Vertiv Liebert MCS056, Liebert MCM080, Liebert MCM160, Liebert MCL055, Liebert MCL165 User Manual

...

Liebert® MC™

60-Hz Air-cooled MicrochannelCondenser

-Premium/EC Fan

Installer/User Guide

Technical Support Site

If you encounter any installation or operational issues with your product, check the pertinent section of

this manual to see if the issue can be resolved by following outlined procedures. Visit

https://www.VertivCo.com/en-us/support/ for additional assistance.

TABLE OF CONTENTS

Important Safety Guidelines 5

Liebert MC Nomenclature 9

1 Introduction 11

1.1 Product Description and Features 11

1.2 Control, Fan Types and Features 11

1.2.1 Premium Efficiency Control/EC Fan 11

1.3 Liebert Lee-Temp™ Refrigerant Control 12

1.4 Surge Protective Device 13

2 Site Preparation 15

2.1 Site Considerations 15

2.2 Dimensions and Weights 15

2.2.1 Condenser and Options Net Weights 16

3 Inspection and Installation 27

3.1 Equipment Inspection 28

3.1.1 Packing Material 28

3.2 Handling Unit on the Skid 28

3.3 Unit Storage 29

3.4 Unpacking the Condenser—All Unit Sizes 29

3.5 Preparing a Condenser for Moving and Installation 30

3.5.1 Attaching 18" (457mm) Legs, RemovingtheSkidandAttachingSlings 30

3.5.2 Attaching36to60in.(914to1524mm)Legs, RemovingtheSkidandAttaching Slings 33

3.6 Mounting the Condenser 36

3.6.1 Standard Mounting Requirements 36

3.6.2 Seismic-Certified and Wind-Certified Mounting Requirements 36

4 Electrical Connections 39

4.1 Line Voltage Wiring 40

4.1.1 Wye- vs. Delta-Connected Power Supply 42

4.2 Low-voltage Control Wiring—CANbus Communication andInterlock Connections 43

4.2.1 Electrical Field Connection Descriptions 50

5 Piping 53

5.1 Piping Guidelines 53

5.2 Field Piping Guidelines 61

5.2.1 Field Piping Guidelines foraLiebertDXSystemandLiebertMCCondenser 62

5.2.2 Field Piping Guidelines foraLiebertDSEandLiebertPremiumMCCondenser 68

5.3 Refrigerant Planning Values 75

5.3.1 Recommended Refrigerant Line Sizes 76

5.4 Equipment Application Guidelines 78

5.5 Refrigerant Oil Addition Procedures 78

5.6 System Dehydration/Leak Test 78

5.7 System Charging with Liebert MC 78

Vertiv | Liebert® MC™ Installer/User Guide | 3

5.7.1 Liebert MC Charging, Units with Liebert Lee-Temp™ Receivers 78

5.7.2 Liebert MC Condenser Charging with Liebert DSE™ Receivers 79

5.7.3 Liebert MC Charging, Premium Efficiency Control, Units without Receivers 79

6 Checklist for Completed Installation 83

6.1 Moving and Placing Equipment 83

6.2 Electrical 83

6.3 Piping 83

6.4 Other 84

7 Initial Startup Checks and Commissioning 85

7.1 Startup Checklist 86

7.2 Initial Startup 86

8 Troubleshooting 87

9 Control Operation 89

9.1 Premium Efficiency Control Board and Interface 89

9.1.1 Initial Screen Upon Power-On 91

9.1.2 Main Menu Description 91

9.1.3 Analog Signals Menu Description 92

9.2 Premium Efficiency Condenser Alarm Codes 93

9.2.1 Active Alarms Menu Description 94

9.2.2 History Alarms Menu Description 94

10 Liebert Seismic Application—OptionalUnitConfiguration 99

10.1 Seismic Anchoring Considerations 99

10.2 Seismic piping considerations 107

10.3 Seismic wiring considerations 107

11 System Maintenance 109

11.1 General Procedures 109

11.2 Condenser Cleaning 110

11.2.1 When to Clean the Condenser Coil 110

11.2.2 What to Use to Clean the Condenser Coil 110

11.2.3 How to Clean the Condenser Coil 110

11.3 Fan Replacement 111

11.3.1 Verify the Fan Address 115

11.4 Premium Efficiency Control Board Replacement 120

11.4.1 Replacement Preparation 120

11.4.2 Installation 121

12 Preventive Maintenance Checklist 123

Vertiv | Liebert® MC™ Installer/User Guide | 4

IMPORTANT SAFETY GUIDELINES

Save These Instructions

This manual contains important safety instructions that should be followed during the installation and

maintenance of the Liebert MC. Read this manual thoroughly before attempting to install or operate this

unit.

Only qualified personnel should move, install or service this equipment.

Adhere to all warnings, cautions and installation, operating and safety instructions on the unit and in this

manual. Follow all operating and user instructions.

WARNING! Risk of improper handling, installation and service. Can cause property damage,

injury or death.

Only properly trained and qualified personnel should install or perform repairs or maintenance

on this unit. Read all installation, operation and safety alerts and instructions and wear

appropriate protective headgear, safety glasses, gloves and clothing before installing,

operating or servicing this unit.

WARNING! Arc flash and electric shock hazard. Open all local and remote electric power

disconnect switches, verify with a voltmeter that power is Off and wear personal protective

equipment per NFPA 70E before working within the electric control enclosure. Failure to

comply can cause serious injury or death.

Customer must provide earth ground to unit, per NEC, CEC and local codes, as applicable.

Before proceeding with installation, read all instructions, verify that all the parts are included

and check the nameplate to be sure the voltage matches available utility power.

The LiebertiCOM® microprocessor does not isolate power from the unit, even in the “Unit Off”

mode. Some internal components require and receive power even during the “Unit Off” mode of

LiebertiCOM control.

The factory-supplied disconnect switch is inside the unit. The line side of this switch contains

live high-voltage.

The only way to ensure that there is NO voltage inside the unit is to install and open a remote

disconnect switch. Refer to unit electrical schematic.

Follow all local codes.

Vertiv | Liebert® MC™ Installer/User Guide | 5

WARNING! Risk of contact with high-speed, rotating fan blades. Can cause serious personal

injury or death.

Fan blades can automatically start rotating without warning at any time during a cooling cycle

or after power is restored after a power failure. Open all local and remote electric power supply

disconnect switches, wait 10 minutes and verify with a voltmeter that power is Off before

working within the unit cabinet, removing the fan guards or servicing the fan speed control, fan

blades or EC fan motors.

WARNING! Risk of electrical fire and short circuit. Can cause property damage, injury or death.

Select and install the line side electrical supply wire and overcurrent protection device(s)

according to the specifications on the unit nameplate(s), per the instructions in this manual

and according to the applicable national, state and local code requirements. Use copper

conductors only.

Verify that all electrical connections are tight. Unit-specific wiring diagrams are provided on

each unit.

WARNING! Risk of electric shock. Can cause injury or death.

The fan speed control and the EC fan electrical enclosures may contain a stored electrical

charge. Open all local and remote electric power disconnect switches, verify with a voltmeter

that power is Off and wait 10 minutes before working within the fan speed control and the EC

fan electrical enclosures.

WARNING! Risk of heavy condenser falling or tipping over. Can cause property damage,

serious injury or death.

Confirm that all components of the lifting system are rated for the weight of the condenser by

an OSHA Certified rating organization before attempting to lift and/or move the condenser. See

2.2 on page15 throughCondenser and option net weights—Large condensers on page17 for

the condenser weights.

CAUTION: Risk of contact with hot surfaces. Can cause injury.

Fan motors, transformers, piping and other components may become extremely hot during

normal operation. Wear thermally insulated gloves and appropriate protective clothing and

allow time for components to cool when working within the cabinet or electric control

enclosure.

Vertiv | Liebert® MC™ Installer/User Guide | 6

CAUTION: Risk of contact with sharp edges, splinters and exposed fasteners. Can cause

personal injury.

Only properly trained and qualified personnel wearing appropriate safety headgear, gloves,

shoes and glasses should attempt to move, lift, remove packaging from or prepare unit for

installation.

CAUTION: Risk of explosive discharge of high-pressure gas. Can cause injury.

Relieve system pressure and verify that the indoor and outdoor units are Off before making

piping connections/disconnections.

Do not exceed the design pressure rating that is marked on the nameplate.

Do not install a shutoff valve between the compressor and the field-installed pressure relief

valve.

NOTICE

Risk of interference with building doorways, openings and passages. Can cause unit and/or building

damage.

Refer to the installation plans and measure the unit and building opening before moving the unit to verify

clearances.

NOTICE

Risk of improper storage. Can cause unit damage.

Keep unit upright and protected from contact damage.

NOTICE

Risk of improper forklift handling. Can cause unit damage.

Keep the forklift tines level and at a height that will fit under the skid.

NOTICE

Risk of improper refrigerant charging. Can cause equipment damage.

Refrigerant R-407C and R-410A are blended refrigerants and must be introduced and charged from the

cylinder only as a liquid.

When adding liquid refrigerant to an operating system, it may be necessary to add the refrigerant

through the compressor suction service valve. Care must be exercised to avoid damage to the

compressor.

Vertiv™ recommends connecting a sight glass between the charging hose and the compressor suction

service valve. This will permit adjusting the cylinder hand valve so that liquid can leave the cylinder while

allowing vapor to enter the compressor.

Vertiv | Liebert® MC™ Installer/User Guide | 7

NOTICE

Risk of refrigerant overcharge. Can cause equipment damage.

Do not use the sight glass as an indicator when charging Liebert MC condenser systems.

NOTICE

Risk of using damaging cleaning agents, including non-base paint solvents. Can cause equipment

damage and damage to property and loss of refrigerant charge.

