Page 1

CERT IFI ED

D

E

S

I

G

N

C

E

R

T

I

F

I

E

D

Installation and Operating

Instructions for Vented Gas Log

Sets - Remote Hearth Kits

Models:

SA18SHKRN, SA18SHKRP,

SA24SKHRN, SA24SHKRP,

SA30SKHRN, SA30SKHRP

Decorative Gas Appliance For Installation In Solid Fuel Burning Fireplaces

If the information in this manual is not followed exactly, a fire or explosion may result causing

property damage, personal injury or loss of life.

— Do not store or use gasoline or other flam-

mable vapors and liquids in the vicinity of

this or any other appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not

use any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call

the fire department.

Please record your gas log’s model number for

future reference here:

Note: This model # can be found on the box or

the label attached to the back of the burner pan.

WARNING

Certified to ANSI Z21.60

and CGA 2.26 Standards

ATTENTION

Installation, service, and repair of this appliance must be performed by a qualified

installer, service agency, company or gas

supplier experienced with this type of gas

appliance.

INSTALLER:

Read these instructions completely and carefully prior to beginning installation. After installation, leave these instructions with the owner.

OWNER:

Read these instructions and follow the warnings. Save this manual for future reference.

Check local codes before installing this log set.

In some areas of the country, gas log sets are

restricted.

The installation and the provisions for combus

tion and ventilation air must conform with the

National Fuel Gas Code, ANSI Z223.1/NFPA 54.

Carbon Monoxide Poisoning May Lead To Death

When used without fresh air, gas logs may give off carbon monoxide, an odorless, poisonous gas. Some

people such as pregnant women, people with heart or lung disease, and persons at high altitudes are

more affected by carbon monoxide than others.

Early signs of carbon monoxide poisoning resemble the flu: Headache, dizziness, and/or nausea. If

you have these signs, the gas logs may not be installed or working properly. Get fresh air at once!

Have the gas log set and chimney serviced before using it again.

CFM Corporation

410 Admiral Blvd. • Mississauga, Ontario, Canada L5T 2N6 • 905-670-7777

www.majesticproducts.com • www.vermontcastings.com

3311857 12/05 Rev. 5

Page 2

WARNING

Improper installation, adjustment, alteration, service or maintenance can cause injury or

property damage. Read these directions thoroughly before installation. For assistance or additional

information, consult your gas log dealer, qualified installer, service agency or

gas supplier.

WARNING

Do not use this appliance or any part that has

been under water. Immediately call a qualified

service technician to inspect the appliance and

to replace any part of the control system and any

gas control which has been under water.

Young children are not allowed to operate this

unit and must be supervised when they are in

the same room as the appliance.

Children and adults should be alerted to the

hazards of high surface temperature and should

stay away to avoid burns or clothing ignition.

WARNING

WARNING

Due to high temperatures, the appliance should be located out of traffic and away from furniture and

draperies. In addition, clothing or other flammable material should not be placed on or near the appliance.

WARNING

A properly sized, unobstructed chimney will normally vent all fumes and products of combustion. Any

odor or smoke detected in the room is an indication that the flue is not properly removing the combustion

products. Turn off the gas supply valve immediately! The cause of the venting problem must be discovered and corrected before using this gas log set. Disregarding this warning can cause illness as well as

soot damage to your fireplace, room, and furnishings.

Technical Information

The operation of a gas log set, and the provision for combustion and ventilation air must conform with

the National Fuel Gas Code, ANSI Z223.1/NFPA 54 and applicable codes.

Gas Pressure Testing: This gas log set and its individual shut-off valve MUST be disconnected from

the gas supply piping system during any pressure testing of that system at test pressures in excess

of 1/2 psig (3.5 kPA). The gas log set must be isolated from the gas supply piping system by closing

its individual manual shut-off valve during any pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2 psig (3.5 kPa)

Component Parts: Only factory authorized components listed in these instructions may be used in

accordance with the manufacturer’s instructions and all codes and requirements of the authority having jurisdiction. Any modifications to this kit, or use of unauthorized components or accessory items will

void the manufacturer’s warranty, and may result in a hazardous condition.

2

3311857

Page 3

Before You Begin -- Attention!

A. The appliance should be inspected before use and at least annually by a professional service person.

More frequent cleaning may be required due to excessive lint from carpeting, bedding material,

etc. It is imperative that control compartments, burners and circulating air passageways of the appliance be kept clean.

B. Your fireplace must include a chain mesh or similar screen. The screen must remain fully closed

while operating your log set. Any safety screen or guard removed for servicing this appliance must be

replaced prior to operation.

C. If your fireplace includes glass doors, they must remain

operation, and to prevent overheating of the gas valve.

D. Your log set must be installed in a solid fuel burning fireplace constructed of noncombustible material

with a working flue.

E. Solid fuels shall not be burned in the fireplace where your gas log set is installed.

F. If this log set is to be used with propane gas, your propane supply tank MUST include a high to low

gas pressure regulator, and must be located outside.

.

G. Never use sand or other dense pan material with propane gas: use vermiculite only.

H. Be sure to apply pipe joint compound to all non-flared, threaded connections involved in this installa

tion to avoid possible gas leaks. Compounds used in liquid propane applications must be resistant to

the action of that gas.

