Page 1

UHF FM Transceiver

VX-2500U

Service Manual

2004 VERTEX STANDARD CO., LTD.

©

VERTEX STANDARD CO., LTD.

4-8-8 Nakameguro, Meguro-Ku, Tokyo 153-8644, Japan

VERTEX STANDARD

US Headquarters

10900 Walker Street, Cypress, CA 90630, U.S.A.

YAESU EUROPE B.V.

P.O. Box 75525, 1118 ZN Schiphol, The Netherlands

YAESU UK LTD.

Unit 12, Sun Valley Business Park, Winnall Close

Winchester, Hampshire, SO23 0LB, U.K.

VERTEX STANDARD HK LTD.

Unit 5, 20/F., Seaview Centre, 139-141 Hoi Bun Road,

Kwun Tong, Kowloon, Hong Kong

Introduction

This manual provides technical information necessary for servicing the VX-2500U Transceiver.

Servicing this equipment requires expertise in handling surface-mount chip components. Attempts by non-qualified

persons to service this equipment may result in permanent damage not covered by the warranty, and may be illegal in

some countries.

Two PCB layout diagrams are provided for each double-sided circuit board in the transceiver. Each side of thr board is

referred to by the type of the majority of components installed on that side (“leaded” or “chip-only”). In most cases one

side has only chip components, and the other has either a mixture of both chip and leaded components (trimmers, coils,

electrolytic capacitors, ICs, etc.), or leaded components only.

While we believe the technical information in this manual to be correct, Vertex Standard assumes no liability for dam-

age that may occur as a result of typographical or other errors that may be present. Your cooperation in pointing out any

inconsistencies in the technical information would be appreciated.

Contents

Specifications ..................................................... 2

DSUB 9-pin Accessory Connector .................. 3

Exploded View & Miscellaneous Parts ......... 4

Block Diagram .................................................... 5

Interconnection Diagram ................................. 9

Circuit Description ..........................................11

Alignment ...................................................... 13

RF Unit Jumper Information ......................23

Clone ............................................................... 24

Board Unit (Schematics, Layouts & Parts)

RF Unit .......................................................................... 25

RF-1- Unit ...................................................................... 43

RF-2- Unit ...................................................................... 57

Panel Unit ..................................................................... 69

1

Page 2

Specifications

General

Frequency range: 400-470 MHz (Ver. CS1)

450-490 MHz (Ver. D)

450-520 MHz (Ver. DS1)

Number of Groups:10

Number of Channels : 128 channels

PLL Steps: 5.0 kHz/6.25kHz

Power Supply Voltage: 13.8V DC ±15 %

Channel Spacing: 12.5 / 25.0 kHz

Current Consumption (Approx.): TX: 6 A

RX: 700 mA

STBY: 250 mA

Operating Temperature range: –22 °F to 140 °F (–30 °C to +60 °C)

Frequency Stability: Better than ±2.5 ppm

RF Input-Output Impedance: 50 ohms

Audio Output Impedance: 4 ohms

Dimensions: 6.3 x 1.6 x 4.3 inch (160 x 40 x 110 mm)

Weight (Approx.): 1.87 lb (0.85 kg)

Receiver (Typical Values)

Circuit type: Double conversion Super-heterodyne

Sensitivity: 0.25 uV (12 dB SINAD)

Adjacent Channel Selectivity: 80/67 dB

Intermodulation: 75 dB

Spurious and Image Rejection: 90 dB

Audio Output: 4 W @ 4 ohms 5% THD

Audio Distortion: <3 % @1 kHz

Transmitter (Typical Values)

Power Output: 25 W (low: 5W)

Modulation: 16K0F3E, 11K0F3E

Max Deviation: 5.0/2.5 kHz

Conducted Spurious Emission: 70 dB below carrier

Audio Distortion: <3 % @ 1 kHz

Microphone type: Dynamic

Microphone impedance: 600 ohms

2

Page 3

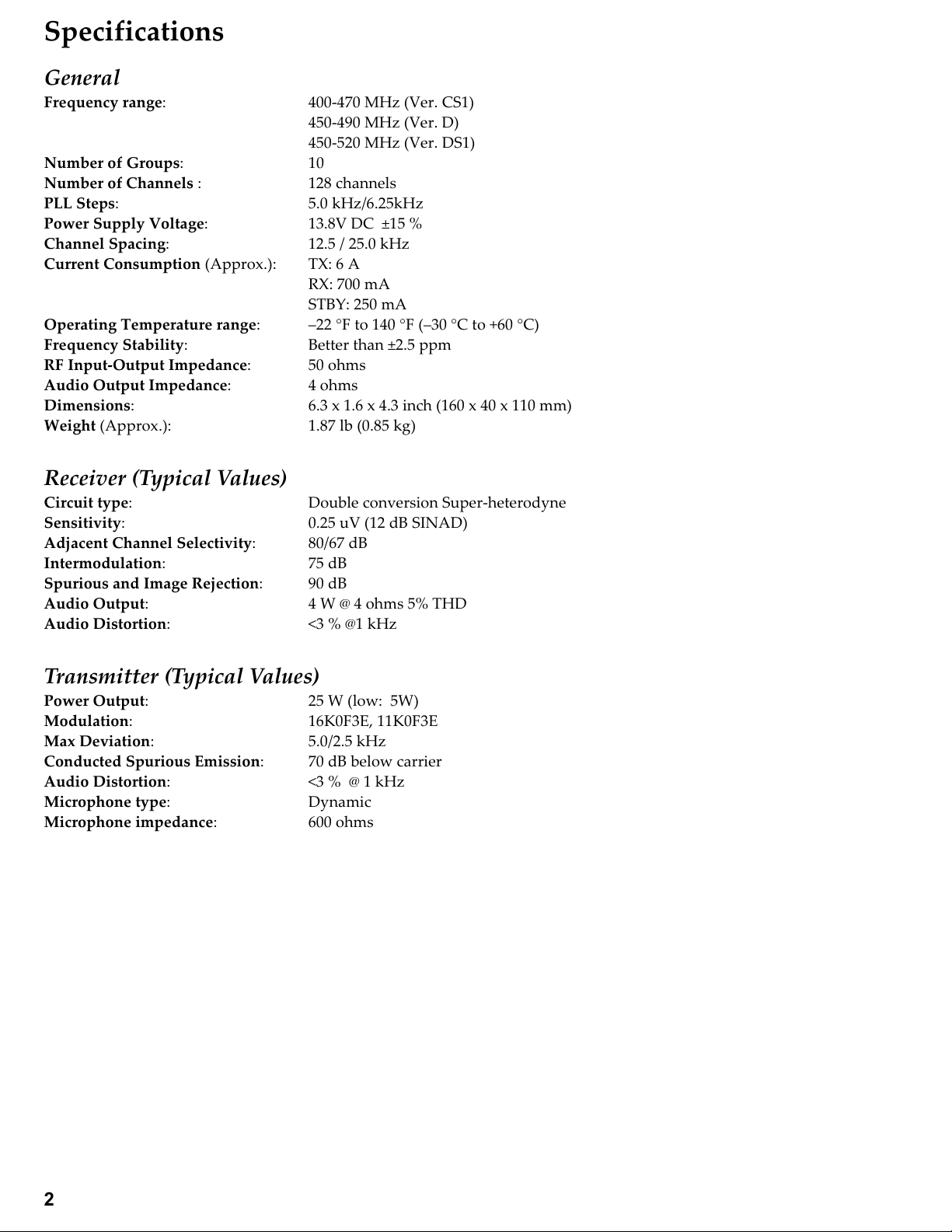

DSUB 9-pin Accessory Connector

Pin 1: Output Logic squelch (Will be effective this output during Data transmission – Inputting logic Low

level signal to the Pin #4 as the DTR signal)

High: Radio receiving the signal with the correct CTCSS, DCS, or LTR ID.

Low: Radio not receiving the signal with the correct CTCSS, DCS, or LTR ID.

Pin 2: Output Rx discriminator (Need to set the solder short on the PCB)

JP3 (JP1503) - Flat: 10 Hz to 3.0 kHz (140 mVrms / STD deviation with 600 ohm termination)

or

JP4 (JP1504) - Filtered 300 Hz to 3.0 kHz (70 mVrms / STD deviation with 600 ohm termination)

* Both JP3 and JP4 are not closed from the factory.

Pin 3: Input TX data to the radio modulator. (Flat: 10 Hz to 3.0 kHz)

(40 mVrms / STD deviation)

Pin 4: Input DTR (to switch the radio operation between dispatch operation and Data mode)

[DTR Low: Turn on the Data transmission, less than 0.5 V]

[DTR High: Turn off the Data transmission, more than 4.0 V]

Pin 5: Ground

Pin 6: Output Horn alert signal (Open collector with maximum 16.0 V, 100 mA sink).

Pin 7: Input external PTT (effective when in the Data mode)

[Low: Request the transmission]

[High: Request the Receiving]

Pin 8: Output supply voltage (Need to set the solder short on the PCB)

JP1 (JP1501) Output 5.0 V (Maximum 100 mA output)

or

JP2(JP1502) Output 13.8 V (Maximum 100 mA output)

* Both JP1 and JP2 are not closed from the factory.

Pin 9: Input the ignition signal of the CAR.

This signal is for the following operation,

(1) Disable the Horn alert during the ignition is turned on.

(2) Turn on and off the radio. This function requires the solder short JP8 (JP1508).

3

Page 4

Exploded View & Miscellaneous Parts

WIRE ASSY

T9206634A

SUPPORT

RA0060700

PM HOLDER

RA0066400

SHIELD SHEET

(Ver. CS1, DS1)

RA0513400

BLIND SEET (70 x 10)

RA0365500

CONNECTOR

P1090654

SPONGE RUBBER (SHIELD)

RA0365500

(Ver. D)

SHIELD GASKET

RA0517900

(Ver. CS1, DS1)

REF.

VXSTD P/N

U20206002

U20306002

U20308002

U24306002

U24308001

U31206007

SHIELD GASKET (Ver. CS1, DS1)

RA0515100

BINDING HEAD SCREW M2.6 x 6 NI

BINDING HEAD SCREW M3 x 6 NI

BINDING HEAD SCREW M3 x 8 NI

TAPTITE SCREW M3 x 6 NI

TAPTITE SCREW M3 x 8

OVAL HEAD SCREW M2.6 x 6 B

SHIELD GASKET (Ver. D)

S5000238

DESCRIPTION

CASE

RA0060100

MAIN UNIT

GAP PAD

S6000379

QTY.

1

2

2

4

1

7

FERRITE BEADS

L9190001

VOL KNOB

RA0377000

PANEL ASSY

RA0376000

IC

G1093909 (Ver. CS1)

G1093885 (Ver. D, DS1)

TUBE

RA0392000

BLIND SEET (4 x 3)

RA0405200

PANEL UNIT

BLIND SEET (4 x 3)

RA0405200

SPEAKER

M4090154

BLIND SHEET (4 x 25) (Lot. 1~3)

RA0425500

WIRE ASSY

T9206979

BLIND SHEET (34 x 8) (Lot. 1~4)

RA0404900

WIRE ASSY

T9206633

BLIND SHEET (35 x 4) (Lot. 1~4)

RA0405000

SPONGE RUBBER

RA0383600

CONNECTOR

P1090984

CHASSIS

RA005600C

SPONGE

RA0460200

SP HOLDER

RA0378300

4

Page 5

Block Diagram (1)

5

Page 6

Block Diagram (2)

6

Page 7

Block Diagram (3)

7

Page 8

Block Diagram (4)

8

Page 9

Interconnection Diagram

9

Page 10

Note

10

Page 11

Circuit Description

1. Overview

The VX-2500U is a UHF FM mobile transceiver designed

to operate in the frequency range of 400 to 520 MHz.

2. Circuit Configuration by Frequency

The receiver is a double-conversion superheterodyne with

a first intermediate frequency (IF) of 44.25 MHz and a

second IF of 450 kHz. Incoming signals from the antenna

are mixed with the local signal from PLL to produce the

first IF of 44.25 MHz.

This is then mixed with the 43.8 MHz second local oscil-

lator (using the 14.6 MHz reference crystal) output to pro-

duce the 450 kHz second IF. This is detected to give the

demodulated signal.

The transmit signal frequency is generated by PLL VCO,

and modulated by the signal from the microphone. It is

then amplified and sent to the antenna.

3. Receive Signal Path

Incoming RF signals from the antenna connector are de-

livered to the RF Unit, and pass through a low-pass filter

(LPF) antenna switching network consisting of coils L1001,

L1002, L1003, L1005, and L1007, capacitors C1004,

C1009,C1016, C1019, and C1025, and antenna switching

diodes D1005 and D1007 (both XB15A709A0HR) for de-

livery to the receiver front end.

Signals within the frequency range of the transceiver are

then passed through a varactor-tuned bandpass filter con-

sisting of L1008, L1009 before RF amplification by Q1011

(2SC4227:Ver. D or 2SC4226:Ver. CS1, DS1).

The amplified RF is then band-pass filtered again by var-

actor-tuned resonators L1019, L1023 to ensure pure in-

band input to 1st mixer Q1026 (3SK228:Ver. D or

SGM2016AM:Ver. CS1, DS1).

Buffered output from the VCO Unit is amplified by Q1021

(2SC5107) and low-pass filtered by L1030/L1032 and

C1184/C1188/C1192, to provide a pure 1st local signal

between 355.75 and 475.75 MHz to the 1st mixer.

The 44.25 MHz 1st mixer product then passes through

dual monolithic crystal filters XF1001 and XF1002, and is

amplified by Q1029 (2SC4215Y) and delivered to the in-

put of the FM IF subsystem IC Q1028 (TA31136FN).

This IC contains the 2nd mixer, 2nd local oscillator, limit-

er amplifier, FM detector, noise amplifier, and squelch

gates.

