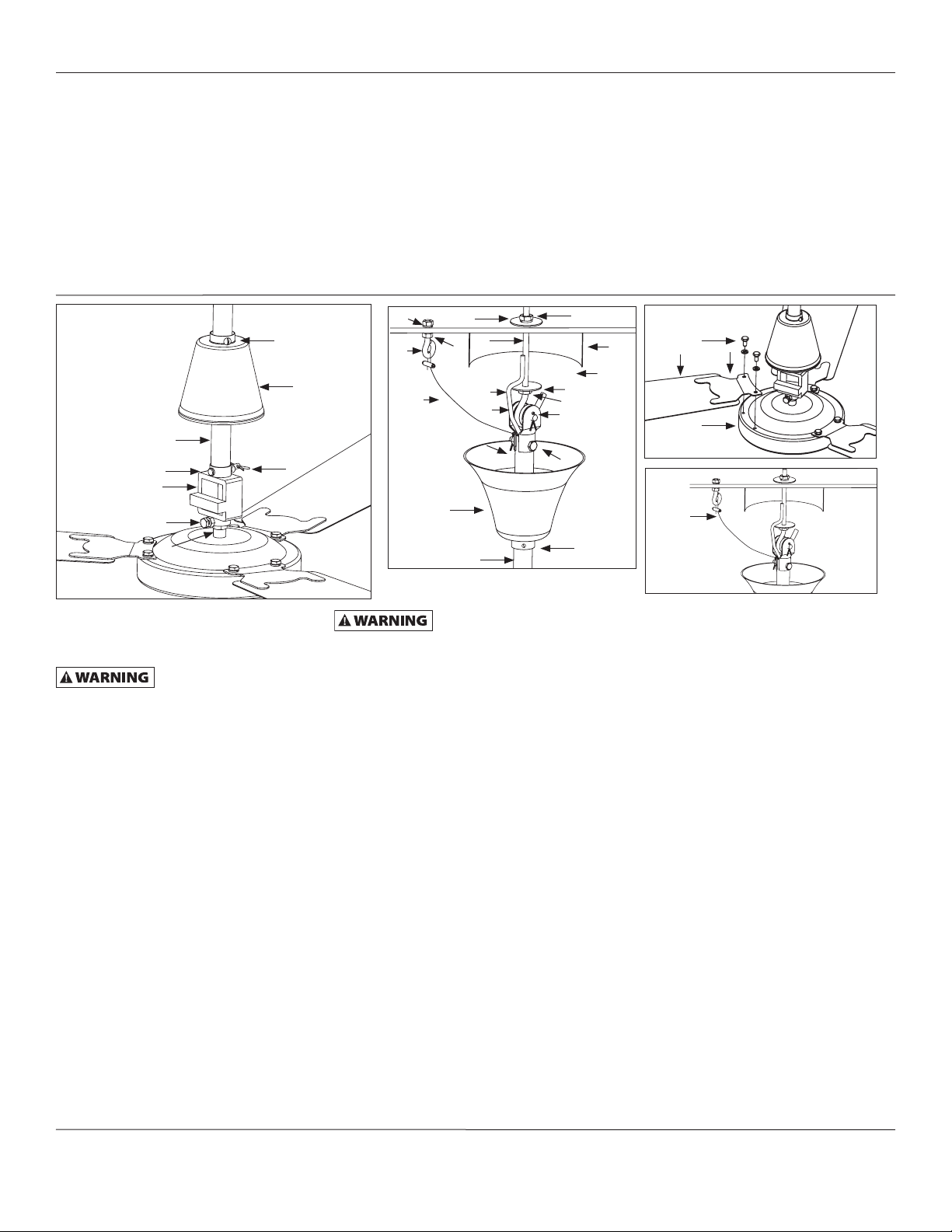

8

1

4

17

6

7

5

Figure #1

Installation

Safety Product Inspection of Fan Prior to

Installation (Figure #1 and #2)

To reduce the risk of

personal injury, do not

bend the blade brackets when installing the

brackets, balancing the blades or cleaning

the fan. Do not insert foreign objects in

between rotating fan blades.