Using acid-based or sodium hydroxide-based cleaners can damage the Liebert MC condenser coil and

cause a loss of charge. This could cause equipment damage as well as damage to the surrounding

structure.

Vertiv | Liebert® MC™ Installer/User Guide | 8

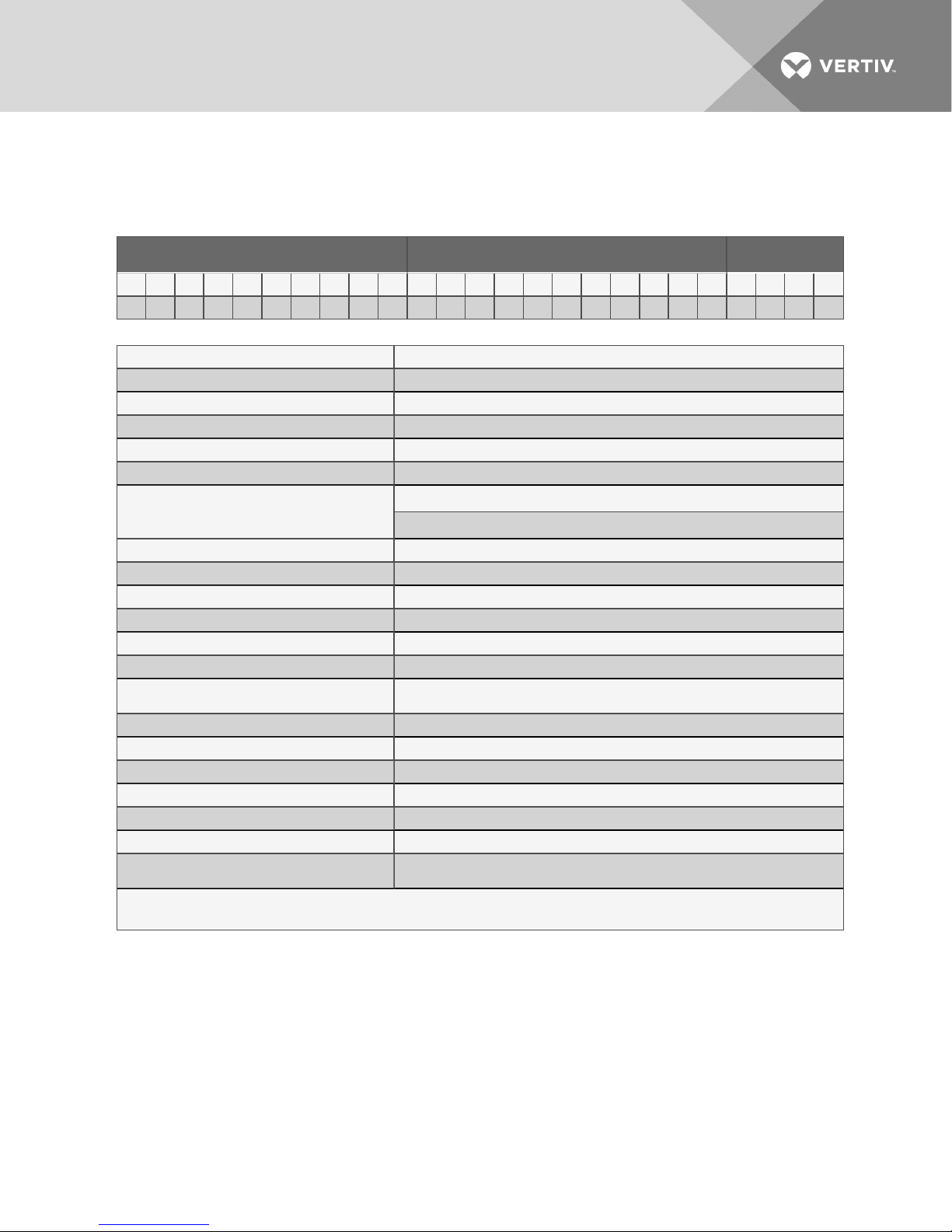

LIEBERT MC NOMENCLATURE

Model Number – Part 1/2 Model Details Part 2/2

1 2 3 4 5 6 7 8 9 10 11 12 13 14 1 5 16 17 18 19 20 21 22 23 24 25

M C M 0 4 0 E 1 A D 0 A 0 V U 0 0 0 0 0 0 * * * *

1-2. UnitFamily;MC = Liebert® MC™ 11. Coil Coating

3. PlatformSize 0 = None

S = S mall E = E-Coat (E poxy)

M = Medium 12. Panel Material

L = Large A = BrightAluminum

4-6. NominalCondenser Capacity, kW 13. Connection Pipe Unitof Measurement

028, 056, 040, 055, 080, 1 10, 160, 165, 220

Example: 040 = 40kW @ 95°F(35°C) &27°R

(15°K) ITD

7. Control/Fan Type V = 18" TallLegs (Std.)

E = Premium & EC Fan X = 36" Tall L egs with Bracing

8.RefrigerantCircuits/System Refrigeranttype Y = 48" Tall Legs with Bracing

1 = S ingle Refrigerant Circuit, R- 410A Z = 60" Tall Legs with Br acing

2 = Dual RefrigerantCircuit, R-410A 15. AgencyCertification

7 = Single RefrigerantCircuit, R-407C, R-22 U = CSA L isted, Marked with CSA c-us logo

8 = Dual Refrigerant Circuit, R- 407C, R-22

9.Power Supply 16.Undefined- Reservedfor Future Use

A = 4 60V / 3ph/60Hz 17. Liebert Lee-Temp™ Configuration

B = 575V / 3ph/60Hz 0 = No Receiver Leg/Software

Y = 208/230V/3ph/60Hz 1 = L iebert Lee-Temp Receiver L eg/Software

2 = 380V/3ph/60Hz 2 = Liebert DSE Receiver Leg/Software

10. Packaging 18-21. Undefined - Reserved For Future Use

D = D omestic, Non-Stackable (HorizontalAirflow

Orientation)

E = E xport Crating- Non-Stackable (HorizontalAirflow Orientation)

0 = Inches (Std. ACR Copper)

14. L egs Included

1 = IBC/OSHPD Seismic Certification, IBC/FBCWind Load Certification and

IBCSnowLoad Certification.

22-25. FactoryConfiguration Number

Vertiv | Liebert® MC™ Installer/User Guide | 9

This page intentionally left blank.

Vertiv | Liebert® MC™ Installer/User Guide | 10

1 INTRODUCTION

1.1 Product Description and Features

The Liebert MC condenser is a low-profile, direct-drive propeller fan-type air-cooled unit suitable for

mounting outdoors. It provides heat rejection for either one or two separate refrigeration circuits, matches

the heat rejection capacity corresponding with the outdoor ambient temperature and with each

corresponding compressor heat rejection requirements. Constructed with an aluminum cabinet,

galvanized steel frame and microchannel coil, the unit is quiet and corrosion resistant. The condenser is

quickly and easily installed, because all internal wiring is completed at the factory with only electrical

connections to be made at the job site. All electrical connections and controls are enclosed in an integral

weatherproof section of the condenser.

Figure 1.1 Two-fan Liebert MC

1.2 Control, Fan Types and Features

1.2.1 Premium Efficiency Control/EC Fan

Premium Efficiency Controls and EC fans are matched to provide superior system energy efficiency. The

premium control board allows CANbus communication with the indoor unit’s Liebert iCOM® control. This

communication feature provides compressor run signals, condenser operating mode changes, condenser

alarm monitoring, simplified system charging procedures and outdoor temperature monitoring. The fans

are controlled by the premium control board using pressure transducer signals from the refrigerant

circuit and factory programming to control the refrigerant head pressure.

Vertiv | Liebert® MC™ Installer/User Guide | 11

The Premium Efficiency Control board on a Liebert MC with a dual refrigeration circuit adjusts the speed

of fans on each circuit to match each circuit’s head pressure conditions. On a Liebert MC with multiple

fans and a single refrigeration circuit, the premium control adjusts the fans to the same speed to maintain

head pressure. The control system provides refrigerant head pressure control for outdoor ambient

temperatures as low as -30°F (-35°C), provided that the total design range (from minimum to maximum) is

125°F (70°C) or less. For traditional DX applications, Liebert Lee-Temp™ kits are required only when the

design temperature ranges exceed 125°F (70°C) for standard match-ups and 115°F (65°C) for Liebert

Quiet-Line™ match-ups.

Anti-Freezing Operation

The EC fans must be operated periodically in cold weather to reduce the possibility of lockup due to ice

and snow accumulation. During periods of inactivity and outdoor temperatures below 35°F (1.6°C), the EC

fans will spin for at least 30 seconds every 15 minutes at 60% of the maximum fan speed.

Fan Reversal for Cleaning

The Liebert iCOM® can be used to run the Premium EC fans in reverse to clear loose debris from the coil

between scheduled coil cleanings. The fan reversal may be done manually or automatically based on a

user-programmed schedule. Automatic fan reversal interval occurs when the indoor unit is Off (BMS Off,

U2U network standby or Remote Shut Down [RSD]).

Low-Noise Feature

The low-noise feature allows setting the condenser fans to operate at a specified speed to reduce

operating noise at certain times. Special match-ups of premium condensers are available for applications

needing to meet stringent sound regulations. Lower sound levels are achieved by oversizing the

condenser, which decreases the maximum airflow and sound level produced by the condenser. This

feature requires special setup of the indoor unit. One or more Liebert Lee-Temp receivers are required.

The premium control has gain schedules that will override the user-defined low-noise schedule to prevent

a high-pressure condition from occurring.

