Vertiv Liebert MCV Series, Liebert MCV330, Liebert MCV440, Liebert MC Installer/user Manual

Liebert® MCV™

60-Hz, High-density Microchannel Condenser

Installer/User Guide

Technical Support Site

If you encounter any installation or operational issues with your product, check the pertinent section of

this manual to see if the issue can be resolved by following outlined procedures. For additional assistance,

visit https://www.VertivCo.com/en-us/support/.

TABLE OF CONTENTS

1 Important Safety Instructions 5

2 Nomenclature and Components 7

2.1 Liebert MCV Model-number Nomenclature 7

2.2 Component Location 8

2.3 Product Description and Features 9

2.4 Control, Fan Types and Features 9

2.4.1 Premium Efficiency Control/EC Fan 9

2.4.2 Anti-Freezing Operation 9

2.4.3 Surge Protective Device 10

3 Pre-installation PreparationandGuidelines 11

3.1 Planning Dimensions 11

3.2 Unit Weights 11

4 Equipment Inspection and Handling 13

4.1 Packaging Material 13

4.2 Remove Shipping Panels and Brackets 14

5 Piping 15

5.1 Refrigerant Piping and Charging 15

5.1.1 Refrigerant Piping Guidelines forAir-cooledSystems 16

5.1.2 Additional Oil Requirements 17

5.2 System Dehydration/Leak Test 17

5.3 Charging Condensers with DSE Receivers 17

6 Electrical Connections 19

6.1 Line Voltage Wiring 20

6.1.1 Acceptable Power Supplies—380V to 460V Nominal Units 21

6.1.2 Unacceptable Power Supplies 21

7 Checklist for Completed Installation 23

7.1 Moving and Placing Equipment 23

7.2 Electrical Installation Checks 23

7.3 Piping Installation Checks 23

7.4 Other Installation Checks 23

8 Initial Start-up Checks andCommissioningProcedure forWarrantyInspection 24

9 Troubleshooting 25

10 Control Operation 27

10.1 Premium Efficiency Control Board and Interface 27

10.1.1 Initial Display upon Power-On 29

10.1.2 Navigating the Controller-interface Main Menu 29

10.1.3 Analog Signals Menu 30

10.1.4 Active Alarms Menu 31

10.1.5 History Alarms Menu 32

11 Maintenance 35

Vertiv | Liebert® MCV™ Installer/User Guide | 3

11.1 General Condenser Maintenance 36

11.2 Condenser Cleaning 36

11.2.1 When to Clean the Condenser Coil 36

11.2.2 What to Use to Clean the Condenser Coil 36

11.2.3 Cleaning the Condenser Coil 37

11.3 Replacing the Condenser Fan 37

11.3.1 Verifing the Fan Address 43

11.4 Replacing the Premium-efficiency Control Board 47

11.4.1 Preparing to Replace the Board 47

11.4.2 Installing the Replacement Board 48

12 Preventive Maintenance Checklist 50

Appendices 55

Appendix A: Technical Support and Contacts 55

Appendix B: Submittal Drawings 57

Vertiv | Liebert® MCV™ Installer/User Guide | 4

1 IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

This manual contains important safety instructions that should be followed during the installation and

maintenance of the LiebertMCV. Read this manual thoroughly before attempting to install or operate this

unit.

Only qualified personnel should move, install or service this equipment.

Adhere to all warnings, cautions, notices and installation, operating and safety instructions on the unit

and in this manual. Follow all installation, operation and maintenance instructions and all applicable

national and local building, electrical and plumbing codes.

WARNING! Arc flash and electric shock hazard. Open all local and remote electric power-supply

disconnect switches, verify with a voltmeter that power is Off and wear appropriate,

OSHA-approved personal protective equipment (PPE) per NFPA 70E before working within the

electric control enclosure. Failure to comply can cause serious injury or death. Customer must

provide earth ground to unit, per NEC, CEC and local codes, as applicable. Before proceeding

with installation, read all instructions, verify that all the parts are included and check the

nameplate to be sure the voltage matches available utility power. The Liebert controller does

not isolate power from the unit, even in the “Unit Off” mode. Some internal components require

and receive power even during the “Unit Off” mode of the controller. The only way to ensure

that there is NO voltage inside the unit is to install and open a remote disconnect switch. Refer

to unit electrical schematic. Follow all local codes.

WARNING! Risk of over-pressurization of the refrigeration system. Can cause explosive

discharge of high-pressure refrigerant, loss of refrigerant, environmental pollution, equipment

damage, injury, or death. This unit contains fluids and gases under high pressure. Use extreme

caution when charging the refrigerant system. Do not pressurize the system higher than the

design pressure marked on the unit's nameplate.

WARNING! Risk of contact with high-speed, rotating fan impeller blades. Can cause injury or

death. Open all local and remote electric power-supply disconnect switches, verify with a

voltmeter that power is off, and verify that all fan impellers have stopped rotating before

working in the unit cabinet.

WARNING! Risk of contact with high-speed rotating fan blades. Can cause serious injury or

death. If control voltage is applied, the fan motor can restart without warning after a power

failure. Open all local and remote electric power-supply disconnect switches, verify with a

voltmeter that power is off, and verify that all fan blades have stopped rotating before working

on the fan assembly. After working on the fan assembly, remove any used tools or other

objects from the unit cabinet before restoring electric power.

Vertiv | Liebert® MCV™ Installer/User Guide | 5

WARNING! Risk of improper wiring, piping, moving, lifting and handling. Can cause equipment

damage, serious injury or death. Installation and service of this equipment should be done only

by qualified personnel, wearing appropriate, OSHA-approved PPE, who have been speciallytrained in the installation of air-conditioning equipment.