I. Always test for leaks using a soapy solution.

J. The manufacture and shipping of your log set involves compounds which may cause detectable yet

harmless odors during initial operation. Provide extra ventilation to the room for the initial 2-3 hour

break-in period.

K. This gas log set may be installed in the approved fireplace in an aftermarket* manufactured (mobile)

home where not prohibited by state or local codes. *Aftermarket: Completion of sale, not for purpose

of resale, from the manufacturer.

L. The fireplace damper MUST be fully open when operating this log set.

NEVER USE OPEN FLAME.

fully open to allow for combustion air during

DO NOT place supply tanks inside any structure

-

Fireplace Specifications

Before installation, the chimney flue, venting system, and firebox must be cleaned of all soot, creosote,

ashes and loose paint, by a qualified chimney cleaner.

Your Fireplace Must Include:

• A working flue and venting system with the minimum openings indicated on page 8.

• A gas supply shut off valve. If your fireplace does not have such a valve, one must be installed

33311857

Page 4

Pre-Installation Checklist Yes No

Is the gas supply inlet pressure correct?

NG: Min. 5.5” w.c./Max. 14.0” w.c. LP: Min. 11” w.c./Max. 14.0” w.c.

Does the firebox meet the minimum size dimensions below?

Is your fireplace plumbed with gas on the right side (facing) of the fireplace?

If not, refer to ee Page 5

Is the gas supply line sized properly (Minimum 1/2” iron pipe)?

Do you have a solid fuel (wood burning) fireplace with a vented flue?

Do you have a manual gas supply valve installed at your fireplace? If not, a licensed

plumber, gas company technician or other qualified installer must install one.

Have you checked local building codes? (Check with your local building department)

Does your fireplace have a wire mesh screen in place?

CAUTION: If you answered “NO” to any item, or have any questions regarding your installation, please

contact your dealer/distributor for assistance.

Minimum Clearances & Specifications

Natural Gas Units

Minimum Firebox Dimensions Minimum Gas Fuel Line Manifold

Set Input Width Flue Pressure Pressure

Size Btu/hr Back Front Depth Height Size Minimum Maximum”

18” 45,000 16” 33” 15” 18” 51 sq.in. 5.5”w.c. 14.0”w.c. 3.5”w.c.

24” 60,000 20” 36” 15” 18” 51 sq.in. 5.5”w.c. 14.0”w.c. 3.5”w.c.

30” 60,000 27” 39” 15” 18” 51 sq.in. 5.5”w.c. 14.0”w.c. 3.5”w.c.

NOTE: All dimensions are minimums.

Propane Gas Units

Minimum Firebox Dimensions Minimum Gas Fuel Line Manifold

Set Input Width Flue Pressure Pressure

Size Btu/hr Back Front Depth Height Size Minimum Maximum

18” 40,000 16” 33” 15” 18” 51 sq.in. 11.0”w.c. 14.0”w.c. 10.0”w.c.

24” 45,000 20” 36” 15” 18” 51 sq.in. 11.0”w.c. 14.0”w.c. 10.0”w.c.

30” 60,000 27” 39” 15” 18” 51 sq.in. 11.0”w.c. 14.0”w.c. 10.0”w.c.

NOTE: All dimensions are minimums.

4

3311857

Page 5

Tools Required

8” adjustable crescent wrench ; Pipe thread sealant compound or teflon tape ; 12” pipe wrench or channel

lock pliers.

Gas Plumbed on Left Hand Side of Fireplace

NOTE: Your gas log set is assembled at the factory to be installed in a fireplace plumbed with the gas on

the right side (facing). If your fireplace is plumbed with the gas on the left side, you will need to run a flexible connector (or as per local codes) along the back wall of the fireplace to bring your gas line to the right

hand side. You can then place the set in front of the flexible connector.

