Page 1

Hardware Description & Installation

Manual

Page 2

Vertical SUMMIT IP

Hardware Description and Installation Manual Issue 1.2

Regulatory Information

Before connecting the Vertical SUMMIT IP to the telephone network, you may be required to notify your

local serving telephone company of your intention to use "customer provided equipment". You may

further be required to provide any or all of the f ol l owing information:

PSTN line Telephone numbers to be connected to the syst em:

Model name: Vertical SUMMIT IP

Local regulatory agency registration number: consult local Ericsson-LG Enterprise

representative

Ringer equivalence: 0.1B

Registered jack: RJ-11

This equipment complies with the following reg ul atory standards, that is, the safety requirements of

EN60950-1, and the EMC requirement of EN55022 a nd E N55024.

If the telephone company determines that custom er provided equipment is faulty and may possibly cause

harm or interruption in service to the telephone network, it should be disconnected until repair can be

affected. If this is not done, the telephone company may temporarily disconnect service.

The local telephone company may make change s in i ts communications facilities or procedures. If these

changes could reasonably be expected to affect t he use of the Vertical SUMMIT IP or compatibility with

the network, the telephone company is required to give advanced written notice to the user, allowing the

user to take appropriate steps to maintain telephone service.

The Vertical SUMMIT IP complies with rules regarding radiation and radio frequency emission as defined

by local regulatory agencies. In accordance with these agencies, you may be required to provide

information such as the following to the end user.

FCC/CSA Interference Statement

This equipment has been tested and found to comply with the limits of a Class A digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a residential environment. This equipment generates,

uses, and radiates radio frequency energy, and if not installed and used in accordance with the

instructions, may cause harmful interference. However, there is no guarantee that interference wil l not

occur. If this equipment does cause interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to correct the interference by

one of the following measure;

Reorient or relocate the receiving antenna.

Increase separation between the equipment and receiver.

Connect the equipment to an outlet on a circuit different from which the receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

This device complies with part 15 /RSS-GEN of the FCC/I C rules. Operation is subject to the following

two conditions:

(1) This device may not cause harmful interference; and (2) This device must accept any interference

received, including interference that may cause undesired operation.

This Class A digital apparatus complies with Canadian I CES-003.

Page 3

Vertical SUMMIT IP

Hardware Description and Installation Manual Issue 1.2

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

The use of this device in a system operating either partially or completely outdoors may require the user

to obtain a license for the system according to t he Ca nadi an regulations. For further information contact

your Local Industry Canada office.

CAUTION

Any changes or modifications in construction of this device which are not expressly approved by the

party responsible for compliance could void the us er's authority to operate the equipment.

Regulatory Information/Disclaimers

Privacy of communications may not be ensured when using this telephone. Any changes or modificatio ns

made to this device that are not expressly approved by the manufacturer may void the user’s authority to

operate the equipment.

The Manufacturer is not responsible for any radio or television interference caused by unauthorized

modification of this device, or the substituti on or attachment of connecting cables and equipment other

than those specified by the manufacturer. It i s t he res ponsibility of the user to correct any interference

caused by such unauthorized modification, substitution or attachment.

The manufacturer and its authorized reseller s or distributors will assume no liability for any damage or

violation of government regulations arising from failure to comply with these guidelines.

The device is certified to the requirements of RS S-210 for 2.4GHz spread-spectrum devices.

WARNING

This is a class A product. In a domestic environment this product may cause radio interference in which

case the user may be required to take adequate measures.

WARNING

This equipment generates and uses R.F. energy, and if not installed and used in accordance with the

Instruction Manual, it may cause interference to radio communications. It has been tested and found to

comply with the appropriate limits for a telecom m unication device. The limits are designed to prov i de

reasonable protection against such interference, when operated in a commercial environment. Operation

of this equipment in a residential area could cause interference, in which case the user, at their expense,

will be required to take whatever measures may be re qui red to correct the interference.

Disposal of Old Appliance

When the displayed symbol (crossed-out wheeled bin) is adhered to a product, it designates the product

is covered by the European Directive 2012/19/EC.

All electric and electronic products should be disposed of only in special

collection facilities appointed by government or l ocal/municipal authorities.

The correct disposal of your old appliance will help prevent potential

negative consequences for the environment and human health.

For more detailed information about disposal of your old appliances, please

contact your city office, waste disposal service or the place of product

purchase.

Page 4

Vertical SUMMIT IP

Hardware Description and Installation Manual Issue 1.2

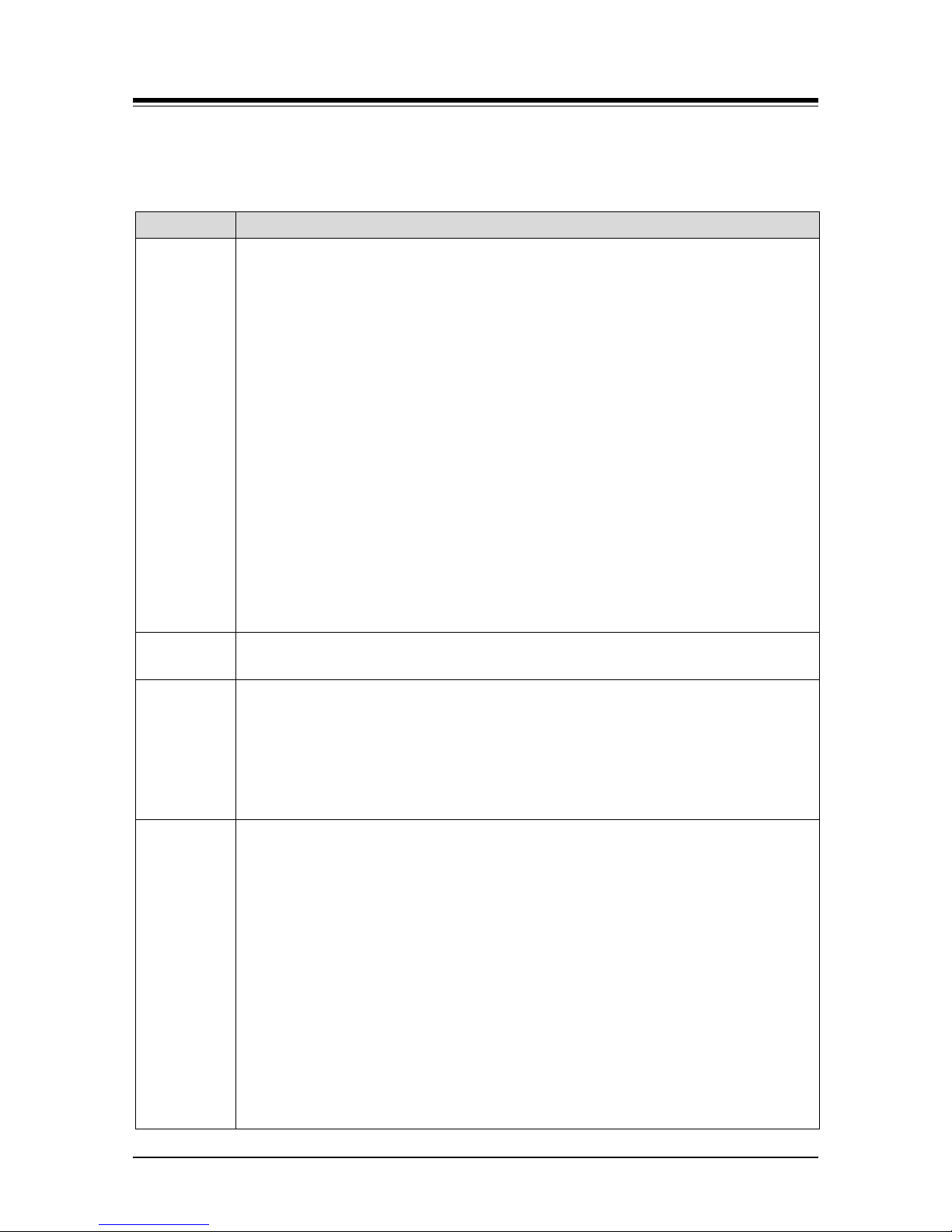

Safety Information in English

Item

Contents

Safety

Instructions Rack Mount

"Rack Mount Instructions - The following or similar rack-mount instructions are

included with the installation instructions:

A) Elevated Operating Ambient - If installed in a closed or multi-unit rack

assembly, the operating ambient temperature of the rack environment may be

greater than room ambient. Therefore, consideration should be given to installing

the equipment in an environment compatible with the maximum ambient

temperature (Tma) specified by the manufacturer.

B) Reduced Air Flow - Installation of the equipment in a rack should be such that

the amount of air flow required for safe operation of the equipment is not

compromised.

C) Mechanical Loading - Mounting of the equipment in the rack should be such

that a hazardous condition is not achieved due to uneven mechanical loading.

D) Circuit Overloading - Consideration should be given to the connection of the

equipment to the supply circuit and the effect that overloading of the circuits

might have on over current protection and supply wiring. Appropriate

consideration of equipment nameplate ratings should be used when addressing

this concern.

E) Reliable Earthing - Reliable earthing of rack-mounted equipment should be

maintained. Particular attention should be given to supply connections other than

direct connections to the branch circuit (e.g. use of power strips)."

Replaceable

batteries

"CAUTION: Risk of Explosion if Battery is replaced by an Incorrect Type.

Dispose of Used Batteries According to the Instructions."

Leakage

currents due

to ringing

voltage Earthing

installation

marking

"HIGH LEAKAGE CURRENT - Connect permanent earthing conductor before

connecting telephone lines"

Leakage

currents due

to ringing

voltage Earthing

installation

instructions

"1.A supplementary equipment earthing conductor is to be installed between the

product or system and earth, that is, in addition to the equipment earthing

conductor in the power supply cord.

2.The supplementary equipment earthing conductor may not be smaller in size

than the unearthed branch-circuit supply conductors. The supplementary

equipment earthing conductor is to be connected to the product at the terminal

provided, and connected to earth in a manner that will retain the earth

connection when the power supply cord is unplugged. The connection to earth of

the supplementary earthing conductor shall be in compliance with the

appropriate rules for terminating bonding jumpers in Part K of Article 250 of the

National Electrical Code, ANSI/NFPA 70 and Article 10 of Part 1 of the Canadian

Electrical Code, Part 1, C22.1. Termination of the supplementary earthing

conductor is permitted to be made to building steel, to a metal electrical raceway

system, or to any earthed item that is permanently and reliably connected to the

electrical service equipment earthed.

3.Bare, covered, or insulated earthing conductors are acceptable. A covered or

Page 5

Vertical SUMMIT IP

Hardware Description and Installation Manual Issue 1.2

Item

Contents

insulated conductor must have a continuous outer finish that is either green, or

green with one or more yellow stripes."

Telephone

line cord

"CAUTION: To reduce the risk of fire, use only No. 26 AWG or larger (e.g., 24

AWG) UL Listed or CSA Certified Telecommunication Line Cord"

Separation

of TNV and

SELV Pluggable A.

"The separate protective earthing terminal provided on this product shall be

permanently connected to earth." or similar (Instruction)

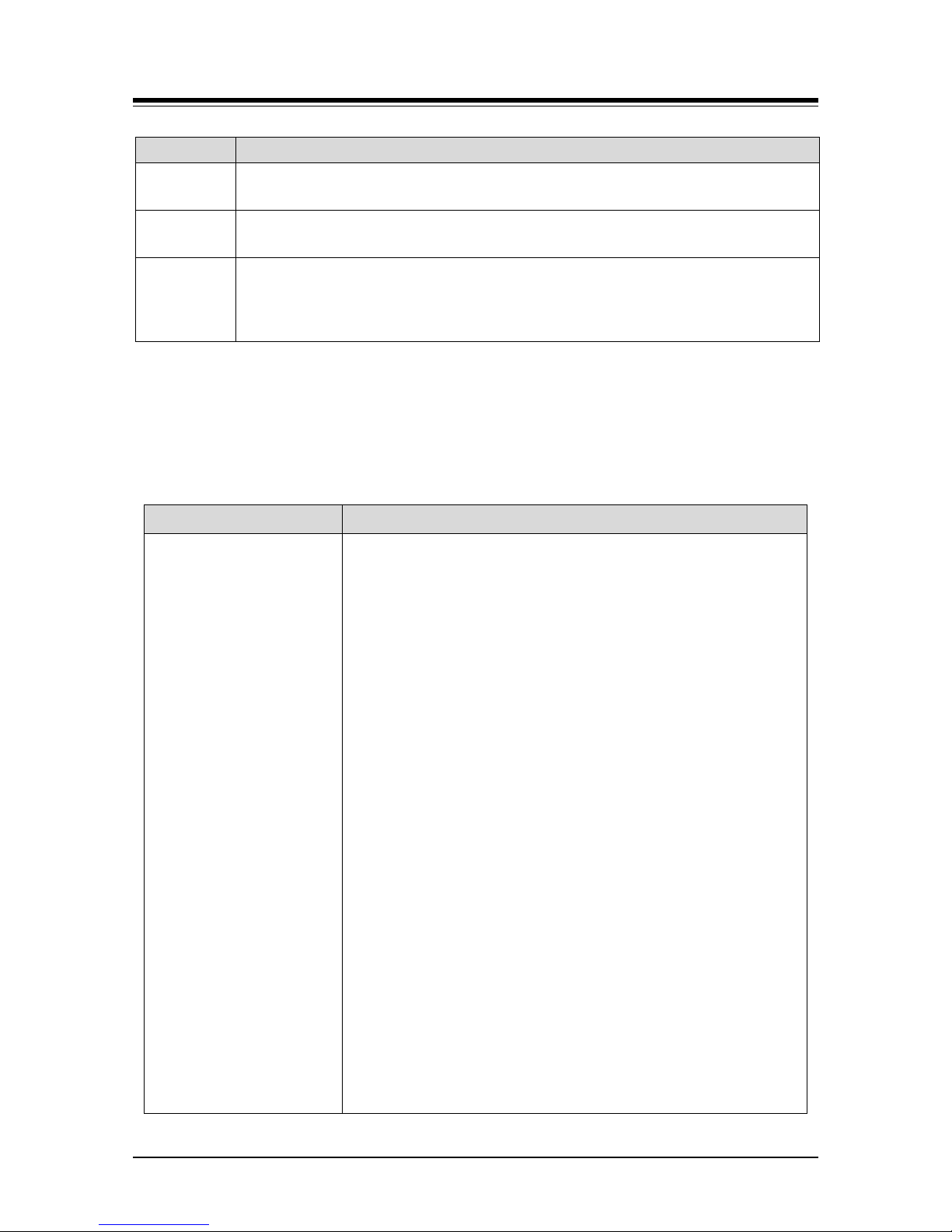

Safety Information in French

Item

Contents

Consignes de sécurité -

Montage sur bâti

« Instructions pour montage sûr bâti - Les instructions pour

montage sûr bâti suivantes ou des instructions similaires sont

fournies avec les instructions d'installation :

A) Température ambiante de fonctionnement élevée - En cas

d'installation dans un ensemble de bâti fermé ou comportant

plusieurs unités, il est possible que la température ambiante de

fonctionnement de l'environnement du bâti soit supérieure à

celle de la pièce. De ce fait, vous devez envisager l'installation

de l'équipement dans un environnement compatible avec la

température ambiante maximale (Tam) indiquée par le

fabricant.