1.3 Liebert Lee-Temp™Refrigerant Control

The Liebert Lee-Temp head pressure control system utilizes head pressure control valve(s), extra

refrigerant and insulated refrigerant receiver(s) with heater pads to assist system starting. The Liebert

Lee-Temp control system also maintains proper operating head pressures in outdoor temperatures below

the rating point of the Liebert MC control type. The system works by flooding the condenser coil with

liquid refrigerant to a level that balances the system condensing requirements with the condenser coil

surface available to reject the system heat. During the summer, the system requires the entire condenser

coil surface for heat rejection and most of the refrigerant is stored in the receiver. In the winter, the same

amount of heat can be rejected by only a fraction of the coil surface. As head pressure begins to fall, the

control valve restricts the flow of liquid refrigerant from the condenser. This extra liquid refrigerant

reduces the effective condenser surface area available for heat transfer. The head pressure control valve

also bypasses hot gas into the receiver to warm the liquid and maintain liquid pressure for proper

operation of the expansion valve. Liebert Lee-Temp kit is optional for condensers and is field-installed.

Condenser control boards are factory-configured for Liebert Lee-Temp if they are ordered with Liebert

Lee-Temp receivers. They can be field-configured if a Liebert Lee-Temp system is added later.

Vertiv | Liebert® MC™ Installer/User Guide | 12

1.4 Surge Protective Device

An optional Surge Protective Device (SPD) can be field-wired to protect the condenser from power surges

that threaten sensitive equipment. The condenser’s electrical panel provides a terminal block to allow the

SPD to be wired in parallel with the high-voltage power. An additional low-voltage terminal block is

provided on condensers with Premium Control Boards to allow monitoring of the SPD alarm circuit.

ASCO 420™ Series surge protective device provides 50kA per mode of surge current protection. An

illuminated green LED indicates the SPD is On and operating properly. An illuminated red LED indicates

that the device may require replacement.

When both LEDs are Off, there is no power to the condenser, either from a power failure or because the

condenser disconnect is in the Off position.

Vertiv | Liebert® MC™ Installer/User Guide | 13

This page intentionally left blank.

Vertiv | Liebert® MC™ Installer/User Guide | 14

2 SITE PREPARATION

2.1 Site Considerations

• Condensers should be installed in a location offering maximum security and access for

maintenance.

• Avoid ground-level sites with public access and areas prone to heavy snow or ice

accumulations.

• To ensure adequate air supply, Vertiv™ recommends that condensers be installed in an area

with clean air, away from loose dirt and foreign matter that might clog the coil. In addition,

condensers should be located no closer than 3 feet (1m) from a wall, obstruction or adjacent

unit.

• For roof installation, mount the condenser on suitable curbs or other supports in accordance

with local codes.

• Condensers must not be installed in a pit.

• Condensers must be installed on a level surface to ensure proper refrigerant flow.

• Use caution when installing condensers below the indoor unit. Condensers must not be

installed more than 15ft. (4.6m) below the indoor unit. Condensers with Liebert Lee-Temp™

receivers must be installed at or above the level of the indoor units to maintain proper

subcooling.

• Liebert Lee-Temp receiver tanks should be mounted on the condenser legs for proper

operation. Contact Vertiv™ Application Engineering Department for assistance with

applications requiring remote mounting of receivers.

• Condensers must be installed in vertical airflow orientation to maintain the electrical box’s

NEMA 3R rating.

2.2 Dimensions and Weights

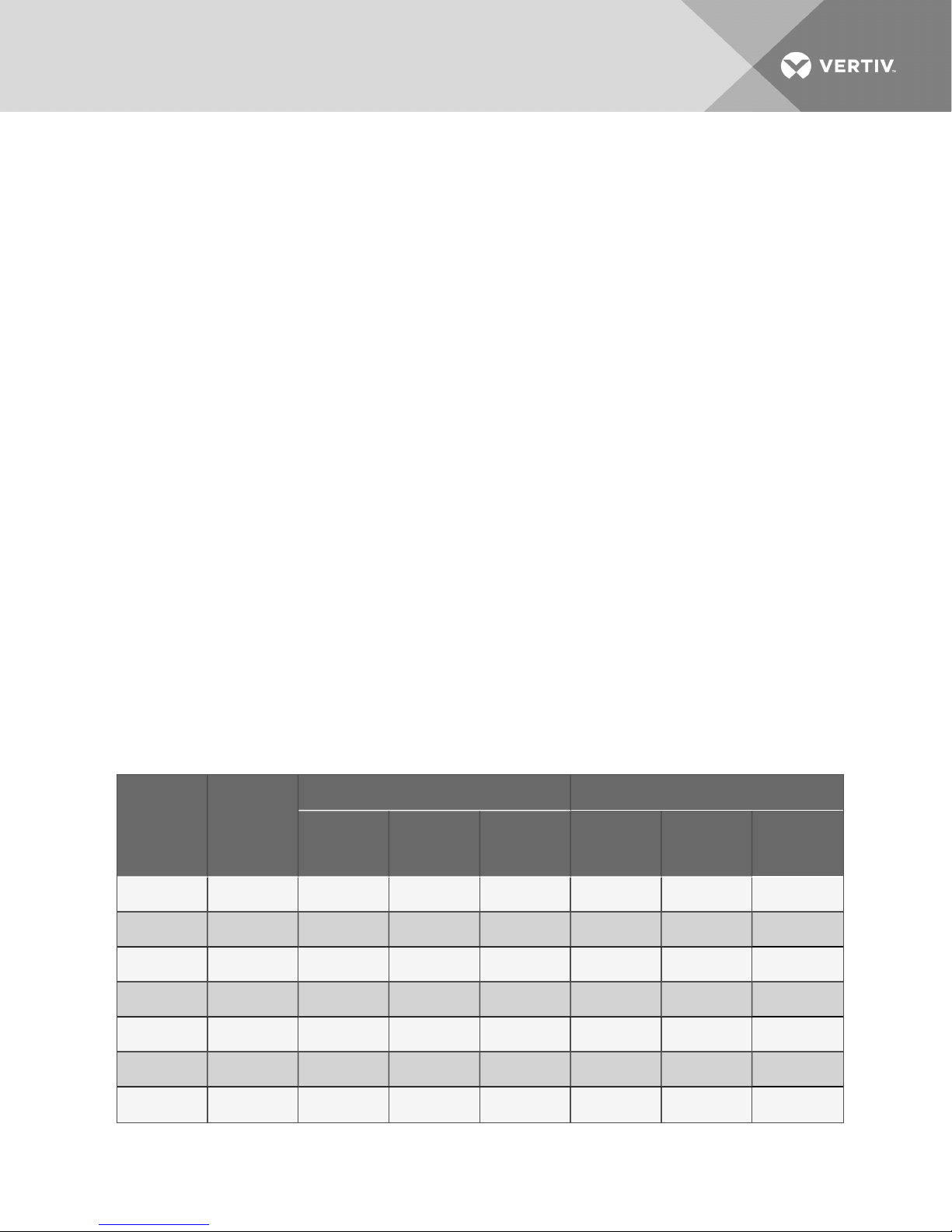

Table 2.1 Condenser shipping weights, dimensions and volume, approximate

Domestic Packaging Export Packaging

Model #

MCS028 1

MCS056 2

MCM040 1

MCM080 2

MCM160 4

MCL055 1

MCL110 2

Number of

Fans

Weight lb (kg)

359

(163)

562

(255)

439

(199)

769

(349)

1509

(684)

552

(250)

962

(436)

Dimensions

(L x W x H) in.

(cm)

76 x 36 x 63

(193 x 91 x 160)

122 x 36x 63

(310 x 91 x 160)

76 x 36 x 63

(193 x 91 x 160)

122 x 36x 63

(310 x 91 x 160)

256 x 36 x 63

(650 x 91 x 160)

76 x 36 x 63

(193 x 91 x 160)

136 x 36 x 63

(345 x 91 x 160)

Volume ft

3

(m3)

100 (2.8) 476 (216)

160 (4.5) 734 (333)

100 (2.8) 556 (252)

160 (4.5) 941 (427)

336 (9.5) 1834 (832)

100 (2.8) 669 (303)

179 (5.0) 1134 ( 514)

Weight lb (kg)

Dimensions

(L x W x H) in.

(cm)

77 x 37 x 64

(196x 94 x 163)

123 x 37 x 64

(312 x 94 x 163)

77 x 37 x 64

(196x 94 x 163)

123 x 37 x 64

(312 x 94 x 163)

257 x 37 x 64

(653 x 94 x 163)

77 x 37 x 64

(196x 94 x 163)

137 x 37 x 64

(348 x 94 x 163)

Volume ft

(m3)

106 (3.0)

161 (4.8)

106 (3.0)

161 (4.8)

352 ( 10)

106 (3.0)

188 ( 5.3)

3

Vertiv | Liebert® MC™ Installer/User Guide | 15

Table 2.1 Condenser shipping weights, dimensions and volume, approximate (continued)

Domestic Packaging Export Packaging

Model #

Number of

Fans

Weight lb (kg)

Dimensions

(L x W x H) in.

(cm)

Volume ft

(m3)

3

Weight lb (kg)

Dimensions

(L x W x H) in.

(cm)

Volume ft

(m3)

3

MCL165 3

MCL220 4

1. Packaged weights willincrease with factory options, such as legs taller than 1 8" (457mm) , coatedcoils, 575V andseismic/wind

options. See Table 2.2 below, Table 2.3 below and Table 2.4 on the facing page for option weights to add to the packaged weights

above. Consultfactory for additional information.