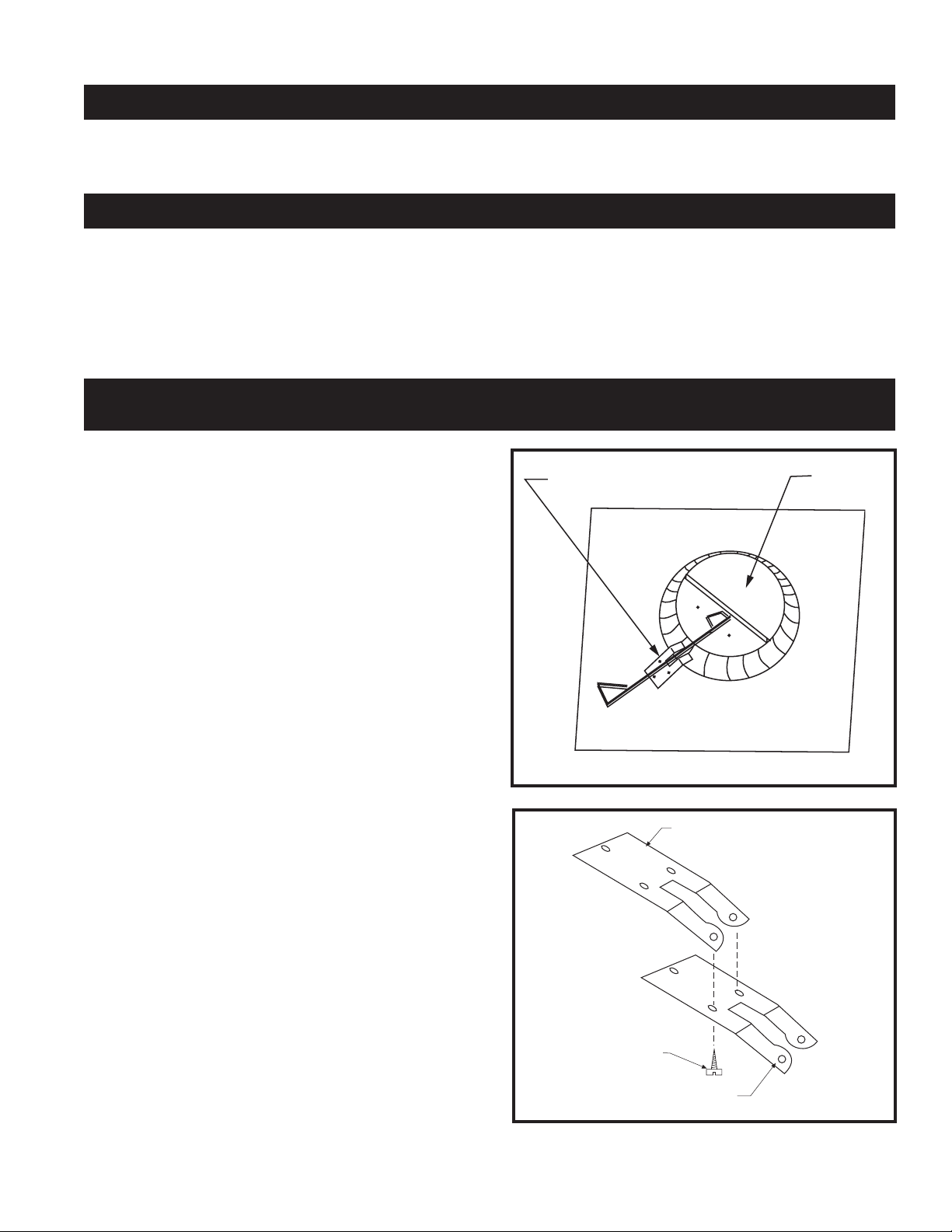

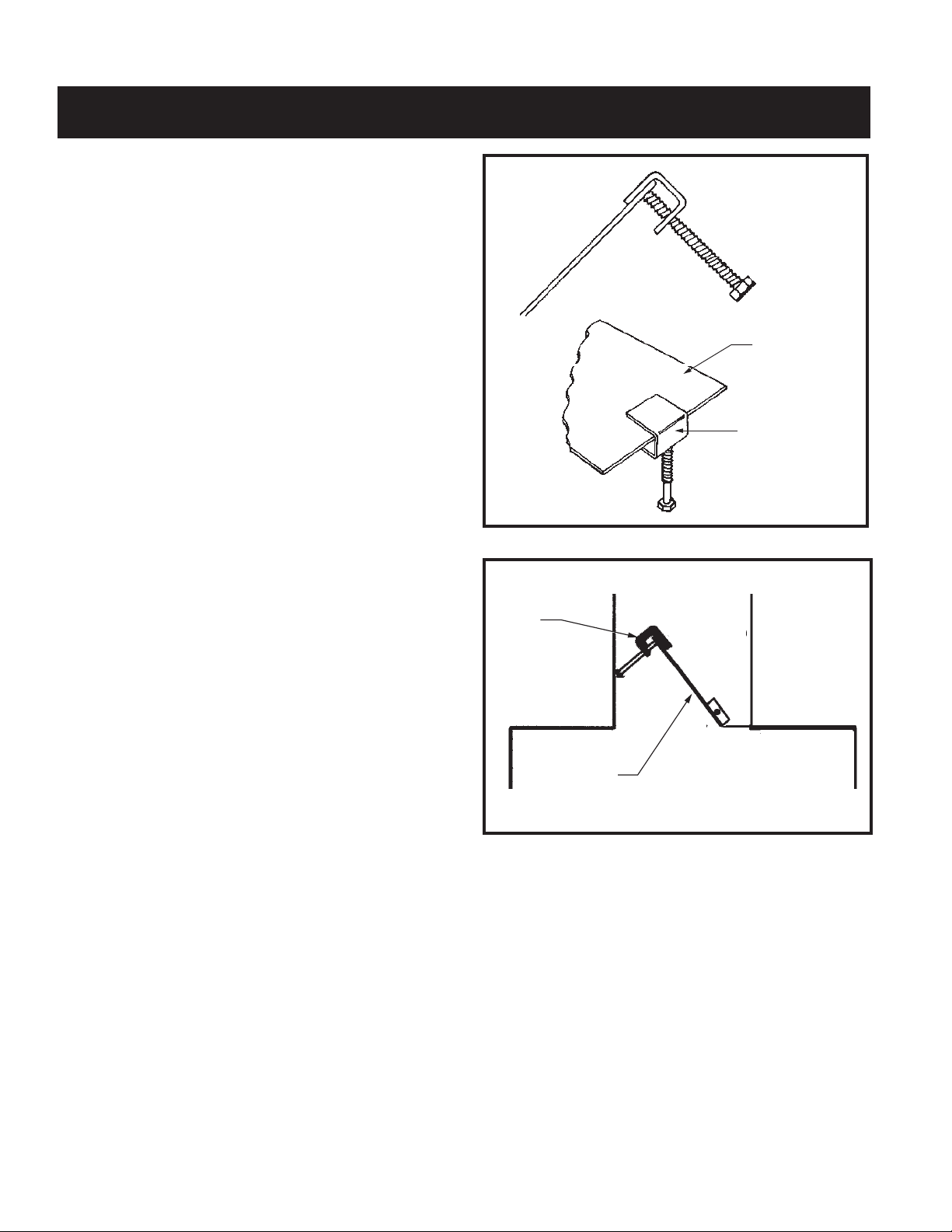

Damper Stop Installation:

For Use with BR, BC, SR, SC, TF and TL Series CFM Corporation Fireplaces

This Damper Stop is designed to work on all CFM

Corporation BR, BC, SR, SC, TF and TL series

fireplaces. For all other fireplaces, refer to Page 6.

When installing a decorative gas appliance in a

fireplace, some local codes require this Damper

Stop to be used so the Damper will not close completely. To install the Damper Stop:

The Damper Locking Bracket is already installed

on all BR, BC, SR, SC, TF and TL fireplaces. Locate the Damper Locking Bracket on the left side

of the fireplace’s Combustion Dome. (Fig. 1)

With the Damper open, align the two slots on

either side of the cut-out on the Damper Stop with

the two small holes on the angled portion of the

Damper Locking Bracket. Attach the Damper Stop

with the Screws provided, as shown in Figure 2.

NOTE: Some of the early fireplace units may not

have the holes in the end of the Damper Locking Bracket. If this is the case, use the Damper

Stop as a template to drill two (2) 1/8” holes in the

Damper Locking Bracket to mount the Damper

Stop.

Damper Locking Bracket

Figure 1

Damper Locking Bracket

Damper

Plate

DP100

Damper Stop Screw

Figure 2

Damper Stop

DP101

53311857

Page 6

Damper Stop Installation:

For Use With All Other Fireplaces

The Damper Clamp provided keeps your damper

from accidentally closing during operation of your

set. This Damper Clamp must be installed

onto your Damper at all times. NOTE: The

damper clamp is designed to hold the damper

plate open 3 inches. However, the damper

must be fully open when the log set is in operation.

Install the Damper Clamp onto the edge of the

damper plate. Attach by securing the bolt provided to the damper plate with an adjustable wrench.

(Fig. 3)

If the Damper Clamp does not fit, drill a 1/4” hole

into the damper plate and install an anchor bolt

with nut, at a 90 degree angle, so that the damper