B) Débit d'air réduit - L'installation de l'équipement dans un bâti

doit être effectuée de manière à ne pas compromettre le débit

d'air requis pour un fonctionnement en toute sécurité de

l'équipement.

C) Charge mécanique - Le montage de l'équipement dans le

bâti doit être réalisé de manière à ne pas provoquer de risque

dû à une charge mécanique inégale.

D) Surcharge des circuits - Vous devez être vigilant aux

branchements de l'équipement sur le circuit d'alimentation et

aux effets que la surcharge des circuits pourrait avoir sur la

protection de surintensité et le câblage d'alimentation. Vous

devez être vigilant aux caractéristiques nominales des plaques

signalétiques de l'équipement à utiliser lorsque vous abordez ce

problème.

E) Mise à la terre fiable - Vous devez faire en sorte de maintenir

une mise à la terre fiable de l'équipement monté sur bâti. Vous

devez être particulièrement vigilant aux branchements

d'alimentation autres que les connexions directes sur le circuit

de dérivation (par ex, utilisation de prises multiples). »

Page 6

Vertical SUMMIT IP

Hardware Description and Installation Manual Issue 1.2

Item

Contents

Batteries remplaçables

« ATTENTION : risque d'explosion si la batterie est remplacée

par un type de batterie incorrect. Mettez les batteries au rebut

conformément aux instructions.»

Courants de fuite dus à la

tension de sonnerie Marquage de l'installation

de mise à la terre

« COURANT DE FUITE ÉLEVÉ - Raccordez un conducteur

permanent de mise à la terre avant de brancher des lignes

téléphoniques.»

Courants de fuite dus la

tension de sonnerie Instructions d'installation

de mise à la terre

« 1. Un conducteur de mise à la terre supplémentaire de

l'équipement doit être installé entre le produit ou le système et

la terre, c'est-à-

dire, en plus du conducteur de mise à la terre de

l'équipement dans le cordon d'alimentation.

2. Le conducteur de mise à la terre supplémentaire de

l'équipement doit être d'une taille inférieure aux conducteurs

d'alimentation du circuit de dérivation non mis à la terre. Le

conducteur de mise à la terre supplémentaire de l'équipement

doit être raccordé au produit sur la borne appropriée et raccordé

à la terre de manière à ce que la connexion de mise à la terre

demeure en place lorsque le cordon d'alimentation est

débranché. La mise à la terre du conducteur de mise à la terre

supplémentaire de l'équipement doit être conforme aux règles

appropriées pour les connecteurs terminaux de la section K de

l'article 250 du Code national de l'électricité, ANSI/NFPA 70 et

de l'article 10 de la section 1 du Code canadien de l'électricité,

section 1, C22. Le raccordement du conducteur de mise à la

terre supplémentaire peut être effectué sur l'acier d'une

construction, sur un système de chemins de câbles électriques

métalliques ou sur tout élément mis à la terre raccordé de

manière permanente et fiable à l'équipement de service

électrique mis à la terre.

3. Des conducteurs de mise à la terre nus, couverts ou isolés

sont acceptables. Un conducteur couvert ou isolé doit posséder

une finition extérieure continue de couleur verte ou de couleur

verte avec une ou plusieurs bandes jaunes.»

Cordon de ligne

téléphonique

« ATTENTION : Afin de réduire les risques d'incendie, utilisez

uniquement du cordon pour ligne de télécommunication certifié

No. 26 AWG ou plus grand (par ex, 24 AWG) répertorié par l'UL

ou la CSA. »

Séparation des Tensions

des réseaux de

télécommunication (TNV)

et Tensions de sécurité

extra basses (SELV) Enfichable A.

« La prise de mise à la terre de protection distincte fournie sur

ce produit doit être raccordée de manière permanente à la terre.

» ou similaire (Instructions)

Page 7

Vertical SUMMIT IP

Hardware Description and Installation Manual Issue 1.2

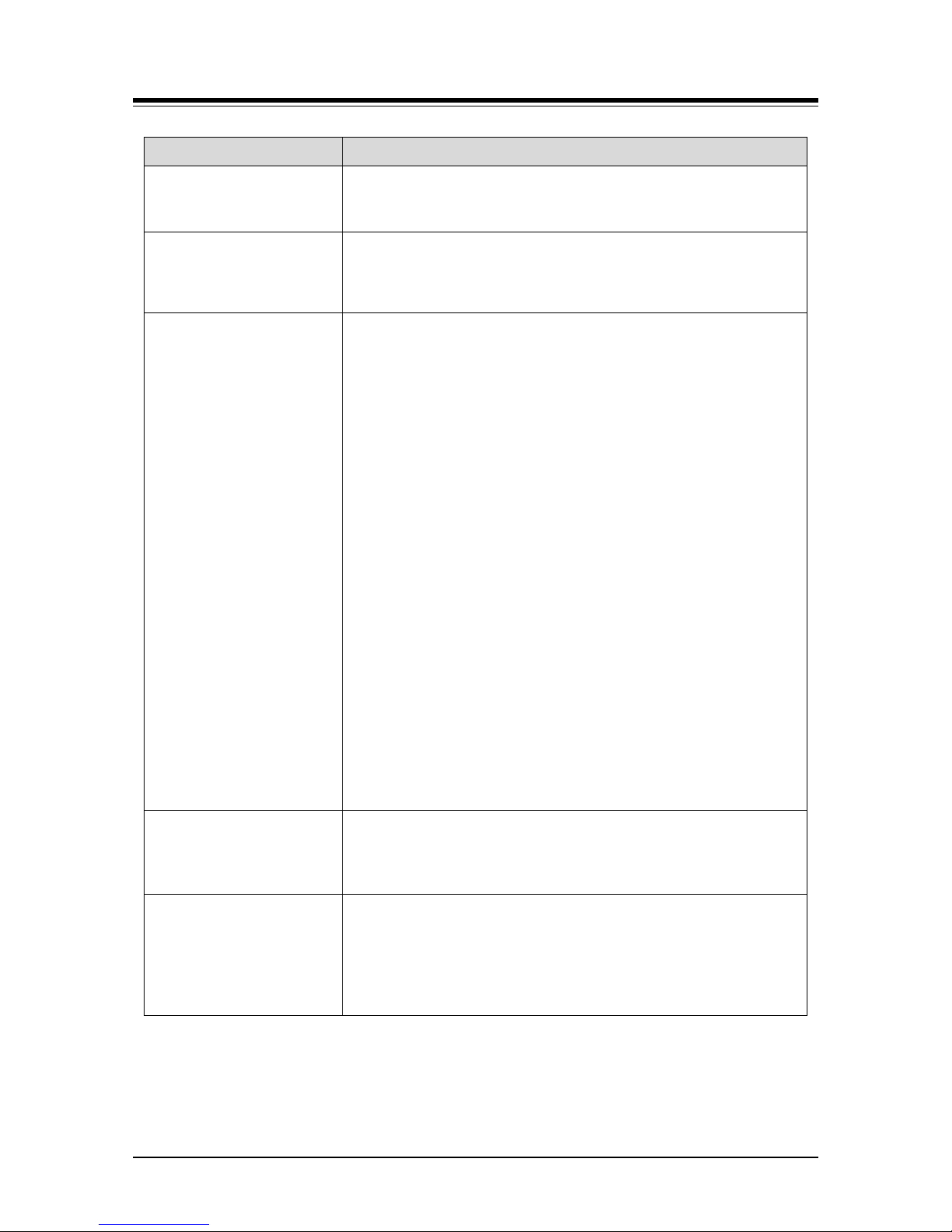

Revision History

Copyright© 2014 Vertical Communications. All Rights Reserved

This material is copyrighted by Vertical Communic ations. Any unauthorized reproductions, use or

disclosure of this material, or any part thereof, is strictly prohibited and is a violation of Copyright Laws.

Vertical Communications reserves the right to make changes in specifications at any time without notice.

The information furnished by Vertical Communications in this material is believed to be accurate and

reliable, but is not warranted to be true in all cases. If you are not the intended recipient, you should

destroy or retrieve this material to Vertical Communications.

All other brand and product names are trademarks or registered trademarks of their respective

companies

.

Issue Date DESCRIPTION OF CHANGES

1.0 Jun, 2014 Initial Release

1.1 May, 2015 Added VOIB48 & M EMU2 content

Update Pre-installation guide for power cord

Update Installation wizard

1.2

Jan, 2016

Added GDC-480H, the terminal, and corrected the minor errors

Page 8

Vertical SUMMIT IP

Hardware Description and Installation Manual Issue 1.2

i

Table of Contents

1. INTRODUCTION .................................................................................... 1

1.1 Important Safety Instructions ..................................................................... 1

1.1.1 Safety Requirements ........................................................................................... 1

1.1.2 Precaution ........................................................................................................... 2

1.2 About This Manual ....................................................................................... 3

2. SYSTEM OVERVIEW ............................................................................ 1

2.1 Vertical SUMMIT IP System Highlights ...................................................... 1

2.2 General Cabinet Description ....................................................................... 1

2.3 System Connection Diagram ...................................................................... 3

2.4 System Components ................................................................................... 4

2.5 Specifications ............................................................................................... 6

2.5.1 General Specifications ........................................................................................ 6

2.5.2 System Capacity ................................................................................................. 7

2.5.3 Base station specification (GDC-600BE) .......................................................... 11

2.5.4 Wireless Terminal specification (GDC-450H/480 H/500H) ................................ 11

3. INSTALLATION OVERVIEW ............................................................... 12

3.1 Pre-Installation Guidelines ........................................................................ 12

3.1.1 Safety Installation Instructions .......................................................................... 12

3.1.2 Installation precautions ..................................................................................... 12

3.1.3 Wiring Precautions ............................................................................................ 13

3.1.4 Checking Power cord ........................................................................................ 13

3.2 Installation Overview ................................................................................. 14

3.3 Preparation ................................................................................................. 14

4. BOARD INSTALLATION AND DESCRIPTION................................... 17

4.1 General information ................................................................................... 17

4.2 Removing and Replacing the KSU & Cord Cover ................................... 17

4.3 Installation of Option Boards .................................................................... 19

4.4 SUMMIT IP KSU Main Board Unit (MBU) .................................................. 20

4.4.1 MBUAD (Main Board Unit) ................................................................................ 20

4.4.2 MBUID (Main Board Unit) ................................................................................. 23

4.5 EKSU Expansion Main Board Unit (EMBU) .............................................. 26

4.6 Optional Interface Boards ......................................................................... 28

4.6.1 CH204 (2 CO Line and 4 Hybrid Interface Board) ............................................ 29

Page 9

Vertical SUMMIT IP

Hardware Description and Installation Manual Issue 1.2

ii

4.6.2 CH408 (4 CO Line and 8 Hybrid Interface Board) ............................................ 30

4.6.3 CD408 (4 CO and 8 Digital Interface Board) ..................................................... 31

4.6.4 CS416 (4 CO and 16 SLT Interface Board) ...................................................... 32

4.6.5 PRIU (PRI/T1 Interface Board) ......................................................................... 33

4.6.6 HYB8 (Hybrid 8 Interface Board) ...................................................................... 35

4.6.7 DTIB8 (Digital Telephone Interface Board – 8 ports) ........................................ 36

4.6.8 SLB16 (SLT 16 Interface Board) ....................................................................... 37

4.6.9 WTIB4 (Wireless DECT Interface Board) .......................................................... 38

4.7 Optional Function Boards ......................................................................... 40

4.7.1 VVMU (VoIP & Voice Mail Unit) ........................................................................ 40

4.7.1 VOIB48 (VoIP Unit) ........................................................................................... 41

4.7.2 MEMU (Memory Expansion Module Unit) ......................................................... 43

4.7.3 MEMU2 (Memory Expansion Module Unit2) ..................................................... 43

4.7.4 VS-5030-00 (Modem Function Unit) ................................................................. 44

5. MOUNTING THE KSU AND EKSU ..................................................... 45

5.1 KSU Exterior and Dimension .................................................................... 45

5.2 Desk Mount ................................................................................................. 46

5.3 Wall Mount .................................................................................................. 47

5.4 Rack Mount ................................................................................................. 48

6. KSU WIRING ....................................................................................... 50

6.1 Connecting the SUMMIT IP and Expansion KSUs .................................. 50

6.2 Grounding the KSUs .................................................................................. 51

6.3 External Backup Battery Installation ........................................................ 53

6.4 Line and Station Modular Jack Wiring ..................................................... 55

6.4.1 CO Line Modular Jack Wiring ........................................................................... 55

6.4.2 PRI Line Modular Jack Wiring ........................................................................... 56

6.4.3 Digital Station Modular Jack Wiring .................................................................. 56

6.4.4 Hybrid Station Modular Jack Wiring .................................................................. 57

6.4.5 DKT/SLT Station Modular Jack Wiring .............................................................. 57

6.4.6 SLT Station Modular Jack Wiring ...................................................................... 58

6.4.7 WTIB4 Base Station Modular Jack Wiring ........................................................ 58

6.5 MBU and VVMU LAN Port Wiring ............................................................. 61

6.6 USB port ..................................................................................................... 61

6.7 Connecting Miscellaneous Devices ......................................................... 62

6.8 RS-232 Serial Port Wiring .......................................................................... 64

6.9 Cable Wiring ............................................................................................... 65

6.9.1 Dressing the Wall Mount Wiring ........................................................................ 65

Page 10

Vertical SUMMIT IP

Hardware Description and Installation Manual Issue 1.2

iii

6.9.2 Rack Mount Wiring ............................................................................................ 66

7. TERMINAL CONNECTION AND WIRING .......................................... 67

7.1 Terminal Models ......................................................................................... 67

7.2 Terminal Cabling Distance ........................................................................ 69

7.3 Terminal Connection ................................................................................. 70

7.3.1 DKTU Wiring ..................................................................................................... 70

7.3.2 SLT Wiring ........................................................................................................ 70

7.3.3 LIP Phone Wiring .............................................................................................. 71

7.3.4 DSS/BLF Console Installation & Wiring ............................................................ 73

7.4 Terminal Wall Mount .................................................................................. 77

7.4.1 LDP-7000/9000/9200 series Wall Mount .......................................................... 77

7.4.2 LIP-8000/8000E Wall Mount ............................................................................. 77

7.4.3 LIP-9000 Wall Mount ......................................................................................... 78

8. STARTING THE VERTICAL SUMMIT IP ............................................ 79

8.1 Vertical SUMMIT IP System Initial Power-up ........................................... 79

8.2 Verify the Nation Code ............................................................................... 80

8.2.1 Using the DKT ................................................................................................... 80

8.3 Installation Wizard ..................................................................................... 81

9. MAINTENANCE & TROUBLESHOOTING .......................................... 87

9.1 General Maintenance ................................................................................. 87

9.2 PSU Fuse Replacement ............................................................................. 87

9.3 Troubleshooting ......................................................................................... 88

10. OPEN SOURCE SOFTWARE NOTICE .......................................... 89

Page 11

Vertical SUMMIT IP

Hardware Description and Installation Manual Issue 1.2

1

1. INTRODUCTION

1.1 Important Safety Instructions

1.1.1 Safety Requirements

When using your telephone equipment, basic safety precautions should always be followed

to reduce the risk of fire, electric shock and other personal injury, including the following:

Please read and understand all instructions.

