Page 1

Liebert®

PFD™ Prop Fan Digital Condensing Unit

ThermalManagementSystems

Installer/User Guide

Page 2

The information contained in this document is subject to change

without notice and may not be suitable for all applications. While

every precaution has been taken to ensure the accuracy and

completeness of this document, Vertiv assumes no responsibility

and disclaims all liability for damages resulting from use of this

information or for any errors or omissions. Refer to other local

practices or building codes as applicable for the correct methods,

tools, and materials to be used in performing procedures not

specifically described in this document.

The products covered by this instruction manual are manufactured

and/or sold by Vertiv This document is the property of Vertiv and

contains confidential and proprietary information owned by Vertiv.

Any copying, use or disclosure of it without the written permission

of Vertiv is strictly prohibited.

Names of companies and products are trademarks or registered

trademarks of the respective companies. Any questions regarding

usage of trademark names should be directed to the original

manufacturer.

Technical Support Site

If you encounter any installation or operational issues with your product, check the pertinent

section of this manual to see if the issue can be resolved by following outlined procedures.

Visit https://www.VertivCo.com/en-us/support/ for additional assistance.

Vertiv | Liebert® PFD™ Installer/User G uide

Page 3

TABLE OF CONTENTS

1 Important Safety Instructions 5

1.1 Agency Listed 6

2 Nomenclature and Components 7

2.1 PFD Model Number Nomenclature 7

2.2 Component Location 8

3 Pre-installation PreparationandGuidelines 9

3.1 Planning Dimensions 9

3.1.1 Location Considerations for Outdoor Condensing Unit 9

3.2 Connections and System Setup 10

3.3 PFD Unit Weights 10

3.4 Equipment Inspection and Handling 10

4 Piping and Refrigerant Requirements 11

4.1 Refrigerant Piping 11

4.1.1 Refrigerant Piping Guidelines forAir-cooledSystems 12

4.1.2 Piping when Condensing Unit is Above or Below Evaporator 13

4.2 Refrigerant-line Sizes and Equivalent Lengths 14

4.2.1 Refrigerant Charge Requirements 14

4.2.2 Additional Oil Requirements for Digital-scroll Compressors 19

5 Electrical Connection Requirements 21

5.1 Low-voltage, Control Connections 22

6 Checklist for Completed Installation 23

7 Initial Start-up Checks andCommissioning ProcedureforWarrantyInspection 25

8 Maintenance 27

8.1 General Maintenance 28

8.2 Compressor Maintenance 28

8.2.1 Compressor Oil 28

8.2.2 Replacement Compressors 28

8.2.3 Compressor Motor Burnout 29

8.2.4 Unloading Solenoid(s) on a Digital-scroll Compressor 29

8.2.5 Replacing the Compressor 29

8.3 Condensing Unit Maintenance 30

9 Troubleshooting 31

Appendices 33

Appendix A: Technical Support and Contacts 33

Appendix B: Submittal Drawings 35

Vertiv | Liebert® PFD™ Installer/User Guide | 3

Page 4

Vertiv | Liebert® PFD™ Installer/User Guide | 4

Page 5

1 IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

This manual contains important safety instructions that should be followed during the installation and

maintenance of the Liebert®PFD. Read this manual thoroughly before attempting to install or operate

this unit.

Only qualified personnel should move, install or service this equipment.

Adhere to all warnings, cautions, notices and installation, operating and safety instructions on the unit

and in this manual. Follow all installation, operation and maintenance instructions and all applicable

national and local building, electrical and plumbing codes.

WARNING! Arc flash and electric shock hazard. Open all local and remote electric power-supply

disconnect switches, verify with a voltmeter that power is Off and wear appropriate,

OSHA-approved personal protective equipment (PPE) per NFPA 70E before working within the

electric control enclosure. Failure to comply can cause serious injury or death. Customer must

provide earth ground to unit, per NEC, CEC and local codes, as applicable. Before proceeding

with installation, read all instructions, verify that all the parts are included and check the

nameplate to be sure the voltage matches available utility power. The Liebert® controller does

not isolate power from the unit, even in the “Unit Off” mode. Some internal components require

and receive power even during the “Unit Off” mode of the controller. The only way to ensure

that there is NO voltage inside the unit is to install and open a remote disconnect switch. Refer

to unit electrical schematic. Follow all local codes.

WARNING! Risk of over-pressurization of the refrigeration system. Can cause explosive

discharge of high-pressure refrigerant, loss of refrigerant, environmental pollution, equipment

damage, injury, or death. This unit contains fluids and gases under high pressure. Use extreme

caution when charging the refrigerant system. Do not pressurize the system higher than the

design pressure marked on the unit's nameplate. Relieve pressure before cutting into or

making connections/disconnections to the piping system.

Do not close off any field-installed, refrigerant-line isolation valves for repairs unless a

pressure-relief valve is field- installed in the line between the isolation valve and the check valve.

The pressure-relief valve must be rated 5% to 10% higher than the system-design pressure. An

increase in ambient temperature can cause the pressure of the isolated refrigerant to rise and

exceed the system-design pressure rating (marked on the unit nameplate).

WARNING! Risk of contact with high-speed, rotating fan impeller blades. Can cause injury or

death. Open all local and remote electric power-supply disconnect switches, verify with a

voltmeter that power is off, and verify that all fan impellers have stopped rotating before

working in the unit cabinet.

WARNING! Risk of electric shock. Can cause serious injury or death. The Liebert® iCOM

microprocessor does not isolate power from the unit, even in the "Unit Off" mode. Some internal

components require and receive power even during the "unit off" mode of the Liebert® iCOM

control. Open all local and remote electric power disconnect switches and verify with a

voltmeter that power is Off before working on any component of the system.

CAUTION: Risk of contact with sharp edges, splinters, and exposed fasteners. Can cause

injury. Only properly trained and qualified personnel wearing appropriate, OSHA-approved PPE

should attempt to move, lift, remove packaging from or prepare the unit for installation.

1 Important Safety Instructions 5

Page 6

NOTICE

NOTICE

CAUTION: Risk of contact with hot surfaces. Can cause injury. The compressor, refrigerant

discharge lines, fan motor, and some electrical components are extremely hot during unit

operation. Allow sufficient time for them to cool to a touch-safe temperature before working

within the unit cabinet. Use extreme caution and wear appropriate, OSHA-approved PPE when

working on or near hot components.

Risk of oil contamination with water. Can cause equipment damage.

Liebert®PFD systems require the use of POE (polyolester) oil. POE oil absorbs water at a much

faster rate when exposed to air than previously used oils. Because water is the enemy of a

reliable refrigeration system, extreme care must be used when opening systems during

installation or service. If water is absorbed into the POE oil, it will not be easily removed and will

not be removed through the normal evacuation process. If the oil is too wet, it may require an oil

change. POE oils also have a property that makes them act as a solvent in a refrigeration

system. Maintaining system cleanliness is extremely important because the oil will tend to

bring any foreign matter back to the compressor.

Risk of improper refrigerant charging. Can cause equipment damage.

Refrigerant charge must be weighed into air-cooled compressorized systems before they are

started. Starting digital scroll compressors without proper refrigerant charging can cause the

compressors to operate at less than 5°F (–15°C) evaporator temperature and at less than

55psig (379kPa). Operation for extended periods at less than 55psig (379kPa) can cause

premature compressor failure.

NOTICE

Risk of damage from forklift. Can cause unit damage. Keep tines of the forklift level and at a

height suitable to fit below the skid and/or unit to prevent exterior and/or underside damage.

NOTICE

Risk of improper storage. Can cause unit damage.

Keep the unit upright, indoors and protected from dampness, freezing temperatures and

contact damage.

1.1 Agency Listed

Standard 60-Hz units are CSA Certified to the harmonized U.S. and Canadian product safety standard

CSA C22.2 No 236/UL 1995 for “Heating and Cooling Equipment” and are marked with the CSA c-us logo.

6

Vertiv | Liebert® PFD™ Installer/User G uide

Page 7

2 NOMENCLATURE AND COMPONENTS

This section describes the model number for Liebert® PFD units and components.

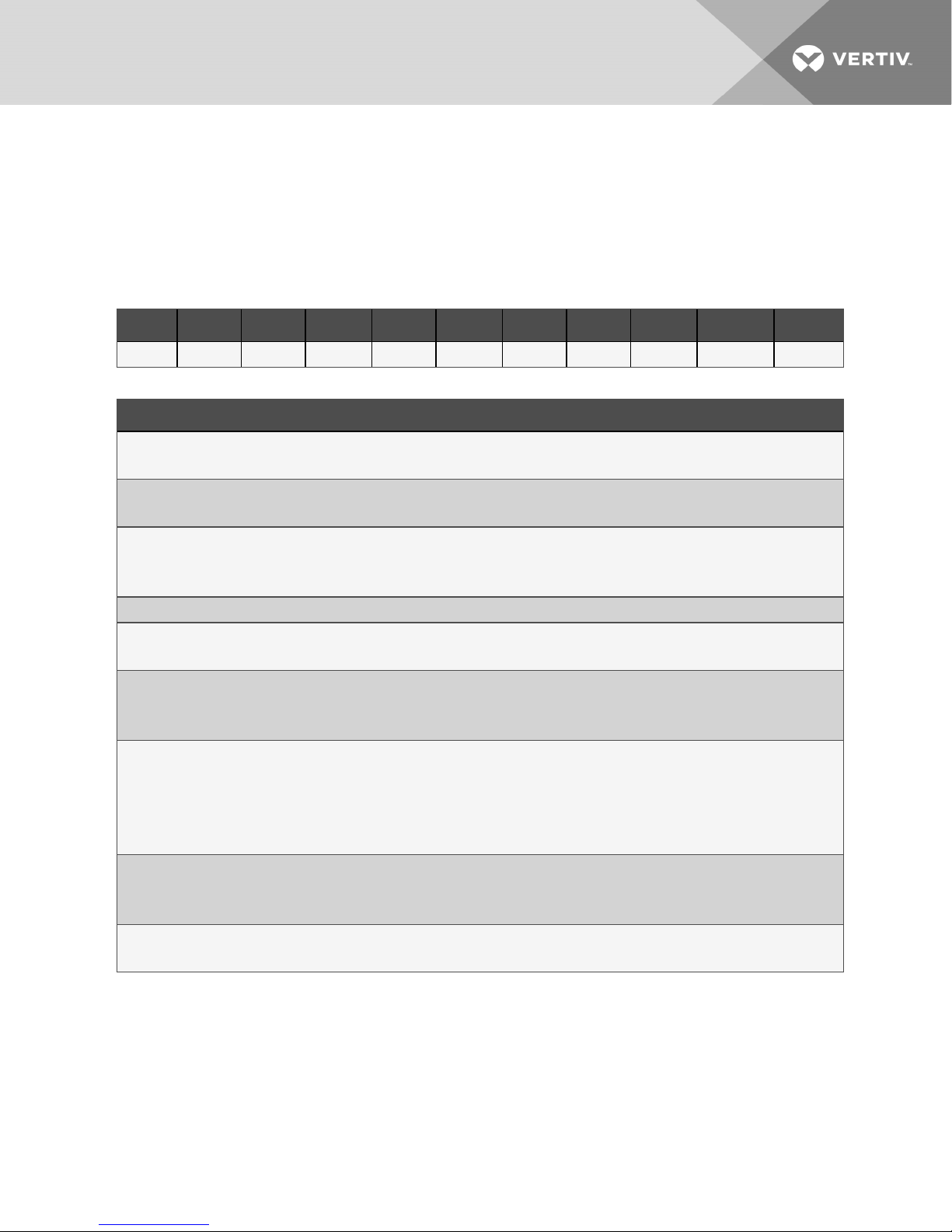

2.1 PFD Model Number Nomenclature

Table 2.2 below describes each digit of the model number.