1. Make certain set screw (4) is tight to

ascertain wobble free operation.

2. Make certain cotter pin (5) is in place

and secure.

3. Make certain lock-nut (7) is tight and

set screw (6) is in place and secure.

4. Slide lower canopy (8) down over

rubber gasket (21) to create a tight

seal.

5. Make certain lower canopy set

screws (2) are tight on downrod (1).

6. Make certain cotter pin (13) is in

place and secure.

7. Make certain bolt, cotter pin and nut

(16) are tight.

Hanging of Fan (Figure #1 and #2)

. Wind one nut (9) down to bottom of

J hook (12) towards the curve. Add a

lock washer and then flat washer (3)

on top of the nut (9).

30

31

11

Figure #2

Figure #4). Make certain safety cable is

attached properly to hook or structural

member. Failure to comply with instructions could result in personal injury and/

or property damage.

20

12

29

10

14

16

19

1

Make certain crimp on

safety loop is secure (See

22

3

9

13

15

18

2. Drill a 5/32” pilot hole for safety

hook (31) within a 12” radius of J

hook (12) support for fan. Wind one

nut down (29) to bottom of safety

hook towards the loop. Add a lock

washer (29) and slide safety hook

through pilot hole. Slide lock washer

(30)on top side of the safety hook

and add nut (30). Tighten so lock

washer on top and bottom of the

structure are secure.

3. Drill a 1/2” pilot hole for J hook. Put

J hook (12) through pilot hole in

joist. Add flat washer and then lock

washer (20) and nut (22). Do not

tighten completely until fan is put in

place on J hook. A lubricant should

not be used on the single mounting screw; and the pilot hole should

be drilled no larger than the minor

diameter of the mounting screw

threads, and at least 38 mm (1-1/2”)

28

27

23

25

26

24

Figure #3

11

Safety

Cable

Figure #4

of the threaded part of the mounting screw should be secured into

a structural joist to provide secure

mounting.

4. Loosen set screw (18) on top canopy

(19) on fan downrod (1) and lower

the canopy to make room to place

rubber grommet (14) onto

mounting hook.

5. Tighten top nut (22) on J hook to

raise fan into proper installation

position.

6. Ensure power to outlet box is off before hooking up wiring (10) (except

INDA56P see note below). Wire the

fan according to NEC, CEC and local

electrical codes (see Figure #5 or 6).

After making the wire connections

as outlined in Figure #5 or 6, the

wires should be spread apart with

the grounded conductor and the

equipment-grounding conductor on

one side of the outlet box and the

ungrounded conductor on the other

side of the outlet box. Splices should

be turned upward and pushed carefully up into the outlet box.