Follow all warnings and instructions marked on the product.

Unplug this product from the wall outlet before cleaning. A slightly damp cloth should be

used for cleaning; do not use liquid or aerosol cleaners.

Do not use this product near water, such as bathtub, washbowl, kitchen sink or laundry tub,

a wet basement, or near a swimming pool.

Do not place this product on an unstable stand or table. The product may fall, causing

serious damage to the product or serious injury.

Slots and openings in the KSU and the back or bottom are provided for ventilation, to

protect it from overheating, these openings must not be blocked or covered. The openings

should never be blocked by placing the product on a bed, sof a, or other similar surface.

This product should never be placed near or over a radiator or other heat source. This

product should not be placed in a built-in installatio n without proper ventilation.

This product should be operated only from the t ype of power source indicated on the

product label. If you are not sure of the type of power s upply to your location, consult your

dealer or local power company.

Do not allow anything to rest on the power cord. Do not locate this product where the cord

could be abused by people walking on it.

Do not overload wall outlets and extension cords as this can result in the risk of fire or

electric shock.

Never push objects of any kind into this product thr ough KSU slots or connectors as they

may touch dangerous voltage points or short out parts that could result in a risk of fire,

electric shock or product failure. Never spill liqui d of any kind on the product.

To reduce the risk of electric shock, do not disassemble this product. Instead, take it to a

qualified person when service or repair work is required. Opening or removing covers may

expose you to dangerous voltages or other risk. I ncorrect reassemble can cause electric

shock when the appliance is subsequently used.

Unplug this product from the wall outlet and refer servicing to qualified service personnel

under the following conditions:

1. When the power supply cord or plug is damaged or frayed.

2. If liquid has been spilled into the product.

3. If the product has been exposed to rain or water.

4. If the product does not operate normally by following the operating i nst ructions. Adjust

only those controls that are covered by the operat i ng instructions because improper

adjustment of other controls may result in damage and will often require extensive work

by a qualified technician to restore the product t o normal operation.

5. If the product has been dropped or the KSU has been damaged.

Page 12

Vertical SUMMIT IP

Hardware Description and Installation Manual Issue 1.2

2

6. If the product exhibi ts a distinct change in performance.

Avoid using a telephone during an electrical storm. There is a remote risk of electric shock

from lightning.

In the event of a gas leak, do not use the telephone near the leak.

1.1.2 Precaution

Keep the system away from heating appliances and electrical noi se generat ing devi ces

such as florescent lamps, motors and television s. These noise sources can interfere with

the performance of the Vertical SUMMIT IP System.

This system should be kept free of dust, moisture, high temperature (more than 40

degrees) and vibration, and should not be exposed to direct sunlight.

Never attempt to insert wires, pins, etc. int o the system. If the system does not operate

properly, the equipment should be repaired by an authorized Ericsson-LG Enterprise

service center.

Do not use benzene, paint thinner, or an abrasive powder to clean the KSU. Wipe it with a

soft cloth only.

This system should only be installed and serviced by qual ified service personnel.

When a failure occurs which exposes any internal parts, disconnect the power supply cord

immediately and return this system to your de aler.

To prevent the risk of fire, electric shock or failure of the sy st em, do not expose this

product to rain or any type of moisture.

To protect the internal components from static electricity, discharge body st atic before

touching connectors and/or components by touching ground or wearing a ground strap.

To reduce the risk of fire, use only No. 26 AWG or la rger (e.g., 24 AWG) UL Listed or CSA

Certified Telecommunication Line Cord.

The Power supply cord is used as the main disconnect device. Ensure that the socket-

outlet is located, installed near the equipment and is easily accessible.

A supplementary equipment earthing conductor i s t o be installed between the product or

system and earth, that is, in addition t o the equipment earthing conductor in the power

supply cord.

Disconnect the Telecom connection before disco nnecting the power connection prior to

relocating the equipment, and reconnect the power first.

This system is equipped with an earthing conta ct pl ug. For safety reasons this plug must

only be connected to an earthing contact socket which has been installed according to

regulations.

WARNING

There is the potential danger of explosion if battery is not correctly replaced.

Replace only with the same or equivalent type recommended by the manufacturer.

Dispose of used batteries according to the manufact urer’s instructions.

Page 13

Vertical SUMMIT IP

Hardware Description and Installation Manual Issue 1.2

3

1.2 About This Manual

This document provides general information covering the description and installation of the

Vertical SUMMIT IP System hardware. While every effort has been taken to ensure the

accuracy of this information, Ericsson-LG Enterprise makes no warranty of accuracy or

interpretations thereof.

The document is divided into ten (10) sections as described in the following. A glossary of

telephony terms and abbreviations is provided in Appendix A.

Section 1 Introduction

This section introduces important safety information and the manual.

Section 2 System Overview

Provides general information on the Vertical SUMMIT IP System, including the system

specifications and capacity.

Section 3 Installation Overview

Describes detailed instructions for planning the installation site and procedures to install

the Vertical SUMMIT IP System.

Section 4 Board Installation & Description

Provides a description and instructions for installing components of the Vertical SUMMIT IP.

Section 5 Mounting the KSU and EKSU

Provides instructions for mounting the KSU and EKSU.

Section 6 KSU and EKSU Wiring

Provides instructions on wiring the KSU and EKSU including Modular jacks for Lines,

stations, LAN ports, and Miscellaneous connections as well as Earth Grounding and

Battery Backup.

Section 7 Terminal Connections and Wiring

Describes the various terminals, maximum wiring distance, and other device connections

for the terminals.

Section 8 Starting the Vertical SUMMIT IP System

This section provides general information for starting the System, assigning the Nation

code, and running the Installation Wizard.

Section 9 Maintenance & Troubleshooting

Provides information on maintenance the Vertical SUMMIT IP System, replacing the PSU

fuse and deals with common troubleshooting issues.

Section 10 Open Source Software Notice

Provides information on open source software and General Public Licenses.

Page 14

Vertical SUMMIT IP

Hardware Description and Installation Manual Issue 1.2

1

2. SYSTEM OVERVIEW

2.1 Vertical SUMMIT IP System Highlights

The SUMMIT IP system employs a unique digital and IP converge architecture to deliver an

affordable, flexible powerful telecommunications platform for 8 to more than 100 phones that

is easy to install, manage and use. The SUMMIT IP interfaces with analog CO lines, digital

and ISDN lines, and SIP trunks. For flexibility and ease of use, an array of user terminals are

available including proprietary digital and IP multi-button phones, as well as standard SLTs

and SIP phones. Also, terminals are available for mobility including DECT cordless and soft

clients for smart phones and laptops.

The system installs easily by inserting option boards to meet the customer configuration and

wiring with standard modular jacks. Web based management simplifies the admin process

locally or remotely and the Keyset admin is ideal for minor configuration changes desired by

the end-user.

The rich feature set spans all the basic features and functions of a modern communications

platform such as Transfer, Caller Id, MOH, etc. and delivers advanced functions including an

integrated multi-level Auto Attendant and Voice Mail with both mobile and E-mail notification.

In addition, the SUMMIT IP is compatible with Ericsson-LG Enterprise optional advanced

communication applications supporting TAPI, desktop softphones, Unified Communication,

Call Center operation and more. Details on these advanced applications are available in the

respective product manuals available from Ericsson-LG Enterprise.

2.2 General Cabinet Description

The SUMMIT IP system consists of an SUMMIT IP Key Service Unit (BKSU) and, if required,

an Expansion Key Service Unit (EKSU). Each KSU consists of a plastic housing, a Main

board and Power Supply Unit as well as built-in outside line and station interfaces. Optional

Interface and Function boards may be equipped in the SUMMIT IP KSU. In addition, on the

bottom of each KSU are the connections from the SUMMIT IP KSU to the EKSU.

As shown in Figure 2.2-1, on the left side of the SUMMIT IP KSU are connections for Battery

Backup, AC Power and Earth Ground as well as a Power switch. On the right side are

modular jack connections for Stations, external networks (Analog CO and PRI lines), a

Miscellaneous jack, a DB9 for the RS232 serial connection and LAN connections for Web

Admin access and SIP trunks,. In addition, a recessed reset button is located between the

modular jacks for the external networks and the miscellaneous modular jack.

The EKSU, shown in Figure 2.2-2, is similar to the SUMMIT IP KSU except that on the right

side there are no LAN or RS232 connector, and no reset button.

Page 15

Vertical SUMMIT IP

Hardware Description and Installation Manual Issue 1.2

2

Figure 2.2-1 SUMMIT IP KSU Appearance

Figure 2.2-2 EKSU Appearance

Page 16

Vertical SUMMIT IP

Hardware Description and Installation Manual Issue 1.2

3

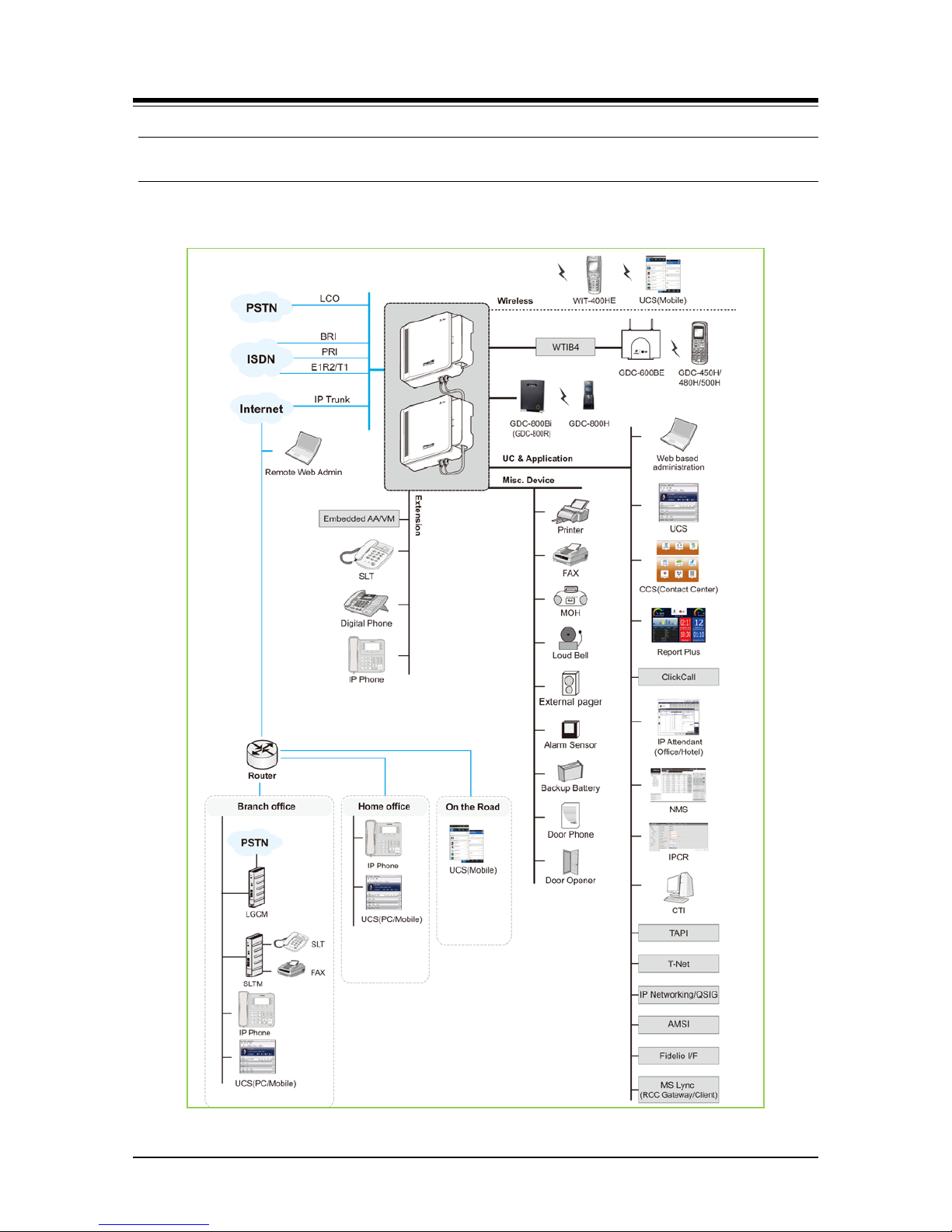

2.3 System Connection Diagram

The following figure represents the interconnections available with the Vertical SUMMIT IP

including external network, terminals, miscellaneous, and admin interfaces.

