Vertex Standard VX-820 Series, VX-820E Series Service Manual

VERTEX STANDARD CO., LTD.

4-8-8 Nakameguro, Meguro-Ku, Tokyo 153-8644, Japan

VERTEX STANDARD

US Headquarters

10900 Walker Street, Cypress, CA 90630, U.S.A.

VX-820/-820E Series

UHF Band

Service Manual

©2009 VERTEX STANDARD CO., LTD. EC058U90D

YAESU UK LTD.

Unit 12, Sun Valley Business Park, Winnall Close

Winchester, Hampshire, SO23 0LB, U.K.

VERTEX STANDARD HK LTD.

Unit 5, 20/F., Seaview Centre, 139-141 Hoi Bun Road,

Kwun Tong, Kowloon, Hong Kong

VERTEX STANDARD (AUSTRALIA) PTY., LTD.

Normanby Business Park, Unit 14/45 Normanby Road

Notting Hill 3168, Victoria, Australia

Introduction

This manual provides the technical information necessary for servicing the VX-820 Series Transceiver.

Servicing this equipment requires expertise in handing surface-mount chip components. Attempts by non-qualified persons to service this equipment may result in permanent damage not covered by the warranty, and may be illegal in

some countries.

Two PCB layout diagrams are provided for each double-sided board in this

transceiver. Each side of the board is referred to by the type of the majority of

components installed on that side (“Side A” or “Side B”). In most cases one side

has only chip components (surface-mount devices), and the other has either a

mixture of both chip and leaded components (trimmers, coils, electrolytic capacitors, ICs, etc.), or leaded components only.

As described in the pages to follow, the advanced microprocessor design of the

VX-820 Series Transceiver allows a complete alignment of this transceiver to be

performed without opening the case of the radio; all adjustments can be performed from the front panel, using the “Alignment Mode” menu.

While we believe the information in this manual to be correct, VERTEX STANDARD assumes no liability for damage that may occur as a result of typographical or other errors that may be present. Your cooperation in pointing out any

inconsistencies in the technical information would be appreciated.

Important Note

After Lot. 11 of this transceiver was assembled using Pb (lead) free solder, based on the RoHS specification.

Only lead-free solder (Alloy Composition: Sn-3.0Ag-0.5Cu) should be used for repairs performed on this apparatus. The

solder stated above utilizes the alloy composition required for compliance with the lead-free specification, and any solder with

the above alloy composition may be used.

Contents

Specifications...........................................................2

Exploded View & Miscellaneous Parts .................4

Block Diagram ........................................................ 5

Circuit Description ................................................7

Alignment ................................................................9

Board Units (Schematics, Layouts & Parts)

MAIN Unit ....................................................... 15

Display Unit ..................................................... 47

Cable Unit ........................................................ 64

1

Specifications (VTX/EXP Version)

General

Frequency range: 400-470 MHz (Version A)

450-512 MHz (Version D, VTX)

450-520 MHz (Version D, EXP)

Channel / Group: 32 CH / 1 Group (w/o LCD version)

512 CH / 16 Groups (w/ LCD version)

Channel Spacing: 12.5/20/25 kHz

PLL Stepping: 5/6.25 kHz

Power Supply Voltage: 7.4 V

Current Consumption: 30 mA (Standby w/saver)

(Approx. @7.4 V) 75 mA (Standby)

200 mA (Receive)

1.9 A (Transmit)

Battery Life (Approx.): 7 hours (w/ FNB-V86LI)

11.5 hours (w/ FNB-V87LI)

Operating Temperature Range: –22 °F to +140 °F (–30 °C to +60 °C)

Frequency Stability: ±2.5ppm

Case Size (W x H x D): 2.3” x 3.8” x 1.5” (57.5 x 96.5 x 37.5 mm)

Weight (Approx.): 10.9 oz (310g) (w/FNB-V86LI, ATU-6, CLIP-920)

Receiver (Measurement per TIA/EIA-603)

Circuit Type: Double Conversion Super-heterodyne

Sensitivity (12dB SINAD): 0.25 μV/0.32 μV(W/N)

Adjacent Channel Selectivity: 75/70 dB (W/N)

Intermodulation: 75/70 dB (W/N)

Spurious Image Rejection: 75 dB

Audio output: 700 mW @ 16 ohms 5% THD

Transmitter (Measurement per TIA/EIA-603)

RF Power Output: 5/2.5/1/0.25 W

Modulation Type: Direct FM (16K0F3E/11K0F3E)

Maximum Frequency Deviation: ±2.5/±4.0/±5.0 kHz

Audio Distortion: Less than 3% @ 1kHz

Spurious Emissions: 70 dB below carrier

Specifications subject to change without notice or obligation.

2

Specifications (EU Version)

General

Frequency range: 400-470 MHz

Channel / Group: 32 CH / 1 Group (w/o LCD version)

512 CH / 16 Groups (w/ LCD version)

Channel Spacing: 12.5/20/25 kHz

PLL Stepping: 5/6.25 kHz

Power Supply Voltage: 7.4 V

Current Consumption: 30 mA (Standby w/saver)

(Approx. @7.4 V) 75 mA (Standby)

200 mA (Receive)

1.9 A (Transmit)

Battery Life (Approx.): 7 hours (w/ FNB-V86LI)

11.5 hours (w/ FNB-V87LI)

Operating Temperature Range: –30 °C to +60 °C

Frequency Stability: ±2.5ppm

Case Size (W x H x D): 57.5 x 96.5 x 37.5 mm

Weight (Approx.): 310g (w/FNB-V86LI, ATU-6, CLIP-920)

Receiver

Circuit Type: Double Conversion Super-heterodyne

Sensitivity (12dB SINAD): 0.25 μV/0.32 μV(W/N)

Adjacent Channel Selectivity: 75/65 dB (W/N)

Intermodulation: 65 dB (W/N)

Spurious and Image Rejection: 70 dB

Num & Noise: 48/42 dB (W/N)

Audio output: 700 mW @ 16 ohms 5% THD

Transmitter

RF Power Output: 5/2.5/1/0.25 W

Modulation Type: Direct FM (16K0F3E/11K0F3E)

Maximum Frequency Deviation: ±2.5/±4.0/±5.0 kHz

FM Hum & Noise: 45/40 dB (W/N)

Audio Distortion: Less than 3% @ 1kHz

Spurious Emissions: –36 dBm @under 1 GHz

–30 dBm @above 1 GHz

Measurements per: EN 300 086 standards unless noted above.

Specifications subject to change without notice or obligation.

3

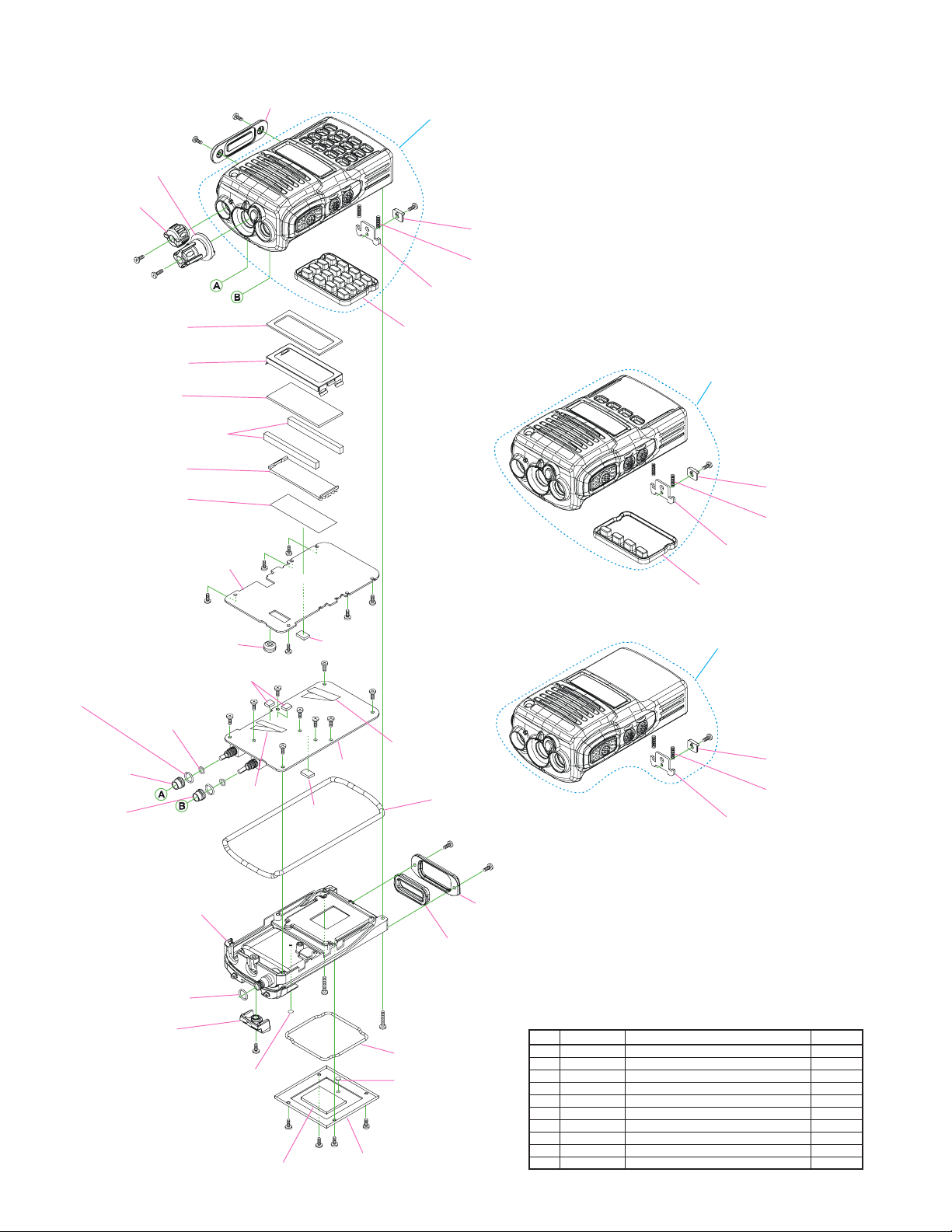

Exploded View & Miscellaneous Parts

RA0611500

ROTARY KNOB (CH)

RA0601700

ROTARY KNOB (VOL)

RA0727300

PAD

RA068970A

FRAME

G6090163

LCD

RA0663700 (x2 pcs)

INTER CONNECTOR

RA0689100

LIGHT GUIDE

RA0698000

REFERECTOR

SHEET

RA0712300

HOLDER RUBBER (SW)

RA0603700 (x2 pcs, WP: STD)

RA0811600 (x2 pcs, WP: HIGH)

O RING

RA060450A

SPECIAL NUT (M)

RA060460A

SPECIAL NUT (L)

RA0603600 (x2 pcs)

O RING (1x4.2)

CP8256001 (IS: OFF)

CP8256002 (IS: ON, WP: STD)

CP8256001 (IS: ON, WP: HIGH)

REAR CASE ASSY

DISPLAY UNIT

RA0731500 (x2 pcs)

PAD (E1)

T9207216

FW-ASSY

RA0601800

SIDE COVER

RA0697900

SHEET (FET)

RA0727300

PAD (LCD)

MAIN UNIT

CP8254003 (Water Proof: Standard)

CP8254006 (Water Proof: High Spec.)

