Page 1

Liebert® CRV Row

BasedCoolingSystem

Installer/User Guide

600 mm and 300 mm Wide

Page 2

Vertiv Liebert®CRV Installer/User Guide

The information contained in this document is subject to change without notice

and may not be suitable for all applications. While every precaution has been

taken to ensure the accuracy and completeness of this document, Vertiv

assumes no responsibility and disclaims all liability for damages result from

use of this information or for any errors or omissions.

Vertiv recommends installing a monitored fluid detection system that is wired

to activate the automatic closure of field-installed coolant fluid supply and

return shut off valves, where applicable, to reduce the amount of coolant fluid

leakage and consequential equipment and building damage. Refer to local

regulations and building codes relating to the application, installation, and

operation of this product. The consulting engineer, installer, and/or end user is

responsible for compliance with all applicable laws and regulations relation to

the application, installation, and operation of this product.

The products covered by this instruction manual are manufactured and/or sold

by Vertiv. This document is the property of Vertiv and contains confidential

and proprietary information owned by Vertiv. Any copying, use, or disclosure of

it without the written permission of Vertiv is strictly prohibited.

Names of companies and products are trademarks or registered trademarks of

the respective companies. Any questions regarding usage of trademark names

should be directed to the original manufacturer.

Technical Support Site

If you encounter any installation or operational issues with your product, check the pertinent section of this

manual to see if the issue can be resolved by following outlined procedures.

Visit https://www.vertiv.com/en-us/support/ for additional assistance.

Vertiv | Liebert ® CRV Installer/User Guide

Page 3

TABLE OF CONTENTS

1 Important Safety Instructions 1

2 Nomenclature and Components 7

2.1 Model Number Nomenclature 7

2.2 Component Location 7

2.3 Cooling Configurations and Liebert® CRV Overview 8

3 Pre-installation PreparationandGuidelines 9

3.1 Planning Dimensions 9

3.2 Unit Weights 9

4 Equipment Inspection and Handling 11

4.1 Packaging Material 12

4.2 Handling the Unit while Packaged 12

4.3 Unpacking the Export Shipped 600 mm(24 in.) Unit 12

4.4 Unpacking the Domestic Shipped 600 mm(24 in.) Unit 13

4.5 Removing 600 mm (24 in.) Units from the Pallet 14

4.6 Unpacking the Export Shipped 300 mm(24 in.) Unit 16

4.7 Unpacking the Domestic Shipped 300 mm(12 in.) Unit 17

4.8 Removing 300 mm (12 in.) Units from the Pallet 18

5 Installing in Enclosure Row 21

5.1 Adjusting Base Supports/Leveling Feet 21

5.2 Optional Tie Down Brackets for 300 mm (12 in.) Units 23

5.2.1 What’s Included 23

5.2.2 Tools Required 24

5.2.3 Installing Tie Down Brackets on300 mm(12 in.) andonCabinetsofDifferentHeights 24

5.2.4 Installing Tie Down Brackets on300 mm(12 in.) andonCabinetsoftheSameHeight 26

6 Piping and Refrigerant Requirements 27

6.1 Drain and Humidifier Fluid Piping 28

6.1.1 Humidifier Water Supply Line Requirements 28

6.1.2 Condensate Pump Drain Line Requirements 29

6.1.3 Condensate Pump Drain Piping for300 mm(12 in.) Models 30

6.1.4 FieldInstalled, Gravity Fed Drain Line Requirements 36

6.2 Refrigerant Piping and Charging 41

6.2.1 Refrigerant Piping Guidelines forAir CooledSystems 42

6.3 Piping Guidelines for Liebert® MC Condensers 43

6.3.1 Piping Layout and Condenser Positioning 44

6.3.2 Top or Bottom Connection for Refrigerant Piping onAir Cooled Units 45

6.3.3 Refrigerant Line Sizes and Equivalent Lengths 46

6.3.4 Refrigerant Charge Requirements for Air Cooled Systems 47

6.3.5 Additional Oil Requirements for Digital ScrollCompressors 50

6.3.6 Evacuation, Leak Testing, and Charging Air Cooled Systems without Receivers 52

Vertiv™ | Liebert® CRV Installer/User Guide | i

Page 4

6.3.7 Evacuation, Leak Testing, and Charging Air Cooled Systems withLiebert® Lee-Temp Flooded Condenser

Head PressureControlSystem 56

6.3.8 Superheat and Refrigerant Charge Optimization 58

6.4 Water/Glycol Loop Piping Guidelines 59

6.4.1 Glycol Mixture 62

6.4.2 Water/Glycol Cooled Piping Connections 62

6.4.3 Leak Checking for Unit and Field Installed Piping 64

6.5 Chilled Water Loop Piping 64

7 Electrical Connections 67

7.1 Power Supply Cable Connection Guidelines 67

7.2 Wiring Connection Guidelines 67

7.3 Electrical Field Connections Descriptions 68

7.3.1 Locating the Serial Tags and Removing the Electrical Panel on 600mm (24 in.) Units 68

7.3.2 Cable Entry Points on 600mm (24in.) Units 71

7.3.3 Protective Features of Electrical Heaters—600-mm (24-in.) Units 72

7.3.4 Accessing the Electrical Panel on 300 mm (12 in) Units 72

7.3.5 Releasing the Electric Panel Lock 73

7.4 Protective Features of the Electronically Commutated (EC) Fans—All Models 74

8 Humidifier 600 mm (24 in.) Units Only 77

8.1 Principal of Operation 77

8.2 Connecting Water Supply to the Humidifier 78

8.3 Humidifier Startup and Operation 79

8.3.1 Low Water Conductivity 79

8.4 Humidifier Canister Replacement 79

8.4.1 Removing the Old Canister 80

8.4.2 Mandatory Cleaning of the Drain Valve 81

8.4.3 Installing the New Canister 82

8.5 Humidifier Maintenance during Extended Shutdown 83

8.5.1 Humidifier Troubleshooting 83

8.5.2 Humidifier Troubleshooting Steps 85

9 Startup 87

9.1 Checks to Perform after Startup 88

9.2 Automatic Restart 89

9.3 Chilled Water Valve— All Chilled Water Models 90

9.4 Adjust Baffles to Direct Air Properly 91

9.4.1 Adjusting Baffles—600mm (24in.) 92

9.4.2 Adjusting Blocker Plate—600mm (12in.) 93

9.4.3 Adjusting Baffles—300mm (12 in.) 94

10 Troubleshooting 97

11 Maintenance 101

11.1 Safety Instructions 101

11.2 Facility Fluid and Piping Maintenance forWaterandGlycolSystems 102

Vertiv™ | Liebert® CRV Installer/User Guide | ii

Page 5

11.3 Glycol Solution Maintenance 102

11.4 Spare Parts 102

11.5 Maintenance Schedule 102

11.6 Thermostatic Expansion Valve (TXV) Maintenance 104

11.6.1 Determining Suction Superheat 104

11.6.2 Adjusting Superheat Setting with the TXV 105

11.7 Compressor Maintenance 105

11.7.1 Compressor Oil 105

11.7.2 Replacement Compressors 105

11.7.3 Rotalock Valve on Digital Scroll Compressors 106

11.7.4 Unloading Solenoid(s) on a Digital Scroll Compressor 106

11.7.5 Compressor Electrical Failure (Motor Burnout) 107

11.7.6 Compressor Mechanical Failure 107

11.7.7 Replacing a Compressor with Mechanical Failure 107

11.8 Inspect and Replace the Air Filters—600 mm (24in.) Models 108

11.9 Inspect and Replace the Air Filters—300mm (12in.) Models 110

11.10 Condensate Drain and Condensate Pump System Maintenance 111

11.10.1 Condensate Drain 111

11.10.2 Condensate Pump, Dual Float 111

11.11 Air-Cooled Condenser and Drycooler Maintenance 112

11.12 Electric Reheat Maintenance 112

11.13 Fan Replacement 113

11.13.1 Replacing a Fan in 600mm (24in.) Models 113

11.13.2 Replacing a Fan in 300mm (12in.) Models 114

11.14 Considerations when Dismantling the Unit 115

11.15 F-Gas Regulation (EC) No. 842/2006 116

12 Preventive Maintenance Worksheet 119

Appendices 125

Appendix A: Technical Support and Contacts 125

Appendix B: Model Number Nomenclature Detail 127

Appendix C: Submittal Drawings 131

Vertiv™ | Liebert® CRV Installer/User Guide | iii

Page 6

Vertiv™ | Liebert® CRV Installer/User Guide | iv

Page 7

Vertiv Liebert®CRV Installer/User Guide

1 Important Safety Instructions

SAVE THESE INSTRUCTIONS

This manual contains important safety instructions that should be followed during the installation and maintenance of the

Liebert® CRV. Read this manual thoroughly before attempting to install or operate this unit.

Only qualified personnel should move, install or service this equipment.

Adhere to all warnings, cautions, notices and installation, operating and safety instructions on the unit and in this manual.

Follow all installation, operation and maintenance instructions and all applicable national and local building, electrical and

plumbing codes.

Any operation that requires opening doors or equipment panels must be carried out only by properly-trained and qualified

personnel.

To identify the unit model and serial number for assistance or spare parts, locate the identification label on the unit. The

label is inside the door on 600 mm (24 in.) units and at the electrical box on 300 mm (12 in.) units.

A warning label on the front and back panels reminds users that:

• The Liebert® CRV restarts automatically

• The main switch must be opened before opening the internal compartments for any operation.

WARNING! Arc flash and electric shock hazard. Open all local and remote electric power-supply disconnect

switches, verify with a voltmeter that power is Off and wear appropriate, OSHA-approved personal protective

equipment (PPE) per NFPA 70E before working within the electric control enclosure. Failure to comply can

cause serious injury or death. Customer must provide earth ground to unit, per NEC, CEC and local codes, as

applicable. Before proceeding with installation, read all instructions, verify that all the parts are included and

check the nameplate to be sure the voltage matches available utility power. The Liebert® controller does not

isolate power from the unit, even in the “Unit Off” mode. Some internal components require and receive

power even during the “Unit Off” mode of the controller. The only way to ensure that there is NO voltage

inside the unit is to install and open a remote disconnect switch. Refer to unit electrical schematic. Follow all

local codes.

Installation, service, and maintenance work must be performed only by properly trained and qualified

personnel and in accordance with applicable regulations and manufacturers’ specifications. Opening or

removing the covers to any equipment may expose personnel to lethal voltages within the unit even when it is

apparently not operating and the input wiring is disconnected from the electrical source.

WARNING! Risk of over pressurization of the refrigeration system. Can cause explosive discharge of high

pressure refrigerant, loss of refrigerant, environmental pollution, equipment damage, injury, or death. This

unit contains fluids and gases under high pressure. Use extreme caution when charging the refrigerant

system. Do not pressurize the system higher than the design pressure marked on the unit's nameplate.

1 Importan t Safety Inst ructions

1

Page 8

Vertiv Liebert®CRV Installer/User Guide

WARNING! Risk of contact with high speed rotating fan blades. Can cause serious injury or death. Open all

local and remote electric power-supply disconnect switches, verify with a voltmeter that power is off, and

verify that all fan blades have stopped rotating before working in the unit cabinet or on the fan assembly. Fan

motor controls can maintain an electric charge for 10 minutes after power is disconnected. If control voltage

is applied, the fan motor can restart without warning after a power failure.

WARNING! Risk of top-heavy unit falling over. Improper handling can cause equipment damage, injury or

death. Read all of the following instructions and verify that all lifting and moving equipment is rated for the

weight of the unit before attempting to move, lift, remove packaging from or prepare the unit for installation.

Unit weights are specified in Table 3.2 on page9

WARNING! Risk of unsecured unit rolling off pallet. Can cause equipment damage, injury or death. The unit is

on casters. Ensure that the pallet is located on a flat surface before loosening the hardware securing the to

its shipping pallet.

