Page 1

Liebert® 10 Fan Drycooler/Fluid

Cooler™

Including Quiet-LineModels, 120to150Tons,

50&60Hz

User Manual

Page 2

Technical Support Site

If you encounter any installation or operational issues with your product, check the pertinent section of

this manual to see if the issue can be resolved by following outlined procedures. Visit

https://www.VertivCo.com/en-us/support/ for additional assistance.

Page 3

TABLE OF CONTENTS

1 Introduction 1

1.1 System Description and Standard Features 1

1.2 Optional Features 1

2 Product Performance Data & Selection 5

2.1 Standard Data 5

2.2 Typical Application 7

2.3 Engineering Data, Calculations and Selection Procedure 8

2.4 Selection Example 11

3 Installation 13

3.1 Location Considerations 13

3.2 Site Preparation 15

3.3 Equipment Inspection Upon Delivery 16

3.4 Lifting and Handling the Drycooler 16

3.4.1 Unit Weight 17

3.5 Piping Connections 17

3.5.1 Expansion Tanks, Fluid Relief Valves and Other Devices 18

3.6 Filling Instructions 22

3.6.1 Preparing the System for Filling 22

3.6.2 Glycol Solutions 22

3.6.3 Filling the System 23

3.7 Electrical Connections 24

3.7.1 Line Voltage 24

3.7.2 Low Voltage Control Wiring 25

3.8 Checklist for Completing Installation 26

4 Operation 29

4.1 Initial Startup Procedure 29

4.1.1 Control Setpoints 29

4.1.2 Current-Sensing Relays 30

4.1.3 Cold Weather Operation 31

5 System Maintenance 33

5.1 General Procedures 33

5.2 Special Procedures 34

5.2.1 Drycooler Cleaning 34

5.2.2 Maintenance Inspection Checklist 35

6 Troubleshooting 37

Vertiv | Liebert® 10-fan Drycooler User Manual | i

Page 4

Vertiv | Liebert® 10-fan Drycooler User Manual | ii

Page 5

Important Safety Instructions - Save These Instructions

This manual contains important safety instructions that should be followed during the installation and

maintenance of the Liebert®10 Fan Drycooler™. Read this manual thoroughly before attempting to install

or operate this unit.

Only properly trained and qualified personnel should move, install or service this equipment.

Adhere to all warnings, cautions and installation, operating and safety instructions on the unit and in this

manual. Follow all operating and user instructions.

WARNING! Arc flash and electric shock hazard. Disconnect all electric power supplies and wear

protective equipment per NFPA 70E before working within electric control enclosure. Failure to

comply can cause serious injury or death.

Customer must provide earth ground to unit, per NEC, CEC and local codes, as applicable.

Before proceeding with installation, read all instructions, verify that all the parts are included

and check the nameplate to be sure the voltage matches available utility power.

The line side of the disconnect switch on the front of the unit contains live high-voltage.

The only way to ensure that there is NO voltage inside the unit is to install and open a remote

disconnect switch. Refer to unit electrical schematic.

Follow all local codes.

WARNING! Risk of high-speed moving parts. Can cause injury or death.

Disconnect all local and remote electric power supplies before working in the unit.

Do not operate this unit with any or all cabinet panels and/or blower guards removed.

CAUTION: Risk of contact with hot surfaces. Can cause injury.

The blower motors may become extremely hot during unit operation. Allow sufficient time for

them to cool before working within the unit cabinet. Use extreme caution and wear protective

gloves and arm protection when working on or near hot blower motors.

CAUTION: Risk of sharp edges, splinters and exposed fasteners. Can cause injury.

Only properly trained and qualified personnel wearing appropriate safety headgear, gloves,

shoes and glasses should attempt to move the unit, lift it, remove packaging or prepare the unit

for installation.

Vertiv | Liebert® 10-fan Drycooler User Manual | iii

Page 6

NOTICE

NOTICE

NOTICE

Risk of clogged or leaking coolant fluid lines. Can cause equipment and building damage.

Improper installation, application and service practices can result in coolant fluid leakage from

the unit that can result in severe property damage.

Vertiv™ recommends installing leak detection equipment for unit and supply lines.

Risk of a leaking coil due to freezing and/or corrosion. Can cause equipment and building

damage.

Cooling coils and piping systems that are connected to open cooling towers or other open

water/glycol systems are at high risk for freezing and premature corrosion. Fluids in these

systems must contain the proper antifreeze and inhibitors to prevent freezing and premature

coil corrosion. The water or water/glycol solution must be analyzed by a competent water

treatment specialist before startup to establish the inhibitor requirement. The water or

water/glycol solution must be analyzed every six months to determine the pattern of inhibitor

depletion. The complexity of water-caused problems and their correction makes it important to

obtain the advice of a water treatment specialist and follow a regularly scheduled maintenance

program.

Risk of damage from forklift. Can cause unit damage.

NOTICE

Keep tines of the forklift level and at a height suitable to fit below the skid and/or unit to

prevent exterior and/or underside damage.

Risk of improper storage. Can cause unit damage.

Keep the Liebert 10-Fan Drycooler upright and protected from freezing temperatures and

contact damage.

Vertiv | Liebert® 10-fan Drycooler User Manual | iv

Page 7

1 INTRODUCTION

1.1 System Description and Standard Features

The Liebert® 10 Fan Drycooler/Fluid Cooler™ is designed for maximum heat rejection with minimum

footprint and to be used with glycol solutions for large-site installations. It has a nominal range of 150tons

of heat rejection and is ideal for rejecting the heat of multiple evaporator units. Standard features include:

• Three different coil circuits: 068 (half), 136 (full), 272 (double). Each coil circuit is designed for a

range of specific flow rates based on the particular application.

• Coil constructed of copper tubes in a staggered pattern expanded into continuous corrugated

aluminum fins. The fins have full depth fin collars completely covering the copper tubes which

are connected to heavy-wall type L headers. Inlet coil connector tubes pass through relieved

holes in the tube sheet for maximum resistance to piping strain and vibration. Coil maximum

operating pressure is 150 PSIG (1035 kPa).

• Wire guards constructed of coated wire, in 1" x 4" pattern, mounted to protect the exposed

vertical coil surface.

• Current sensing relays are provided with customer connection to monitor change in motor

current to detect possible motor/fan failure.

• Choice of either 60 or 50Hz models as well as a Liebert Quiet-Line™ 60Hz; comes from the

factory completely assembled and pre-wired. Units are available in 208, 230, 460 and 575V, 3phase, 60Hz, and 380/415V, 3-phase, 50Hz.

• Locking disconnect switch and fan cycling control.

• Unit frame of heavy galvanized steel for strength and corrosion resistance, divided internally

into individual fan sections by full-width baffles to prevent fan reverse windmilling when not

energized.

1.2 Optional Features

Quiet-Line

The Liebert Quiet-Line 10 Fan Drycooler includes the same features as the standard Liebert10 Fan

Drycooler, except that it has 8-pole motors in lieu of 6-pole motors for lower sound levels as well as

reduced airflow and capacity. This option is not available on 50Hz units.

Aluminum Grilles

Aluminum grilles are used for unit aesthetic and general mechanical security purposes. The aluminum

grilles extend from the base of the unit and protect the exposed coil sides.

Coil Fin Options

Pre-Coated Fin Stock provides pre-coated coil fins for added protection in corrosive environments.

Phenolic Coated Coil provides a baked phenolic coated coil for added protection in corrosive

environments.

Copper Fin/Copper Tube Coil provides coil constructed of copper fins and copper tubes.

Vertiv | Liebert® 10-fan Drycooler User Manual | 1

Page 8

Enclosed Motor Option

TEAO motors are totally enclosed and are used in industrial applications. They are not available for

Liebert Quiet-Line, or 575V models.

Ancillary Items

Tanks for fluid expansion, pumps, pump control panels, flow switches, shut off valves and relief valves

should also be considered for the site/installation. Since these items are custom-sized per application,

please consult with your sales representative for selection.