PANEL ASSY (16 KEY)

RA0688700

LATCH NAIL

RA0745400 (x2 pcs)

COIL SPRING

RA060400B

LATCH PLATE

RA0663800

RUBBER KNOB (16KEY)

CP8254002 (Water Proof: Standard)

CP8254005 (Water Proof: High Spec.)

PANEL ASSY (4 KEY)

RA0688700

LATCH NAIL

RA0745400 (x2 pcs)

COIL SPRING

RA060400B

LATCH PLATE

RA070350A

RUBBER KNOB (4KEY)

CP8254001 (Water Proof: Standard)

CP8254004 (Water Proof: High Spec.)

PANEL ASSY (NO KEY)

T9207217

FW-ASSY

RA0602800

GASKET

RA060400B

LATCH PLATE

RA0688700

LATCH NAIL

RA0745400 (x2 pcs)

COIL SPRING

RA0681900

HOLDER PLATE (POW)

RA0607300 (WP: STD)

RA0811500 (WP: HIGH)

O RING (1.8x5.3)

RA0602000

COVER (BAT)

WP: STD = Water Proof: Standard

WP: HIGH = Water Proof: High Spec.

4

RA0729100

BLIND SHEET

RA0697400

PAD (ACS)

RA0664000

RUBBER PACKING (POW)

Non-designated parts are available only as

part of a designated assembly.

RA0663500

GASKET (ACS)

RA0731400 (WP: STD)

RA0775800 (WP: HIGH)

SHEET

RA068950A

COVER (ACS)

Ref.

VXSTD P/N

RA0606200

U00103002

U07230227

U07A35220

U07A60220

U44104002

U44110020

U51106027

U9900094

RA0604400

SPECIAL SCREW

PAN HEAD SCREW

PAN HEAD SCREW

PAN HEAD SCREW

PAN HEAD SCREW

TAPTITE SCREW

TAPTITE SCREW

HEX SOCKET BOLT

TAPTITE SCREW

SPECIAL SCREW

Description

(M2.6X5)

M2X3NI

M2X3BSUS #2

M2X3.5 SUS #2

M2X6 SUS #2

M2X4NI

2X10SUS

M2X6BSUS

M2X5NI #2

(M3X6)

Qty.