Table 2.1 Prop-fan Condensing Unit Model-number Example

1 2 3 4 5 6 7 8 9 10 11

P F D 0 6 7 A — A L 1

Table 2.2 Model-number Digit Definitions for Outdoor, Prop-fan Condensing Units

Digit and Description

Digits 1, 2 = The base unit

PF = Prop-fan condensing unit

Digit 3 = Compressor type

D = Digital-scrollcompressor

Digit 4= Sound level

0 = Standard

Z = Quiet-Line (067 models only)

Digits 5 and 6 = Nominal Capacity, 1,000 BTU/hr

Digit 7= Unit type

A = Air-cooled

Digit 8 = Coil type

— = Standard coil

C = Coated coil

Digit 9= Supplypower

A = 460V / 3ph / 60Hz

B = 575V/ 3ph/ 60Hz(054 and067 models only)

P = 208-230 V / 1 ph / 60 Hz (037 model only)

Y = 208-230 V / 3ph/ 60Hz

Digit 10 = Head-pressure control

L = 95°F Ambient, Liebert® Lee-Temp™

H = 105°F Ambient, Liebert® Lee-Temp™ (not available on 048 model)

Digit 11= Refrigerant

1 = R-410A, field-supplied

2 Nomenclature and Components 7

Page 8

2.2 Component Location

The unit component locations are described in the submittal documents included in the Submittal

Drawings on page35.

The following tables list the relevant documents by number and title.

Table 2.3 Component-location Drawings

Document Number Title

DPN004180 PFDCondensing Unit, 3-, 4-, and 5-ton

8

Vertiv | Liebert® PFD™ Installer/User G uide

Page 9

3 PRE-INSTALLATION PREPARATIONANDGUIDELINES

NOTE: Before installing unit, determine whether any building alterations are required to run piping,

wiring and ductwork. Follow all unit dimensional drawings and refer to the submittal engineering

dimensional drawings of individual units for proper clearances.

Refer to PFD Model Number Nomenclature on page7, and submittal drawings to determine the type of

system being installed and anticipate building alterations, piping and ductwork needed.

The unit dimensions, pipe-connection locations, and piping schematics are described in the submittal

documents included in the Submittal Drawings on page35.

• Allow at least the minimum recommended clearances maintenance, and service. See the

appropriate submittal drawings for dimensions.

• Be mindful of the placement of the PFD in relation to the connected evaporator unit, other

outside units, barriers, and walls for air flow clearance, equivalent piping distances, and

differences in elevation between the PFD and connected evaporator unit.

• When applications do not meet or exceed any of these specifications, contact your Vertiv

representative.

3.1 Planning Dimensions

The unit dimensions described in the submittal documents included in the Submittal Drawings on

page35.

The following table lists the relevant documents by number and title.

Table 3.1 Dimension Planning Drawings

Document Number Title

Outdoor Condensing Unit

DPN004058 Cabinet dimensions, 5-ton, top discharge

DPN004063 Cabinet dimensions, 3-, 4-, and 5-ton, horizontaldischarge

DPN004066 Optional anchoring plan, 3-, 4-, and 5-ton, horizontaldischarge

3.1.1 Location Considerations for Outdoor Condensing Unit

Observe the following when planning the installation of the outdoor unit:

• To ensure a satisfactory air supply, locate air-cooled condensing units in an environment with

clear air, away from loose dirt and foreign matter that may clog the coil.

• Condensing units must not be located in the vicinity of steam, hot air or fume exhausts or

closer than 18 inches from a wall, obstruction or adjacent unit.

• For multiple-unit installations, space the units so that the hot, condensing-unit exhaust air is

not directed toward the air inlet of an adjacent unit.

• Avoid areas where heavy snow will accumulate at air inlet and discharge locations.

• The condensing unit should be located for maximum security and maintenance accessibility.

Avoid ground-level sites with public access. Install a solid base, capable of supporting the

weight of the condensing unit.

• The base should be at least 2in. (51mm) higher than the surrounding grade and 2 in. (51mm)

larger than the dimensions of the condensing-unit base. For snowy areas, a base of sufficient

height to clear snow accumulation must be installed.

Before beginning, refer to Piping and Refrigerant Requirements on page11 for unit placement, piping

guidelines, and refrigerant-charge requirements for your system.

The condensing unit must be located within the maximum distance from evaporator per the guidelines

listed in Pipe length and condenser elevation relative to evaporator.

3 Pre-installation PreparationandGuidelines 9

Page 10

3.2 Connections and System Setup

• Electrical service is required for all models. Electrical service must conform to national and local

electrical codes. See equipment nameplate for details.

• Plan the routing of wiring, piping and ductwork to the unit. Refer to the appropriate piping

connection location drawings, piping schematics, and electrical-connection drawings for your

system in .

3.3 PFD Unit Weights

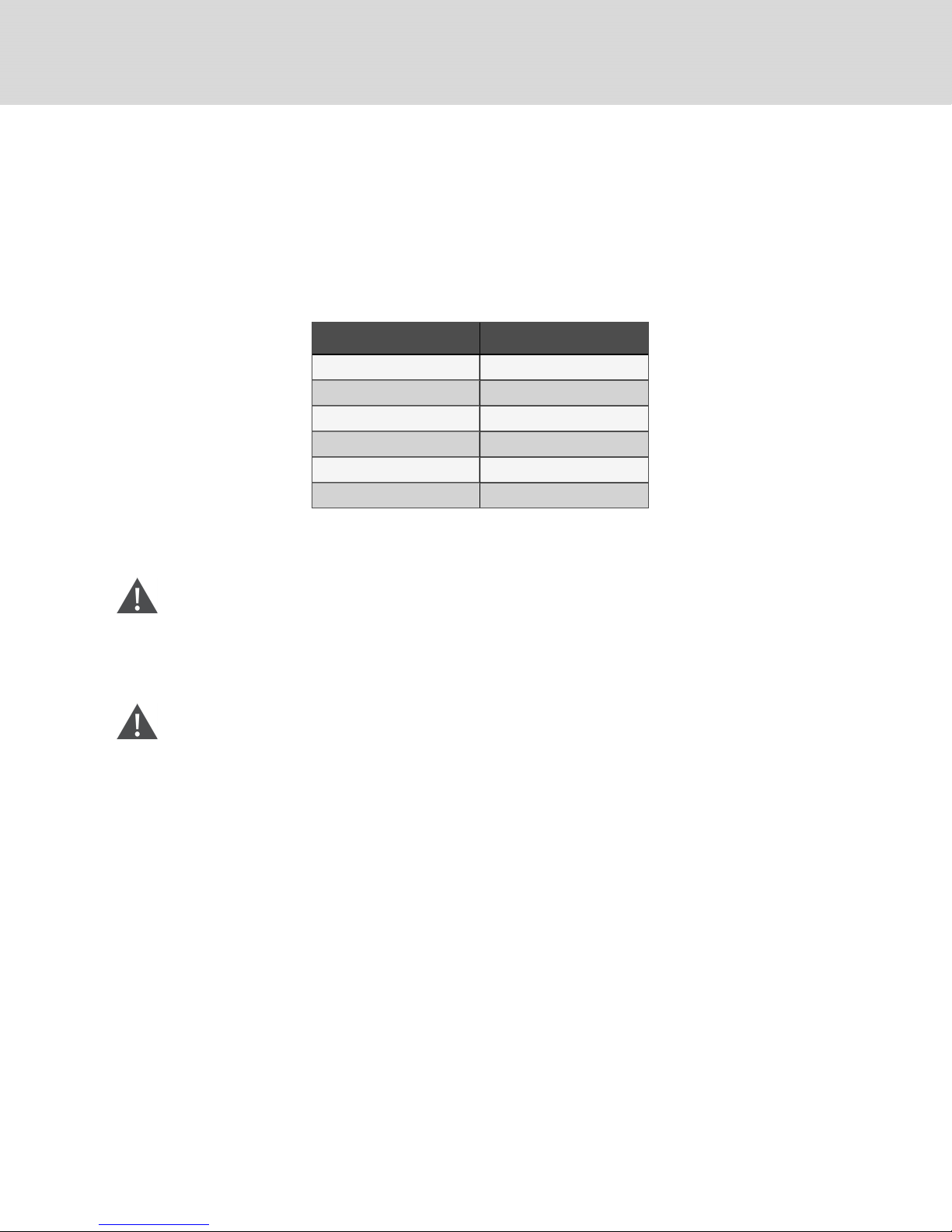

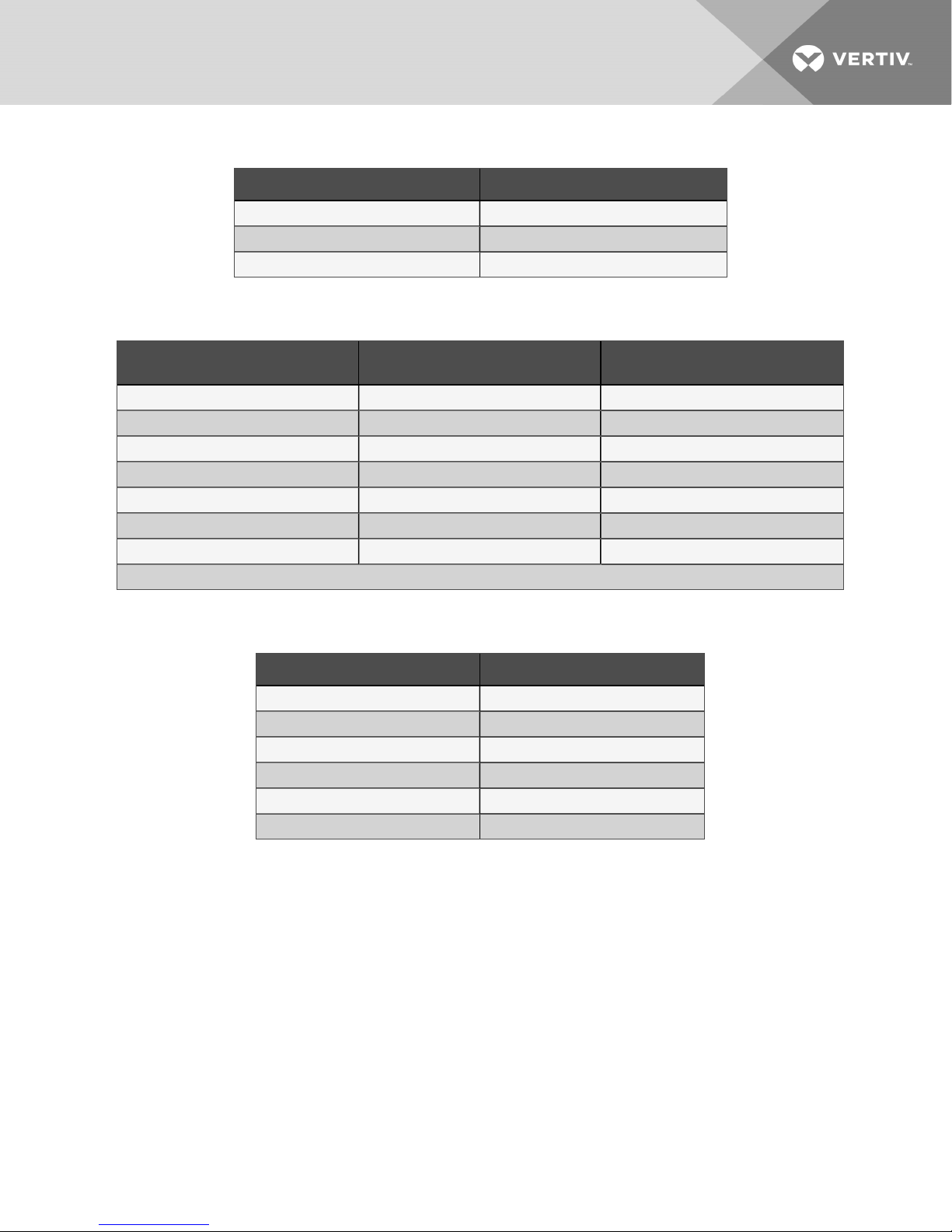

Table 3.2 PFD Unit weights

Model # Weight, lb (kg)

PFD037A-L 244 (111)

PFD037A-H 351 (159)

PFD054A-L 351 (159)

PFD067A-L 351 (159)

PFD067A-H 488 (222)

PFDZ67A-L 488 (222)

3.4 Equipment Inspection and Handling

SAFETY INFORMATION

WARNING! Risk of improper moving, lifting, or handling of the unit. Can cause equipment

damage, injury or death. Read all of the following instructions and verify that all lifting and

moving equipment is rated for the weight of the unit before attempting to move, lift, remove

packaging from or prepare the unit for installation. Unit weights are specified in Table 3.2

above.

