Vertiv Liebert NX 225 kVA, Liebert NX 400 kVA, Liebert NX 300 kVA, Liebert NX 250 kVA, Liebert NX 600 kVA Installation Manual

...

Liebert® NX™ UPS

Installation Manual — 225-600kVA, 1.0PF, 60Hz, Three-Phase, Single-Module &

Multi-Module

CONTACTING VERTIV FOR SUPPORT

To contact Vertiv Liebert Services for information or repair service in the United States, call 800-543-2378.

Liebert Services offers a complete range of startup services, repair services, preventive maintenance plans and

service contracts.

For repair or maintenance service outside the 48 contiguous United States, contact Liebert Services, if available

in your area. For areas not covered by Liebert Services, the authorized distributor is responsible for providing

qualified, factory-authorized service.

For Liebert Services to assist you promptly, please have the following information available:

Part numbers: ___________________________________________________________________________________________________________

Serial numbers:__________________________________________________________________________________________________________

Rating: __________________________________________________________________________________________________________________

Date purchased:_________________________________________________________________________________________________________

Date installed: ___________________________________________________________________________________________________________

Location: ________________________________________________________________________________________________________________

Input voltage/frequency:________________________________________________________________________________________________

Output voltage/frequency:______________________________________________________________________________________________

Battery reserve time:____________________________________________________________________________________________________

Product Warranty Registration

To register for warranty protection, visit the Service and Support section of our Web site at:

www.liebert.com

Click on Product Registration and fill out the form.

TABLE OF CONTENTS

CONTACTING VERTIV FOR SUPPORT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . INSIDE FRONT COVER

IMPORTANT SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

SAVE THESE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.0 MECHANICAL INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.2 Preliminary Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.3 Environmental Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3.1 UPS Room. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3.2 Storing the UPS and Batteries for Delayed Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3.3 Installation Altitude . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4 Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.4.1 Moving the Cabinets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4.2 Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4.3 Raised-Floor Installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4.4 Kick Plates and Floor Anchors for Special Seismic Certification—Optional . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4.5 Kick Plate Installation—Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4.6 Special Considerations for 1+N Parallel Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4.7 Unpacking and Unloading the Cabinet from the Pallet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.5 System Composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.6 Cable Entry. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.0 UPS ELECTRICAL INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 External Protective Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Power Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3 Sizing the Input Breaker Feeding a Liebert NX UPS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.3.1 Single or Dual Input Feeds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3.2 Automatic Transfer Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3.3 Power Cable Connection Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.4 Control Cable and Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

2.4.1 Slot for Liebert IntelliSlot™ or ManageUPS™ Communication Cards—XS3 . . . . . . . . . . . . . . . . . . . . . . . . . . .12

2.4.2 Slot for LIFE Services Products—XS6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

2.4.3 Serial Interface for Liebert LIFE Services Cards (Serial Input/Output)—X6 . . . . . . . . . . . . . . . . . . . . . . . . . .13

2.4.4 Connector for REPO (Input and Status)—XT3/8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

2.4.5 Customizable Output—TB2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.4.6 Customizable Input Contact—TB1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.4.7 Contact Control for Eco Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

2.4.8 Connector for Parallel UPS Connection—X19A, X19B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

2.4.9 RJ-45 Interface for Synchronization with External Signal—X20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

2.4.10 UPS Control Contacts with Battery Cabinet or Module Battery Disconnect . . . . . . . . . . . . . . . . . . . . . . . . . .15

2.4.11 UPS Control Contacts with Global Maintenance Bypass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

2.5 Configuring Ground Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

2.5.1 Three-Wire Input Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

2.5.2 Preferred Grounding Configuration, Battery Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

2.5.3 High-Resistance Ground Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Vertiv |Liebert® NX™ 225-600kVA Installation Manual | Rev. 8 | 07/2017 i

2.6 Distributed Static Switch (1+N) System Cabling Layouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

3.0 OPTIONAL EQUIPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.1 Single-Module System Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.1.1 Input Circuit Breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.1.2 External Battery Temperature Sensor—Optional . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.1.3 Matching Liebert NX Battery Cabinet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.1.4 Battery Interface Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.1.5 Local EPO Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.2 Communication and Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.2.1 Remote Status Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.2.2 Alber Monitoring System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.2.3 Capacity on Demand (Softscale) Upgrades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.3 Multi-Module System Options and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.3.1 Paralleling Cable Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.3.2 Load Bus Sync Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.3.3 Multi-Bus Synch Module (MBSM). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.0 INSTALLATION DRAWINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.0 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