WARNING! Risk of hair, clothing and jewelry entanglement with high speed rotating fan blades. Can cause

equipment damage, serious injury or death. Keep hair, jewelry and loose clothing secured and away from

rotating fan blades during unit operation.

WARNING! Risk of contact with extremely hot and/or cold surfaces. Can cause injury. Verify that all

components have reached a temperature that is safe for human contact or wear appropriate, OSHA-approved

PPE before working within the electric connection enclosures or unit cabinet. Perform maintenance only

when the system is de-energized and component temperatures have become safe for human contact.

WARNING! Risk of improper wiring, piping, moving, lifting and handling. Can cause equipment damage,

serious injury or death. Installation and service of this equipment should be done only by qualified personnel

who have been specially trained in the installation of air conditioning equipment and who are wearing

appropriate, OSHA-approved PPE.

WARNING! Risk of improper wire sizing/rating and loose electrical connections. Can cause overheated wire

and electrical connection terminals resulting in smoke, fire, equipment and building damage, injury or death.

Use correctly sized copper wire only and verify that all electrical connections are tight before turning power

On. Check all electrical connections periodically and tighten as necessary.

WARNING! Risk of humidifier canister meltdown, smoke and fire. Can cause fire suppression system

activation, fire and smoke alarm activation, building evacuation, dispatching of fire and rescue equipment

and personnel and water leaks resulting in expensive equipment or building damage, injury or death. Check

steam generating humidifier electrode plugs to ensure that they are pressed firmly onto pins. Loose

connections will cause overheating of cylinder and plugs.

2

1 Importan t Safety Inst ructions

Page 9

Vertiv Liebert®CRV Installer/User Guide

CAUTION: Risk of contact with sharp edges, splinters, and exposed fasteners. Can cause injury. Only

properly trained and qualified personnel wearing appropriate, OSHA-approved PPE should attempt to move,

lift, remove packaging from or prepare the unit for installation.

CAUTION: Risk of improper moving, lifting and handling. Can cause equipment damage or injury. Only

properly trained and qualified personnel should work on this equipment. Condenser fan modules weigh in

excess of 125 lb (56.7 kg). Use proper lifting techniques and wear appropriate, OSHA-approved PPE to avoid

injury and dropping the fan module during removal. Equipment used in handling/lifting, and/or installing the

fan assembly must meet OSHA requirements. Use handling/lifting equipment rated for the weight of the fan

assembly. Use ladders rated for the weight of the fan assembly and technicians if used during installation.

Refer to handling/lifting, and/or installation equipment operating manual for manufacturer's safety

requirements and operating procedures.

CAUTION: Risk of exposure to harmful noise levels. Can cause hearing injury or loss. Depending on the

installation and operating conditions, a sound pressure level greater than 70dB(A) may arise. Take

appropriate technical safety measures. Operating personnel must wear appropriate, OSHA-approved PPE

and observe all appropriate hearing protection safety requirements.

NOTICE

NOTICE

CAUTION: Risk of excessive refrigerant line pressure. Can cause tubing and component rupture resulting in

equipment damage and personal injury. Do not close off the refrigerant line isolation valve for repairs unless

a pressure-relief valve is field installed in the line between the isolation valve and the check valve. The

pressure relief valve must be rated 5% to 10% higher than the system design pressure. An increase in

ambient temperature can cause the pressure of the isolated refrigerant to rise and exceed the system design

pressure rating (marked on the unit nameplate).

Risk of improper power supply connection. Can cause equipment damage and loss of warranty coverage.Prior

to connecting any equipment to a main or alternate power source (for example: backup generator systems) for

startup, commissioning, testing, or normal operation, ensure that these sources are correctly adjusted to the

nameplate voltage and frequency of all equipment to be connected. In general, power source voltages should

be stabilized and regulated to within ±10% of the load nameplate nominal voltage. Also, ensure that no three

phase sources are single phased at any time.

Risk of oil contamination with water. Can cause equipment damage.

Liebert® CRV systems require the use of POE (polyolester) oil. POE oil absorbs water at a much faster rate

when exposed to air than previously used oils. Because water is the enemy of a reliable refrigeration system,

extreme care must be used when opening systems during installation or service. If water is absorbed into the

POE oil, it will not be easily removed and will not be removed through the normal evacuation process. If the oil

is too wet, it may require an oil change. POE oils also have a property that makes them act as a solvent in a

refrigeration system. Maintaining system cleanliness is extremely important because the oil will tend to bring

any foreign matter back to the compressor.

1 Importan t Safety Inst ructions

3

Page 10

Vertiv Liebert®CRV Installer/User Guide

NOTICE

Risk of improper refrigerant charging. Can cause equipment damage.

Refrigerant charge must be weighed into air-cooled compressorized systems before they are started. Starting

scroll and digital scroll compressors without proper refrigerant charging can cause the compressors to operate

at less than 5°F (–15°C) evaporator temperature and at less than 20psig (138kPa). Operation for extended

periods at less than 20psig (138kPa) can cause premature compressor failure.

NOTICE

Risk of clogged or leaking drain lines and leaking water supply lines. Can cause equipment and building

damage.

This unit requires a water drain connection. Drain lines must be inspected at startup and periodically, and

maintenance must be performed to ensure that drain water runs freely through the drain system and that lines

are clear and free of obstructions and in good condition with no visible sign of damage or leaks. This unit may

also require an external water supply to operate.

Improper installation, application and service practices can result in water leakage from the unit. Water

leakage can result in catastrophic and expensive building and equipment damage and loss of critical data

center equipment.

NOTICE

Do not locate unit directly above any equipment that could sustain water damage.

We recommend installing a monitored fluid detection system to immediately discover and report coolant fluid

system and condensate drain line leaks.

Risk of piping system corrosion and freezing fluids. Can cause leaks resulting in equipment and very expensive

building damage. Cooling coils, heat exchangers and piping systems are at high risk of freezing and premature

corrosion. Fluids in these systems must contain the proper antifreeze and inhibitors to prevent freezing and

premature coil, heat exchanger and piping corrosion. The water or water/glycol solution must be analyzed by a

competent local water treatment specialist before start up to establish the inhibitor and antifreeze solution

requirement and at regularly scheduled intervals throughout the life of the system to determine the pattern of

inhibitor depletion.

The complexity of water/glycol solution condition problems and the variations of required treatment programs

make it extremely important to obtain the advice of a competent and experienced water treatment specialist

and follow a regularly scheduled coolant fluid system maintenance program.

Water chemistry varies greatly by location, as do the required additives, called inhibitors, that reduce the

corrosive effect of the fluids on the piping systems and components. The chemistry of the water used must be

considered, because water from some sources may contain corrosive elements that reduce the effectiveness of

the inhibited formulation. Sediment deposits prevent the formation of a protective oxide layer on the inside of

the coolant system components and piping. The water/coolant fluid must be treated and circulating through

the system continuously to prevent the buildup of sediment deposits and or growth of sulfate reducing

bacteria.

Proper inhibitor maintenance must be performed in order to prevent corrosion of the system. Consult glycol

manufacturer for testing and maintenance of inhibitors.

4

1 Importan t Safety Inst ructions

Page 11

NOTICE

NOTICE

Vertiv Liebert®CRV Installer/User Guide

Commercial ethylene glycol, when pure, is generally less corrosive to the common metals of construction than

water itself. It will, however, assume the corrosivity of the water from which it is prepared and may become

increasingly corrosive with use if not properly inhibited.

We recommend installing a monitored fluid detection system that is wired to activate the automatic closure of

field installed coolant fluid supply and return shutoff valves to reduce the amount of coolant-fluid leakage and

consequential equipment and building damage. The shutoff valves must be sized to close off against the

maximum coolant fluid system pressure in case of a catastrophic fluid leak.

Risk of frozen pipes and corrosion from improper coolant mixture. Can cause water leaks resulting in

equipment and building damage.

When the cooling unit or piping may be exposed to freezing temperatures, charge the system with the proper

percentage of glycol and water for the coldest design ambient temperature. Automotive antifreeze is

unacceptable and must NOT be used in any glycol fluid system. Use only HVAC glycol solution that meets the

requirements of recommended industry practices.

NOTICE

NOTICE

NOTICE

Risk of no flow condition. Can cause equipment damage.

Do not leave the water/coolant fluid supply circuit in a no flow condition. Idle fluid allows the collection of

sediment that prevents the formation of a protective oxide layer on the inside of tubes. Keep unit switched On

and water/coolant fluid-supply circuit system operating continuously.

Risk of doorway/hallway interference. Can cause unit and/or structure damage. The unit may be too large to fit

through a doorway or hallway while on the skid. Measure the unit and passageway dimensions, and refer to the

installation plans prior to moving the unit to verify clearances.

Risk of improper water supply. Can reduce humidifier efficiency or obstruct humidifier plumbing.

Do not use completely demineralized water with this unit. The water must contain minerals for the electrode

principle to work.

Do not use a hot water source. It will cause deposits that will eventually block the fill valve opening.

Risk of water backing up in the drain line. Leaking and overflowing water can cause equipment and building

damage.

Do not install an external trap in the drain line. This line already has a factory installed trap inside the cabinet

(except for 300 mm (12 in.)) Chilled water models). Installation of a second trap will prevent drain water flow

and will cause the water to overflow the drain pan.

1 Importan t Safety Inst ructions

This line may contain boiling water. Use cooper or other material that is rated for handling boiling water for the

drain line. Sagging condensate drain lines may inadvertently create an external trap.

5

Page 12

Vertiv Liebert®CRV Installer/User Guide

NOTICE

Risk of doorway/hallway interference. Can cause unit and/or structure damage. The unit may be too large to fit

through a doorway or hallway while on the skid. Measure the unit and passageway dimensions, and refer to the

installation plans prior to moving the unit to verify clearances.

NOTICE

Risk of damage from forklift. Can cause unit damage. Keep tines of the forklift level and at a height suitable to

fit below the skid and/or unit to prevent exterior and/or underside damage.

NOTICE

Risk of improper storage. Can cause unit damage.

Keep the unit upright, indoors and protected from dampness, freezing temperatures and contact damage.

NOTICE

Risk of release of hazardous substances into the environment. Can cause environmental pollution and violation

of environmental regulations.

The Liebert® CRV contains substances and components hazardous for the environment (electronic

components, refrigerating gases and oils). At the end of its useful life, the Liebert® CRV must be dismantled by

specialized refrigerating technicians. The unit must be delivered to suitable centers specializing in the

collection and disposal of equipment containing hazardous substances.

NOTE: The Liebert indoor cooling unit has a factory installed high pressure safety switch in the high side refrigerant

circuit. Consult local building codes to determine whether the Liebert® MC Condensers without receivers will require

field provided pressure relief devices such as a fusible plug. A pressure relief valve is provided with Liebert® LeeTemp receivers.

Agency Listed

Standard 60 Hz units are CSA Certified to the harmonized U.S. and Canadian product safety standard CSA C22.2 No

236/UL 1995 for “Heating and Cooling Equipment” and are marked with the CSA c-us logo.

6

1 Importan t Safety Inst ructions

Page 13

Vertiv Liebert®CRV Installer/User Guide

2 Nomenclature and Components

This section describes the model number for Liebert® CRV units and components.

2.1 Model Number Nomenclature

The tables describe the 25 digitconfigurationnumber. The 14 digit model number consists of the first 10 digits and last 4

digits of the configuration number.

For the full description of configuration and model number refer to Model Number Nomenclature Detail on page127 .