The 2nd LO in the IF-IC is produced from crystal X1001

(14.600 MHz), and the 1st IF is converted to 450 kHz by

the 2nd mixer and stripped of unwanted components by

ceramic filter CF1001 or CF1002. After passing through a

limiter amplifier, the signal is demodulated by the FM

detector CD1001 (CDBC450CX24).

Detected audio from Q1029 is applied to Q2016 (AK2345)

and audio low-pass filter. After volume adjustment by

Q2014 (M62364FP), the audio signal is amplified by the

AF power amplifier Q1509 (TDA2003H) and passed to

speaker jack.

4. Transmit Signal Path

Voice audio from the microphone is delivered via the MIC

(Jack) Unit to the PANEL Unit, after passing through

amplifier Q2022(NJM2902V), Mic gain-volume Q2014

(M62364FP) pre-emphasis Q2015 (NJM2902V), and lim-

iter Q2016 (IDC instantaneous deviation control), is ad-

justed for optimum deviation level and delivered to the

next stage.

Voice input from the microphone and CTCSS are FM-

modulated to the VCO of the synthesizer, while DCS au-

dio is modulated by the reference frequency oscillator of

the synthesizer.

Synthesizer output, after passing through diode switch

D1022 (1SS321), is amplified by driver Q1022

(2SC5415E), Q1025 (2SC5107:Ver. D or 2SC4226:Ver.

CS1, DS1) and power module Q1014 (RA30H4452M:Ver.

D, DS1 or RA30H4047M:Ver. CS1) to obtain full RF out-

put. The RF energy then passes through antenna switch

D1005/D1007 and a low-pass filter circuit and finally to

the antenna connector.

RF output power from the final amplifier is sampled by

CM coupler and is rectified by D1011, D1012 (both

HSM88AS). The resulting DC is fed through Automatic

Power Controller Q1003 (M5223AGP), Q1002

(2SC4154E), Q1032 (2SC4254E), and TH1003 to trans-

mitter RF amplifier and thus the power output.

Generation of spurious products by the transmitter is min-

imized by the fundamental carrier frequency being equal

to the final transmitting frequency, modulated directly in

the transmit VCO. Additional harmonic suppression is

provided by a low-pass filter consisting of L1002, L1003,

L1005, C1004, C1009, C1016, C1019, and C1025, resulting

in more than 60dB of harmonic suppression prior to de-

livery to the RF energy to the antenna.

5. PLL Frequency Synthesizer

PLL frequency synthesizer consists of the VCO Q1013

(2SK508-K52: RX) and Q1015 (2SC4226-R24: TX), VCO

buffers Q1018, Q1020, Q1021 (all 2SC5107-0), PLL sub-

system IC Q1023 (SA7025DK:Ver. D) or Q1038

(MB15A02PFV1:Ver. CS1, DS1) and 14.6 MHz reference

crystal X1001.

The frequency stability is ±2.5ppm within temperature

range of –30 to +60 degree. The output of the 14.6 MHz

reference is applied to pin 8 (Ver. D) or pin 1 (Ver. CS1,

DS1) of the PLL IC.

11

Page 12

Circuit Description

While receiving, VCO Q1013 oscillates between 355.75 and

475.75 MHz according to the transceiver version and the

programmed receiving frequency. The VCO generates

355.75 to 475.75 MHz for providing to the first local sig-

nal. In TX, the VCO generates 400 to 520 MHz.

The output of the VCO is amplified by the Q1020 and

routed to the pin 5 (Ver. D) or pin 8 (Ver. CS1, DS1) of the

PLL IC. Also the output of the VCO is amplified by the

Q1021 and routed first local/Power Module according to

D1022.

PLL data is output from "DCS_E" (pin100), "CLOCK"

(pin2) and "PLL_E" (pin98) of the microprocessor Q2013.

The data are input to PLL IC when the channel is changed

or when transmission is changed to reception and vice

versa. A PLL lock condition is always monitored by the

pin20 of the Q2013. When the PLL is unlocked, the UL

goes low.

6. Miscellaneous Circuits

6-1 DCS/LTR Demodulator

DCS signals are demodulated on the PANEL-UNIT, It is

demodulated by Q2116 (AK2345), amplifier Q2015, and

comparator Q2021.

6-2 CTCSS encoder/decoder

The CTCSS code is generation and encoding by CTCSS

encoder/decoder IC Q2016 (AK2345).

6-3 MPU

Operation is controlled by 8-bit MPU IC Q2013

(LC87F72C8A). The system clock uses a 3.6864MHz crys-

tal for a time base. IC Q2003 (S-80735SN) resets the MPU

when the power is on, and monitors the voltage of the

regulated 5V power supply line.

6-4 DCS/LTR Encorder

The DCS code is generation and encoding by MPU IC

Q2013 (LC87F72C8A). It is filtered by Q2021 (NJM2902V)

and adjusted the level by Q2014 (M62364FP).

7. Power Supply Circuits

7-1 All 13.8V

13.8V is always supplied to Power AMP Q1014

(RA30H4452M:Ver. D, DS1 or RA30H4047M:Ver. CS1).

Switched 13.8V is supplied to AF Power AMP Q1509

(TDA2003H) and 9V Regulator Q1004 (MM1216EN) and

Q1005 (2SB1201STP).

7-2 All 9V 9V regulated from 13.8V by Q1004 (MM1216EN) and Q1005 (2SB1201STP).

7-3 VCO 9V

9V is filtered by Ripple Filter and is supplied to VCO Os-

cillator Q1013 (2SK508-K52), Q1015 (2SC5107-O), and

VCO BUFFER AMP Q1015 (2SC5107-O).

7-4 5V (RF-UNIT)

5V in RF-UNIT is regulated by REGULATOR IC Q1024

(NJM78L05UA). 5V is supplied to PLL IC Q1023

(SA7025DK:Ver. D) or Q1038 (MB15A02PFV1:Ver. CS1,

DS1), FM IC Q1028 (TA31136FN), and Reference Oscilla-

tor Q1027 (23C4116GR).

7-5 TX 9V

TX 9V is active on transmit. TX 9V is supplied to ANT SW

D1005, D1007 (XB15A709A0HR) and TX DRIVER Q1022

(2SC5415E), Q1025 (2SC5107-O).

7-6 RX 9V

RX 9V is active on receive. RX 9V is supplied to RX RF

AMP Q1011 (2SC4227:Ver. D or 2SC4226:Ver. CS1, DS1)

and MIXER Q1026 (3SK228:Ver. D or SGM2016AM:Ver.

CS1, DS1).

7-7 5V (RF-UNIT)

9V from RF-UNIT is regulated to 5V by REGULATOR IC

Q2006 (NJM78L05UA) in PANEL-UNIT.

6-5 Compandor

The Compandor is active when Pin90 of Q2013

(LC87F72C8A) is “High”. When the Compandor is ac-

tive, MIC Audio is compressed, and detected audio is ex-

panded by Q2017 (LA8630M).

12

Page 13

Alignment

Introduction

The VX-2500U is carefully aligned at the factory for the

specified performance across the frequency range speci-

fied for each version. Realignment should therefore not

be necessary except in the event of a component failure,

or altering version type. All component replacement and

service should be performed only by an authorized Ver-

tex Standard representative,or the warranty policy may

be void.

The following procedures cover the sometimes critical and

tedious adjustments that are not normally required once

the transceiver has left the factory. However, if damage

occurs and some parts subsequently are placed, realign-

ment may be required. If a sudden problem occurs dur-

ing normal operation, it is likely due to component fail-

ure; realignment should not be done until after the faulty

component has been replaced.

We recommend that servicing be performed only by au-

thorized Vertex Standard service technicians who are ex-

perienced with the circuitry and fully equipped for re-

pair and alignment. Therefore, if a fault is suspected, con-

tact the dealer from whom the transceiver was purchased

for instructions regarding repair. Authorized Vertex Stan-

dard service technicians realign all circuits and make com-

plete performance checks to ensure compliance with fac-

tory specifications after replacing any faulty components.

Those who do undertake any of the following alignments

are cautioned to proceed at their own risk. Problems

caused by unauthorized attempts at realignment are not

covered by the warranty policy. Also, Vertex Standard

reserves the right to change circuits and alignment proce-

dures in the interest of improved performance, without

notifying owners.

Under no circumstances should any alignment be attempt-

ed unless the normal function and operation of the trans-

ceiver are clearly understood, the cause of the malfunc-

tion has been clearly pinpointed and any faulty compo-

nents replaced, and realignment determined to be abso-

lutely necessary.

The following test equipment (and thorough familiarity

with its correct use) is necessary for complete realignment.

Correction of problems caused by misalignment result-

ing from use of improper test equipment is not covered

under the warranty policy. While most steps do not re-

quire all of the equipment listed, the interactions of some

adjustments may require that more complex adjustments

be performed afterwards.

Required Test Equipment

RF Signal Generator with calibrated output level

at 1000MHz

Deviation Meter (linear detector)

In-line Wattmeter with 5% accuracy at 1000MHz

50Ω RF Dummy Load with power rating 100W

at 1000MHz

4Ω AF Dummy Load

Regulated DC Power Supply (standard 13.8V DC,

15A)

Frequency Counter with 0.1ppm accuracy at

1000MHz

AC Voltmeter

DC Voltmeter

VHF Sampling Coupler

IBM PC/compatible Computer

Oscilloscope

Vertex Standard VPL-1 Connection Cable &

Alignment program

Alignment Preparation & Precautions

A 50Ω RF Dummy Load and in-line wattmeter must be

connected to the main antenna jack in all procedures that

call for transmission, except where specified otherwise.

Correct alignment is not possible with an antenna.

After completing one step, read the following step to de-

termine whether the same test equipment will be required.

If not, remove the test equipment (except dummy load

and wattmeter, in connected) before proceeding.

Correct alignment requires that the ambient temperature

be the same as that of the transceiver and test equipment,

and that this temperature be held constant between 68°F

and 86°F (20°C ~ 30°C). When the transceiver is brought

into the shop from hot or cold air, it should be allowed

time to come to room temperature before alignment.

Whenever possible, alignments should be made with os-

cillator shields and circuit boards firmly affixed in place.

Also, the test equipment must be thoroughly warmed up

before beginning.

Note: Signal levels in dB referred to in the alignment pro-

cedure are based on 0dBm EMF = 0.5mV.

Do not attempt to perform only a single step unless it is

clearly isolated electrically from all other steps. Have all

test equipment ready before beginning, and follow all of

the steps in a section in the order presented.

13

Page 14

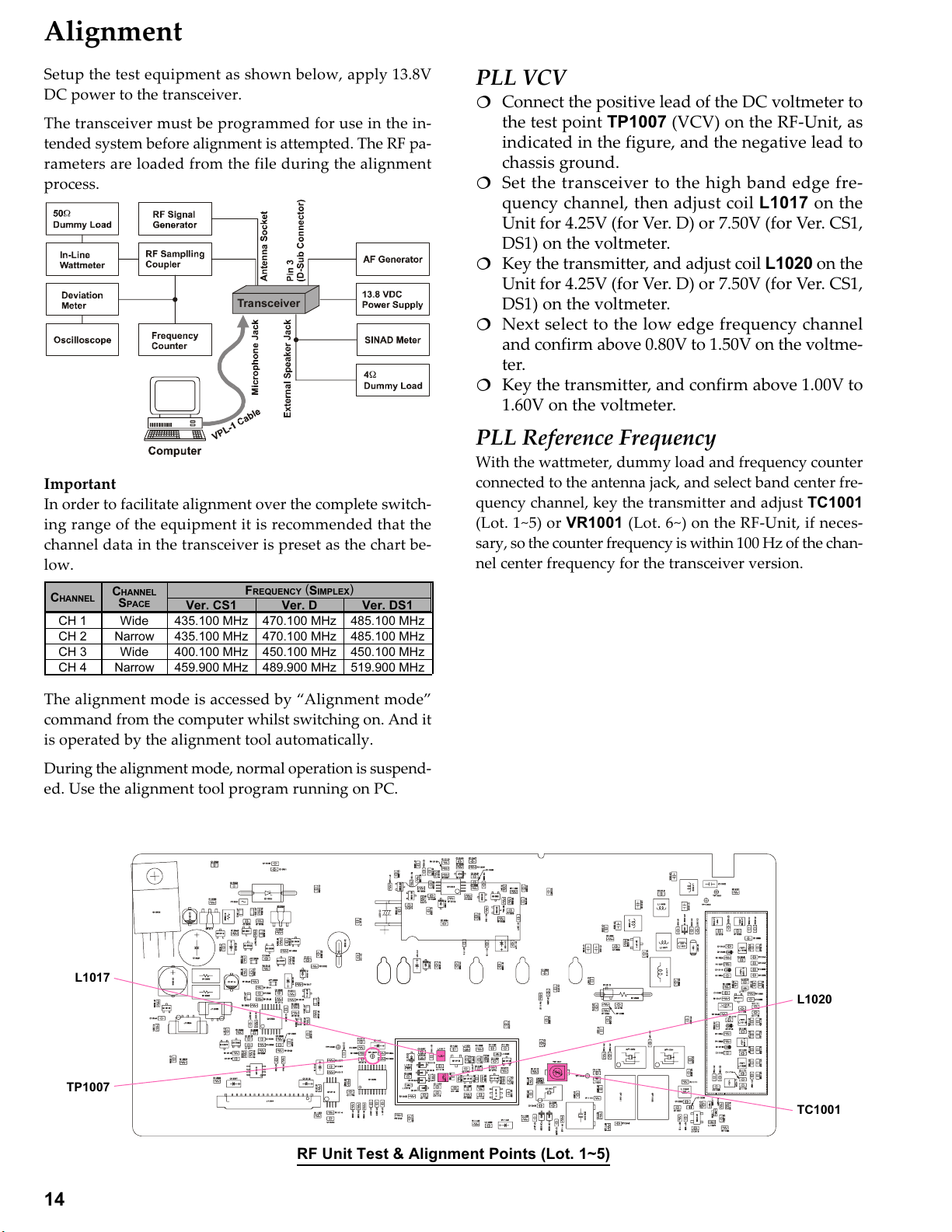

Alignment

Setup the test equipment as shown below, apply 13.8V

DC power to the transceiver.