FIGURES

Figure 1 Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Figure 2 Cabinet arrangement—Liebert NX matching battery cabinets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Figure 3 Grounding diagram—Three-wire single-module systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 4 Grounding diagram—Three-wire multi-module systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Figure 5 System layout, 1+N . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 6 SKRU connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Figure 7 Control wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 8 REPO connections 1+N system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 9 Main components, 225-300kVA Liebert NX UPS, SMS and 1+N multi-module unit with static

bypass. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 10 Outline drawing, 225-300kVA Liebert NX, SMS and 1+N multi-module unit with static

bypass. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 11 225-300kVA low-voltage cable routing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 12 Base Drawing, 225-300kVA Liebert NX, SMS and 1+N multi-module unit with static

bypass. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 13 Terminal details, 225-300kVA Liebert NX, SMS and 1+N multi-module unit with static

bypass. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 14 Terminal details Liebert NX 225kVA - 300kVA UPS 1+N multi-module or SMS . . . . . . . . . . . . . . . . . 29

Figure 15 Main components, 400-600kVA Liebert NX UPS, SMS and 1+N multi-module unit with

static bypass. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 16 Outline drawing, 400-600kVA Liebert NX, SMS and 1+N multi-module unit with static

bypass. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 17 Base Drawing, 400-600kVA Liebert NX, SMS and 1+N multi-module unit with static bypass . . . 32

Figure 18 Terminal details, 400-600kVA Liebert NX, SMS and 1+N multi-module unit with static

bypass. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Vertiv |Liebert® NX™ 225-600kVA Installation Manual | Rev. 8 | 07/2017 ii

Figure 19 Terminal details Liebert NX 400kVA - 600kVA UPS 1+N multi-module or SMS. . . . . . . . . . . . . . . . . 34

Figure 20 Recommended control wiring for Liebert NX 225-600kVA single module, Eco Mode . . . . . . . . . . . 35

Figure 21 Recommended control wiring for Liebert NX 225-600kVA multi-module, Eco Mode . . . . . . . . . . . . 36

TABLES

Table 1 REPO connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 2 Customizable output contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Table 3 Customizable input contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Table 4 Battery interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Table 5 Maintenance bypass key status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Table 6 Maintenance Bypass SKRU Enable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Table 7 Liebert NX UPS specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 8 UPS rating at altitude . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Table 9 Current ratings—rectifier input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Table 10 Current ratings—battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 11 Recommended DC circuit breaker rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 12 Current ratings—bypass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 13 Current ratings—output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 14 Current-versus-time curves of overload capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Table 15 Recommended conduit and cable sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Table 16 Recommended torque values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table 17 Recommended lug sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table 18 Components required for seismic configuration meeting OSHPD regulations . . . . . . . . . . . . . . . . . . 43

Vertiv |Liebert® NX™ 225-600kVA Installation Manual | Rev. 8 | 07/2017 iii

Vertiv |Liebert® NX™ 225-600kVA Installation Manual | Rev. 8 | 07/2017 iv

IMPORTANT SAFETY INSTRUCTIONS

!

!

SAVE THESE INSTRUCTIONS

This manual contains important instructions that should be followed during installation of your Liebert NX UPS.

Read this manual thoroughly, paying special attention to the sections that apply to your installation, before

working with the UPS. Retain this manual for use by installing personnel.

WARNING

Risk of electrical shock. Can cause personal injury or death.

This UPS has several circuits that are energized with high DC as well as AC voltages. Check for voltage

with both AC and DC voltmeters before working within the UPS. Check for voltage with both AC and DC

voltmeters before making contact.

Only properly trained and qualified personnel wearing appropriate safety headgear, gloves, shoes and

glasses should be involved in installing the UPS or preparing the UPS for installation. When performing

maintenance with any part of the equipment under power, service personnel and test equipment should

be standing on rubber mats.

In case of fire involving electrical equipment, use only carbon dioxide fire extinguishers or those approved

for use in fighting electrical fires.

Extreme caution is required when performing installation and maintenance.