CAUTION: Risk of contact with sharp edges, splinters, and exposed fasteners. Can cause

injury. Only properly trained and qualified personnel wearing appropriate, OSHA-approved PPE

should attempt to move, lift, remove packaging from or prepare the unit for installation.

NOTICE

Risk of damage from forklift. Can cause unit damage. Keep tines of the forklift level and at a

height suitable to fit below the skid and/or unit to prevent exterior and/or underside damage.

When the unit arrives, inspect all items for any visible or concealed damage. Report any damage to the

carrier immediately and file a damage claim. Send a copy of the claim to your Vertiv representative.

If possible, maintain equipment and packaging until it is at the installation location.

10

Vertiv | Liebert® PFD™ Installer/User G uide

Page 11

4 PIPING AND REFRIGERANT REQUIREMENTS

All refrigeration connections to the unit are sweat copper. Factory-installed piping brackets must not be

removed. Field-installed piping must be installed in accordance with local codes and must be properly

assembled, supported, isolated and insulated. Avoid piping runs through noise-sensitive areas, such as

office walls and conference rooms.

Refer to specific text and detailed diagrams in this manual for other unit-specific piping requirements.

The pipe connection locations, piping general arrangement and schematics are described in the

submittal documents included in the Submittal Drawings on page35.

The following tables list the relevant documents by number and title.

Table 4.1 Piping General-arrangment Drawings

Document Number Title

DPN004060 Piping arrangement, 3-, 4- and 5-ton split-system

Table 4.2 Piping Connection Drawings

Document Number Title

DPN004059 Primary connection locations, top discharge

DPN004064 Primaryconnection locations, horizontaldischarge

4.1 Refrigerant Piping

WARNING! Risk of over-pressurization of the refrigeration system. Can cause explosive

discharge of high-pressure refrigerant, loss of refrigerant, environmental pollution, equipment

damage, injury, or death. This unit contains fluids and gases under high pressure. Use extreme

caution when charging the refrigerant system. Do not pressurize the system higher than the

design pressure marked on the unit's nameplate. Relieve pressure before cutting into or

making connections/disconnections to the piping system.

Do not close off any field-installed, refrigerant-line isolation valves for repairs unless a

pressure-relief valve is field- installed in the line between the isolation valve and the check valve.

The pressure-relief valve must be rated 5% to 10% higher than the system-design pressure. An

increase in ambient temperature can cause the pressure of the isolated refrigerant to rise and

exceed the system-design pressure rating (marked on the unit nameplate).

Consult local building and plumbing codes for installation requirements of additional pressure-relief

devices when isolation valves are field installed. Do not isolate any refrigerant circuits from overpressurization protection. The PFD condensing unit includes a factory-installed pressure-relief valve

mounted on top of the receiver. The valve is rated for a maximum working pressure of 675psig.

4 Piping and Refrigerant Requirements 11

Page 12

NOTICE

Risk of oil contamination with water. Can cause equipment damage.

Liebert®PFD systems require the use of POE (polyolester) oil. POE oil absorbs water at a much

faster rate when exposed to air than previously used oils. Because water is the enemy of a

reliable refrigeration system, extreme care must be used when opening systems during

installation or service. If water is absorbed into the POE oil, it will not be easily removed and will

not be removed through the normal evacuation process. If the oil is too wet, it may require an oil

change. POE oils also have a property that makes them act as a solvent in a refrigeration

system. Maintaining system cleanliness is extremely important because the oil will tend to

bring any foreign matter back to the compressor.

NOTICE

Risk of improper refrigerant charging. Can cause equipment damage.

Refrigerant charge must be weighed into air-cooled compressorized systems before they are

started. Starting digital scroll compressors without proper refrigerant charging can cause the

compressors to operate at less than 5°F (–15°C) evaporator temperature and at less than

55psig (379kPa). Operation for extended periods at less than 55psig (379kPa) can cause

premature compressor failure.

4.1.1 Refrigerant Piping Guidelines forAir-cooledSystems

• Evaporators and condensing units ship with an inert-gas holding charge. Do not vent the

evaporator and condensing unit until all refrigerant piping is in place, ready for connection to

the unit and condensing unit.

• Use copper piping with a brazing alloy with a minimum temperature of 1350°F (732°C), such as

Sil-Fos. Avoid soft solders, such as 50/50 or 95/5.

• Use a flow of dry nitrogen through the piping during brazing to prevent formation of copper

oxide scale inside the piping. When copper is heated in the presence of air, copper oxide forms.

POE oils will dissolve these oxides from inside the copper pipes and deposit them throughout

the system, clogging filter driers and affecting other system components.

• A pure dry nitrogen flow of 1-3 ft3/min (0.5-1.5 l/s) inside the pipe during brazing is sufficient to

displace the air. Control the flow using a suitable measuring device.

• Ensure that the tubing surfaces to be brazed are clean and that all burrs have been removed

from the ends of the tubes.

• Ensure that all loose material has been cleaned from inside the tubing before brazing.

• Protect all refrigerant line components within 18in. (460mm) of the brazing site by wrapping

them with a wet cloth or with a suitable heat-sink compound.

• Isolate piping from building using vibration-isolating supports.

• When sealing openings in walls and to reduce vibration transmission, use a soft, flexible

material to pack around the tubes to prevent tube damage.

• When installing remote condensing units above the evaporator, the suction gas lines should be

trapped at the evaporator. These traps will retain refrigerant oil in the off cycle. When the unit

starts, oil in the traps is carried up the vertical risers and returns to the compressors. For rises

over 25ft (7.6m), trap every 20ft (6m)or evenly-divided.

• Consult factory if piping run exceeds 150ft(46m) equivalent length.

• Keep piping clean and dry, especially on units with R-410A refrigerant.

• Avoid piping runs through noise-sensitive areas.

• Do not run piping directly in front of discharge air stream.

• Refrigerant oil – do not mix oil types.

Refer to ASHRAE Refrigeration Handbook for general, good-practice refrigeration piping.

12

Vertiv | Liebert® PFD™ Installer/User G uide

Page 13

NOTE: All indoor and outdoor suction-line piping must have 1/2 in. minimum of insulation. All outdoor

insulation must be UV and ozone resistant.

NOTE: Proper safety equipment and proper refrigeration tools are required when working with R-410A

refrigerant. Check unit serial tag for correct refrigerant type before topping-off or recharging a system.

NOTE: Refrigerant R-410A uses a POE (polyolester) lubricant. The refrigerant must be introduced and

charged from the cylinder only as a liquid.

NOTE: When installing field piping, you must take care to protect all refrigerant lines from the

atmosphere especially when using refrigerants with POE oils. Do not allow the piping to stand open to

air for more than 15minutes. Units designed for R-410A have a compressor that contains POEoil,

which quickly absorbs water from the air. The longer that the refrigerant piping is left open to air, the

harder it will be to fully evacuate the system. If left open too long, the POE oil may require replacement

to achieve the required vacuum level.

• Refer to Refrigerant-line Sizes and Equivalent Lengths on the next page,for recommended

refrigerant piping sizes based on equivalent pipe lengths.

• Refer to Refrigerant Charge Requirements on the next page, for the refrigerant-charge

requirements of the system.