plate will remain fully open.

The proper finished installation of the Damper

Clamp is shown in Figure 4. If the bolt fails to

block the damper in an open position, the damper

should be removed from the chimney.

To check your vent for proper drafting:

tightly rolled newspaper on one end and place it at

the inside front edge of the fireplace. Observe the

smoke and be sure the vent is properly drawing it

up the chimney. If the smoke is drawn back into

the room, extinguish the flame and remove any

obstruction until proper venting is achieved. If that

fails, check with a qualified chimney sweep.

Light a

Figure 3

Chimney

Clamp

Damper Plate

Damper Clamp

DP104

Damper

Figure 4

6

DP103

3311857

Page 7

Adding Pan Material

1. Open the bag of Vermiculite and spread it

evenly across the Burner Pan, to the top, as

shown in Figure 5. You may overflow the front

and sides of the pan to cover the entire pan

and connecting hardware.

2. Next, open the bag of Glowing Embers and

place them on top of the Vermiculite, evenly

across the Burner Pan. Be sure to separate

the Glowing Embers into very small pieces

before placing them.

Grate Clip Installation

1. Hook the U-Shaped part of the Grate Clips over

the back horizontal bar of the Grate, as shown

in Figure 6. Repeat with the other Clip.

2. Slide the rear edge of the burner pan into the

three-pronged slot in the front edge of the grate

clip, as shown in Figure 6.

Figure 5

Grate Clip

Glowing Embers

Vermiculite

LG216

Connection To Gas Supply

1. Center the burner pan from left to right in the

fireplace and with the back of the grate against

the back wall of the fireplace.

2. Attach the Gas Supply Fitting onto your fire

place’s gas supply pipe. Remember to use pipe

thread sealant or teflon tape on this connection.

3. Attach one end of the Flexible Gas

4. Connector to the brass fitting on the back of

the control valve, as shown in Figure 7.

5. Attach the other end of the Gas Connector to

the flared side of the Gas Supply Fitting.