Special safety precautions are required for procedures involving handling, installation and maintenance of

the UPS system. Observe all safety precautions in this manual before handling or installing the UPS

system. Observe all precautions in the Operation and Maintenance Manual, SL-25434, before as well as

during performance of all maintenance procedures. Observe all DC safety precautions before working on

or near the DC system.

WARNING

Risk of heavy unit falling over. Improper handling can cause equipment damage, injury or death.

Exercise extreme care when handling UPS cabinets to avoid equipment damage or injury to personnel.

The UPS module weight is up to 4450 lb. (2019kg).

Locate center of gravity symbols and determine unit weight before handling each cabinet. Test lift and

balance the cabinets before transporting. Maintain minimum tilt from vertical at all times.

Slots at the base of the module cabinets are intended for forklift use. Base slots will support the unit only

if the forks are completely beneath the unit.

Read all of the following instructions before attempting to move, lift, or remove packaging from unit, or

prepare unit for installation.

Vertiv™| Liebert® NX™ 225-600kVA Installation Manual | Rev. 8 | 07/2017 1

!

WARNING

!

!

Risk of electrical shock and fire. Can cause equipment damage, personal injury or death.

Under typical operation and with all UPS doors closed, only normal safety precautions are necessary.

The area around the UPS system should be kept free of puddles of water, excess moisture and debris.

Only test equipment designed for troubleshooting should be used. This is particularly true for

oscilloscopes.

Always check with an AC and DC voltmeter to ensure safety before making contact or using tools. Even

when the power is turned Off, dangerously high potential electric charges may exist at the capacitor

banks and at the DC connections.

All wiring must be installed by a properly trained and qualified electrician.

All power and control wiring must comply with all applicable national, state and local codes.

One person should never work alone, even if all power is disconnected from the equipment. A second

person should be standing by to assist and to summon help in case of an accident.

WARNING

Risk of electrical shock and fire. Can cause equipment damage, injury and death.

Internal battery strapping must not be removed. Failure to heed this warning could result in smoke, fire or

electric hazard. If strapping is removed, consult your local representative before attempting to transport

the battery cabinet.

NOTICE

This unit complies with the limits for a Class A digital device, pursuant to Part 15 Subpart J of FCC rules. These limits

provide reasonable protection against harmful interference in a commercial environment. This unit generates uses and

radiates radio frequency energy and, if not installed and used in accordance with this instruction manual, may cause

harmful interference to radio communications. Operation of this unit in a residential area may cause harmful interference

that the user must correct at his own expense.

NOTE

Materials sold hereunder cannot be used in the patient vicinity (e.g., use where UL, cUL or IEC 60601-1 is

required). Medical applications such as invasive procedures and electrical life support equipment are subject to

additional terms and conditions.

Vertiv™| Liebert® NX™ 225-600kVA Installation Manual | Rev. 8 | 07/2017 2

1.0 MECHANICAL INSTALLATION

!

1.1 INTRODUCTION

This section describes the requirements that must be taken into account when planning the positioning and

cabling of the Liebert NX uninterruptible power supply and related equipment.

This chapter is a guide to general procedures and practices that should be observed by the installing personnel.

The particular conditions of each site will determine the applicability of such procedures.

WARNING

Risk of electrical shock. Can cause injury or death.

Special care must be taken when working with the batteries associated with this equipment.

When they are connected together, the battery terminal voltage will exceed

400VDC and is potentially lethal.

NOTE

All equipment not referred to in this manual is shipped with details of its own mechanical and electrical

installation.

NOTICE

Risk of incorrect input power connection. Can cause equipment damage.

The standard Liebert NX UPS is suitable for connection to three-phase, three-wire plus ground input power.

NOTE

Do not apply electrical power to the UPS equipment before the arrival of the commissioning engineer.

Connecting power before the commissioning engineer determines the system is properly installed may void the

warranty.

1.2 PRELIMINARY CHECKS

Before installing the UPS, please carry out the following preliminary checks:

• Visually examine the UPS equipment for transit damage, both internally and externally. Report any damage to the shipper

immediately.

• Verify that the correct equipment is being installed. The equipment supplied has an identification tag on the interior doors

reporting the type, size and main calibration parameters of the UPS.

• Verify that the UPS room satisfies the environmental conditions stipulated in the equipment specification, paying

particular attention to the ambient temperature and air exchange system.