WARNING! Risk of improper wire and loose electrical connections. Can cause overheated wire

and electrical connection terminals resulting in smoke, fire, equipment and building damage,

injury or death. Use correctly sized copper wire only and verify that all electrical connections are

tight before turning power On. Check all electrical connections periodically and tighten as

necessary.

CAUTION: Risk of contact with sharp edges, splinters, and exposed fasteners. Can cause

injury. Only properly trained and qualified personnel wearing appropriate, OSHA-approved PPE

should attempt to move, lift, remove packaging from or prepare the unit for installation.

CAUTION: Risk of improper moving, lifting and handling. Can cause equipment damage or

injury. Only properly trained and qualified personnel should work on this equipment. Fan

modules weigh in excess of 115lb(52.2kg). Use proper lifting techniques and wear appropriate,

OSHA-approved PPE to avoid injury and dropping the fan module during removal. Equipment

used in handling/lifting, and/or installing the fan assembly must meet OSHA requirements. Use

handling/lifting equipment rated for the weight of the fan assembly. Use ladders rated for the

weight of the fan assembly and technicians if used during installation. Refer to handling/lifting,

and/or installation equipment operating manual for manufacturer's safety requirements and

operating procedures.

CAUTION: Risk of exposure to harmful noise levels. Can cause hearing injury or loss.

Depending on the installation and operating conditions, a sound pressure level greater than

70dB(A) may arise. Take appropriate technical safety measures. Operating personnel must

wear appropriate, OSHA-approved PPE and observe all appropriate hearing-protection safety

requirements.

NOTICE

Risk of oil contamination with water. Can cause equipment damage.

LiebertMCV systems require the use of POE (polyolester) oil. POE oil absorbs water at a much

faster rate when exposed to air than previously used oils. Because water is the enemy of a

reliable refrigeration system, extreme care must be used when opening systems during

installation or service. If water is absorbed into the POE oil, it will not be easily removed and will

not be removed through the normal evacuation process. If the oil is too wet, it may require an oil

change. POE oils also have a property that makes them act as a solvent in a refrigeration

system. Maintaining system cleanliness is extremely important because the oil will tend to

bring any foreign matter back to the compressor.

Vertiv | Liebert® MCV™ Installer/User Guide | 6

2 NOMENCLATURE AND COMPONENTS

This section describes the model-number configuration for Liebert MCV units and components.

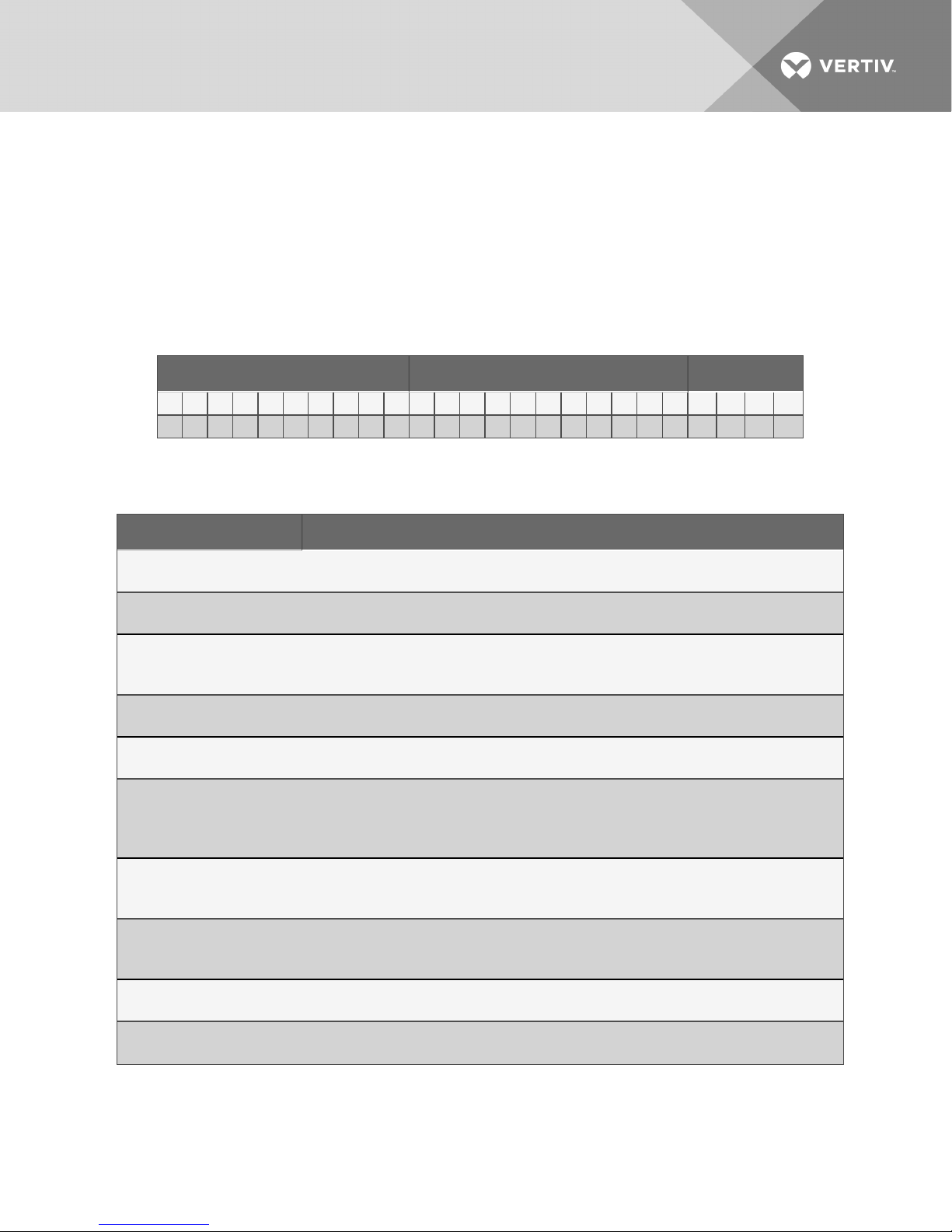

2.1 Liebert MCV Model-number Nomenclature

Table 2.2 below describes each digit of the 25-digitconfigurationnumber. The 14-digit model number

consists of the first 10 digits and last four digits of the configuration number.