-

Back Bar Of Grate

Figure 6

Figure 7

LG217

Gas Supply Fitting

Flexible Gas

Connector

LG218

73311857

Page 8

Leak Test Procedures

O

F

F

O

N

TP

TH

TH/TP

Create a mixture of equal parts soap and water. Apply to all the joints of the pipe fittings from the gas supply pipe to the burner. Turn on the gas supply valve for no longer than 3-5 seconds. If bubbles appear

in the soap solution applied to the joints, there is a leak. Turn off the gas supply valve and tighten those

fittings. Repeat the above procedure until no bubbles appear in the soap solution. Remember to test all

joints.

WARNING: DO NOT USE AN OPEN FLAME TO TEST FOR LEAKS!

NOTE: Always perform a leak test any time the appliance has been moved or disconnected from the gas

supply line.

Remote Installation

Connect remote (GWSK or MRC 1, 2, 3) wires to

ON/OFF/RS switch. (Fig. 8) If the MRC (remote) is

used, the receiver can be placed to the front right

of the gas valve to ensure safe operation.

Pilot

Assembly

Remote

Switch

Figure 8

Thermo Generator

(“T(“Thermopile”)

On/Off/Rs

Switch

LG188

8

3311857

Page 9

Optional Fettel Cast Front Grate

Available Log Sets

Attach the fettel to the front of the grate as shown

in Figure 9.

Grate

LG204

Figure 9

Grate Clip

Fettel Cast Front Grate

Log Placement

1. Place the larger bottom logs onto the grate,

leaving as much space between them as possible. When burning, the flames should come

up directly between the logs.

2. Place the smaller top logs diagonally onto the

bottom logs. The top logs can be arranged to

achieve your desired flame pattern.

you leave as much open space between the

logs as possible to minimize flame impingement and sooting.

3. Open the bag of lava rock and spread the rocks

onto the fireplace floor around the burner pan

for decorative purposes.

Be sure

18” Standard Round Log Set

LG330

24” Standard Round Log Set

LG331

30” Standard Round Log Set

LG332

93311857

Page 10

18” Standard Split Log Set

18” Standard Combination Log Set

LG333

24” Standard Split Log Set

30” Standard Split Log Set

LG334

LG336

24” Standard Combination Log Set

LG337

30” Standard Combination Log Set

10

LG338

LG335

3311857

Page 11

For Your Safety Read Before Lighting

WARNING: If you do not follow these directions exactly, a fire or explosion may result

causing property damage, personal injury, or loss of life.

What To Do If You Smell Gas

• Do not try to light any appliance

• Do not touch any electrical switch, do not use any phone in your build-

ing

• Immediately call your gas supplier from a neighbor’s phone. Follow the

gas supplier’s instructions

• If you cannot reach your gas supplier, call the fire department

Before operating, smell all around the appliance area for gas odor. Be sure to smell near the floor because

some gases (propane) are heavier than air and will “pool” on the floor.

Use only your hand to push or turn the gas control dial. NEVER USE TOOLS. If the knob will not push in

or turn by hand, don’t try to repair it, call a qualified technician. Force or attempted repair may result in a

fire or explosion.

Lighting the Pilot

The pilot will resist lighting on new installations due to air in the gas supply line. It may

take several minutes to bleed air completely

out of the gas plumbing system through the

pilot line.

This appliance has a pilot which is lit by a spark

ignition device (piezo). If the piezo fails, then light

the pilot using matches following the Match Lighting instructions below.

1. STOP!

2. Push in gas control knob slightly and turn clock

wise to “OFF”.

3. NOTE: Knob cannot be turned from “PILOT”

to “OFF” unless knob is pushed in slightly.

Do not force.

4. Wait five (5) minutes to clear out any gas. If

you then smell gas, STOP! Follow the safety

information above. If you don’t smell gas, go on

to the next step.

5. Turn the control knob counterclockwise

“PILOT” and push in. Continue to hold the control knob in and push the piezo igniter button in

until the pilot lights.

Read the safety information above.

to

6. Continue to hold the control knob in for about

one (1) minute after the pilot is lit. Release the

knob and it will pop back up. Pilot should remain lit. If it goes out, repeat steps 3 and 4.

7. If the knob does not pop out when released,

stop and call your service technician or gas

supplier. If the pilot will not stay lit after several

tries, turn the gas control knob to “OFF’ and call

your service technician or gas supplier.

8. Turn gas control knob counterclockwise

-

to “ON”. CAUTION: Be sure ON/OFF/RS switch

is in the off (middle) position. Also, the GWSK

should be in the “OFF” position and/or the

remote should be in the “OFF” position before

turning the control knob “ON”. If pilot goes out,

repeat steps 4 and 5.

9. Turn ON/OFF/RS switch to “ON” or remote po

sition. Turn remote switch to “ON”.

10. Flame is adjustable by rotating the “HI/LO”

knob.

-

113311857

Page 12

Match Lighting

1. Follow the “Lighting the Pilot” instructions steps 1 thru 4 above.

2. Push the control dial in all the way and hold. Immediately light the pilot with a match. Continue to hold

the pilot for about one minute after the pilot is lit. Pilot should remain lit. If the pilot goes out, repeat

Lighting the Pilot steps 1 thru 4 above and this step 2.