2

1

1

4

4

12

2

2

2

1

Ú1: w/ LCD, Ú2: w/o LCD

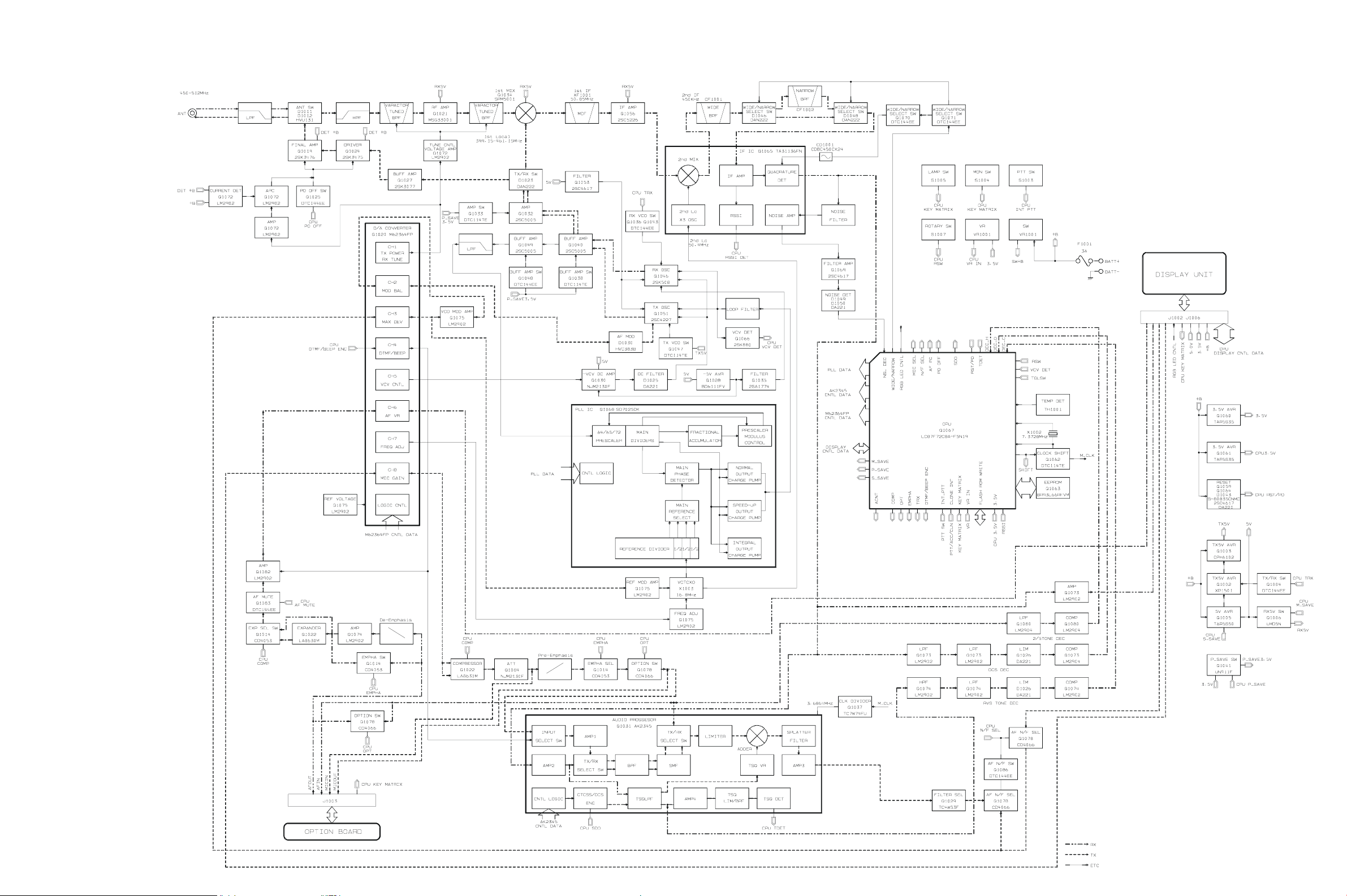

Block Diagram

Main Unit

5

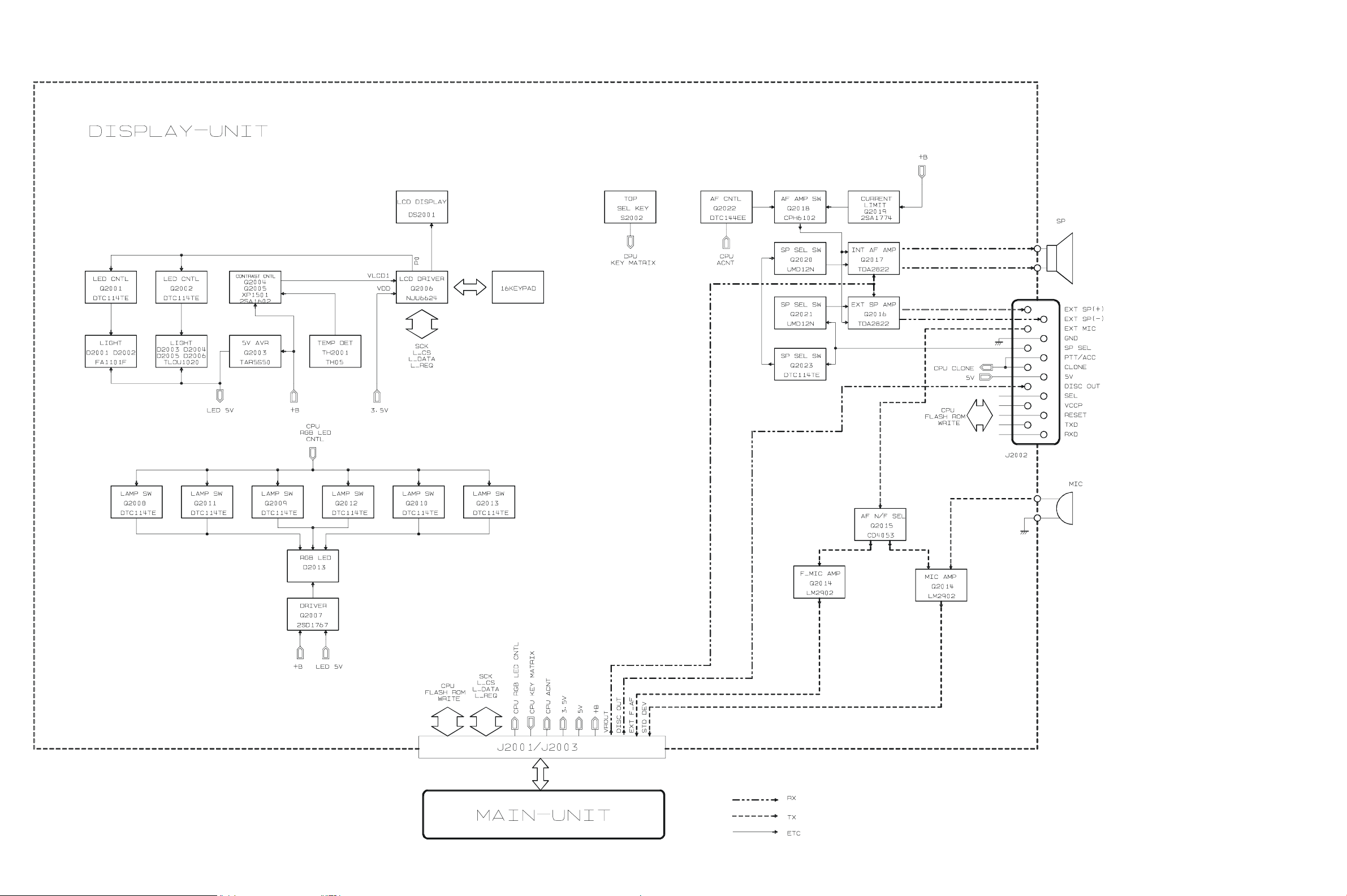

Block Diagram

Display Unit

6

Circuit Description

1. Circuit Configuration by Frequency

The receiver is a double-conversion superheterodyne

type, with a first Intermediate Frequency (IF) of 50.85

MHz and a second IF of 450 kHz. Incoming signals

from the antenna are mixed with the local signal from

the VCO/PLL to produce the first IF of 50.85 MHz.

The signals are then mixed with the 50.4 MHz second local oscillator output to produce the 450 kHz

second IF. This is detected to give the demodulated

signal. The transmit signal frequency is generated

by the PLL VCO, and modulated by the signal from

the microphone. It is then amplified and sent to the

antenna.

2. Receiver System

2-1. Front-end RF amplifier

Incoming RF signals from the antenna are delivered

to the Main Unit and pass through a Low-pass filter,

antenna switching diode D1011 (HVU131), and a

high pass filter, and undesired out-of-band signals

are then removed by a varactor-diode-tuned bandpass filter D1013 and D1015 (both 1SV323). The re-

sidual signals are amplified by Q1021 (MSG33001)

and then pass through a varactor-diode-tuned image-stripping band pass filter D1020 and D1022 (both

1SV323) prior to delivery to the 1st mixer.

2-2. First Mixer

The 1st mixer consists of Q1034 (SPM5001), T1001,

T1002, and T1003. Buffered output from the VCO is

amplified by Q1032 (2SC5005) to provide a pure first

local signal between 349.15 and 419.15 MHz (Version A) or 399.15 and 461.15 MHz (Version D) for

injection to the first mixer. The IF signal then passes

through monolithic crystal filter XF1001 (±5.5 kHz

BW) to strip away undesired mixing products.

filter CF1001 (wide channels), CF1002 (narrow channels) to strip away all but the desired signal, and is

applied to the limiter amplifier in Q1065

(TA31136FN), which removes amplitude variations

in the 450 kHz IF, before detection of the speech by

the ceramic discriminator CD1001.

2-4. Audio amplifier

Detected audio from Q1065 (TA31136FN) is applied

to Q1031 (AK2345) and is fed to the bandpass filter

inside Q1031 (AK2345).

If an optional signaling unit is installed, Q1078

(CD4066BPWR) is set to “OFF,” and the AF signal

from Q1032 (AK2345) is fed to the optional unit. If a

signaling unit is not installed, Q1078

(CD4066BPWR) is switched “ON,” and the signal

passes through Q1078 (CD4066BPWR). The signal

then proceeds through the de-emphasis stage and

the expander at Q1022 (LA8630M). When the ex-

pander function is off, the signal will be bypassed

via Q1014 (CD4053BPWR). The output signal of the

expander (or a signal from de-emphasis) goes

through AF mute switch Q1083 (DTC114TE) and is

amplified by Q1082 (LM2902PWR). The output from

Q1082 LM2902PWR) is amplified by the AF power

amplifier Q2017 (TDA2822) after passing through

the AF volume control Q1020 (M62364FP).

put of Q2017 (TDA2822) drives the internal speaker.

2-5. Squelch Circuit

There are 13 levels of squelch setting, from “0” to

“12.” The level “0” corresponds to an “open” squelch.

The level “1” is the lowest squelch threshold setting

level, and level “11” means tight squelch. From “2”

to “10” are intermediate, increasingly-tight settings.

The level “12” represents carrier squelch.

The out-

2-3. IF Amplifier

The first IF signal is amplified by Q1056 (2SC5226).

The amplified first IF signal is applied to FM IF subsystem IC Q1065 (TA31136FN) which contains the

second mixer, second local oscillator, limiter amplifier, noise amplifier, and S-meter amplifier. The signal from reference oscillator X1003 is multiplied by

three by Q1065 (TA31136FN), and then is mixed with

the IF signal to produce a 450 kHz second IF.

The second IF signal then passes through the ceramic

2-5-1. Noise Squelch

The Noise Squelch circuit is composed of the

bandpass filter at Q1065 (TA31136FN), noise ampli-

fier Q1069 (2SC4617), and noise detector D1049/

D1050 (both DA221). When a carrier is not being re-

ceived, the noise components passed from demodulator Q1065 (TA31136FN) are amplified by Q1069

(2SC4617), fed through bandpass filter Q1065

(TA31136FN), detected as a DC voltage by D1049/

D1050 (both DA221), and applied to pin 16 (the A/D

7

Circuit Description

port) of Q1067 (CPU: LC87F5BP6A). When a carrier is received, the DC voltage becomes low because

the noise is compressed. When the detected voltage

to the CPU is high, the CPU stops AF output by setting Q1083 (DTC114TE) “OFF” (by making pin 59

of the CPU “High” level). When the detection voltage is low, the CPU switches Q1083 (DTC114TE)

“ON” by making pin 59 “Low,” and the AF signal is

allowed to flow.

2-5-2. Carrier Squelch

The pin 15 (A/D port) of CPU Q1067 (LC87F5BP6A)

detects the RSSI voltage output from Q1065

(TA31136FN) at pin 12, and controls the AF output.

The RSSI output voltage changes according to the

signal strength of carrier; a stronger signal makes

the RSSI voltage higher. The processing of the AF

signal control is same as Noise Squelch, except that

the switching threshold is adjusted so as to be 3 dB

higher than the “tight squelch” sensitivity.

The high frequency signal components are amplified by Q1075 (LM2902PWR), and their level is set

by Q1020 (M62364FP) to establish proper balance

of the level between high- and low-frequency components. After that, the signals modulate the transmit carrier via modulator D1030 (1SV286) of the

VCO.

3-2. Drive and Final Amplifier Stages

The modulated signal from VCO Q1051 (2SC4227)

is buffered by Q1040 (2SC5005) and amplified by

Q1032 (2SC5005). Then the signal is buffered by

Q1027 (2SK3077) for delivery to the final amplifier

driver Q1024 (2SK3475). The low-level transmit signal is then applied to Q1019 (2SK3476) for final am-

plification up to 5 watts output power. The transmit

signal then passes through the antenna switch D1012

(HVU131) and is low-pass filtered to suppress harmonic spurious radiation before delivery to the antenna.

3. Transmitter System

3-1. MIC Amplifier

The AF signal from the internal microphone (pin 21

of J2002 on the Display Unit) or an external microphone (pin 6 of J2002 on the Display Unit) passes

through microphone selection switch Q2015

(CD4053BPWR) and is amplified by microphone

amplifier Q2014 (LM2904PWR), thereafter passing

through the microphone gain controller, Q1020

(M62364FP). The AF signal then passes through

compandor Q1022 (LA8630M). When not using the

compandor, the CPU bypasses the compandor circuit and feeds the signal to the pre-emphasis circuit.

Q1078 (CD4066BPWR) becomes “OFF” when an op-

tional signaling unit is attached, and the AF signal

from Q1022 (LA8630M) is redirected via the signaling unit. If a signaling unit is not installed, Q1078

(CD4066BPWR) becomes “ON,” the signal bypasses

Q1078 (CD4066BPWR), and it instead is applied to

the pre-emphasis amplifier Q1031 (AK2345). The sig-

nal passes through the limiter and splatter filter of

Q1031 (AK2345), and is adjusted for proper devia-

tion at Q1020 (M62364FP). The low frequency sig-

nal components (CTCSS, DCS, etc.) are then amplified by Q1075 (LM2902PWR) and used for direct

modulation of the reference oscillator, TCXO X1003.

3-3. Automatic Transmit Power Control

The current detector Q1072 (NJM12902V) detects the

current drawn by Q1019 (2SK3476) and Q1024

(2SK3475), and converts the current difference to a

voltage difference. The output from the current detector Q1072 (NJM12902V) is compared with the reference voltage and amplified by the power control

amplifier Q1072 (NJM12902V). The output from

Q1072 (NJM12902V) controls the gate bias of the fi-

nal amplifier Q1019 (2SK3476) and the driver Q1024

(2SK3475). The reference voltage switches among

four values of TX Power (“High,” “Low3,” “Low2,”

and “Low1”), as controlled by Q1020 (M62364FP).