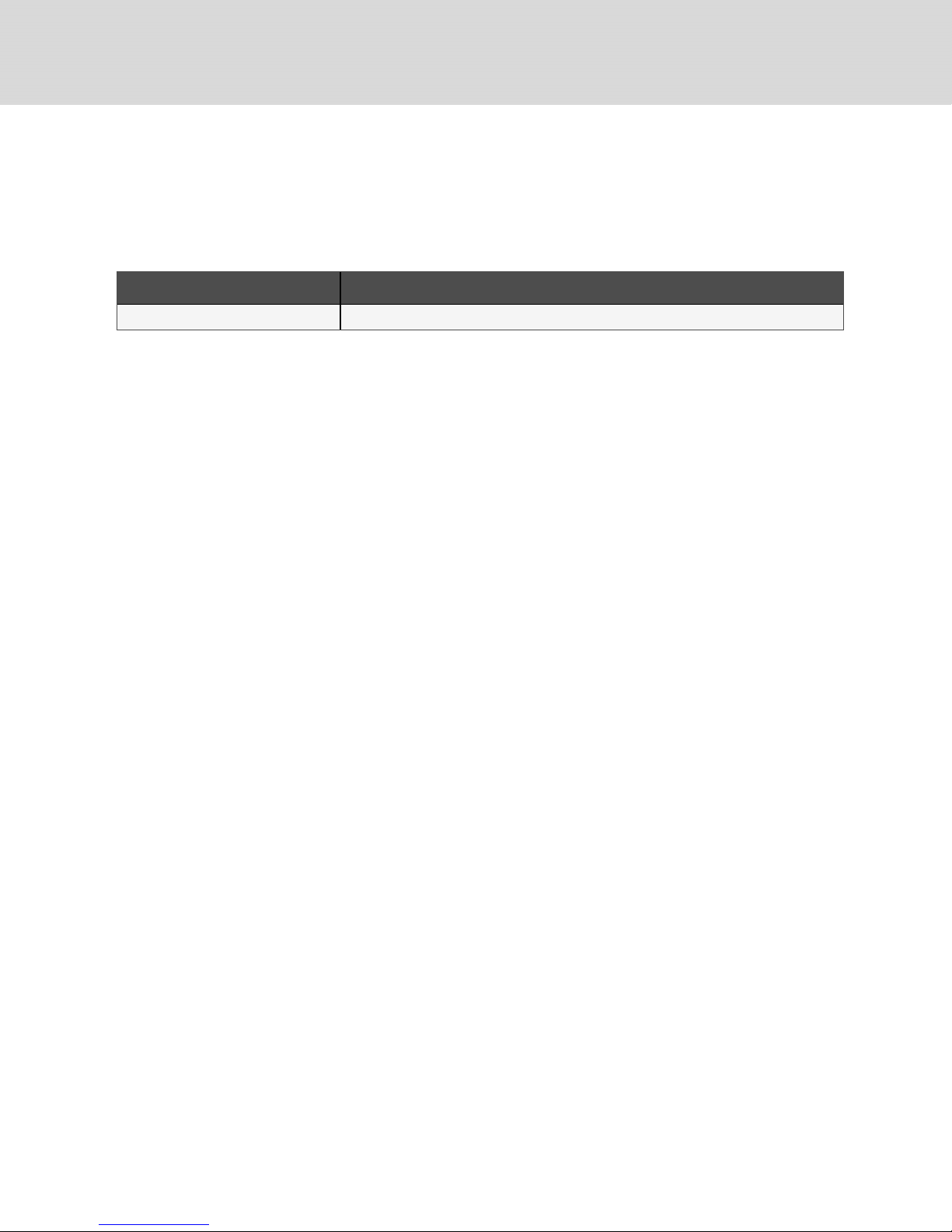

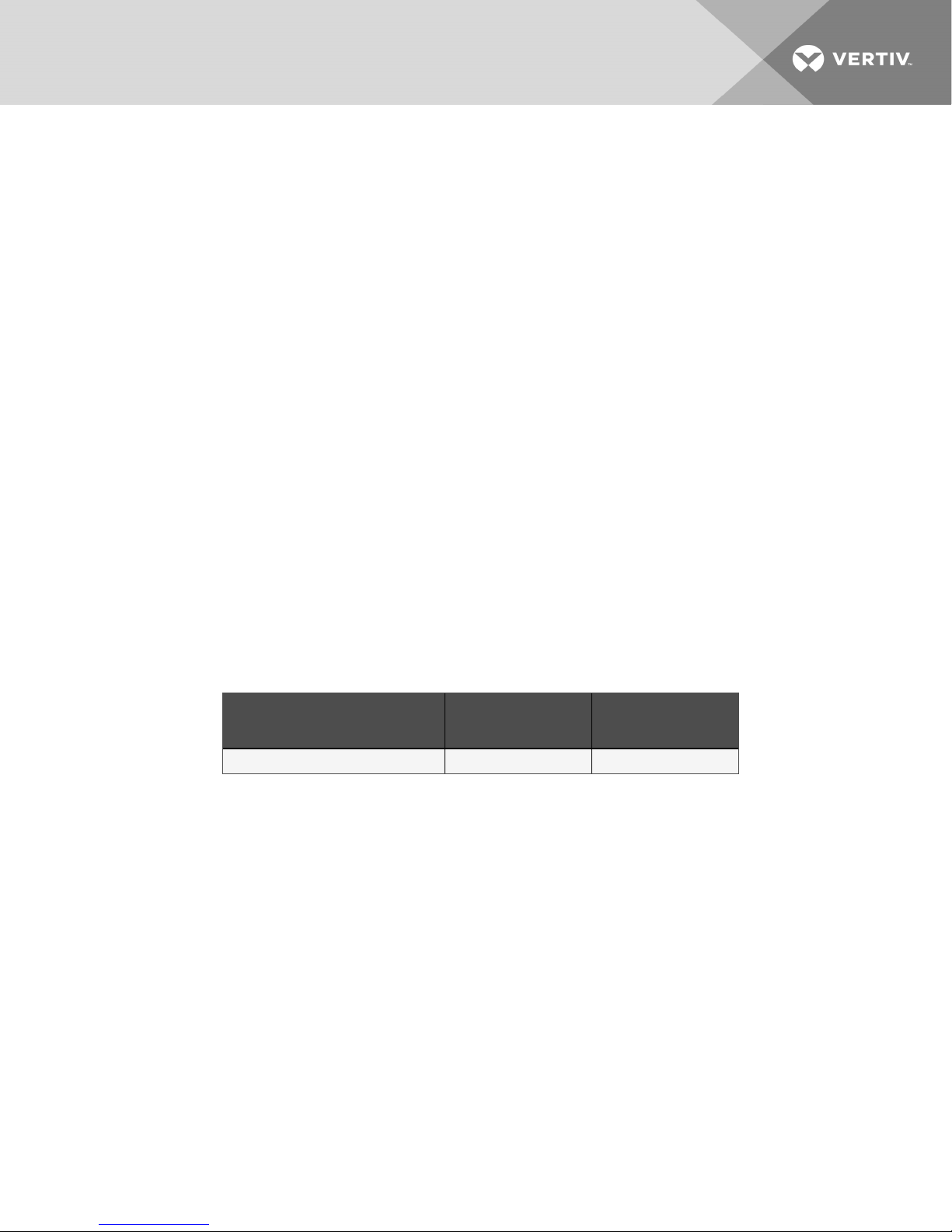

4.1.2 Piping when Condensing Unit is Above or Below Evaporator

Refer to Table 4.3 below for the maximum vertical rise/fall between condensing unit and evaporator.

When installing remote condensing units above the evaporator, trap the suction gas line at the

evaporator as shown in Figure 4.1 on the next page. This trap will retain refrigerant oil during the "Off"

cycle. When the unit starts, oil in the trap is carried up the vertical riser and returns to the compressor.

When installing remote condensing units below the evaporator, trap the suction gas line with an inverted

trap the height of the evaporator as shown in the following figure. This prevents refrigerant migration to

the compressor during "Off" cycles.

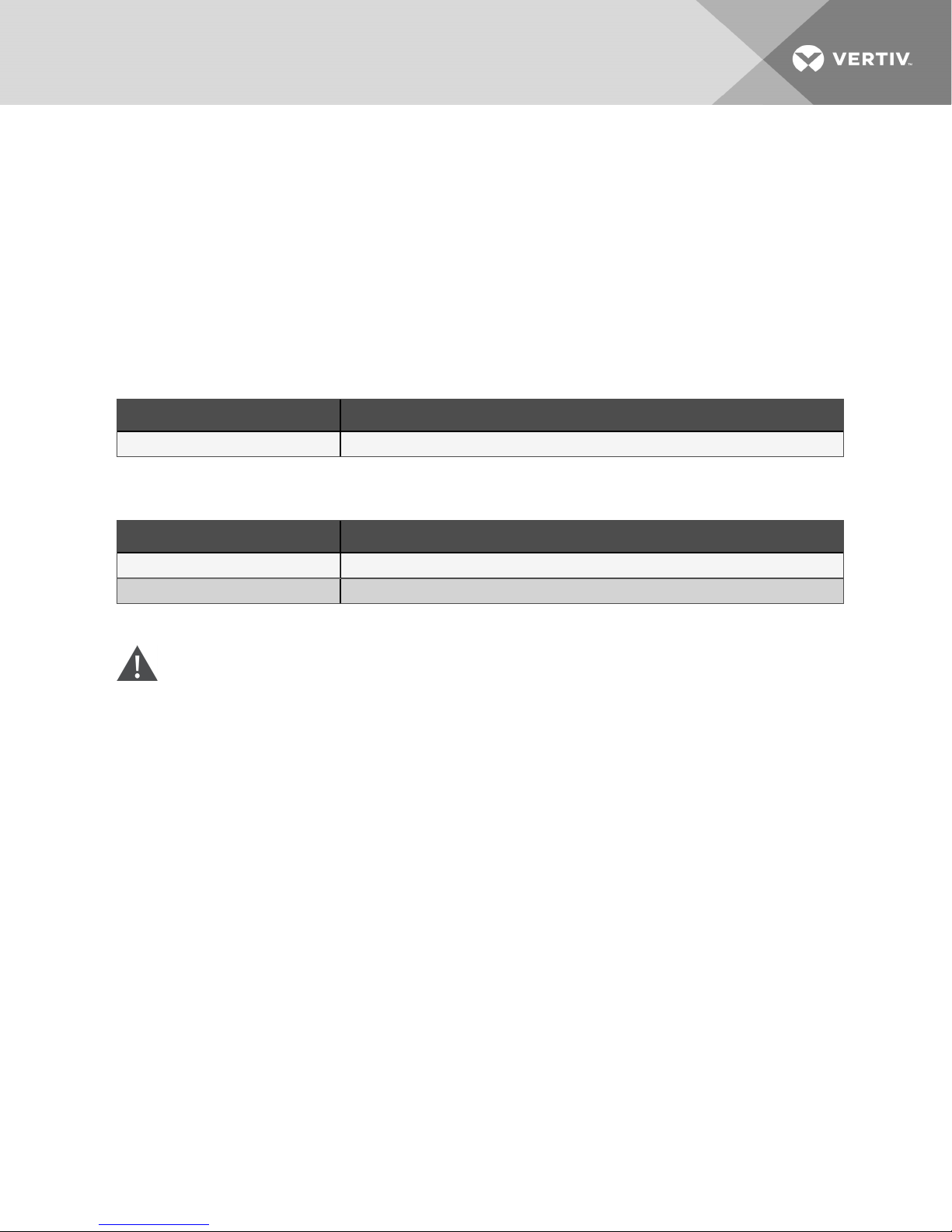

Table 4.3 Pipe length and condensing unit elevation relative to

evaporator

Maximum Equivalent Pipe Length, ft (m)

150 (45) 50 (15) 15 (4.6)

Maximum

Condensing-unit Level

Above Evaporator, ft (m)

Maximum

Condensing-unit Level

BelowEvaporator, ft (m)

4 Piping and Refrigerant Requirements 13

Page 14

Figure 4.1 Refrigerant piping when condensing unit is above or below evaporator

Item Description

1 Condensing unit above evaporator

2 Condensing unit below evaporator

3 Evaporator

4 Condensing unit

4.2 Refrigerant-line Sizes and Equivalent Lengths

The following tables list the information required to field-install the refrigerant piping for the system.

Table 4.4 Recommended refrigerant line sizes, O.D.cubyequivalentlength

Equivalent Length, ft (m)

System Models

50 (15) 75 (23) 100 (30) 125 (38) 150 (45)

MT036E/PFD037A-*L or PFD037A-*H

MT048HE/PFD054A-*L

MT060HE/PFD067A-*L

MT060HE/PFDZ67A-*L or PFD067A-*H

Consult factory for proper line sizing for runs longer than maximum equivalent length shown.

1.Use one line size smaller on suction lines for vertical risers.

Suction line, in. 7/8 7/8 7/8 7/8 7/8

Liquid line, in. 1/2 1/2 1/2 1/2 1/2

Suction line, in. 7/8 1-1/8

Liquid line, in. 1/2 1/2 5/8 5/8 5/8

Suction line, in. 1-1/8 1-1/8 1-1/8 1-1/8 1-1/8

Liquid line, in. 1/2 5/8 5/8 5/8 5/8

Suction line, in. 1-1/8 1-1/8 1-1/8 1-1/8 1-1/8

Liquid line, in. 1/2 5/8 5/8 5/8 5/8

1

4.2.1 Refrigerant Charge Requirements

To calculate the charge requirements:

1. Determine the charge for your units by model number from the following tables.

2. Determine the charge for the piping by line size and length.

3. Add these all together to obtain the total refrigerant charge for your system.

1-1/8

1

1-1/8

1

1-1/8

1

14

Vertiv | Liebert® PFD™ Installer/User G uide

Page 15

Table 4.5 Indoor Evaporator Approximate R-410Arefrigerant charge

Model # Charge, lb (kg)

MT036HE 1 (0.45)

MT048HE 2.2 (1.0)

MT060HE 2.2 (1.0)

Table 4.6 Interconnecting piping refrigerant charge for R-410A, lbper 100ft (kgper30m)

Line Size,

O.D., in.