Table 2.1 Liebert MCV 25-digit Configuration Number Example

Model # Part 1 Model Details Model # Part 2

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25

M C V 3 3 0 E 2 A D 0 G 0 0 U 0 2 0 0 0 0 * * * *

Table 2.2 MCV Model-number Digit Definitions

Digit Description

Digits 1 and2 = Unit Family

MC = MicrochannelCondenser

Digit3 Platform Size

V = V-coil arr angement

Digits 3-6 - Nominal Capacity, kW

330 = 330kW

440 = 440kW

Digit7 - Control/Fan Type

E = Pr emium control and E C fan

Digit8 - Refrigerant Circuits/System Refrigerant Type

2 = Dual refrigerant circuit, R-410A

Digit9 - Power Supply

A = 4 60V / 3ph / 60Hz

2 = 380V / 3ph / 60Hz

M = 380-415V / 3ph / 50Hz

Digit10 - Packaging

D = Domestic, non-stackable

E = Export crating, non-stackable

Digit11 - Coil Coating

0 = None

E = E-coat (epoxy)

Digit12 - PanelMaterial

G = Galvanizedsteel

Digit13 - ConnectionPipe Unit of Measurement

0 = Inches (std. ACR copper)

Vertiv | Liebert® MCV™ Installer/User Guide | 7

Table 2.2 MCV Model-number Digit Definitions (continued)

Digit Description

Digit14 - Legs Included

0 = No legs (standard)

Digit15 - Agency Certification

U = CSA listed, mar ked withCSA c-us logo

Digit16 - Undefined, Reserved for future use.

Digit17 - Receiver/Software Configuration

2 = Liebert DSEsoftware

Digits 18-21 - Undefined, Reser ved for future use.

Digits 22-25 - Factory Configuration Number

2.2 Component Location

The unit component locations are described in the submittal documents included in the Submittal

Drawings on page57.

The following table lists the relevant documents by number and title.

Table 2.3 Component-location Drawings

Document Number Titl e

DPN003871 ComponentL ocations, 6-fan MCV330

DPN004210 ComponentL ocation, 8-fan MCV440

Vertiv | Liebert® MCV™ Installer/User Guide | 8

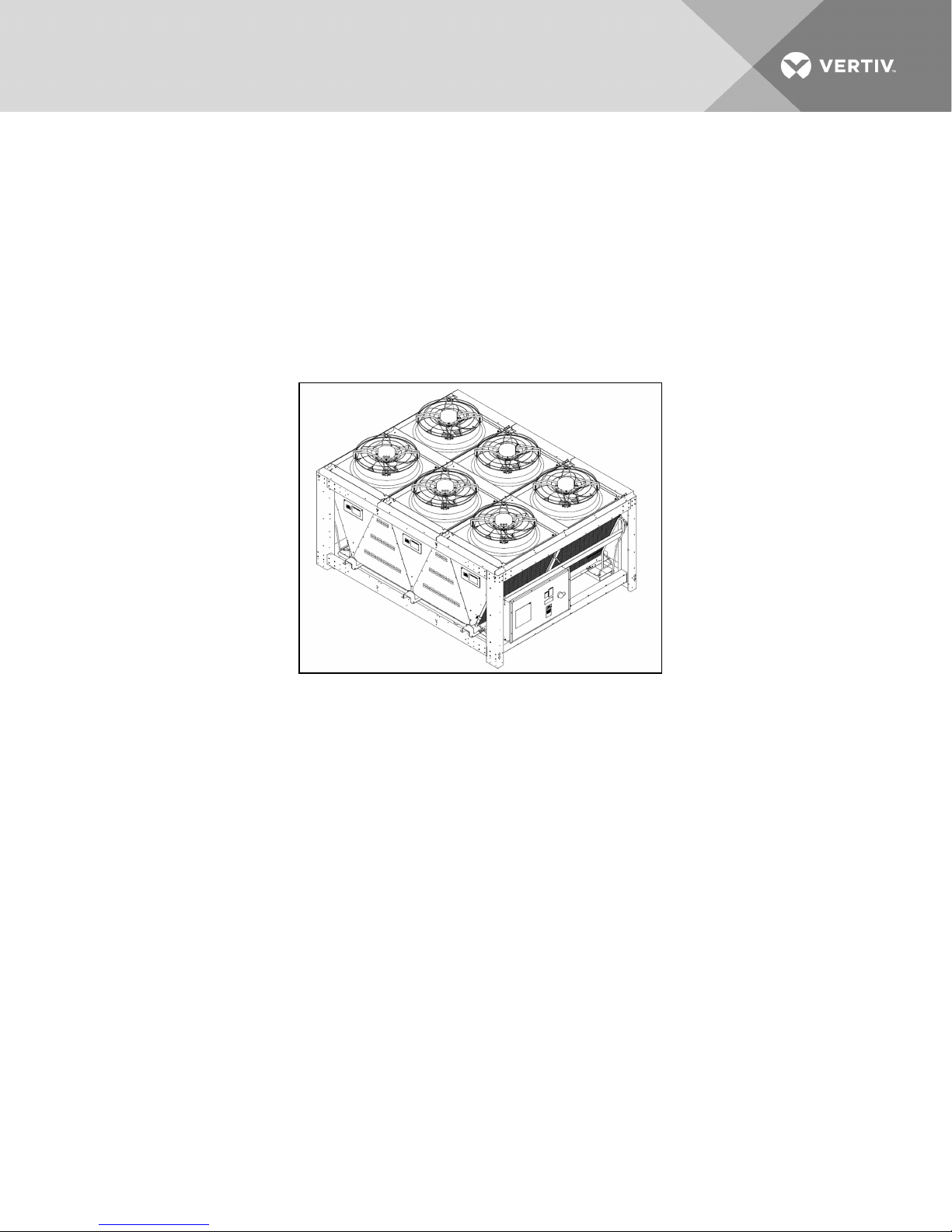

2.3 Product Description and Features

The Liebert MCV condenser is a direct-drive EC-fan type air-cooled heat-rejection unit suitable for