2

Page 3

Operating Instructions & Parts Manual

CEILING

FAN

Commercial Ceiling Fans

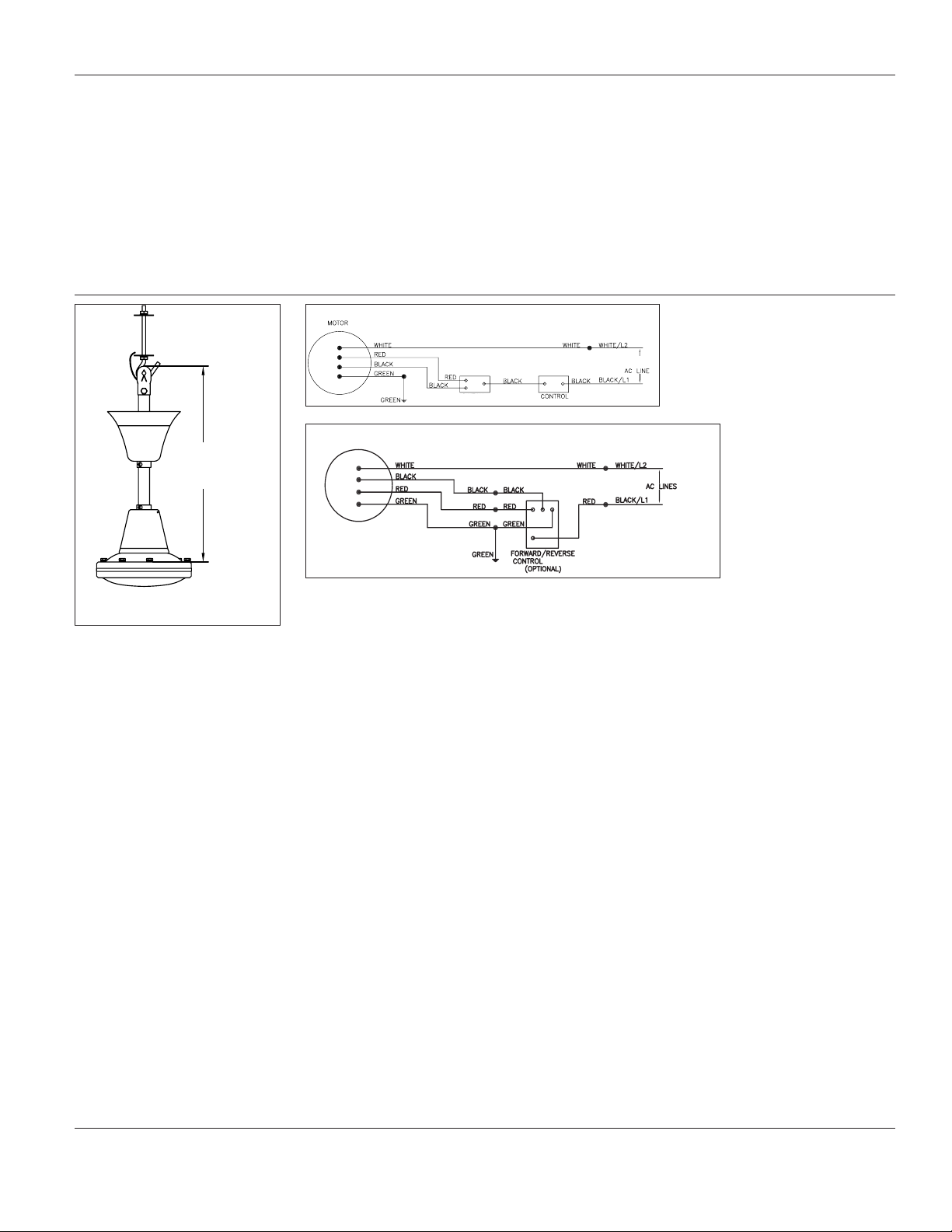

Figure #5 - Wiring diagram for Forward/

Top of Rubber

Grommet

18”

Reverse.

120V

Optional F/R Switch

Figure #6 - Wiring diagram for optional #ICFCFR5 control.

Flat surface

blades attach.

Length of downrod is

measured as shown above.

Note: Model INDA56P already has a 3

prong plug wired for 120V. Cord

must be plugged into a properly

wired 120V grounded outlet.

7. Raise top canopy (19) up the

downrod to cover hook. Leave 1/8”

gap between top canopy (19) and

hanging surface (so downrod does

not move off center which could

make fan wobble or vibrate and

transmit motor noise to ceiling

surface). Tighten set screw (18).

8. Attach blades (23) to motor (24)

with blade bolts (25). (Figure #3)

The blade (24) should be positioned

below the blade arm bracket (26)

when attaching to the motor to get

proper air flow and direction.

ICFCFR5

IMPORTANT:

The standard downrod installed properly

be mounted a minimum 10’ above the floor

level. It is critical that the “J” hook and nut

adjustment is done so that the blades will

be a minimum 12” from the ceiling. If your

ceiling is less that 12’ than the hook and

downrod must be recessed into the ceiling

so that the blades are mounted 10’ above

the floor level to meet OSHA standards.

Operation

For optimum fan performance, use the

VES model ICFCFR5 control to adjust

speed and direction of your fan (see

figure #6 for wiring). Follow the instructions included with the control for

minimum speed setting and operation.

The forward/reverse control will allow

you to adjust the speed and direction of

the fan. The forward/downdraft direction blows air down on high speed for

cooling or low speed for heat de-stratification. The reverse direction is idle

for heat de-stratification or creating air

movement without direct air flow.