Troubleshooting

Log Set Is Smoking/Sooting Excessively

It is natural and unavoidable for vented gas log sets (especially propane) to produce moderate levels of

carbon (soot) where flame contacts the logs. The logs can be cleaned using a soft-bristle brush. However, if soot is produced where there is no flame impingement, one of the following may be the cause:

Fireplace venting system not drafting properly: Make sure the damper is wide open at all times.

Preheat the flue in very cold weather by burning the log set at a very low level, then slowly increasing the flame height over a matter of hours. Have the fireplace and the venting system professionally

cleaned.

Excessive flame impingement or blockage:

they are not smothering the flame. Rearrange the logs so they are touched less by the flames.

Excessive gas supply/pressure: Make sure the gas pressure coming into the fireplace does not exceed the maximum pressure allowed with this gas set (refer to tables on Page 4).

Incorrect Orifice used: Check the orifice size on Page 15 to see if you installed the correct orifice into the

set.

Make sure there is proper spacing between the logs so

Burner Is Excessively Noisy

Please note: The movement and combustion of gas will create low, unavoidable levels of noise.

Passage of air/gas across irregular surfaces: There may be burrs, paint, or other blockages on the

burner bar ports. Check these ports and remove any blockage.

Excessive gas pressure: Make sure the gas pressure coming into the fireplace does not exceed the

maximum pressure allowed with this gas set (refer to tables on Page 4).

Flexible Gas Connector: Relieve any tight bends or kinks in the Flexible Gas Connector. Switch to a

less flexible gas connector, which can be purchased at any hardware or home improvement store.

Incorrect Orifice used: Check the orifice size on Page 15 to see if you installed the correct orifice into

the set.

12

3311857

Page 13

Troubleshooting

Burner Flame Is Too High (8-12” Above Top Logs) Or Too Low:

Incorrect gas supply, pressure, or burner orifice used:

fireplace falls between the minimum and maximum pressures allowed with this gas set (refer to tables on

Page 4). Make sure you installed the correct orifice into the set.

Blocked ports (low flame only): Free the main burner orifice and burner bar ports of any burrs, paint, or

other blockage.

Pilot Will Not Light

Upon initial installation, the pilot may be difficult to light, due to air in the gas line, valve, and pilot tubing.

If the pilot does not light for several minutes, try using a match to ignite it for the first few times. Initialing

lighting the pilot may take up to five minutes of bleeding the line.

Piezo Igniter Out of Position: First make sure that, when the igniter button is pushed in, the igniter

electrode at the Pilot Assembly is sparking. If it is, make sure the Igniter Electrode’s tip sits directly over

the pilot’s hood. If it doesn’t, adjust it carefully into position.

Piezo Igniter Not Sparking: If the electrode is not sparking, first make sure the wire which connects

the electrode to the Piezo Push Button is not loose on either side. If the Piezo wire is not loose, call our

customer service line.

Incorrect Pilot Orifice: Make sure the correct Pilot Orifice is installed: green for Natural Gas, red for

propane.

Incorrect gas supply pressure: Make sure your gas pressure meets the specifications outlined on

Page 4.

Make sure the gas pressure coming into the

Flames at the Air Mixer (Flashback)--Propane Gas Only

Correct Orifice used: Check the chart on Page 15 to see if you used the correct Orifice. Also, be sure

you only used the Orifices that came with this pilot kit. Do not use the Orifice that came with your gas

log set!

Incorrect gas supply pressure: Make sure your gas line meets the specifications outlined on Page 4.

133311857

Page 14

1

2

3

4

5

4

6

7a,b

8

10

9

11

13

14

12

18a,b

20

21

19

15

17

16a,b

22

24

23

Optional

Cast Fettel

CFM Corporation reserves the right to make changes in design, materials, specifications, prices and discontinue colors and products at any time,

without notice.

SA18/24/30SHK Series Vented Gas Logs - Remote Hearth Kit

Ref. Description 18” 24” 30”

1. Log Grate 20000924 20000925 20000926

2. Burner Assembly 20007267 20007268 20007269

3. Cast Front Grate w/Clips CIGF 18” CIGF 24” CIGF 30”

4. Grate Clip - Fettel 3304311 3304311 3304311

5. Screw - Grate Clip 3309078 3309078 3309078

6. Bag of Lava Rock (8lbs.) 4310010 4310010 4310010

7a. Bag of Sand (Natural Gas Models ONLY) 4310006 4310006 4310006

7b. Bag of Vermiculite 4310008 4310008 4310008

8. Bag of Glowing Embers 4310001 4310001 4310001

9. Damper Stop for CFM Corporation

Fireplaces ONLY (BR/BC, SR/SC, TF/TL) 3030176 3030176 3030176

10. Damper Stop for use with all other fireplaces 4304045 4304045 4304045

11. Damper Stop Screws 7521901 7521901 7521901

12. Grate Clips 20000962 20000962 20000962

14

3311857

Page 15

SA18/24/30SHK Series Vented Gas Logs - Remote Hearth Kit (Continued)

Ref. Description 18” 24” 30”