The transceiver must be programmed for use in the in-

tended system before alignment is attempted. The RF pa-

rameters are loaded from the file during the alignment

process.

Transceiver

Important

In order to facilitate alignment over the complete switch-

ing range of the equipment it is recommended that the

channel data in the transceiver is preset as the chart be-

low.

CHANNEL

CH 1

CH 2

CH 3

CH 4

CHANNEL

SPACE

Wide

Narrow

Wide

Narrow

Ver. CS1

435.100 MHz

435.100 MHz

400.100 MHz

459.900 MHz

FREQUENCY (SIMPLEX

Ver. D

470.100 MHz

470.100 MHz

450.100 MHz

489.900 MHz

)

Ver. DS1

485.100 MHz

485.100 MHz

450.100 MHz

519.900 MHz

PLL VCV

Connect the positive lead of the DC voltmeter to

the test point TP1007 (VCV) on the RF-Unit, as

indicated in the figure, and the negative lead to

chassis ground.

Set the transceiver to the high band edge fre-

quency channel, then adjust coil L1017 on the

Unit for 4.25V (for Ver. D) or 7.50V (for Ver. CS1,

DS1) on the voltmeter.

Key the transmitter, and adjust coil L1020 on the

Unit for 4.25V (for Ver. D) or 7.50V (for Ver. CS1,

DS1) on the voltmeter.

Next select to the low edge frequency channel

and confirm above 0.80V to 1.50V on the voltme-

ter.

Key the transmitter, and confirm above 1.00V to

1.60V on the voltmeter.

PLL Reference Frequency

With the wattmeter, dummy load and frequency counter

connected to the antenna jack, and select band center fre-

quency channel, key the transmitter and adjust TC1001

(Lot. 1~5) or VR1001 (Lot. 6~) on the RF-Unit, if neces-

sary, so the counter frequency is within 100 Hz of the chan-

nel center frequency for the transceiver version.

The alignment mode is accessed by “Alignment mode”

command from the computer whilst switching on. And it

is operated by the alignment tool automatically.

During the alignment mode, normal operation is suspend-

ed. Use the alignment tool program running on PC.

L1017

TP1007

L1020

TC1001

14

RF Unit Test & Alignment Points (Lot. 1~5)

Page 15

Alignment

The alignment tool outline

Enter to the alignment mode

To enter the alignment mode, turn the receiver off, select

"Radio" then "Alignment" parameter on Clone Editor

"CE52". You turn off the power of the transceiver, and

turn on the transceiver. When the command has been suc-

cessful, a message on the computer screen will confirm

that the transceiver is now in the alignment mode.

Alignment Sequence

Although the data displayed on the computer screen dur-

ing alignment is temporary data, it is important you fol-

low the basic alignment sequence precisely, so that the

displayed data and the data loaded into the transceiver

are identical.

Basic Alignment Sequence

1. Enter the alignment mode

2. Upload data from transceiver

3. Align data

4. Download data to transceiver

Menu of the tool

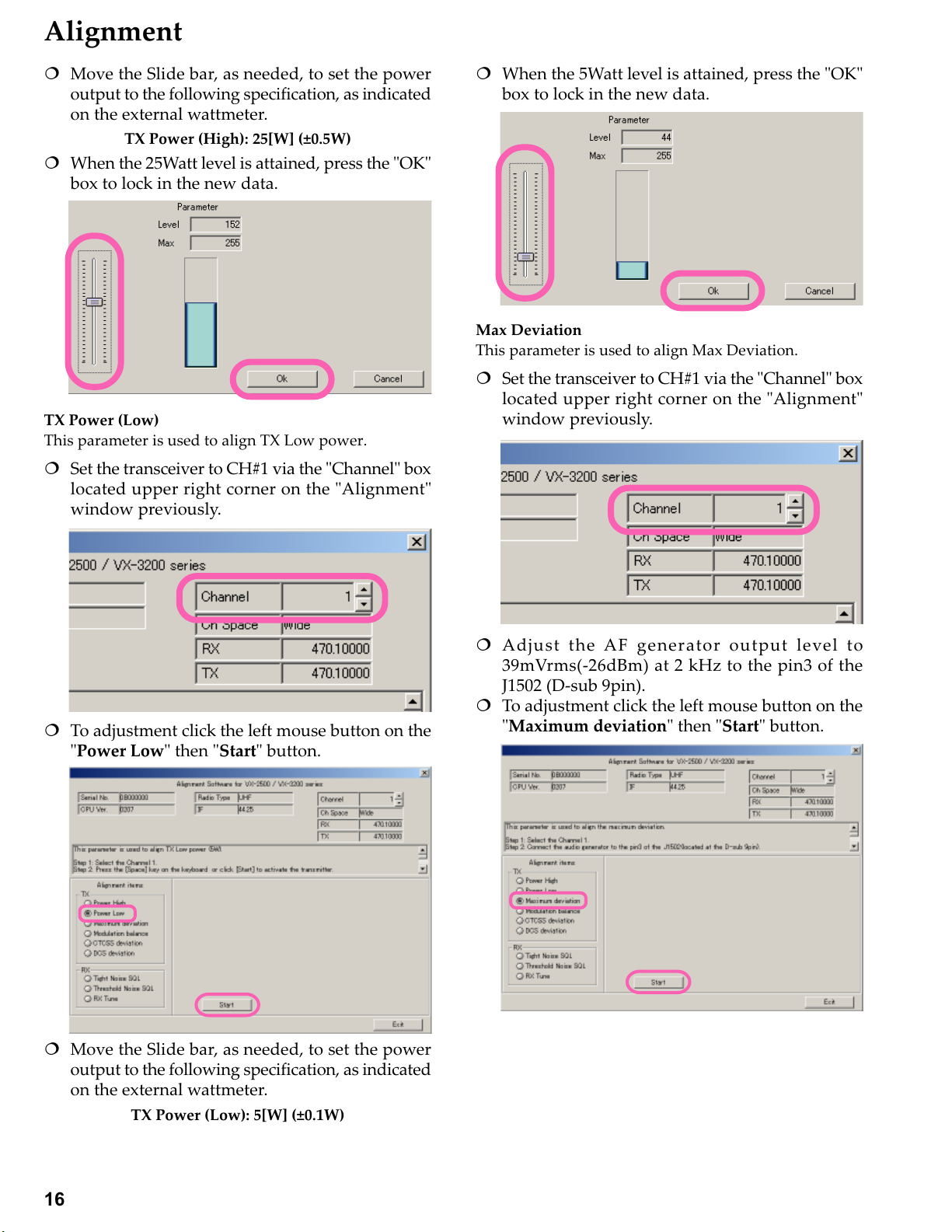

TX Power (High)

This parameter is used to align TX High power.

Set the transceiver to CH#1 via the "Channel" box

located upper right corner on the "Alignment"

window previously.

To adjustment click the left mouse button on the

"Power High" then "Start" button.

L1017

TP1007

L1020

VR1001

RF Unit Test & Alignment Points (Lot. 6~)

15

Page 16

Alignment

Move the Slide bar, as needed, to set the power

output to the following specification, as indicated

on the external wattmeter.

TX Power (High): 25[W] (±0.5W)

When the 25Watt level is attained, press the "OK"

box to lock in the new data.

TX Power (Low)

This parameter is used to align TX Low power.

Set the transceiver to CH#1 via the "Channel" box

located upper right corner on the "Alignment"

window previously.

When the 5Watt level is attained, press the "OK"

box to lock in the new data.

Max Deviation

This parameter is used to align Max Deviation.

Set the transceiver to CH#1 via the "Channel" box

located upper right corner on the "Alignment"

window previously.

To adjustment click the left mouse button on the

"Power Low" then "Start" button.

Move the Slide bar, as needed, to set the power

output to the following specification, as indicated

on the external wattmeter.

TX Power (Low): 5[W] (±0.1W)

Adjust the AF generator output level to

39mVrms(-26dBm) at 2 kHz to the pin3 of the

J1502 (D-sub 9pin).

To adjustment click the left mouse button on the

"Maximum deviation" then "Start" button.

16

Page 17

Alignment

Move the Slide bar, as needed, to set the Max

Deviation (Wide) to the following specification,

as indicated on the deviation meter.

Max Deviation (Wide): 2.8[kHz](±0.1[kHz])

When the desired deviation level is attained,

press "OK" to lock in the new data.

Set the transceiver to CH#2, and set the Max De-

viation (Narrow) to the following specification,

as indicated on the deviation meter.

Max Deviation (Narrow): 1.4[kHz](±0.1[kHz])

When the desired deviation level is attained,

press "OK" to lock in the new data.

To adjustment click the left mouse button on the

"Modulation balance" then "Start" button.

Move the Slide bar, as needed, to set the modula-

tion (Wide) wave as follows.

When the desired the modulation wave is at-

tained, press "OK" to lock in the new data.

Modulation balance

This parameter is used to align Modulation balance.

Set the transceiver to CH#1 via the "Channel" box

located upper right corner on the "Alignment"

window previously.

Adjust the AF generator output level to

774mVrms(0dBm) at 300Hz to the pin3 of the

J1502 (D-sub 9pin).

Set the transceiver to CH#2, and set the modula-

tion (Narrow) wave as follows.

When the desired deviation level is attained,

press "OK" to lock in the new data.

OK NG NG

17

Page 18

Alignment

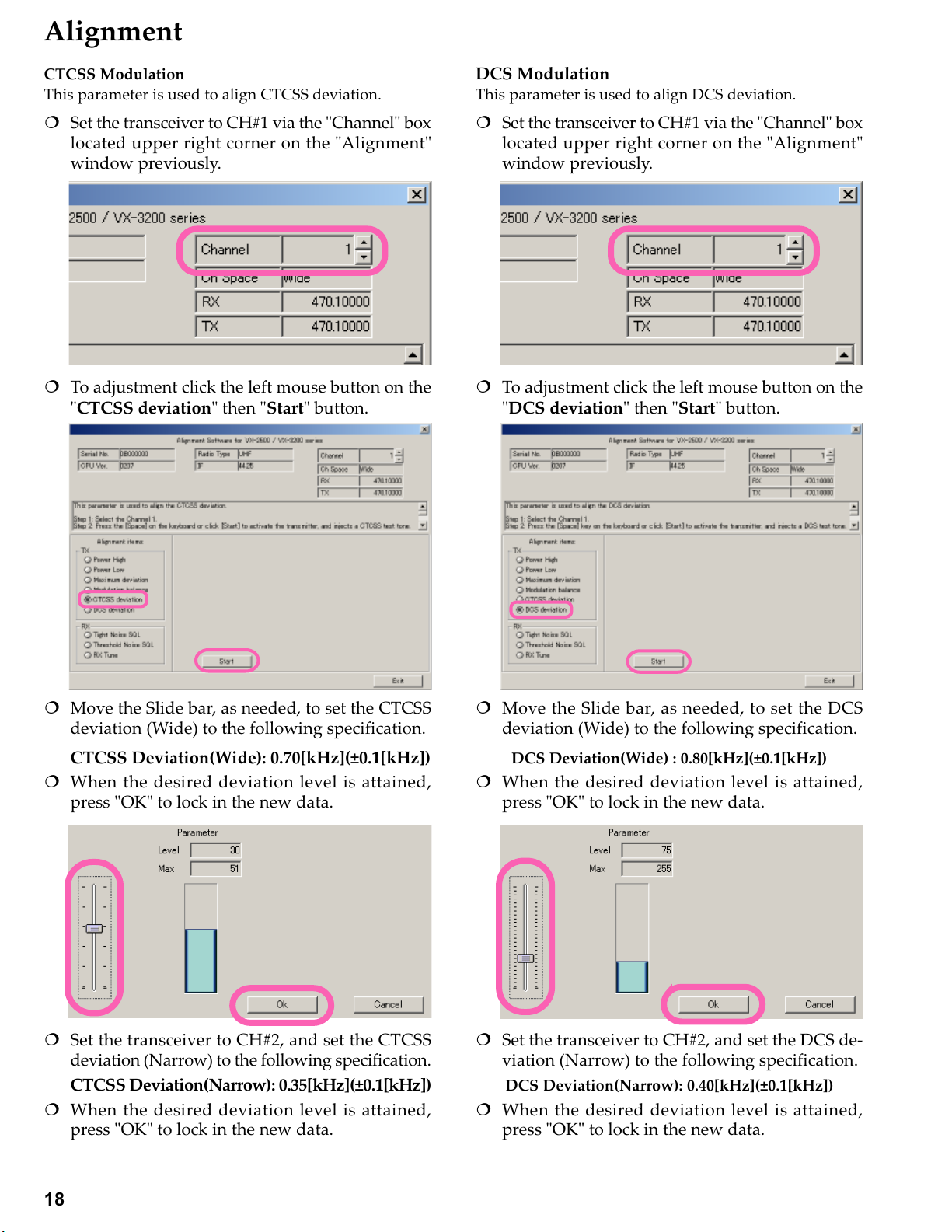

CTCSS Modulation

This parameter is used to align CTCSS deviation.

Set the transceiver to CH#1 via the "Channel" box

located upper right corner on the "Alignment"

window previously.

To adjustment click the left mouse button on the

"CTCSS deviation" then "Start" button.

DCS Modulation

This parameter is used to align DCS deviation.

Set the transceiver to CH#1 via the "Channel" box

located upper right corner on the "Alignment"

window previously.

To adjustment click the left mouse button on the

"DCS deviation" then "Start" button.

Move the Slide bar, as needed, to set the CTCSS

deviation (Wide) to the following specification.