mounting outdoors. It provides heat rejection for two separate refrigeration circuits, matches the heat

rejection capacity corresponding with the outdoor ambient temperature and with each corresponding

compressor heat-rejection requirements. Constructed with a galvanized-steel frame, galvanized-steel

panels and aluminum microchannel coil, the unit is quiet and corrosion resistant. The condenser is quickly

and easily installed, because all internal wiring is completed at the factory with only electrical connections

to be made at the job site. All electrical connections and controls are enclosed in an integral, weatherproof

section of the condenser.

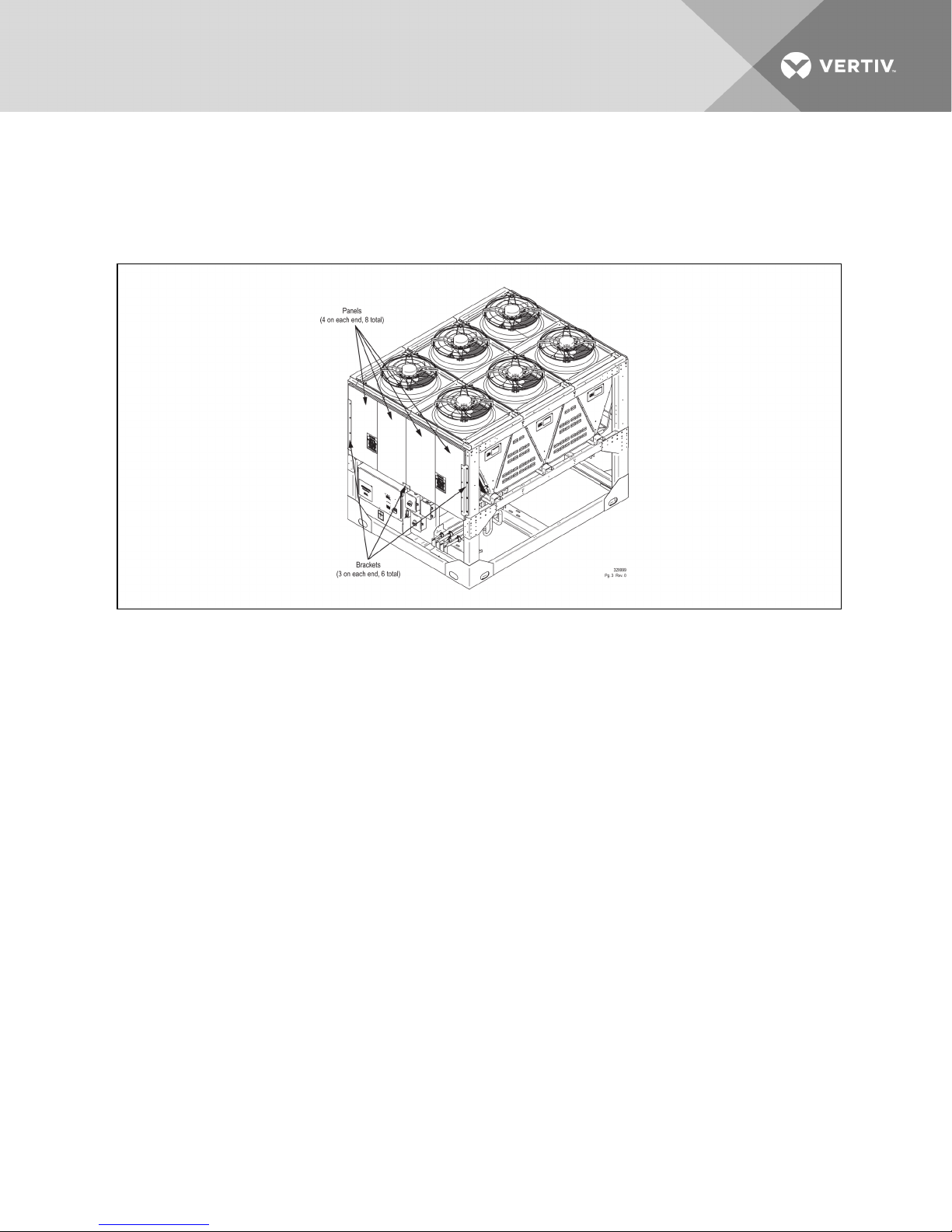

Figure 2.1 Liebert MCV

2.4 Control, Fan Types and Features

2.4.1 Premium Efficiency Control/EC Fan

Premium Efficiency Controls and EC fans are matched to provide superior system energy efficiency. The

premium control board allows CANbus communication with the indoor unit’s Liebert iCOM™ control. This

communication feature provides compressor run signals, condenser operating mode changes, condenser

alarm monitoring, simplified system charging procedures and outdoor temperature monitoring.

The Premium Efficiency Control board on a Liebert MCV maintains EC fans on the same circuit to the

same speed in order to maintain refrigerant head pressure in DX mode and refrigerant temperature in

EconoPhase mode.

2.4.2 Anti-Freezing Operation

The EC fans must be operated periodically in cold weather to reduce the possibility of lockup due to ice

and snow accumulation. During periods of fan inactivity and outdoor temperatures below 35°F (1.6°C), the

EC fans will spin for at least 30 seconds every 15 minutes at 60% of the maximum fan speed.