Vertiv | Liebert® 10-fan Drycooler User Manual | 2

Page 9

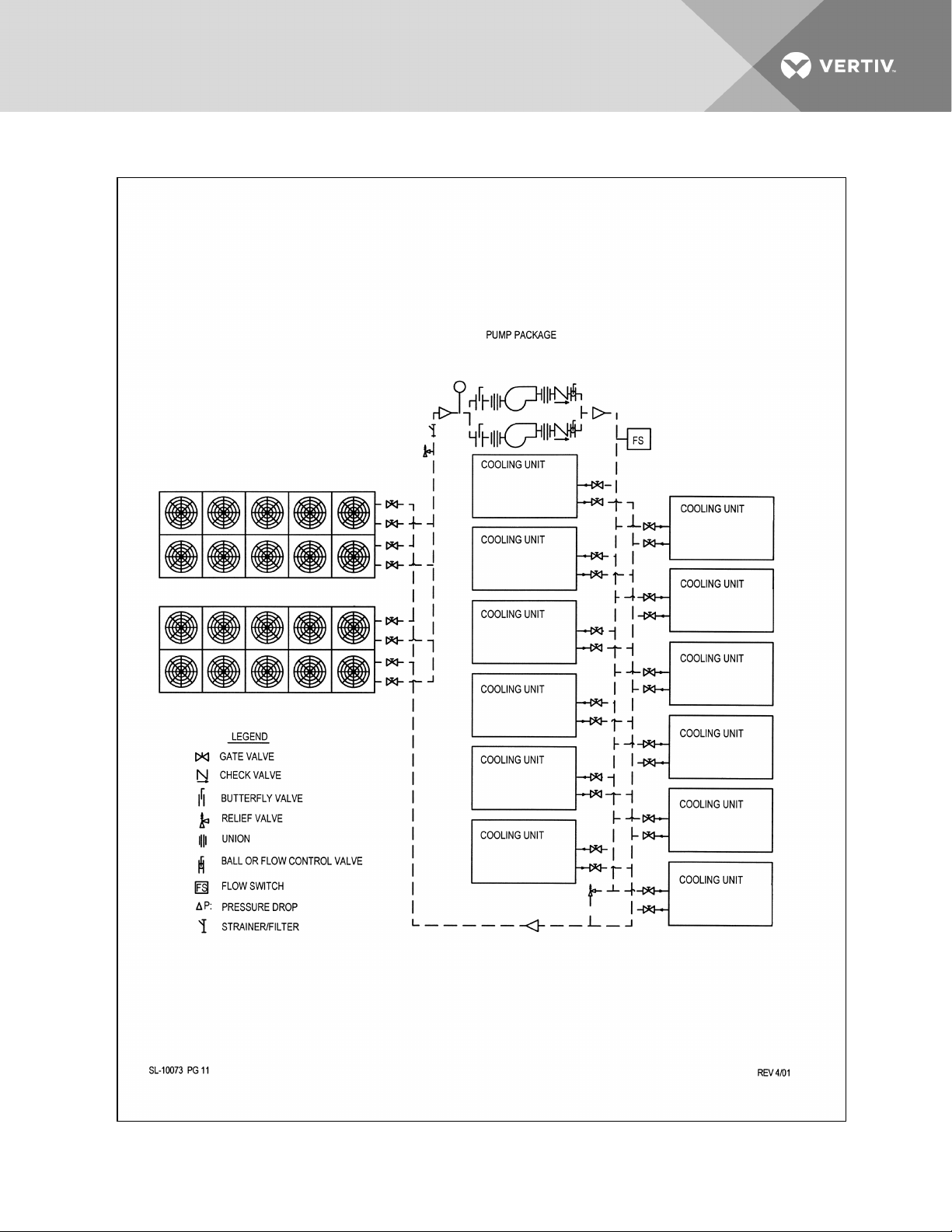

Figure 1.1 Typical application

Vertiv | Liebert® 10-fan Drycooler User Manual | 3

Page 10

Refer to Typical piping diagram on page19 for a detailed installation diagram.

Vertiv | Liebert® 10-fan Drycooler User Manual | 4

Page 11

2 PRODUCT PERFORMANCE DATA & SELECTION

2.1 Standard Data

Vertiv | Liebert® 10-fan Drycooler User Manual | 5

Page 12

6.....Liebert® 10-fan Drycooler User Manual

Shipping

Weight

Internal

Volume

Air Flow Sound

No.ofFans

No. &

Size of

Connec-

tions

(outlet)

No. &

Size of

Connec-

tions

(inlet)

No. of

Internal

Circuits

Pressure

Drop

Flow

Rate

Total Heat

Rejection* @25°F

(13.9°C) ITD

Btu/h kW gpm lps Ft of Water kPa cfm cmh dBA** Gal L Lbs Kg

1,172,000 343 136 8.6 27.2 81.2 68 2@2.625 2@2.625 10 74160 126000 65 92.8 351 5100 2313

1,447,000 424 272 17.2 15.8 47.1 136 2@4.125 2@4.125 10 74160 126000 65 92.8 351 5100 2313

1,579,000 463 544 34.3 15.1 45.1 272 2@4.125 2@4.125 10 74160 126000 65 92.8 351 5100 2313

1,287,000 377 136 8.6 27.3 81.5 68 2@2.625 2@2.625 10 99030 168250 72 92.8 351 5100 2313

1,703,000 499 272 17.2 1 5.8 4 7.1 136 2@4.125 2@4.125 10 99030 168250 72 92.8 351 5100 2313

1,924,000 564 544 34.3 15.1 45.1 272 2@4.125 2@4.125 10 99030 168250 72 92.8 351 5100 2313

1,218,000 357 136 8.6 27.3 81.5 68 2@2.625 2@2.625 10 82450 1 40080 68 92.8 351 5100 2313

1,541 ,000 452 272 17.2 15.8 47.1 136 2@4.125 2@4.125 10 82450 140080 68 92.8 351 5100 2313

1,703,000 499 544 34.3 15.1 45.1 272 2@4.125 2@4.125 10 82450 1 40080 68 92.8 351 5100 2313

Hz

Model

Table 2.1 Drycooler Performance Data

No.

120 60

150 60

150 50

* Ratings based on using 40% ethylene glycol @ 95°F (35°C) entering air, 120°F (48.9°C) enteringglycol; 2 gpm (.13 l/s) circ.

** Sounddata is for sound pres sure measured @ 5 ft. (1.5m) height, 30 ft.(9.1 m) from the unit.

Page 13

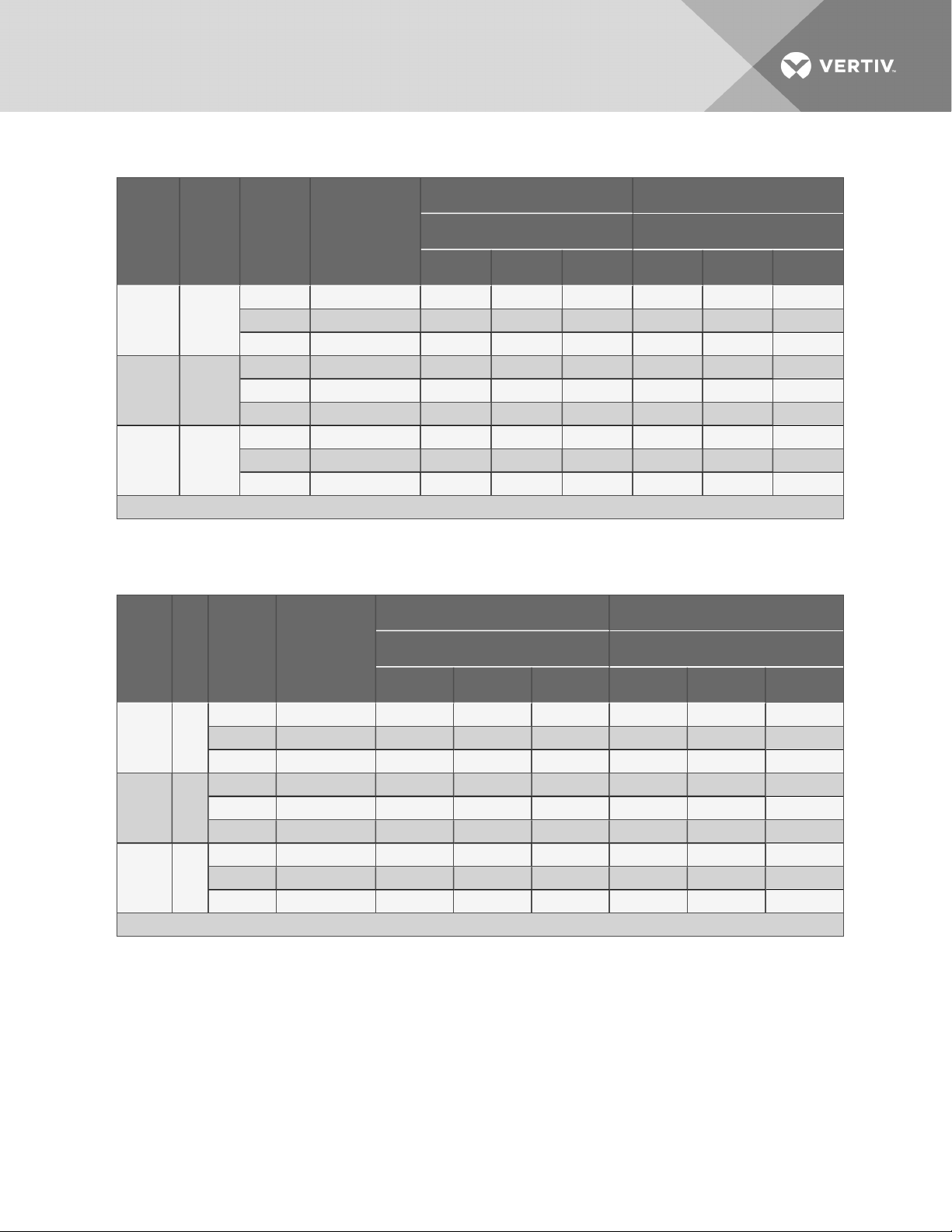

Table 2.2 Drycooler Performance Data per Circuit

Model Hz

120 60

150 60

150 50

* Data is based on 4 0% ethylene glycol solutionat 1 15°F ( 46.1° C) average solution temperature expressed inBtu/h.