2. Receivers and60" legs are shipped separately from the condenser.

1364

(619)

1835

(832)

196 x 36 x 63

(498x 91 x 160)

256 x 36 x 63

(650 x 91 x 160)

257 (7.3) 1619 (734)

336 (9.5) 2160 (980)

197 x 37 x 64

(500 x 94 x

163)

257 x 37 x 64

(653 x 94 x 163)

270 (7.7)

352 ( 10)

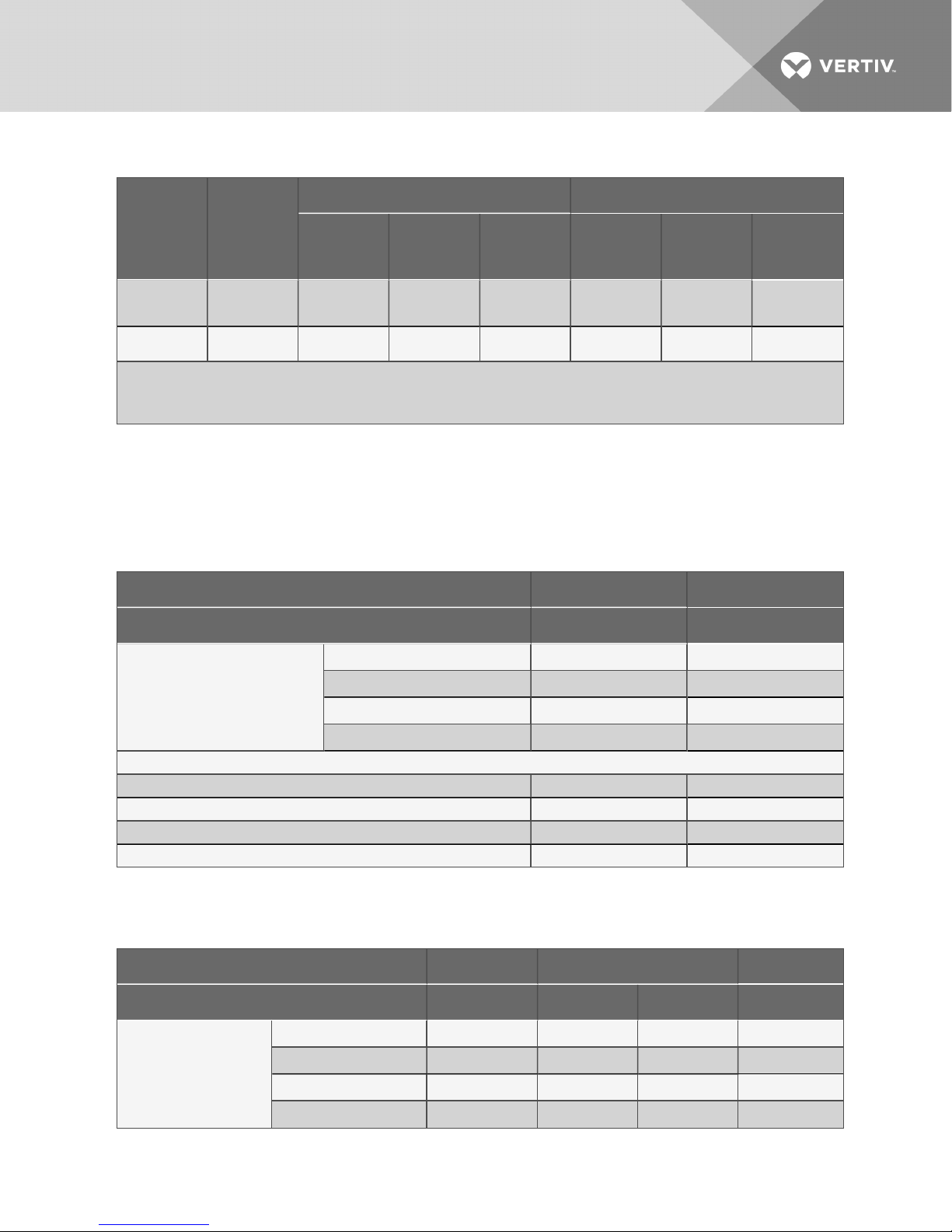

2.2.1 Condenser and Options Net Weights

Total unit weight is the sum of the condenser weight with the selected legs plus the weight of any option.

Source: DPN003034, Rev. 1

Table 2.2 Condenser and option net weights—Small condensers

Condenser Model MCS028 MCS056

RefrigerationCircuits 1 2

154 (70) 270 (122)

286 (130) 419 (190)

318 (144 ) 451 (205)

349 (158) 482 (219)

Condenser Dry

Weight, lb (kg)

Additional Weight for Options, lb(kg)

18" Leg

36" L eg

48" Leg

60" Leg

Liebert L ee-Temp 55 ( 25) 110 (50)

Coated Coil 4 (2) 8 (4)

575V 52 (24) 63 (29)

Seismic/Wind Br acing, 18-in. legs 40 ( 18) 40 ( 18)

Table 2.3 Condenser and option net weights—Medium condensers

Condenser Model MCM040 MCM080 MCM16 0

RefrigerationCircuits 1 1 2 2

Condenser Dry

Weight, lb (kg)

Vertiv | Liebert® MC™ Installer/User Guide | 16

18" Leg

36" L eg

48" Leg

60" Leg

231 (105) 441 ( 200) 441 ( 200) 860 (390)

363 (165) 590 (268) 590 (268) 1066(484)

395 (1 79) 622 (282) 622 (282) 1114 (505)

426 (193) 653 (296) 653 (296) 1160 ( 526)

Table 2.3 Condenser and option net weights—Medium condensers (continued)

Condenser Model MCM040 MCM080 MCM16 0

RefrigerationCircuits 1 1 2 2

Additional Weight for Options, lb(kg)

Liebert L ee-Temp 55 ( 25) 100 (45) 110 (50) 220 (100)

Liebert DSE Receiver DA050 — 44 (20) — —

Liebert DSE Receiver DA080/085 — — — 88 (4 0)

Liebert DSE Receiver DA125/150/165 — — — 184 (83)

Coated Coil 5 ( 2) 10 (5) 10 (5) 20 (9)

575V 52 (24) 63 (29) 63 (29) 76 (34)

Seismic/Wind Br acing, 18-in. legs 4 0 (18) 40 (18) 40 (18) 57 (26)

Table 2.4 Condenser and option net weights—Large condensers

Condenser Model MCL055 MCL1 10 MC L165 MCL 220

RefrigerationCircuits 1 1 2 1 1 2

18" Leg

Condenser Dry

Weight, lb (kg)

Additional Weight for Options, lb(kg)

Liebert DSE Receiver DA050 — 45 (20) — 45 (20) — —

Liebert DSE Receiver DA080/085 — 45 (20) 90 (41) — 45 ( 20) 90 (41)

Liebert DSE Receiver DA125/150/165 — 94 (43) 188(85) 94 (43) 94 (43) 1 88 (85)

Seismic/Wind Br acing, 18-in. legs 40 (18) 40 ( 18) 40 (18) 57 ( 26) 57 (26) 57 (26)

36" L eg

48" Leg

60" Leg

Liebert L ee-Temp 60 (27) 115 (52) 120 (54) 175 (79) 215 (98) 240 (109)

344 (1 56) 602 (273) 602 (273) 891 ( 404 ) 1186 (538) 1186 (538)

486 (220) 766 (34 7) 766 (34 7) 11 36 (515) 1453 (659) 1453 (659)

518 (235) 798 (362) 798 (362) 1 184 (537) 1501 ( 681) 1501 (681)

549 ( 249) 829 ( 376) 829 (376) 1230 (558) 1547 (702) 1547 (702)

Coated Coil 8 (4) 16 (7) 16 (7) 24 (11) 32 (15) 32 (15)

575V 79 (36) 90 ( 41) 90 (41 ) 132 (60) 134 (61) 134 (61)