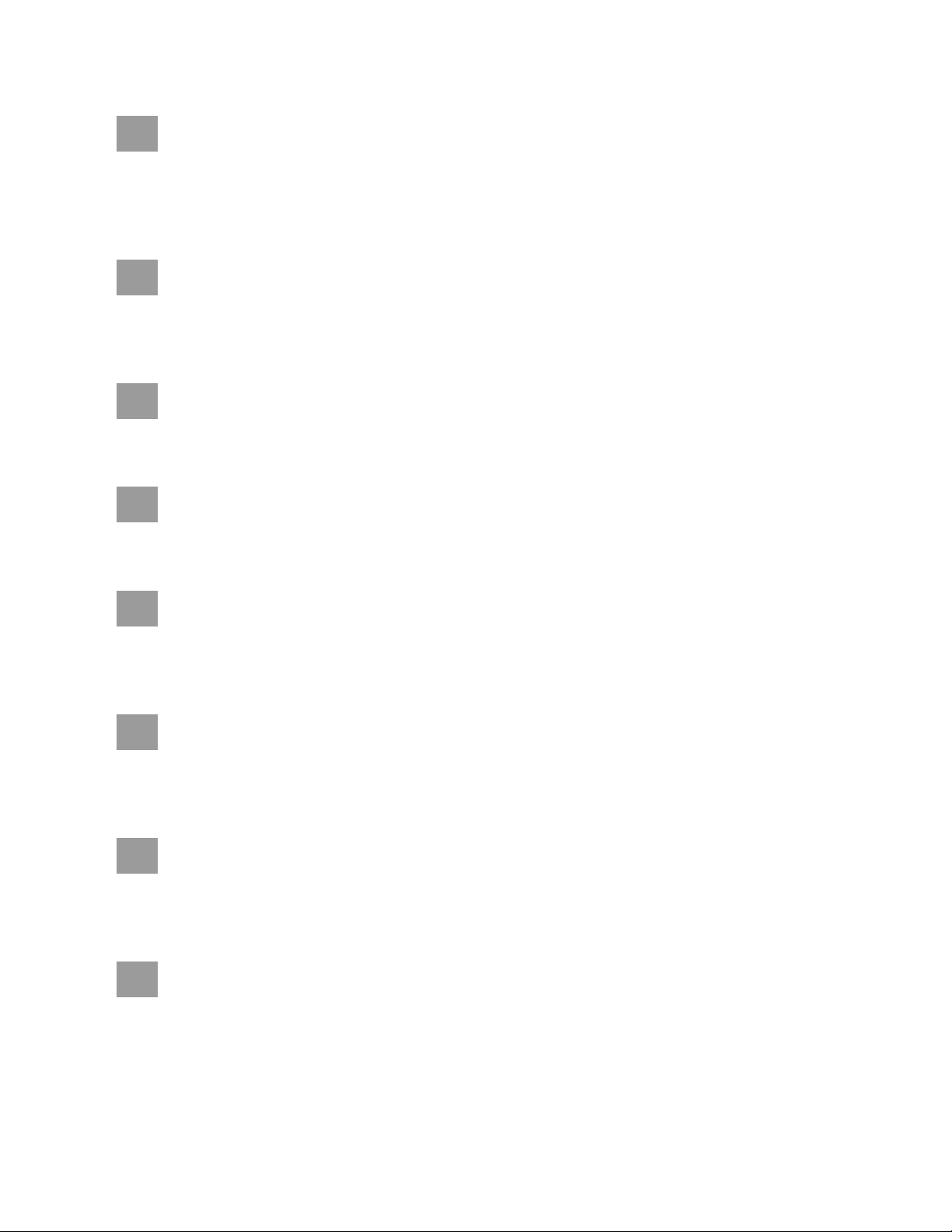

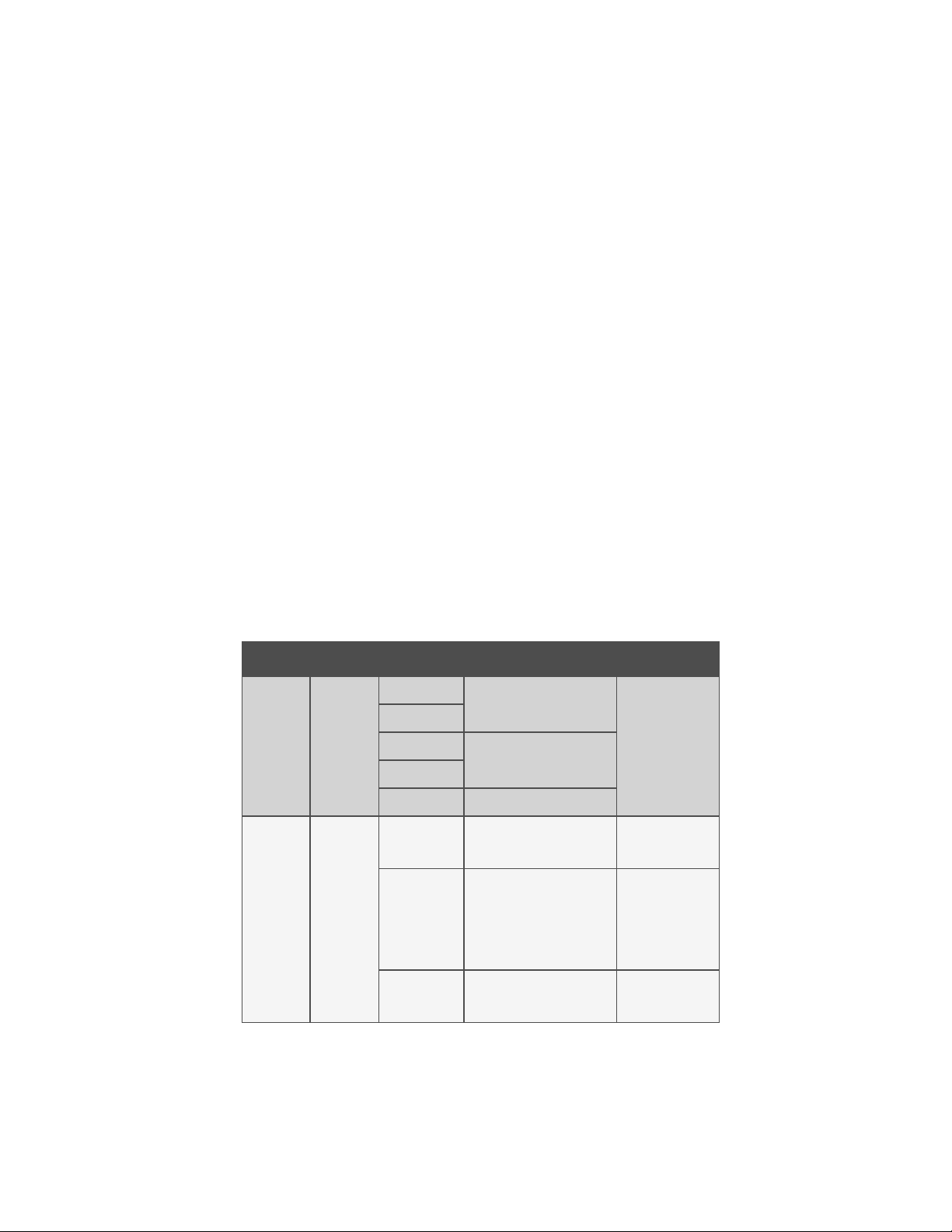

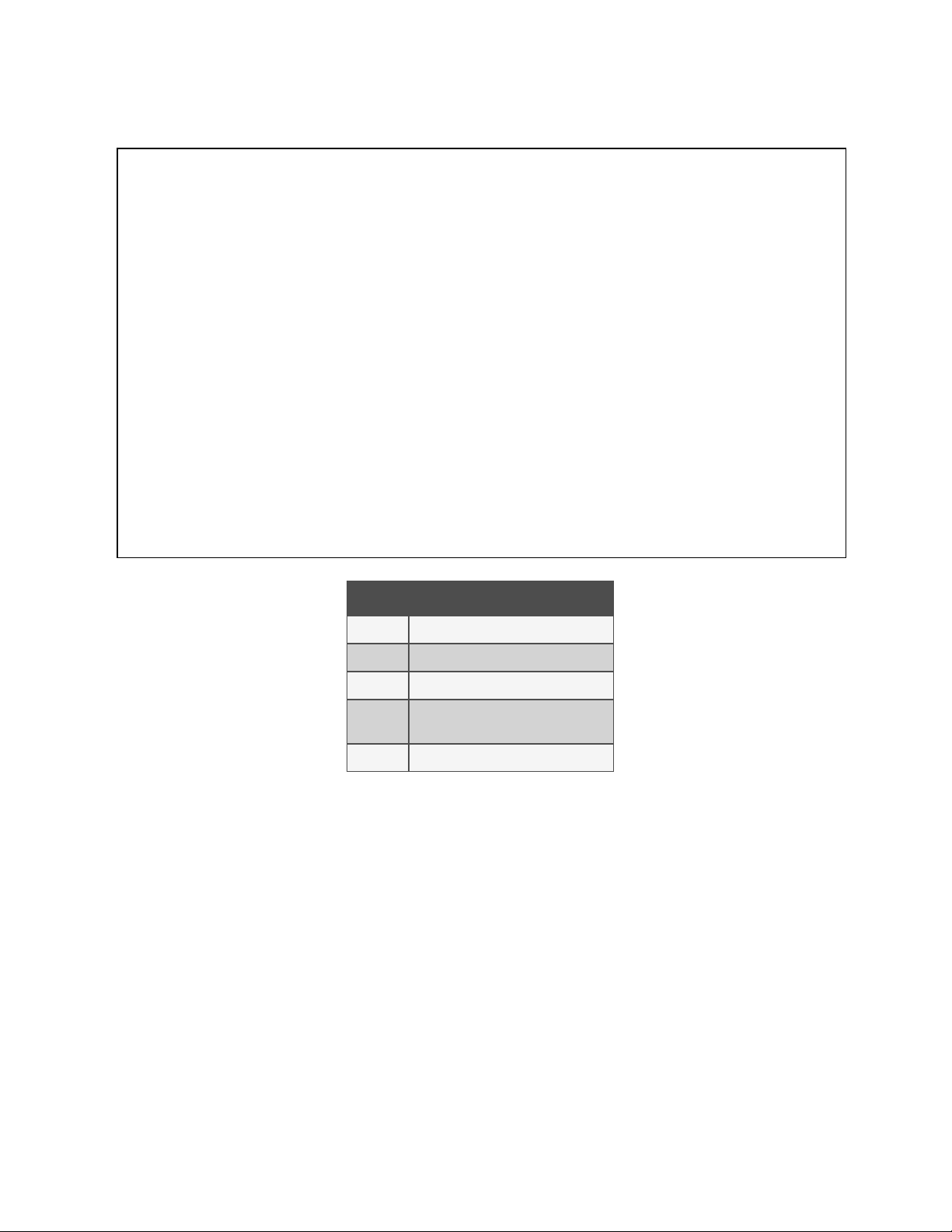

Model Number D igits 1 to 10 Model Details

1 2 3 4 5 6 7 8 9 1 0 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25

C R 0 2 0 R A 1 C 7 S H 1 8 1 1 E L 1 0 P A — — —

Digits 1 -2 - Unit Fam ily Digit14 - Air Filter

Digits 3-5 - Nominal Capacity, kW Digit 15 - Water/Glycol Valve Type

Digit6 - Row-Based, Unit Depth Digit 16 - Enclosure

Digit7 - System Type Digit17 - High Voltage Options

Digit8 - Fan Type Digit18 - Option Package

Digit9 - Power Supply Digit19 - Liebert® IntelliSlot™ Housing

Digit10 - Cooling System Digit20 - Future Options

Digit11 - Humidifier Digit21 - Packaging With Ra mp

Digit12 - Control System Digit22 - Special Features

Digit13 - Reheat Digits 23-25 - Factory Configuration Number

Model Number D igits 11

to 14

2.2 Component Location

The unit component locations are described in the submittal documents included in the Submittal Drawings on page131 .

The following table lists the relevant documents by number and title.