No. of

Internal

Circuits

68 68-136 29,507 39,991 46,972 8.2 16.1 27.3

136 136-34 0 45,829 53,713 57,917 5 9.2 23.7

272 272-544 56,201 60,785 63,153 4 8.7 15.1

68 68-136 30,144 42,440 51,621 8.2 16.1 27.3

136 136-34 0 50,346 61,660 68,219 5 9.2 23.7

272 272-544 65,785 73,11 8 77,019 4 8.7 15.1

68 68-136 29,791 41,011 4 8,823 8.2 16.1 27.3

136 136-34 0 47,617 56,724 61,728 5 9.2 23.7

272 272-544 59,756 65,257 68,146 4 8.7 15.1

Flow Rate Range

min-max

gpm

Heat Rejection per ITD* (Btu/h/°F) Pressure Drop* (ft of water)

Flow Rate per Circuit (gpm/circuit) Flow Rate per Circuit (gpm/circuit)

1 1.5 2 1 1.5 2

Table 2.3 Drycooler Performance Data per Circuit—Metric

Heat Rejection per ITD* (kW/°C) Pressure Drop* (kPa)

Model

No.

Hz

No. of

Internal

Circuits

Flow Rate

Range min-max

lps

Flow Rate per Circuit (lps/circuit) Flow Rate per Circuit (lps/circuit)

0.06 0.09 0.13 0.06 0.09 0.13

68 6-13 23.9 29.8 32.1 24.5 48.0 81.5

120 60

150 60

150 50

* Data is based on 4 0% ethylene glycol solutionat 4 6.1°C (115°F) average solution temperature expressed inkW.

136 13-26 30.8 31.9 32.0 14.9 27.5 70.7

272 26-38 30.7 30.6 30.5 11.9 26.0 45.1

68 6-13 24.9 33.1 37.5 24 .5 48.0 81.5

136 13-26 36.0 39.1 39.8 14.9 27.5 70.7

272 26-38 37.9 38.4 39.0 11.9 26.0 4 5.1

68 6-13 24.4 31.1 34.2 24.5 48.0 81.5

136 13-26 32.8 34.6 34.7 14.9 27.5 70.7

272 26-38 33.3 33.4 33.3 11.9 26.0 45.1

2.2 Typical Application

The most popular use for the Liebert® 10 Fan Drycooler™ is at sites with large cooling loads, such as data

center/telecom sites where multiple indoor air conditioners are used. See 2.2 abovefor a general outline of

suggested quantity of indoor units for each Liebert 10 Fan Drycooler or contact your Vertiv™

representative for custom matchup. See Typical application on page3.