Vertiv™| Liebert® NX™ 225-600kVA Installation Manual | Rev. 8 | 07/2017 3

1.3 ENVIRONMENTAL CONSIDERATIONS

1.3.1 UPS Room

The UPS module is intended for indoor installation and should be located in a cool, dry, clean-air environment

with adequate ventilation to keep the ambient temperature within the specified operating range (see

Environmental Parameters in Tab le 7).

The Liebert NX UPS is cooled with the aid of internal fans. To permit air to enter and exit and prevent

overheating or malfunctioning, do not cover the ventilation openings.

The Liebert NX UPS is equipped with air filters located behind the front doors. A schedule for inspection of the

air filters is required. The period between inspections will depend upon environmental conditions.

When bottom entry is used, the conduit plate must be installed.

NOTE

The UPS is suitable for mounting on concrete or other non-combustible surface only.

NOTICE

There is a potential risk to the operational integrity of an installed UPS system by the presence of foreign material inside or

in the vicinity of the UPS module.

This risk is especially high if conductive materials find their way inside the UPS module.

The risk potentially involves damage to the installed UPS equipment and subsequent degradation or loss of power to the

connected critical site load.

Vertiv applies the highest safety standards in equipment design to ensure that no live parts are exposed to external

contact, and also to ensure that the equipment is protected against the introduction of foreign bodies during operation.

However, it is not possible for Vertiv to ensure that foreign bodies will not be introduced during on-site installation, or

when the UPS doors and covers are “open” and the electrical terminals are exposed to allow power line connections to be

made by the electrical contractor/installer.

To prevent major disruption to site operations and risk to property and personnel, including the possibility of a fatality,

each site’s facility manager or construction manager must prevent foreign bodies from being introduced into the UPS

module.

All UPS modules are thoroughly inspected by Vertiv engineers prior to placement into service and testing on-site.

However, the person responsible for the site must ensure that the UPS module, and the immediate surroundings, are kept

clean and free from any possible conductive material such as metal foil, food wrappers, cable shields, washers and other

hardware, scrap metal and dust.

If the UPS system is shut down after placement into service and testing are completed, the UPS room must be kept clean

to avoid the possibility (during restart) of the considerable volume of air-flow produced by UPS operation to dislodge

and/or drag any foreign bodies into the equipment, which would result in system failure and possible supply interruption to

the critical site load, and several hours of downtime resulting from the damage typically associated with such events.

If the UPS is left running/operational at the completion of placement into service and testing, the room similarly needs to

be kept clean to prevent foreign bodies from entering the UPS module via its forced air-flow.

1.3.2 Storing the UPS and Batteries for Delayed Installation

If the Liebert NX system will not be installed immediately, it must be stored indoors in a clean, dry and cool

location (see Environmental Parameters in Tab le 7 ). If the UPS includes batteries, either internally or in a

battery cabinet, the batteries’ requirements will dictate the storage conditions. Batteries should be unpacked,

installed and charged as soon as possible after delivery.

NOTICE

Risk of failure to properly charge batteries. Can cause permanent damage to batteries and void the warranty.

Batteries will self-discharge during storage. Batteries must be recharged as recommended by the battery manufacturer. A

notice of “Charge Before Date” is affixed to each unit that has batteries inside. The “Charge Before Date” is calculated

based on the batteries being stored at 77°F (25°C). Storage at a higher temperature will increase the rate of self-discharge,

requiring earlier recharge. Consult the battery manufacturer on how to determine when the batteries need to be

recharged.

Vertiv™| Liebert® NX™ 225-600kVA Installation Manual | Rev. 8 | 07/2017 4

1.3.3 Installation Altitude

!

The maximum operating altitude of the UPS, without derating, is 3300ft. (1000m). At higher altitudes the load

must be reduced according to Table 8.

1.4 POSITIONING

The cabinet is structurally designed to handle lifting from the base.

Access to the power terminals, auxiliary terminal blocks and power switches is from the front.

The door can be opened to give access to the power connection bars, auxiliary terminal blocks and power

isolators. The front door can be opened 90 degrees for more flexibility in installations.

1.4.1 Moving the Cabinets

The route to be traveled between the point of arrival and the unit’s position must be planned to make sure that

all passages are wide enough for the unit and that floors are capable of supporting its weight (for instance, check

that doorways, lifts, ramps, etc. are adequate and that there are no impassable corners or changes in the level of

corridors).

Ensure that the UPS weight is within the designated surface weight loading (kg/cm2) of any handling equipment.