Table 2.1 Component Location Drawings

Docu ment Number Title

DPN003738 Component Location Diagram, 600mm (24in.) Models

DPN003583 Component Location Diagram, 30 0mm (12in.) Air Cooled Models

DPN003585 Component Location, 300mm (12in.) Water Glycol Cooled Models

DPN003584 Component Location, 300mm (12in.) Chilled Water Models

2 N omenclature an d Components

7

Page 14

Vertiv Liebert®CRV Installer/User Guide

2.3 Cooling Configurations and Liebert® CRV Overview

The Liebert®CRV is a precision cooling unit available in compressorized (air, water, or glycol cooled) and chilled water

configurations to be installed within a row of high density computing racks in a “hotaisle-coldaisle” configuration.

Air enters the rear of the CRV from the hot aisle, is filtered, cooled and conditioned, then discharged into the cold aisle. The

CRV provides all the necessary functions of a standard Thermal Management unit, including cooling, heating,

humidification, dehumidification, air filtration, condensate management, temperature control, alarm monitoring and data

communication. (The 300 mm [12 in.] models do not provide heating, humidification or dehumidification.) The CRV is

optimized for maximum cooling capacity in a minimal footprint.

The Liebert® CRV 300 series and 600 series Thermal Management units are meant for location within a row of heat

generating IT equipment racks.

The extremely energy efficient components of the CRV are managed by the Liebert® iCOM™ control system. The iCOM

control monitors the environment in real time with rack inlet sensors on the cooled by the in-row CRV. The information

gathered allows optimization of performance and energy efficiency.

All operations and sensor data can be reported remotely via a variety of communication protocols, providing a built-in,

rack-temperature monitoring system.

The supply-air baffle directs the air leaving the CRV to the racks, maximizing its effectiveness, reducing the chance for hot

spots, and improving overall system efficiency. The angle and spacing of the baffle vanes series are optimized through CFD

modeling, laboratory testing and real world installations.

All service and maintenance is performed through the front and rear of the unit, including all component replacement. All

piping and electrical connections are made through the top or bottom of the unit.

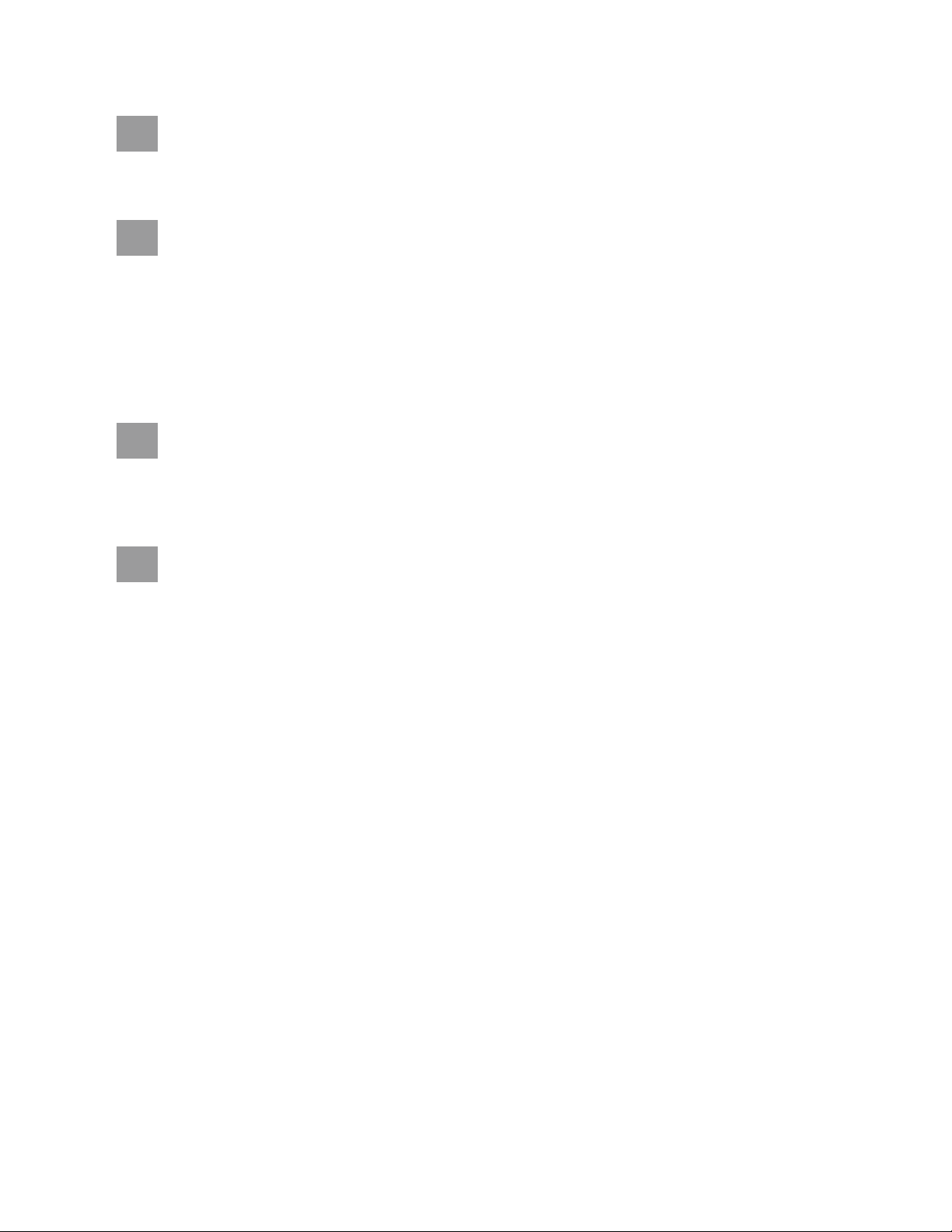

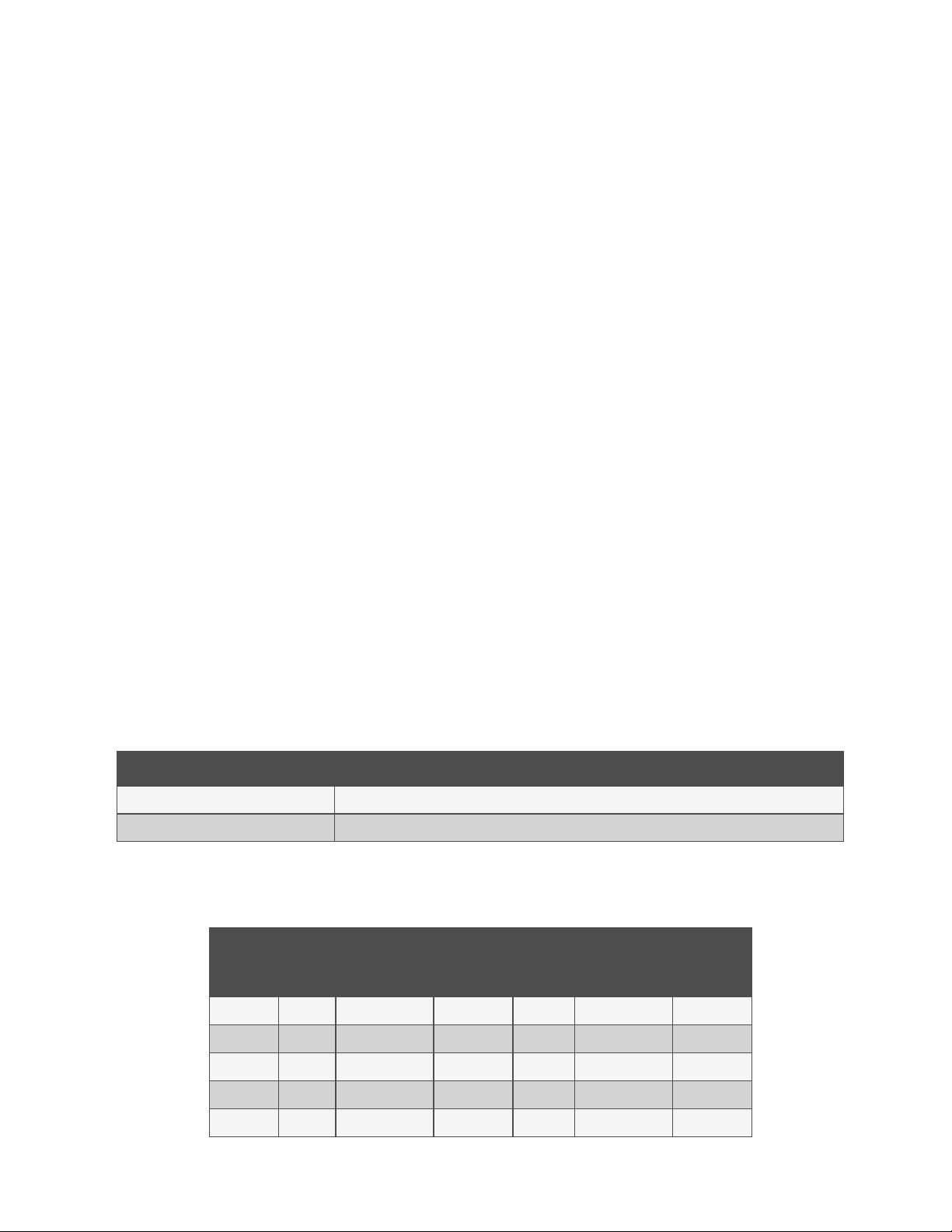

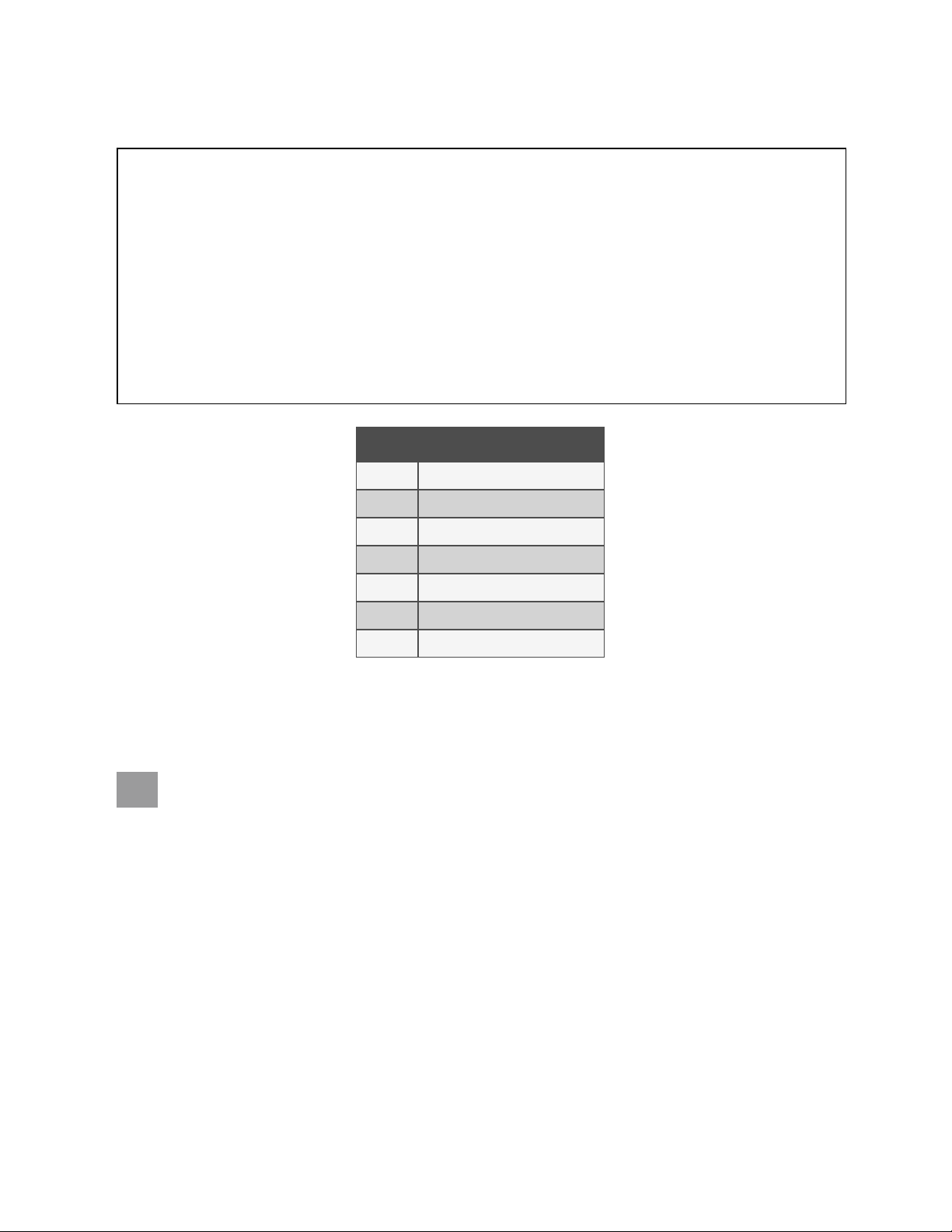

Table 2.2 CRV Configurations

Series Width C oo ling Type Nom inal C oo ling Capacity, kW Input Power 60 Hz

600

300

24 in.