Vertiv | Liebert® MCV™ Installer/User Guide | 9

2.4.3 Surge Protective Device

An optional Surge Protective Device (SPD) can be field-wired to protect the condenser from power surges

that threaten sensitive equipment. The condenser’s electrical panel provides a terminal block to allow the

SPD to be wired in parallel with the high-voltage power. An additional low-voltage terminal block is

provided on condensers to allow monitoring of the SPD alarm circuit.

ASCO Series 420 surge-protective device provides 50kA per mode of surge current protection. An

illuminated green LED indicates the SPD is On and operating properly. An illuminated red LED indicates

that the device may require replacement.

When both LEDs are Off, there is no power to the condenser, either from a power failure or because the

condenser disconnect is in the Off position.

Vertiv | Liebert® MCV™ Installer/User Guide | 10

3 PRE-INSTALLATION PREPARATIONANDGUIDELINES

The unit dimensions, pipe-connection locations, and piping schematics are described in the submittal

documents included in the Submittal Drawings on page57.

• Install the condenser in a location offering maximum security and access for maintenance.

• Avoid ground-level sites with public access and areas prone to heavy snow or ice

accumulations.

• To ensure adequate air supply, we recommend that condensers be installed in an area with

clean air, away from loose dirt and foreign matter that might clog the coil. In addition,

condensers should be located no closer than 3 ft (1m) from a wall, obstruction or adjacent unit.

• For roof installation, mount the condenser on suitable curbs or other supports in accordance

with local codes.

• Condensers must not be installed in a pit.

• Condensers must be installed on a level surface to ensure proper refrigerant flow.

• Condensers must not be installed below the indoor unit.

• Condensers must be installed in vertical airflow orientation to maintain the electrical box’s

NEMA 3R rating.

3.1 Planning Dimensions

The unit, floor stand, and plenum dimensions are described in the submittal documents included in the

Submittal Drawings on page57.

The following table lists the relevant documents by number and title.

Table 3.1 Dimension Planning Drawings

Document Number Titl e

DPN003874 Cabinet and Floor PlanningDimensional Data, MCV330

DPN004209 Cabinet and Floor Planning DimensionalData, MCV440

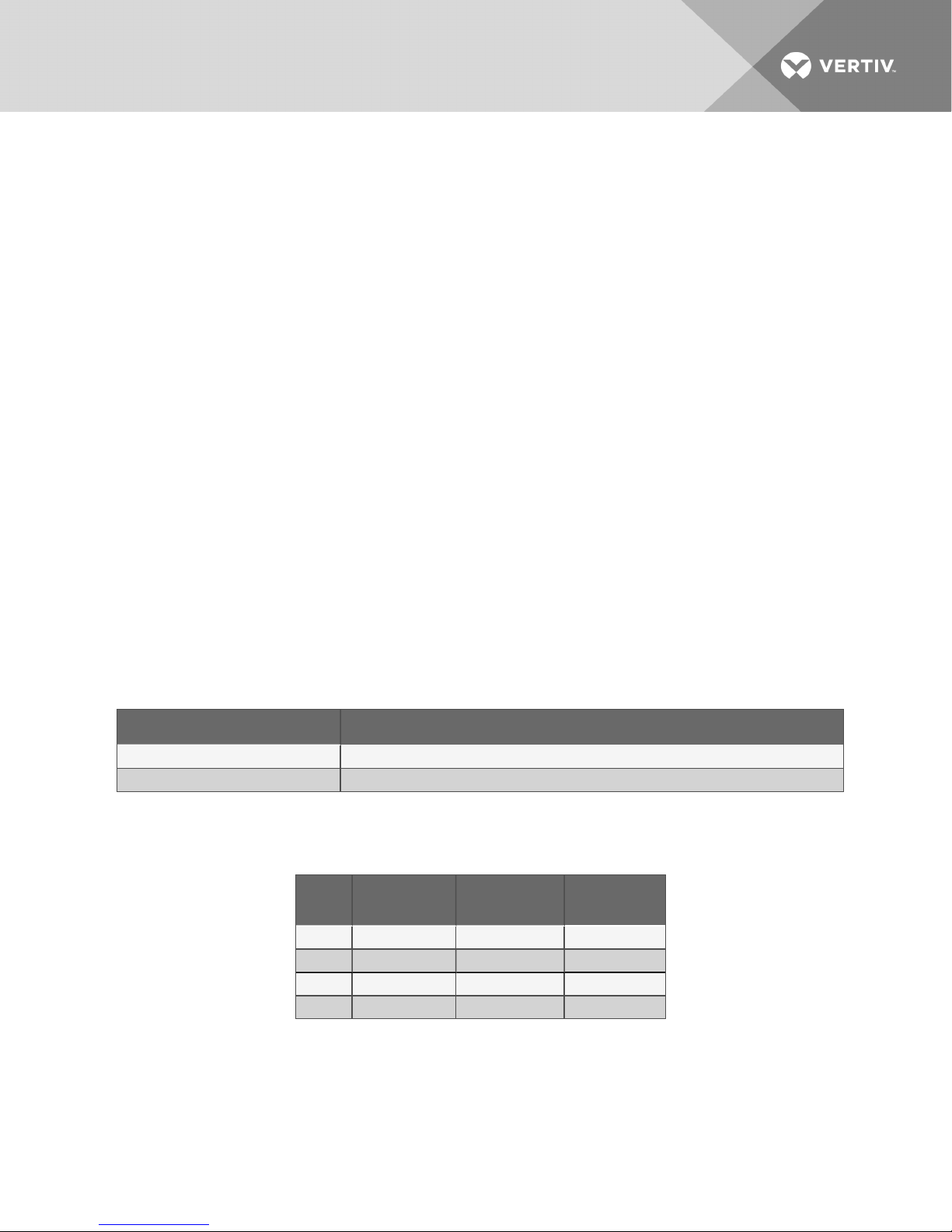

3.2 Unit Weights

Table 3.2 MCV Skid Approximate Weights

Model

MCV330 6 1 4,800 (2,177)

MCV330 6 2 10,000 (4,536)

MCV440 8 1 5,365 (2,433)

MCV440 8 2 10,730 (4 ,867)

Number of Fans

on Condenser

Number of Units

on Skid

Weight, lb(kg)

Vertiv | Liebert® MCV™ Installer/User Guide | 11

This page intentionally left blank.