Figure 2.3-1 System Connection Diagram

SUMMIT IP

Page 17

Vertical SUMMIT IP

Hardware Description and Installation Manual Issue 1.2

4

2.4 System Components

The SUMMIT IP KSU can be equipped with one (1) of three (3) Main Boards (MBUs) and

optional Interface and Function boards. The specific MBU determines the type of external

network and terminal interfaces, and the optional Interface boards that can be installed in an

SUMMIT IP KSU. The Table 2.4-1 below shows all available components for an SUMMIT IP

KSU including the various MBUs, and optional Interface and Function boards. The Table 2.4-2

below indicates the various interface boards available for each MBU as well as the EMBU

(Expansion Main Board Unit) housed in the Expansion KSU.

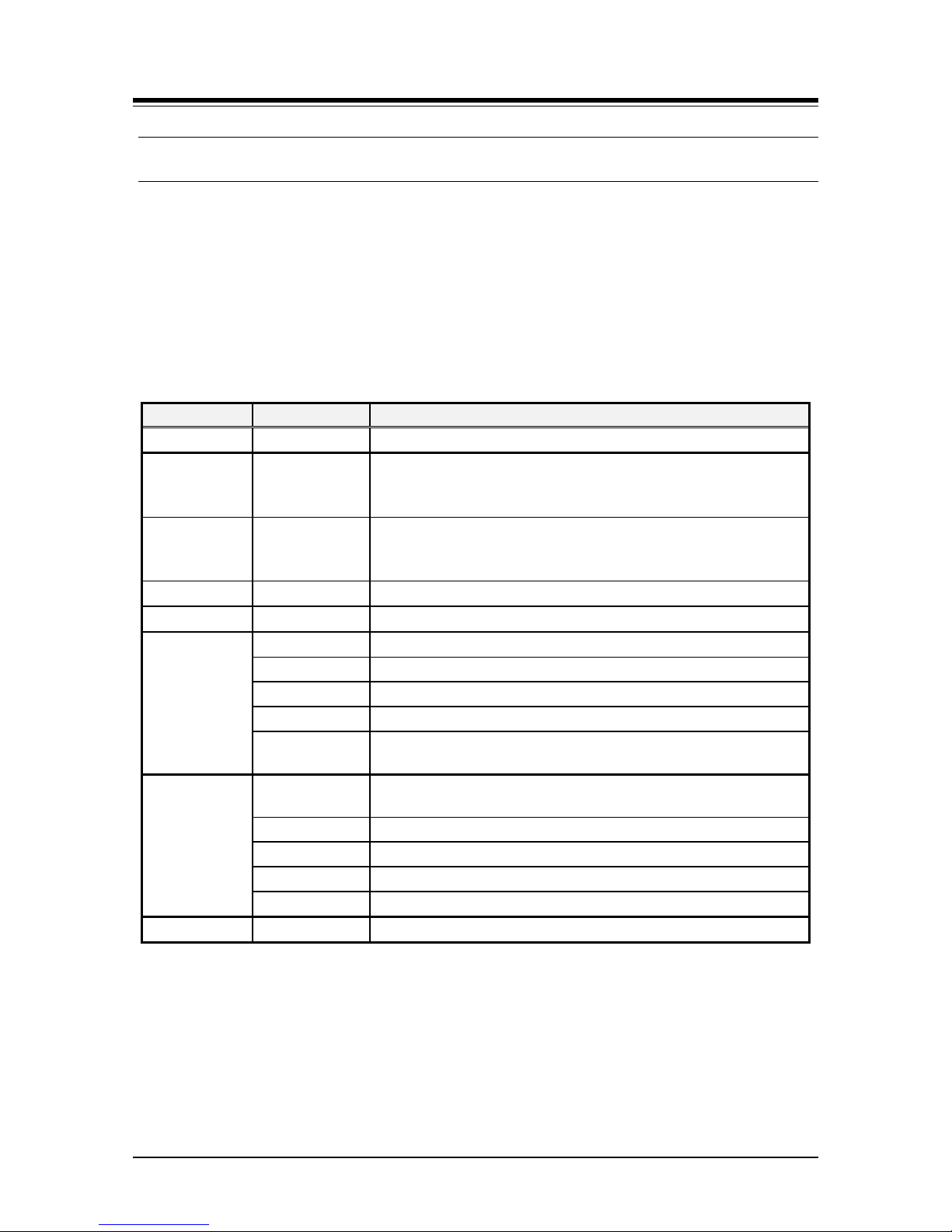

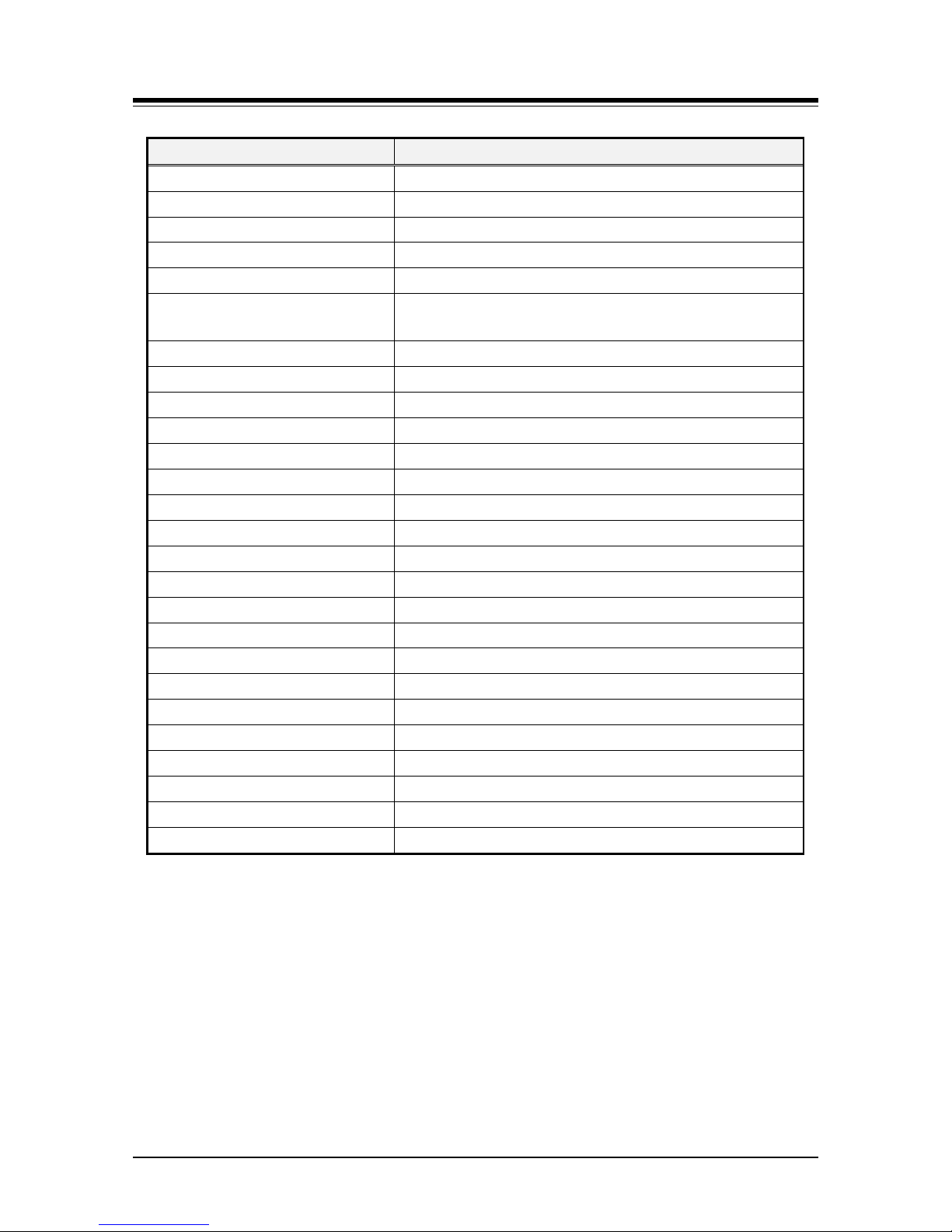

Table 2.4-1 SUMMIT IP Components

Item Board Description

KSU Key Service Unit, KSU and EKSU

KSUAD MBUAD 4 CO, 8 DKT and 4 SLT Interfaces

Voice Mail (4 channels/1 hour default, 8-channel/32 hours Max.)

VoIP (2 channels default, 16 channels Max.)

KSUID MBUID 8 DKT and 4 SLT Interfaces

Voice Mail (4 channels/1 hour default, 8 channels/32 hours Max.)

VoIP (2 channels default, 16 channels Max.)

EKSU EMBU

4 CO and 8 Hybrid

PSU

Power Supply Unit, pre-installed in each cabinet

Interface

Boards

VS-5032-24

2 CO Line and 4 Hybrid Interface Board

VS-5032-48

4 CO Line and 8 Hybrid Interface Board

VS-5033-416

4 CO Line and 16 SLT Interface Board

VS-5035-00

1 PRI or T1 (24 channels) Interface Unit

VS-5032-99

Wireless Terminal Interface Board, supports 4 Base Stations and

24 channels

Function

Boards

VS-5080-00

8 VoIP & VM Channel (by license) and 16 hours for storage

expansion (1 hour default, 15 hours by license)

VOIB48

48 channels for VoIP

VS-5080-01

Memory Expansion Module Unit for VM (15-hour expansion)

MEMU2

Memory Expansion Module Unit for VM (60-hour expansion)