Vertiv | Liebert® MC™ Installer/User Guide | 17

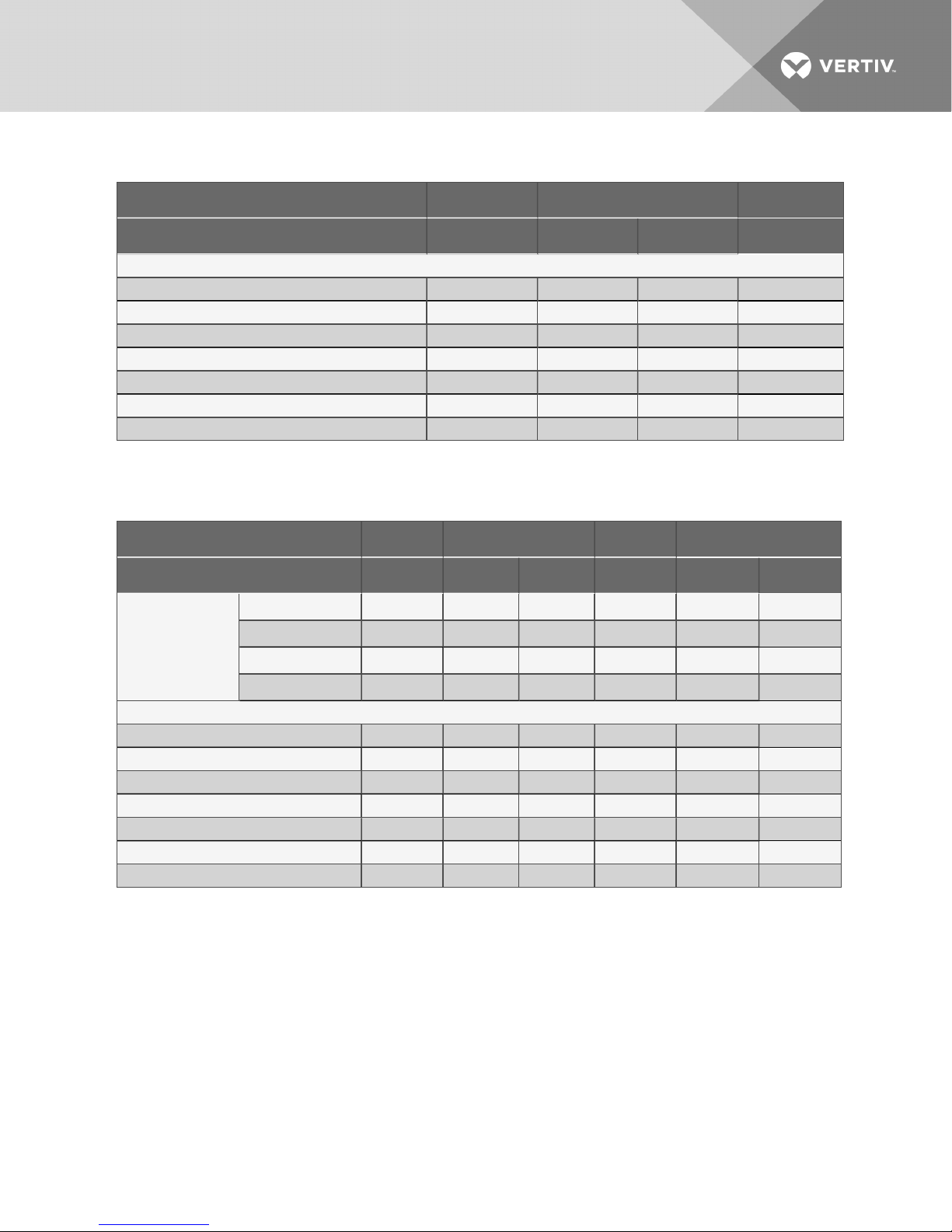

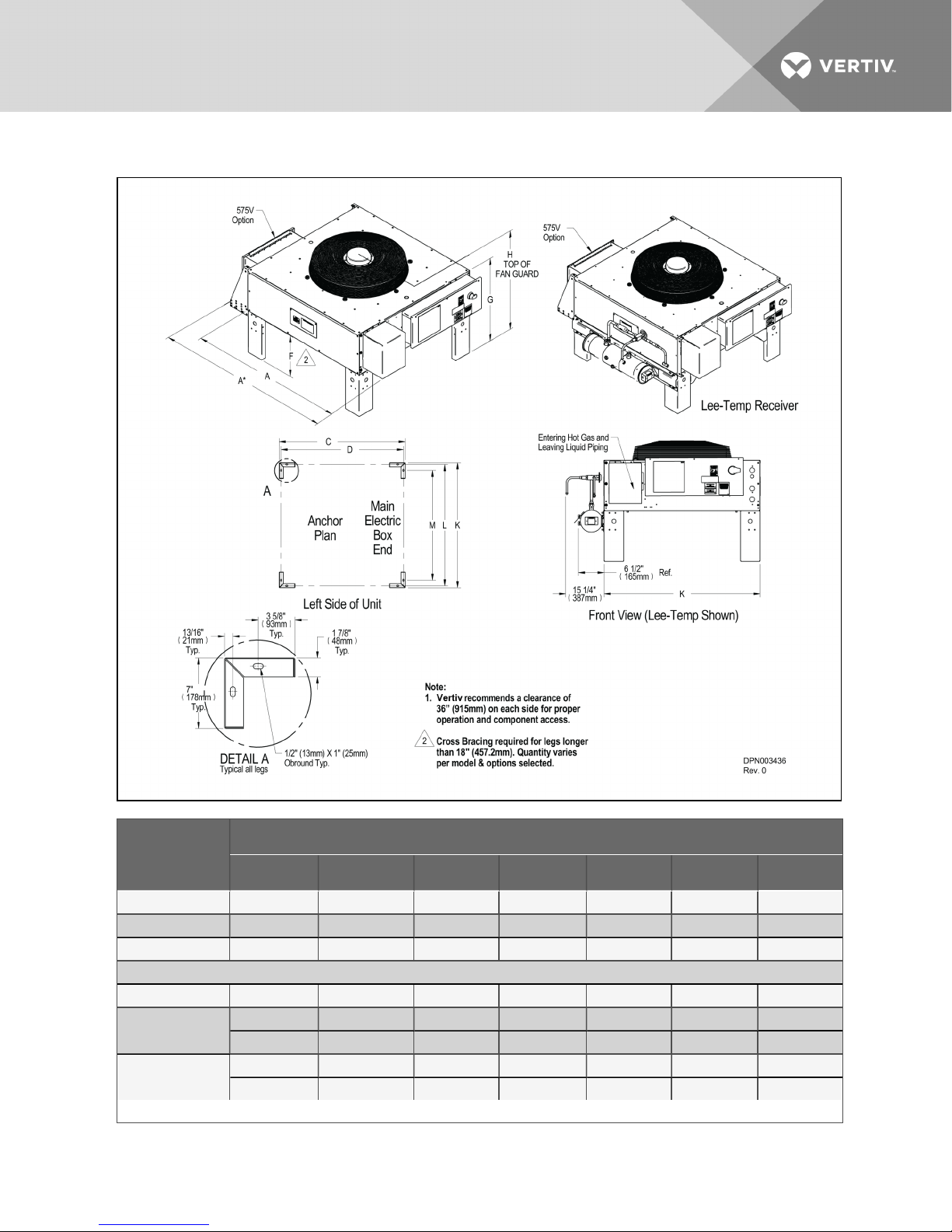

Figure 2.1 Condenser planning dimensional data—MCS028, MCM040 and MCL055

LiebertModel No.

A A* (575Vonly) C D K L M

MCS028 50-5/8 (1287) 58-7/8 (1495) 44-1 /8 (1120) 42-1 /2 (1080) 42- 1/2 ( 1080) 40- 7/8 (1038) 35-7/ 8 ( 910)

MCM040 57- 3/16 (1 453) 65-3/8 (1661) 48 (1219) 46-5/1 6 ( 1177) 46 (1168) 4 4-3/8 (1127) 39-5/16 (999)

MCL055 68 (1727) 77 (1956) 56 (1422) 54-3/8 (1381) 55-1/2 (1410) 53-78 (1368) 48-3/4 (1238)

Leg-heightDimensions in. (mm)

All Models F 1 8 ( 457) 36 (914 ) 4 8 (1219) 60 (1 524) -- --

MCS028

MCM040

MCL055

Source: DPN003436, Rev. 0

G 31-5/8 (803) 4 9-5/8 (1260) 61-5/8 (1565) 73-5/8 (1870) -- --

H 39-5/8 ( 1006) 57- 5/8 (1464) 69-5/8 (1768) 81- 5/8 (2073) -- --

G 35-7/8 (911) 53-7/8 (1368) 65-7/ 8 ( 1673) 77-7/8 (1978) -- --

H 43- 5/8 (1108) 61- 5/8 (1565) 73-5/8 (1870) 85-5/8 ( 2175) -- --

Vertiv | Liebert® MC™ Installer/User Guide | 18

Cabinet Dimensions in. (mm)

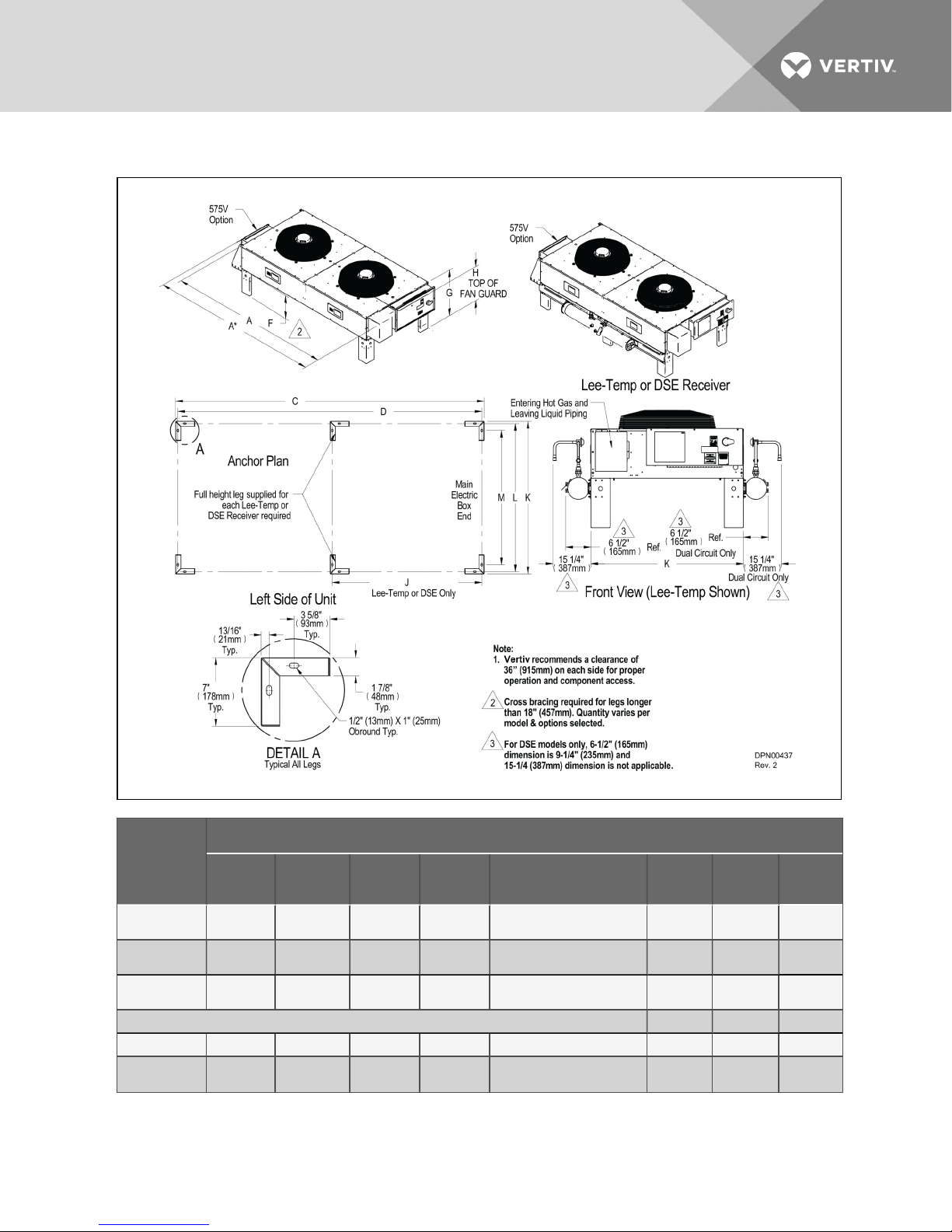

Figure 2.2 Condenser planning dimensional data—MCS056, MCM080, MCL110

LiebertModel

No.