Vertiv | Liebert® MCV™ Installer/User Guide | 12

4 EQUIPMENT INSPECTION AND HANDLING

SAFETY INFORMATION

WARNING! Risk of improperly moving, lifting, or handling. Improper handling can cause

equipment damage, injury or death. Read all of the following instructions and verify that all

lifting and moving equipment is rated for the weight of the unit before attempting to move, lift,

remove packaging from or prepare the unit for installation.

CAUTION: Risk of contact with sharp edges, splinters, and exposed fasteners. Can cause

injury. Only properly trained and qualified personnel wearing appropriate, OSHA-approved PPE

should attempt to move, lift, remove packaging from or prepare the unit for installation.

NOTICE

Risk of improper lifting. Can cause equipment damage. Make sure that the spreader bars wider

are than the unit. If the spreader bars are too short, the slings may crush the unit.

NOTICE

Risk of improper storage. Keep the unit upright, indoors and protected from dampness,

freezing temperatures and contact damage.

Upon arrival of the unit and before unpacking:

• Verify that the labeled equipment matches the bill of lading.

• Carefully inspect all items for visible or concealed damage.

• Report damage immediately to the carrier and file a damage claim with a copy sent to Vertiv™

or to your sales representative.

4.1 Packaging Material

All material used to package this unit is recyclable. Please save for future use or dispose of the

material appropriately.

Vertiv | Liebert® MCV™ Installer/User Guide | 13

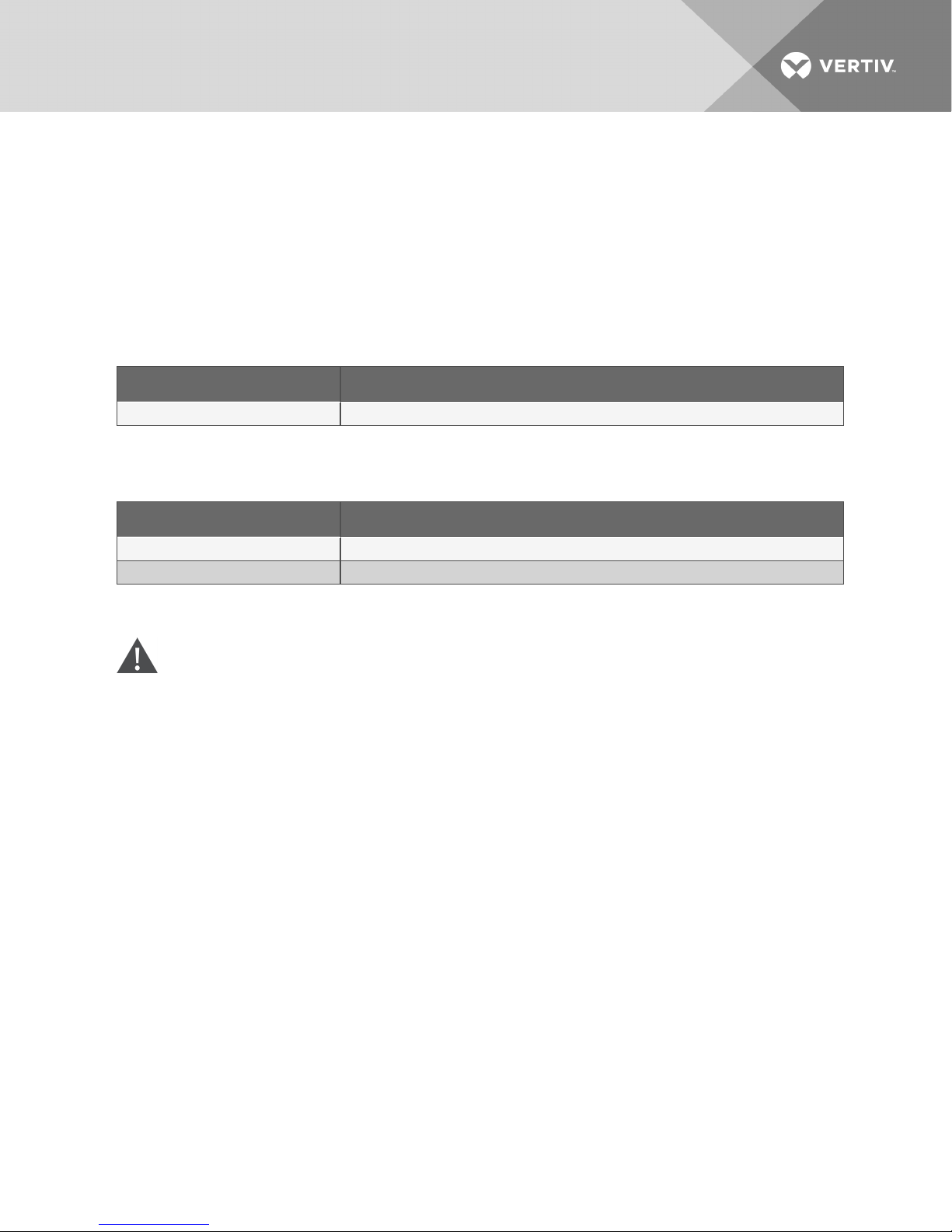

4.2 Remove Shipping Panels and Brackets

Shipping panels and securing brackets are located on each end of the unit. Before operating the unit,

remove the panels and brackets from both ends of the unit, Figure 4.1 below.