For weight details, see Tab le 7.

Move the UPS with a forklift or similar equipment to ease the relocation and to reduce vibration. The optional

battery cabinets should be moved with a forklift or similar equipment.

When handling the UPS with a forklift or similar equipment, ensure any lifting equipment used in moving the UPS

cabinet has sufficient lifting capacity. When moving the unit by forklift, care must be taken to protect the panels.

Do not exceed a 15-degree tilt with the forklift. Bottom structure will support the unit only if the forks are

completely beneath the unit.

Handling with straps is not authorized.

WARNING

Risk of heavy unit falling over. Improper handling can cause equipment damage, injury or death.

Because the weight distribution in the cabinet is uneven, use extreme care while handling and

transporting. Take extreme care when handling UPS cabinets to avoid equipment damage or injury to

personnel.

The UPS module weight is up to 4450 lb. (2019kg).

Locate center of gravity symbols and determine unit weight before handling each cabinet. Test lift and

balance the cabinets before transporting. Maintain minimum tilt from vertical at all times.

1.4.2 Clearances

The Liebert NX has no ventilation grilles at either side or at the rear of the UPS. Clearance around the front of the

equipment should be sufficient to enable free passage of personnel with the doors fully opened. It is important to

leave a distance of 24in (610mm) between the top of the UPS and any overhead obstacles to allow the module to

be serviced and to permit adequate circulation of air coming out of the unit.

1.4.3 Raised-Floor Installations

If the equipment is to be located on a raised floor, it should be mounted on a pedestal suitably designed to

accept the equipment point loading. Refer to the base view to design this pedestal.

Vertiv™| Liebert® NX™ 225-600kVA Installation Manual | Rev. 8 | 07/2017 5

1.4.4 Kick Plates and Floor Anchors for Special Seismic Certification—Optional

For seismic resistant installations and OSHPD compliance, special floor anchors and kickplates must be used for

the UPS and matching battery cabinets; see Table 18.

The California Office of Statewide Health Planning and Development (OSHPD) enforces International Building

Code requirements for Special Seismic Certification except that the office reduces the required scope of

certifications.

1.4.5 Kick Plate Installation—Standard

Kick plates must be installed. If the unit is to be installed in a position that does not permit access to rear kick

plates, then the kick plates must be installed before the unit is placed in its final position.

1.4.6 Special Considerations for 1+N Parallel Systems

Consider the grounding configuration of your system before finalizing module placement See 2.5 - Configuring

Ground Connections.

Vertiv recommends matching the impedance in the bypass path of paralleled systems as closely as possible to

ensure good bypass current sharing.

The impedance mismatch can be minimized by controlling the wiring length of each unit. The design and the

layout of the UPS system and associated panels and cabling should be examined closely to ensure that cable

lengths and impedances are closely matched.

For Liebert NX Systems, the total combined cable length of the bypass feeder cables and the module output

cables for each module must be within 5% from maximum to minimum. The combined cable length is the sum of

the length from the common source feeding all the modules to the common output switchboard.

If the cabling impedances need to be greater than 5%, contact your Vertiv representative to calculate whether

the system will result in an overload condition when operating on bypass.

When bringing the 1+N system on-line for the first time or after removing one unit, Vertiv recommends checking

the bypass current mismatch. To check the bypass current mismatch:

1. Place a load on the bypass of each UPS module.

2. View the output current of each unit.

The accuracy of the currents displayed on the UPS module is sufficient for this check. If the mismatch is greater

than 5%, the bypass impedances must be balanced or the load must be limited to less than the maximum rating.

The output switchboard for any 1+N system must be configured with one Module Output Circuit Breaker (MOB)

for each UPS module that is to be connected to that switchboard. The breaker must be equipped with auxiliary

contacts that will be monitored by the UPS in order for interlocks to function properly and for the HMI to indicate

the bypassed status of the module.

Vertiv recommends using magnetic or thermomagnetic breakers. If molded case switches will be used, Vertiv

recommends installing breakers without electronic trip units or to set the trip units high enough to

accommodate high instantaneous currents that may be present when switching a module into an active bus.

For 225-250kVA Modules—Set instantaneous trip settings to allow for 2000A for 2 milliseconds.