VS-5030-00

Modem Unit

RMB VS-5000-RM Optional 19” Rack Mounting Bracket

Page 18

Vertical SUMMIT IP

Hardware Description and Installation Manual Issue 1.2

5

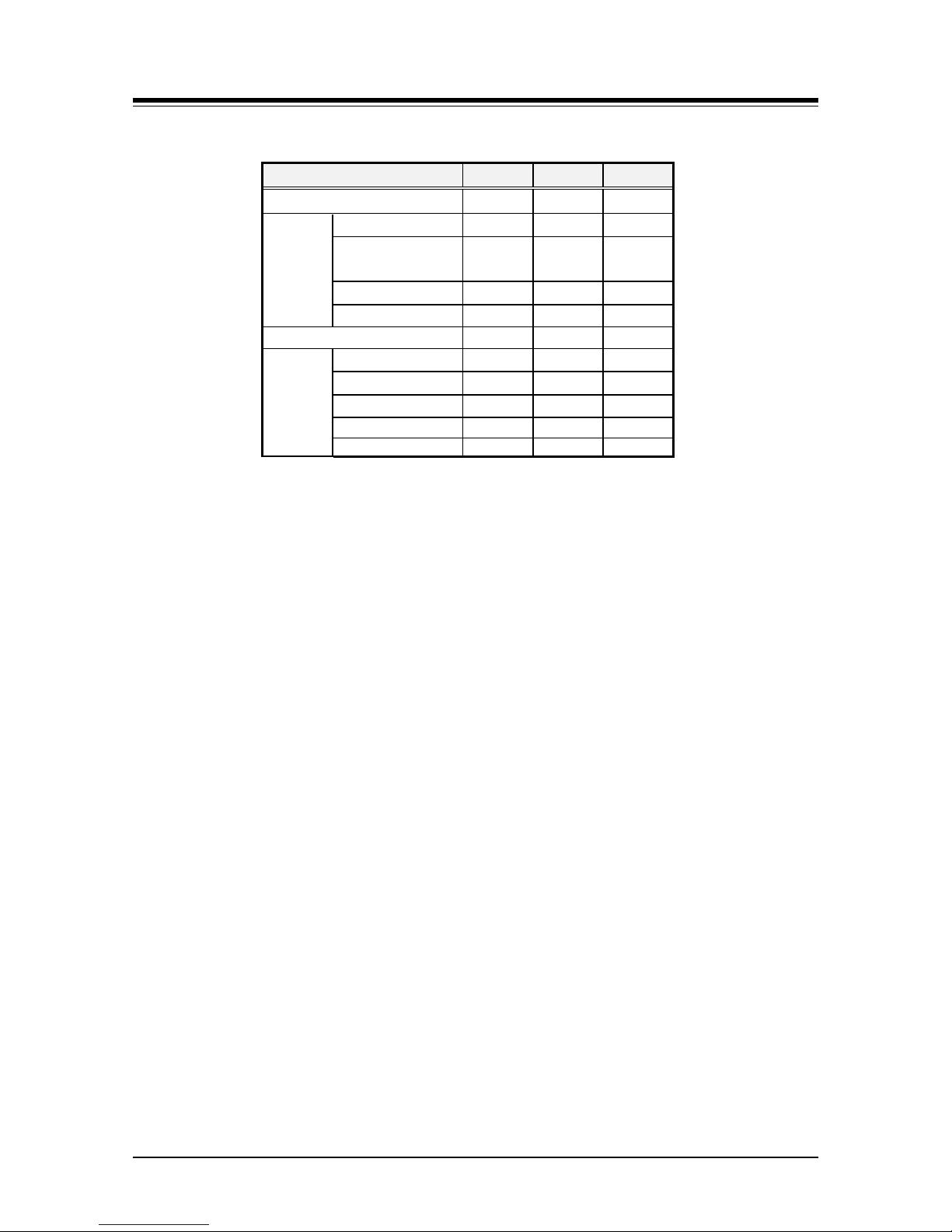

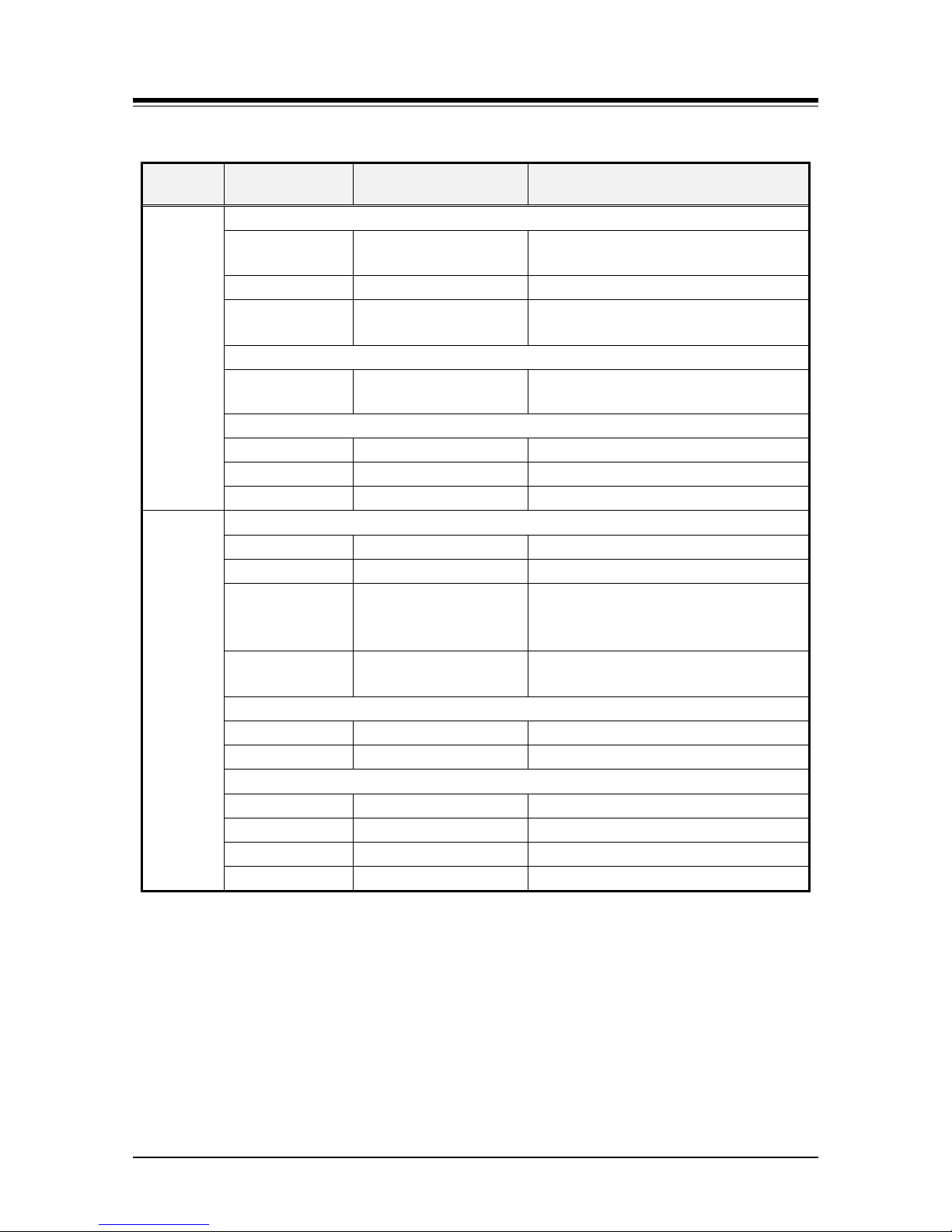

Table 2.4-2 Option Board Compatibility Chart for KSUs

Option Board KSUAD KSUID EKSU

Interface Boards

VS-5032-24

Y Y Y

VS-5032-48

Y Y Y

VS-5033-416

Y Y Y

VS-5035-00 N Y N

VS-5032-99

Y Y N

Function Boards

VS-5080-00

Y Y N

VOIB48

Y Y N

VS-5080-01

Y Y N

MEMU2 Y Y N

VS-5030-00

Y Y N

NOTE

Each KSU permits installation of two (2) Interface boards. However, only one (1) CS416,

SLB16 or WTIB4 Interface board may be installed in a KSU.

Page 19

Vertical SUMMIT IP

Hardware Description and Installation Manual Issue 1.2

6

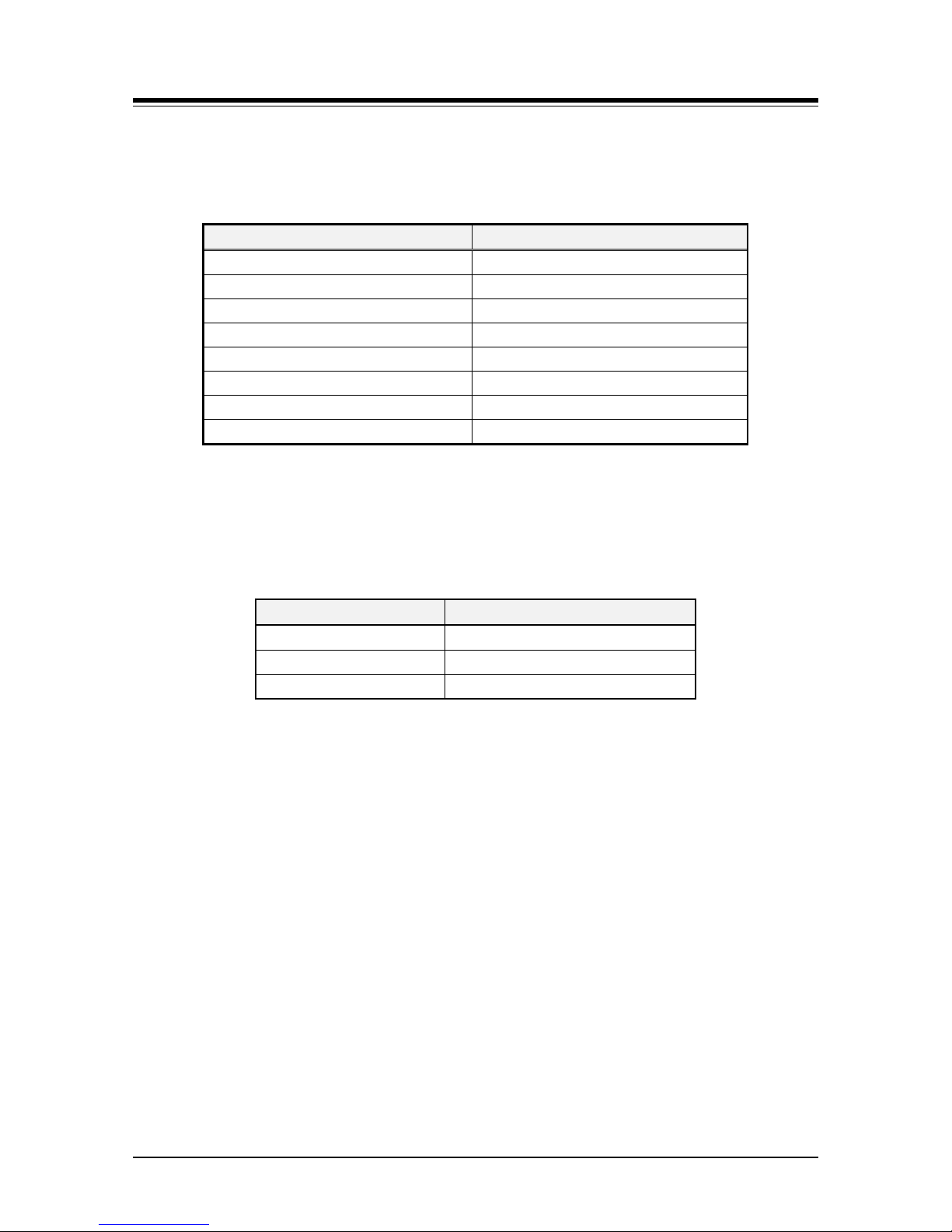

2.5 Specifications

2.5.1 General Specifications

Table 2.5.1-1 General Specifications

Item

Description

Specification

CPU M83261G, ARM11 dual core (32bit, 650MHz)

RTC Back-up Battery

Duration

7 years

PSU

AC Voltage Input 100~240 +/- 10% Volt AC @ 47-63 Hz

AC Power consumption 90 Watts

AC Input Fuse 2A @250 Volt AC

DC Output Voltage +5, -5, +27, +30 Volt DC

External Backup Battery

Input Voltage +24 Volt DC (+12 VDC x 2 each KSU)

Battery Fuse 5.0A @250 Volts AC, 5AG

Charging Current Max. 200 mA

Battery Load Current Max. 3A (KSU only), Max. 6A (KSU+ EKSU)

Ring Signal

65 Vrms @ 25Hz

External Relay Contact

1A @30 Volt DC

Music Source Input

0 dBm @600 ohm

External Paging Port

0 dBm @600 ohm

Ring Detect Sensitivity

30 Vrms @16-55 Hz

DTMF Dialing

Frequency Deviation Less than +/-1.8%

Signal Rise Time 5 ms

Tone Duration, on time Min. 50 ms, Normal 100 ms

Inter-digit Time Min. 30 ms, Normal 100 ms

Pulse Dialing

Pulse Rate 10 PPS

Break/Make Ratio 60/40% or 66/33%

Operating Environment

Temperature 0 (

o

C) - 40 (o C)

Humidity 0 - 80% (non-condensing)

Dimension

KSU 307 mm(W) x 294 mm(H) x126.6 mm(D)

Expansion KSU 307 mm(W) x 294 mm(H) x126.6 mm(D)

Weight

KSU 2.03 Kg

Expansion KSU 1.99 Kg

MODU

Analog Modem Bell, ITU-T, V.34 V.32BIS, V.90

Speed 300 bps up to 33K bps speed rate

Connection Automatic rate negotiation

VoIP

LAN Interface 10/100 Base-T Ethernet (IEEE 802.3)

Speed 10/100 Mbps (Auto-Negotiation)

Duplex Half or Full Duplex (Auto-Negotiation)

VoIP Protocol SIP and H.323 Revision 2

Voice Compression G.711/G.726/G.729/G.723.1

Voice/Fax Switching T.38

Echo cancellation G.165

Page 20

Vertical SUMMIT IP

Hardware Description and Installation Manual Issue 1.2

7

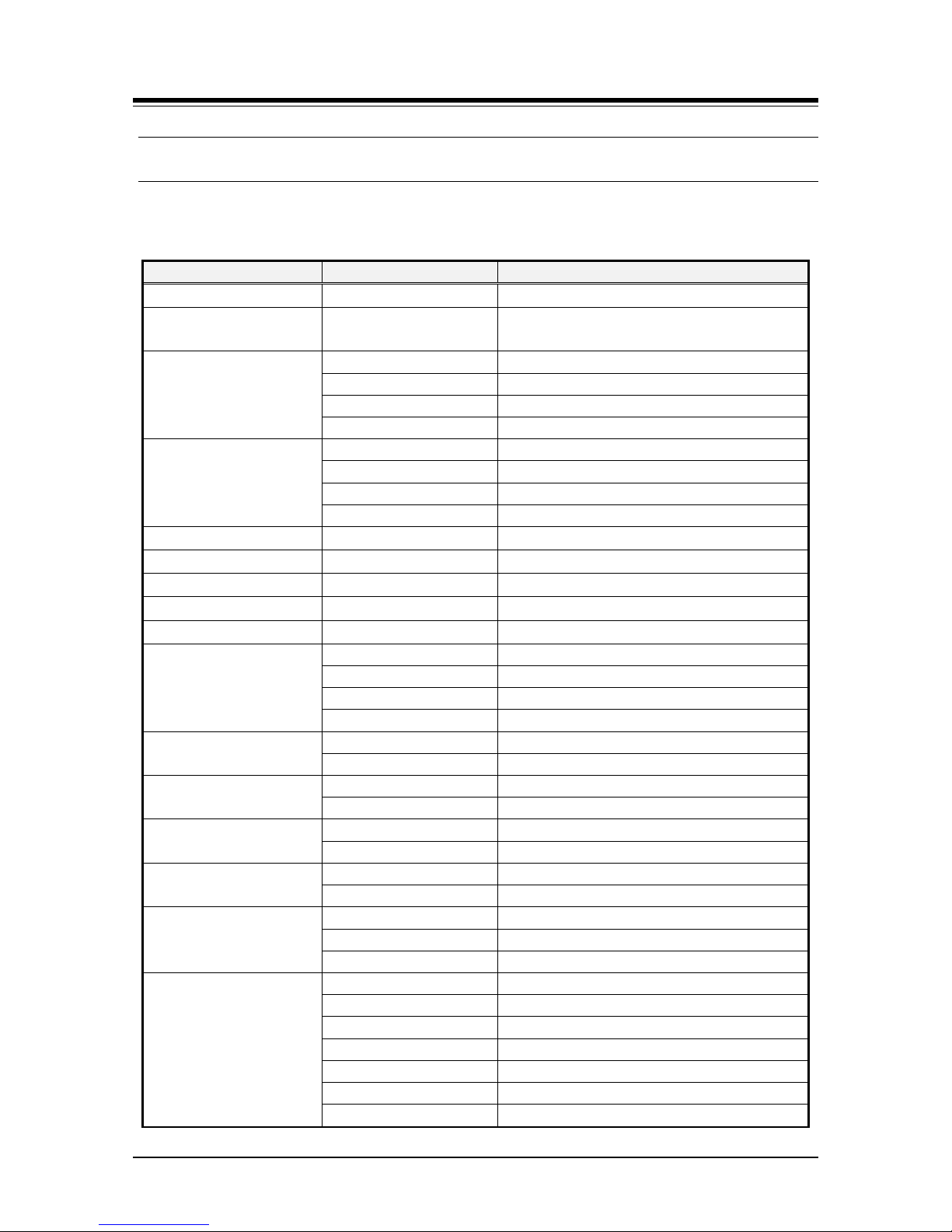

2.5.2 System Capacity

Five System Capacity charts are provided below. These include the General System

Maximum Capacities, Table 2.5.2-1, and the capacity charts for each SUMMIT IP KSU

type in Table 2.5.2-2 to Table 2.5.2-3. Note that the maximums are not simultaneously

achievable. However, the maximum number of VoIP channels is separate from other

external network and station maximums. That is, up to 16 VoIP channels are available in

addition to CO and PRI Lines. Also, the 48 DECT stations are separate from other station

maximums.