3

Page 4

Operating Instructions & Parts Manual

Maintenance

Always disconnect the

power supply before

servicing the ceiling fan or

working with the unit for any reason.

Parts replacement and

troubleshooting to be

performed only by qualified personnel.

Do not place fingers or

objects in the ceiling

fan while motor is connected to the power

source.

Do not attach foreign

objects to the blades of

the ceiling fan.

Do not use gasoline,

benzene, thinner, harsh

cleaners, etc., which are dangerous and will

damage the ceiling fan.

If you see noticeable

vibration, wobbling or

wear the fan should be removed from service

and repaired or replaced by a qualified

maintenance technician or electrician.

• Below is the maintenance schedule

that must be followed and filled out

to be eligible for warranty and ensure

safe operation.

• Inspection should be every 3500

running hours or every 6 months.

• Maintenance schedule should include

repeating the product inspection

procedure and the fan hanging

procedure.

Initial Installation Date : ______________________ Name of installation supervisor : ______________________________

Maintenance Schedule

Maintenance Estimated Approved S - Scheduled Work Performed/

Date Running Hours Inspector Name: U - Unscheduled Notes/Comments

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

4

Page 5

Operating Instructions & Parts Manual

For Repair Parts, call 1-888-622-2999

Please provide following information:

- Model number

- Serial number (if any)

- Part description and number as shown in parts list

3

1

5

Replacement Part List

Ref. # Description

1 18” downrod w/rubber support

2 Lower canopy

3 Support hook

4 Upper canopy

5 Blade set curved (3 blades per set)

6 Capacitor

7 Motor housing with yoke

4

2

6

7

5

Page 6

Operating Instructions & Parts Manual

Troubleshooting Chart

Commercial Ceiling Fan is tested before it leaves the factory, resulting in an extremely low rate of returns. However, due to shipping and installation

procedures, occasionally a fan will need a minor adjustment to run satisfactorily.

If this should happen, we recommend that you identify the problem and try the

simple suggestions listed below.

Turn off power at main circuit breaker before checking!

Symptom Corrective Action

Fan will not start a) Check fuses and circuit breakers.

b) Check wire connections to fan.

c) Check wiring connection in lower canopy.

d) Check voltage at fan connection.

__________________________________________________________________________________________________________________

Fan too fast / slow a) Adjust the trim set screw in fan wall control if using optional wall control. If minimum

setting is too low the fan may shut off with voltage fluctuations. Increase minimum.

b) Check voltage at fan connection.

c) Blades must be attached to motor to reduce the speed.

__________________________________________________________________________________________________________________

Fan makes noise a) Check motor case to make certain all visible screws are snug.

b) Check to make certain that all blade bracket screws are tight.

c) Check for labels or wire nuts that could be rubbing.

d) All ceiling fans may have a slight motor noise known as the “60 cycle hum” when used

with solid state infinite speed controls. Especially on lower speeds. This hum will not

affect the fan performance.

e) Make certain upper canopy is at least 1/8” from ceiling

f) Allow a 30 days break-in period which normally eliminates any Residual noise other

than a), b), c), d) or e).

__________________________________________________________________________________________________________________

Fan wobbles a) Check that all blade brackets are screwed firmly to motor case.

b) Check distance from tip of blades to ceiling. If blades get bent during installation, you

must re-adjust them so that all blades travel on same plane. Gently bend up or down

until all distancea are the same.

c) Make certain upper canopy is 1/8” from ceiling.

d) Make certain that hanging hooks are secured tightly to ceiling.

e) Run fan without blade, if motor does not wobble, then motor is not defective but the

blades maybe bent.

