Vertiv LIEBERT EXS 208/220-V 30 KVA Quick Installation Manual

LIEBERT® EXS™ UPS

208/220‑V30KVA

Quick Installation Guide

I M P O RTANT: Before installing,

connecting to supply or operating

your Liebert EXS UPS, please

review the Safety and Regulatory

Statements sheet. For detailed

installation, operating, maintenance

and troubleshooting information

visit the EXS product page for the

EXS Installer/User Guide available

at www.Vertiv.com or use the QR

code below.

INSTALLATIO N

Inspecting the UPS

Inspect the UPS for any signs of

obvious damage. If damage is

visible, do not proceed. File a

damage claim with the carrier

immediately and send a copy to:

Vertiv Corporation

1050 Dearborn Drive

P.O. Box 29186

Columbus OH 43085

Attn. Traic Department

Choosing a location

The UPS measures 23.6 x 33.5 x

63 in. (600 x 850 x 1600 mm).

Install the UPS in a clean, wellventilated environment with the

ambient temperature range of 32°F

to 104°F (0°C to 40°C).

For installation and maintenance,

3 ft (914 mm) clearance is required

in the front and rear of the unit. For

proper ventilation during normal

operation, leave 8 in. (203 mm)

clearance on the rear. No side

clearance is required for installation

or operation of the UPS.