CTCSS Deviation(Wide): 0.70[kHz](±0.1[kHz])

When the desired deviation level is attained,

press "OK" to lock in the new data.

Set the transceiver to CH#2, and set the CTCSS

deviation (Narrow) to the following specification.

CTCSS Deviation(Narrow): 0.35[kHz](±0.1[kHz])

When the desired deviation level is attained,

press "OK" to lock in the new data.

Move the Slide bar, as needed, to set the DCS

deviation (Wide) to the following specification.

DCS Deviation(Wide) : 0.80[kHz](±0.1[kHz])

When the desired deviation level is attained,

press "OK" to lock in the new data.

Set the transceiver to CH#2, and set the DCS de-

viation (Narrow) to the following specification.

DCS Deviation(Narrow): 0.40[kHz](±0.1[kHz])

When the desired deviation level is attained,

press "OK" to lock in the new data.

18

Page 19

Alignment

RX Tune

This parameter is used to RX Tune.

Set the transceiver to CH#1 via the "Channel" box

located upper right corner on the "Alignment"

window previously.

Set the SG output level to -4dBµ EMF with 3kHz

deviation.

To adjustment click the left mouse button on the

"RX Tune" then "Start" button.

Tight Noise SQL

This parameter is used to Tight Noise SQL.

Set the transceiver to CH#1 via the "Channel" box

located upper right corner on the "Alignment"

window previously.

Set the SG output level to 0dBµ EMF with 3.0kHz

deviation.

To adjustment click the left mouse button on the

"Tight Noise SQL" then "Start" button.

Move the Slide bar, as needed, to set the mini-

mum level for "Receiver Noise Level" bar.

When the desired RX Tune is attained, press "OK"

to lock in the new data.

Press "OK" to lock in the new data.

19

Page 20

Alignment

Set the transceiver to CH#2 via the "Channel" box

located upper right corner on the "Alignment"

window previously.

Set the SG output level to 0dBµ EMF with 1.5

kHz deviation.

To adjustment click the left mouse button on the

"Tight noise SQL" then "Start" button.

Threshold Noise SQL

This parameter is used to Threshold noise SQL.

Set the transceiver to CH#1 via the "Channel" box

located upper right corner on the "Alignment"

window previously.

Set the SG output level to -7dBµ EMF with 3kHz

deviation.

To adjustment click the left mouse button on the

"Threshold noise SQL" then "Start" button.

Press "OK" to lock in the new data.

Press "OK" to lock in the new data.

20

Page 21

Set the transceiver to CH#2 via the "Channel" box

located upper right corner on the "Alignment"

window previously.

Set the SG output level to -7dBµ EMF with 1.5

kHz deviation.

To adjustment click the left mouse button on the

"Threshold noise SQL" then "Start" button.

Alignment

Press "OK" to lock in the new data.

21

Page 22

Note

22

Page 23

RF Unit Jumper Information

JP1501 (JP1): Determine the output supply voltage at pin 8 of DSUB 9-pin Accessory Connector.

Close: +5.0 V (Maximum 100 mA)

Open: No Action

JP1502 (JP2): Determine the output supply voltage at pin 8 of DSUB 9-pin Accessory Connector.

Close: +13.8 V (Maximum 100 mA)

Open: No Action

JP1503 (JP3): Determine the Rx discriminator output characteristic at pin 2 of DSUB 9-pin Accessory Connec-

tor.

Close: Flat 10 Hz to 3.0 kHz (140 mVrms / STD deviation with 600 ohm termination)

Open: No Action

JP1504 (JP4): Determine the Rx discriminator output characteristic at pin 2 of DSUB 9-pin Accessory Connec-

tor.

Close: Filtered 300 Hz to 3.0 kHz (70 mVrms / STD deviation with 600 ohm termination)

Open: No Action

JP1505 (JP5): No Action (Spare Jumper).

JP1506 (JP6): Define whether the TX Data Input at pin 3 of DSUB 9-pin Accessory Connector shall be "on" or

"off" according to the external PTT Input signal signal (pin 7 of DSUB 9-pin Accessory Connec-

tor).

Close: on (Enabled)

Open: off (Disabled)

JP1507 (JP7): Determine the TX Data Input level at pin 3 of DSUB 9-pin Accessory Connector.

Close: 400 mVrms / STD deviation with 600 ohm termination

Open: 40 mVrms / STD deviation with 600 ohm termination

JP1508 (JP8): Define whether the Transceiver's power shall be "on" or "off" according to the Ignition Signal

Input (pin 9 of DSUB 9-pin Accessory Connector).

Close: Turn the transceiver on when the Ignition Signal Input (pin 9 of DSUB 9-pin Accessory

Connector) is turned to "High" while the VOL/PWR knob is set to the "ON" position (out

of the click-stop position).

Open: No Action

23

Page 24

Clone

The VX-2500 includes a convenient “Clone” feature,

which allows the programming data from one trans-

ceiver to be transferred to another VX-2500. Here is

the procedure for Cloning one radio's data to anoth-

er.

Note: Enable the "Clone" function in the [Common

2-Radio advanced setting] menu of the CE52.

1. Turn both transceivers off.

2. Connect the optional CT-4 cloning cable between

the Microphone jacks of the two transceivers.

3. Press and hold the A Button and

Button while turning the transceiver on.

4. "CLONE" will appear on the displays both trans-

ceivers when clone mode is successfully activat-

ed in this step.

5. On the Destination transceiver, press the

Down] Button. "LOADING" will appear on the

LCD.

[

Ch. Down

[

Ch.

[

6. Press the

ceiver, "SENDING" will appear on the source

transceiver, and the data will be transferred.

7. If there is a problem during the cloning process,

sound an error beep from source the transceiver.

Check your cable connections and battery volt-

age, and try again.

8. After completing the data transfer (clone),

"COMPLETE" will appear on the LCD. Tune

transceiver off and disconnect the CT-4 cable.

You can then turn the transceiver back on and

]

begin normal operation.

Ch. Up] Button on the source trans-

24

Optional cable:CT-4

Page 25

RF Unit (Ver. D: Lot. 1~5)

Circuit Diagram (1)

WIDE: 4.4 V

NARROW: 4.9 V

HIGH POWER: 6.1 V

LOW POWER: 5.3 V

HIGH POWER: 3.7 V

LOW POWER: 3.2 V

RX: 0 V

TX: 0.8 V

HIGH POWER: 3.2 V

LOW POWER: 1.3 V

HIGH POWER: 3.2 V

LOW POWER: 1.3 V

HIGH POWER: 3.2 V

LOW POWER: 1.3 V

9.0 V

3.9 V

0 V

HIGH POWER: 1.3 V

LOW POWER: 0.5 V

8.8 V

RX: 8.9 V

TX: 8.2 V

RX: 0 V

TX: 1.6 V

HIGH POWER: 0.7 V

LOW POWER: 0.3 V

RX: 0 V

TX: 8.9 V

8.1 V

4.0 V

7.4 V

RX: 5.0 V

TX: 4.9 V

RX: 0.2 V

TX: 1.8 V

RX: 4.6 V

TX: 0 V

RX: 1.4 V

TX: 1.8 V

RX: 0 V

TX: 1.8 V

3.2 V

7.0 V

7.0 V

RX: 4.6 V

TX: 4.5 V

RX: 0 V

TX: 7.4 V

RX: 0 V

TX: 7.2 V

RX: 0 V

TX: 1.3 V

2.5 V

RX: 0 V

TX: 7.2 V

0.6 V

0.4 V

RX: 0 V

TX: 7.7 V

TX: 1.7 V

4.8 V

RX: 0 V

8.1 V

3.9 V

1.4 V

RX: 0 V

TX: 2.4 V

1.7 V

2.4 V

6.4 V

6.8 V

4.9 V

5.0 V

2.9 V

RX: 6.8 V

TX: 0 V

1.4 V

WIDE: 1.9 V

NARROW: 1.7 V

4.8 V

1.9 V

3.0 V

WIDE: 1.9 V

NARROW: 1.7 V

WIDE: 2.4 V

NARROW: 0 V

WIDE: 0.4 V

NARROW: 2.2 V

2.4 V

0 V

4.9 V

2.1 V

RX: 0.6 ~ 2.3 V

1.0 V

3.8 V

WIDE: 0.4 V

NARROW: 4.5 V

2.1 V

4.1 V

4.6 V

5.0 V

1.2 V

WIDE: 4.2 V

NARROW: 0 V

WIDE: 0.4 V

NARROW: 4.5 V

1.6 V

0.8 V

3.7 V

3.7 V

3.7 V

3.7 V

3.7 V

3.7 V

0.7 ~ 4.8 V

RX: 0 V

TX: 5.0 V

RX: 0 V

TX: 8.9 V

RX: 8.9 V

TX: 0 V

RX: 5.0 V

TX: 0 V

RX: 0 V

TX: 0.4 V

RX: 1.3 V

TX: 0 V

RX: 4.0 V

TX: 0 V

3.0 V

2.1 V

3.0 V

RX: 8.8 V

TX: 0 V

RX: 8.8 V

0 V

0 V

TX: 0 V

RX: 0.3 V

TX: 0 V

0.7 V

8.4 V

8.4 V

25

Page 26

RF Unit (Ver. D: Lot. 1~5)

Circuit Diagram (2)

4.8 V

0.7 V

2.2 V

1.3 V

1.2 V

RX WIDE: 0.2 ~ 3.8 V

RX NARROW: 0.2 ~ 3.5 V

RX WIDE: 0.3 ~ 5.6 V

RX NARROW: 0.3 ~ 5.1 V

3.7 V

TX: 0.2 V

TX: 0.3 V

3.7 V

RX WIDE: 0.8 ~ 3.8 V

RX NARROW: 0.8 ~ 3.1 V

TX: 0.8 V

1.2 V

0.7 V

3.7 V

8.5 V

3.7 V

RX: 0.3 V

TX: 0 V

3.7 V

3.7 V

26

5.3 V

5.8 V

3.7 V

HORN OFF: 0 V

HORN ACTIVE: 8.9 V

HORN OFF: 0 V

HORN ACTIVE: 0.6 V

3.7 V

HORN OFF: 0 V

HORN ACTIVE: 5.0 V

HORN OFF: 8.9 V

HORN ACTIVE: 8.3 V

HORN OFF: 8.9 V

HORN ACTIVE: 0 V

HORN OFF: 0 V

HORN ACTIVE: 4.2 V

BUSY: 5.0 V

MUTE: 0 V

HORN OFF: 10.0 V

HORN ACTIVE: 0 V

0.8 V

BUSY: 4.2 V

MUTE: 0 V

BUSY: 0 V

MUTE: 13.7 V

0.9 V

0.8 V

13.8 V

1.3 V

1.6 V

0 V

13.1 V

7.3 V

Page 27

RF Unit (Ver. D: Lot. 1~5)

Parts Layout (side A)

ACB ED GFH

1

2

3

4

TDA2003H

(Q1509)

SA7025DK

(Q1023)

NJM2902V

(Q1503)

M5223

(Q1003, 1019)

2SA1602A (MF)

(Q1505)

2SB1301 (ZQ)

(Q1511)

2SD1368CB (CB)

(Q1504)

2SC4154 (E)

(Q1501)

2SC4226 (R24)

(Q1015)

2SC4227 (R34)

(Q1011)

2SC5107 (MF0)

(Q1018)

2SK508 (K52)

(Q1013)

IMH6A (H6)

(Q1017)

3SK228 (XR)

(Q1026)

RT1N241M (N2)

(Q1002, 1006,

1016, 1032, 1033,

1034, 1502, 1506,

1507, 1512, 1518)

HSM88AS (C1)

(D1011, 1012)

MC2850 (A7)

(D1506, 1507)

27

Page 28

RF Unit (Ver. D: Lot. 1~5)

Parts Layout (Side B)

a

b

c

d

e

fh

g

1

1SS321 (F9)

(D1022)

MC2848 (A6)

(D1024, 1026)

2

MC2850 (A7)

(D1501, 1502, 1503)

RT1N241M (N2)

(Q1012, 1030,

3

4

1516, 1517)

PDTC114TE (24)

(Q1508, 1510)

28

RA30H4452M

(Q1014)

TA31136FN

(Q1028)

2SB1201S

(Q1005)

2SA1602A (MF)

(Q1031)

2SB1132 (BA)

(Q1009)

2SC4116 (LG)

(Q1001, 1027)

2SC4154 (LE)

(Q1007, 1519)

2SC4215Y (QY)

(Q1029)

2SC5107 (MFO)

(Q1020, 1021, 1025)

2SC5415E (EA)

(Q1022)

2SJ125D (JD)

(Q1515)

DTB123EK (F12)

(Q1008)

IMH6A (H6)

(Q1017)

MM1216ENRE

(Q1004)

NJM78L05

(Q1024)

Page 29

RF Unit (Ver. D: Lot. 6~)

Circuit Diagram (1)

29

Page 30

RF Unit (Ver. D: Lot. 6~)

Circuit Diagram (2)

30

Page 31

RF Unit (Ver. D: Lot. 6~)

Parts Layout (side A)

ACB ED GFH

1

2

3

4

TDA2003H

(Q1509)

SA7025DK

(Q1023)

NJM2902V

(Q1503)

(Q1003:Lot. 6~)

M5223

(Q1003, 1019)

2SA1602A (MF)

(Q1505)

2SB1301 (ZQ)

(Q1511)

2SD1368CB (CB)

(Q1504)

2SC4154 (E)

(Q1501)

2SC4226 (R24)

(Q1015)

2SC4227 (R34)

(Q1011)

2SC5107 (MF0)

(Q1018)

2SK508 (K52)

(Q1013)

IMH6A (H6)

(Q1017)

3SK228 (XR)

(Q1026)

RT1N241M (N2)

(Q1002, 1006,

1016, 1032, 1033,

1034, 1502, 1506,

1507, 1512, 1518)

(Q1035:Lot. 6~)

HSM88AS (C1)

(D1011, 1012)

MC2850 (A7)

(D1506, 1507)

31

Page 32

RF Unit (Ver. D: Lot. 6~)

Parts Layout (Side B)

a

b

c

d

e

fh

g

1

2

3

4

32

RA30H4452M

(Q1014)

TA31136FN

(Q1028)

2SB1201S

(Q1005)

2SB1132 (BA)

(Q1009)

2SA1602A (MF)

(Q1031)

2SC4116 (LG)

(Q1001)

2SC4154 (LE)

(Q1007, 1519)

2SC4215Y (QY)

(Q1029)

2SC5107 (MFO)

(Q1020, 1021, 1025)

2SC5415E (EA)

(Q1022)

2SJ125D (JD)

(Q1515)

DTB123EK (F12)

(Q1008)

IMH6A (H6)

(Q1010)

MM1216ENRE

(Q1004)

NJM78L05

(Q1024)

PDTC114TE (24)

(Q1508, 1510)

RT1N241M (N2)

(Q1012, 1030,

1516, 1517)

MC2850 (A7)

(D1501, 1502, 1503)

1SS321 (F9)

(D1022)

MC2848 (A6)

(D1024, 1026)

Page 33

RF Unit (Ver. D)

Parts List

REF DESCRIPTION VALUE V/W TOL. MFR'S DESIG VXSTD P/N VERS.