For 400-600kVA Modules—Set instantaneous trip settings to accommodate 3000A for 2 milliseconds

Vertiv™| Liebert® NX™ 225-600kVA Installation Manual | Rev. 8 | 07/2017 6

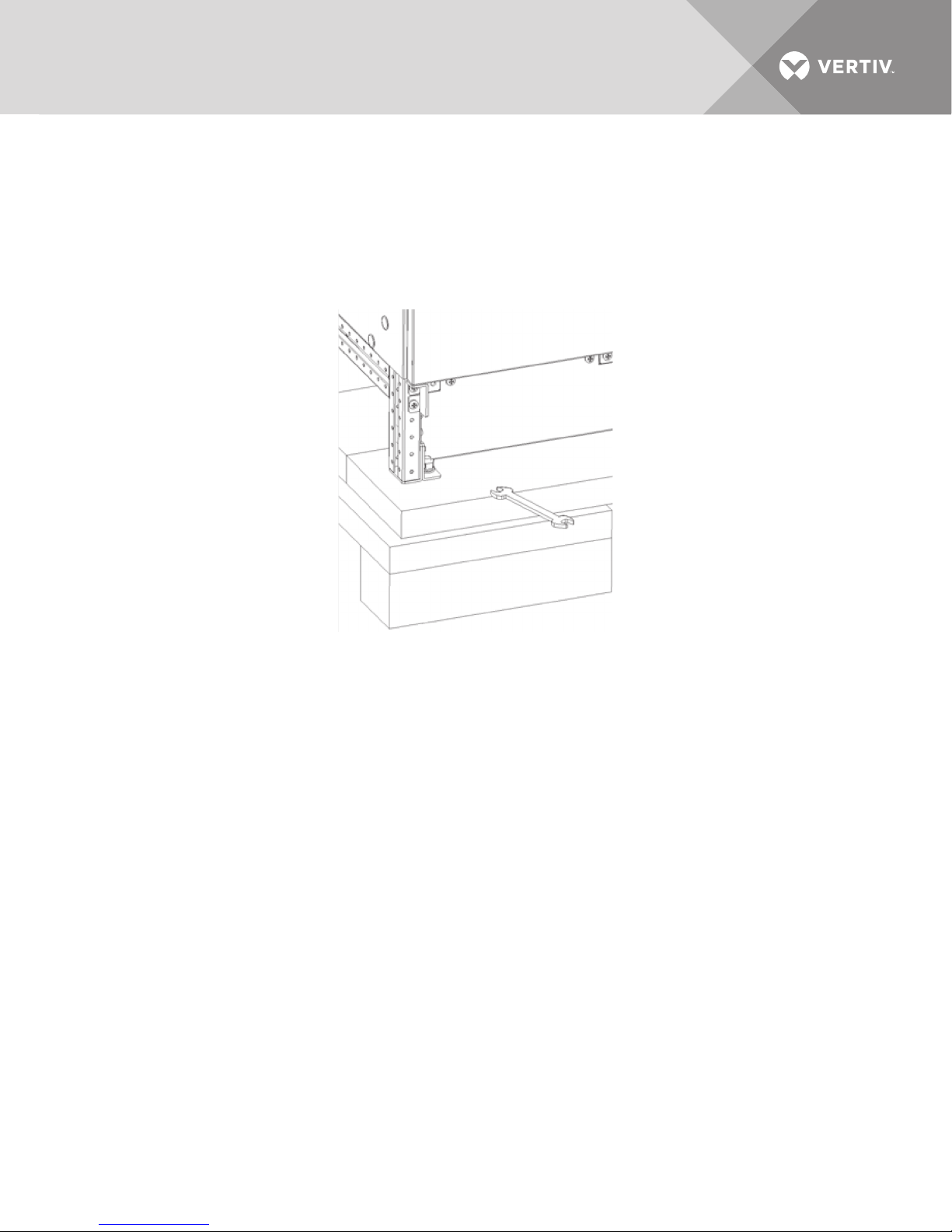

1.4.7 Unpacking and Unloading the Cabinet from the Pallet

The utmost care must be taken when removing the packaging to prevent damage to the equipment. Check all

packaging materials to ensure that no important items are discarded. Once the packaging has been removed,

the UPS must be taken off the pallet by removing the retaining screws, as illustrated in Figure 1, and lifting the

unit off using a fork lift Do not remove the retaining brackets securing the UPS to the pallet because they are

used to fasten the UPS to the floor, except where OSHPD compliance is required and the optional OSHPD

seismic anchoring kits are used.