3/8 3.2 (1.4) —

1/2 5.9 (2.7) 0.2 (0.1)

5/8 9.6 (4.3) 0.4 (0.2)

3/4 14.3 (6.4) 0.6 (0.3)

7/8 19.8 (8.8) 0.8 (0.4)

1-1/8 33.8 (15.1) 1.4 (0.6)

1-3/8 51.5 (23.0) 2.1 (1.0)

Source:DPN003099 Rev. 1

Liquid Line,lb (kg) Suction Line, lb (kg)

Table 4.7 Liebert® PFD R-410A refrigerant charge

Model # Charge, lb (kg)

PFD037A-*L1 13.4 (6.1)

PFD037A-*H1 27 (12.2)

PFD054A-*L1 27 (12.2)

PFD067A-*L1 27 (12.2)

PFDZ67A-*L1 57 (25.8)

PFD067A-*H1 57 (25.8)

Evacuation and Leak-testing Air-cooled Systems

For proper leak-check and evacuation, you must open all system valves and account for all check valves,

see Figure 4.2 on the next page.

4 Piping and Refrigerant Requirements 15

Page 16

Figure 4.2 Valves and Connections

Item Description

1 Apply a manifold gauge hose on the suction-line Schraderport.

2 Apply a manifold gauge hose on the discharge-line Schrader port.

3 Remove the solenoid-valve holding coil then applysolenoid-valve service magnet to the valve.

4 External equalizer

5 Sensing bulb

6 Suction-pressure transducer

7 Suction line

8 Schrader port with valve core

9 Digital-scroll compressor

10 Discharge-temperature thermistor

11 High-pressure switch

12 Condenser coil

13 3-way head-pressure control valve

16

Vertiv | Liebert® PFD™ Installer/User G uide

Page 17

Item Description

14 Check valve

15 Pressure-balancing valve

16 Sight glass

17 Pressure-relief valve

18 Lee-Temp receiver

19 Receiver-heater pressure-limiting switch

Schrader port with valve core

NOTE: The system includes a factory-installed Schrader valve with core in the liquid line downstream of the

20

receiver. Proper evacuation of the condenser side of the system can be accomplished only using the downstream

Schrader valve. See the appropriate piping schematic for your system in Submittal Drawings on page35.

21 Liquid-line solenoid valve

22 Liquid line

23 Filter drier

24 Expansion valve

25 Evaporator coil

To evacuate and leak-test the system:

1. Open the liquid-line solenoid valve by removing the holding coil, and apply a solenoid-valve

service magnet to the valve.

2. Connect manifold-gauge hoses on the discharge- and suction-line Schrader ports, open the

service valves, and place a 150PSIG(1034kPa)charge of dry nitrogen with a tracer of

refrigerant, then check the system for leaks with a suitable leak detector.

3. After completion of leak testing, release the test pressure, (observe local code) and pull an

initial deep vacuum of 500microns on the system with a suitable pump.

4. After 4hours, check the pressure readings and, if they have not changed, break vacuum with

dry nitrogen. Pull a second and third vacuum to 500 microns or less. Re-check the pressure

after 2hours.

When the 3 checks are complete, proceed to Charging Air-cooled Systems below.

Charging Air-cooled Systems

NOTICE

Risk of improper refrigerant charging. Can cause equipment damage.

R-410A is a blended refrigerant and must be introduced and charged from the cylinder only as

a liquid.

When adding liquid refrigerant to an operating system, it may be necessary to add the

refrigerant through the valve in the compressor suction line. Care must be exercised to avoid

damage to the compressor. We recommend connecting a sight glass between the charging

hose and the compressor suction service valve. This will permit adjustment of the cylinder

hand valve so that liquid can leave the cylinder while allowing vapor to enter the compressor.

NOTICE

Risk of improper component re-installation. Can cause equipment damage.

Identify and mark location of the discharge pressure switch. It must be reinstalled in its original

location.

Initially charging the system:

1. Check the nameplate on the indoor unit for refrigerant type to use.

4 Piping and Refrigerant Requirements 17

Page 18

2. Refer to Refrigerant Charge Requirements on page14, and calculate the amount of charge for

the system including the evaporator, condensing unit, and interconnecting piping.

3. Accurately weigh-in as much of the system charge as possible before re-installing the coil on

the liquid-line solenoid valve and starting the unit.

Field Charge Verification

The unit receiver includes an integral sight glass to assist with charge verification in the field.

To verify the refrigerant charge:

1. To keep the unit operating, use the Service menu at the iCOMtouchscreen control:

• Touch the Service icon to display the service menu, then touch Diagnostics/Service.

• Touch the Compressor Circuit options, and select 2 (charge mode) in the Compressor

Mode field.

The compressor runs at 100% for 30 minutes in charge mode.

2. At design ambient temperature between 95°F and 105°F (35°C and 41°C), the charge level

should be in the middle of the sight glass.

• If the charge level is below the sight glass, an under-charge condition is likely.

• If the charge level is above the sight glass, and you observe a higher than normal

discharge pressure, an over-charge condition is likely. However, before removing charge,

make sure that there are no other possible causes of high discharge pressure such as a

dirty coil or restricted air flow.

3. Below design ambient temperatures, refrigerant backs-up into the condenser coil and the

charge level drops below the sight glass. At lower ambient temperatures, block the condenser

coil to maintain 418psig (2882kPa) discharge pressure to ensure that the head-pressure

control valve is closed. The charge level should be in the middle of the sight glass with the

valve closed.

• If the charge level is below the sight glass, an under-charge condition is likely.

• If the charge level is above the sight glass, an over-charge condition is likely.

NOTE: In systems with two condenser coils and two receivers, block-off coils proportionally. If one coil

is restricted significantly more than the other, liquid can remain in the restricted coil causing lower

levels in the receiver. The liquid level should be in the middle of the sight glass in both receivers. There

may be some variation in charge level between the receivers. When adding charge, use the receiver

showing a lower charge level and use that sight glass to determine the charge level.

4. If no level is visible in the sight glass, add charge until the level is in the middle of the glass.

Check the discharge pressure and adjust the coil restrictions to maintain418psig (2882kPa).

5. After conditions have stabilized, restrict the coil, if required, to maintain 418 psig (2882kPa)

discharge pressure and verify that the charge level is in the middle of the sight glass.

18

Vertiv | Liebert® PFD™ Installer/User G uide

Page 19

4.2.2 Additional Oil Requirements for Digital-scroll Compressors

NOTICE

Risk of improper compressor lubrication. Can cause compressor and refrigerant system

damage.

Failure to use oil types, viscosities and quantities recommended by the compressor

manufacturer may reduce compressor life and void the compressor warranty. See Table 8.1

on page28 for the recommended oil for the system.

• Do not mix polyolester (POE) and mineral-based oils.

• Do not mix oils of different viscosities.

• Consult your Vertiv sales representative, visit https://www.vertivco.com/en-us/support/,

or contact the compressor manufacturer if questions arise.

System charges may require additional oil charge to be added. See Table 4.8 below, for the amount

required for various system charge levels.

After the system has been fully charged with refrigerant, use a hand pump to add the additional oil at the

suction side of the system while the system is running.

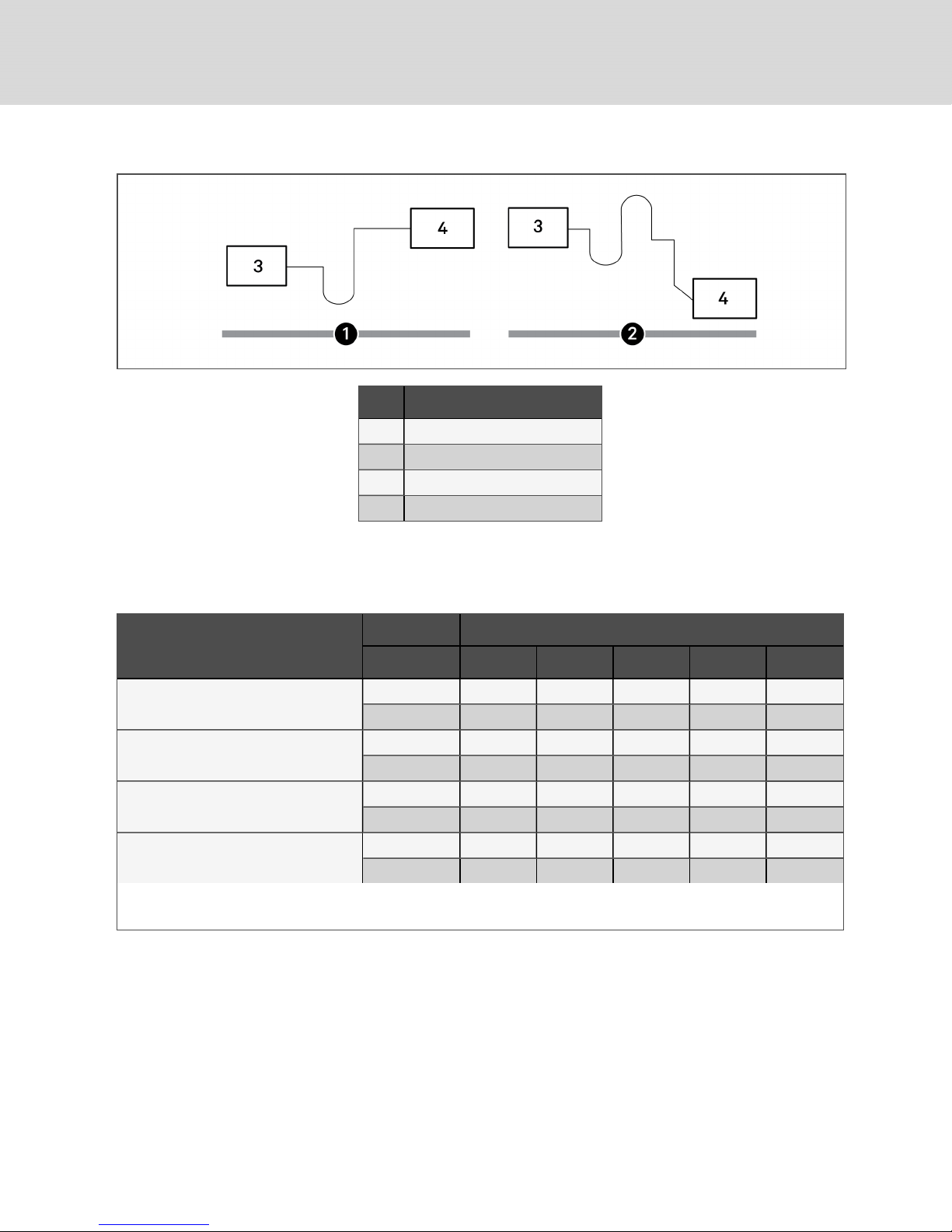

Table 4.8 Additional oil required per refrigerant charge

Model

PFD037 PFD054 PFD06 7, PFDZ67

Refrigerant S ystem

Charge per Circuit,

lb (kg) *

Additional Oil Required Per C ircuit, oz (ml)

<40 (18.1) 0 0 0

40 (18.1) 4 (120) 4 (120) 6(180)

50 (22.7) 6 (180) 6 (180) 9 (270)

60 (27.2) 8 (240) 8 (240) 12 (350)

70 (31.8) 10 (300) 10 (300) 15 (440)

80 (36.3) 12 (350) 12 (350) 18 (530)

* System Charge = indoor unit +condensing unit + refrigerant lines.

For system charges over 80lb. (36.3 kg), consult your Vertiv representative.

Source: DPN003950 Rev 5.

Documenting Refrigerant Charge and Oil Addition

When the unit is charged, you must record the total system refrigerant charge value on the condensing

unit's serial tag. The total system charge includes the evaporator, condensing unit, and interconnecting

lines, plus any adjustments made during the field-charge verification step.