PCB with Components CB1731001

Printed Circuit Board AC031U000 FR007620C 1-

FR007620D 6-

C 1001 CHIP CAP. 470pF 50V CH GRM39CH471J50PT K22174249 1- A G3

C 1002 CHIP CAP. 0.001uF 630V R GHM1030R102K630PT K22281801 1- A G2

C 1003 CHIP CAP. 220pF 50V CH GRM39CH221J50PT K22174243 1- A D2

C 1004 CHIP CAP. 3pF 200V CJ GRM40CJ030C200PT K22230210 1- A G2

C 1005 CHIP CAP. 0.1uF 25V B GRM40B104M25PT K22140811 1- A E2

C 1007 CHIP CAP. 4pF 50V CH GRM39CH040C50PT K22174205 1- A G2

C 1008 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1- B g3

C 1009 CHIP CAP. 10pF 200V CH GRM40CH100D200PT K22230216 1- A G2

C 1010 CHIP CAP. 220pF 50V CH GRM39CH221J50PT K22174243 1- A E3

C 1010 CHIP CAP. 0.01uF 50V B GRM39B103M50PT K22174823 6- A E3

C 1011 CHIP CAP. 470pF 50V CH GRM39CH471J50PT K22174249 1- A E2

C 1011 CHIP CAP. 0.01uF 50V B GRM39B103M50PT K22174823 6- A E2

C 1012 CHIP TA.CAP. 6.8uF 6.3V TEMSVA0J685M-8R K78080025 1- A C3

C 1013 CHIP TA.CAP. 6.8uF 6.3V TEMSVA0J685M-8R K78080025 1- A B3

C 1014 AL.ELECTRO.CAP. 10uF 16V RV2-16V100MB55-R K48120014 1- A B2

C 1015 CHIP CAP. 4pF 50V CH GRM39CH040C50PT K22174205 1- A G2

C 1017 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1- A C2

C 1019 CHIP CAP. 12pF 200V CH GRM40CH120J200PT K22230217 1- A F2

C 1020 CHIP CAP. 2pF 50V CK GRM39CK020C50PT K22174203 1- A G2

C 1021 CHIP CAP. 100pF 50V CH GRM39CH101J50PT K22174235 1- B f2

C 1022 CHIP CAP. 3pF 50V CJ GRM39CJ030C50PT K22174204 1- A G2

C 1023 CHIP CAP. 0.047uF 16V B GRM39B473K16PT K22124804 1- A D2

C 1025 CHIP CAP. 10pF 200V CH GRM40CH100D200PT K22230216 1- A F2

C 1026 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1- A B2

C 1027 AL.ELECTRO.CAP. 3300uF 16V RE3-16V332M 3300UF K40129065 1- A C2

C 1028 CHIP CAP. 3pF 50V CJ GRM39CJ030C50PT K22174204 1- A H1

C 1029 CHIP CAP. 0.0022uF 50V B GRM39B222K50PT K22174822 1- A D2

C 1031 CHIP CAP. 5pF 50V CH GRM39CH050C50PT K22174206 1- A G2

C 1032 CHIP CAP. 0.0047uF 50V B GRM39B472K50PT K22174833 1- A D2

C 1033 CHIP TA.CAP. 47uF 16V TEMSVC1C476M12R K78120057 1- B f2

C 1034 CHIP CAP. 0.5pF 50V CK GRM39CK0R5C50PT K22174201 1- A G2

C 1035 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1- A D2

C 1036 CHIP CAP. 10pF 50V CH GRM39CH100D50PT K22174211 1- A G2

C 1037 CHIP CAP. 47pF 50V CH GRM39CH470J50PT K22174227 1- A C3

C 1038 CHIP CAP. 470pF 50V CH GRM39CH471J50PT K22174249 1- B c3

C 1039 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1- A D2

C 1040 CHIP CAP. 4pF 50V CH GRM39CH040C50PT K22174205 1- A G2

C 1042 CHIP CAP. 4pF 50V CH GRM39CH040C50PT K22174205 1- A H2

C 1043 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1- A D2

C 1045 CHIP CAP. 4pF 50V CH GRM39CH040C50PT K22174205 1- A H2

C 1046 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1- B c3

C 1047 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1- A D2

C 1048 CHIP CAP. 27pF 50V CH GRM39CH270J50PT K22174221 1- A G2

C 1049 CHIP CAP. 0.1uF 16V B GRM39B104K16PT K22124805 1- A D2

C 1050 CHIP TA.CAP. 10uF 10V TEMSVA1A106M-8R K78100028 1- B d2

C 1051 CHIP CAP. 470pF 50V CH GRM39CH471J50PT K22174249 1- B a2

C 1052 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1- B a2

C 1053 CHIP TA.CAP. 10uF 10V TEMSVA1A106M-8R K78100028 1- B d3

C 1054 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1- B d3

C 1055 CHIP CAP. 0.5pF 50V CK GRM39CK0R5C50PT K22174201 1- A H2

C 1056 CHIP CAP. 3pF 50V CJ GRM39CJ030C50PT K22174204 1- A H2

C 1057 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1- A E2

C 1058 CHIP CAP. 470pF 50V CH GRM39CH471J50PT K22174249 1- A D2

C 1059 CHIP CAP. 0.01uF 50V B GRM39B103M50PT K22174823 1- A C2

C 1060 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1- B b2

C 1062 CHIP CAP. 470pF 50V CH GRM39CH471J50PT K22174249 1- B d3

C 1063 CHIP CAP. 470pF 50V CH GRM39CH471J50PT K22174249 1- A E2

C 1064 CHIP CAP. 4pF 50V CH GRM39CH040C50PT K22174205 1- A G2

C 1065 CHIP CAP. 0.01uF 50V B GRM39B103M50PT K22174823 1- B c2

C 1066 CHIP CAP. 470pF 50V CH GRM39CH471J50PT K22174249 1- A G2

C 1067 CHIP CAP. 3pF 50V CJ GRM39CJ030C50PT K22174204 1- A H2

C 1068 CHIP CAP. 6pF 50V CH GRM39CH060D50PT K22174207 1- A F2

C 1069 CHIP CAP. 470pF 50V CH GRM39CH471J50PT K22174249 1- B e2

C 1070 CHIP CAP. 9pF 50V CH GRM39CH090D50PT K22174210 1- A G2

C 1071 CHIP CAP. 470pF 50V CH GRM39CH471J50PT K22174249 1- B a3

C 1072 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1- A F2

C 1073 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1- B f2

C 1074 CHIP CAP. 470pF 50V CH GRM39CH471J50PT K22174249 1- B f2

C 1075 CHIP CAP. 470pF 50V CH GRM39CH471J50PT K22174249 1- B a3

C 1076 CHIP CAP. 470pF 50V CH GRM39CH471J50PT K22174249 1- B g3

C 1077 CHIP CAP. 8pF 50V CH GRM39CH080D50PT K22174209 1- B c2

C 1078 CHIP CAP. 6pF 50V CH GRM39CH060D50PT K22174207 1- A F2

C 1079 CHIP CAP. 470pF 50V CH GRM39CH471J50PT K22174249 1- A F2

LOT

SIDE

LAY ADR

33

Page 34

RF Unit (Ver. D)

Parts List

REF DESCRIPTION VALUE V/W TOL. MFR'S DESIG VXSTD P/N VERS.

C 1080 CHIP CAP. 220pF 50V CH GRM39CH221J50PT K22174243 1- B c4

C 1081 CHIP CAP. 470pF 50V CH GRM39CH471J50PT K22174249 1- B g3

C 1082 CHIP CAP. 220pF 50V CH GRM39CH221J50PT K22174243 1- A D3

C 1083 CHIP CAP. 470pF 50V CH GRM39CH471J50PT K22174249 1- B g2

C 1084 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1- B a2

C 1085 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1- A H2

C 1087 CHIP CAP. 470pF 50V CH GRM39CH471J50PT K22174249 1- A F2

C 1088 CHIP CAP. 220pF 50V CH GRM39CH221J50PT K22174243 1- A G2

C 1090 CHIP CAP. 220pF 50V CH GRM39CH221J50PT K22174243 1- A G2

C 1092 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1- B d3

C 1093 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1- A D4

C 1096 CHIP CAP. 10pF 200V CH GRM40CH100D200PT K22230216 1- A F2

C 1097 CHIP CAP. 22pF 50V CH GRM39CH220J50PT K22174219 1- A D3

C 1098 CHIP CAP. 0.1uF 16V B GRM39B104K16PT K22124805 1- B e3

C 1100 CHIP CAP. 4pF 50V CH GRM39CH040C50PT K22174205 1- A D3

C 1101 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1- A C2

C 1102 CHIP TA.CAP. 4.7uF 25V TEMSVB21E475M-8R K78140019 1- A E2

C 1104 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1- B e4

C 1105 CHIP CAP. 220pF 50V CH GRM39CH221J50PT K22174243 1- A G2

C 1107 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1- A E2

C 1108 CHIP CAP. 470pF 50V CH GRM39CH471J50PT K22174249 1- A F2

C 1109 CHIP CAP. 5pF 50V CH GRM39CH050C50PT K22174206 1- A D3

C 1111 CHIP CAP. 15pF 50V CH GRM39CH150J50PT K22174215 1- A H2

C 1112 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1- A E2

C 1113 CHIP CAP. 6pF 50V CH GRM39CH060D50PT K22174207 1- A D3

C 1114 CHIP CAP. 470pF 50V CH GRM39CH471J50PT K22174249 1- A D2

C 1115 FILM CAP. 0.033uF 16V ECHU1C333JB5 K57120013 1- B e3

C 1116 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1- B e2

C 1117 CHIP CAP. 4pF 50V CH GRM39CH040C50PT K22174205 1- A G2

C 1118 CHIP CAP. 4pF 50V CH GRM39CH040C50PT K22174205 1- A H2

C 1119 CHIP CAP. 0.5pF 50V CK GRM39CK0R5C50PT K22174201 1- A D3

C 1121 CHIP TA.CAP. 0.1uF 35V TESVA1V104M1-8R K78160025 1- A D2

C 1122 CHIP CAP. 8pF 50V CH GRM39CH080D50PT K22174209 1- A D3

C 1124 CHIP CAP. 4pF 50V CH GRM39CH040C50PT K22174205 1- A H2

C 1125 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1-5 A G2

C 1126 FILM CAP. 0.022uF 16V ECHU1C223JB5 K57120011 1- B e3

C 1127 CHIP TA.CAP. 4.7uF 10V TEMSVA1A475M-8R K78100022 1- B d3

C 1128 CHIP CAP. 6pF 50V CH GRM39CH060D50PT K22174207 1- A D3

C 1129 CHIP CAP. 3pF 50V CJ GRM39CJ030C50PT K22174204 1- A D3

C 1130 CHIP CAP. 22pF 50V CH GRM39CH220J50PT K22174219 1- A G3

C 1131 CHIP CAP. 220pF 50V CH GRM39CH221J50PT K22174243 1- B d3

C 1132 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1- A E3

C 1133 CHIP CAP. 220pF 50V CH GRM39CH221J50PT K22174243 1- A D3

C 1134 CHIP CAP. 22pF 50V CH GRM39CH220J50PT K22174219 6- B c3

C 1135 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1- A G3

C 1136 CHIP CAP. 7pF 50V CH GRM39CH070D50PT K22174208 1- B e2

C 1137 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1- A D3

C 1138 CHIP CAP. 12pF 50V CH GRM39CH120J50PT K22174213 1- A D3

C 1139 CHIP CAP. 10pF 50V CH GRM39CH100D50PT K22174211 1- A D3

C 1140 CHIP CAP. 8pF 50V CH GRM39CH080D50PT K22174209 1- B c2

C 1141 CHIP TA.CAP. 1uF 16V TESVA1C105M1-8R K78120009 1- B e3

C 1142 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1- A D3

C 1143 CHIP CAP. 7pF 50V CH GRM39CH070D50PT K22174208 1- B e2

C 1144 CHIP CAP. 0.5pF 50V CK GRM39CK0R5C50PT K22174201 1- A H3

C 1145 CHIP CAP. 0.5pF 50V CK GRM39CK0R5C50PT K22174201 1- A D3

C 1146 CHIP CAP. 4pF 50V CH GRM39CH040C50PT K22174205 1- A G3

C 1147 CHIP CAP. 3pF 50V CJ GRM39CJ030C50PT K22174204 1- A H3

C 1148 CHIP CAP. 10pF 50V CH GRM39CH100D50PT K22174211 1- B e2

C 1149 CHIP TA.CAP. 6.8uF 6.3V TEMSVA0J685M-8R K78080025 1- A E4

C 1149 CHIP TA.CAP. 2.2uF 10V TESVA1A225M1-8R K78100021 6- A E4

C 1150 CHIP CAP. 0.01uF 50V B GRM39B103M50PT K22174823 1- B e3

C 1151 CHIP CAP. 3pF 50V CJ GRM39CJ030C50PT K22174204 1- A H3

C 1152 CHIP CAP. 1pF 50V CK GRM39CK010C50PT K22174202 1- A D3

C 1153 CHIP CAP. 9pF 50V CH GRM39CH090D50PT K22174210 1- A H3

C 1154 CHIP CAP. 6pF 50V CH GRM39CH060D50PT K22174207 1- B e2

C 1155 CHIP CAP. 0.1uF 16V B GRM39B104K16PT K22124805 1- A E3

C 1156 CHIP CAP. 1pF 50V CK GRM39CK010C50PT K22174202 6- A F3

C 1157 CHIP CAP. 15pF 50V CH GRM39CH150J50PT K22174215 1- A F3

C 1157 CHIP CAP. 10pF 50V CH GRM39CH100D50PT K22174211 6- A F3

C 1158 CHIP CAP. 470pF 50V CH GRM39CH471J50PT K22174249 1- A E3

C 1159 CHIP CAP. 5pF 50V CH GRM39CH050C50PT K22174206 1- A G3

C 1160 CHIP CAP. 3pF 50V CJ GRM39CJ030C50PT K22174204 1- A H3

C 1161 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1- B d3

C 1162 CHIP TA.CAP. 33uF 10V TEMSVB21A336M-8R K78100047 1- B b3

C 1163 CHIP CAP. 220pF 50V CH GRM39CH221J50PT K22174243 1- A E3

C 1164 CHIP CAP. 12pF 50V CH GRM39CH120J50PT K22174213 1- A E3

LOT

SIDE

LAY ADR

34

Page 35

RF Unit (Ver. D)

Parts List

REF DESCRIPTION VALUE V/W TOL. MFR'S DESIG VXSTD P/N VERS.