3-4. PLL Frequency Synthesizer

The frequency synthesizer consists of PLL IC Q1068

(SA7025DK), the VCO, TCXO (

amplifier. The output frequency from the TCXO is

16.8 MHz, and the tolerance is ±2.5 ppm (in the temperature range —30 °C to +60 °C).

3-4-1. VCO (Voltage-Controlled Oscillator)

While the radio is receiving, the RX oscillator Q1046

(2SK508) in the VCO generates a programmed frequency between 349.15 and 419.15 MHz (Version A)

or 399.15 and 461.15 MHz (Version D) as the 1st lo-

X1003), and buffer

8

Circuit Description

cal signal. While the radio is transmitting, the TX oscillator Q1051 (2SC4227) in the VCO generates a frequency between 400 and 470 MHz (Version A) or 450

and 512 MHz (Version D) (the actual transmitting

frequency). The output from the oscillator is amplified by buffer amplifier Q1040 (2SC5005) and becomes the output of the VCO. The output from VCO

is divided: one part is amplified by Q1049 (2SC5005)

and fed back to the PLL IC at pin 5. The other is amplified by Q1032 (2SC5005) and, in case of the re-

ception, it is fed via D1023 (DAN222) to the mixer as

the 1st local signal. On transmit, it is fed via D1023

(DAN222) to buffer amplifire Q1027 (2SK3077), and

passed through the final amplifier driver Q1024

(2SK2375) to the final amplifier Q1019 (2SK2376).

3-4-2. VCV (Varactor Control Voltage) Control

The tuning voltage (VCV) of the VCO establishes the

lock range of the VCO by controlling the anode of a

varactor diode using a negative voltage and the control voltage from PLL IC Q1068 (SA7025DK). The

negative voltage is fed to the varactor diode after

conversion to a negative value at Q1030 (NJM2130F),

using the output voltage of the D/A converter, Q1020

(M62364FP).

3-4-3. PLL

The PLL IC Q1068 (SA7025DK) consists of a refer-

ence divider, main divider, phase detector, charge

pumps and a fractional accumulator. The reference

frequency from TCXO is applied to pin 8 of the PLL

IC Q1068 (SA7025DK) and is divided by the reference divider. This IC is a decimal point dividing PLL

IC, and the dividing ratio becomes 1/8 of the usual

PLL frequency step. Therefore, the output of reference divider is 8 times the frequency of the channel

step. For example, when the channel steps are set to

5 kHz, the output of reference divider becomes 40

kHz. The feedback signal from the VCO applied to 5

pin of the PLL IC Q1068 (SA7025DK) is divided ac-

cording to the dividing ratio so as to become the same

frequency as that of the output of reference divider.

These two signals are compared by the phase detector, and a phase difference pulse is generated. The

phase difference pulse and the pulse from the fractional accumulator pass through the charge pumps

and low-pass filter, producing a DC voltage (VCV)

to control the VCO. The oscillation frequency of the

VCO is therefore locked via the control of this DC

voltage. The PLL serial data from the CPU Q1067

(LC87F5BP6A) is sent with three lines of data: SDO

(pin 20), SCK (pin 22) and PSTB (pin 27). The lock

condition of the PLL is sent from the UL (pin 17) terminal, and UL becomes “High” at the time of a

proper lock condition and becomes “Low” at the time

of an unlocked condition. The CPU always watches

over the UL condition, and when it becomes “Low”

(unlocked condition), the CPU Q1067

(LC87F5BP6A) prohibits transmission and reception.

9

Circuit Description

Note

10

Alignment

Introduction

The VX-820 series is carefully aligned at the factory

for the specified performance across the frequency

range specified for each version. Realignment should

therefore not be necessary except in the event of a

component failure, or altering version type. All component replacement and service should be performed only by an authorized Vertex Standard rep-

resentative, or the warranty policy may be void.

The following procedures cover the sometimes critical and tedious adjustments that are not normally

required once the transceiver has left the factory.

However, if damage occurs and some parts subsequently are placed, realignment may be required. If

a sudden problem occurs during normal operation,

it is likely due to component failure; realignment

should not be done until after the faulty component

has been replaced.

We recommend that servicing be performed only by

authorized Vertex Standard service technicians who

are experienced with the circuitry and fully equipped

for repair and alignment. Therefore, if a fault is suspected, contact the dealer from whom the transceiver was purchased for instructions regarding repair.

Authorized Vertex Standard service technicians realign all circuits and make complete performance

checks to ensure compliance with factory specifications after replacing any faulty components.

Those who do undertake any of the following alignments are cautioned to proceed at their own risk.

Problems caused by unauthorized attempts at realignment are not covered by the warranty policy.

Also, Vertex Standard reserves the right to change

circuits and alignment procedures in the interest of

improved performance, without notifying owners.

The following test equipment (and thorough familiarity with its correct use) is necessary for complete

realignment. Correction of problems caused by misalignment resulting from use of improper test equipment is not covered under the warranty policy. While

most steps do not require all of the equipment listed, the interactions of some adjustments may require

that more complex adjustments be performed afterwards. Do not attempt to perform only a single step

unless it is clearly isolated electrically from all other

steps. Have all test equipment ready before beginning, and follow all of the steps in a section in the

order presented.

Required Test Equipment

RF Signal Generator with calibrated output level

at 1 GHz

Deviation Meter (linear detector)

In-line Wattmeter with 5 % accuracy at 1 GHz

50 Ohm RF Dummy Load with power rating 10

W at 1 GHz

16 Ohm AF Dummy Load (Attention : Audio out-

put is BTL output)

Regulated DC Power Supply (standard 7.5 V DC,

3 A)

Frequency Counter with 0.2 ppm accuracy at 1

GHz

Audio Generator

AC Voltmeter

DC Voltmeter

UHF Sampling Coupler

IBM PC / compatible Computer with Microsoft®

Windows® 95 or later operating system

Vertex Standard CE59 (version 2.06 or later) Align-

ment program and CT-109 PC Programming

Ú

Cable or FIF-10A

gramming Cable

USB Interface/CT-108 PC Pro-

Under no circumstances should any alignment be

attempted unless the normal function and operation

of the transceiver are clearly understood, the cause

of the malfunction has been clearly pinpointed and

any faulty components replaced, and realignment

determined to be absolutely necessary.

: When using the FIF-10A USB Interface, requires

Ú

the Windows® 2000 or Windows® XP

11

Alignment

Alignment Preparation & Precautions

A 50-Ohm RF Dummy Load and in-line wattmeter

must be connected to the main antenna jack in all

procedures that call for transmission, except where

specified otherwise. Correct alignment is not possible with an antenna.

After completing one step, read the following step

to determine whether the same test equipment will

be required. If not, remove the test equipment (except dummy load and wattmeter, in connected) before proceeding.

Correct alignment requires that the ambient temperature be the same as that of the transceiver and test

equipment, and that this temperature be held constant between 68 and 86 °F (20 ~ 30 °C). When the

transceiver is brought into the shop from hot or cold

air, it should be allowed time to come to room temperature before alignment.

Whenever possible, alignments should be made with

oscillator shields and circuit boards firmly affixed in

place. Also, the test equipment must be thoroughly

warmed up before beginning.

Setup the test equipment as shown for transceiver

alignment, apply 7.5 V DC power to the transceiver.

Refer to the drawings above for Alignment Points.

The transceiver must be programmed for use in the

intended system before alignment is attempted. The

RF parameters are loaded from the file during the

alignment process.

In order to facilitate alignment over the complete

switching range of the equipment it is recommended that the channel data in the transceiver is preset

as the chart below.

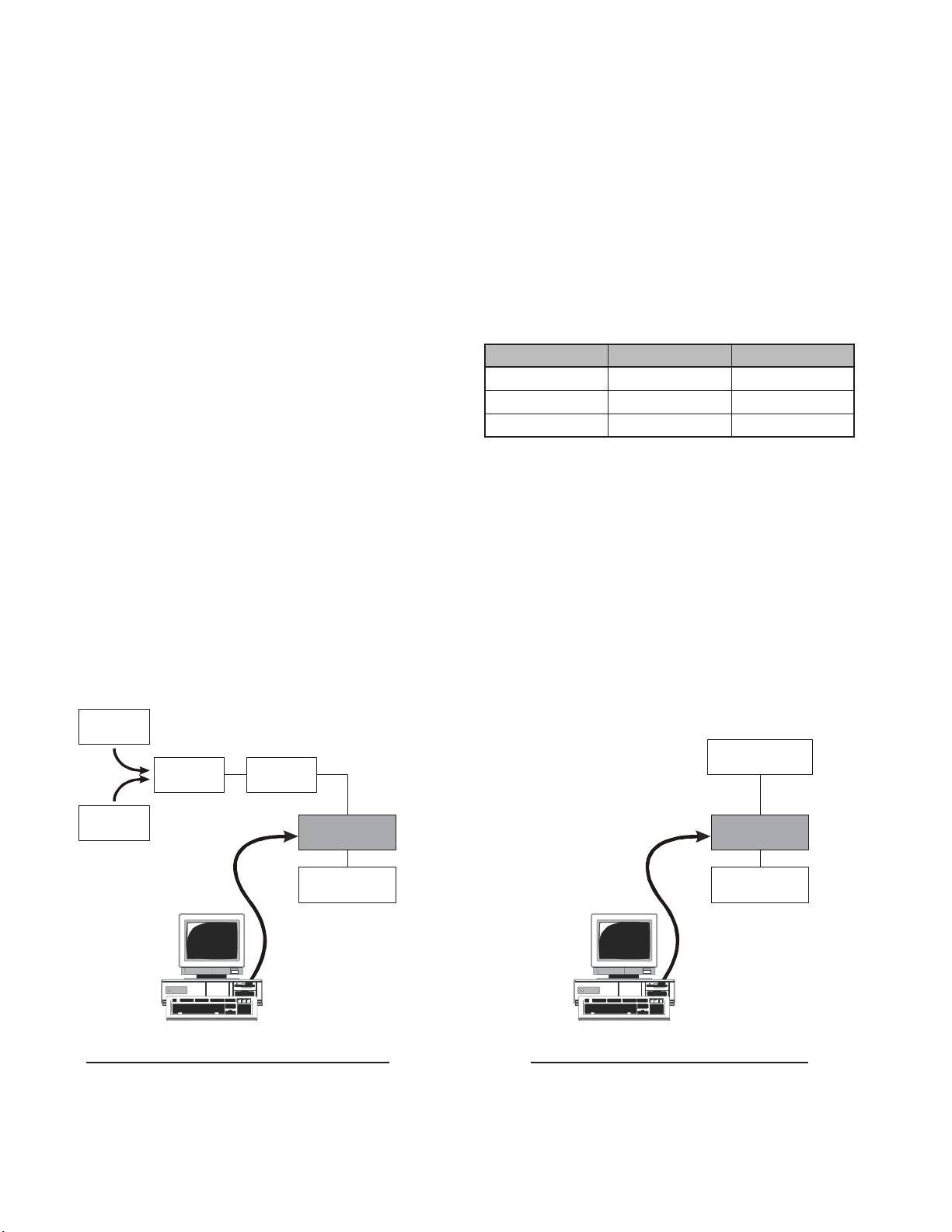

CHANNEL

BAND-LOW

BAND-MID

BAND-HIGH

VERSION A

400.000 MHz

435.000 MHz

470.000 MHz

VERSION D

450.000 MHz

480.000 MHz

512.000 MHz

The alignment mode is accessed by “Alignment

mode” command from the computer, and the alignment tool operates it automatically. During the alignment mode, normal operation is suspended. Use the

alignment tool program running on PC.