Vertiv | Liebert® 10-fan Drycooler User Manual | 7

Page 14

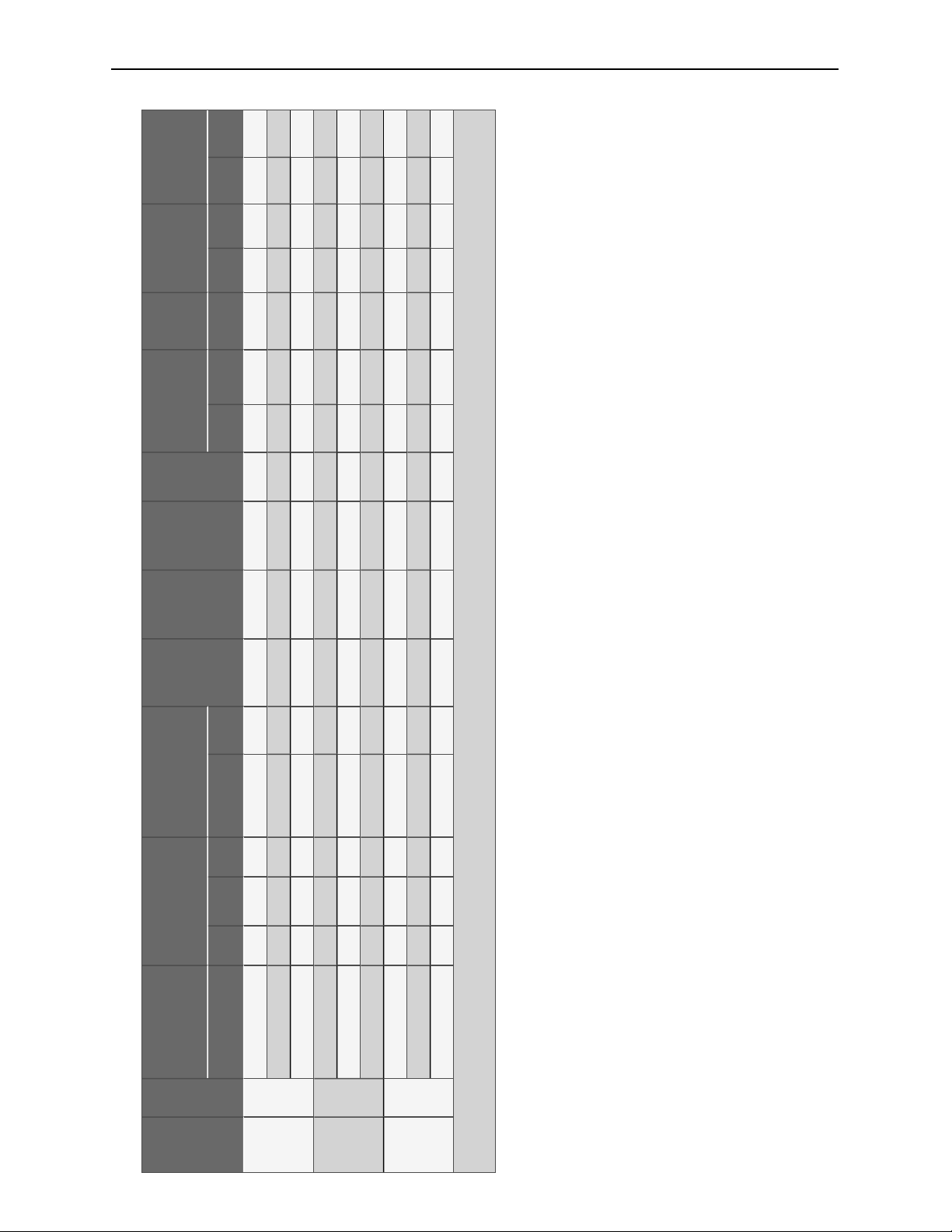

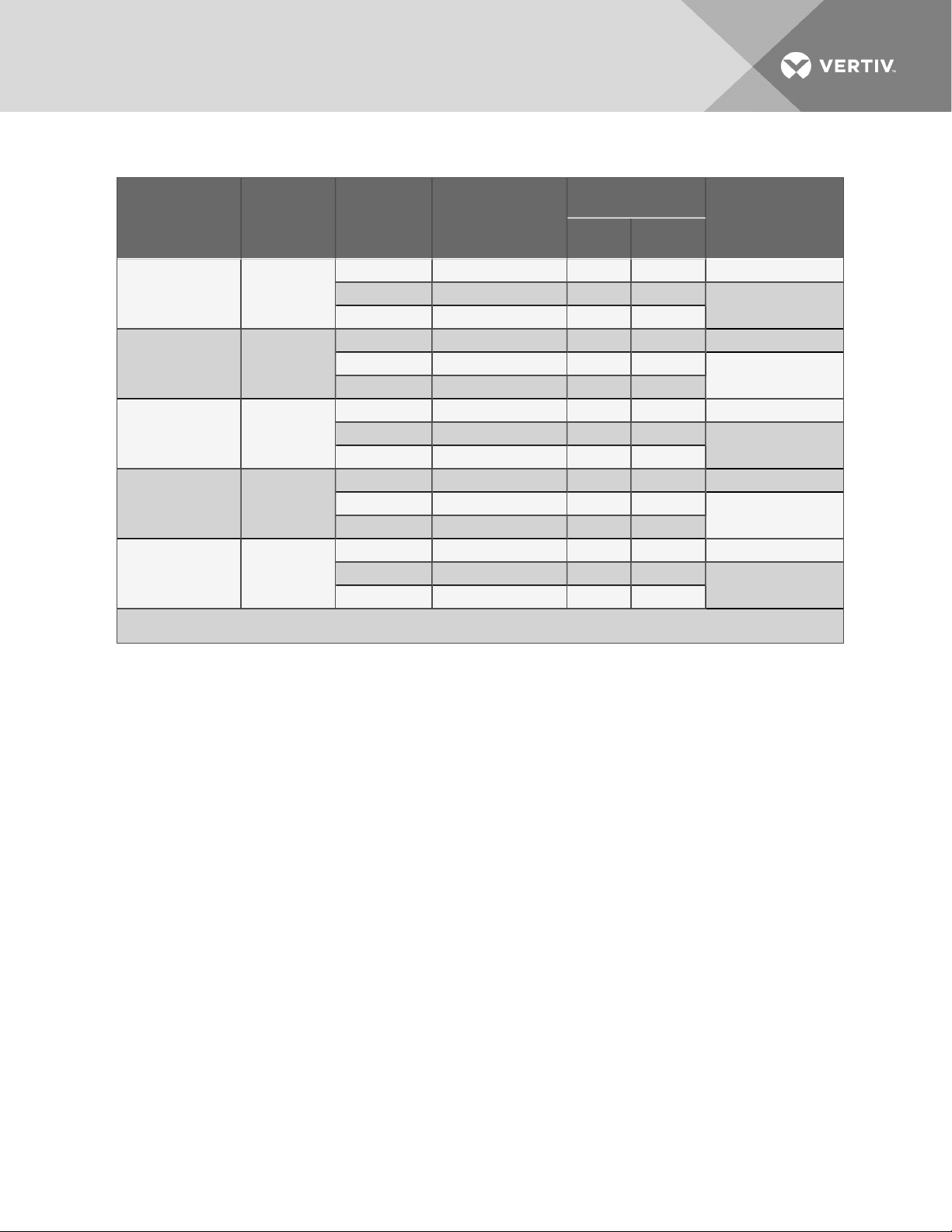

Table 2.4 Maximum Liebert evaporator units per Every 10 Fan Drycooler

Liebert Deluxe

Model 60 Hz

(50 Hz)

110 G

(111 G)

116 G

(121 G)

192 G

240 G

363 G

1. Ratings based on using40% ethylene glycol @ listed outdoor ambient rating temperature, 120°F (48.9°C) entering glycol. Selections are validfor

standard or TEAO motors. Consult your localLiebert representative for Quiet-Line selections.

Liebert

Deluxe

Unit

Capacity

8 tons

(28.1 kW)

10 tons

(35.2 kW)

15 tons

(52.7 kW)

20 tons

(70.3 kW)

30 tons

(105 kW)

Maximum

Deluxe

Units/10 Fan

Drycooler

12 95°F (35°C) 384 (24.2) D*N*150**272

9 100°F ( 37.8°C) 288 (18.2)

6 105°F (40.6°C) 192 (12.1)

10 95°F (35°C) 380 (24.0) D*N*150** 272

7 100°F (37.8°C) 266 (16.8)

5 105°F (40.6°C) 190 (12.0)

7 95°F (35°C) 378 (23.8) D*N*150**272

5 100°F (37.8°C) 270 (17.0)

4 105°F (40.6°C) 216 (13.6)

6 95°F (35°C) 402 (25.4) D*N*150* *272

4 100°F (37.8°C) 268 ( 16.9)

3 105°F (40.6°C) 201 (12.7)

4 95°F (35°C) 31 2 (19.7) D*N*150**272

3 100°F (37.8°C) 234 (14.8)

2 105°F (40.6°C) 156 (9.8)

Outdoor

Ambient

Rating

Total Syst em

gpm (lps)

Drycooler

Model #

D*N*150* *136

D*N*150* *136

D*N*150* *136

D*N*150* *136

D*N*150* *136

1

2.3 Engineering Data, Calculations and Selection Procedure

An alternate, detailed procedure is available to calculate values and select the correct the 10 Fan

Drycooler(s) for the application. This can be used to assist in selecting drycoolers for applications for

ambient conditions that are not standard. Use the following steps.

1. Determine the following items to begin this procedure:

• Design outdoor ambient air temperature, Toa(F or C)

• Fluid Flow Rate, VT(gpm or lps)

• % ethylene glycol concentration

• Fluid temperatures at drycooler: Entering, Tefand leaving Tlf(F or C), or

• Total Required Heat Rejection, QRT(Btu/h or kW) and one of the fluid temperatures

above

2. Find the following values using these equations and known values above:

• Initial Temperature Difference (ITD) of entering fluid to outdoor design air,

ITD = Tef- T

• Total Required Heat Rejection, QRT= VT* cv* (Tef- Tlf), where cvis found in the following

table, or

• Leaving fluid temperature, Tlf= Tef- QRT/ (VT* cv) where cvis found in the following

table.

3. Find the Average Fluid Temperature, T

oa

= (Tef+ Tlf) / 2

f,avg

Vertiv | Liebert® 10-fan Drycooler User Manual | 8

Page 15

4. Find Required Heat Rejection per ITD, QR

= QRT/ (ITD * f), where f is the capacity

ITD

correction factor found in Capacity Correction Factor on the next page.

5. Using Product Performance Data & Selection on page5 with columns titled Flow Rate Range

and Heat Rejection per ITD, choose the Drycooler Model matching application fluid flow rate

and meeting/exceeding the required Heat Rejection per ITD, QR

from Step4. above.

ITD

6. Find the Flow Rate per Circuit, VC= VT/ circuits for the drycooler selected in Product

Performance Data & Selection on page5. This should be in the range of 1.0 to 2.0 gpm/circuit

(0.06 to 0.13 lps/circuit) for proper long-term performance.

7. In Product Performance Data & Selection on page5, for the selected Model Number, find the

Actual Heat Rejection per ITD using the gpm/circuit from Step6. above. You may interpolate

between columns as required. The Actual Heat Rejection should be equal to or greater than

per ITD, QR

(higher altitude application sites should use correction factors to reduce Actual

ITD

Heat Rejection results). If it is less, repeat process from Step5. above using a larger model. If 10

Fan Drycooler solution is oversized, lower capacity drycoolers are available and may be

considered as an alternative solution.

8. Calculate the Total Actual Heat Rejection, QA, for the drycooler, using the Actual Heat

Rejection per ITD (Step7. above) and actual ITD and correcting for % glycol and AFT (see

Capacity Correction Factor on the next page).

QA = QA

ITD

* ITD * f

9. After selecting a model, look up the unit’s Pressure Drop in Product Performance Data &

Selection on page5. Multiply this pressure drop by the correction factor found in Pressure

drop correction factor on page11. If the resulting pressure drop is higher than your system

design, go back to Step5. above and select a model with more circuits or consider multiple

units. Contact your sales representative for additional design assistance.

10. Electrical data for model selected is found in Electrical Specifications on page11.

Table 2.5 Specific Heats for Aqueous Ethylene Glycol Solutions (Cv)

% Ethylene Glycol 0% 10% 20% 30% 40% 50%

Btu/h/gpm°F 500 490 480 470 450 433

kW/lps°C 4.18 4.09 4.01 3.93 3.76 3.62

Table 2.6 Altitude Correction

Alt it ude - Feet (M)

Correction Factor 1 .000 0.979 0.960 0.900 0.841 0.762 0.703

0

(0)

1000

(305)

2000

(610)

5000

(1525)

8000

(2440)

12000

(3660)

15000

(4575)

Vertiv | Liebert® 10-fan Drycooler User Manual | 9

Page 16

Figure 2.1 Capacity Correction Factor

Vertiv | Liebert® 10-fan Drycooler User Manual | 10

Page 17

Figure 2.2 Pressure drop correction factor

Table 2.7 Electrical Specifications

Voltag

Drycool

er

Model

D0N*150

DTN*1 50 TEAO 70 72 90 70 72 90 35 36 45 n/a n/a n/a n/a 32 35

DGN*120 QuietLine 48 50 60 48 50 60 24 25 30 28 30 35 24 25 30

ePhase

Motor

Type

STANDA

RD

60 Hz 50 Hz

208-3 230-3 460-3 575-3 380/415-3

FLAMCAOPDFLAMCAOPDFLAMCAOPDFLAMCAOPDFLAMCAOP

D

70 72 90 70 72 90 35 36 45 28 30 35 35 36 40

2.4 Selection Example

For the following example, English (I-P) units will be used. Metric units are also provided in the tables and

figures.