C 1165 CHIP CAP. 0.5pF 50V CK GRM39CK0R5C50PT K22174201 1- A H3

C 1166 CHIP CAP. 3pF 50V CJ GRM39CJ030C50PT K22174204 1- A H3

C 1167 CHIP CAP. 6pF 50V CH GRM39CH060D50PT K22174207 1- B c3

C 1168 CHIP CAP. 470pF 50V CH GRM39CH471J50PT K22174249 1- A G3

C 1169 CHIP CAP. 0.01uF 50V B GRM39B103M50PT K22174823 1- B e3

C 1169 CHIP CAP. 0.1uF 16V B GRM39B104K16PT K22124805 6- B e3

C 1170 CHIP CAP. 22pF 50V CH GRM39CH220J50PT K22174219 1- B e3

C 1171 CHIP CAP. 7pF 50V CH GRM39CH070D50PT K22174208 1- A G3

C 1172 CHIP CAP. 220pF 50V CH GRM39CH221J50PT K22174243 1- B e2

C 1173 CHIP CAP. 15pF 50V CH GRM39CH150J50PT K22174215 1- B e3

C 1175 CHIP CAP. 3pF 50V CJ GRM39CJ030C50PT K22174204 1- A G3

C 1176 CHIP CAP. 9pF 50V CH GRM39CH090D50PT K22174210 1- A F3

C 1177 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1- B e2

C 1178 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1- A C3

C 1179 CHIP CAP. 0.01uF 50V B GRM39B103M50PT K22174823 1- A F3

C 1180 CHIP CAP. 3pF 50V CJ GRM39CJ030C50PT K22174204 1- A G3

C 1181 CHIP CAP. 15pF 50V CH GRM39CH150J50PT K22174215 1- B c3

C 1182 CHIP CAP. 9pF 50V CH GRM39CH090D50PT K22174210 1- B e3

C 1183 CHIP CAP. 0.1uF 16V B GRM39B104K16PT K22124805 1- B f3

C 1183 CHIP CAP. 470pF 50V CH GRM39CH471J50PT K22174249 6- B f3

C 1184 CHIP CAP. 3pF 50V CJ GRM39CJ030C50PT K22174204 1- B b3

C 1185 CHIP CAP. 5pF 50V CH GRM39CH050C50PT K22174206 1- A G3

C 1186 CHIP CAP. 220pF 50V CH GRM39CH221J50PT K22174243 1- B e2

C 1187 CHIP CAP. 220pF 50V CH GRM39CH221J50PT K22174243 1- B e2

C 1188 CHIP CAP. 12pF 50V CH GRM39CH120J50PT K22174213 1- B a3

C 1189 CHIP CAP. 220pF 50V CH GRM39CH221J50PT K22174243 1- B e3

C 1190 CHIP CAP. 100pF 50V CH GRM39CH101J50PT K22174235 1- B e3

C 1191 CHIP CAP. 220pF 50V CH GRM39CH221J50PT K22174243 1- B c3

C 1192 CHIP CAP. 12pF 50V CH GRM39CH120J50PT K22174213 1- B a3

C 1193 CHIP CAP. 470pF 50V CH GRM39CH471J50PT K22174249 1- B c2

C 1194 CHIP CAP. 220pF 50V CH GRM39CH221J50PT K22174243 1- B g3

C 1195 CHIP CAP. 5pF 50V CH GRM39CH050C50PT K22174206 1- B d2

C 1196 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1- B d2

C 1197 CHIP CAP. 220pF 50V CH GRM39CH221J50PT K22174243 1- B c3

C 1198 CHIP CAP. 220pF 50V CH GRM39CH221J50PT K22174243 1- B f2

C 1199 CHIP CAP. 100pF 50V CH GRM39CH101J50PT K22174235 1- B e3

C 1200 CHIP CAP. 12pF 50V CH GRM39CH120J50PT K22174213 1- B c3

C 1201 CHIP CAP. 470pF 50V CH GRM39CH471J50PT K22174249 1- B c2

C 1202 CHIP CAP. 10pF 50V CH GRM39CH100D50PT K22174211 1- B e3

C 1203 CHIP CAP. 33pF 50V CH GRM39CH330J50PT K22174223 1- B e3

C 1204 CHIP CAP. 6pF 50V CH GRM39CH060D50PT K22174207 1- A G3

C 1205 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1- A C3

C 1206 CHIP CAP. 220pF 50V CH GRM39CH221J50PT K22174243 1- B d2

C 1207 CHIP CAP. 2pF 50V CK GRM39CK020C50PT K22174203 1- B a3

C 1208 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1- B d2

C 1209 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1- A C3

C 1210 CHIP CAP. 0.1uF 16V B GRM39B104K16PT K22124805 1- B e3

C 1211 CHIP CAP. 220pF 50V CH GRM39CH221J50PT K22174243 1- A C3

C 1212 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1- B e3

C 1213 CHIP CAP. 220pF 50V CH GRM39CH221J50PT K22174243 1- B d2

C 1214 CHIP CAP. 0.1uF 16V B GRM39B104K16PT K22124805 1- B e3

C 1215 CHIP CAP. 10pF 50V CH GRM39CH100D50PT K22174211 1- B c2

C 1216 CHIP CAP. 22pF 50V CH GRM39CH220J50PT K22174219 1- B c2

C 1217 CHIP TA.CAP. 10uF 6.3V TEMSVA0J106M-8R K78080027 1- B f3

C 1218 CHIP CAP. 22pF 50V CH GRM39CH220J50PT K22174219 1- B d2

C 1219 CHIP CAP. 0.01uF 50V B GRM39B103M50PT K22174823 1- A G4

C 1220 CHIP CAP. 470pF 50V CH GRM39CH471J50PT K22174249 1- B c2

C 1221 CHIP CAP. 470pF 50V CH GRM39CH471J50PT K22174249 1- A F3

C 1222 CHIP CAP. 15pF 50V CH GRM39CH150J50PT K22174215 1- A G3

C 1223 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1- A G3

C 1224 CHIP CAP. 3pF 50V CJ GRM39CJ030C50PT K22174204 1- A G3

C 1224 CHIP CAP. 2pF 50V CK GRM39CK020C50PT K22174203 6- A G3

C 1225 CHIP CAP. 0.01uF 50V B GRM39B103M50PT K22174823 1- A G3

C 1226 CHIP TA.CAP. 4.7uF 10V TEMSVA1A475M-8R K78100022 1- B f2

C 1227 CHIP CAP. 0.01uF 50V B GRM39B103M50PT K22174823 1- B b3

C 1228 CHIP CAP. 470pF 50V CH GRM39CH471J50PT K22174249 1- A E4

C 1229 CHIP CAP. 0.01uF 50V B GRM39B103M50PT K22174823 1- B a3

C 1230 CHIP CAP. 18pF 50V CH GRM39CH180J50PT K22174217 1-5 A E2

C 1231 CHIP CAP. 2pF 50V CK GRM39CK020C50PT K22174203 1- A E2

C 1231 CHIP CAP. 0.1uF 16V B GRM39B104K16PT K22124805 6- A E2

C 1232 CHIP CAP. 220pF 50V CH GRM39CH221J50PT K22174243 1- A C2

C 1232 CHIP CAP. 470pF 50V CH GRM39CH471J50PT K22174249 6- A C2

C 1233 CHIP CAP. 0.01uF 50V B GRM39B103M50PT K22174823 1- B b4

C 1234 CHIP CAP. 0.01uF 50V B GRM39B103M50PT K22174823 1- B b3

C 1235 CHIP CAP. 0.01uF 50V B GRM39B103M50PT K22174823 1- B b2

C 1236 CHIP CAP. 2pF 50V CK GRM39CK020C50PT K22174203 1- A B4

LOT

SIDE

LAY ADR

35

Page 36

RF Unit (Ver. D)

Parts List

REF DESCRIPTION VALUE V/W TOL. MFR'S DESIG VXSTD P/N VERS.