13. Gas Supply Fitting 3304145 3304145 3304145

14. Flexible Gas Connector 3304176 3304176 3304176

15. Pilot Bracket 4303232 4303232 4303232

16a. Natural Gas Pilot Assembly 20000540 20000540 20000540

16b. Propane Gas Pilot Assembly 20000971 20000971 20000971

17. Pilot Mounting Screws 3309075 3309075 3309075

18a. Control Valve - NG 20000965 20000965 20000965

18b. Gas Valve - Propane 20000966 20000966 20000966

19. On/Off/RS Switch 7522355 7522355 7522355

20. Gas Supply Tube 20001240 20001240 20001240

21a. Brass Elbow/Orifice Holder - NG 3304006 3304006 3304006

21b. Brass Elbow/Orifice Holder - Propane 3304146 3304146 3304146

22. Short Stem Orifice for Natural Gas 20001574 (#23) 20000961 (#15) 20000961 (#15)

23. Brass Air Mixer/Orifice Holder 20000012 20000012 20000012

24. Long Stem Orifice for Propane Gas 20001281 (#49) 20007346 (#46) 20001279 (#41)

Log Set Replacement Parts

Ref. Description Log Sets

1. 18” Standard Round Log Set 20007854

1a. 24”/30” Round Right Front 20007833

1b. 18” Round Left Front 20007835

1c. 24”/30” Round Front Cross Log 20007834

1d. 18”/24”/30” Cross Log 20007837

1e. 18” Cross Log 20007836

1f. Top Log 20008335

2. 24” Standard Round Log Set 20007855

2a. 24”/30” Round Left Front 20007839

2b. 24”/30” Round Right Front 20007838

2c. 24”/30” Back Log 20007841

2d. 18”/24”/30” Cross Log 20007705

2e. 24”/30” Round Front Cross Log 20007704

2f. 24”/30” Cross Log 20007840

2g. Top Log (2 per set) 20008335

3. 30” Standard Round Log Set 20007856

3a. 24”/30” Round Left Front 20007839

3b. 24”/30” Round Right Front 20007842

3c. 30” Middle Front Log 20007706

3d. 24”/30” Back Log 20007841

3e. 18”/24”/30” Cross Log 20007705

3f. 24”/30” Round Front Cross Log 20007704

3h. Top Log 20008335

4. 18” Standard Split Log Set 20007857

4a. 18”/24”/30” Back Log 20007820

4b. 18”/24”/30” Cross Log 20007699

4c. 18” Split Right Front 20007823

4d. 18” Split Left Front 20007825

4e. Top Log #3 (2 per set) 20008337

4f. Top Log 20008336

5. 24” Standard Split Log Set 20007858

5a. 18”/24”/30” Back Log 20007820

5b. 18”/24”/30” Cross Log 20007699

153311857

Page 16

5a

5b

5c

5d

5e

5f

1a

1b

1c

1d

1e

1f

1

2a

2b

2c

2d

2e

2f

2g (2)

2

3a

3b

3c

3e

3f

3g

3d

3h

3

4a

4b

4c

4d

4e

4f

4

5

6a

6b

6c

6d

6e (2)

6f (2)

6

7a

7b

7c

7d

7e

7

8a

8b

8c

8d

8e

8f

8g

8

9a

9b

9c

9d

9e (2)

9f

9g

9h

9j

9

CFM Corporation reserves the right to make changes in design, materials, specifications, prices and discontinue colors and products at any time,

without notice.

SA18/24/30SHK Series Vented Gas Logs - Remote Hearth Kit

16

3311857

Page 17

SA18/24/30SHK Series Vented Gas Logs - Remote Hearth Kit (Continued)

Ref. Description Log Sets

5c. 24” Split right Front 20007828

5d. 24” Split Left Front 20007830

5e. Top Log #3 (2 per set) 20008337

5f. Top Log (2 per set) 20008336

6. 30” Standard Split Log Set 20007859

6a. 18”/24”/30” Back Log 20007820

6b. 18”/24”/30” Cross Log 20007699

6c. 30” Split Right Front 20007831

6d. 30” Split Left Front 20007832

6e. Top Log #3 (2 per set) 20008337

6f. Top Log (2 per set) 20008336

7. 18” Standard Combination Log Set 20007860

7a. 18” Split Right Front 20007805

7b. 18”/24”/30” Back Log 20007804

7c. Top Log 20008336

7d. 24”/30” Round Front Cross Log 20007806

7e. 18”/24”/30” Cross Log 20007705

8. 24” Standard Combination Log Set 20007861

8a. 18”/24”/30” Back Log 20007807

8b. 24” Split Right Front 20007808

8c. Top Log #3 20008337

8d. Top Log 20008336

8e. Top Log 20008335

8f. 24”/30” Cross Log 20007810

8g. 24”/30” Round Front Cross Log 20007809

9. 30” Standard Combination Log Set 20007862

9a. 18”/24”/30” Back Log 20007818

9b. 30” Split Left Front 20007816

9c. 18”/24”/30” Cross Log 20007813

9d. Top Log 20007811

9e. Top Log (2 per set) 20008335

9f. 24”/30” Cross Log 20007812

9g. 24”/30” Round Front Cross Log 20007814

9h. 18”/24”/30” Cross Log 20007705

9j. 30” Middle Log 20007815

173311857

Page 18

Page 19

LIMITED 2/20 YEAR WARRANTY

For VERMONT CASTINGS Decorative Gas Appliances

CFM Corporation extends the warranties specified in

paragraphs A and B below with respect to its Vermont

Castings Decorative Gas Appliances (the “Gas Appliance”),

including CFM Corporation supplied accessories and

components referred to in those paragraphs, subject to the

following conditions and limitations:

(1) These warranties are extended only to the Gas Ap

pliance installed in the continental United States, including

Alaska, and Canada; only if and so long as the accordance

with the installation and operating instructions furnished

therewith; and only if and so long as Gas Appliance is not

removed from its original installation.