Note: Signal levels in dB referred to in the alignment

procedure are based on 0 dBm EMF = 1 mV.

Deviation

Meter

Signal Generator

MIC/SP

COM Port or USB Jack

Frequency

Counter

CT-109 or FIF-10/CT-108

30 dB PAD

Inline

Wattmeter

MIC/SP

Power Supply

7.5 VDC

COM Port or USB Jack

ANT

VX-820

CT-109 or FIF-10/CT-108

TRANSMITTER SECTION ALINGMENT SETUP RECEIVER SECTION ALINGMENT SETUP

RF

ANT

VX-820

Power Supply

7.5 VDC

12

Alignment

The Alignment Tool Outline

Installation the tool

Install the CE59 (version 2.06 or later) to your PC.

The re-alignment for VX-820 series uses the

“Alignment“ menu of CE59.

Action of the switches

When the transceiver is in the “Alignment mode,“ the

actions of the PTT switch and keys are ignored. All of

the commands are remotely controlled by the PC.

Basic sequence

The data displayed in screen of this tool is temporary data, and you must take care to ensure the preservation of the command sequence which is specified below.

1. Enter the “Alignment mode“

2. Upload data from radio

3. Edit/set alignment data

4. Download data to radio

When you finish one alignment parameter, the tool

will ask you “Save the Aligned Data?“ If you select

“Yes,“ the temporary data will updated. If you select “No,“ the tool will not update the temporary data

and the setting will return to its original value.

Basic Alignment Mode

The Basic Alignment mode allows you to align the

entire radio. The value of each parameter can be

changed to the desired position by use of the “” /

“” and up/down arrow keys, along with direct

number input and dragging of the PC mouse.

To enter the Basic Alignment Mode, select “Basic

Alignment” in the main “Radio” menu. It will start

to “Upload” the written personalized data from the

radio. Pressing the “OK” button will then start the

Basic Alignment Mode.

Note: when all items are to be aligned, it is strongly

recommended to align them according to following

sequence. Detailed information for each step may be

found in the “Help” file within CE59 (Clone Editor).

1. RX VCO Tune Voltage (RX VCO)

2. TX VCO Tune Voltage (TX VCO)

3. PLL Reference Frequency (Frequency)

4. RX Sensitivity (RX Tune)

5. Squelch (SQL)

6. TX Power

7. Maximum Deviation <Wide>

8. Maximum Deviation <Narrow>

9. Sub Audio Deviation <CTCSS>

10. Sub Audio Deviation <DCS>

BATTERY TERMINAL POLARITY

13

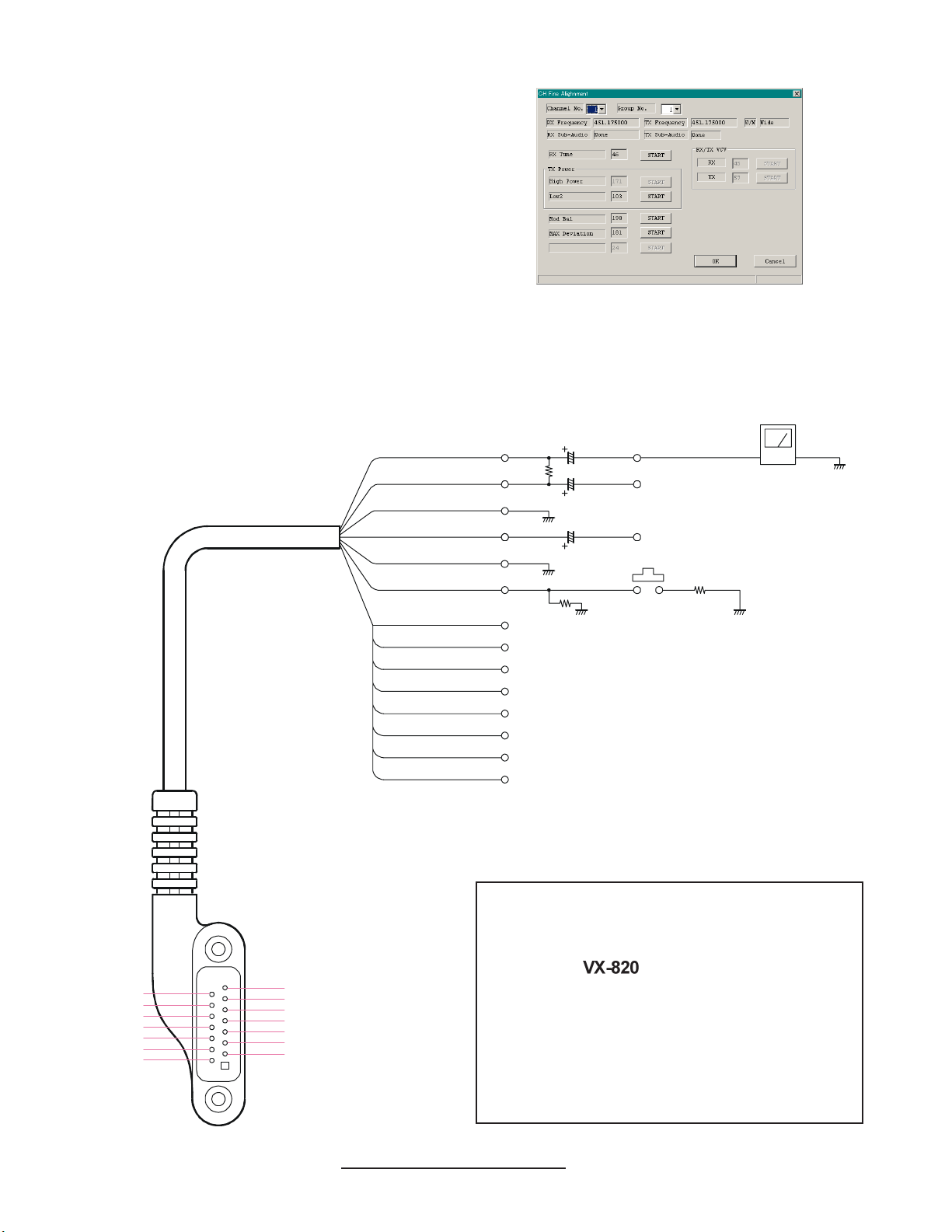

Alignment

CH (C

HANNEL-BY-CHANNEL

) Fine Alignment Mode

The CH Fine Alignment Mode allows you to align

the radio separately for every operating channel. The

value of each parameter can be changed to the desired position using the “” / “” and up/down

arrow keys, direct number input, and by dragging

the PC mouse.

To enter the CH Fine Alignment Mode, select “CH

Fine Alignment” in the main “Radio” menu. It will

start to “Upload” the written personalized data from

the radio. Pressing the “OK” button will then start

the CH Fine Alignment Mode.

Note: Detailed information for each step may be found

in the “Help” file within CE59 (Clone Editor).

Pin 1: WHITE

Pin 2: RED

VXSTD P/N: T9207094

Pin 3: SHIELD

Pin 4: BLACK

Pin 5: BLUE

Pin 6: YELLOW

Pin 7: GRAY

Pin 8: GREEN

Pin 9: PURPLE

Pin 10: ORANGE

Pin 11: L_GREEN

Pin 12: CLEAR

Pin 13: PINK

Pin 14: BROWN

220 µF

16-Ohm 2W

220 µF

10 µF

27 k-Ohm

1/2 OUTPUT LEVEL

AF METER

AUDIO GENERATOR

PTT SW

2.2 k-Ohm

Pin 2: SP

Pin 4: MIC

Pin 6: PTT/AC C

Pin 10: SEL

Pin 12: RESET

Pin 14: RXD

14

(- )

Pin 8: 5V

Note!

Because of the bridge audio amplifier circuit

used in the

-

Pin 1: SP (+

Pin 3: GND

Pin 5: SELECT

Pin 7: CLONE

Pin 9: DISC OUT

Pin 11: VCCP

Pin 13: TXD

)

and use a simple audio load test adapter as

shown in the schematic diagram, when conducting receiver alignment steps.

Do not connect either side of the speaker leads

to chassis “ground.”