Find a drycooler to cool 340 gpm of 20% ethylene glycol/water solution from 125°F to 115°F. Application is

near sea level and has an outdoor design air temperature of 95°F.

Vertiv | Liebert® 10-fan Drycooler User Manual | 11

Page 18

1. Assume the following values:

• Toa= 95°F

• VT= 340 gpm

• 20% ethylene glycol

• Tef= 125°F

• Tlf= 115°F

2. Initial temperature difference, ITD = Tef- Toa= 125 - 95 = 30°F

• Since Tefis known, calculate Total Required Heat Rejection, QRT= VT* cv* (Tef- Tlf)

• Using Specific Heats for Aqueous Ethylene Glycol Solutions (Cv) on page9, cv= 480 for

20% ethylene glycol.

• QRT= 340 gpm * 480 Btu/h / gpm°F * (125°F - 115°F) = 1,632,000 Btu/h

3. Average Fluid Temperature, T

4. Required Heat Rejection per ITD, QR

= (Tef+ Tlf) / 2 = 125°F + 115°F) / 2 = 120°F

f,avg

= QRT/ (ITD * f), where f is found from Figure 2.1 on

ITD

page10.

• Using Figure 2.1 on page10, f = 1.04 for 120°F and 20% EG concentration.

• QR

= 1,632,000 Btu/h / (30°F * 1.04) = 52,300 Btu/h / °F

ITD

5. Locate Model Number(s) in Product Performance Data & Selection on page52 on page5,

matching flow rate of 340 gpm and meeting or exceeding 52,300 Btu/h / °F. Either Model 120

with 272 circuits or the Model 150 with 272 circuits matches the flow rate requirements and

meets or exceeds the Required Heat Rejection per ITD. For this example, Model 150 will be

chosen to complete the procedure.

6. Flow rate per circuit, VC= VT/ circuits = 340 gpm / 272 circuits = 1.25 gpm/circuit. This is within

the 1.0 to 2.0 gpm/circuit range.

7. Using Product Performance Data & Selection on page5, the actual Heat Rejection per ITD,

QA

for Model 150 with 272 circuits @ 1.25 gpm/circuit is 69,526 Btu/h / °F, which exceeds our

ITD

Required Heat Rejection per ITD of 52,300 Btu/h / °F. No correction for altitude is required.

8. Total Actual Heat Rejection for the drycooler, QA = QA

* ITD * f, where f is found in Capacity

ITD

Correction Factor on page10.

• QA = 69,526 Btu/h / °F * 30°F * 1.04 = 2,169,211 Btu/h

9. Pressure drop for 1.25 gpm/circuit is 6.25 ft., water using Product Performance Data & Selection

on page5 for 40% ethylene glycol and T

find correction factor for the pressure drop for 20% ethylene glycol and T

= 115°F. Use Figure 2.2 on the previous page to

f,avg

= 120° F.

f,avg

Therefore, the pressure drop will be 6.259 * 0.93 = 5.8 ft., water.

10. Using Electrical Specifications on the previous page and Drycooler Model D0N*150 with a 460

VAC, 3-phase, 60 Hz motor, the electrical requirements will be FLA = 31 amps, WSA = 32 amps

and OPD = 35 amps.

Vertiv | Liebert® 10-fan Drycooler User Manual | 12

Page 19

3 INSTALLATION

NOTE: Follow all unit dimensional drawings carefully. Determine whether any building alterations are

required to run piping and wiring. Also refer to the submittal engineering dimensional drawings.

3.1 Location Considerations

The drycooler should be located for maximum security and maintenance accessibility. Avoid ground level

sites with public access or areas which contribute to heavy snow or ice accumulations. To assure an

adequate air supply, it is recommended that drycoolers be located in a clean air area, away from loose dirt

and foreign matter that may clog the coil. In addition, drycoolers must not be located in the vicinity of

steam, hot air, or fume exhausts.

The unit may be mounted either at ground level or on a roof, given proper structural support and

following a review of local codes. Pit installations are not recommended. Air re-circulation will severely

affect unit and/or system performance. For these same reasons, units should not be installed closer than

72" (1829 mm) from a wall. This clearance should be increased to 96" (2438mm) in corner wall situations.

In multiple unit installations, units should not be installed closer than 72" (1829 mm) end to end or 96"

(2438 mm) side to side. For further details, see the following figure.

Vertiv | Liebert® 10-fan Drycooler User Manual | 13

Page 20

Figure 3.1 Clearance considerations

Vertiv | Liebert® 10-fan Drycooler User Manual | 14

Page 21

3.2 Site Preparation

Drycoolers should be installed in a level position to assure proper venting and drainage. This space should

have all services (electrical, drain, water) in close proximity. Also, the space should be level and free of

loose gravel, sand, flooring or roofing. For roof installation, mount drycoolers on steel supports in

accordance with local codes. To minimize sound and vibration transmission, mount steel supports across

load-bearing walls. For ground installations, a concrete pad is sufficient to carry the load. The base should

be at least 2 inches (51 mm) higher than the surrounding grade and 2 inches (51 mm) larger than the

dimensions of the unit base. The drycooler base has mounting holes for securing the drycooler once

installed. See the following figure.

Figure 3.2 Unit Dimensions

Vertiv | Liebert® 10-fan Drycooler User Manual | 15

Page 22

Table 3.1 Drycooler Physical Data

Model #Model #

D*N*150* *068 10

D*N*150* *136 10

D*N*150* *272 10

DGN*120**068 10

DGN*120**1 36 10

DGN*120**272 10

No. of

Fans

CFM (CMH)

60Hz.

99030

(168250)

99030

(168250)

99030

(168250)

74160

(126000)

74160

(126000)

74160

(126000)

CFM (CMH)

50Hz.

82450

(140080)

82450

(140080)

82450

(140080)

N/A 92.8 (351) 5100 (2313)

N/A 92.8 (351) 5100 (2313)

N/A 92.8 (351) 5100 (2313)

Coil Internal

Vol. Gal (L)

92.8 (351) 5100 (2313)

92.8 (351) 5100 (2313)

92.8 (351) 5100 (2313)

Net Weight

Lb (kg)

3.3 Equipment Inspection Upon Delivery

When the Liebert® 10 Fan Drycooler™ arrives, inspect it for any visible or concealed damage. Do not

accept a damaged unit from the shipper!

NOTE: Any damage caused in transit must be reported immediately to the carrier and a damage claim

filed with a copy sent to your sales representative. Failure to do so may result in an inability to recover

costs for damage.

Before removing the drycooler from the truck/container, review the previous section, Site Preparation on

the previous page.

NOTICE

Risk of exposure to freezing temperatures. Can cause equipment damage.

If the drycooler is not installed immediately upon receipt, special storage precautions should be

taken. It is recommended that the unit be stored in a dry, heated place. Do not store the unit at

temperatures below 36°F (2.2°C). If the storage temperature is below 36°F (2.2°C), water vapor

can condense in the coil, freeze and cause permanent damage. Failure to store unit properly

will void the warranty.

3.4 Lifting and Handling the Drycooler

WARNING! Risk of unit very heavy unit tipping over. Can cause equipment damage, personal

injury and death.

Do not unload the drycooler with a forklift. The drycooler’s high center of gravity makes it a

tipping hazard. Further, tilted forks may damage the drycooler. Use chains and hooks when

removing the unit from the truck and when moving it between areas of equal height.

Riggers are required to lift the unit into place. Refer to Rigging Instructions belowFigure 3.3 below for lift

locations. Any time the unit is lifted, use slings or chains (with spreader bars) attached to the three lifting

eyes on either side of the unit base. Do not allow any part of the lifting apparatus to bear against the coil

fins. All lifting apparatus must also clear the fan guards on the top of the unit.

Vertiv | Liebert® 10-fan Drycooler User Manual | 16

Page 23

3.4.1 Unit Weight

Dry weight of the unit is 5100 lb. (2313kg).

WARNING! Risk of unit very heavy unit tipping over. Can cause equipment damage, personal

injury and death.

To avoid a tilt hazard, adjustment may be necessary to locate the center of gravity before lifting

the unit.

Figure 3.3 Rigging Instructions

3.5 Piping Connections

See Figure 3.4 on page19 for a typical piping diagram. See Figure 3.5 on page20 piping locations.

Notice

Risk of overpressurization. Can cause equipment damage.

To avoid the possibility of burst pipes, it is necessary to install a relief valve in the system. This

valve may be obtained from your supplier as an option or may be sourced from another vendor.

Galvanized pipe must not be used in glycol systems. To help prevent piping failures, supply

and return lines must be supported such that their weight does not bear on the piping of the

unit or pumps.

NOTE: Units are shipped pressurized with a 30 psig dry air holding charge.