MCS056

MCM080

MCL110

Leg-heightDimensions in. (mm)

All Models F 18 (457) 36 (914) 48 ( 1219) 60 (1524) -- - - --

MCS056

MCM080

A

94-7/8

(2411)

105-1/4

2674)

124- 1/8

(3152)

G 31 -5/8 (803)

A* (575V

only)

103-1/8

(2619)

113- 7/1 6

(2882)

133-1 /8

(3381)

Vertiv | Liebert® MC™ Installer/User Guide | 19

C D

88-3/8

(2245)

96-1/16

(2440)

112- 1/8

(2848)

49-5/8

(1260)

Cabinet Dimensions in. (mm)

J L ee-Temp or DSE

Receivers Only

86-3/4

(2203)

94-7/16

(2398)

110-1/ 2

(2806)

61-5/8

(1565)

42-1/2 (1079)

45-5/19 (1177) 46 (1168)

54-3/ 8 ( 1381)

73-5/8 (1870) -- -- --

K L M

42-1/2

(1080)

55-1/2

(1410)

40-7/8

(1038)

44- 3/8

(1127)

53-7/8

(1368)

35-7/8

(910)

39-5/16

(999)

48-34

(1238)

LiebertModel

No.

Cabinet Dimensions in. (mm)

A

A* (575V

only)

C D

J L ee-Temp or DSE

Receivers Only

K L M

H

G 35-7/8 (911)

MCL110

H

Source: DPN003437, Rev. 2

39-5/8

(1006)

43-5/8

(1108)

57-5/8

(1464)

53-7/8

(1368)

61-5/8

(1565)

69-5/8

(1768)

65-7/8

(1673)

73-5/8

(1870)

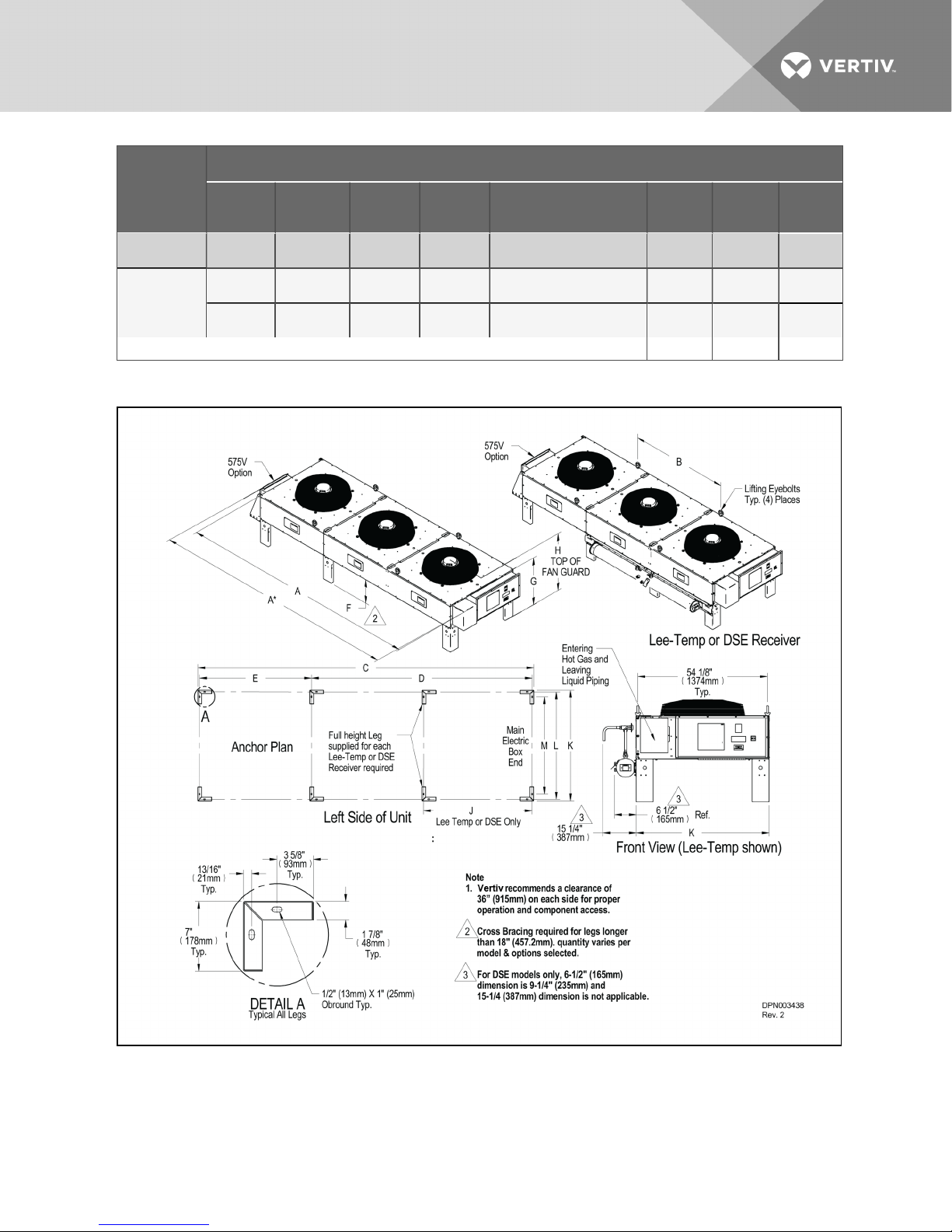

Figure 2.3 Condenser planning dimensional data—MCL165

81-5/8 (2073) -- -- --

77-7/8 (1978) -- -- --

85-5/8 (2175) - - -- --

Vertiv | Liebert® MC™ Installer/User Guide | 20

LiebertModel

No.

Dimensions in. (mm)

A

A*

(57Vonly)

B C D E

J

Lee-Temp or DSE

Receivers Only

K L M

MCL165

Leg-height Dimensions in. (mm)

MCL165

Source: DPN003438, Rev. 2

180-1/4

(4578)

F 18 (457) 36 (914) 48 (1219) 60 (1524) - -

G 35-7/ 8 ( 911) 53-7/8 (1368) 65-7/8 (1673) 77-7/8 (1978) --

H 43-5/8 ( 1108) 61-5/8 (1565) 73- 5/8 (1870) 85-5/8 (2175) --

189-1/4

(4807)

73-7/ 16

(1866)

168-1/4

(4274)

110-1/ 2

(2806)

56-1/8

(1425)

54-3/ 8 ( 1381)

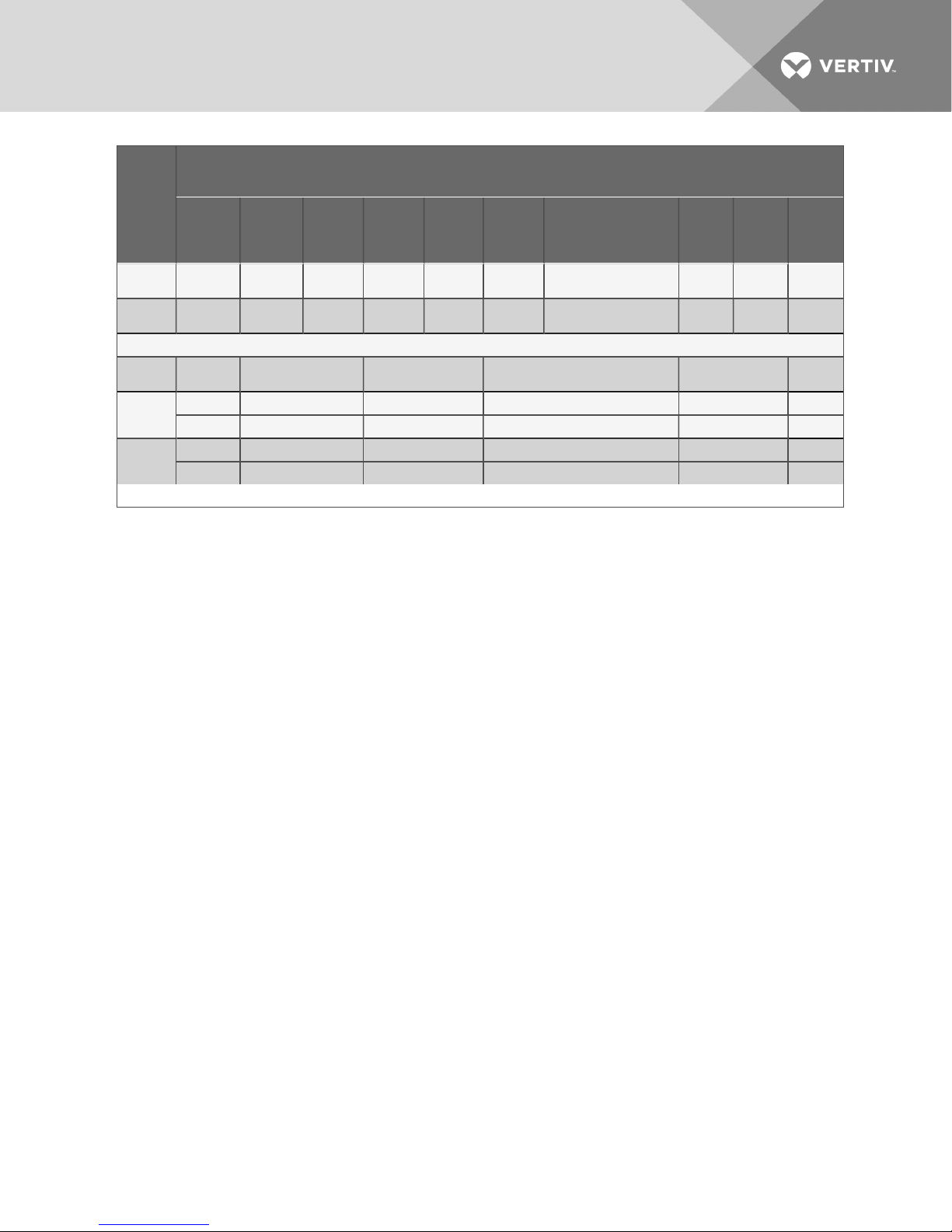

Figure 2.4 Condenser planning dimensional data—MCM160 and MCL220

55-1/2

(1410)

53-7/8

(1368)

48-3/4

(1238)

Vertiv | Liebert® MC™ Installer/User Guide | 21

Liebert

Model

No.