(600 m m)

12 in.

(300 mm)

Air

Water/Glycol

Air

Water/Glycol

Chilled Water 40

Air 19

Chilled Water 32

20

35

208 V/3 ph

460 V/3 ph

208-230 V/3 ph

460 V/3 ph-Wye

208-230 V/1 ph

208-230 V/3 ph

460 V/3 ph-Wye

120 V/1 ph

Water/Glycol 19

8

208-230 V/3 ph

460 V/3 ph-Wye

2 N omenclature an d Components

Page 15

Vertiv Liebert®CRV Installer/User Guide

3 Pre-installation PreparationandGuidelines

NOTE: Before installing unit, determine whether any building alterations are required to run piping, wiring and duct

work. Follow all unit dimensional drawings and refer to the submittal engineering dimensional drawings of individual

units for proper clearances.

Refer to Model Number Nomenclature on page7 and the appropriate submittal drawings, to determine the type of system

being installed and anticipate building alterations, piping and duct work needed.

The unit dimensions, pipe connection locations, and piping schematics are described in the submittal documents included

in the Submittal Drawings on page131 .

• Verify that the floor is level, solid and sufficient to support the unit. See Unit Weights below for unit weights.

• Confirm that the room is properly insulated and has a sealed vapor barrier.

• For proper humidity control, keep outside or fresh air to an absolute minimum (less than 5% of total air

circulated in the room).

• Do not install a Liebert® CRV in an alcove or at the end of a long, narrow room.

• Install the units as close as possible to the largest heat load.

• Allow at least the minimum recommended clearances for maintenance and service. See the appropriate

submittal drawings for dimensions.

• We recommend installing an under floor leak detection system. Contact your Vertiv representative for

information.

3.1 Planning Dimensions

The unit, floor stand, and plenum dimensions are described in the submittal documents included in the Submittal Drawings

on page131 .

The following table lists the relevant documents by number and title.

Table 3.1 Dimension Planning Drawings

Docu ment Number Title

DPN001791 Cabinet Dimensional Data 600 m m (24 in.) Models

DPN002807 Cabinet Dimensional Data 300 mm (12 in,) Models

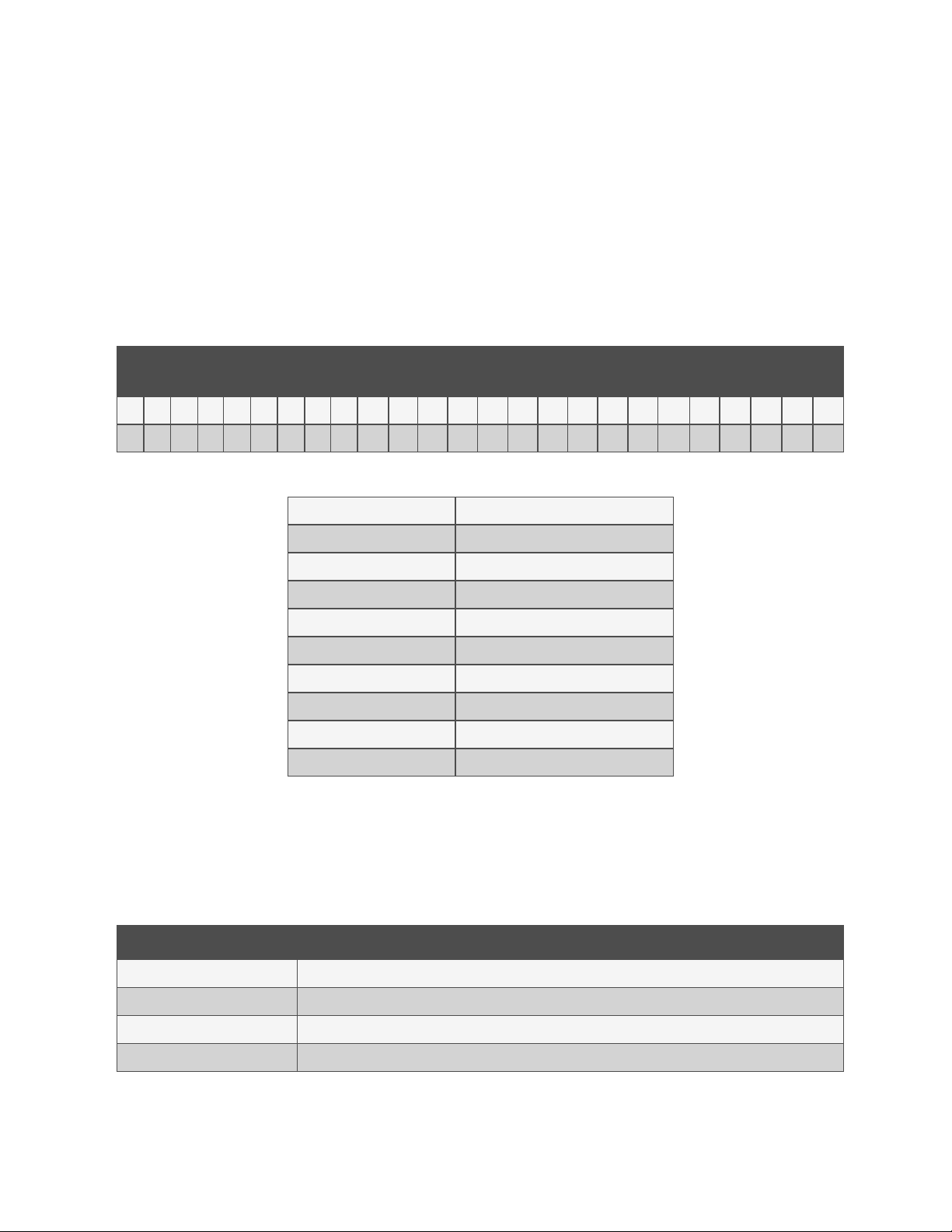

3.2 Unit Weights

Table 3.2 Shipping Weights

Dom estic Packaging, lb (kg) Export Packaging, lb (kg)

Model No .

Air Water/Glycol Chilled Water Air Water/Glycol Chilled Water

CR019 649(294) 687 (311) — 721 (327) 782 (355) —

CR032 — — 560 (254.0) — — 683 (309.8)

CR020 846 (384) 879 (399) — 953 (432) 986 (447) —

CR035 912 (414) 956 (434) — 1019 (462) 1063 (482) —

CR040 — — 835 (379) — — 942 (427)

3 Pre-installation Prep arationand Guidelin es

9

Page 16

Vertiv Liebert®CRV Installer/User Guide

This page intentionally left blank

10

3 Pre-installation Prep arationand Guidelin es

Page 17

4 Equipment Inspection and Handling

WARNING! Risk of top-heavy unit falling over. Improper handling can cause equipment damage, injury or

death. Read all of the following instructions and verify that all lifting and moving equipment is rated for the

weight of the unit before attempting to move, lift, remove packaging from or prepare the unit for installation.

Unit weights are specified in Table 3.2 on page9

WARNING! Risk of contact with sharp edges, splinters, and exposed fasteners. Can cause injury. Only

properly trained and qualified personnel wearing appropriate, OSHA-approved PPE should attempt to move,

lift, remove packaging from or prepare the unit for installation.

NOTICE

Risk of passageway interference. Can cause unit and/or structure damage. The unit may be too large to fit

through a passageway while on or off the skid. Measure the unit and passageway dimensions, and refer to the

installation plans prior to moving the unit to verify clearances.

Vertiv Liebert®CRV Installer/User Guide

NOTICE

Risk of damage from forklift. Can cause unit damage. Keep tines of the forklift level and at a height suitable to

fit below the skid and/or unit to prevent exterior and/or underside damage.

NOTICE

Risk of improper storage. Can cause unit damage.Keep the unit upright, indoors and protected from dampness,

freezing temperatures and contact damage.

Upon arrival of the unit and before unpacking:

• Verify that the labeled equipment matches the bill of lading.

• Carefully inspect all items for visible or concealed damage.

• Report damage immediately to the carrier and file a damage claim with a copy sent to Vertiv or to your sales

representative.

• For initial access, use a 7/32 in. Allen wrench for panel removal.

Equipment Recommended for Handling the Unit:

• Forklift

• Pallet jack

• Piano jacks

• Slings

• Spreader bars

4 Equipment Insp ection and Handl ing

11

Page 18

Vertiv Liebert®CRV Installer/User Guide

4.1 Packaging Material

All material used to package this unit is recyclable. Please save for future use or dispose of the material appropriately.

4.2 Handling the Unit while Packaged

Transport the unit with a forklift or pallet jack.

When using a forklift or pallet jack:

• Make sure that the forks (if adjustable) are spread to the widest allowable distance that will fit under the skid.

• Make sure the fork length is suitable for the skid length. Skid length is 60in (1524mm)

• When moving the packaged unit, do not lift the unit any higher than 2to4in. (51to102 mm). All personnel

except those moving the unit must be kept 12ft (3.7m) or more from the unit while it is being moved.

• If the unit must be lifted higher than 4in. (102 mm), all personnel not directly involved in moving the unit must

be 20ft (5m) or farther from the unit.

4.3 Unpacking the Export Shipped 600 mm(24 in.) Unit

1. Remove the metal clips (12 places typical) that secure the top panel of the crate to the side panels, see Figure

4.1 on the facing page .

2. Use a Phillips head screw driver to remove all the wood screws (34 places typical) that secure the side panels

together and to the pallet, see Figure 4.1 on the facing page .

3. To remove the remaining packaging, start with Step 1 , of Unpacking the Domestic Shipped 600 mm(24 in.)

Unit on the facing page .

12

4 Equipment Insp ection and Handl ing

Page 19

Figure 4.1 Metal Clips and Wood Screws on Crate

Vertiv Liebert®CRV Installer/User Guide

Item Description

1 Metal clips, typical 12 places

2 Wood screws, m inimum 34 places

4.4 Unpacking the Domestic Shipped 600 mm(24 in.) Unit

1. Use a 9/16 in. socket drive or wrench to remove the lag screws (4 places typical) that secure the ramp to the

pallet, see Figure 4.2 on the next page . Set the ramps aside for use later when preparing move the unit from

the pallet.

2. Remove the exterior packaging from around the unit

NOTE: The bag may remain in place to protect from dust and to protect the unit panels, or it may be removed for

immediate installation.

3. Remove the bag from the unit when ready to move off the pallet and install the unit. See Removing 600 mm

(24 in.) Units from the Pallet on the next page .