On the tag marked “Oil Added Field Service Record,” attached to each compressor, record the date the oil

was added and the amount of oil added.

4 Piping and Refrigerant Requirements 19

Page 20

This page intentionally left blank

20

Vertiv | Liebert® PFD™ Installer/User G uide

Page 21

5 ELECTRICAL CONNECTION REQUIREMENTS

WARNING! Arc flash and electric shock hazard. Open all local and remote electric power-supply

disconnect switches, verify with a voltmeter that power is Off and wear appropriate,

OSHA-approved personal protective equipment (PPE) per NFPA 70E before working within the

electric control enclosure. Failure to comply can cause serious injury or death. Customer must

provide earth ground to unit, per NEC, CEC and local codes, as applicable. Before proceeding

with installation, read all instructions, verify that all the parts are included and check the

nameplate to be sure the voltage matches available utility power. The Liebert® controller does

not isolate power from the unit, even in the “Unit Off” mode. Some internal components require

and receive power even during the “Unit Off” mode of the controller. The only way to ensure

that there is NO voltage inside the unit is to install and open a remote disconnect switch. Refer

to unit electrical schematic. Follow all local codes.

WARNING! Risk of improper wire sizing/rating and loose electrical connections. Can cause

overheated wire and electrical connection terminals resulting in smoke, fire, equipment and

building damage, injury or death. Use correctly sized copper wire only and verify that all

electrical connections are tight before turning power On. Check all electrical connections

periodically and tighten as necessary.

NOTICE

Risk of improper electrical connection of three-phase input power. Can cause backward

compressor rotation and unit damage. Service technicians should use a gauge set on the

system during the initial start up to verify that the three-phase power is connected properly.

Three-phase power must be connected to the unit line voltage terminals in the proper

sequence so that the compressors rotate in the proper direction. Incoming power must be

properly phased to prevent compressors from running backward. We recommend checking

the unit’s phasing with proper instrumentation to ensure that power connections were made

correctly. We also recommend verifying discharge and suction pressures during start up to

ensure that the compressors are running in the correct direction.

NOTICE

Risk of compressor slugging. Can cause equipment damage.

Apply power to the condensing unit 8 hours before operating the system. This time is required

to drive liquid refrigerant out of the compressor. This is especially important at low ambient

temperatures. The compressor's crank-case heater is energized as long as power is supplied to

the unit.

NOTICE

Risk of improper electrical supply connection. Can cause equipment damage.

See transformer label for primary tap connections. Installer will need to change transformer

primary taps if applied unit voltage is other than pre-wired tap voltage.

5 Electrical Connection Requirements 21

Page 22

Electrical service is required for all models. All power and control wiring and ground connections must be

in accordance with the National Electrical Code and local codes. Refer to the equipment serial-tag data

for electrical requirements.

A field-supplied, manual, electrical-disconnect switch should be installed in accordance with local codes

and distribution system. Consult local codes for external disconnect requirements.

NOTE: Input-power requirements: For 3-phase units, only 3 power wires and an earth ground are

required.

Each unit is shipped from the factory with internal wiring completed. Refer to the electrical schematic

when making connections.

The electrical connections are described in the submittal documents included in the Submittal Drawings

on page35.

The following table lists the relevant documents by number and title.

Table 5.1 Electrical Field-connection Drawings

Document Number Title

DPN004168 ElectricalField Connections, top discharge

DPN004169 ElectricalField Connec tions, horizontal discharge

5.1 Low-voltage, Control Connections

A field-supplied, shielded, 6-wire control connection (24 VAC) is required between the evaporator and the

condensing unit.

Control wiring must be installed in accordance with the National Electrical Code (NEC) Class 1 or Class 2

circuit according to wire-routing conditions chosen and local codes.

Low-voltage wiring should be sized to allow a 1-Volt maximum drop due to line resistance between the

evaporator and condensing unit. Use NEC Class 1 or 2 wiring according to wire routing conditions chosen

and local codes, sizing wire per maximum wire lengths using Table 5.2 below. Connect the shield wire to

earth (ground) at the Liebert® equipment. Avoid running the low-voltage connections near high-voltage

lines or loads such as light ballasts.

NOTE: Do not connect additional electrical devices to the control circuit. The internal control

transformer is only sized for factory-supplied components. Refer to the appropriate submittal

drawings for your system for electrical connections. See Table 5.1 above.

Table 5.2 Recommended minimum wire size betweenindoorandoutdoorunits

Max. Distance, * ft (m) Min. Wire Gauge, AWG (mm2)

50 (15) 20 (0.75)

100 (30) 18 (1.0)

150 (45) 16 (1.5)

* One-way control wire run between outdoor condensing unit and evaporator.

22

Vertiv | Liebert® PFD™ Installer/User G uide

Page 23

6 CHECKLIST FOR COMPLETED INSTALLATION

1. All items are unpacked and checked.

2. Proper clearances for service access have been maintained around the equipment.

3. Equipment is level and mounting fasteners are tight.

4. Piping completed to refrigerant loop.

5. All piping connections are leak-free.

6. Piping is routed to prevent chafing and rub-through.

7. System was evacuated and refrigerant charge and any necessary oil charge added.

8. Line voltage to power wiring matches equipment serial tag.

9. Power wiring connections completed including earth ground.

10. Power-line circuit breakers or fuses have proper ratings for equipment installed.

11. Control wire to condensing unit is shielded, connections completed, including shield wire

connected to earth (ground) at Liebert® units.

12. All wiring connections are tight.

13. Foreign materials have been removed from inside and around all equipment installed (shipping

materials, construction materials, tools, etc.)

14. Fan rotates freely.

15. Fan and compressor are rotating in the correct direction.

16. Blank start-up sheet included with the condensing unit is ready for completion by installer.

6 Checklist for Completed Installation 23

Page 24

This page intentionally left blank

24

Vertiv | Liebert® PFD™ Installer/User G uide

Page 25

7 INITIAL START-UP CHECKS ANDCOMMISSIONING

PROCEDUREFORWARRANTYINSPECTION

WARNING! Arc flash and electric shock hazard. Open all local and remote electric power-supply

disconnect switches, verify with a voltmeter that power is Off and wear appropriate,

OSHA-approved personal protective equipment (PPE) per NFPA 70E before working within the

electric control enclosure. Failure to comply can cause serious injury or death. Customer must

provide earth ground to unit, per NEC, CEC and local codes, as applicable. Before proceeding

with installation, read all instructions, verify that all the parts are included and check the

nameplate to be sure the voltage matches available utility power. The Liebert® controller does

not isolate power from the unit, even in the “Unit Off” mode. Some internal components require

and receive power even during the “Unit Off” mode of the controller. The only way to ensure

that there is NO voltage inside the unit is to install and open a remote disconnect switch. Refer

to unit electrical schematic. Follow all local codes.

WARNING! Risk of improper wiring, piping, moving, lifting and handling. Can cause equipment

damage, serious injury or death. Installation and service of this equipment should be done only

by qualified personnel who have been specially-trained in the installation of air-conditioning

equipment and who are wearing appropriate, OSHA-approved PPE.

NOTICE

Risk of improper electrical connection of three-phase input power. Can cause backward

compressor rotation and unit damage. Service technicians should use a gauge set on the

system during the initial start up to verify that the three-phase power is connected properly.

Three-phase power must be connected to the unit line voltage terminals in the proper

sequence so that the compressors rotate in the proper direction. Incoming power must be

properly phased to prevent compressors from running backward. We recommend checking

the unit’s phasing with proper instrumentation to ensure that power connections were made

correctly. We also recommend verifying discharge and suction pressures during start up to

ensure that the compressors are running in the correct direction.

• Confirm that all items on Checklist for Completed Installation have been done.

• Locate “Liebert® PFD Warranty Inspection Check Sheet” in the unit’s electric panel.

(PSWI-8542-438RE)

• Complete “Liebert® PFD Warranty Inspection Check Sheet” during start-up.

(PSWI-8542-438RE)

• Forward the completed “Liebert® PFD Warranty Inspection Check Sheet” to your local sales

office. This information must be completed and forwarded to validate warranty.

• Contact your local sales representative or technical support if you have any questions or

problems during unit start-up and commissioning. Visit https://www.vertivco.com/enus/support/ or call 1-800-543-2778 for contacts.

Local sales offices and product support contacts can be found at https://www.vertivco.com/enus/support/ or 1-800-543-2778.

7 Initial Start-up Checks andCommissioning ProcedureforWarrantyInspection 25

Page 26

This page intentionally left blank

26

Vertiv | Liebert® PFD™ Installer/User G uide

Page 27

8 MAINTENANCE

WARNING! Arc flash and electric shock hazard. Open all local and remote electric power-supply

disconnect switches, verify with a voltmeter that power is Off and wear appropriate,

OSHA-approved personal protective equipment (PPE) per NFPA 70E before working within the

electric control enclosure. Failure to comply can cause serious injury or death. Customer must

provide earth ground to unit, per NEC, CEC and local codes, as applicable. Before proceeding

with installation, read all instructions, verify that all the parts are included and check the

nameplate to be sure the voltage matches available utility power. The Liebert® controller does

not isolate power from the unit, even in the “Unit Off” mode. Some internal components require

and receive power even during the “Unit Off” mode of the controller. The only way to ensure

that there is NO voltage inside the unit is to install and open a remote disconnect switch. Refer

to unit electrical schematic. Follow all local codes.

WARNING! Risk of electric shock. Can cause equipment damage, injury or death. Open all local

and remote electric power supply disconnect switches and verify with a voltmeter that power is

off before working within any electric connection enclosures. Service and maintenance work

must be performed only by properly trained and qualified personnel and in accordance with

applicable regulations and manufacturers’ specifications. Opening or removing the covers to

any equipment may expose personnel to lethal voltages within the unit even when it is

apparently not operating and the input wiring is disconnected from the electrical source.

WARNING! Risk of improper wiring, piping, moving, lifting and handling. Can cause equipment

damage, serious injury or death. Installation and service of this equipment should be done only

by qualified personnel who have been specially-trained in the installation of air-conditioning

equipment and who are wearing appropriate, OSHA-approved PPE.

The Liebert® PFD units are single components in the facility heat-removal system. The system includes

evaporator, air distribution (duct systems), outdoor heat rejection (condensing unit) and indoor cooling

and humidity loads (equipment load, location, outside air infiltration). Proper application and maintenance

of the entire system is critical to the life and reliability of the thermal-management units.

• Good maintenance practices are essential to minimizing operation costs and maximizing

product life.

• Read and follow monthly and semi-annual maintenance schedules included in this manual.

These MINIMUM maintenance intervals may need to be more frequent based on site-specific

conditions.

• See the Liebert® iCOM™ user manual for instructions on using the controller to predict some

service maintenance intervals.

• We recommend the use of trained and authorized service personnel, extended service

contracts and factory-specified replacement parts. Contact your Vertiv sales representative.

8 Maintenance 27

Page 28

8.1 General Maintenance

WARNING! Arc flash and electric shock hazard. Open all local and remote electric power

disconnect switches, verify with a voltmeter that power is Off and wear personal protective

equipment (PPE) per NFPA 70E before working within the electric control enclosure. Failure to

comply can cause serious injury or death. The Liebert® controller does not isolate power from

the unit, even in the “Unit Off” mode. Some internal components require and receive power

even during the “Unit Off” mode of the controller. The only way to ensure that there is NO

voltage inside the unit is to install and open a remote disconnect switch. Refer to unit electrical

schematic. Follow all local codes.