Cabinet Dimensions

in.(mm)

A

A*

(575V

only)

B C D E

J L ee-Temp or DSE

Receivers Only

K L M

MCM160

MCL220

Leg-heightDimensions in. (mm)

All

Models

MCM160

MCL220

Source: DPN003439, Rev. 2

202-7/ 16

(514 2)

236-5/16

(6003)

F 18 ( 457) 36 (914) 48 (1219) 60 (1524) - -

G 31-5/8 ( 803) 49-5/8 (1260) 61-5/8 (1565) 73-5/8 (1870) - -

H 39-5/8 (1006) 57-5/8 ( 1464) 69-5/8 (1768) 81-5/8 (2073) --

G 35-7/8 (911) 53-7/8 (1368) 65-7/8 (1673) 77-7/8 (1978) - -

H 4 3-5/8 (1108) 61-5/8 ( 1565) 73-5/8 (1870) 85-5/8 ( 2175) --

210-5/8

(5350)

245-5/16

(6231)

113- 1/2

(2883)

129-9/16

(3291)

192-1/ 4

(4883)

224-3/8

(5699)

94-7/16

(2398)

110-1/ 2

(2806)

96-3/16

(2444)

112- 1/4

(2851)

45-5/16 (1177)

54-3/ 8 ( 1381)

46

(1168)

55-1/2

(1410)

44- 3/8

(1127)

53-7/8

(1368)

39-5/16

(999)

48-3/4

(1238)

Vertiv | Liebert® MC™ Installer/User Guide | 22

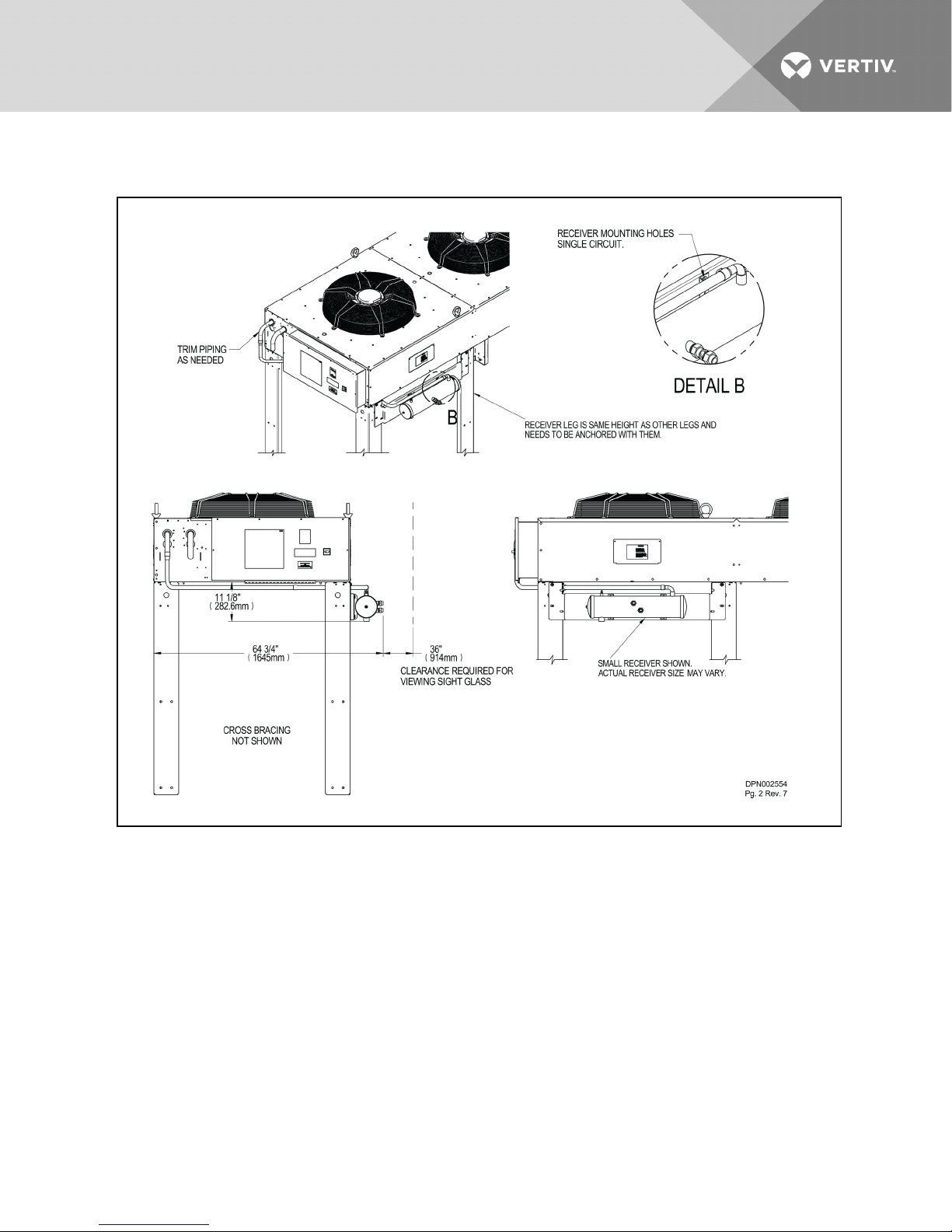

Figure 2.5 Liebert DSE receiver mounting—MCL165 and MCL220, single-circuit condenser,

left-sidecondenser outlet receiver

Vertiv | Liebert® MC™ Installer/User Guide | 23

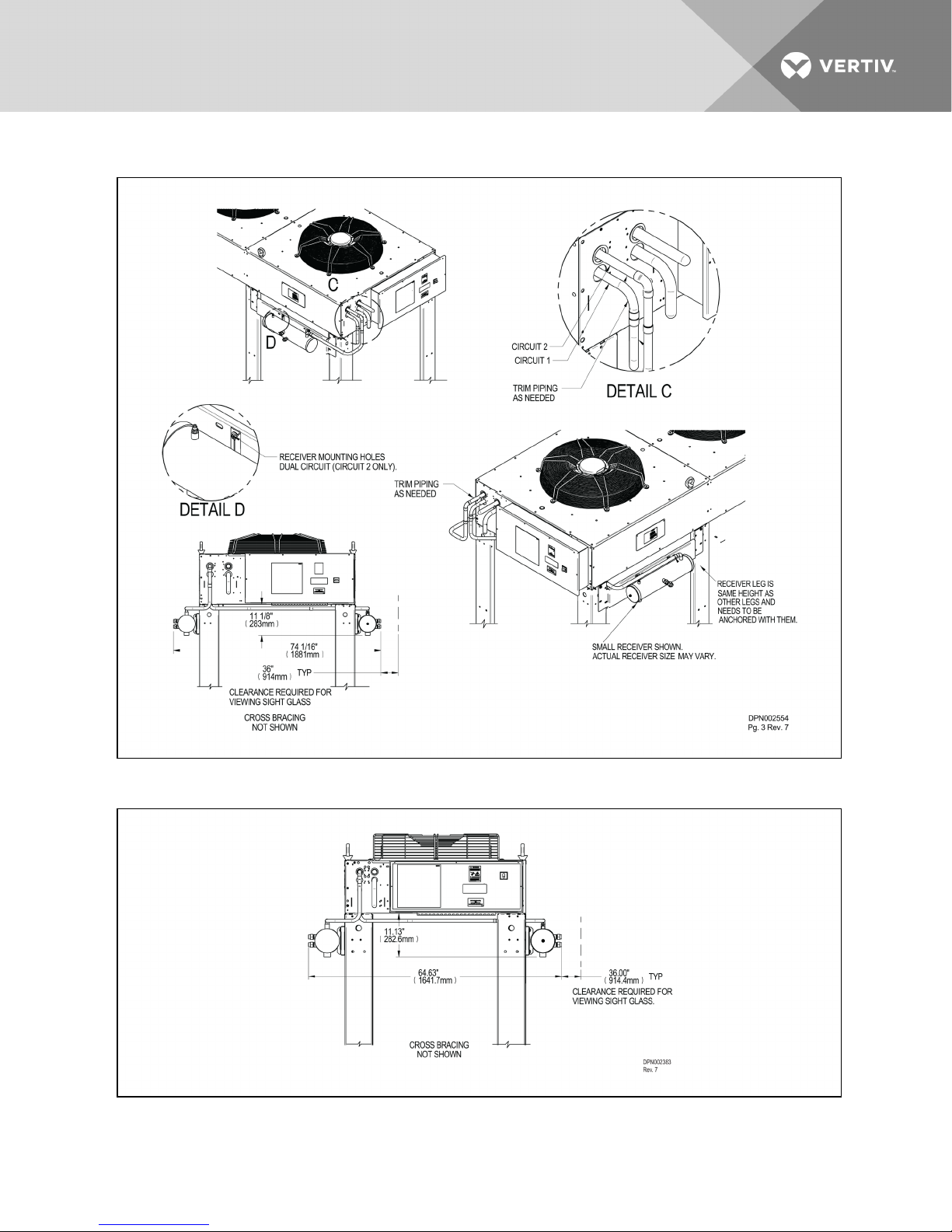

Figure 2.6 Liebert DSE receiver mounting—MCL165 and MCL220, single-circuit condenser,

right-sidecondenser outlet receiver

Vertiv | Liebert® MC™ Installer/User Guide | 24

Figure 2.7 Liebert DSE receiver mounting—MCL110 and MCL220, dual-circuit condenser

Figure 2.8 Liebert DSE receiver mounting—MCM160 dual circuit condenser

Vertiv | Liebert® MC™ Installer/User Guide | 25

This page intentionally left blank.