AF TEST ADAPTER SCHEMATIC

, it is necessary to construct

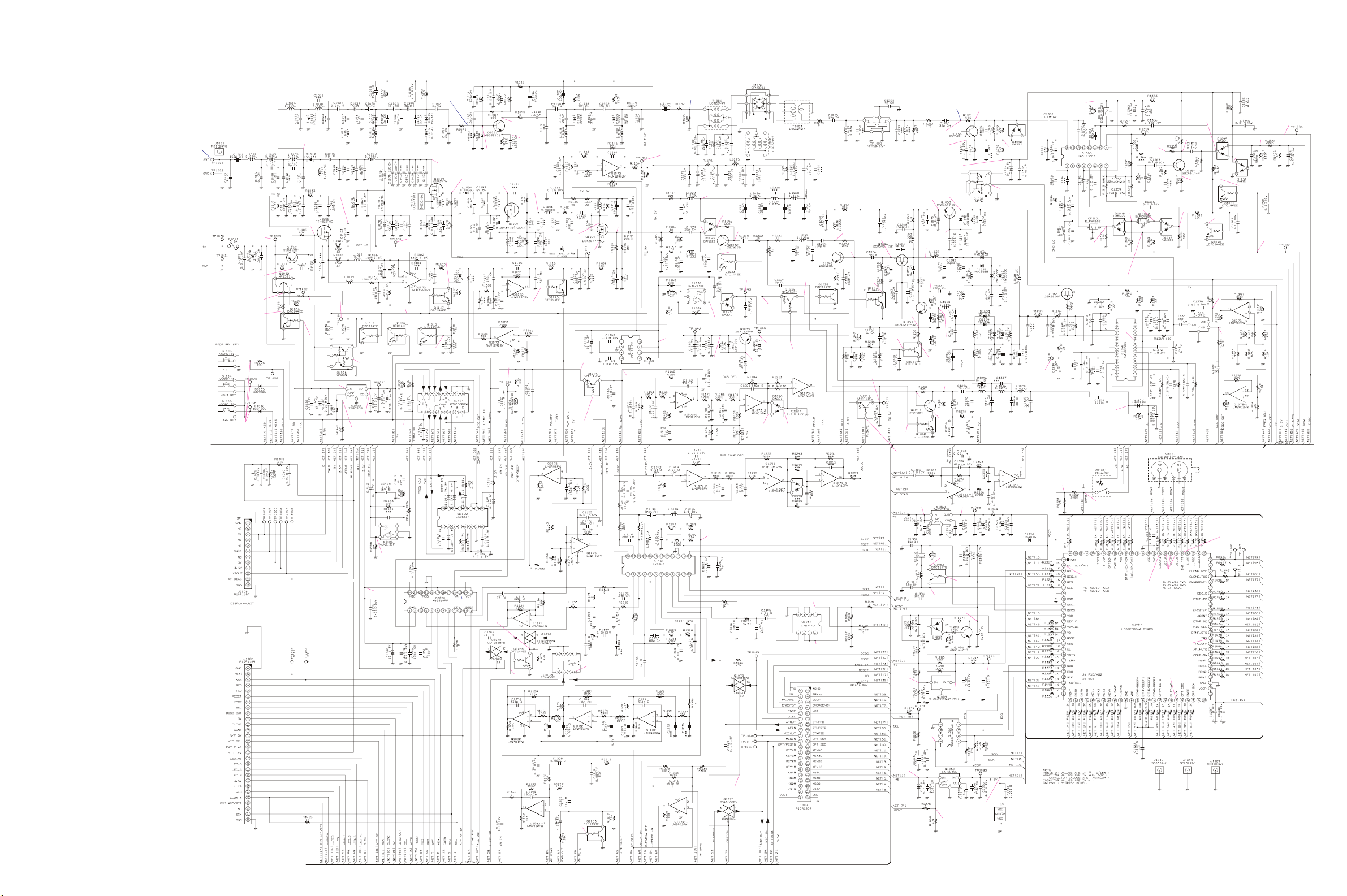

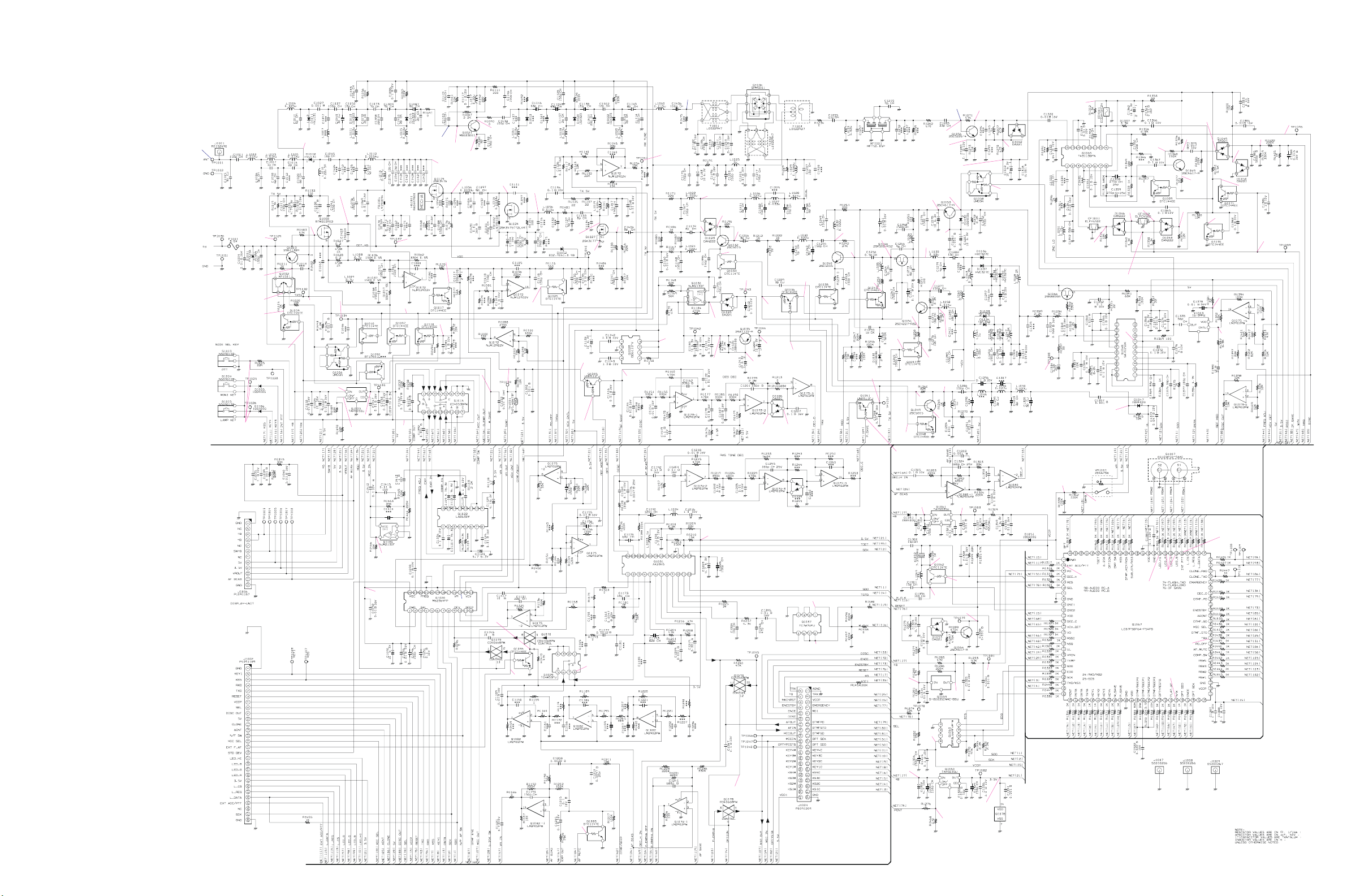

Main Unit (Lot. 1 ~ 2)