Figure 1 Unpacking

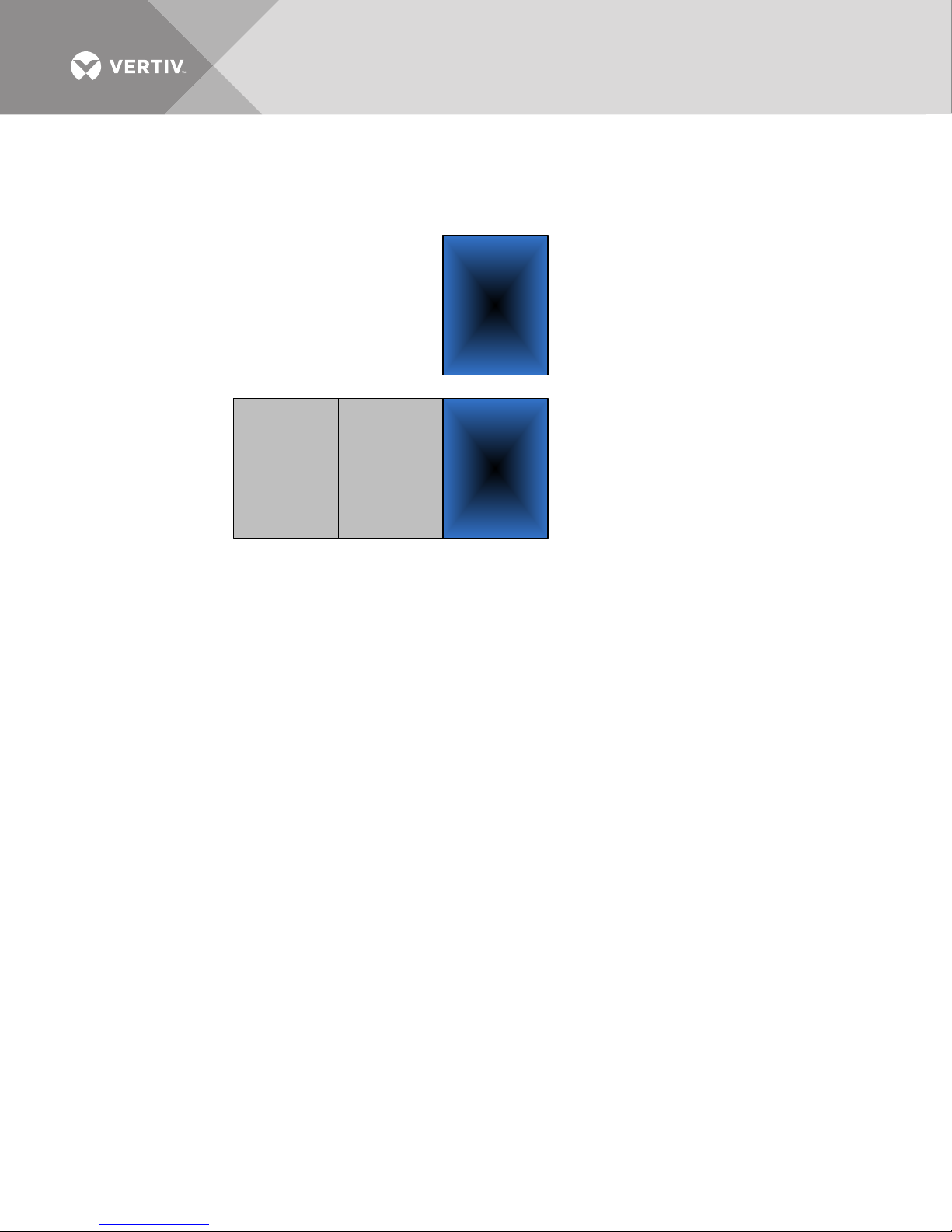

1.5 SYSTEM COMPOSITION

A UPS system can comprise a number of equipment cabinets, depending on the individual system design

requirements: e.g., UPS cabinet, battery cabinet, maintenance bypass cabinet. In general, all the cabinets used in

a particular installation are of the same height. Refer to the drawings provided in 4.0 - Installation Drawings for

the positioning of the cabinets as shown in Figure 2.