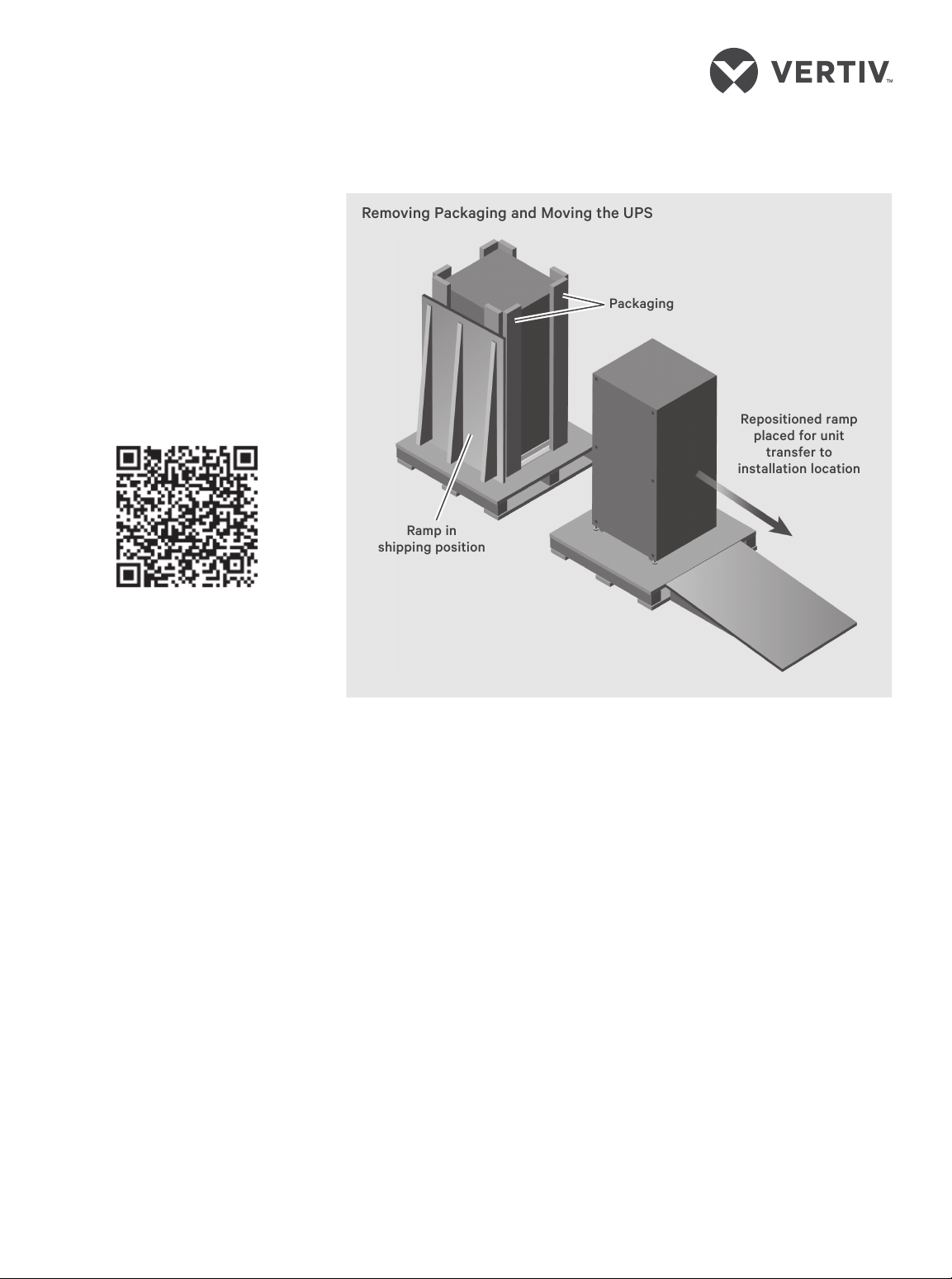

Removing Packaging and Moving the UPS

Packaging

Ramp in

shipping position

Handling and unpacking

the unit

The unit weighs up to 1,650 lb

(748 kg), depending on the number

of batteries included. The UPS

ships on a pallet and is equipped

with casters that permit two or

more people to roll it o the pallet

for installation. Use a forklift or

pallet jack to move the palleted

UPS as close as possible to the

installation location before

removing packing material or

loosening shipping brackets.

1. Remove the protective

packaging, shown in the

illustration at the top-right.

2. Locate the accessories

package on top of the UPS and

set aside.

3. Use a 16-mm (5/8 -in.) wrench

or socket to un-bolt the

shipping brackets from the

pallet.

Repositioned ramp

placed for unit

transfer to

installation location

4. Un-bolt the shipping brackets

from the front and rear of the

UPS. Remove the front lower

panel from the UPS to remove

the front bracket.

5. Make sure the leveling feet are

raised so they do not interfere

when rolling the unit on the

casters.

6. Roll the unit down the ramp to

the installation location, see

the illustration above, then

lower the leveling feet to x the

UPS in the install location.