Circuit Diagram

–8.5 dBμV emf

@485.1 MHz

RX: 7.4 V

TX: 7.1 V

RX: 7.4 V

TX: 6.7 V

RX: 5.0 V

TX: 4.3 V

RX: 5.0 V

TX: 0.1 V

SW ON: 0 V

SW OFF: 3.5 V

RX: 0 V

TX: 0.8 V

PWR ON: 0 V

PWR OFF: 6.7 V

RX: 0 V

TX: 5.0 V

RX: 0.1 V

TX: 3.4 V

PWR ON: 7.4 V

PWR OFF: 1.1 V

TX: 7.1 V

SAVE ON: 0 V

SAVE OFF: 4.9 V

TX: 0 V

7.4 V

PWR ON: 1.7 V

PWR OFF: 0 V

SAVE ON: 0 V

SAVE OFF: 3.4 V

TX: 0 V

PWR ON: 5.0 V

PWR OFF: 0 V

RX: 0 V

TX: 5.0 V

3.5 V

RX: 7.4 V

TX: 6.9 V

–10.5 dBμV emf

@485.1 MHz

RX: 4.1 V

TX: 0 V

RX: 7.4 V

TX: 6.9 V

RX: 1.3 V

TX: 0 V

RX: 0 V

TX: 2.0 V

RX: 1.5 V

TX: 0 V

RX: 7.4 V

TX: 6.9 V

RX: 3.0 V

TX: 0 V

RX: 0.7 V

TX: 0 V

RX: 3.1 V

TX: 0 V

2.5 V @25 °C

RX: 0 V

TX: 3.1 V

RX: 0 V

TX: 3.9 V

RX: 0 V

TX: 3.0 V

3.5 V

MUTE: 3.5 V

BUSY: 0.5 V

TX: 0.5 V

RX: 0 V

TX: 1.2 V

MUTE: 0 V

BUSY: 3.5 V

TX: 3.5 V

RX: 1.6 V

TX: 0.6 V

@485.1 MHz

5.1 V

–0.2 dBμV emf

@485.1 MHz

RX: 0 V

TX: 3.9 V

RX: 3.2 V

TX: 0 V

RX: 2.5 V

TX: 3.2 V

RX: –2.1 V

TX: –1.3 V

@485.1 MHz

RX: –4.9 V

TX: –5.0 V

0.1 V

RX: 0.8 V

TX: 0.9 V

RX: –1.7 V

TX: –1.0 V

@485.1 MHz

RX: –4.8 V

TX: –5.0 V

MUTE: 0 V

BUSY: 0.3 V

TX: 0 V

3.5 V

RX: –4.2 V

TX: –4.6 V

RX: 0.1 V

TX: 3.4 V

MUTE: 0 V

BUSY: 0.3 V

TX: 0 V

RX: 3.5 V

TX: –4.6 V

2.7 V

0.8 V

RX: –3.3 V

TX: 0.1 V

RX: –4.2 V

TX: 0 V

SAVE ON: 0 V

SAVE OFF: 3.5 V

RX: 3.0 V

TX: 2.0 V

RX: 0 V

TX: 5.0 V

3.5 V

SAVE ON: 3.5 V

SAVE OFF: 0.6 V

RX: 3.8 V

TX: 4.2 V

0.8 V

4.2 V

RX: 3.0 V

TX: 0 V

–3.2 dBμV emf

RX: 1.4 V

TX: 0 V

RX: 0.7 V

TX: 0 V

SAVE ON: 0 V

SAVE OFF: 4.9 V

TX: 0 V

5.0 V

4.9 V

RX: 4.2 V

TX: 3.7 V

RX: 3.0 V

TX: 2.5 V

2.7 V

0.1 V

RX: 2.9 V

TX: 0 V

RX: 2.9 V

TX: 0 V

SAVE ON: 0 V

SAVE OFF: 3.4 V

TX: 0 V

RX: 2.7 V

TX: 2.1 V

@485.1 MHz

RX: 4.9 V

TX: 0 V

RX [W]: 1.0 V

RX [N]: 1.9 V

TX [W]: 0 V

TX [N]: 1.9 V

PLL LOCK: 3.4 V

PLL UNLOCK: 0 V

RX [W]: 0 V

RX [N]: 2.4 V

RX [W]: 1.5 V

RX [N]: 0 V

TX: 0 V

3.4 V

RX: 0.6 V

TX: 0 V

RX: 2.8 V

TX: 0 V

RX: 2.4 V

TX: 0 V

0 V

RX [W]: 1.0 V

RX [N]: 1.9 V

TX [W]: 0 V

TX [N]: 1.9 V

0 V

3.5 V

1.5 V

RX: 1.3 V

TX: 0 V

RX [W]: 3.6 V

RX [N]: 0.1 V

TX: 0 V

RX: 3.4 V

TX: 0 V

RX [W]: 0 V

RX [N]: 3.0 V

RX: 0.8 V

TX: 0 V

3.5 V

3.5 V

0.2 V p-p

RX: 3.5 V

TX: 0 V

RX: 0 V

TX: 3.4 V

MUTE: 3.1 V

BUSY: 0 V

TX: 3.1 V

3.5 V

3.5 V

OPTION ON: 0 V

OPTION OFF: 3.5 V

MUTE: 0 V

BUSY: 1.7 V

TX: 1.7 V

MUTE: 0 V

BUSY: 3.5 V

TX: 3.5 V

PWR ON: 6.7 V

PWR OFF: 7.0 V

5.1 V

7.4 V

e

3.5 V

3.5 V

c

d

3.5 V

5.7 V

PWR ON: 3.5 V

PWR OFF: 0 V

PWR ON: 3.4 V

PWR OFF: 0 V

4.1 V

PWR ON: 3.6 V

PWR OFF: 0 V

PWR ON: 7.4 V

PWR OFF: 0 V

RX: 2.7 V

TX: 0.7 V

c

PWR OFF: 3.5 V

PWR ON: 1.8 V

d

PWR OFF: 3.5 V

CLOCK SHIFT ON: 2.7 V

CLOCK SHIFT OFF: 3.4 V

e

PWR OFF: 3.5 V

PWR ON: 1.8 V

LED HI: 3.3 V

LED LOW: 0 V

LED OFF: 0 V

LED ON: 3.4 V

LED OFF: 0 V

RX: 0 V

TX: 3.5 V

RX [W]: 0 V

RX [N]: 3.3 V

RX: 3.5 V

TX: 0 V

15

Main Unit (Lot. 1 ~ 2)

Note

16

LC87FF5BP6A

(Q1067)

Main Unit (Lot. 1 ~ 2)

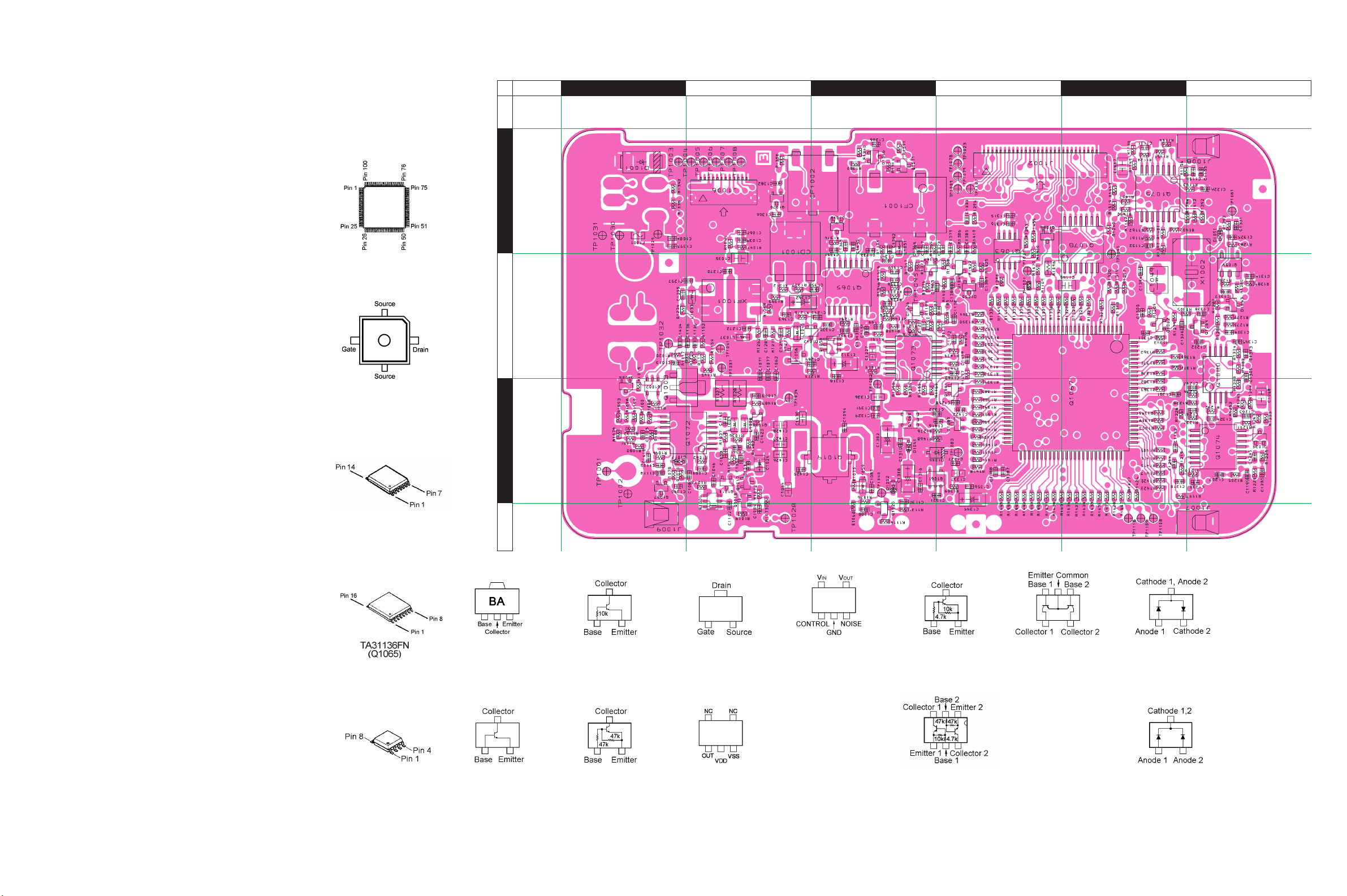

Parts Layout (Side A)

A B C D E F

1

2

2SK3476

(Q1019)

CD4066BPWR

(Q1078)

LM2902PWR

(Q1073, 1074, 1075)

NJM12902V

(Q1072)

3

4

2SB1132 (BA)

(Q1003)

DTC114TE (04)

(Q1010, 1025,

1062)

RTM002 (BA)

(Q1088)

TAR5S35U

(Q1060, 1061)

UNR911FJ0L (6O)

(Q1041, 1085)

XP1501 (5R)

(Q1002)

DA221 (K)

(D1026, 1042,

1043, 1049, 1050)

BR93L66RFVM

(Q1063)

LM2904PWR

(Q1080)

2SC4617 (BR)

(Q1064, 1069)

2SC5226 (R22)

(Q1056)

DTC144EE (26)

(Q1004, 1017,

1018, 1070, 1071,

1086, 1087)

S-80835CNMC

(Q1059)

UMD5N

(Q1006, 1058)

DAN222 (N)

(D1046, 1048)

17

Main Unit (Lot. 1 ~ 2)