NOTICE

Risk of compressor slugging. Can cause equipment damage.

Apply power to the condensing unit 8 hours before operating the system. This time is required

to drive liquid refrigerant out of the compressor. This is especially important at low ambient

temperatures. The compressor's crank-case heater is energized as long as power is supplied to

the unit.

Access the condensing unit by removing the unit housing panel.

• Clean the air cooled condenser coil of all debris that will inhibit airflow. This can be done with

compressed air, with water from a garden hose, or with a commercial coil cleaner.

• Check for bent or damaged coil fins and repair as necessary.

• During winter, do not permit snow to accumulate on or around the condensing unit.

• Check all refrigerant lines and capillaries for vibration isolation and support as necessary.

• Check all refrigerant lines for signs of leaks.

8.2 Compressor Maintenance

8.2.1 Compressor Oil

NOTICE

Risk of improper compressor lubrication. Can cause compressor and refrigerant system

damage.

Failure to use oil types, viscosities and quantities recommended by the compressor

manufacturer may reduce compressor life and void the compressor warranty.

• Do not mix polyolester (POE) and mineral-based oils.

• Do not mix oils of different viscosities.

• Consult Vertiv technical support or the compressor manufacturer if questions arise.

Table 8.1 Compressor oil types for R-410A Refrigerant

Compressor Type Oil Type

CopelandScroll and Digital Scroll POE Oil- ISO 32 Centistoke Viscosity

1. Use CopelandPOE OilULTRA 32-3MAF or other Copeland-approved oils.

Source: DPN003950. Rev.5

8.2.2 Replacement Compressors

Replacement compressors are available through your Vertiv sales office. If the unit is under warranty, the

replacement compressor must be obtained from and the original compressor returned to your local Vertiv

sales office. Compressors are shipped in reusable packaging, and the original compressor should be

returned in the same packaging.

1

28

Vertiv | Liebert® PFD™ Installer/User G uide

Page 29

8.2.3 Compressor Motor Burnout

If a burnout has occurred, a full system clean-out is required. If not cleaned, compressor and system

problems will continue.

Consult the factory for compressor maintenance. Do not attempt to remove the compressor without first

contacting Vertiv support at 1-800-543-2778.

8.2.4 Unloading Solenoid(s) on a Digital-scroll Compressor

When replacing a digital-scroll compressor, the digital solenoid valve and coil must be replaced. The

compressor and valve kit are shipped separately. The valve kit must be field-brazed to the top of the

compressor in proper orientation and supported with the original factory bracket.

8.2.5 Replacing the Compressor

WARNING! Risk of electric shock. Can cause serious injury or death. The Liebert® iCOM

microprocessor does not isolate power from the unit, even in the "Unit Off" mode. Some internal

components require and receive power even during the "unit off" mode of the Liebert® iCOM

control. Open all local and remote electric power disconnect switches and verify with a

voltmeter that power is Off before working on any component of the system.

WARNING! Risk of over-pressurization of the refrigeration system. Can cause explosive

discharge of high-pressure refrigerant, loss of refrigerant, environmental pollution, equipment

damage, injury, or death. This unit contains fluids and gases under high pressure. Use extreme

caution when charging the refrigerant system. Do not pressurize the system higher than the

design pressure marked on the unit's nameplate. Relieve pressure before cutting into or

making connections/disconnections to the piping system.

NOTICE

Risk of improper component re-installation. Can cause equipment damage.

Identify and mark location of the discharge pressure switch. It must be reinstalled in its original

location.

NOTE: Failure to properly clean the system after compressor-motor burnout voids the compressor

warranty. Follow the manufacturer's procedure.

NOTE: Release of refrigerant to the atmosphere is harmful to the environment. Refrigerant must be

recycled or discarded in accordance with federal, state and local regulations.

1. Disconnect power.

2. Attach suction and discharge gauges to access fittings.

3. Recover refrigerant using an approved recovery procedure and equipment. Use a filter drier

when charging the system with recovered refrigerant.

4. Remove the temperature thermistor from the discharge line and make a note of its location

because you will need to re install it.

5. Unsweat refrigerant connections and disconnect all electrical connections.

6. Remove failed compressor.

8 Maintenance 29

Page 30

7. Install replacement compressor and make all connections.

8. Re-install the temperature thermistor at its original location (noted in step 4), which is within 6

inches of the compressor connection, and insulate making sure that the bulb makes good

contact with the discharge line.

9. Pressurize and leak-test the system.

10. Follow compressor manufacturer’s suggested clean-out procedures..

11. After completion of leak testing, release the test pressure, (observe local code) and pull an

initial deep vacuum of 500microns on the system with a suitable pump.

12. After 4 hours, check the pressure readings and, if they have not changed, break vacuum with

dry nitrogen. Pull a second and third vacuum to 500 microns or less, and verify that the

vacuum levels are maintained.

13. With the system in a 500micron or lower vacuum, charge the system based on the

requirements listed in Refrigerant Charge Requirements on page14.

8.3 Condensing Unit Maintenance

Restricted airflow will reduce operating efficiency and could result in high compressor-head pressure and

loss of cooling.

• Clear coil surface of all debris that will inhibit airflow.

• Check for bent or damaged coil fins and correct.

• Do not permit snow to accumulate around or under outdoor unit.

• Periodically consider commercial cleaning of coil surface

• Inspect fans, motors and controls for proper operation.

• Check all piping and capillaries for proper support.

• Inspect for leaks.

• Check contactors for pitting. Replace if pitted.

30

Vertiv | Liebert® PFD™ Installer/User G uide

Page 31

9 TROUBLESHOOTING

Table 9.1 below, lists problems you may encounter, the possible cause, and a suggested remedy.

Table 9.1 Troubleshooting

Problem Cause Remedy

No power to unit Check voltage at input terminal block.

Check for 24VAC±2VAC at control connections 1 & 2.

If there is voltage, then:

• Check 24VACat c ontrol connections 3 and 6. If there is voltage,

then there is compressor high discharge pressure situation. The

compressor will attempt to start once the high-pressure situation

has resolved.

• Check 24VAC at control connections 5 and 6. If there is no voltage,

then there is high discharge temperature situation. The

compressor will attempt to start once the high-temperature

situation has resolved and minimum 30 minhave elapsed.

• Check control settings for cooling requirement.

• Check 24VAC at control connections 3 and 6. If there is voltage,

there is compressor lock-out due to high discharge pressure

condition. Check display for high pressure alarm. Set S302 to 0 or

recycle power to indoor unit.

• Check 24VACat c ontrol connections 5 and 6. If there is no voltage,

there is compressor lock-out due to high discharge temperature

condition. Check display for high temperature alarm. Set S303 to 0

or recycle power to indoor unit.

Unit willnot start

High discharge

pressure

Low discharge

pressure

Low suction

pressur/c ompressor

cycling

Compressor contactor

not pulling in

Control voltage fuses (at

transformer in evaporator

module) open

Short cycle prevention

control

Compressor high

discharge pressure/

lockout relay

Insufficient air flow across

condenser coil

High refrigerant charge Check refrigerant charge.

Faultyhead pressure

control valve

Compressor rotation in

reverse direction

Insufficient refrigerant in

system

Plugged filter drier Replace filter drier.

Improper superheat

adjustment

Defective liquid line

solenoid valve

If there is no voltage between 1 & 2, then:

Locate short and replace fuses.

Control software delays compressor 3 minutes from stop to start.

Check for 24VAC ±2VAC at control connections 2 & 3. Remove 24VACsignalat

Connection 2 by turning indoor unit control off, then back on, or byraising the

setpoint to remove the cab for cooling, then resetting to re-establish operation.

Check fan operation. Remove debris from coil and air inlets.

Replace ifdefective.

Check for proper power phase wiring to unit andto compressor motor.

Check for leaks; repair andadd refrigerant.

Reset expansionvalve for 10-15°F (5.6 to 8.4°C)superheat at evaporator.

Check valve and coil; replace if necessary.

9 Troubleshooting 31

Page 32

Table 9.1 Troubleshooting (continued)

Problem Cause Remedy

Low compressor

capacity/ no cooling

Defective liquid line

solenoid valve

Plugged filter drier Chec k pressure drop across filter drier. Replace filter drier.

Check valve and coil; replace if necessary.

Check for normal system operating pressures. Refer to abnormal pressure

Low refrigerant charge

causes ifapplicable. Check for leaks. Proper refrigerant charge is very important

at low ambient operation.

Loose compressor or

piping support

Tighten clamps.

Compressor noisy

Compressor rotation in

reverse direction

Check for proper power phase wiring to unit andto compressor motor.

Pipe Rattle Loose pipe connections Check pipe c onnections andsupports.

Compressor running

hot

Compression ratio too

high

Check for normal system operating pressures. Refer to abnormal pressure

causes ifapplicable.

High discharge pressure Check for blocked condenser fanor coil.

Compressor motor

protec tors tripping

or cycling

High suction

temperature

Loose power or control

circuit wiring connection

Defective motor

Check expansionvalve and hot gas bypass valve setting. Chec k liquid quenching

valve operation.

Check allpower and c ontrol circuit connec tions.

Check for motor ground or short. Replace compressor ifeither condition is

found.

Low line voltage Check line voltage anddetermine location of voltage drop.

Compressor cycles

on locked rotor

Compressor motor

defective

Check for motor winding short or ground.

Single phasing Check voltage across all 3 legs at contactor. Correct source of problem.

Check control panel for

Motor burnout

welded contactor

contacts or welded

Replace defective components.

overload contacts.

32

Vertiv | Liebert® PFD™ Installer/User G uide

Page 33

APPENDICES

Appendix A: Technical Support and Contacts

A.1 Technical Support/Service in the United States

Vertiv™ Corporation

24x7 dispatch of technicians for all products.

1-800-543-2378

Liebert® Thermal Management Products

1-800-543-2778

Liebert® Channel Products

1-800-222-5877

Liebert® AC and DC Power Products

1-800-543-2378

A.2 Locations

United States

Vertiv Headquarters

1050 Dearborn Drive

Columbus, OH, 43085, USA

Europe

Via Leonardo Da Vinci 8 Zona Industriale Tognana

35028 Piove Di Sacco (PD) Italy

Asia

7/F, Dah Sing Financial Centre

3108 Gloucester Road

Wanchai, Hong Kong

33

Page 34

This page intentionally left blank

34

Vertiv | Liebert® PFD™ Installer/User G uide

Page 35

Appendix B: Submittal Drawings

The submittal drawings are in the order of document part number (DPN). Table B.1 below, groups the

drawings by topic/application.

Table B.1 Submittal-drawings Contents

Document Number Title

PFD Component Location

DPN004180 PFDCondensing Unit, 3-, 4-, and 5-ton

PFD Planning Dimensions

DPN004058 Cabinet dimensions, 5-ton, top discharge

DPN004063 Cabinet dimensions, 3-, 4-, and 5-ton, horizontaldischarge

DPN004066 Optionalanchoring plan, 3-, 4-, and 5-ton, horizontaldischarge

PFD Piping Schematics

DPN004060 Piping arrangement, 3-, 4- and 5-ton split-system

DPN004062 Piping arrangement, Condensing unit

PFD Piping Connections

DPN004059 Primary connection locations, top discharge

DPN004064 Primaryconnection locations, horizontaldischarge

PFD ElectricalConnections

DPN004168 ElectricalField Connections, top discharge

DPN004169 ElectricalField Connec tions, horizontal discharge

35

Page 36

This page intentionally left blank

36

Vertiv | Liebert® PFD™ Installer/User G uide

Page 37

35 15/16"

913mm

LIEBERT PFD

CABINET DIMENSIONAL DATA

5 TON HIGH AMBIENT/QUIET-LINE OUTDOOR CONDENSING UNIT

TOP AIR DISCHARGE

Top Air Discharge

18" (457mm) min. clearance

required for proper air flow

on both air inlet sides

Air Inlet

5 5/16"

135mm

38 5/16"

973mm

2"

51mm

53 1/8"

1349mm

24" (610mm) min. clearance recommended

for component access

1/2"

O

13mm

Typical 6 places

2 1/8"

53mm

Air Inlet

23 9/16"

599mm

3 11/16"

94mm

4 3/4"

121mm

3"

76mm

Removable Panel - Access to

electrical components and connections

44 11/16"

1136mm

53 1/4"

1352mm

refrigeration components,

32 1/8"

816mm

MODEL

60Hz

PFD067A-H

PFDZ67A-L

MODULE WEIGHT

lbs. (kg) net.