590-1971-501A/SL-70330_REV0 1

LIEBERT® EXS™ UPS 208/220 ‑V 30 KVA

Quick Installation Guide

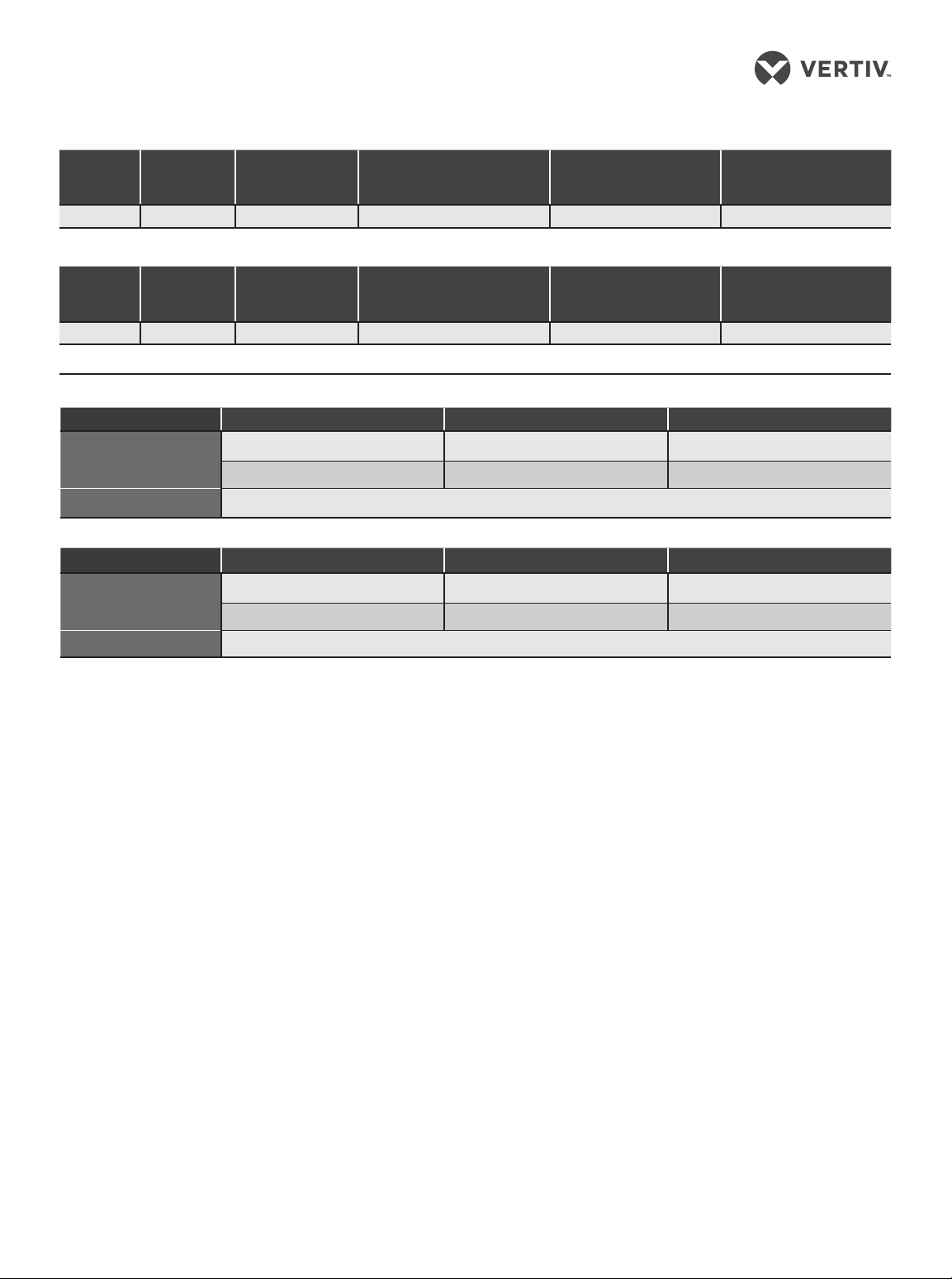

Table 1 Currents and Wire Size — UPS rectier input

Unit Rating

30 kVA /kW 105 150 2/0 2/0 6 AWG

Table 2 AC Currents and Wire Size — UPS bypass input* and output

Unit Rating

30 kVA /kW 83 125 1/0 1/0 6 AWG

*Bypass input for dual-input congurations only.

Table 3 Recommended lug sizes for phase, neutral and ground conductors

Recommended Torque 50 lb-in. / 4.2 lb-ft . / 5.6 Nm

Table 3 Recommended lug sizes for external battery conductors

Recommended Torque 126 lb-in. / 10.5 lb-ft . / 14.2 Nm

Maximum Input

Current (A)

Maximum Input

Current (A)

Part Number

Part Number

Recommended OPD,

Amp Tri p

Recommended OPD,

Amp Tri p

6 AWG (13.3 mm2) 1/0 AWG (53.5 mm2) 2/0 (67.4 mm2)

McMaster-Carr: 7113K366 Thomas & Betts: 54152NT Thomas & Betts: 54157NT

Thomas & Betts: RE6-14

6 AWG (13.3 mm2) 1/0 AWG (53.5 mm2) 2/0 (67.4 mm2)

Thomas & Betts: RE6-516 Thomas & Betts: 54153NT Thomas & Betts: 54158NT

Thomas & Betts: CTL6-516

75°C THW Copper Wire (phase)

Number of Cables per phase:1

75°C THW Copper Wire (phase)

Number of Cables per phase:1

75°C THW Copper Wire

neutral)

Number of Cables:1

75°C THW Copper Wire

(neutral)

Number of Cables:1

75°C THW Copper Wire

(ground)

Number of Cables: 1

75°C THW Copper Wire

(ground)

Number of Cables: 1

POWER WIRING AND

CONDUIT

When connecting wiring, follow the

local wiring regulations, and take the

environment situation into account.

NOTE : The conduit size and wiring

method must be in accordance with

all local, regional and national codes

and regulations, including NEC

ANSI/NFPA 70.

The maximum current for operating

modes, the recommended wire

sizes, and the recommended power

cables and plugs are listed in Tables

1 to 3, above, and are based upon

an

86°F (30°C) ambient temperature.

Lock-out and tag before

you begin

Ensure that the feeder breakers are

open and locked, and tagged to

prevent inadvertent operation by

unauthorized personnel.

HARDWIRE INPUT/OUTPUT

CONNECTIONS

Connecting a

single-input conguration

1. On the rear panel of the UPS,

remove the upper conduitentry panel, punch holes for

the conduit, connect the

conduit to the panel, and

re-install the conduit-entry

panel.

2. Remove the lower cover plate

to access the terminal blocks,

shown in the “Terminal-block

Connections” illustration on the

next page.

3. Leave the factory-installed

single-input jumpers on the

input terminal blocks and make

the following input connections

from the upstream feeder

panel to the input terminal:

• Phase A to rA

• Phase B to rB

• Phase C to rC

• Neutral to inN

• Ground cable to PE

4. Make the following output

connections from the UPS

output terminal to the

downstream distribution-panel

main lug breaker:

• oA to Phase A

• oB to Phase B

• oC to Phase C

• oN to neutral bus

• PE to ground bus

5. Torque phase conductor

connections to 50 lb-in, and

neutral and ground conductor

connections to 126 lb-in.

6. Reinstall the terminal-block

cover plate.

Connecting a

dual-input conguration

2 590-1971-501A/SL-70330_REV0

Loading...

Loading...