Vertiv | Liebert® MC™ Installer/User Guide | 26

3 INSPECTION AND INSTALLATION

Safety Information

WARNING! Risk of improper handling. Can cause equipment damage, injury or death.

Read all of the following instructions before attempting to move, lift, remove packaging from or

preparing unit for installation.

WARNING! Risk of heavy condenser falling or tipping over. Can cause property damage,

serious injury or death.

Confirm that all components of the lifting system are rated for the weight of the condenser by

an OSHA Certified rating organization before attempting to lift and/or move the condenser. See

2.2 on page15 throughCondenser and option net weights—Large condensers on page17 for

the condenser weights.

CAUTION: Risk of contact with sharp edges, splinters and exposed fasteners. Can cause

personal injury.

Only properly trained and qualified personnel wearing appropriate safety headgear, gloves,

shoes and glasses should attempt to move, lift, remove packaging from or prepare unit for

installation.

NOTICE

Risk of interference with building doorways, openings and passages. Can cause unit and/or building

damage.

Refer to the installation plans and measure the unit and building opening before moving the unit to verify

clearances.

NOTICE

Risk of improper forklift handling. Can cause unit damage.

Keep the forklift tines level and at a height that will fit under the skid.

NOTICE

Risk of improper storage. Can cause unit damage.

Keep unit upright and protected from contact damage.

Vertiv | Liebert® MC™ Installer/User Guide | 27

3.1 Equipment Inspection

Upon arrival of the unit and before unpacking, verify that the labeled equipment matches the Bill of

Lading. Carefully inspect all items for either visible or concealed damage. Damage should be immediately

reported to the carrier and a damage claim filed with a copy sent to Vertiv™ or to your sales

representative.

If you have the seismic mounting kit, refer to Liebert Seismic Application—OptionalUnitConfiguration on

page99

3.1.1 Packing Material

All material used to package this unit is recyclable. Please save it for future use or dispose

of the material appropriately.

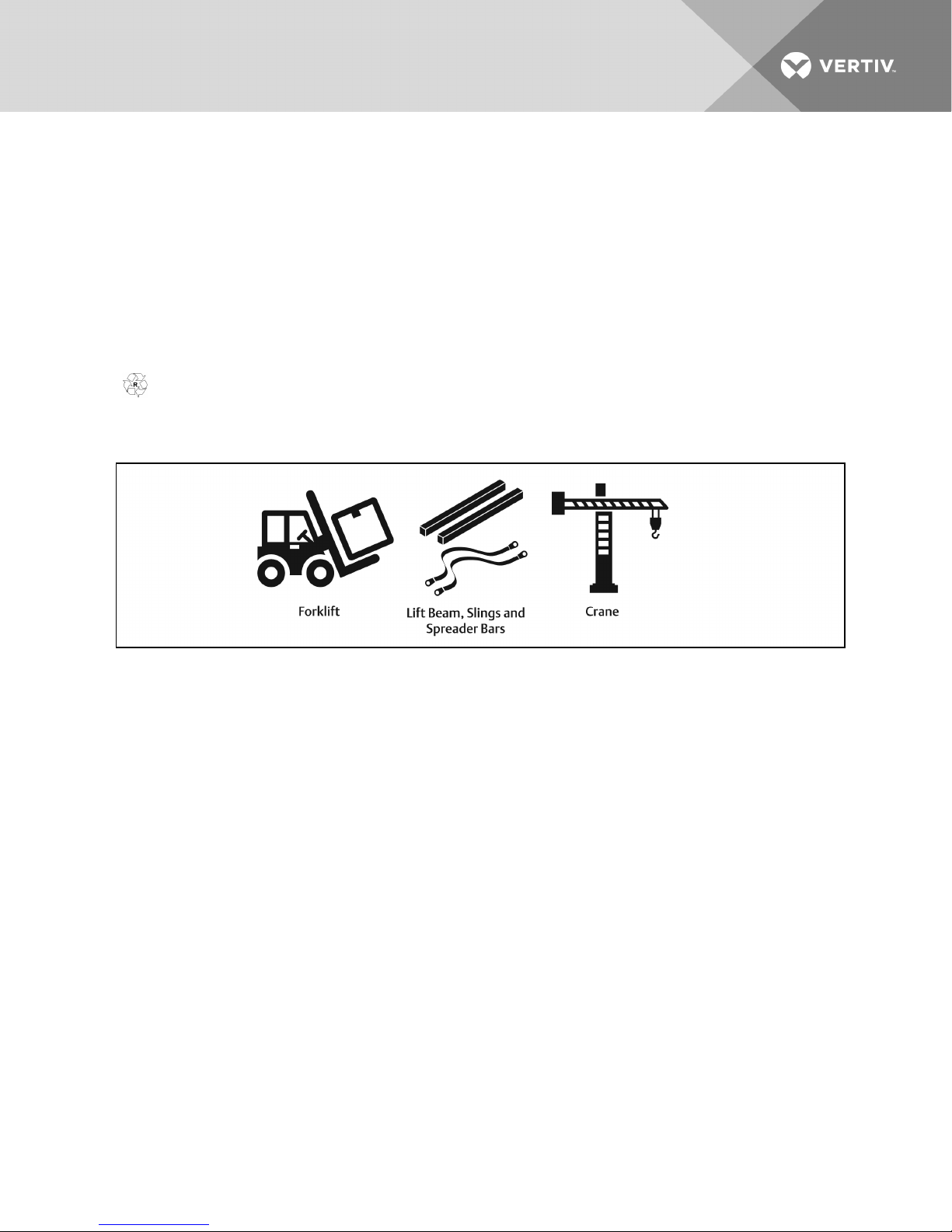

Figure 3.1 Equipment recommended for handling a Liebert condenser

3.2 Handling Unit on the Skid

Transport unit using a fork lift or a crane with sling and spreader bars.

Using a forklift

NOTICE

Risk of improper forklift handling. Can cause unit damage.

Keep the forklift tines level and at a height that will fit under the skid.

• Make sure the forks (if adjustable) are spread to the widest allowable distance to still fit under

the skid.

• Type of forklift used will depend on the terrain the unit is to be moved across during handling.

• Minimum forklift fork length:

• for 1-fan and 2-fan units—48” (1219mm)

• for 3-fan and 4-fan units—72” (1829mm)

• When moving the packaged unit, do not lift it any higher than 6" (152mm). If the unit must be

lifted higher than 6" (152mm), great care must be exercised and no one may be closer than 20'

(6m) to the lift point.

• Vertiv™ recommends lifting one end off the ground no more than 6" (152mm)and using the

forklift to push or pull the unit.

Vertiv | Liebert® MC™ Installer/User Guide | 28

Figure 3.2 Forklift position with 1- to 4-fan condensers

Using a Crane

• Vertiv™ recommends using slings rated for the unit weight.

• Spreader bars must be used for sling stability and to keep the slings from pressing against the

unit. Make sure spreader bars are wider than the unit.

• Place the slings near the ends of the unit, under the top deck boards of the skid.

3.3 Unit Storage

Store the condenser in the original packaging in an area protected from excessive dirt, debris and

contact damage until final installation.

3.4 Unpacking the Condenser—All Unit Sizes

CAUTION: Risk of contact with sharp edges, splinters and exposed fasteners. Can cause

personal injury.

Only properly trained and qualified personnel wearing appropriate safety headgear, gloves,

shoes and glasses should attempt to move, lift, remove packaging from or prepare unit for

installation.

Refer to Figure 3.3 on the next page for the following steps:

1. Remove the fence for domestic packaging (for export packaging, remove the crate).

2. Remove the exterior foam from around the unit and the electric box.

3. Remove the steel straps securing the unit to the skid.

4. Set the legs aside, but keep accessible if legs are shipped together with the unit.

• Depending on the number of fans, more or less steel straps may be removed at this step.

5. Remove corrugated panels covering the condenser’s coil(s).

6. Remove the bolts securing unit to the skid.

7. Remove the bolts securing the brackets to the unit and recycle the brackets.

Vertiv | Liebert® MC™ Installer/User Guide | 29

Figure 3.3 Removing protective material

3.5 Preparing a Condenser for Moving and Installation

The following procedure is one method for removing a Liebert condenser from its shipping skid. Other

methods may be used, provided that they are safe for personnel, the condenser and other equipment.

3.5.1 Attaching 18" (457mm) Legs, RemovingtheSkidandAttachingSlings

NOTE: Units supplied with 36-60” (914-1524mm) legs go to Attaching36to60in.

(914to1524mm)Legs, RemovingtheSkidandAttaching Slings on page33.

1. Attach legs to the unit at indicated locations, using the fasteners provided with the legs.

• Recommended tools for attachment is a 1/2” (13mm) socket and ratchet.

• More legs may be available for installation than are shown. This will depend on the unit

type and number of fans.

Vertiv | Liebert® MC™ Installer/User Guide | 30

Loading...

Loading...