6

Page 7

Operating Instructions & Parts Manual

LIMITED WARRANTY

VES ONE-YEAR LIMITED WARRANTY. MODELS COVERED IN THIS MANUAL, ARE WARRANTED BY VES ENVIRONMENTAL

SOLUTIONS, LLC. (VES) TO THE ORIGINAL USER AGAINST DEFECTS IN WORKMANSHIP OR MATERIALS UNDER NORMAL USE

FOR ONE YEAR AFTER DATE OF PURCHASE. ANY PART WHICH IS DETERMINED TO BE DEFECTIVE IN MATERIAL OR WORKMANSHIP AND RETURNED TO AN AUTHORIZED SERVICE LOCATION, AS VES DESIGNATES, SHIPPING COSTS PREPAID, WILL

BE, AS THE EXCLUSIVE REMEDY, REPAIRED OR REPLACED AT VES’S OPTION. FOR LIMITED WARRANTY CLAIM PROCEDURES,

SEE “PROMPT DISPOSITION” BELOW. THIS LIMITED WARRANTY GIVES PURCHASERS SPECIFIC LEGAL RIGHTS WHICH VARY

FROM JURISDICTION TO JURISDICTION.

LIMITATION OF LIABILITY. TO THE EXTENT ALLOWABLE UNDER APPLICABLE LAW, VES’S LIABILITY FOR

CONSEQUENTIAL AND INCIDENTAL DAMAGES IS EXPRESSLY DISCLAIMED. VES’S LIABILITY IN ALL EVENTS IS

LIMITED TO AND SHALL NOT EXCEED THE PURCHASE PRICE PAID.

WARRANTY DISCLAIMER. A DILIGENT EFFORT HAS BEEN MADE TO PROVIDE PRODUCT INFORMATION AND ILLUSTRATE

THE PRODUCTS IN THIS LITERATURE ACCURATELY; HOWEVER, SUCH INFORMATION AND ILLUSTRATIONS ARE FOR THE

SOLE PURPOSE OF IDENTIFICATION, AND DO NOT EXPRESS OR IMPLY A WARRANTY THAT THE PRODUCTS ARE

MERCHANTABLE, OR FIT FOR A PARTICULAR PURPOSE, OR THAT THE PRODUCTS WILL NECESSARILY CONFORM TO THE

ILLUSTRATIONS OR DESCRIPTIONS. EXCEPT AS PROVIDED BELOW, NO WARRANTY OR AFFIRMATION OF FACT, EXPRESSED

OR IMPLIED, OTHER THAN AS STATED IN THE “LIMITED WARRANTY” ABOVE IS MADE OR AUTHORIZED BY VES.

Technical Advice and Recommendations, Disclaimer. Notwithstanding any past practice or dealings or trade custom,

sales shall not include the furnishing of technical advice or assistance or system design. VES assumes no obligations or

liability on account of any unauthorized recommendations, opinions or advice as to the choice, installation or use of

products.

Product Suitability. Many jurisdictions have codes and regulations governing sales, construction, installation, and/or use of

products for certain purposes, which may vary from those in neighboring areas. While attempts are made to ascertain that

VES products comply with such codes, VES cannot guarantee compliance, and cannot be responsible for how the

product is installed or used. Before purchase and use of a product, review the product applications, and all applicable

national and local codes and regulations, and be certain that the product, installation, and use will comply with them.

Certain aspects of disclaimers are not applicable to consumer products; e.g., (a) some jurisdictions do not allow the

exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you;

(b) also, some jurisdictions do not allow a limitation on how long an implied warranty lasts, consequently the above

limitation may not apply to you; and (c) by law, during the period of this Limited Warranty, any implied warranties of

implied merchantability or fitness for a particular purpose applicable to consumer products purchased by consumers, may

not be excluded or otherwise disclaimed.

Prompt Disposition. A good faith effort will be made for prompt correction or other adjustment with respect to any

product which proves to be defective within limited warranty. For any product believed to be defective within limited

warranty, first write or call dealer from whom the product was purchased. Dealer will give additional directions. If unable

to resolve satisfactorily, write to VES at address below, giving dealer’s name, address, date, and number of dealer’s

invoice, and describing the nature of the defect. Title and risk of loss pass to buyer on delivery to common carrier.

If product was damaged in transit to you, file claim with carrier.

Manufactured for VES Environmental Solutions, LLC. 8296 Commerce Pkwy, Ste 2, Chippewa Falls, WI 54729 USA U.S.A.

7

Loading...

Loading...