C 1236 CHIP CAP. 3pF 50V CJ GRM39CJ030C50PT K22174204 4-5 A B4

C 1237 CHIP CAP. 0.01uF 50V B GRM39B103M50PT K22174823 1-5 B c3

C 1238 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1- B c3

C 1239 CHIP CAP. 22pF 50V CH GRM39CH220J50PT K22174219 1- B c3

C 1240 CHIP CAP. 0.1uF 16V B GRM39B104K16PT K22124805 1- B c3

C 1241 CHIP CAP. 15pF 50V CH GRM39CH150J50PT K22174215 1- B c4

C 1242 CHIP CAP. 39pF 50V CH GRM39CH390J50PT K22174225 1- B c3

C 1243 CHIP CAP. 0.01uF 50V B GRM39B103M50PT K22174823 1- B c3

C 1244 CHIP CAP. 100pF 50V CH GRM39CH101J50PT K22174235 1- B c3

C 1245 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1- B f4

C 1246 CHIP CAP. 47pF 50V CH GRM39CH470J50PT K22174227 1- B f2

C 1246 CHIP CAP. 0.01uF 50V B GRM39B103M50PT K22174823 6- B f2

C 1247 CHIP CAP. 6pF 50V CH GRM39CH060D50PT K22174207 1-5 A C3

C 1248 CHIP CAP. 0.1uF 16V B GRM39B104K16PT K22124805 1- A F4

C 1249 CHIP CAP. 12pF 50V CH GRM39CH120J50PT K22174213 1- B c3

C 1250 CHIP CAP. 0.01uF 50V B GRM39B103M50PT K22174823 1- B b3

C 1251 CHIP CAP. 68pF 50V CH GRM39CH680J50PT K22174231 1- A F3

C 1252 CHIP CAP. 0.1uF 16V B GRM39B104K16PT K22124805 1- A F3

C 1253 CHIP CAP. 0.1uF 16V B GRM39B104K16PT K22124805 1- A E2

C 1254 CHIP CAP. 470pF 50V CH GRM39CH471J50PT K22174249 1- B b2

C 1255 CHIP CAP. 100pF 50V CH GRM39CH101J50PT K22174235 1- B e3

C 1256 CHIP CAP. 0.1uF 16V B GRM39B104K16PT K22124805 1- A D2

C 1257 CHIP CAP. 470pF 50V CH GRM39CH471J50PT K22174249 1- A E2

C 1258 CHIP CAP. 470pF 50V CH GRM39CH471J50PT K22174249 1- A C2

C 1260 CHIP CAP. 470pF 50V CH GRM39CH471J50PT K22174249 1- A F2

C 1261 CHIP TA.CAP. 4.7uF 16V TEMSVA1C475M-8R K78120031 1- B f2

C 1268 CHIP TA.CAP. 10uF 10V TEMSVA1A106M-8R K78100028 1- B f3

C 1269 CHIP CAP. 470pF 50V CH GRM39CH471J50PT K22174249 1- A D2

C 1270 CHIP CAP. 470pF 50V CH GRM39CH471J50PT K22174249 1- B f2

C 1271 CHIP CAP. 470pF 50V CH GRM39CH471J50PT K22174249 1- A D2

C 1272 CHIP CAP. 470pF 50V CH GRM39CH471J50PT K22174249 1- A E2

C 1273 CHIP CAP. 470pF 50V CH GRM39CH471J50PT K22174249 1- A E2

C 1274 CHIP CAP. 220pF 50V CH GRM39CH221J50PT K22174243 1- A E3

C 1277 CHIP CAP. 220pF 50V CH GRM39CH221J50PT K22174243 1- B f3

C 1279 CHIP CAP. 0.1uF 16V B GRM39B104K16PT K22124805 1-5 B d4

C 1280 CHIP CAP. 3pF 50V CJ GRM39CJ030C50PT K22174204 1- A G2

C 1281 CHIP CAP. 18pF 50V CH GRM39CH180J50PT K22174217 1- A G3

C 1282 CHIP CAP. 1pF 50V CK GRM39CK010C50PT K22174202 3 B e3

C 1287 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 6- A F3

C 1288 CHIP CAP. 470pF 50V CH GRM39CH471J50PT K22174249 6- A E2

C 1289 CHIP CAP. 0.01uF 50V B GRM39B103M50PT K22174823 6- A F2

C 1291 CHIP CAP. 0.1uF 16V B GRM39B104K16PT K22124805 6- A E2

C 1292 CHIP CAP. 10pF 50V CH GRM39CH100D50PT K22174211 6- B c3

C 1293 CHIP CAP. 0.01uF 50V B GRM39B103M50PT K22174823 6- B c4

C 1294 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 6- A E2

C 1295 CHIP CAP. 1pF 50V CK GRM39CK010C50PT K22174202 6- A F3

C 1501 CHIP CAP. 100pF 50V CH GRM39CH101J50PT K22174235 1- A B2

C 1502 CHIP CAP. 100pF 50V CH GRM39CH101J50PT K22174235 1- B f2

C 1503 CHIP CAP. 100pF 50V CH GRM39CH101J50PT K22174235 1- A A2

C 1504 CHIP CAP. 100pF 50V CH GRM39CH101J50PT K22174235 1- B g2

C 1505 CHIP CAP. 0.1uF 16V B GRM39B104K16PT K22124805 1- A B2

C 1506 CHIP CAP. 100pF 50V CH GRM39CH101J50PT K22174235 1- A B2

C 1507 CHIP TA.CAP. 10uF 10V TEMSVA1A106M-8R K78100028 1- A B2

C 1508 CHIP CAP. 100pF 50V CH GRM39CH101J50PT K22174235 1- A B2

C 1509 CHIP CAP. 1uF 10V F GRM39F105Z10PT K22105001 1- A B2

C 1510 CHIP CAP. 1uF 10V F GRM39F105Z10PT K22105001 1- B g2

C 1511 CHIP CAP. 0.01uF 50V B GRM39B103M50PT K22174823 1- A B3

C 1512 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1- B g2

C 1513 CHIP CAP. 0.01uF 50V B GRM39B103M50PT K22174823 1- A B3

C 1513 CHIP CAP. 0.047uF 16V B GRM39B473K16PT K22124804 4- A B3

C 1515 AL.ELECTRO.CAP. 10uF 16V RV2-16V100MB55-R K48120014 1- A A2

C 1516 CHIP CAP. 0.1uF 16V B GRM39B104K16PT K22124805 1- A B3

C 1517 CHIP CAP. 0.1uF 16V B GRM39B104K16PT K22124805 1- A B3

C 1518 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1- B g2

C 1519 CHIP TA.CAP. 4.7uF 10V TEMSVA1A475M-8R K78100022 1- B f3

C 1520 AL.ELECTRO.CAP. 100uF 16V ECEV1CA101WP K48120012 1- A A2

C 1521 AL.ELECTRO.CAP. 470uF 16V RE3-16V471M 470UF K40129066 1- A A2

C 1523 CHIP TA.CAP. 1uF 16V TESVA1C105M1-8R K78120009 1- B f2

C 1523 CHIP TA.CAP. 10uF 10V TEMSVA1A106M-8R K78100028 4- B f2

C 1524 CHIP CAP. 0.1uF 16V B GRM39B104K16PT K22124805 1- B g2

C 1525 CHIP CAP. 120pF 50V CH GRM39CH121J50PT K22174237 1- A B3

C 1526 CHIP CAP. 470pF 50V CH GRM39CH471J50PT K22174249 1- A B3

C 1527 CHIP CAP. 0.1uF 16V B GRM39B104K16PT K22124805 1- A B2

C 1528 CHIP CAP. 0.1uF 16V B GRM39B104K16PT K22124805 1- A B2

C 1529 CHIP CAP. 470pF 50V CH GRM39CH471J50PT K22174249 1- A B3

C 1530 CHIP CAP. 470pF 50V CH GRM39CH471J50PT K22174249 1- A B3

LOT

SIDE

LAY ADR

36

Page 37

RF Unit (Ver. D)

Parts List

REF DESCRIPTION VALUE V/W TOL. MFR'S DESIG VXSTD P/N VERS.

C 1531 CHIP CAP. 0.0047uF 50V B GRM39B472K50PT K22174833 1- A B3

C 1532 CHIP CAP. 6pF 50V CH GRM39CH060D50PT K22174207 1- A B2

C 1533 CHIP CAP. 1uF 10V F GRM39F105Z10PT K22105001 1- A B2

C 1534 CHIP TA.CAP. 10uF 10V TEMSVA1A106M-8R K78100028 1- B f2

C 1535 CHIP CAP. 1uF 10V F GRM39F105Z10PT K22105001 1- A B3

C 1536 CHIP CAP. 470pF 50V CH GRM39CH471J50PT K22174249 1- B f3

C 1537 CHIP TA.CAP. 2.2uF 10V TESVA1A225M1-8R K78100021 1- A B3

C 1538 CHIP CAP. 0.0047uF 50V B GRM39B472K50PT K22174833 1- A A3

C 1539 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1- B g2

C 1540 CHIP CAP. 1uF 10V F GRM39F105Z10PT K22105001 1- B h2

C 1541 CHIP CAP. 0.1uF 16V B GRM39B104K16PT K22124805 1- B f2

C 1543 CHIP CAP. 0.1uF 16V B GRM39B104K16PT K22124805 1- B f2

C 1544 CHIP CAP. 0.1uF 16V B GRM39B104K16PT K22124805 1- A A2

C 1545 CHIP CAP. 0.1uF 16V B GRM39B104K16PT K22124805 1- A B2

C 1546 CHIP CAP. 0.1uF 16V B GRM39B104K16PT K22124805 1- A B2

C 1549 CHIP CAP. 0.1uF 16V B GRM39B104K16PT K22124805 1- B f3

C 1550 CHIP CAP. 470pF 50V CH GRM39CH471J50PT K22174249 1- B f3

CD1001 CERAMIC DISC CDBC450CX24-TC H7901340 1- A F3

CF1001 CERAMIC FILTER CFWM450E H3900466 1- A F3

CF1001 CERAMIC FILTER ALFYM450E-002S2=K H3900555 11- A F3

CF1002 CERAMIC FILTER CFWM450G H3900435 1- A F3

CF1002 CERAMIC FILTER ALFYM450G-002S2=K H3900557 11- A F3

D 1001 DIODE RLS135 TE-11 G2070128 1- A G2

D 1002 DIODE BAS316 G2070716 1- A G2

D 1003 DIODE DSA3A1 G2090445 1- A C2

D 1004 SURGE ABSORBER P6KA18 Q9000721 1- A B2

D 1005 DIODE UM9957F/TR G2070562 1- B b2

D 1005 DIODE XB15A709A0HR G2070826 8- B b2

D 1006 DIODE BAS316 G2070716 1- A D2

D 1007 DIODE UM9957F/TR G2070562 1- B b2

D 1007 DIODE XB15A709A0HR G2070826 8- B b2

D 1008 DIODE HVC358B(TAPE) G2070590 1- A G2

D 1009 DIODE BAS316 G2070716 1- A D2

D 1010 DIODE HVC358B(TAPE) G2070590 1- A G2

D 1011 DIODE HSM88AS TR G2070170 1- A F2

D 1012 DIODE HSM88AS TR G2070170 1- A F2

D 1013 DIODE HVU306A5TRF G2070132 1- A D3

D 1014 DIODE HVU306A5TRF G2070132 1- A D3

D 1015 DIODE 1SV276(TPH3) G2070420 1- A D3

D 1016 DIODE 1SV276(TPH3) G2070420 1- A D3

D 1017 DIODE 1SV214 TPH G2070356 1- A D3

D 1018 DIODE HVC358B(TAPE) G2070590 1- A G2

D 1019 DIODE HVC358B(TAPE) G2070590 1- A G3

D 1020 DIODE HVU300A-TR G2070140 1-5 A C3

D 1021 DIODE BAS316 G2070716 1- B d2

D 1022 DIODE 1SS321 TE85R G2070076 1- B c2

D 1023 DIODE HVU359TRF G2070452 1-5 A C3

D 1024 DIODE MC2848-T11-1 G2070694 1- B b3

D 1025 DIODE HVU359TRF G2070452 1-5 A D3

D 1026 DIODE MC2848-T11-1 G2070694 1- B b4

D 1027 DIODE HZU5ALL-TR G2070754 1- A D2

D 1501 DIODE MC2850-T11-1 G2070704 1- B g3

D 1502 DIODE MC2850-T11-1 G2070704 1- B g3

D 1503 DIODE MC2850-T11-1 G2070704 1- B g2

D 1504 DIODE BAS316 G2070716 1- B g2

D 1505 DIODE D1F20-4063 G2070474 1- B f2

D 1506 DIODE MC2850-T11-1 G2070704 1- A B3

D 1507 DIODE MC2850-T11-1 G2070704 1- A B3

F 1501 CHIP FUSE 0.25A KAB-2402-251NA31 Q0000085 1- A B2

J 1501 CONNECTOR IL-FPR-36S-VF-E1500 P1091126 1- A B3

J 1502 CONNECTOR AE0031-00 P1090998 1- B g1

J 1503 CONNECTOR 53398-0290 P0091191 1- A A2

J 1504 CONNECTOR 53398-0390 P0091192 1- A A2

L 1001 COIL E2 0.4-1.5-4T-L L0022475 1- A G2

L 1002 COIL 0.015uH AS0803-15NK L0022536 1- A G2

L 1003 COIL 0.015uH AS0803-15NK L0022536 1- A G2

L 1004 COIL E2 0.35-1.6-4T-L L0022456 1- A G2

L 1005 COIL 0.015uH AS0803-15NK L0022536 1- A F2

L 1006 COIL E2 0.35-1.6-4T-L L0022456 1- A G2

L 1007 COIL 0.015uH AS0803-15NK L0022536 1- A G2

L 1008 COIL E2 0.35-1.6-4T-L L0022456 1- A G2

L 1009 COIL E2 0.35-1.6-4T-L L0022456 1- A G2

L 1010 COIL 0.068uH AS0807-68NK L0022541 1- A F2

L 1011 M.RFC 0.0047uH LL1608-FS4N7S L1690905 1- A G2

L 1012 M.RFC 0.39uH 2% C1608CA-R39G L1691107 1- A D3

L 1013 M.RFC 0.082uH HK1608 82NJ-T L1690527 1- A D3

LOT

SIDE

LAY ADR

37

Page 38

RF Unit (Ver. D)

Parts List

REF DESCRIPTION VALUE V/W TOL. MFR'S DESIG VXSTD P/N VERS.