Table 2.5.2-1 General System Capacities

Item Capacity

CO/Trunk lines Max. 74

Stations Max. 140

Attendants 4

LAN port 2 (1 each SUMMIT IP KSU and VVMU)

Modem Channel 1 (MODU)

Serial Port(RS-232C) 1

USB(2.0) Host port 1

Alarm/Doorbell input 2 (1 per KSU)

External Control Relays 2 (1 per KSU)

Music Source Inputs

1 Internal: select one of 13 melodies

1 External source input

5 SLT ports

3 VSF announcements

Power Fail Circuit

Max. 6 (1 per SUMMIT IP KSU, EKSU, CH204, CH408,

CS416)

VSF Device 1: Built-in AA/VM

w/MEMU

w/MEMU2

VSF Device 2: (VVMU)

8 channels (4 default, 1 by license), 1 hour

15 hours (no license required)

60 hours (no license required)

8 channels (by license) & 15 hours (by license), 1 hour (by

default)

Conference channels 148 channels/13 party per group

WTIB 1

DECT Phones 48

Built-in VoIP channels 8 channels (2 default, 6 by license)

VVMU VoIP channels 8 channels by license

VOIB48 VoIP channels 48 channels by license

IP Stations and SIP Trunks 48 port (32 Stations+16 SIP Trunks)

External Page 1 port

Internal Page 35 zones

Page 21

Vertical SUMMIT IP

Hardware Description and Installation Manual Issue 1.2

8

Item Capacity

System Speed Dial 3000 numbers, 25 digits each

System Speed Dial Zones (Groups) 10 zones

Station Speed Dial 100 per station, 25 digits each (Max. 4000 numbers)

Last Number Redial 10 numbers

Save Number Redial 1 number

Call Log(Outgoing/Incoming/Missed

Call)

15 ~ 50, 23 digits (programmable)

DSS Consoles per Station 3

Serial DSS - System 100

Serial DSS – Station (LIP-8000) 4

Serial DSS – Station (LIP-9000) 1

SMDR buffer 5000

CO Line Groups 20

Station & Station Groups 40

Station & Station Group Members 70

Pickup Group 50

Pickup Group Member 140

Conference Groups - System 40

Conference Groups - Station 20 per station

Executive/Secretary pairs 36

Authorization Codes 500 (Station: 140, System: 360)

Transparent Networking Table 15

ICLID Routing table 250

Tenancy (ICM) Group 15

Attendant Station 4

DID Digits Analysis 4

MSN Table 500

Page 22

Vertical SUMMIT IP

Hardware Description and Installation Manual Issue 1.2

9

Table 2.5.2-2 KSUAD Device Type Maximums

Resource

Type

Device Maximum Capacity Interface Boards

External

Network

KSUAD: 4 CO & 8 DKT+4 SLT & 2 VoIP

CO Line 12

2 CH408/CD408 or 1 CH408/CD408 + 1

CS416

SIP Trunk 56 channels

VOIU (8) + VOIB48

Shared w/Local/Remote IP &SIP phones

EKSU

CO Line 12

2 CH408/CD408 or 1 CH408/CD408 + 1

CS416

KSUAD + EKSU

CO Line 24

SIP Trunk 56 channels

Stations

KSUAD

DKT 24 & 4 SLT 2 CH408/CD408

SLT 28 & 8-DKT 1 CH408 + 1 CS416

LIP/SIP 96

VOIU (8) + VOIB48

Shared w/SIP Trunks

56 simultaneous calls

DECT 48 24 simultaneous calls

EKSU

DKT 24 2 CH408/CD408

SLT 32 1 CH408 +1CS416

KSUAD + EKSU

DKT 48 & 4SLT

SLT 60 & 8-DKT

LIP/SIP 96 SIP Phones require per seat license

DECT 48

NOTE

Maximum non-blocking configuration: 40 CO Lines (24 analog CO Line + 16 S IP trunks)

108 Stations (68 SLT/DKT + 16 IP Phones + 24 DECT)

Page 23

Vertical SUMMIT IP

Hardware Description and Installation Manual Issue 1.2

10

Table 2.5.2-3 KSUID Device Type Maximums

Resource

Type

Device Maximum Capacity Interface Boards

External

Network

KSUID: 0 CO & 8 DKT + 4 SLT & 2 VoIP

CO Line 8

2 CH408/CD408 or 1 CH408/CD408 + 1

CS416

PRI/T1 Line 23+1/24 channels 1 PRIU

SIP Trunk 56 channels

VOIU (8) + VOIB48

Shared w/Local/Remote IP &SIP phones

KSUID

CO Line 12

2 CH408/CD408 or 1 CH408/CD408 + 1

CS416

KSUID + EKSU

CO Line 20

PRI/T1 Line 23+1/24 channels

SIP Trunk 56 channels

Stations

KSUID

DKT 24 & 4 SLTs 2 CH408/CD408

SLT 28 & 8-DKT 1 CH408 + 1 CS416

LIP/SIP 96

VOIU (8) + VOIB48

Shared w/SIP Trunks

56 simultaneous calls

DECT 48

WTIB4

24 simultaneous calls

EKSU

DKT 24 2 CH408

SLT 32 1 CH408 +1CS416

KSUID + EKSU

DKT 48 & 4 SLT

SLT 60 & 8-DKT

LIP/SIP 96 SIP Phones require per seat license

DECT 48

NOTE

Maximum non-blocking configuration: 60 CO Lines (20 analog CO Line + 24 T1 Lines + 16 SI P

trunks)

108 Stations (68 SLT/DKT + 16 IP Phones + 24 DECT)

Page 24

Vertical SUMMIT IP

Hardware Description and Installation Manual Issue 1.2

11

2.5.3 Base station specification (GDC-600BE)

Table 2.5.3-1 DECT Base Station Specifications

Item Specification

Power feeding +30VDC

Transmission Max Power 100mW

Access Method/Duplex TDMA/TDD

Frequency Band 1,920~1,930MHz

Channel Spacing 1.728MHz

Modulation GFSK

Data rate 1.152Mbps

Base Station distance to WTIB4 600m (twisted 2-pair cable) maximum

2.5.4 Wireless Terminal specification (GDC-450H/480H/500H)

Table 2.5.4-1 DECT Handset Specifications

Item

Specification

Transmission Power 250mW maximum

Modulation Method GFSK

Frequency Band 1,920MHz ~ 1,930MHz

Page 25

Vertical SUMMIT IP

Hardware Description and Installation Manual Issue 1.2

12

3. INSTALLATION OVERVIEW

3.1 Pre-Installation Guidelines

Please read the following guidelines concerning installation and connection before installing

the Vertical SUMMIT IP System. Be sure to comply with applicable local regulations.

3.1.1 Safety Installation Instructions

When installing the telephone wiring, basic safety precautions, including those below,

should always be followed to reduce the risk of fire, electric shock and personal injury:

Never install the telephone wiring during a lightning storm.

Never install the telephone jack in wet locations unless the jack is specifically

designed for wet locations.

Never touch non-insulated telephone wires or terminals unless the telephone line

has been disconnected at the network interface.

Use caution when installing or modifying telephone lines.

Anti-static precautions should be taken during installation of optional boards in a

KSU.

3.1.2 Installation precautions

The Vertical SUMMIT IP KSUs are designed for desktop mounting, wall mounting or a freestanding rack mounting. In no case should one cabinet be mounted on top of the other

when desktop mounting. Avoid installing in the following places:

In direct sunlight and hot, cold, or humid places. Temperature range = 0

o

C to 40oC.

Places where shocks or vibrations are frequent or strong.

Dusty places or places where water or oil may come into contact with the KSU or

wiring.

Near strong RF generating devices such as sewing machines or electric welders.

On or near computers, fax machines, or other office equipment, as well as

microwave ovens or air conditioners.

Do not obstruct the openings in cabinets of the Vertical SUMMIT IP.

Do not stack the optional service boards.

Page 26

Vertical SUMMIT IP

Hardware Description and Installation Manual Issue 1.2

13

3.1.3 Wiring Precautions

Be sure to follow these precautions when wiring:

Do not wire the telephone cable in parallel with an AC power source to a computer,

fax machine, etc. If the cables are run near such wires, shield the cables with metal

tubing or use shielded cables and ground the shields.

If the cables are run on the floor, use protectors to prevent the wires from being

stepped on. Do not place wiring under carpets.

Avoid using the same power supply outlet for computers, fax machine, and other

office equipment to avoid induction of electrical noise into the system resulting in

poor audio quality or static.

The power and battery switches must be OFF during wiring. Further, while wiring,

power must not be connected to the SUMMIT IP KSU. After wiring is completed, the

power can be connected and the switch may be turned ON.

Incorrect wiring may cause the Vertical SUMMIT IP System to operate improperly.

If an extension does not operate properly, disconnect the telephone from the

extension line and then re-connect, or turn the System power OFF and then ON

again.

Use twisted pair cable for connecting CO lines.

3.1.4 Checking Power cord

Checking the power cord at least once a year to prevent fire hazard or electric shock.

Be sure to disconnect the power cord from the wall outlet and System’s inlet for the following

symptoms:

1. Burn marks on the plug.

2. The prongs on the plug are deformed.

3. The power cord’s inner wires are exposed, broken, etc.

4. The power cord’s coating has a crack.

5. The power cord is overheating.

6. The power cord is damaged.

If the above symptoms find, do not use the power cord and consult your dealer or service

representative.

The following is the simple guide to avoid the hazard or disaster:

1. Make sure Power cord is properly rated for their intended use, indoor or outdoor, and

meet or exceed the power needs of the system being used.

2. Inspect cords for damage before use. Check for cracked or frayed sockets, loose or

bare wires, and loose connections.

3. Never use a cord that feels hot or is damaged in any way.

4. Insert plugs fully so that no part of the prongs is exposed when the power cord is in use.

Make sure that the power cord is connected to the system firmly, and then connect the plug to

the wall outlet.

Page 27

Vertical SUMMIT IP

Hardware Description and Installation Manual Issue 1.2

14

3.2 Installation Overview

The installation is conducted in 7 steps as indicated in the below list.

1. Pre-Install preparations, section 3.3

2. Install Interface and Function boards, section 4

3. Mount the KSU and EKSU, section 5

4. Wire the KSU and EKSU, section 6

5. Terminal Installation and Wiring, section 7

6. Power-up & run Wizard, section 8

7. DECT Installation, refer to the DECT manuals, GDC-600TBE (CRS tool) and GDC600BE Manual, available from the local Ericsson-LG Enterprise representative.

3.3 Preparation

In preparation for the installation, locate an appropriate site for the KSU installation

considering the precautions mentioned in earlier sections, wiring, access to power, etc. Also,

if installing DECT, locate the best estimated position for the Base Stations. The permanent

location of the Base Station will be determined using the GDC-600TBE CSR Tool to perform a

RF coverage survey.