Vertiv | Liebert® 10-fan Drycooler User Manual | 17

Page 24

It is recommended that manual service shutoff valves be installed at the supply and return connections to

each unit. This enables routine service and/or emergency isolation of the unit. In addition, multiple pump

packages require a check valve at the discharge of each pump to prevent backflow through the standby

pump(s).

Vertiv™ recommends installing filters/strainers in the supply line. These filters or strainers should be a

type that can be easily replaced or cleaned, with 16-20 mesh screen. These filters extend the service life of

the drycooler and the system’s pumps.

Vertiv™ recommends installing hose bibs at the lowest point of the system to facilitate filling.

Consideration of the minimum glycol temperature to be supplied from the drycooler will determine if the

glycol supply and return lines must be insulated toprevent condensation on the glycol lines in low

ambient conditions.

All fluid piping must comply with local codes. Care in sizing pipes will help reduce pumping power and

operating costs.

3.5.1 Expansion Tanks, Fluid Relief Valves and Other Devices

An expansion tank must be provided for expansion and contraction of the fluid due to temperature

change in this closed system. Vents are required at system high points to vent trapped air when filling the

system. A relief valve is also a necessary piping component.

Depending on the complexity of the system, various other devices may be specified. Pressure gauges, flow

switches, automatic air separator, tempering valves, standby pumps and sensors for electrical controls are

just a few of these devices.

NOTICE

Risk of burst pipes and leaking water from freezing temperatures. Can cause equipment and

building damage.

Immediately following the use of water for leak testing or system cleaning, charge the tested

system with the proper percentage of glycol and water for the coldest design ambient

expected. Complete system drain-down cannot be ensured, and damage to the system could

result from freezing of residual water.

Vertiv | Liebert® 10-fan Drycooler User Manual | 18

Page 25

Figure 3.4 Typical piping diagram

Vertiv | Liebert® 10-fan Drycooler User Manual | 19

Page 26

Figure 3.5 Piping dimensions

Vertiv | Liebert® 10-fan Drycooler User Manual | 20

Page 27

Table 3.2 Piping, drycoolers

Model #. No. Fans

D*N*150* *068 10 68 2 2 2.625" (66.7mm) 2.625" (66.7mm)

D*N*150* *136 10 136 2 2 4.125'' (104.8mm) 4.125'' (104 .8mm)

D*N*150* *272 10 272 2 2 4.125'' (104 .8mm) 4.125'' (104.8mm)

DGN*120**068 10 68 2 2 2.625" (66.7mm) 2.625" ( 66.7mm)

DGN*120**1 36 10 136 2 2 4.125'' (1 04.8mm) 4.125'' (104.8mm)

DGN*120**272 10 272 2 2 4.125'' (1 04.8mm) 4.125'' (104 .8mm)

No. of

Internal

Circuits

No. of

Inlets

No. of

Outlets

Connection Sizes (ODS)

(A) Inlet (B) Outlet

Table 3.3 Piping specifications

Model

D0N*150** 68

DGN*120** 272

*Cut off closed end of connection tube; connectcouplings and elbows as required.

No. of Internal

Circuits

No. of

Inlets (A)

2 2

No. of

Outlets (B)

Connection Sizes, Inlet

and Outlet OD (in.)*

2.625

4.125

Coil Internal

Volume, Gal. (l)

92.8 (351)DTN*1 50** 1 36

Table 3.4 Volume in Standard Type L Copper Piping

Diameter (in.) Volume

Outside Inside gal/ft l/m

1-3/8 1.265 0.065

1-5/8 1.505 0.092 1.15

2-1/8 1.985 0.161 2.00

2-5/8 2.465 0.248 3.08

3-1/ 8 2.945 0.354 4.40

3-5/8 3.425 0.479 5.95

4-1/8 3.905 0.622 7.73

Vertiv | Liebert® 10-fan Drycooler User Manual| 21

Page 28

3.6 Filling Instructions

3.6.1 Preparing the System for Filling

It is important to remove any dirt, oil or metal filings that may contaminate the cooling system piping in

order to prevent contamination of the fresh glycol solution and fouling of the drycooler piping. The

system should be flushed thoroughly using a mild cleaning solution or high-quality water and then

completely drained before charging with glycol. Cleaning new systems is just as important as cleaning old

ones. New systems can be coated with oil or a protective film; dirt and scale are also common. Any residual

contaminants could adversely affect the heat transfer stability and performance of your system. In many

cases, in both old and new systems, special cleaners are needed to remove scale, rust and hydrocarbon

foulants from pipes, manifolds and passages. Clean heat transfer surfaces are important in maintaining

the integrity of the heating/cooling system. For more information on cleaners and degreasers, contact

your sales representative. Follow the manufacturer’s instructions when using these products.

Calculate the internal volume of the system as closely as possible. The Liebert® 10 Fan Drycooler™ volume,

not including the load or field-supplied piping, is 92.8 gallons (351 l). Use Volume in Standard Type L

Copper Piping on the previous page for field-installed piping volumes.

3.6.2 Glycol Solutions

NOTE: Glycol solutions should be considered for the protection of the coil. When glycol solutions are

not used, damage can occur either from freezing or from corrosion from water.

When considering the use of any glycol products in a particular application, you should review the latest

Material Safety Data Sheets and ensure that the use you intend can be accomplished safely. For Material

Safety Data Sheets and other product safety information, contact the supplier nearest you. Before

handling any other products mentioned in the text, you should obtain available product safety

information and take necessary steps to ensure safety of use.

NOTICE

Risk of improper handling of glycol. Can cause environmental damage.

When mishandled, glycol products pose a threat to the environment. Before using any glycol

products, review the latest Material Safety Data Sheets and ensure that you can use the

product safely. Glycol manufacturers request that the customer read, understand and comply

with the information on the product packaging and in the current Material Safety Data Sheets.

Make this information available to anyone responsible for operation, maintenance and repair of

the drycooler and related equipment.

NOTICE

Risk of using improper glycol. Can cause equipment damage.

Automotive antifreeze is unacceptable and must NOT be used.

No chemical should be used as or in a food, drug, medical device, or cosmetic, or in a product or process in

which it may contact a food, drug, medical device, or cosmetic until the user has determined the suitability

and legality of the use. Since government regulations and use conditions are subject to change, it is the

user's responsibility to determine that this information is appropriate and suitable under current,

applicable laws and regulations.

Vertiv | Liebert® 10-fan Drycooler User Manual| 22

Page 29

Typical inhibited formula ethylene glycol and propylene glycol manufacturers and suppliers are Union

Carbide (Ucartherm) and Dow Chemical (Dowtherm SR-1, Dowfrost). These glycols are supplied with

corrosion inhibitors and do not contain a silicone anti-leak formula. Commercial ethylene glycol, when

pure, is generally less corrosive to the common metals of construction than water itself. Aqueous solutions

of these glycols, however, assume the corrosivity of the water from which they are prepared and may

become increasingly corrosive with use when not properly inhibited.

There are two basic types of additives:

• Corrosion inhibitors and

• Environmental stabilizers

The corrosion inhibitors function by forming a surface barrier that protects the metals from attack.

Environmental stabilizers, while not corrosion inhibitors in the strictest sense of the word, decrease

corrosion by stabilizing or favorably altering the overall environment. An alkaline buffer, such as borax, is a

simple example of an environmental stabilizer, since its prime purpose is to maintain an alkaline condition

(pH above 7).

The percentage of glycol to water must be determined by using the lowest design outdoor temperature in

which the system is operating. The following table indicates the solution freeze point at several c

concentration levels of ethylene glycol. Propylene glycol concentrations should be 1% higher than

ethylene glycol table values to find the freeze point. For example, 41% propylene glycol freezes at -10°F.

Table 3.5 Ethylene glycol concentrations

% Glycol by Volume 0* 10 20 30 40 50

Freezing Point °F (°C) 32 ( 0) 25 (-3.9) 1 6 (-8.9) 5 (-15.0) -10 (- 23.3) -32 ( -35.5)

Apparent Specific Gravity

@ 50°F ( 10°C)

* A minimal amount of glycol should be considered for inhibitive coil protection.

1 1,014 1.028 1,04 2 1,057 1.071

Notice

Risk of poor water quality. Can cause equipment damage.

The quality of water used for dilution must be considered because water may contain corrosive

elements that reduce the effectiveness of the inhibited formulation. Surface water that is

classified as soft (low in chloride and sulfate ion content—less than 100 ppm each) should be

used.

3.6.3 Filling the System

Vertiv™ recommends installing hose bibs at the lowest point of the system.

When filling a glycol system, keep air to a minimum. Air in glycol turns to foam and is difficult and timeconsuming to remove. (Anti-foam additives are available and may be considered.)