L 1014 M.RFC 0.39uH 2% C1608CA-R39G L1691107 1- A D3

L 1015 CHIP COIL 0.017uH LQN1A17NJ04 L1690249 1- A G2

L 1016 M.RFC 0.1uH 5% C1608CA-R10J L1691063 1- A D3

L 1017 COIL E2 0.35-1.6-4T-L L0022456 1- A D3

L 1018 M.RFC 0.39uH 2% C1608CA-R39G L1691107 1- A D3

L 1019 COIL E2 0.35-1.6-4T-L L0022456 1- A G2

L 1020 COIL E2 0.35-1.6-4T-L L0022456 1- A D3

L 1021 M.RFC 0.39uH 2% C1608CA-R39G L1691107 1- A D3

L 1022 COIL E2 0.45-1.4-4T-L L0022391 1- B e2

L 1023 COIL E2 0.35-1.6-4T-L L0022456 1- A G3

L 1025 M.RFC 0.022uH HK1608 22NJ-T L1690520 1- A E3

L 1026 COIL E2 0.35-1.6-4T-L L0022456 1- A G3

L 1027 M.RFC 0.018uH HK1608 18NJ-T L1690519 1- B e3

L 1028 COIL E2 0.35-1.6-4T-L L0022456 1- A G3

L 1029 COIL E2 0.45-1.4-4T-L L0022391 1- B e2

L 1030 M.RFC 0.022uH HK1608 22NJ-T L1690520 1- B a3

L 1031 M.RFC 0.015uH HK1608 15NJ-T L1690518 1- B e3

L 1032 M.RFC 0.022uH HK1608 22NJ-T L1690520 1- B a3

L 1033 M.RFC 0.047uH HK1608 47NJ-T L1690524 1- B c3

L 1034 M.RFC 0.015uH HK1608 15NJ-T L1690518 1- B d2

L 1035 M.RFC 0.047uH HK1608 47NJ-T L1690524 1- A G3

L 1036 M.RFC 0.01uH HK1608 10NJ-T L1690516 1- B c2

L 1037 M.RFC 0.068uH HK1608 68NJ-T L1690526 1- A G3

L 1038 M.RFC 0.039uH HK1608 39NJ-T L1690523 1- A G3

L 1039 M.RFC 0.047uH HK1608 47NJ-T L1690524 1- B c2

L 1040 CHIP COIL 0.82uH C2520C-R82J L1690555 1- A G3

L 1041 M.RFC 0.82uH LK1608 R82K-T L1690417 1- B c3

L 1042 M.RFC 0.33uH LK1608 R33K-T L1690412 1- B c4

Q 1001 TRANSISTOR 2SC4116GR TE85R G3341167G 1- B c3

Q 1002 TRANSISTOR RT1N241M-T11-1 G3070249 1- A E2

Q 1003 IC M5223AGP 600C G1093020 1- A D2

Q 1003 IC NJM2902V-TE1 G1091679 6- A D2

Q 1004 IC MM1216ENRE G1092432 1- B f2

Q 1005 TRANSISTOR 2SB1201S-TL G3070195 1- B f2

Q 1006 TRANSISTOR RT1N241M-T11-1 G3070249 1- A D2

Q 1007 TRANSISTOR 2SC4154-T11-1E G3341548E 1- B d3

Q 1008 TRANSISTOR DTB123EK T146 G3070022 1- B f2

Q 1009 TRANSISTOR 2SB1132 T100 R G3211327R 1- B f2

Q 1010 TRANSISTOR IMH6A T108 G3070066 1- B f2

Q 1011 TRANSISTOR 2SC4227-T2 R34 G3342277D 1- A G2

Q 1012 TRANSISTOR RT1N241M-T11-1 G3070249 1- B e3

Q 1013 FET 2SK508-T2B K52 G3805087B 1- A D3

Q 1014 IC RA30H4452M G1093557 1- B e2

Q 1014 IC RA30H4452M-22 G1093885

Q 1014 IC RA30H4452M-22 G1093885 VERSION D 14- B e2

Q 1015 TRANSISTOR 2SC4226-T2B R24 G3342267D 1- A D3

Q 1016 TRANSISTOR RT1N241M-T11-1 G3070249 1- A E3

Q 1017 TRANSISTOR IMH6A T108 G3070066 1- A E3

Q 1018 TRANSISTOR 2SC5107-O(TE85R) G3351077O 1- A E3

Q 1019 IC M5223AGP 600C G1093020 1- A C3

Q 1020 TRANSISTOR 2SC5107-O(TE85R) G3351077O 1- B e3

Q 1021 TRANSISTOR 2SC5107-O(TE85R) G3351077O 1- B c3

Q 1022 TRANSISTOR 2SC5415E-TD G3354158E 1- B d2

Q 1023 IC SA7025DK G1093014 1- A C3

Q 1024 IC NJM78L05UA TE1 G1091325 1- B f3

Q 1025 TRANSISTOR 2SC5107-O(TE85R) G3351077O 1- B d2

Q 1026 FET 3SK228XR-TR G4802287 1- A G3

Q 1027 TRANSISTOR 2SC4116GR TE85R G3341167G 1-5

Q 1028 IC TA31136FN(EL) G1091605 1- B c3

Q 1029 TRANSISTOR 2SC4215Y TE85R G3342157Y 1- B c3

Q 1030 TRANSISTOR RT1N241M-T11-1 G3070249 1- B b4

Q 1031 TRANSISTOR 2SA1602A-T11-1F G3116028F 1- B c3

Q 1032 TRANSISTOR RT1N241M-T11-1 G3070249 1- A E2

Q 1033 TRANSISTOR RT1N241M-T11-1 G3070249 1- A D2

Q 1034 TRANSISTOR RT1N241M-T11-1 G3070249 1- A E2

Q 1035 TRANSISTOR RT1N241M-T11-1 G3070249 6- A E2

Q 1501 TRANSISTOR 2SC4154-T11-1E G3341548E 1- A B2

Q 1502 TRANSISTOR RT1N241M-T11-1 G3070249 1- A B2

Q 1503 IC NJM2902V-TE1 G1091679 1- A B2

Q 1504 TRANSISTOR 2SD1368CB TL G3413688B 1- A B2

Q 1505 TRANSISTOR 2SA1602A-T11-1F G3116028F 1- A B2

Q 1506 TRANSISTOR RT1N241M-T11-1 G3070249 1- A B2

Q 1507 TRANSISTOR RT1N241M-T11-1 G3070249 1- A B2

Q 1508 TRANSISTOR PDTC114TE G3070238 1- B f2

Q 1509 IC TDA2003H G1090815 1- A A2

Q 1510 TRANSISTOR PDTC114TE G3070238 1- B f2

LOT

SIDE

4-13

Be2

LAY ADR

38

Page 39

RF Unit (Ver. D)

Parts List

REF DESCRIPTION VALUE V/W TOL. MFR'S DESIG VXSTD P/N VERS.

Q 1511 TRANSISTOR 2SB1301-T2 ZQ G3213017Q 1- A A2

Q 1512 TRANSISTOR RT1N241M-T11-1 G3070249 1- A A2

Q 1515 FET 2SJ125D-T12-1D G3701257D 1- B g2

Q 1516 TRANSISTOR RT1N241M-T11-1 G3070249 1- B f2

Q 1517 TRANSISTOR RT1N241M-T11-1 G3070249 1- B f2

Q 1518 TRANSISTOR RT1N241M-T11-1 G3070249 1- A A2

Q 1519 TRANSISTOR 2SC4154-T11-1E G3341548E 1- B f3

R 1001 CHIP RES. 47k 1/16W 5% RMC1/16 473JATP J24185473 1- A G2

R 1002 CHIP RES. 0 1/16W 5% RMC1/16 000JATP J24185000 1- A E2

R 1002 CHIP RES. 22k 1/16W 5% RMC1/16 223JATP J24185223 6- A E2

R 1003 CHIP RES. 820k 1/16W 5% RMC1/16 824JATP J24185824 1- B c4

R 1004 CHIP RES. 1k 1/16W 5% RMC1/16 102JATP J24185102 1- B c4

R 1005 CHIP RES. 18 1/16W 5% RMC1/16 180JATP J24185180 1- A E3

R 1006 CHIP RES. 680 1/16W 5% RMC1/16 681JATP J24185681 6- B c3

R 1007 CHIP RES. 47k 1/16W 5% RMC1/16 473JATP J24185473 1- A C3

R 1008 CHIP RES. 470 1/16W 5% RMC1/16 471JATP J24185471 1- A E2

R 1009 CHIP RES. 1k 1/16W 5% RMC1/16 102JATP J24185102 1- A D2

R 1010 CHIP RES. 220k 1/16W 5% RMC1/16 224JATP J24185224 1- A C3

R 1011 CHIP RES. 10k 1/16W 5% RMC1/16 103JATP J24185103 1- B f2

R 1012 CHIP RES. 0 1/16W 5% RMC1/16 000JATP J24185000 1- A C2

R 1013 CHIP RES. 0 1/16W 5% RMC1/16 000JATP J24185000 1- B f3

R 1014 CHIP RES. 390k 1/16W 5% RMC1/16 394JATP J24185394 1- A C3

R 1015 CHIP RES. 100k 1/16W 5% RMC1/16 104JATP J24185104 1- A D2

R 1016 CHIP RES. 100k 1/16W 5% RMC1/16 104JATP J24185104 1- A D2

R 1017 CHIP RES. 150k 1/16W 5% RMC1/16 154JATP J24185154 1- A C3

R 1018 CHIP RES. 4.7k 1/16W 5% RMC1/16 472JATP J24185472 1- A D2

R 1019 CHIP RES. 4.7k 1/16W 5% RMC1/16 472JATP J24185472 1- A D2

R 1020 CHIP RES. 1.2k 1/16W 5% RMC1/16 122JATP J24185122 1- B e3

R 1021 CHIP RES. 0 1/16W 5% RMC1/16 000JATP J24185000 1- A D2

R 1022 CHIP RES. 1.2k 1/16W 5% RMC1/16 122JATP J24185122 1- B d3

R 1023 CHIP RES. 150k 1/16W 5% RMC1/16 154JATP J24185154 1- A D2

R 1024 CHIP RES. 100k 1/16W 5% RMC1/16 104JATP J24185104 1- A G2

R 1025 CHIP RES. 100k 1/16W 5% RMC1/16 104JATP J24185104 1- B f2

R 1026 CHIP RES. 100k 1/16W 5% RMC1/16 104JATP J24185104 1- B a2

R 1027 CHIP RES. 100k 1/16W 5% RMC1/16 104JATP J24185104 1- A G2

R 1028 CHIP RES. 1.2k 1/16W 5% RMC1/16 122JATP J24185122 1- B f2

R 1029 CHIP RES. 100k 1/16W 5% RMC1/16 104JATP J24185104 1- A D2

R 1030 CHIP RES. 220k 1/16W 5% RMC1/16 224JATP J24185224 1- A E2

R 1031 CHIP RES. 2.7k 1/16W 5% RMC1/16 272JATP J24185272 1- A F2

R 1032 CHIP RES. 10k 1/16W 5% RMC1/16 103JATP J24185103 1- A F2

R 1033 METAL FILM RES. 120 1W 5% ERG-1SJ121P 120 J22309011 1- A F2

R 1034 CHIP RES. 2.7k 1/16W 5% RMC1/16 272JATP J24185272 1- A F2

R 1035 CHIP RES. 10k 1/16W 5% RMC1/16 103JATP J24185103 1- A F2

R 1036 CHIP RES. 100 1/10W 5% RMC1/10T 101J J24205101 1- B b2

R 1037 CHIP RES. 47 1/16W 5% RMC1/16 470JATP J24185470 1- B a2

R 1038 CHIP RES. 22k 1/16W 5% RMC1/16 223JATP J24185223 1- A G2

R 1039 CHIP RES. 10k 1/16W 5% RMC1/16 103JATP J24185103 1- A H2

R 1040 CHIP RES. 22k 1/16W 5% RMC1/16 223JATP J24185223 1- A D3

R 1041 CHIP RES. 330k 1/16W 5% RMC1/16 334JATP J24185334 1- A E2

R 1042 CHIP RES. 100 1/16W 5% RMC1/16 101JATP J24185101 1- B d3

R 1043 CHIP RES. 100 1/16W 5% RMC1/16 101JATP J24185101 1- B d3

R 1044 CHIP RES. 2.7k 1/16W 5% RMC1/16 272JATP J24185272 1- B e3

R 1045 CHIP RES. 100 1/10W 5% RMC1/10T 101J J24205101 1- B c2

R 1046 CHIP RES. 47k 1/16W 5% RMC1/16 473JATP J24185473 1- A D3

R 1047 CHIP RES. 100 1/16W 5% RMC1/16 101JATP J24185101 1- A G2

R 1048 CHIP RES. 1k 1/16W 5% RMC1/16 102JATP J24185102 1- A G2

R 1049 CHIP RES. 470k 1/16W 5% RMC1/16 474JATP J24185474 1- B e3

R 1050 CHIP RES. 330k 1/16W 5% RMC1/16 334JATP J24185334 1- B e3

R 1051 CHIP RES. 330k 1/16W 5% RMC1/16 334JATP J24185334 1- B d3

R 1052 CHIP RES. 10k 1/16W 5% RMC1/16 103JATP J24185103 1- B e4

R 1053 CHIP RES. 0 1/16W 5% RMC1/16 000JATP J24185000 1- B e3

R 1054 CHIP RES. 100k 1/16W 5% RMC1/16 104JATP J24185104 1- A G3

R 1055 CHIP RES. 68 1/10W 5% RMC1/10T 680J J24205680 1- B e2

R 1056 CHIP RES. 5.6 1/10W 5% RMC1/10T 5R6J J24205569 1- B e2

R 1057 CHIP RES. 4.7k 1/16W 5% RMC1/16 472JATP J24185472 1- B e3

R 1058 CHIP RES. 10k 1/16W 5% RMC1/16 103JATP J24185103 1- A D3

R 1059 CHIP RES. 270 1/10W 5% RMC1/10T 271J J24205271 1- B e2

R 1060 CHIP RES. 100k 1/16W 5% RMC1/16 104JATP J24185104 1- B a3

R 1061 CHIP RES. 4.7k 1/16W 5% RMC1/16 472JATP J24185472 1- A D3

R 1062 CHIP RES. 180 1/16W 5% RMC1/16 181JATP J24185181 1- A D3

R 1063 CHIP RES. 100k 1/16W 5% RMC1/16 104JATP J24185104 1- A G3

R 1064 CHIP RES. 1.8k 1/16W 5% RMC1/16 182JATP J24185182 1- B e3

R 1065 CHIP RES. 270 1/16W 5% RMC1/16 271JATP J24185271 1- A C3

R 1066 CHIP RES. 680 1/16W 5% RMC1/16 681JATP J24185681 1- A D3

R 1067 CHIP RES. 4.7k 1/16W 5% RMC1/16 472JATP J24185472 1- A D3

R 1068 CHIP RES. 100 1/16W 5% RMC1/16 101JATP J24185101 1- B d3

LOT

SIDE

LAY ADR

39

Page 40

RF Unit (Ver. D)

Parts List

REF DESCRIPTION VALUE V/W TOL. MFR'S DESIG VXSTD P/N VERS.

R 1069 CHIP RES. 18k 1/16W 5% RMC1/16 183JATP J24185183 1- A E2

R 1069 CHIP RES. 8.2k 1/16W 5% RMC1/16 822JATP J24185822 8- A E2

R 1070 CHIP RES. 4.7k 1/16W 5% RMC1/16 472JATP J24185472 1- A E3

R 1071 CHIP RES. 4.7k 1/16W 5% RMC1/16 472JATP J24185472 1- A E3

R 1072 CHIP RES. 220k 1/16W 5% RMC1/16 224JATP J24185224 1- A E3

R 1072 CHIP RES. 0 1/16W 5% RMC1/16 000JATP J24185000 6- A E3

R 1073 CHIP RES. 220 1/16W 5% RMC1/16 221JATP J24185221 1- A E3

R 1074 CHIP RES. 120 1/16W 5% RMC1/16 121JATP J24185121 1- B e3

R 1075 CHIP RES. 470 1/16W 5% RMC1/16 471JATP J24185471 1- B c3

R 1076 CHIP RES. 120 1/16W 5% RMC1/16 121JATP J24185121 1- B d3

R 1077 CHIP RES. 120 1/16W 5% RMC1/16 121JATP J24185121 1- B d3

R 1078 CHIP RES. 10 1/16W 5% RMC1/16 100JATP J24185100 1- B c3

R 1079 CHIP RES. 1k 1/16W 5% RMC1/16 102JATP J24185102 1- B e2

R 1080 CHIP RES. 270k 1/16W 5% RMC1/16 274JATP J24185274 1- B e3

R 1081 CHIP RES. 27 1/10W 5% RMC1/10T 270J J24205270 1- B e2

R 1082 CHIP RES. 10k 1/16W 5% RMC1/16 103JATP J24185103 1-5 A E2

R 1083 CHIP RES. 22 1/10W 5% RMC1/10T 220J J24205220 1- B d2