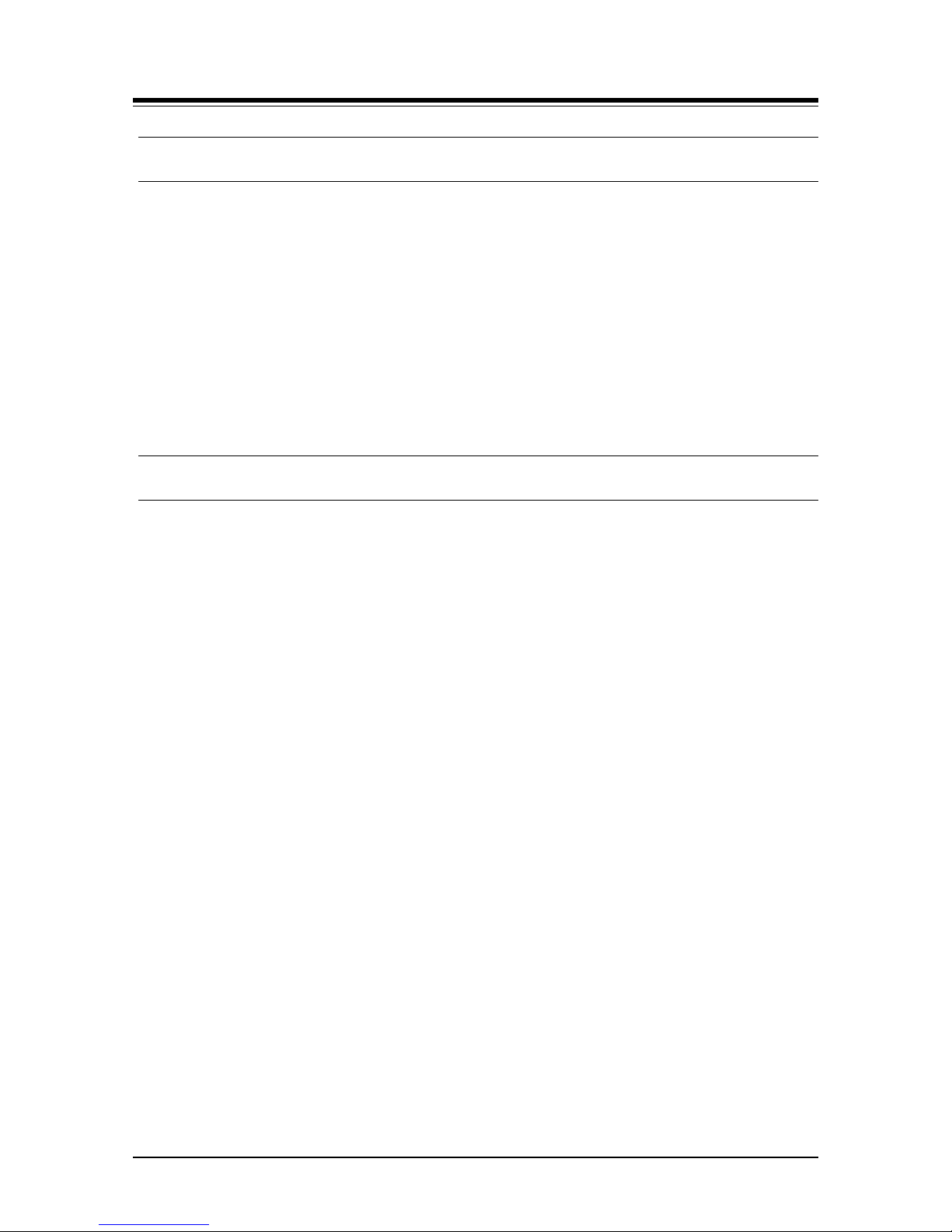

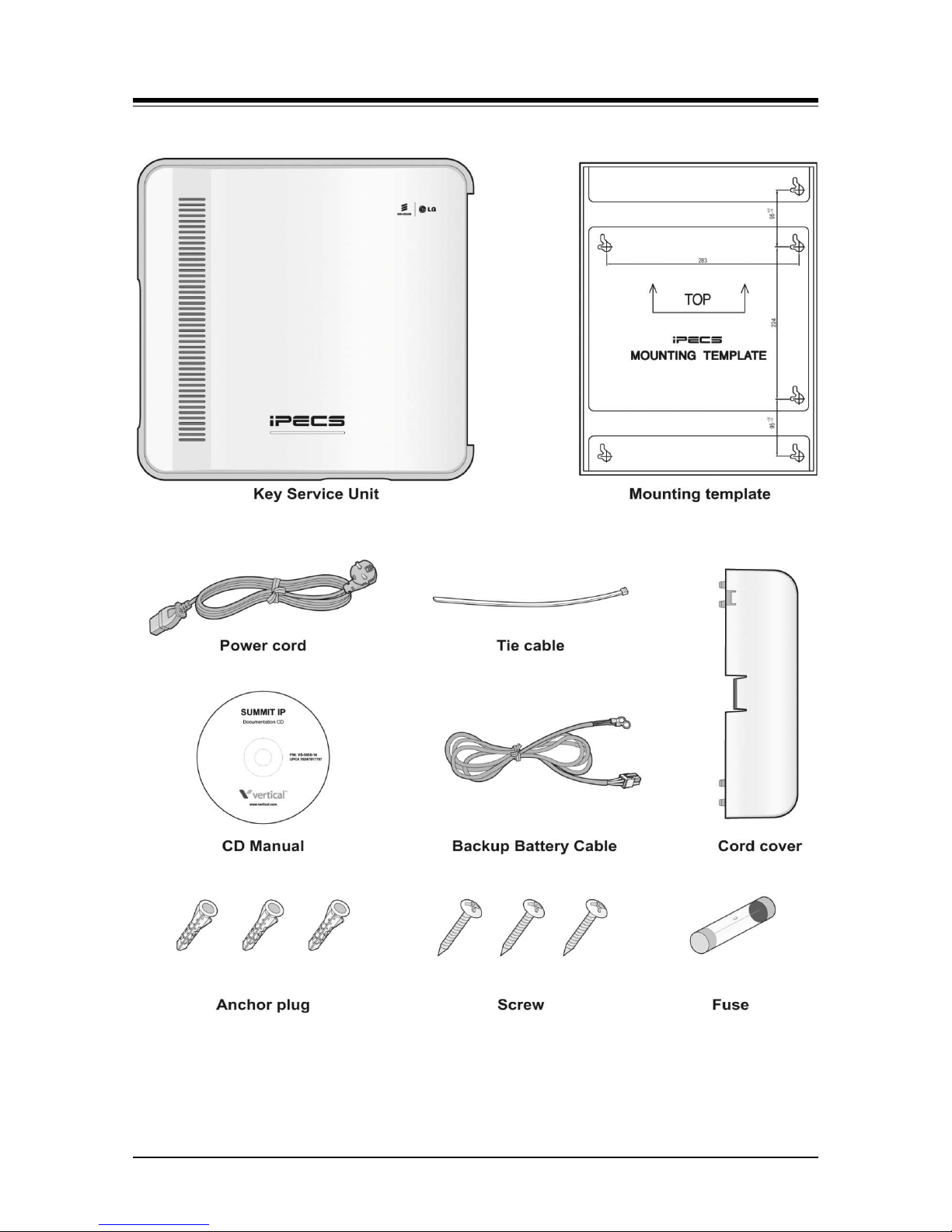

Once the mounting site is identified, verify all equipment and wiring charts are available onsite. Unpack the SUMMIT IP KSU and, if required, the EKSU and verify the contents include

the items shown in Figure 3.1 and 3.2.

Note the Expansion cable is provided only with the Expansion KSU.

Page 28

Vertical SUMMIT IP

Hardware Description and Installation Manual Issue 1.2

15

Figure 3.1 SUMMIT IP KSU Carton Contents

Page 29

Vertical SUMMIT IP

Hardware Description and Installation Manual Issue 1.2

16

Figure 3.2 EKSU Carton Contents

Page 30

Vertical SUMMIT IP

Hardware Description and Installation Manual Issue 1.2

17

4. BOARD INSTALLATION AND DESCRIPTION

4.1 General information

The SUMMIT IP KSU houses the Main Board with processor, memory and interface circuitry.

Optional Interface boards are installed on the MBU to expand the external network interfaces

as well as terminals available. Both the KSU and Expansion KSUs can be equipped with two

(2) optional Interface boards. In addition, optional Function boards can be installed on the

KSU MBU to enhance various system functions. This section provides descriptions of the

various components and step by step instructions to mount the option boards.

4.2 Removing and Replacing the KSU & Cord Cover

Prior to installing option boards in the KSU or EKSU, it is necessary to remove the KSU and

Cord covers. To remove the cord & KSU cover and expose the MBU:

1. Locate and remove the Cord cover hold-down screw as shown in #1 in the below

figure.

2. Press down slightly on the top of the Cord cover to be away from the KSU.

3. Remove the two screws holding the KSU cover as shown in #3 in the below figure.

4. Lift the front of the KSU cover in the direction of the arrow.

5. Remove the cover. Be sure to place both covers in a safe location.

Figure 4.1 Opening the KSU and Cord Cover

NOTE

For safety, prior to operation, replace the KSU and Cord cover before operating the

SUMMIT IP.

Page 31

Vertical SUMMIT IP

Hardware Description and Installation Manual Issue 1.2

18

To replace the covers, reverse the removal procedure as below.

1. Insert the tabs of the KSU cover into the KSU slots.

2. Press the KSU cover down on to the KSU.

3. Insert the screws and tighten screws with screwdriver to fix the front cover.

4. Install the Cord cover

5. Insert and tighten the cover hold-down screw.

Page 32

Vertical SUMMIT IP

Hardware Description and Installation Manual Issue 1.2

19

4.3 Installation of Option Boards

Prior to installing any option board, assure power is OFF. We recommend wearing a wriststrap connected to a known ground. At a minimum, before touching any board discharge any

built-up static charge by touching a grounded object.

To install a board, perform the following Steps as depicted in Figure 4.4 below:

1. Remove the KSU and Cord cover as detailed in section 4.2.

2. For an Interface board, remove the modular jack cover plate as shown in #1.

3. If the board is provided with standoffs, remove two screws holding the MBU in the

locations indicated in the figure.

4. Insert 2 standoffs through the MBU and into the cabinet. Tighten the standoffs with

Wrench as shown in #2.

5. Holding the board as shown in #3, insert the board carefully in the direction of the

arrow.

6. Carefully align the connector on the board with the mating MBU connector pins, then

push the board down to fully engage the connectors.

7. To securely fix the board in place, insert and tighten 2 screws as shown in #5.

Figure 4.2 Board Installation

Page 33

Vertical SUMMIT IP

Hardware Description and Installation Manual Issue 1.2

20

4.4 SUMMIT IP KSU Main Board Unit (MBU)

One of two (2) MBUs (MBUAD or MBUID) is factory install in the SUMMIT IP KSU. The

specifics of each MBU are discussed in sections 4.4.1 to 4.4.2.

4.4.1 MBUAD (Main Board Unit)

Description

The MBUAD, which is shown in Figure 4.4.1-1, controls communication between the

peripheral interfaces, supervises all resources in the system, controls the gain adjustment

of the PCM signal, generates the System tones, and manages System call processing. The

MBUAD contains switches for database protection and initialization. A built-in LAN port

provides access to the SUMMIT IP Web Admin and basic VoIP channels. In addition, a

USB port is provided to allow backup and restore of the system database.

The MBUAD has 4 (four) CO lines, eight (8) DKT station and 4 SLT interfaces, and two (2)

VoIP channels. The CO line ports support loop start CO lines with detection of supervisory

signals including Caller Identification (CID), Polarity Reversal (PR) and Call Progress Tone

(CPT) detection.

The SLT line interface of the Hybrid ports supports FSK (ITU-T V.23 or Bell 202) or DTMF

(ITU-T Q.23) Caller ID and the Message Wait Indication (MWI), DTMF detection, sinusoidal

ringing generator, -48V DC feeding voltage, current limiting and GR-909 Line Testing

function.

A VoIP channel is required to support each SIP Trunk line, LIP or SIP Phone, and remote

users and devices. The two (2) basic VoIP channels on the MBU can be increased to eight

(8) with an unlock code.

As shown in the figure, the MBU has connectors for the various option boards including

connector CN1 which is used to connect optional Interface boards. A maximum of two (2)

Interface boards can be installed with the first board mounted on the CN1 connector of the

MBU and the second mounted on the pass-through connector on the first board. Interface

boards available for the MBUAD include:

CH204 - CO Line & Hybrid board, 2 CO & 4 Hybrid ports

CH408 - CO Line & Hybrid board, 4 CO & 8 Hybrid ports

CD408 – CO Line and Digital telephone board, 4 CO & 8 DKT ports

HYB8 - Hybrid board, 8 Hybrid ports

CS416 - CO Line & SLT Board, 4 CO & 16 SLT ports

SLB16 - SLT board, 16 SLT ports

DTIB8 – Digital telephone board, 8 DKT ports

WTIB4 - Wireless Terminal Interface board, 4 Base Station ports

Page 34

Vertical SUMMIT IP

Hardware Description and Installation Manual Issue 1.2

21

Figure 4.4.1-1 MBUAD

The following are included on the MBUAD:

4 CO Line interface circuits

8 DKT interface circuits

4 SLT interface circuits

1 External Relay contact for LBC or general purpose

1 Alarm detection circuit, External Page port, and External MOH port

Internal MOH (13 music resources)

Built-in VoIP channels (default 2 channels, maximum 8 channels with license)

Built-in VM channel (default 2 channels, maximum 4 channels with license)

Master Clock Generation & PLL circuit

1 PFT circuit [CO1 connects to the last SLT port (STA12)]

1 RS-232C Interface circuit

1 LAN Interface & USB interface circuit

PCM Voice Processing circuit (ACT2 - ASIC, voice switching, including DSP)

- PCM Tone Generation and PCM Gain Control

- Tone (DTMF/CPT/FAX) detection and CID Signal (FSK/DTMF/RUS CID)

detection

NOTE

Should AC Power fail, the last SLT port on MBU is connected automatically to CO1.

Connectors, Jacks and Switches

The following chart lists the various connectors for option boards, RJ modular jacks for

connecting CO Lines, Stations and miscellaneous functions, and switches on the Main

Board.

Page 35

Vertical SUMMIT IP

Hardware Description and Installation Manual Issue 1.2

22

Table 4.4.1-1 KSU with MBUAD Connector, Modular Jack and Switch Function

Connector

Functions

Remark

CN1 CO and Extension board i nst al lation 70 pins

CN3 VVMU/VOIB48 Installation 32 pins

CN4 MODU Installation 20 pins

CN5 & CN6 Connection KSU to EKSU with Expansion cable 19 pins x 2

CN7 PSU Connector 7 pins

CN8 & CN9 MG-CMU4 Installation Not used

CN10 FPGA JTAG for development 10 pins

CN11 RS-232C Port Connection 9 pins

CN12 CPU JTAG for development 20 pins

CN15 MEMU/MEMU2 Installation 20 pins

MJ1

CO lines 1 & 2

2 ports each

CO lines 3 & 4

MJ2 8 DKT and 4 SLT ports 12 ports

MJ3 LAN & USB Port 1 LAN/1 USB

MJ4 Relay/Alarm/Page/External MOH Connection 1 Port

SW1 2 pole Database protect switch

SW2 Push-button System reset switch

Switch setting

Table 4.4.1-2 MBUAD SW1 – 2-pole Dip switch

Pole Function

Switch State

Remarks

ON OFF

1

Database

protection

Protect database, no

admin allowed

Unprotect Default = OFF

2

Initialization for

Database

Initialize Database on

reset

Use stored Database Default = ON

LED Indications

Table 4.4.1-3 MBUAD LED Indication

LED Color Description

LD1 Blue Flash 300ms ON and OFF, normal operation

LD2 Blue Station port in use status

ON - A station is in use

OFF - All station are idle

LD3 Green External Clock Synchronization

ON: PLL circuit sync to ISDN interface clock

OFF: PLL circuit sync to internal clock

Page 36

Vertical SUMMIT IP

Hardware Description and Installation Manual Issue 1.2

23

4.4.2 MBUID (Main Board Unit)

Description

The MBUID, which is shown in Figure 4.4.2-1, controls communication between the

peripheral interfaces, supervises all resources in the system, controls the gain adjustment

of the PCM signal, generates the System tones, and manages System call processing. The

MBUID contains switches for database protection and initialization. A built-in LAN port

provides access to the SUMMIT IP Web Admin and basic VoIP channels. In addition, a

USB port is provided to allow backup and restore of the system database.

The MBUID has eight (8) DKT and four (4) SLT station interface ports, and two (2) VoIP

channels. The SLT interfaces support FSK (ITU-T V.23 or Bell 202) or DTMF (ITU-T Q.23)

Caller ID and the Message Wait Indication (MWI), DTMF detection, sinusoidal ringing

generator, -48V DC feeding voltage, current limiting and GR-909 Line Testing function.

A VoIP channel is required to support each SIP Trunk line, LIP or SIP Phone, and remote

users and devices. The two (2) basic VoIP channels on the MBU can be increased to eight

(8) with an unlock code.

As shown in the figure, the MBU has connectors for the various option boards including

connector CN1 which is used to connect optional Interface boards. A maximum of two (2)

Interface boards can be installed with the first board mounted on the CN1 connector of the

MBU and the second mounted on the pass-through connector on the first board. Interface

boards available for the MBUID include:

CH204 - CO Line & Hybrid board, 2 CO & 4 Hybrid ports

CH408 - CO Line & Hybrid board, 4 CO & 8 Hybrid ports

CD408 – CO Line and Digital telephone board, 4 CO & 8 DKT ports

HYB8 - Hybrid board, 8 Hybrid ports

CS416 - CO Line & SLT Board, 4 CO & 16 SLT ports

SLB16 - SLT board, 16 SLT ports

DTIB8 – Digital telephone board, 8 DKT ports

WTIB4 - Wireless Terminal Interface board, 4 Base Station ports

In addition to the CN1 connector, a PRIU may be installed on the CN2 connector.