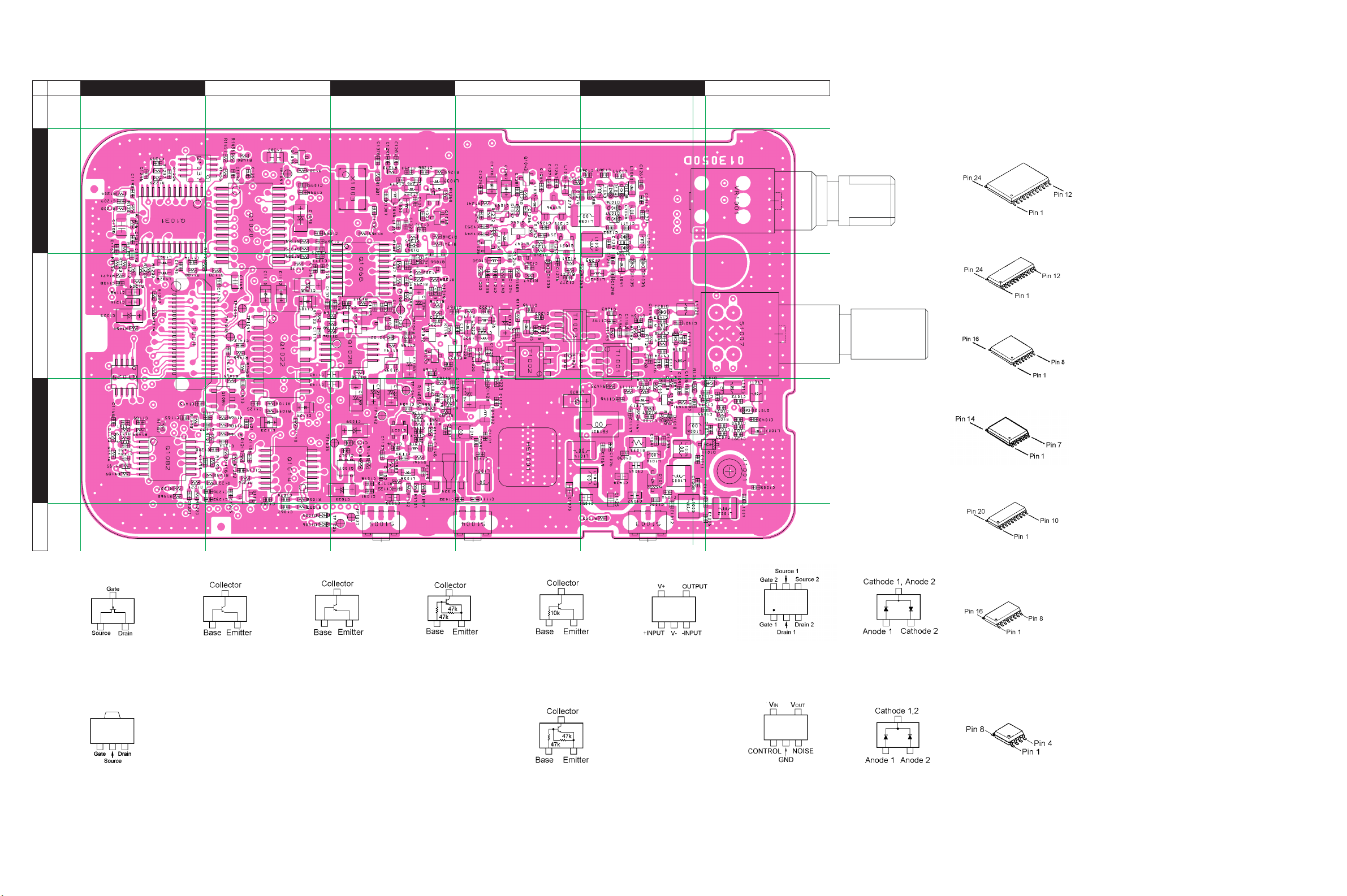

Parts Layout (Side B)

a b c d e f

1

2

AK2345

(Q1031)

M62364FP

(Q1020)

CD4053BPWR

(Q1014)

3

LM2902PWR

(Q1082)

4

SA7025DK

(Q1068)

2SK508 (K52)

(Q1046)

2SK880GR (XG)

(Q1066)

2SA1774 (FR)

(Q1035)

2SC3356 (R24)

(Q1027)

2SC4227 (R32)

(Q1051)

2SC4617 (BR)

(Q1053)

2SC5005 (73)

(Q1032, 1040, 1049)

2SC5226 (R22)

(Q1021)

DTA144EE (16)

(Q1036)

DTC114TE (04)

(Q1038, 1047,

1083)

NJM2130F

(Q1030, 1084)

SPM5001

(Q1034)

DA221 (K)

(D 1025)

LA8630M

(Q1022)

18

2SK3475

(Q1024)

DTC144EE (26)

(Q1033, 1043,

1048)

TAR5S50U

(Q1005)

DAN222 (N)

(D1023)

BD6111FV

(Q1028)

TC4W53FU

(Q1029)

TC7W74FU

(Q1037)

–8.5 dBμV emf

@485.1 MHz

RX: 7.4 V

TX: 7.1 V

RX: 7.4 V

TX: 6.7 V

RX: 5.0 V

TX: 4.3 V

RX: 5.0 V

TX: 0.1 V

SW ON: 0 V

SW OFF: 3.5 V

PWR ON: 0 V

PWR OFF: 6.7 V

RX: 0.1 V

TX: 3.4 V

RX: 0 V

TX: 0.8 V

RX: 0 V

TX: 5.0 V

PWR ON: 7.4 V

PWR OFF: 1.1 V

TX: 7.1 V

SAVE ON: 0 V

SAVE OFF: 4.9 V

TX: 0 V

7.4 V

PWR ON: 1.7 V

PWR OFF: 0 V

PWR ON: 5.0 V

PWR OFF: 0 V

RX: 0 V

TX: 5.0 V

3.5 V

–10.5 dBμV emf

@485.1 MHz

RX: 7.4 V

TX: 6.9 V

RX: 7.4 V

TX: 6.9 V

RX: 1.3 V

TX: 0 V

RX: 4.1 V

TX: 0 V

RX: 1.5 V

TX: 0 V

RX: 0.7 V

TX: 0 V

RX: 0 V

TX: 2.0 V

SAVE ON: 0 V

SAVE OFF: 3.4 V

TX: 0 V

RX: 3.0 V

TX: 0 V

RX: 7.4 V

TX: 6.9 V

RX: 3.1 V

TX: 0 V

2.5 V @25 °C

RX: 0 V

TX: 3.1 V

RX: 0 V

TX: 3.9 V

RX: 0 V

TX: 3.0 V

3.5 V

MUTE: 3.5 V

BUSY: 0.5 V

TX: 0.5 V

RX: 0 V

TX: 1.2 V

MUTE: 0 V

BUSY: 3.5 V

TX: 3.5 V

–0.2 dBμV emf

@485.1 MHz

RX: 1.6 V

TX: 0.6 V

@485.1 MHz

5.1 V

RX: 0 V

TX: 3.9 V

RX: 3.2 V

TX: 0 V

RX: 2.5 V

TX: 3.2 V

RX: –2.1 V

TX: –1.3 V

@485.1 MHz

RX: –4.9 V

TX: –5.0 V

0.1 V

RX: 0.8 V

TX: 0.9 V

RX: –1.7 V

TX: –1.0 V

@485.1 MHz

RX: –4.8 V

TX: –5.0 V

MUTE: 0 V

BUSY: 0.3 V

TX: 0 V

3.5 V

RX: –4.2 V

TX: –4.6 V

RX: 0.1 V

TX: 3.4 V

MUTE: 0 V

BUSY: 0.3 V

TX: 0 V

RX: 3.5 V

TX: –4.6 V

2.7 V

0.8 V

RX: –3.3 V

TX: 0.1 V

RX: –4.2 V

TX: 0 V

SAVE ON: 0 V

SAVE OFF: 3.5 V

RX: 3.0 V

TX: 2.0 V

RX: 0 V

TX: 5.0 V

3.5 V

SAVE ON: 3.5 V

SAVE OFF: 0.6 V

RX: 3.8 V

TX: 4.2 V

0.8 V

4.2 V

RX: 3.0 V

TX: 0 V

–3.2 dBμV emf

RX: 1.4 V

TX: 0 V

RX: 0.7 V

TX: 0 V

SAVE ON: 0 V

SAVE OFF: 4.9 V

TX: 0 V

5.0 V

4.9 V

RX: 4.2 V

TX: 3.7 V

RX: 3.0 V

TX: 2.5 V

2.7 V

0.1 V

RX: 2.9 V

TX: 0 V

RX: 2.9 V

TX: 0 V

SAVE ON: 0 V

SAVE OFF: 3.4 V

TX: 0 V

RX: 2.7 V

TX: 2.1 V

@485.1 MHz

RX: 4.9 V

TX: 0 V

RX [W]: 1.0 V

RX [N]: 1.9 V

TX [W]: 0 V

TX [N]: 1.9 V

Main Unit (Lot. 3 ~ 12)

Circuit Diagram

RX: 2.8 V

TX: 0 V

RX: 2.4 V

TX: 0 V

0 V

RX [W]: 1.0 V

RX [N]: 1.9 V

TX [W]: 0 V

TX [N]: 1.9 V

0 V

3.5 V

1.5 V

RX: 1.3 V

TX: 0 V

RX [W]: 3.6 V

RX [N]: 0.1 V

TX: 0 V

PLL LOCK: 3.4 V

PLL UNLOCK: 0 V

RX [W]: 0 V

RX [N]: 2.4 V

RX [W]: 1.5 V

RX [N]: 0 V

TX: 0 V

3.4 V

RX: 0.6 V

TX: 0 V

RX: 3.4 V

TX: 0 V

RX [W]: 0 V

RX [N]: 3.0 V

RX: 0.8 V

TX: 0 V

3.5 V

3.5 V

0.2 V p-p

RX: 3.5 V

TX: 0 V

RX: 0 V

TX: 3.4 V

MUTE: 3.1 V

BUSY: 0 V

TX: 3.1 V

3.5 V

3.5 V

OPTION ON: 0 V

OPTION OFF: 3.5 V

MUTE: 0 V

BUSY: 1.7 V

TX: 1.7 V

MUTE: 0 V

BUSY: 3.5 V

TX: 3.5 V

PWR ON: 6.7 V

PWR OFF: 7.0 V

5.1 V

7.4 V

e

3.5 V

3.5 V

c

d

3.5 V

5.7 V

PWR ON: 3.5 V

PWR OFF: 0 V

PWR ON: 3.4 V

PWR OFF: 0 V

4.1 V

PWR ON: 3.6 V

PWR OFF: 0 V

PWR ON: 7.4 V

PWR OFF: 0 V

RX: 2.7 V

TX: 0.7 V

c

PWR OFF: 3.5 V

PWR ON: 1.8 V

d

PWR OFF: 3.5 V

CLOCK SHIFT ON: 2.7 V

CLOCK SHIFT OFF: 3.4 V

e

PWR OFF: 3.5 V

PWR ON: 1.8 V

LED HI: 3.3 V

LED LOW: 0 V

LED OFF: 0 V

LED ON: 3.4 V

LED OFF: 0 V

RX: 0 V

TX: 3.5 V

RX [W]: 0 V

RX [N]: 3.3 V

RX: 3.5 V

TX: 0 V

19

Main Unit (Lot. 3 ~ 12)

Note

20

Loading...

Loading...