4 Equipment Insp ection and Handl ing

13

Page 20

Vertiv Liebert®CRV Installer/User Guide

Figure 4.2 Lag Screws that Secure Ramps

4.5 Removing 600 mm (24 in.) Units from the Pallet

1. Remove front panel, see Figure 4.3 on the facing page

• Open the top panel door (with controller display).

• Using a 8 mm hex head or T30 Torx screwdriver, remove the screws securing the bottom front panel

assembly, and set aside until instructed to re attach.

• Close and latch the top panel door.

2. Lower the 4 leveling feed to touch the pallet deck as shown in Figure 4.3 on the facing page . Open the rear,

hinged door to access the rear leveling feet.

3. Using a 13 mm socket-drive or wrench, remove the screws that secure the shipping brackets to the side of the

unit, 3 each side, see Figure 4.3 on the facing page .

4. Using a 9/16 in. socket drive or wrench, remove the lag screws that secure the shipping brackets to the pallet, 4

each side, see Figure 4.3 on the facing page .

5. Adjust the 4 leveling feet equally, to raise the unit off the shipping blocks, and remove the blocks, see Figure

4.3 on the facing page .

14

4 Equipment Insp ection and Handl ing

Page 21

Figure 4.3 Preparing to Attach Ramps

Vertiv Liebert®CRV Installer/User Guide

Item Description

1 Leveling feet touching pallet, front view

2 13 mm hex head screw, 3 ea ch side

3 9/16-in. hex head screw, 4 each side

4 Leveling feet raise unit off shipping blocks, front view

6. Locate the ramps and attach to the pallet using the hook and loop strips, see Figure 4.4 on the next page , for

placement of the strips.

WARNING! Risk of unsecured unit rolling off pallet. Can cause equipment damage, injury or death. The unit is

on casters. Ensure that the pallet is located on a flat surface before loosening the hardware securing the to

its shipping pallet.

7. Adjust the 4 leveling feet equally until casters make contact with the pallets, then continue to raise all the feet

to the full up position, see Figure 4.4 on the next page .

IMPORTANT! Two or more properly trained and qualified personnel are required to move the unit to its installation

location.

8. With two or more personnel, move the unit from the pallet, to the ramps, to the floor, and then to the installation

location.

4 Equipment Insp ection and Handl ing

15

Page 22

Vertiv Liebert®CRV Installer/User Guide

Figure 4.4 Ramps Attached and Leveling Feet Raised

Item Description

1 Leveling feet fully raised. Casters ready to roll.

4.6 Unpacking the Export Shipped 300 mm(24 in.) Unit

1. Remove the metal clips (12 places typical) that secure the top panel of the crate to the side panels, see Figure

4.5 on the facing page .

2. Use a Phillips-head screw driver to remove all the wood screws (34 places typical) that secure the side panels

together and to the pallet, see Figure 4.5 on the facing page .

3. To remove the remaining packaging, start with Step 1 , of Unpacking the Domestic Shipped 300 mm(12 in.)

Unit on the facing page .

16

4 Equipment Insp ection and Handl ing

Page 23

Figure 4.5 Metal Clips and Wood Screws on Crate

Vertiv Liebert®CRV Installer/User Guide

4.7 Unpacking the Domestic Shipped 300 mm(12 in.) Unit

1. Use a 9/16 in. socket drive or wrench to remove the lag screws (4 places typical) that secure the ramp to the

pallet, see Figure 4.6 on the next page . Set the ramps aside for use later when preparing move the unit from

the pallet.

2. Remove the exterior packaging from around the unit

NOTE: The bag may remain in place to protect from dust and to protect the unit panels, or it may be removed for

immediate installation.

3. Remove the bag from the unit when ready to move off the pallet and install the unit. See Removing 300 mm (12

in.) Units from the Pallet on the next page .

4 Equipment Insp ection and Handl ing

17

Page 24

Vertiv Liebert®CRV Installer/User Guide

Figure 4.6 Lag Screws that Secure Ramps

4.8 Removing 300 mm (12 in.) Units from the Pallet

1. Locate the ramps and attach to the pallet using the hook and loop strips, see Figure 4.7 on the facing page ,

for placement of the strips.

WARNING! Risk of unsecured unit rolling off pallet. Can cause equipment damage, injury or death. The unit is

on casters. Ensure that the pallet is located on a flat surface before loosening the hardware securing the to

its shipping pallet.

2. Using a 13-mm socket-drive or wrench, remove the screws that secure the shipping brackets to the side of the

unit, 3 each side, see Figure 4.7 on the facing page .

3. Using a 9/16-in. socket-drive or wrench, remove the lag screws that secure the shipping brackets to the pallet,

3 each side, see Figure 4.7 on the facing page .

IMPORTANT! Two or more properly-trained and qualified personnel are required to move the unit to its installation

location.

4. With two or more personnel, move the unit from the pallet, to the ramps, to the floor, and then to the installation

location.

18

4 Equipment Insp ection and Handl ing

Page 25

Figure 4.7 Attach Ramps and Remove Shipping Brackets

Vertiv Liebert®CRV Installer/User Guide

Item Description

1 13 mm hex-head screw, 3 ea ch side

2 9-16 in. hex-head screw, 3 ea ch side

4 Equipment Insp ection and Handl ing

19

Page 26

Vertiv Liebert®CRV Installer/User Guide

This page intentionally left blank

20

4 Equipment Insp ection and Handl ing

Page 27

Vertiv Liebert®CRV Installer/User Guide

5 Installing in Enclosure Row

Built-in casters let you roll the Liebert® CRV into position for installation. For 300 mm units, optional stabilizers reduce the

likelihood of the module tipping over. These stabilizers, shown in Figure 5.1 on the next page , must be removed before the

unit is positioned in the row. Adjustable leveling feet prevent it from moving after positioning, See Adjusting Base

Supports/Leveling Feet below .

Once positioned, secure the unit to the floor or to an adjacent cabinet.

Adjustable brackets for attaching the unit to an adjacent cabinet are included with each unit. A bracket to attach the unit to

the floor is available from your Vertiv representative.

5.1 Adjusting Base Supports/Leveling Feet

1. After the unit is in its final installation position, open the display door and remove the lower front baffle panel

using a 10 mm nut driver or T30 Torx Bit to prepare for installation.

2. Open the rear panel.

3. Using an adjustable wrench, adjust the four base supports, or feet, shown in Figure 5.1 on the next page .

Ensure that the unit is level to avoid corrosion or health hazards caused by condensate accumulation.

4. Turning the base supports (leveling feet) clockwise, extends them, and lifts the unit one corner at a time.

5. Tighten the nut on the top of each foot to lock the feet. The nut on 600 mm (24 in.) units is inside the cabinet.

The nut on 300 mm (24 in.) units is under the cabinet, as shown in Figure 5.2 on page23 .

5 In stalling in Enclosure Row

21

Page 28

Vertiv Liebert®CRV Installer/User Guide

Figure 5.1 Caster Locations

Item Description

1 Rear of 300 mm (12 in.) unit, bottom view

2 Rear of 600 mm (24 in.) unit, bottom view

3 Caster, 1 at each corner

4

Stabilizer (optional), 1 at ea ch corner.

Only available for 300 mm (12 in.) units.

5 Adjustable leveling foot, 1 at ea ch corner

22

5 In stalling in Enclosure Row

Page 29

Figure 5.2 Adjust Leveling Feet

Vertiv Liebert®CRV Installer/User Guide

Item Description

1 600 mm (24 in.) unit

2 300 mm (12 in.) unit

3 Nut on top of foot.

4 Adjust foot with wrench

5 Adjust foot with wrench

6 Jam nut, secures foot and final height

7 Nut to raise/lower foot.

5.2 Optional Tie Down Brackets for 300 mm (12 in.) Units

An optional tie down bracket may be installed on the unit to secure it in the row. The bracket keeps the space between the

cooling unit and adjacent equipment constant, preventing noise from vibration.

WARNING! Risk of electric shock and/or improper drilling. Can cause equipment damage, injury or death.

Open all local and remote electric power disconnect switches, verify that power is off with a voltmeter and

verify that no servers or other equipment is located in the intended area for drilling or use of mounting

screws. Verify that there are no electric wires or equipment that may be damaged by the drill or by the

resulting shavings and debris.

5.2.1 What’s Included

5 In stalling in Enclosure Row

• Brackets: 4 (2 piece, L-shaped components; for cabinets of different heights)

• Bracket tie-downs: 2 (flat brackets; for cabinets of same height)

• M6 bolts: 2

• M6 nuts: 2

• Washers: 2

• Self-tapping screws: 16

23

Page 30

Vertiv Liebert®CRV Installer/User Guide

5.2.2 Tools Required

• Screwdriver, Phillips #2 Bit

• Drill

• Drill bit: 1/8” diameter

• 10 mm wrench or adjustable wrench

5.2.3 Installing Tie Down Brackets on300 mm(12 in.)

andonCabinetsofDifferentHeights

To install the tie down bracket:

1. Insert the M6 bolt through the longest slot in the two-piece tie-down bracket as shown in Figure 5.3 on the

facing page .

2. Secure the tie-down bracket loosely with the washer and M6 nut.

3. Position the tie-down bracket over the factory fabricated holes on the top of the Liebert® CRV and over the top

of the adjacent cabinet as shown in Tie Down Bracket on Cabinets of Different Heights—300mm (12 in.) on the

facing page .

4. Mark where the self-tapping screws will attach the tie down bracket to the adjacent cabinet.

5. Taking proper precautions to collect the metal shavings and protect equipment, drill holes in the adjacent

cabinet for the two screws.

6. Use a vacuum cleaner or other method to remove all metal particles.

7. Position the bracket over the holes in the Liebert® CRV and the adjacent cabinet.

8. Insert and tighten the four screws.

9. Tighten the M6 nut installed in step 2 securely.

24

5 In stalling in Enclosure Row

Page 31

Figure 5.3 Tie Down Bracket on Cabinets of Different Heights—300mm (12 in.)

Vertiv Liebert®CRV Installer/User Guide

Item Description

1 Top of a djacent cabinet

2 Rear of unit

3 Top of unit

4 Screw holes for tie-down brackets

5 Front of unit

6 Screws in drilled holes.

5 In stalling in Enclosure Row

25

Page 32

Vertiv Liebert®CRV Installer/User Guide

5.2.4 Installing Tie Down Brackets on300 mm(12 in.)

andonCabinetsoftheSameHeight

To install the tie down bracket:

1. Position the tie-down bracket over the factory fabricated holes on the top of the Liebert® CRV and over the top

of the adjacent cabinet of the same height as shown in Figure 5.4 below .

2. Mark where the self-tapping screws will attach the tie-down bracket to the adjacent cabinet.

3. Taking proper precautions to collect the metal shavings and protect equipment, drill holes in the adjacent

cabinet for the two screws.

4. Use a vacuum cleaner or other method to remove all metal particles.

5. Position the bracket over the holes in the Liebert® CRV and the adjacent cabinet.

6. Insert and tighten the four screws.

Figure 5.4 Tie Down Bracket on Cabinets of the Same height—300mm (12 in.)

Item Description

1 Top of a djacent cabinet

2 Rear of unit

3 Screw holes for tie-down brackets

4 Top of the unit

5 Front of the unit

6 Bracket

26

5 In stalling in Enclosure Row

Page 33

Vertiv Liebert®CRV Installer/User Guide

6 Piping and Refrigerant Requirements

The chilled water and water/glycol piping use threaded connections. The air cooled unit and internal refrigeration

connections are sweat copper. The humidifier and condensate supply are threaded connections. Factory installed piping

brackets must not be removed. Field installed piping must be installed in accordance with local codes and must be

properly assembled, supported, isolated and insulated. Avoid piping runs through noise sensitive areas, such as office walls

and conference rooms.

Refer to specific text and detailed diagrams in this manual for other unit-specific piping requirements.