Open all operating systems to the loop. With the top vent(s) open, fill the system from the bottom of the

loop. This will allow the glycol to push the air out of the top of the system, minimizing trapped air. Fill to

approximately 80% of calculated capacity. Fill slowly from this point, checking fluid levels until full.

NOTE: For glycol solution preparation and periodic testing, follow manufacturer’s recommendations.

Do not mix products of different manufacturers.

Vertiv | Liebert® 10-fan Drycooler User Manual| 23

Page 30

3.7 Electrical Connections

Each unit is shipped from the factory with all internal unit wiring completed. Refer to the electrical

schematic when making connections. All wiring must be done in accordance with the National Electric

Code and all local and state codes.

WARNING! Risk of electric shock. Can cause injury or death. Disconnect all local and remote

electric power supplies before working within the unit.

The fans may start unexpectedly. The line side of the factory disconnect remains energized

when the disconnect is Off. Use a voltmeter to confirm that the electric power is turned Off

before making any electrical connections.

3.7.1 Line Voltage

Drycooler rated voltage should be verified with available power supply upon receipt of unit but before

installation. Refer to the unit electrical schematic and serial tag for specific electrical requirements. All

wiring must be done in accordance with the National Electric Code as well as all local and state codes.

CAUTION: Risk of using improper wire. Can cause equipment damage or a safety hazard from

overheated wire and/or connections.

Size the system electrical service for the total of all drycoolers and ancillary components

FLA/WSA/OPD. Unit-specific wiring diagrams are provided on each unit. Use copper wiring

only. Make sure that all connections are tight.

Line voltage electrical service is required for all drycoolers at the location of the drycooler. The power

supply does not necessarily have to be the same voltage supply as required by the indoor unit for which

the drycooler operates. This power source may be 208, 230, 460 or 575V 60Hz; or 380/415V 50Hz. A unit

disconnect is standard. However, a site disconnect may be required per local code to isolate the unit for

maintenance. Route the supply power to the site disconnect switch and then to the unit. Route the

conduit through the hole provided in the cabinet. Connect earth ground to lug provided near terminal

board. For units with multi-voltage transformer, the transformer connections should match (change if

necessary) the local power supply. See the following figure.

Vertiv | Liebert® 10-fan Drycooler User Manual| 24

Page 31

Figure 3.6 Electrical Field Connections

3.7.2 Low Voltage Control Wiring

A control interlock between the drycooler and the heat load(s) will require 24V Class 2 copper wiring for

remote On/Off sequencing of the drycooler with the load. Refer to the electrical schematic for wiring to

Terminals 70 & 71. See the following figure for typical low-volt system wiring.

If the current sensing relay option is provided, 24V Class 2 wiring will be necessary to make the

connections to monitor motor operation.

NOTE: Make sure all electrical connections are tight.

Vertiv | Liebert® 10-fan Drycooler User Manual| 25

Page 32

Figure 3.7 Typical Low Volt Wiring Diagram

3.8 Checklist for Completing Installation

NOTE: After installation, proceed with the following list to verify that the installation is complete.

Complete and return the Warranty Inspection Check Sheet which is shipped with the unit and return to

the address indicated on the check sheet.

1. Proper clearances for service access have been maintained around the equipment.

2. Equipment is level and mounting fasteners are tight.

3. Piping completed to coolant loop.

4. All piping connections are tight as well as secured and isolated for vibration reduction.

5. All piping connections inspected for leaks during initial operation.

6. Line voltage to power wiring matches equipment nameplate.

7. Power wiring connections completed to disconnect switch, including earth ground.

8. Power line circuit breakers or fuses have proper ratings for equipment installed.

9. Control wiring connections completed to heat loads/evaporator(s), including wiring to optional

controls.

10. All wiring connections are tight.

11. Foreign materials have been removed from in and around all equipment installed (shipping

materials, construction materials, tools, etc.).

Vertiv | Liebert® 10-fan Drycooler User Manual| 26

Page 33

12. Fans rotate freely and in correct direction without unusual noise and discharge the air

upwards.

13. Glycol has been added to the drycooler to prevent freeze damage.

Vertiv | Liebert® 10-fan Drycooler User Manual| 27

Page 34

This page intentionally left blank.

Vertiv | Liebert® 10-fan Drycooler User Manual| 28

Page 35

4 OPERATION

WARNING! Risk of electric shock. Can cause injury or death. Disconnect all local and remote

electric power supplies before working within the unit.

The fans may start unexpectedly. Disconnect the power supply before working on the unit.

Line side of factory disconnect remains energized when the disconnect is Off. Use a voltmeter

to make sure power is turned off before checking any electrical connections or functions.

4.1 Initial Startup Procedure

Refer to Checklist for Completing Installation on page26 and verify that all installation items have been

completed prior to proceeding.

Turn the unit ON. Check the fans for proper rotation (air discharging up). Check the pumps for proper

rotation.

Notice

Risk of overheated pumps. Can cause equipment damage.

Do not run pumps without fluid in the system. Pump seals require fluid to keep them cool;

running them for any amount of time will damage the seals, which may cause a failure.

4.1.1 Control Setpoints

The fluid temperature controls should be set according to the following table for standard cooling only or

free-cooling GLYCOOL applications. See the following figure.

Table 4.1 Control Settings

Heat Rejection

Method

Standard

Free-Cooling

(GL YCOOL)

Fluid

Temperature

Control

1TAS 68°F ( 20°C) -

1STG - 5°F (2.8°C) 73°F (22.8°C) 85°F ( 29.4°C)

2STG - 10°F (5.6°C) 78°F (25.6°C) 90°F (32.2°C)

1TAS 42°F (5.6°C) -

1STG - 2°F (1.1°C) 44° F (6.7°C) 52°F (11.1°C)

2STG - 4°F (2.2°C) 46°F (7.8°C) 54° F (12.2°C)

Setpoint Offset Differential Open Close

68°F (20°C) 80°F (26.7°C)

12°F (6.7°C)

42°F ( 5.6°C) 50°F (10°C)

8°F ( 4.4°C)

Vertiv | Liebert® 10-fan Drycooler User Manual| 29

Page 36

Figure 4.1 Fluid Temperature Controls

4.1.2 Current-Sensing Relays

If supplied, be sure that the current-sensing relays (CSR) are wired as per the wiring schematic using 24V

Class 2 copper wiring. When the thermostat closes, a 24-volt signal will be sent to the relevant terminals of

the CSR. When this occurs, a time delay starts, allowing the amperage to be sensed on the load side of the

contactors.

First, set selection under amperage on selector switch, then start all fans. Set the trip delay for 50%.

Disconnect one of the load side wires from a fan being monitored by the control. Turn the potentiometer

until the LED is lit. Reconnect the fan wire. Check and repeat for the other circuits. Be sure to set the fluid

temperature controls as per the specifications, as illustrated within the unit electrical schematic (supplied

with the unit), or refer to Control Setpoints on the previous page. See the following figure or current

sensing relay layout.

Vertiv | Liebert® 10-fan Drycooler User Manual| 30

Page 37

Figure 4.2 Current Sensing Relays

4.1.3 Cold Weather Operation

Glycol solution should be used for operation of units located where outdoor ambients will include

temperatures at or below freezing. Refer to the installation sections referring to Piping Connections on

page17 and Glycol Solutions on page22 for further details.

Vertiv | Liebert® 10-fan Drycooler User Manual| 31

Page 38

This page intentionally left blank.

Vertiv | Liebert® 10-fan Drycooler User Manual| 32

Page 39

5 SYSTEM MAINTENANCE

WARNING! Risk of electric shock. Can cause injury or death. Disconnect all local and remote

electric power supplies before working within the unit.

The fans may start unexpectedly. Disconnect power supply before working on unit. Line side of

factory disconnect remains energized when disconnect is off. Use a voltmeter to make sure

power is turned off before checking any electrical connections or functions

5.1 General Procedures

NOTE: When ordering replacement parts for equipment, it is necessary to specify the unit’s model

number, serial number and voltage. Record those numbers in the spaces below.

Model Number ___________________

Serial Number ___________________

Voltage __________________________

Periodic attention is necessary for continued satisfactory operation of your unit. A daily inspection of the

system should be made to verify that the unit is performing satisfactorily. It is suggested that a daily log

be maintained recording inlet and outlet coolant temperature, ambient temperature and the coolant

pressure gauge readings. The coolant sight glass should be checked and the fans checked for unusual

sounds which may indicate wear or future trouble.

Monthly inspections should include removal and cleaning of strainer, and cleaning and inspection of coil.

The coil can be cleaned with water, compressed air or steam as required. During monthly inspections, it is

also wise to check the coolant to assure sufficient glycol in the mixture to prevent freeze-up. Each fan

motor amp draw should be checked. If performance or operation problems are also detected, refer to

Troubleshooting on page37 for required action. Use copies of the Maintenance Inspection Checklist on

page35.