Page 37

Vertical SUMMIT IP

Hardware Description and Installation Manual Issue 1.2

24

Figure 4.4.2-1 MBUID

The following are included on the MBUID:

8 DKT interface circuits

4 SLT interface circuits

PRIU interface connector

1 External Relay contact for LBC or general purpose

1 Alarm detection circuit, External Page port, and External MOH port

Internal MOH (13 music resources)

Built-in VoIP channels (default 2 channels, maximum 8 channels with license)

Built-in VM channel (default 2 channels, maximum 4 channels with license)

Master Clock Generation & PLL circuit

1 RS-232C Interface circuit

1 LAN Interface & USB interface circuit

PCM Voice Processing circuit (ACT2 - ASIC, voice switching, including DSP)

- PCM Tone Generation and PCM Gain Control

- Tone (DTMF/CPT/FAX) detection and CID Signal (FSK/DTMF/RUS CID)

detection

NOTE

Should AC Power fail, the last SLT port on MBU is connected automatically to CO1.

Connectors, Jacks and Switches

The following chart lists the various connectors for option boards, RJ modular jacks for

connecting CO Lines, Stations and miscellaneous functions, and switches on the Main

Board.

Page 38

Vertical SUMMIT IP

Hardware Description and Installation Manual Issue 1.2

25

Table 4.4.2-1 KSU with MBUID Connector, Modular Jack and Switch Function

Connector Functions Remark

CN1 CO and Extension board i nst al lation 70 pins

CN2 PRIU Installation 40 pins

CN3 VVMU/VOIB48 Installation 32 pins

CN4 MODU Installation 20 pins

CN5 & CN6 Connection KSU to EKSU with Expansion cable 19 pins x 2

CN7 PSU Connector 7 pins

CN10 FPGA JTAG for development 10 pins

CN11 RS-232C Port Connection 9 pins

CN12 CPU JTAG for development 20 pins

CN15 MEMU/MEMU2 Installation 20 pins

MJ2 8 DKT and 4 SLT ports 12 ports

MJ3 LAN & USB Port 1 LAN/1 USB

MJ4 Relay/Alarm/Page/External MOH Connection 1 Port

SW1 2 pole Database protect switch

SW2 Push-button System reset switch

Switch setting

Table 4.4.2-2 MBUID SW1 – 2-pole Dip switch

Pole Function

Switch State

Remarks

ON

OFF

1

Database

protection

Protect database, no

admin allowed

Unprotect Default = OFF

2

Initialization for

Database

Initialize Database on

reset

Use stored Database Default = ON

LED Indications

Table 4.4.2-3 MBUID LED Indication

LED

Color

Description

LD1 Blue Flash 300ms ON and OFF, normal operation

LD2 Blue Station port in use status

ON - A station is in use

OFF - All station are idle

LD3 Green External Clock Synchronization

ON: PLL circuit sync to ISDN interface clock

OFF: PLL circuit sync to internal clock

Page 39

Vertical SUMMIT IP

Hardware Description and Installation Manual Issue 1.2

26

4.5 EKSU Expansion Main Board Unit (EMBU)

Description

The EKSU houses the EMBU, which is shown in Figure 4.6-1 and controls communication

between the EKSU and the installed optional Interface boards and the KSU that controls

the interfaces.

The EKSU has four (4) CO line and eight (8) Hybrid interface ports. The CO line ports

support loop start CO lines with detection of supervisory signals including Caller

Identification (CID), Polarity Reversal (PR), and Call Progress Tone (CPT).

The SLT interface of the Hybrid ports support FSK (ITU-T V.23 or Bell 202) or DTMF (ITUT Q.23) Caller ID and the Message Wait Indication (MWI), DTMF detection, sinusoidal

ringing generator, -48V DC feeding voltage, current limiting and GR-909 Line Testing

function.

As shown in the figure, the EMBU has connector CN1 for the various Interface boards and

connectors, and CN8 and CN9 for installation of the Call metering CO Line daughter board

for the built-in CO lines. A maximum of two (2) Interface boards can be installed with the

first board mounted on the CN1 connector of the EMBU and the second mounted on the

pass-through connector on the first board. Interface boards available for the EMBU include:

CH204 - CO Line & Hybrid board, 2 CO & 4 Hybrid ports

CH408 - CO Line & Hybrid board, 4 CO & 8 Hybrid ports

CD408 – CO Line and Digital telephone board, 4 CO & 8 DKT ports

HYB8 - Hybrid board, 8 Hybrid ports

CS416 - CO Line & SLT Board, 4 CO & 16 SLT ports

DTIB8 – Digital telephone board, 8 DKT ports

SLB16 - SLT board, 16 SLT ports

Figure 4.5-1 EMBU

Page 40

Vertical SUMMIT IP

Hardware Description and Installation Manual Issue 1.2

27

The following are included on the EMBU:

4 CO Line interface circuits

8 Hybrid interface circuits

1 External Relay contact for LBC or general purpose

1 Alarm Detection circuit

1 PFT circuit [CO1 connects to the last SLT port(STA8)]

PCM Voice Processing circuit (ACT2 - ASIC, voice switching, including DSP)

- PCM Tone Generation and PCM Gain Control

- Tone (DTMF/CPT/FAX) detection and CID Signal (FSK/DTMF/RUS CID)

detection

NOTE

Should AC Power fail, the last SLT port on MBU is connected automatically to CO1.

Connectors, Jacks and Switches

The following chart lists the various connectors for option boards, RJ modular jacks for

connecting CO Lines, Stations and miscellaneous functions, and switches on the Main

Board.

Table 4.5-1 EKSU with EMBU Connector, Modular Jack and Switch Function

Connector

Functions

Remark

CN1 CO and Extension board i nst al lation 70 pins

CN5 & CN6 Connection KSU to EKSU with Expansion cable 19 pins x 2

CN7 PSU Connector 7 pins

CN8 & CN9 MG-CMU4 Installation Not used

MJ1

1/2 CO line

2 ports each

3/4 CO line

MJ2 8 Hybrid (DKT or SLT) ports 8 ports

MJ4 Relay/Alarm 1 port

LED Indications

Table 4.5-2 EMBU LED Indication

LED

Color

Description

LD1 Blue Flash 300ms ON and OFF, normal operation toggle

LD2 Blue Station port in use status

ON - A station is in use

OFF - All station are idle

Page 41

Vertical SUMMIT IP

Hardware Description and Installation Manual Issue 1.2

28

4.6 Optional Interface Boards

Optional Interface Boards permit the expansion of the external network and terminal interface

ports available in the SUMMIT IP system are mounted on the Main board in the SUMMIT IP

KSU or EKSU. Interface boards available are shown in the chart below. Note that the boards

that can be installed in a KSU are dependent on the type of Main Board as discussed in

section 4.4.

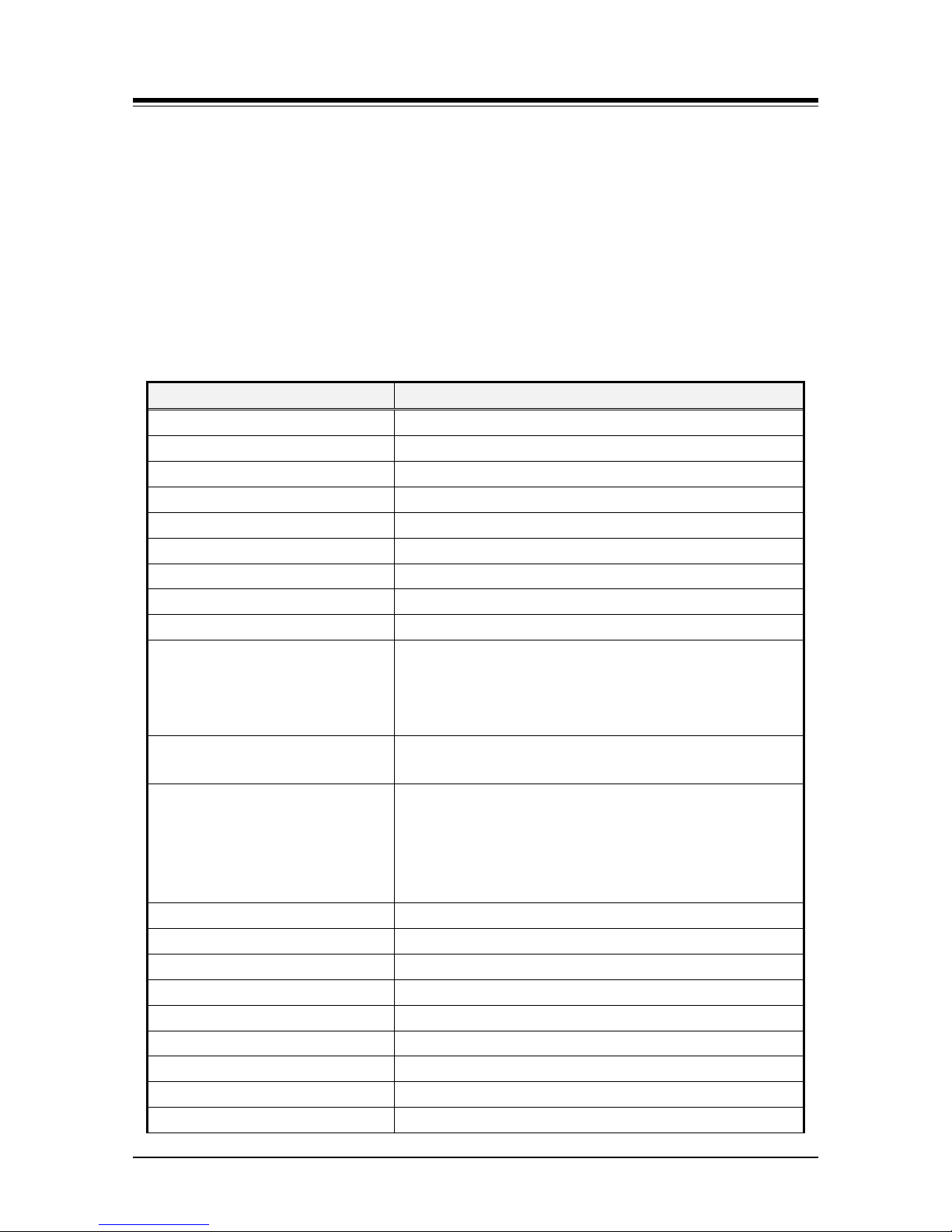

Table 4.6-1 Optional Interface Boards

Board

Description

Connectors

Cable

CH204 2 CO Line & 4 Hybrid ports RJ45 & RJ11 2-wire

CH408 4 CO Line and 8 Hybrid ports RJ45 & RJ11 2-wire

CD408 4 CO Line and 8 DKT ports RJ45 & RJ11 2-wire

CS416 4 CO Line & 16 SLT ports RJ45 & RJ11 2-wire

PRIU 1 PRI (24 T1 channels or 23B + 1D PRI channels) RJ45 4-wire

HYB8 8 Hybrid ports RJ11 2-wire

SLB16 16 SLT ports RJ11 2-wire

DTIB8 8 DKT ports RJ-11 2-wire

WTIB4 4 Base Station ports RJ11 4-wire

The CO line ports of the Interface boards support loop start CO lines with detection of

supervisory signals including Caller Identification (CID), Polarity Reversal (PR), and Call

Progress Tone (CPT). The SLT interface of the Hybrid ports support FSK (ITU-T V.23 or Bell

202) or DTMF (ITU-T Q.23) Caller ID and the Message Wait Indication (MWI), DTMF

detection, sinusoidal ringing generator, -48V DC feeding voltage, current limiting and GR-909

Line Testing function.

Page 42

Vertical SUMMIT IP

Hardware Description and Installation Manual Issue 1.2

29

4.6.1 CH204 (2 CO Line and 4 Hybrid Interface Board)

Description

The CH204 board has two (2) CO line and four (4) Hybrid (DKT & SLT) interface ports. The

board may be installed on the CN1 connector of the KSU.

The board is provided with two Standoffs that must be installed prior to mounting the board.

To install the board in the KSU, refer to Section 4.3.

Figure 4.6.1-1 CH204

Connector and Modular jack

The following chart indicates the connectors and modular jacks equipped on the CH204.

Table 4.6.1-1 Connector and Modular Jack Function

Connector

Functions

Remark

CN1 Pass through to second Interface board 70 pins

CN2 Connection to CN1 connector of MBU 70 pins

CN3 CPLD JTAG for development 10 pins

CN790 & CN791 MG-CMU4 Installation Not used

MJ1 1 & 2 CO line RJ45

MJ2 4 Hybrid DKT or SLT ports RJ11

LED Indications

Table 4.6.1-2 CH204 LED Indications

LED

Color

Description

LD1 Blue Station port in use status

ON – A station port is in use

OFF – All station ports are idle

Page 43

Vertical SUMMIT IP

Hardware Description and Installation Manual Issue 1.2

30

4.6.2 CH408 (4 CO Line and 8 Hybrid Interface Board)

Description

The CH408 board has four (4) CO line and eight (8) Hybrid (DKT & SLT) interface ports.

The board can be installed on the CN1 connector of the KSU.

The board is provided with two Standoffs that must be installed prior to mounting the board.

To install the board in the KSU, refer to Section 4.3.

Figure 4.6.2-1 CH408

Connector and Modular jack

The following chart indicates the connectors and modular jacks equipped on the CH408.

Table 4.6.2-1 Connector and Modular Jack Function

Connector

Functions

Remark

CN1 Pass-through to second Interface board 70 pins

CN2 Connection to CN1 connector of MBU 70 pins

CN3 CPLD JTAG for development 10 pins

CN790 & CN791 MG-CMU4 Installation Not used

MJ1

1 & 2 CO line

RJ45

3 & 4 CO line

MJ2 8 Hybrid DKT or SLT ports RJ11

LED Indications

Table 4.6.2-2 CH408 LED Indications

LED

Color

Description

LD1 Blue Station port in use status

ON – A station port is in use

OFF – All station ports are idle

Page 44

Vertical SUMMIT IP

Hardware Description and Installation Manual Issue 1.2

31

4.6.3 CD408 (4 CO and 8 Digital Interface Board)

Description

The CD408 board has four (4) CO Line and eight (8) Digital Key Telephone interface ports.

The board can be installed on the CN1 connector of the KSU or EKSU as shown in Figure

4.6.3-1 below.

The board is provided with two Standoffs that must be installed prior to mounting the board.