Figure 4.1 Shipping panels and securing brackets to remove

Vertiv | Liebert® MCV™ Installer/User Guide | 14

5 PIPING

All refrigeration connections to the unit are sweat copper. Factory-installed piping brackets must not be

removed. Field-installed piping must be installed in accordance with local codes and must be properly

assembled, supported, isolated and insulated.

Refer to specific text and detailed diagrams in this manual for other unit-specific piping requirements.

The following tables list the relevant documents by number and title.

Table 5.1 Piping General-arrangment Drawings

Document Number Titl e

DPN004476 PipingSchematic, Liebert MCV with Liebert DS E models DA125 to DA250

Table 5.2 Piping Connection Drawings

Document Number Titl e

DPN003877 Piping connection locations, MCV330

DPN004211 Piping connection locations, MCV440

5.1 Refrigerant Piping and Charging

WARNING! Risk of over-pressurization of the refrigeration system. Can cause explosive

discharge of high-pressure refrigerant, loss of refrigerant, environmental pollution, equipment

damage, injury, or death. This unit contains fluids and gases under high pressure. Use extreme

caution when charging the refrigerant system. Do not pressurize the system higher than the

design pressure marked on the unit's nameplate.

Consult local building and plumbing codes for installation requirements of additional pressure-relief

devices when isolation valves are field installed. Do not isolate any refrigerant circuits from overpressurization protection.

NOTICE

Risk of oil contamination with water. Can cause equipment damage.

LiebertMCV systems require the use of POE (polyolester) oil. POE oil absorbs water at a much

faster rate when exposed to air than previously used oils. Because water is the enemy of a

reliable refrigeration system, extreme care must be used when opening systems during

installation or service. If water is absorbed into the POE oil, it will not be easily removed and will

not be removed through the normal evacuation process. If the oil is too wet, it may require an oil

change. POE oils also have a property that makes them act as a solvent in a refrigeration

system. Maintaining system cleanliness is extremely important because the oil will tend to

bring any foreign matter back to the compressor.

Vertiv | Liebert® MCV™ Installer/User Guide | 15

5.1.1 Refrigerant Piping Guidelines forAir-cooledSystems

• Air-cooled units and condensers ship with an inert-gas holding charge. Do not vent the

evaporator until all refrigerant piping is in place, ready for connection to the unit and

condenser

• Use copper piping with a brazing alloy with a minimum temperature of 1350°F (732°C), such as

Sil-Fos. Avoid soft solders, such as 50/50 or 95/5.

• Use a flow of dry nitrogen through the piping during brazing to prevent formation of copper

oxide scale inside the piping. When copper is heated in the presence of air, copper oxide forms.

POE oils will dissolve these oxides from inside the copper pipes and deposit them throughout

the system, clogging filter driers and affecting other system components.

• A pure dry nitrogen flow of 1-3 ft3/min (0.5-1.5 l/s) inside the pipe during brazing is sufficient to

displace the air. Control the flow using a suitable measuring device.

• Ensure that the tubing surfaces to be brazed are clean and that all burrs have been removed

from the ends of the tubes.

• Ensure that all loose material has been cleaned from inside the tubing before brazing.

• Protect all refrigerant line components within 18in. (460mm) of the brazing site by wrapping

them with a wet cloth or with a suitable heat-sink compound.

• Isolate piping from building using vibration-isolating supports.

• Install traps on hot-gas (discharge) lines at the base of vertical risers over 5ft(1.5m) and every

20ft(6m) for vertical rises over 25 ft (7.6m), then install a trap in 20-ft (6-m) increments or

evenly-divided over the vertical rise.

• When connecting to a DA250 indoor unit: Install traps on hot-gas (discharge) lines at the base

of vertical risers over 5ft(1.5m) and every 20ft(6m) or evenly-divided over the vertical rise.

The DA250 has internally-installed traps on the hot-gas lines.

• Pitch horizontal hot-gas piping down at a minimum rate of 1/2in.per 10ft (42mm per 10m) so

that gravity will aid in moving oil in the direction of refrigerant/oil flow.

• When connecting to a DA165 indoor unit: Consult factory if piping run exceeds 300ft (91m)

actual length or 450ft(137.2m) equivalent length.

• Keep piping clean and dry, especially on units with R-410A refrigerant.

• Avoid piping runs through noise-sensitive areas.

• Do not run piping directly in front of discharge air stream.

• Refrigerant oil – do not mix oil types. Consult the indoor-unit installation/user guide for

refrigerant type and oil requirements.

Refer to ASHRAE Refrigeration Handbook for general, good-practice refrigeration piping. The indoor

cooling unit has a factory-installed high-pressure safety switch in the high side refrigerant circuit. A

fusible plug kit is installed in each Liebert MCV receiver.

NOTE: All indoor and outdoor field refrigerant piping must have 1/2 in. minimum of insulation. All

outdoor insulation must be UV and ozone resistant.

Vertiv | Liebert® MCV™ Installer/User Guide | 16

• Refer to the indoor unit's Installer/User Guide for recommended refrigerant piping sizes based

on equivalent pipe lengths.

• Refer to the indoor unit's Installer/User Guide for the refrigerant-charge requirements of the

system. Table 5.3 below, provides the approximate charge for an MCV condenser.

Table 5.3 Approximate R-410A refrigerant required per circuit for condenser with DSE large receiver

(dual circuit)

Condenser Model Charge per circuit, lb (kg)

MCV330 27.8 (12.6)

MCV440 34.6 (15.7)

5.1.2 Additional Oil Requirements

Refer to the indoor unit's Installer/User Guide to determine if additional oil is required for each circuit. The

need for additional oil is affected by compressor type, piping lengths, receiver, and total refrigerant

charge.