Restricted air flow through the drycooler coil will reduce the operating efficiency of the unit and can

result in high fluid temperatures and loss of cooling. Clean the drycooler coil of all debris that will inhibit air

flow. This can be done with compressed air or a commercial coil cleaner. Check for bent or damaged coil

fins and repair as necessary. In winter, do not permit snow to accumulate around the sides or underneath

the drycooler.

Check all fluid lines and capillaries for vibration isolation. Support as necessary. Visually inspect all fluid

lines for signs of fluid leaks.

Inspect the motor/fan assemblies to insure bearings are free and the motor is secure within the mount.

The glycol level in drycooler systems must be periodically checked. At the high point of the system, check

for:

• Positive pressure

• Air to be vented

• An unclogged expansion tank

• Proper concentration of inhibitors and antifreeze

Vertiv | Liebert® 10-fan Drycooler User Manual| 33

Page 40

The first three checks may give an indication of leaks in the system.

5.2 Special Procedures

5.2.1 Drycooler Cleaning

Keeping the outdoor drycooler coils clean is an important factor in maintaining peak efficiency, reliability

and long life of the equipment. It is much easier to keep up on frequent cleanings rather than wait until

heavy build up has occurred which may create head pressure problems with the evaporator units.

When to Clean

Normal conditions typically dictate cleaning twice a year, spring and fall. On-site or area conditions such

as cottonwood trees, construction, etc., can increase cleaning frequency. On your standard bimonthly or

quarterly preventive maintenance schedule, a visual inspection of the coil is recommended to monitor

conditions.

What to Use

The best overall drycooler coil cleaner to use is plain water. If the coil has been maintained and cleaned at

regular intervals, water is sufficient to remove dirt and debris from the fins. Heavy buildup on the exterior

of the fins can be removed with a brush. Water pressure from a garden hose and sprayer usually works

well. If a pressure washer is used, make sure the equipment is set to a lower pressure setting and that the

nozzle is set to the fan spray, not stream. Otherwise, damage to the fins could result. If a cleaner is

required, Vertiv™ recommends using a non-acidic type cleaner. Acid-type cleaners can be aggressive to

the coil fins as well as surrounding areas. Many sites do not allow the use of acidic cleaners for

environmental reasons.

How to Clean

The best way to clean coils is from the inside out. This requires removing the coil guards or grilles (if

provided), the fan guards and blades to access the coil surface. The sprayer can then be worked across

the coil pushing the dirt and debris out. Although this does extend the time involved, the results are well

worth it. This method should be used at least once a year. Spraying the coil from the outside repeatedly

can push a majority of the dirt to the inner section of the fins and continue to restrict air flow. Keep in

mind you may not have the luxury of shutting the unit(s) down for an extended time. A scheduled

shutdown with the operator may be in order. If using a cleaner along with the spraying process, follow

recommended manufacturer instructions and be sure to rinse the coil thoroughly. Any residue left on the

coil can act as a magnet to dirt.

Vertiv | Liebert® 10-fan Drycooler User Manual| 34

Page 41

5.2.2 Maintenance Inspection Checklist

Date:____________________________________ Prepared By:____________________________________

Model #:_________________________________ Serial Number:__________________________________

NOTE: Regular inspections are necessary to assure proper cleanliness of the cooling fins. Should

inspection reveal dirt or corrosion, appropriate cleaning should be performed.

Monthly Semiannually

Drycooler Drycooler

_____1. Coil surfaces free of debris _____1. Complete all monthly items

_____2. Fans/grilles free of debris _____2. Piping in good condition

_____3. Fan motors securely mounted _____3. Piping secure

_____4. Motor bearings in good condition _____4. Wash coil as needed

_____5. No water/glycol leaks Pump Package

Pump Package _____ 1. Complete all monthly items

_____1. Pump rotation _____2. Test changeover operation

_____2. Pump securely mounted _____3. Pump #1 amp draw __________

_____3. No water/glycol leaks Pump #1 amp draw __________

_____4. No abnormal noises Pump #1 amp draw __________

_____4. Glycol level and general condition

_____5. Glycol freeze point ____°F and pH ____

_____6. Check all electrical connect

_____7. Check contactors for pitting

Drycooler Electric Panel

_____1. Check all electrical connections

_____2. Check all electrical connections

_____3. Operational sequence/setpoints

Fan Motors

_____1. Motor #1 amp draw __________ amps

_____2. Motor #2 amp draw __________ amps

_____3. Motor #3 amp draw __________ amps

_____4. Motor #4 amp draw __________ amps

_____5. Motor #5 amp draw __________ amps

_____6. Motor #6 amp draw __________ amps

_____7. Motor #7 amp draw __________ amps

_____8. Motor #8 amp draw __________ amps

_____9. Motor #9 amp draw __________ amps

____10. Motor #10 amp draw __________ amps

Vertiv | Liebert® 10-fan Drycooler User Manual| 35

Page 42

NOTES:

Signature: ______________________________________________________________________________

Make photocopies of this form for your records.

Vertiv | Liebert® 10-fan Drycooler User Manual| 36

Page 43

6 TROUBLESHOOTING

Symptom Possible Cause C heck Or Remedy

No main power Check L1, L 2 and L 3 for r ated voltage

Disconnect switch open Close disconnect switch

Blown fuse or circuit breaker

tripped

Unit will not operate

Unit runs, butmotor protector

keeps tripping

Outlet temperature from unittoo

high

Liquidsquirts from surge tank fill

cap when pump is turned off

Pump suddenly stops pumping Clogged strainer or impeller Clean outdebris

Pumping suddenly slows Clogged impeller, diffuser or line Cleanoutdebris and use s trainer

Excessive leakage around the

pumps haft while operating

Pump performance poor

Pump has noisy operation

Pump discharge press ure too

high

Control fuse or circuitbreaker

tripped

Improperly wired Check wiring diagram

No outputvoltage from

transformer

Motor protector defective Replace protector

Motor protector too small Check amp. draw

Fan or pumpmotor has shorted

winding

Low or unbalanced voltage Determine r eason and correct

Low or no coolant flow

Ambientair temperature higher

thandesign

Heat load higher thandesign

Throttling valve improperly Res et valve to proper differential pres sure

Air in system Ventall highpoints, repeat as necessar y. Check liquidlevel in surge tank.

Worn seal or packing Replace seal or packing

Worn impeller or seal Replace withnew impeller or s eal

Suctionlifttoo high Relocate pumpcloser to supply

Motor not up to speed; low

voltage

Worn bearings Replace pump

Worn motor bearings Replace pump

Low discharge head Throttle discharge -- improve conditions

Debris lodgedin impeller Remove cover and clean out

Cavitating pumps Adjust s ystem pres sures

Throttling valve improperly set Reset valve to proper differential pressure

Valve closed in circuit Open all valves downstream of unit

Strainer cloggedor dirty Remove strainer plug and clean

Check fuses or circuitbreaker

Check for 24 VAC. If no voltage, check for s hort. Replace fuse or res et circuit

breaker.

Check for 24 VAC. If no voltage, check primary voltage

Repair motor

See Pump will not operate or no coolant flow on the next page entry in this

table

Correct possible hot air discharge to fans from another source

Check for misapplication, need larger cooler. Correct possible additionalheat

loadbeing added to cooling circuit.

Larger lead wires may be required. Check for proper line voltage,±10%

Vertiv | Liebert® 10-fan Drycooler User Manual| 37

Page 44

Symptom Possible Cause C heck Or Remedy

No power to pump motor See Unit will notoperate on the previous page in this table

Low coolant level Check coolantlevel

Tubes plugged in cooling coil Flush coil withreputable cleaner

Pump will notoperate or no

coolantflow

Valve closed downstream of

cooling unit

Strainer cloggedor dirty Remove strainer plug and clean

Pump cavitating ( err atic gauge

operation)

Open all valves

Possibility of air in lines. Bleed all components. Check surge tank to pump inlet

connection. Check for pipingrestrictions.

Vertiv | Liebert® 10-fan Drycooler User Manual| 38

Page 45

Page 46

VertivCo.com | Vertiv Headquarters, 1050 Dearborn Drive, Columbus, OH, 43085, USA

© 2017 Vertiv Co. Allrights reserved. Vertiv and the Vertivlogo are trademarks or registered trademarks of VertivCo. All other names and logos referred to

are trade names, trademarks or registered trademarks of their respective owners. While every precaution has been taken to ensure accuracy and

completeness herein, Vertiv Co. assumes no responsibility, and disclaims allliability, for damages resulting from use of this information or for any errors or

omissions. Spec ifications are subject to change without notice.

SL-10061_REV3_10-17/590-1691-501A

Loading...

Loading...