All piping below the elevated floor must be arranged so that it offers the least resistance to airflow. Careful planning of the

piping layout under the raised floor is required to prevent the airflow from being blocked. When installing piping on the

subfloor, we recommend installing the pipes in a horizontal plane rather than stacked one above the other. Whenever

possible, the pipes should be run parallel to the airflow.

The pipe connection locations, piping general arrangement and schematics are described in the submittal documents

included in the Submittal Drawings on page131 .

The following tables list the relevant documents by number and title.

Table 6.1 Piping General Arrangement Drawings

Docu ment Number Title

Air Cooled Systems

DPN002858 General Arrangement Diagram 600 mm (24 in.) Air Cooled with Liebert® MC Models

DPN002808 General Arrangement Diagram 300 mm (12 in.) Air Cooled with Liebert®MC Models

Water/Glycol Cooled Systems

DPN001985 General Arrangement Diagram 600 mm (24 in.) Water/Glycol Cooled Models

DPN003039 General Arrangement Diagram, 30 0 mm (12 in) Water/Glycol Cooled Models

Chilled Water Systems

DPN001986 General Arrangement Diagram 600 mm (24 in.) Chilled Water Models

DPN002976 Primary Connection Locations CR040 Chilled Water Models

Table 6.2 Piping Connection Drawings

Docu ment Number Title

Air Cooled Systems

DPN003954 Air Cooled Piping Schem atic Condenser Above Indoor Unit

DPN001792 Primary Connection Locations CR02 0RA & CR035RA Air Cooled Models

DPN002813 Primary Connection Locations 300 mm (12 in.) Air Cooled Models

DPN001793 Primary Connection Locations CR020 RW & CRO35RW Water/Glycol Models

DPN003040 Primary Connection Locations 300 mm (12 In.) Water/Glycol Cooled Models

6 Pip ing and Refrigerant Requiremen ts

Water/Glycol Cooled Systems

27

Page 34

Vertiv Liebert®CRV Installer/User Guide

Table 6.2 Piping Connection Drawings (continued)

Docu ment Number Title

DPN001794 Connection Locations, CR040R Chilled Water Models

DPN002814 Liebert® IntelliSlot Cable Connection P aths Liebert® IntelliSlot Wiring Routing Top of Unit300 m m (12 in.) all Models

DPN002815 Prima ry Connections 300 mm (12 in.) Chilled Water Models

6.1 Drain and Humidifier Fluid Piping

NOTICE

Risk of water leakage. Can cause severe property damage and loss of critical data center equipment.

The Liebert® CRV requires a water drain connection. The 600 mm (24 in.) model may require an external water

supply to operate the humidifier. Improper installation, application and service practices can result in water

leakage from the unit.

Do not locate the unit directly above any equipment that could sustain water damage.

Chilled Water Systems

We recommend installing monitored leak detection equipment for the water supply lines and the internal unit

water lines.

6.1.1 Humidifier Water Supply Line Requirements

NOTE: The humidifier is an option on 600 mm (24 in.) units only.

The fill valve is sized for an extended water pressure range of 30 to 80 psi.

For installations where water pressure is less than 15 psi, add a pressure-boost pump and notify your Vertiv representative. A

fill valve with an oversized opening will be supplied.

For installations where water pressure is greater than 80 psi, install a pressure reducing valve in the water feed line to the

unit.

With dirty or muddy water sources (for example, some well sources), ensure proper filtration by adding an external filter to

the water line entering the unit. (Consult your Vertiv for accessories such as filters.)

NOTICE

Risk of improper water supply. Can reduce humidifier efficiency or obstruct humidifier plumbing.

Do not use a hot water source. It will cause deposits that will eventually block the fill valve opening.

See Connecting Water Supply to the Humidifier on page78 to connect the humidifier.

28

6 Pip ing and Refrigerant Requiremen ts

Page 35

6.1.2 Condensate Pump Drain Line Requirements

NOTICE

Risk of water backing up in the drain line. Leaking and overflowing water can cause equipment and building

damage.

Do not install an external trap in the drain line. This line already has a factory installed trap inside the cabinet

(except for 300 mm (12 in.)) Chilled water models). Installation of a second trap will prevent drain water flow

and will cause the water to overflow the drain pan.

This line may contain boiling water. Use cooper or other material that is rated for handling boiling water for the

drain line. Sagging condensate drain lines may inadvertently create an external trap.

Observe the following requirements when installing and routing the drain line:

• The drain line must be located so it will not be exposed to freezing temperatures.

• The drain should be the full size of the drain connection.

• Drain is trapped internally. Do not externally trap the drain line.

• The drain line must be rigid enough that it does not sag between supports, which unintentionally creates traps.

• Use cooper or other material suitable for draining water that can reach temperatures up to 212°F (100°C).

• We recommend installing monitored, under floor leak detection equipment.

Vertiv Liebert®CRV Installer/User Guide

When your unit includes the factory installed, optional condensate pump, refer to the additional details and specific

installation instructions depending on the configuration of your unit:

• Condensate Pump Drain Piping for 600 mm (24 in.) Models below

• Bottom Connection for Humidifier Supply andCondensateDrainWateron600 mm(24

in.)Water/GlycolSystems below

• Condensate Pump Drain Piping for300 mm(12 in.) Models on the next page

Condensate Pump Drain Piping for 600 mm (24 in.) Models

• 1/2 in. FPT connection is provided on units with top and bottom connections for optional factory installed

condensate pump.

• Condensate pump is rated for approximately 6GPM at 30 ft (22.7 l/m) at 9m total head.

• Size piping based on available condensate head.

Bottom Connection for Humidifier Supply andCondensateDrainWateron600 mm(24

in.)Water/GlycolSystems

NOTE: A humidifier is optional: See Humidifier 600 mm (24 in.) Units Only on page77 .

Units with a condensate pump and humidifier are preset to be connected from the top. If floor connections are used, the

water lines can be intercepted at the following points shown in Figure 6.1 on the next page .

6 Pip ing and Refrigerant Requiremen ts

29

Page 36

Vertiv Liebert®CRV Installer/User Guide

Figure 6.1 Water Connection Points, Bottom Entry, 600 mm (24 in.) Models

Item Description

1 Condensate pump drain

2 Humidifier water supply

6.1.3 Condensate Pump Drain Piping for300 mm(12 in.) Models

• Condensate pump is rated for approximately 4.6GPH at 17feet (0.28l/m at 5.18m) total head. Maximum coil

condensate design flow rate is 4.6 GPH.

• Size piping based on available condensate head.

Before connecting the drain line, refer to the appropriate instructions to the discharge hose to the drain line opening based

on the cooling type of the unit:

• Connecting Discharge Hose onAir Cooled,300 mm(12 in.)Models on the facing page

• Connecting Discharge Hose onWater/Glycol Cooled,300mm(12 in.)Models on page32

• Connecting Discharge Hose onChilled Water,300mm(12 in.)Models on page34

30

6 Pip ing and Refrigerant Requiremen ts

Page 37

Vertiv Liebert®CRV Installer/User Guide

Connecting Discharge Hose onAir Cooled,300 mm(12 in.)Models

The unit has a 3/8 in.IDx5/8 in.OD vinyl hose on the condensate discharge with a factory installed 3/8-in hose barb. Refer

to Figure 6.3 on the next page for the condensate pump components.

For field connection to the drain piping, a factory supplied 1/2 in. MPT x 3/8 in. hose-barb threaded adapter is included.

Figure 6.2 Condensate Pump Piping Adapters, Air Cooled, 300°mm (12°in.)

Item Description

1 3/8 in. Nylon adapter hose (factory supplied, installed on the condensate pump.

2 1/2 in. MPT X 3/8 in. hose barb threaded a dapter (factory supplied)

For top discharge:

Connect the discharge tubing to the tubing exiting the top of the unit.

For bottom discharge:

Run the tubing out the bottom of the unit.

6 Pip ing and Refrigerant Requiremen ts

31

Page 38

Vertiv Liebert®CRV Installer/User Guide

Figure 6.3 CondensatePump Drain Piping, Air Cooled, 300 mm (12 in.)

Item Description

1

2 Hose barb (field installed)

3 Drain line knockout

Bushing for bottom condensate exit

(field installed in drain line knockout hole)

Connecting Discharge Hose onWater/Glycol Cooled,300mm(12 in.)Models

The 300 mm(12 in.) water/glycol cooled units have separate models for top and bottom fluid connections. Both have a

factory installed top discharge for the condensate pump drain connection. The discharge can be changed to the bottom of

the unit in the field.

The unit has a 3/8 in.IDx5/8 in.OD vinyl, drain hose on the condensate discharge with a factory installed 3/8 in. hose barb.

Refer to the figure for the condensate pump components.

For field connection to the drain piping, a factory supplied 1/2 in. MPT x 3/8 in. hose barb threaded adapter is included.

For top discharge:

Connect the discharge tubing to the tubing exiting the top of the unit.

For bottom discharge, run the condensate drain through the bottom of the unit:

Refer to the following figure and:

1. Unbolt the fasteners that hold the condensate pump in the unit.

2. Unplug the fan wiring pin connectors from the fan control board and remove the fan control board.

3. Loosen the hose barb and hole bushing from the condensate pump.

32

6 Pip ing and Refrigerant Requiremen ts

Page 39

4. Remove the drain line from the evaporator coil and pump discharge line.

5. Remove the condensate pump.

6. Remove the wire ties that secure the wire harness inside the corner post to get slack in the wires.

7. Remove the vertical access plate behind the pump and fan control board.

8. Remove the access plate beside the brazed plate exchange so that unit the condensate drain line can be run

under the unit.

Figure 6.4 Condensate Pump Drain Piping, Water/Glycol Cooled, 300 mm (12 in.)

Vertiv Liebert®CRV Installer/User Guide

6 Pip ing and Refrigerant Requiremen ts

Item Description

1 Back panel

2 Fan control board

3

4 Drain hose

5 Wiring from electrical panel

6 Wire tires on wiringrouted inside fram e

Bushing for bottom condensate exit

(field installed in drain line knockout hole)

33

Page 40

Vertiv Liebert®CRV Installer/User Guide

Connecting Discharge Hose onChilled Water,300mm(12 in.)Models

The unit has a 3/8 in.IDx5/8 in.OD vinyl hose on the condensate discharge with a factory installed 3/8 in hose barb. Refer to

the figure for the condensate pump components.

For field connection to the drain piping, a factory supplied 1/2 in. MPT x 3/8 in. hose barb threaded adapter is included.

For top discharge:

Refer to the following figure and:

1. Remove the factory supplied adapter that is tied to the condensate line inside the unit.

2. Insert the adapter into the factory installed condensate line at the top of the unit.

3. Insert the barbed connection of the condensate pump line into the factory installed condensate line.

4. Connect field supplied drain line to the connection at the top of the unit.

5. Using field supplied clamps, clamp all connections as needed.

For bottom discharge:

Refer to the following figure and:

1. Remove the factory supplied adapter and bushing that are tied to the condensate line inside the unit.

2. Remove the barbed adapter from the condensate pump discharge hose.

3. Insert the adapter into the condensate pump discharge hose.

4. Remove the knockout in the plate inside the bottom of the unit, and insert the bushing into the knockout.

5. Run the condensate pump discharge hose through the bushing in the bottom of the unit.

6. Connect field installed drain line to the connection under the unit.

7. Using field supplied clamps, clamp all connections as needed.

34

6 Pip ing and Refrigerant Requiremen ts

Page 41

Figure 6.5 Condensate Pump Drain Piping, Chilled Water, 300mm (12 in.)

Vertiv Liebert®CRV Installer/User Guide

Item Description

1 Wiring harness from electrical panel to condensate pump

2 Adapter (field installed)

3 Condensate drain tubing, top exit

4

Bushing for bottom condensate exit

(field installed in drain line knockout hole)

5 Condensate pump

6

Service loop of high and low voltage wiring for condensate pump remova l.

Make sure the service loop remains, and coil as necessary.