(2). These warranties are limited to only the component

parts manufactured and supplied by CFM Corporation. The

use of components manufactured by others with the Gas Ap

pliance (except for a listed Type B venting system as defined

in the installation instructions) could create serious safety

hazard, may result in the denial of certification by recog

nized national safety agencies, and could be in violation of

local building codes.

(3). The Gas Appliance must be operated at all times in

accordance with the operating instruction furnished therewith. The Gas Appliance is designed to burn either natural or

propane gas only. Burning conventional fireplace fuels such

as wood, coal, or any other solid fuel will cause damage to

the Gas Appliance, will produce excessive temperatures and

will result in a fire hazard.

(4). These warranties are limited to repair, replacement or

furnishing a replacement for sale, as specified in Paragraphs

A and B, for a part found to CFM Corporation satisfaction,

after examination, to be defective in materials or workmanship under normal conditions, use and service.

(5). All obligations with respect to these warranties may

be fully discharged by CFM Corporation refunding the whole

sale price of a defective part.

(6) Except as otherwise expressly specified in Para

graphs A and B. NONE OF THESE WARRANTIES COVER,

AND CFM CORPORATION SHALL NOT BE RESPONSIBLE FOR, ANY CONSTRUCTION, INSTALLATION,

LABOR, TRANSPORTATION OR OTHER COSTS OR

EXPENSES ARISING FROM A DEFECTIVE PART, ITS RE

PAIR OR REPLACEMENT OR OTHERWISE, NOR SHALL

CFM CORPORATION IN ANY EVENT BE RESPONSIBLE

FOR ANY INDIRECT, INCIDENTAL OR CONSEQUEN

TIAL DAMAGES. EXCEPT TO THE EXTENT PROVIDED

BY LAW, THERE ARE NO IMPLIED WARRANTIES WITH

RESPECT TO THE GAS APPLIANCE, ITS COMPONENTS

AND ACCESSORIES (INCLUDING IMPLIED WARRANTIES

OF MERCHANTABILITY OR FITNESS FOR A PARTICU

LAR PURPOSE), ALL OF WHICH ARE HEREBY EX

PRESSLY INCLUDED. IN NO EVENT SHALL ANY IMPLIED

WARRANTY PRESCRIBED BY LAW (NOTWITHSTANDING

-

-

-

-

-

-

-

THE FOREGOING EXPRESS EXCLUSION) REMAIN IN

EFFECT AFTER EXPIRATIONS OF THE WARRANTIES

SET FORTH IN PARAGRAPHS A AND B.

A. Gas Appliances, electrical and manual compo

nents, glass panels, all sealants or adhesives and optional accessories (exclusive of CFM Corporation supplied

decorative logs which are covered by a separate warranty

under paragraph B below):

Within two years from the date of manufacture of the gas

appliance, CFM Corporation will repair, or replace (at our

option) a defective part without charge.

B. Cement or ceramic fiber log components:

Within two years from the date of manufacture of the gas

appliance, CFM Corporation will replace a defective part

-

without charge. Within years three through twenty from the

date of manufacture of the gas appliance, CFM Corporation

will provide a replacement for a defective part to the homeowner, but assumes no liability for incurred labor cost.

The foregoing warranties gives you specific legal rights

and you may also have other rights which vary from state to

state. Some states do not allow limitations on how long an

implied warranty may last, so the limitation specified above

on the duration of any implied warranty prescribed by law

may not apply to you. Similarly, some states do not permit

the exclusion or limitation of incidental or consequential

damages, so the above exclusion of such damages may not

apply to you.

In order to obtain performance of any of the above war

ranty obligations, write to CFM Corporation at this address:

CFM Corporation

410 Admiral Blvd

Mississauga, Ontario Canada L5T 2N6

Attention: Manager of Warranty Services

Since local building requirements may vary greatly

throughout the country, users of CFM Corporation products

should determine in advance whether there are any building

code restrictions on the use of a specified product.

CFM CORPORATION MAKES NO REPRESENTATION OR

WARRANTY REGARDING, AND SHALL NOT BE RE

SPONSIBLE FOR, ANY BUILDING CODE COMPLIANCE.

The foregoing warranties give you specific legal rights and you may

also have other rights which vary from state to state.

-

-

-

Page 20

CFM Corporation

410 Admiral Blvd. • Mississauga, Ontario, Canada L5T 2N6 • 905-670-7777

www.majesticproducts.com • www.vermontcastings.com

Loading...

Loading...