Vertiv™| Liebert® NX™ 225-600kVA Installation Manual | Rev. 8 | 07/2017 7

1.6 CABLE ENTRY

Liebert

NX

UPS

Liebert

NX

Battery

Cabinet

Liebert

NX

UPS

Additional

Liebert

NX

Battery

Cabinets

Battery Cabinets must

be installed on left of

UPS to wire internally

Cables can enter the UPS cabinet from bottom or top into the input/output (I/O) section of the unit; see the

figures in 4.0 - Installation Drawings.

Figure 2 Cabinet arrangement—Liebert NX matching battery cabinets

If the cabinets are to be bolted together, the side panels must be removed before beginning.

Vertiv™| Liebert® NX™ 225-600kVA Installation Manual | Rev. 8 | 07/2017 8

2.0 UPS ELECTRICAL INSTALLATION

!

!

This chapter provides guidelines for qualified installers who must have knowledge of local wiring practices

pertaining to the equipment to be installed.

WARNING

Risk of electrical shock. Can cause injury or death.

The UPS contains high DC as well as AC voltages. Check for voltage with both AC and DC voltmeters

before working within the UPS.

Only properly trained and qualified personnel wearing appropriate safety headgear, gloves, shoes and

glasses should be involved in installing the UPS or preparing the UPS for installation.

2.1 EXTERNAL PROTECTIVE DEVICES

For safety, it is necessary to install circuit breakers in the input AC supply and external battery system. Given that

every installation has its own characteristics, this section provides guidelines for qualified installation personnel

with knowledge of operating practices, regulatory standards and the equipment to be installed.

External overcurrent protection must be provided. See Figure 14 for overload capacity.

2.2 POWER CABLES

The UPS requires both power and control cabling. All control cables, whether shielded or not, should be run

separately from the power cables in metal conduits or metal ducts that are electrically bonded to the metalwork

of the cabinets to which they are connected.

The cable design must comply with the voltages and currents in Ta bles 9 through 12, follow local wiring

practices and take into consideration the environmental conditions (temperature and physical support media),

room temperature and conditions of installation of the cable and system’s overload capacity (see 5.0 -

Specifications).

WARNING

Risk of electrical shock. Can cause injury or death.

Before cabling the UPS, ensure that you are aware of the location and operation of the external isolators

that connect the UPS input/bypass supply to the power distribution panel.

Check that these supplies are electrically isolated, and post any necessary warning signs to prevent their

inadvertent operation.

When sizing battery cables, a maximum volt drop of 2VDC is permissible at the current ratings given in Table 12.

The following are guidelines only and are superseded by local regulations and codes of practice where

applicable:

• The grounding conductor should be sized according to the fault rating, cable lengths, type of protection, etc. The

grounding cable connecting the UPS to the main ground system must follow the most direct route possible.

• Consideration should be given to the use of paralleled smaller cables for heavy currents, as this can ease installation

considerably.

• AC and DC cables must be run in conduits according to local codes, national codes and standard best practices. This will

prevent creation of excess EMI fields.

Vertiv™| Liebert® NX™ 225-600kVA Installation Manual | Rev. 8 | 07/2017 9

2.3 SIZING THE INPUT BREAKER FEEDING A LIEBERT NX UPS

NOTE

See 3.2.3 - Capacity on Demand (Softscale) Upgrades.

Nominal input current (considered continuous) is based on full-rated output load. Maximum current includes

nominal input current and maximum battery recharge current (considered noncontinuous).

Continuous and noncontinuous current are defined in the NEC.

Maximum input current is controlled by the current limit setting, which is adjustable. Values shown are for

maximum current limit. If a smaller input feed breaker is used, the input current limit can be adjusted; see your

Vertiv representative for more information. The input current limit should not be set less than 105% of the

current needed to support the inverter at full load for normal operation.

This results in sufficient power to recharge the battery in a reasonable time and to operate over the published

input voltage range.

2.3.1 Single or Dual Input Feeds

The Liebert NX 225-600 kVA may be fed from single reference sources or dual asynchronous sources. If a

single-input configuration will be used, the utility source must be cabled to the rectifier input busbars. See

Figures 13 and 18.

2.3.2 Automatic Transfer Switches

If the UPS is to be fed from an automatic transfer switch, the transfer switch must have a programmed delay of

100 milliseconds for transfers between two sources.

Vertiv™| Liebert® NX™ 225-600kVA Installation Manual | Rev. 8 | 07/2017 10

Loading...

Loading...