6 Pip ing and Refrigerant Requiremen ts

35

Page 42

Vertiv Liebert®CRV Installer/User Guide

6.1.4 FieldInstalled, Gravity Fed Drain Line Requirements

NOTICE

Risk of water backing up in the drain line. Leaking and overflowing water can cause equipment and building

damage.

Do not install an external trap in the drain line. This line already has a factory installed trap inside the cabinet

(except for 300 mm (12 in.)) Chilled water models). Installation of a second trap will prevent drain water flow

and will cause the water to overflow the drain pan.

This line may contain boiling water. Use cooper or other material that is rated for handling boiling water for the

drain line. Sagging condensate drain lines may inadvertently create an external trap.

• A 3/4 in. FPT connection is provided on models with no humidifier.

• A 1-1/4 in. FPT connections is provided on models with a steam-generating humidifier.

Observe the following requirements when installing and routing the drain line:

• The drain line must be sized for 2 gpm (7.6 l/m) flow.

• The drain line must be located so it will not be exposed to freezing temperatures.

• The drain should be the full size of the drain connection.

• The drain line must slope continuously away from the unit. Pitch drain line toward drain a minimum of 1/8in.

(3mm) per 1ft (305mm) of length.

• The drain line must be rigid enough that it does not sag between supports, which unintentionally creates traps.

• The drain line must comply with all applicable codes.

36

6 Pip ing and Refrigerant Requiremen ts

Page 43

Vertiv Liebert®CRV Installer/User Guide

Figure 6.6 Correct and Incorrect Gravity Drain Piping onall600mm(24 in.)andWater/Glycol Cooled300mm(12

in.)Models

Item Description Item Description

1 For downflow units 7 Continuous downward slope

2 For upflow units 8 External trap. Do not trap externally.

3 Correct drain installation 9

4 Incorrect drain installation 10 Internal drain

5 Internal drain 11 CRV unit

6 External drain

6 Pip ing and Refrigerant Requiremen ts

External traps, althoughunintentional. Lines must be rigid enough

to bow.

37

Page 44

Vertiv Liebert®CRV Installer/User Guide

Connecting Gravity Drain Line on All600 mm(24 in.) Models andonAirandWater/Glycol

Cooled 300mm (12 in.)Models

1. Remove the factory supplied adapter and bushing that are tied to the condensate line inside the unit.

2. Remove the knockout in the plate inside the bottom of the unit, and insert the bushing into the knockout.

3. Run the evaporator drain line through the bushing in the bottom of the unit.

4. Connect field installed drain line to the discharge hose.

5. Using field supplied clamps, clamp all connections as needed.

Figure 6.7 Gravity Drain Line Connection on Air Cooled, 300mm (12 in.) Unit

Item Description

1 Bushing for installation a fter knockout is removed

2 Adapter, 1 in. NPT male – 3/4 in. barb

3

38

When coolant supply/return is top-entry, remov e this plate,

remove the knockout for the drain, and then re-install the plate.

6 Pip ing and Refrigerant Requiremen ts

Page 45

Figure 6.8 Gravity Drain Line Connection on all 600°mm°(24°in.) unit

Vertiv Liebert®CRV Installer/User Guide

Item Description

1 Bushing for installation a fter knockout is removed

2 Adapter, 1 in. NPT male – 3/4 in. barb

3

When coolant supply/return is top entry, rem ove this plate,

remove the knockout for the drain, and then re-install the plate.

Connecting Gravity Drain Line onWater/Glycol Cooled,300mm(12-in.)Models

1. Remove the access plate, shown in Figure 6.9 on the next page .

2. Route the evaporator drain line through the bottom of the unit at unit bottom access plate.

3. Fill the drain trap with tap water.

6 Pip ing and Refrigerant Requiremen ts

39

Page 46

Vertiv Liebert®CRV Installer/User Guide

Figure 6.9 Gravity Drain Line Connection on Water/Glycol Cooled, 300mm (12-in.) Unit

Item Description

1 Bushing (field installed after knockout removed)

2 Adapter, 1 in. NPT Male – 3/4 in. barb

3 Access plate

4

When coolant supply/return is top entry, rem ove this plate,

remove the knockout for the drain, and then re-install the plate.

Connecting GravityDrain Line onChilled Water,300 mm(12-in.)Models

1. Remove the factory supplied hose barb, bushing and trap that are tied to piping inside the unit.

2. Remove the knockout in the plate in the bottom of the unit, and insert the bushing into the knockout.

3. Insert factory supplied drain trap through bushing with 90 degree barb inside the unit and the trap beneath the

unit.

4. Connect the barb to the factory installed condensate line.

40

6 Pip ing and Refrigerant Requiremen ts

Page 47

Figure 6.10 Gravity Drain Line Connection on Chilled Water, 300°mm (12 in.) Units

Vertiv Liebert®CRV Installer/User Guide

Item Description

1 Condensate drain (factory installed)

2 Bushing (field installed a fter knockout remov ed)

3 Knockout location below drain tubing (not visible in figure)

4 Connect to field supplied drain line

5 90 degree hose barb

6 Condensate drain and trap under units withouta condensate drain pump

7 Condensate drain tubing routed throughbushing/knockout

6.2 Refrigerant Piping and Charging

WARNING! Risk of over pressurization of the refrigeration system. Can cause explosive discharge of high

pressure refrigerant, loss of refrigerant, environmental pollution, equipment damage, injury, or death. This

unit contains fluids and gases under high pressure. Use extreme caution when charging the refrigerant

system. Do not pressurize the system higher than the design pressure marked on the unit's nameplate.

CAUTION: Risk of excessive refrigerant line pressure. Can cause tubing and component rupture resulting in

equipment damage and personal injury. Do not close off the refrigerant line isolation valve for repairs unless

a pressure-relief valve is field installed in the line between the isolation valve and the check valve. The

pressure relief valve must be rated 5% to 10% higher than the system design pressure. An increase in

ambient temperature can cause the pressure of the isolated refrigerant to rise and exceed the system design

pressure rating (marked on the unit nameplate).

Consult local building and plumbing codes for installation requirements of additional pressure relief devices when isolation

valves are field installed. Do not isolate any refrigerant circuits from over pressurization protection.

6 Pip ing and Refrigerant Requiremen ts

41

Page 48

Vertiv Liebert®CRV Installer/User Guide

NOTICE

Risk of oil contamination with water. Can cause equipment damage.

Liebert® CRV systems require the use of POE (polyolester) oil. POE oil absorbs water at a much faster rate

when exposed to air than previously used oils. Because water is the enemy of a reliable refrigeration system,

extreme care must be used when opening systems during installation or service. If water is absorbed into the

POE oil, it will not be easily removed and will not be removed through the normal evacuation process. If the oil

is too wet, it may require an oil change. POE oils also have a property that makes them act as a solvent in a

refrigeration system. Maintaining system cleanliness is extremely important because the oil will tend to bring

any foreign matter back to the compressor.

NOTICE

Risk of improper refrigerant charging. Can cause equipment damage.

Refrigerant charge must be weighed into air-cooled compressorized systems before they are started. Starting

scroll and digital scroll compressors without proper refrigerant charging can cause the compressors to operate

at less than 5°F (–15°C) evaporator temperature and at less than 20psig (138kPa). Operation for extended

periods at less than 20psig (138kPa) can cause premature compressor failure.

6.2.1 Refrigerant Piping Guidelines forAir CooledSystems

• Air cooled units ship with a nitrogen holding charge. Do not vent the charge until all refrigerant piping is in

place, ready for connection to the unit and condenser.

• Use copper piping with a brazing alloy with a minimum temperature of 1350°F (732°C), such as Sil-Fos. Avoid

soft solders, such as 50/50 or 95/5.

• Use a flow of dry nitrogen through the piping during brazing to prevent formation of copper oxide scale inside

the piping. When copper is heated in the presence of air, copper oxide forms. POE oils will dissolve these

oxides from inside the copper pipes and deposit them throughout the system, clogging filter driers and

affecting other system components.

• A pure dry nitrogen flow of 1-3 ft3/min (0.5-1.5 l/s) inside the pipe during brazing is sufficient to displace the air.

Control the flow using a suitable measuring device.

• Ensure that the tubing surfaces to be brazed are clean and that all burrs have been removed from the ends of

the tubes.

• Ensure that all loose material has been cleaned from inside the tubing before brazing.

• Protect all refrigerant line components within 18in. (460mm) of the brazing site by wrapping them with a wet

cloth or with a suitable heat-sink compound.

• Isolate piping from building using vibration-isolating supports.

• Condensers with receivers cannot be installed below the evaporator. The maximum height of the condenser

above the evaporator is 60ft (18.3m). Refer to DPN003954 included in Submittal Drawings on page131 .

Consult the factory before installing units, condensers, and receivers outside these parameters.

• Pitch horizontal hot-gas piping down at a minimum rate of 1/2in.per 10ft (42mm per 10m) so that gravity will

aid in moving oil in the direction of refrigerant/oil flow.

• Keep piping clean and dry, especially on units with refrigerant.

• Avoid piping runs through noise-sensitive areas.

• Do not run piping directly in front of discharge air stream.

• Refrigerant oil – do not mix oil types (see Compressor Oil on page105 ).

Refer to ASHRAE Refrigeration Handbook for general, good practice refrigeration piping.

42

6 Pip ing and Refrigerant Requiremen ts

Page 49

• Refer to Refrigerant Line Sizes and Equivalent Lengths on page46 , for recommended refrigerant piping sizes

based on equivalent pipe lengths.

• Refer to Refrigerant Charge Requirements for Air Cooled Systems on page47 , for the refrigerant-charge

requirements of the system.

• Refer to Charging Air Cooled Systems withLiebert®Lee-Temp Receiver on page57 , for charging information.

6.3 Piping Guidelines for Liebert® MC Condensers

The following operations must be carried out by an experienced refrigeration technician.

NOTICE

Risk of oil contamination with water. Can cause equipment damage.

Liebert® CRV systems require the use of POE (polyolester) oil. POE oil absorbs water at a much faster rate

when exposed to air than previously used oils. Because water is the enemy of a reliable refrigeration system,

extreme care must be used when opening systems during installation or service. If water is absorbed into the

POE oil, it will not be easily removed and will not be removed through the normal evacuation process. If the oil

is too wet, it may require an oil change. POE oils also have a property that makes them act as a solvent in a

refrigeration system. Maintaining system cleanliness is extremely important because the oil will tend to bring

any foreign matter back to the compressor.

Vertiv Liebert®CRV Installer/User Guide

1. When installing the refrigerant piping, note the following:

Brazing:

• All joints must be brazed.

• Avoid butt brazes by using couplings or swaging one of the pipes with a swaging tool.

• Ensure that all brazed joints are leak free.

• Flow dry nitrogen through the pipes during brazing.

Always use large radius curves (bending radius at least equal to pipe diameter). Bend the pipes as follows:

• soft copper: bend by hand or use bending device;

• hard copper: use preformed curves.

• To minimize oxidation, avoid overheating the pipes when brazing.

2. Connect the pipes to the condenser:

• Condensers with butt brazed pipe connections: Cut the pipe, enlarge it, and braze it to the pipeline.

• Respect the direction of refrigerant flow. (See labels on refrigerant.)

3. Wash out the pipelines as follows:

a. Plug up the free ends of the pipes.

b. Connect a helium or nitrogen cylinder, fitted with a reducer (maximum pressure 10 bar), to the 1/4”SAE

Schrader valve of the condenser.

c. Pressurize the pipes with helium or nitrogen.

d. Unplug the pipes instantaneously.

e. Repeat steps a through d several times.

4. Open all the shutoff valves on the room unit.

6 Pip ing and Refrigerant Requiremen ts

This operation is especially important when hard copper piping is used.

43

Page 50

Vertiv Liebert®CRV Installer/User Guide

5. Discharge the room unit pressurized with helium (at 1bar) by opening the charge valves so that all the