488 (222)

DPN004058

Page :1 /1

Form No.: DPN001040_REV4

Anchorage Plan

Bottom View of Unit

REV : 1

REV DATE : 08/17

Page 38

LIEBERT PFD

PRIMARY CONNECTION LOCATIONS

PRIMARY CONNECTION LOCATIONS

5 TON HIGH AMBIENT/QUIET-LINE OUTDOOR CONDENSING UNIT

W/ TOP AIR DISCHARGE

1" (25 mm) Dia. Electrical Entrance

for High Voltage Connection

3/4" (17mm) Dia. Electrical Entrance for

Low Voltage Connection

2"

50mm

6"

152mm

8-9/16"

217mm

1-15/16"

48mm

3/4" (17 mm) Liquid Line OD CU

1-1/8" ( 29mm) Suction Line OD CU

2-3/8"

60mm

6-1/16"

155mm

12-5/8"

320mm

Removable Panel - Access to

refrigeration components, electrical

components and connections

MODEL NUMBERS

60Hz

PFD067A - H

PFDZ67A - L

DPN004059

Page :1 /1

Form No.: DPN001040_REV4

REV : 1

REV DATE : 5/17

Page 39

LIEBERT MINI-MATE

VARIABLE CAPACITY

GENERAL ARRANGEMENT

SPLIT SYSTEMS W/ AIR COOLED CONDENSING UNIT

Schrader Port

with Valve Core

High Pressure

Cut Out Switch

Digital Scroll

Compressor

Condenser Coil

Suction Pressure

Sensing Bulb

External Equalizer

Transducer

Schrader Port

with Valve Core

Suction Line

Expansion

Valve

Filter Drier

Liquid Line

3 - Way Head

Pressure

Control Valve

Liquid Line

Solenoid Valve

Discharge

Temperature

Thermistor

Schrader

Port with

Valve Core

Check

Valve

Receiver Heater Pressure

Limiting Switch

Atmospheric Pressure

Relief Valve

Sight Glass

Lee - Temp

Receiver

Pressure

Balancing Valve

Evaporator Coil

DPN004060

Page :1 /1

Form No.: DPN001040_REV4

FIELD PIPING

FACTORY PIPING

REV : 2

REV DATE : 06/18

Page 40

LIEBERT PFD

GENERAL PIPING ARRANGEMENT

CONDENSING UNIT

Schrader

Port

With Valve Core

Suction Line

Digital

Compressor

High Pressure

Switch

Discharge

Temperature

Thermistor

Schrader

Port

With Valve Core

3 - Way Head

Pressure

Control Valve

Check Valve

Condenser Coil

Atmospheric

Pressure Relief Valve

Sight Glass

Liquid Line

DPN004062

Page :1 /1

Form No.: DPN001040_REV4

Liquid Line

Solenoid Valve

Schrader

Port

With

Valve Core

Receiver Heater

Pressure Limiting

Switch

Lee - Temp

Receiver

Pressure Balancing

Valve

FACTORY PIPING

REV : 1

REV DATE : 08/17

Page 41

LIEBERT PFD

DIMENSIONAL DATA in. (mm)

CABINET DIMENSIONAL DATA

OUTDOOR CONDENSING UNIT

W/ HORIZONTAL AIR DISCHARGE

18" (457mm) min. clearance required

for proper air flow on both air inlet

and discharge sides

Air Discharge

Air Inlet

A

MODEL NUMBERS

PFD037A-L

PFD037A-H

PFD054A-L

PFD067A-L

24" (610mm) min. clearance recommended

B

Air Inlet

Fan Rotation

Counter Clockwise

UNIT NET WEIGHT lbs. (kg)

351 (159) 36-3/4 (933) 53-1/4 (1352)

for component access

30-3/4 (781) 48-1/4 (1225) 21-1/4 (540)244 (111)

Access to refrigeration components,

electrical components and connections

A B C D

Removable Panel -

D

C

18-5/8 (473)

18-5/8 (473)

21-1/4 (540)

DPN004063

Page :1 /1

Form No.: DPN001040_REV4

REV : 2

REV DATE : 06/18

Page 42

LIEBERT PFD

PRIMARY CONNECTION LOCATIONS

CONDENSING UNIT W/ HORIZONTAL AIR DISCHARGE

1" (25 mm) Dia. Electrical Entrance

for High Voltage Connection

3/4" (17mm) Dia. Electrical Entrance for

Low Voltage Connection

Removable Panel - Access to

refrigeration components, electrical

components and connections

A

B

C

D

Suction Line Connection

Liquid Line Connection

E

F

MODEL NUMBER S

PFD037A-L 2 (51) 5-3/4 (146) 8-1/2 (216) 6 (152) 7-1/2 (191) 10-1/2 (267) 3/4" 3/8"

PFD037A-H

PFD054A-L

PFD067A-L

ELECTR ICAL CONNECTIONS in. (mm)

A B C D E F G H

DPN004064

Page :1 /1

Form No.: DPN001040_REV4

PIPING CONNECTION LOCATION in. (mm) PIPING CONNECTION SIZES O.D. CU

7-1/4 (184) 10 (254)2 (51) 5-1/2 (140) 8 (203) 13-1/4 (337)

7/8" 1/2"

REV : 2

REV DATE : 06/18

Page 43

LIEBERT PFD

OPTIONAL ANCHORAGE PLAN

OUTDOOR CONDENSING UNIT WITH HORIZONTAL AIR DISCHARGE

F G H J

Coil

M

Air

L

K

2Typ. (4) places

E

A

1

B

TOP VIEW

Some Parts not Shown for Clarity

Receiver

Rear of Unit

1

D

C

Front of

Unit

6

MODEL NUMBERS

PFD037A-L

PFD037A-H

PFD054A-L

PFD067A-L

A B C D E F G H J K L M

9-9/16 (243) 37-1/8 (943) 2-1/4 (57) 7-1/8 (181) 6-1/8 (156) 2-9/16 (65) 13-1/8 (333) 14-3/4 (375) 13- 1/4 (337) 2-1/4 (57) 7-1/8 (181) 6-3/8 (162)

9-5/16 (236) 43 (1092) 2-5/16 (58) 7-1/8 (181) 8-19/16 (217) 2-1/2 (63) 15-1/16 (383) 15-11/16 (398) 15-3/8 (391) 2-5/16 (58) 7-1/8 (181) 6-3/8 (162)

Notes:

1. Front Grille and Right End Panel will need to be removed to access anchor holes,

Top panel may be removed for additional access. All removed parts must be reinstalled.

2. 1/2"(13mm) Diameter hole, use for unit anchor.

3. All dimensions have a tolerance of ±1/16".

4. F, G, H, J, K, L and M dimensions are for the foot locations.

5. The use of this anchor plan is optional and installer will assume

responsibility for suitable anchorage.

6. Supply and return piping connections.

DPN004066

Page :1 /1

Form No.: DPN001040_REV4

DIMENSIONAL DATA in. (mm)

3/8"

10mm

Foot

PARTIAL FRONT VIEW

3/8"(10mm) Field supplied spacer

Typical 4 places

REV : 2

REV DATE : 06/18

Page 44

LIEBERT PFD

1

2 345

6

ELECTRICAL FIELD CONNECTIONS

5 TON HIGH AMBIENT/QUIET-LINE OUTDOOR CONDENSING UNIT

W/ TOP AIR DISCHARGE

Electrical Entrance for

High Voltage Connection

Three phase electric

service not provided

by Liebert.

Electrical Entrance for

Low Voltage Connection

Factory wired to components on

electric panel.

Field wired high

voltage connections

Earth ground connection

terminal for field wiring.

Heat rejection connections Field supplied 24V NEC class 1

wiring from evaporator:

1 24V GND

DETAIL A

Note:

1. Disconnect Switch to be field supplied, wired, and mounted by others per local and national codes

2. Refer to specification sheet for full load amp and wire size amp ratings.

2 24V Supply

3 High Pressure Alarm

4 Digital Signal

5 High Temp Alarm

6 24V DCTR GND

123456

A

DPN004168

Page :1 /1

Form No.: DPN001040_REV4

REV : 1

REV DATE : 8/17

Page 45

LIEBERT PFD

1

2 345

6

ELECTRICAL FIELD CONNECTIONS

CONDENSING UNIT W/ HORIZONTAL AIR DISCHARGE

Electrical Entrance for

High Voltage Connection.

Three phase electric service

not provided by Liebert

Electrical Entrance for

Low Voltage Connection

Field wired high voltage connections

Earth ground connection

terminal for field wiring

Electrical entrance for

High Voltage Connection

Electrical entrance for

Low Voltage Connection

MODEL NUMBERS

PFD037A-L

PFD037A-H

PFD054A-L

PFD067A-L

to terminal block or contactor

Factory wired to components

on electric panel

123456

DETAIL A

A

Heat rejection connection.

Field supplied 24V NEC class 1 wiring.

Wire connections from evaporator module:

1 24V GND

2 24V Supply

3 High Pressure Alarm

4 Digital Signal

5 High Temp Alarm

6 24V DCTR GND

Unit view will

vary depending

on model size

Note:

1. Disconnect Switch to be field supplied, wired, and mounted by others per local and national codes.

2. Refer to specification sheet for full load amp and wire size amp ratings.

DPN004169

Page :1 /1

Form No.: DPN001040_REV4

REV : 2

REV DATE : 06/18

Page 46

LIEBERT PFD

1

Fan with Direct-drive motor

2

Condenser coil

3

Electric box

4

Heated Receiver

5

Variable-Capacity Digital Scroll Compressor

6

Head Pressure Control Valve (Lee-Temp)

COMPONENT LOCATION DIAGRAM

TYPICAL HORIZONTAL DISCHARGE

6

A

Top View

2

1

CONDENSING UNIT

DETAIL A

4

3

5

DPN004180

Page :1 /1

Form No.: DPN001040_REV4

REV : 2

REV DATE : 3/18

Page 47

Vertiv | Liebert® PFD™ Installer/User G uide

Page 48

VertivCo.com | Vertiv Headquarters, 1050 Dearborn Drive, Columbus, OH, 43085, USA

© 2018 Vertiv Co. All rights reserved. Vertiv and the Vertiv logo are trademarks or registered trademarks of VertivCo. Allother names andlogos referred to

are trade names, trademarks or registered trademarks of their respective owners. While every precaution has been taken to ensure accuracy and

completeness herein, Vertiv Co. assumes no responsibility, and disclaims all liability, for damages resulting from use of this information or for anyerrors or

omissions. Specificationsare subject to change without notice.

SL-10550_REV2_-10-18/590-1676-501C

Loading...

Loading...