5.2 System Dehydration/Leak Test

Refer to the indoor unit's Installer/User Guide for the leak-check and evacuation procedures for the entire

thermal-management system. Refer to the section that refers to the winter control system used on the

condenser with Liebert DSE receivers.

5.3 Charging Condensers with DSE Receivers

Refer to the indoor unit's Installer/User Guide for the leak-check and evacuation procedures for the entire

thermal-management system. All Liebert DSE Thermal Management Systems require a DSEreceiver on

each condenser circuit whether or not the system includes a Liebert EconoPhase pump module.

Vertiv | Liebert® MCV™ Installer/User Guide | 17

This page intentionally left blank.

Vertiv | Liebert® MCV™ Installer/User Guide | 18

6 ELECTRICAL CONNECTIONS

Line-voltage electrical service is required for all models. Electrical service must conform to national and

local electrical codes. Refer to equipment nameplate regarding wire size and circuit protection

requirements. Refer to electrical schematic when making connections. Refer the appropriate submittal

drawing, listed in Table 6.1 on the next page, for electrical service entrances into unit.

A manual electrical disconnect switch should be installed in accordance with local codes and distribution

system. Consult local codes for external disconnect requirements.

All internal wiring is completed at the factory.

WARNING! Arc flash and electric shock hazard. Open all local and remote electric power-supply

disconnect switches, verify with a voltmeter that power is Off and wear appropriate,

OSHA-approved personal protective equipment (PPE) per NFPA 70E before working within the

electric control enclosure. Failure to comply can cause serious injury or death. Customer must

provide earth ground to unit, per NEC, CEC and local codes, as applicable. Before proceeding

with installation, read all instructions, verify that all the parts are included and check the

nameplate to be sure the voltage matches available utility power. The Liebert controller does

not isolate power from the unit, even in the “Unit Off” mode. Some internal components require

and receive power even during the “Unit Off” mode of the controller. The only way to ensure

that there is NO voltage inside the unit is to install and open a remote disconnect switch. Refer

to unit electrical schematic. Follow all local codes.

WARNING! Risk of improper wiring, piping, moving, lifting and handling. Can cause equipment

damage, serious injury or death. Installation and service of this equipment should be done only

by qualified personnel, wearing appropriate, OSHA-approved PPE, who have been speciallytrained in the installation of air-conditioning equipment.

WARNING! Risk of contact with high-speed rotating fan blades. Can cause serious injury or

death. If control voltage is applied, the fan motor can restart without warning after a power

failure. Open all local and remote electric power-supply disconnect switches, verify with a

voltmeter that power is off, and verify that all fan blades have stopped rotating before working

on the fan assembly. After working on the fan assembly, remove any used tools or other

objects from the unit cabinet before restoring electric power.

NOTE: Use copper wiring only. Make sure that all connections are tightened to the proper torque

mentioned on the component.

The electrical connections are described in the submittal documents included in the Submittal Drawings

on page57.

Vertiv | Liebert® MCV™ Installer/User Guide | 19

The following tables list the relevant documents by number and title.

Table 6.1 Electrical Field-connection Drawings

Document Number Titl e

DPN003879 Electrical FieldConnections, MCV330

DPN004212 E lectrical Field Connections, MCV440

DPN003886 CANbus and Interlock Connections between Unitand Condenser

6.1 Line Voltage Wiring

WARNING! Risk of electrical fire and short circuit. Can cause property damage, injury or death.

Select and install the line side electrical supply wire and overcurrent protection device(s)

according to the specifications on the unit nameplate(s), per the instructions in this manual

and according to the applicable national, state and local code requirements. Use copper

conductors only. Verify that all electrical connections are tight. Unit-specific wiring diagrams

are provided on each unit.

NOTE: The electrically commutated (EC) motors included in the Liebert MCV Condenser are suitable

for connection to power supplies with a solidly-grounded neutral or high-resistance to ground or

corner ground.

Condenser-rated voltage should be verified with available power supply before installation. Refer to the

unit’s electrical schematic and serial tag for specific electrical requirements.

Liebert MCV condenser power connections are provided for three-phase wires and 1 earth ground wire.

Line voltage electrical service is required for all condensers at the location of the condenser. The voltage

supply to the condenser may not be the same voltage supply as required by the indoor unit. Consider

using a UPS on both data center cooling units and MCV condensers to maintain uninterrupted cooling

capability. Refer to the unit’s serial tag for specific condenser electrical requirements. A unit disconnect is

standard. However, a site disconnect may be required by local code to isolate the unit for maintenance.

Route the supply power to the site disconnect switch and then to the unit. Route the conduit to the

knockout provided in the bottom right end of the electrical control enclosure. Connect the earth ground

wire lead to the marked earth ground connection terminal provided near the factory-installed disconnect

switch the appropriate drawing in the Submittal Drawings on page57..

Table 6.2 Electrical data, three-phase, 60Hz condenser, premium models

Model Suppl y Power: 460- 3-60 380-3-60 415-3-50

FLA 16.8 21.0 21

MCV330

MCV440

WSA 17.5 21.9 21.9

OPD 20 25 25

FLA 22.4 28.0 28

WSA 23.1 28.9 28.9

OPD 25 35 35

NOTE: A separate neutral wire does not need to be run to the MCV.

Vertiv | Liebert® MCV™ Installer/User Guide | 20

6.1.1 Acceptable Power Supplies—380V to 460V Nominal Units

• 380V Wye with solidly grounded neutral and 220V line-to-ground

• 480V Wye with solidly grounded neutral and 277V line-to-ground

• Wye with high-resistance (or impedance) ground

• Delta with corner ground

6.1.2 Unacceptable Power Supplies

• Delta without ground or with floating ground

• Delta with grounded center tap

Vertiv | Liebert® MCV™ Installer/User Guide | 21

This page intentionally left blank.

Vertiv | Liebert® MCV™ Installer/User Guide | 22

Loading...

Loading...