Vermont Casting RHE42, RHE25, RHE32 User Manual

Natural Vent Insert

Models: RHE25

RHE32

RHE42

Installation Instructions & Homeowner's Manual

WARNING! IF THE INFORMATION IN THIS MANUAL IS NOT FOLLOWED EXACTLY, A FIRE OR

EXPLOSION MAY RESULT CAUSING PROPERTY DAMAGE,PERSONAL INJURY OR LOSS OF LIFE.

FOR YOUR SAFETY

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electric switch

• Do not use any phone in your building.

• Immediately call your gas supplier from your

neighbours phone. Follow the gas suppliers

instructions.

• If you cannot reach your gas supplier call the

fire department.

I

S

G

E

N

D

Vermont Castings, Majestic Products

410 Admiral Blvd. • Mississauga, Ontario, Canada L5T 2N6 • 905-670-7777

C

E

D

R

E

I

T

I

F

INSTALLER: DO NOT DISCARD THIS MANUAL - Leave For Homeowner

www.majesticproducts.com • www.vermontcastings.com

FOR YOUR SAFETY

DO NOT STORE

OR USE GASOLINE OR OTHER

FLAMMABLE VAPOURS AND LIQUIDS

IN THE VICINITY OF THIS OR ANY

OTHER APPLIANCE.

• Installation and service must be performed by

a qualified installer, service agency or your gas

supplier.

CERTIFIED

10000836 8/03 Rev.3

Vermont Castings, Majestic Products RHE Natural Vent Insert

Table of Contents

Please read the Installation & Operating Instructions before using this appliance.

Thank you and congratulations on your purchase of a Majestic fireplace insert.

IMPORTANT - Read all instructions and warnings carefully before starting installation. Failure to follow these

instructions may result in a possible fire hazard and will void the manufacturers' warranty.

Installation Instructions

General Information .......................................................................................................................... 3

Important Curing/Burn Information .................................................................................................... 3

Locating Your Fireplace .................................................................................................................... 3

Insert Applications ............................................................................................................................. 3

Fireplace Dimensions........................................................................................................................ 4

Mantels.............................................................................................................................................. 5

Framing and Finishing....................................................................................................................... 5

Combustion Air.................................................................................................................................. 5

Zero Clearance Applications ............................................................................................................ 6

Gas Specifications ............................................................................................................................ 6

Gas Line Installation.......................................................................................................................... 6

Remote Switch for RN / RP Valves ................................................................................................... 7

Venting Instructions........................................................................................................................... 8

Venting and Installation ..................................................................................................................... 8

Common Flue Installations................................................................................................................ 9

Liner Installation ................................................................................................................................ 9

Draft Relief Opening.......................................................................................................................... 9

Test Chimney Draw........................................................................................................................... 9

Vent Safety System........................................................................................................................... 9

Fan Kit ............................................................................................................................................. 10

Fan Removal Instructions ............................................................................................................... 10

Operating Instructions

General Glass Information ............................................................................................................. 11

Louvre Removal .............................................................................................................................. 11

Glass Cleaning ................................................................................................................................ 11

Glass Frame Removal..................................................................................................................... 11

Installation of Logs & Burner Lava Rock .........................................................................................11

Large Lava Rock Placement ........................................................................................................... 12

Flame Adjustment (RN /RP Models) ............................................................................................... 12

Temperature Adjustment (TN / TP Models) .................................................................................... 12

Flame Characteristics...................................................................................................................... 12

First Firing ....................................................................................................................................... 13

Lighting & Operating Instructions .................................................................................................... 14

Troubleshooting Gas Control (SIT 820 Gas Valve)......................................................................... 15

Troubleshooting Gas Control (SIT 630 Gas Valve)......................................................................... 16

Troubleshooting Gas Control (Honeywell Valve) ........................................................................... 17

Maintenance

Cleaning the Standing Pilot Control System ................................................................................... 18

Brass Cleaning ................................................................................................................................ 18

Replacement Parts.............................................................................................................................................. 19

Optional Accessories

Ceramic Refractory ......................................................................................................................... 22

Zero Clearance Kit .......................................................................................................................... 22

Remote Controls ............................................................................................................................. 22

A Trim Options for RHE25 .............................................................................................................. 22

B Trim Options for RHE32 .............................................................................................................. 26

C Trim Options for RHE42 .............................................................................................................. 34

Warranty .............................................................................................................................................................. 38

2

10000836

Vermont Castings, Majestic Products RHE Natural Vent Insert

Installation Instructions

This gas appliance should be installed by a qualified installer

in accordance with local building codes and with current CSAB149.1 Installation codes for Gas Burning Appliances and

Equipment.

For U.S.A Installations follow local codes and/or the current

National Fuel Gas Code. ANSI Z223.1.

FOR SAFE INSTALLATION AND OPERATION OF YOUR

MAJESTIC GAS FIREPLACE INSERT PLEASE NOTE THE

FOLLOWING:

1. This appliance gives off high temperatures and should be

located out of high traffic areas and away from furniture

and draperies.

2. Children and adults should be alerted to the hazards of the

high surface temperatures of this appliance and should

stay away to avoid burns or ignition of clothing.

3. Children should be carefully supervised when they are in

the same room as your appliance.

4. Under no circumstances should this appliance be modified.

Parts removed for servicing should be replaced prior to

operating this appliance again.

5. Installation and any repairs to this appliance should be

carried out by a qualified service person. A professional

service person should be contacted to inspect this appliance annually. Make it a practice to have all of your gas

appliances checked annually. More frequent cleaning may

be required due to excess lint and dust from carpeting,

bedding material, etc.

6. Control compartments, burners and air passages in this

appliance should be kept clean and free of dust and lint.

Make sure that the gas valve and pilot light are turned off

before you attempt to clean this unit.

7. The venting system (chimney) of this appliance should be

checked at least once a year and if needed your venting

system should be cleaned.

8. Keep the area around your appliance clear of combustible

materials, gasoline and other flammable vapor and liquids.

This appliance should not be used as a drying rack for

clothing, nor should Christmas stockings or decorations be

hung in the area of it.

9. Under no circumstances should any solid fuels (wood, coal,

paper or cardboard etc.) be used in this appliance.

10.The flow of combustion and ventilation air must not be

obstructed in any way.

11.These appliances are certified for installation in a solid fuel

burning fireplace unless using the model HEZC Zero

Clearance kit. When the Zero Clearance kit is used, and

the appliance is installed directly on carpeting, vinyl tile or

any combustible material other than wood, the appliance

must be installed on a metal or wood panel extending the

full width and depth of the appliance.

12.This appliance requires adequate ventilation and

combustion air to operate properly.

Proposition 65 Warning: Fuels used in gas,

woodburning or oil fired appliances, and the products

of combustion of such fuels, contain chemicals known

to the State of California to cause cancer, birth defects

and other reproductive harm.

California Health & Safety Code Sec. 25249.6

IMPORTANT:

PLEASE REVIEW THE FOLLOWING CAREFULLY

Remove any plastic from trim parts before turning the

fireplace ON.

It is normal for fireplaces fabricated of steel to give

off some expansion and/or contraction noises during

the start up or cool down cycle. Similar noises are

found with your furnace heat exchanger or car

engine.

It is not unusual for your Majestic gas fireplace to

give off some odor the first time it is burned. This is

due to the curing of the paint and any undetected oil

from the manufacturing process.

Please ensure that your room is well ventilated -

open all windows.

It is recommended that you burn your Majestic

fireplace for a least six (6) hours the first time you

use it. If optional fan kit has been installed, place fan

in the "OFF" position during this time.

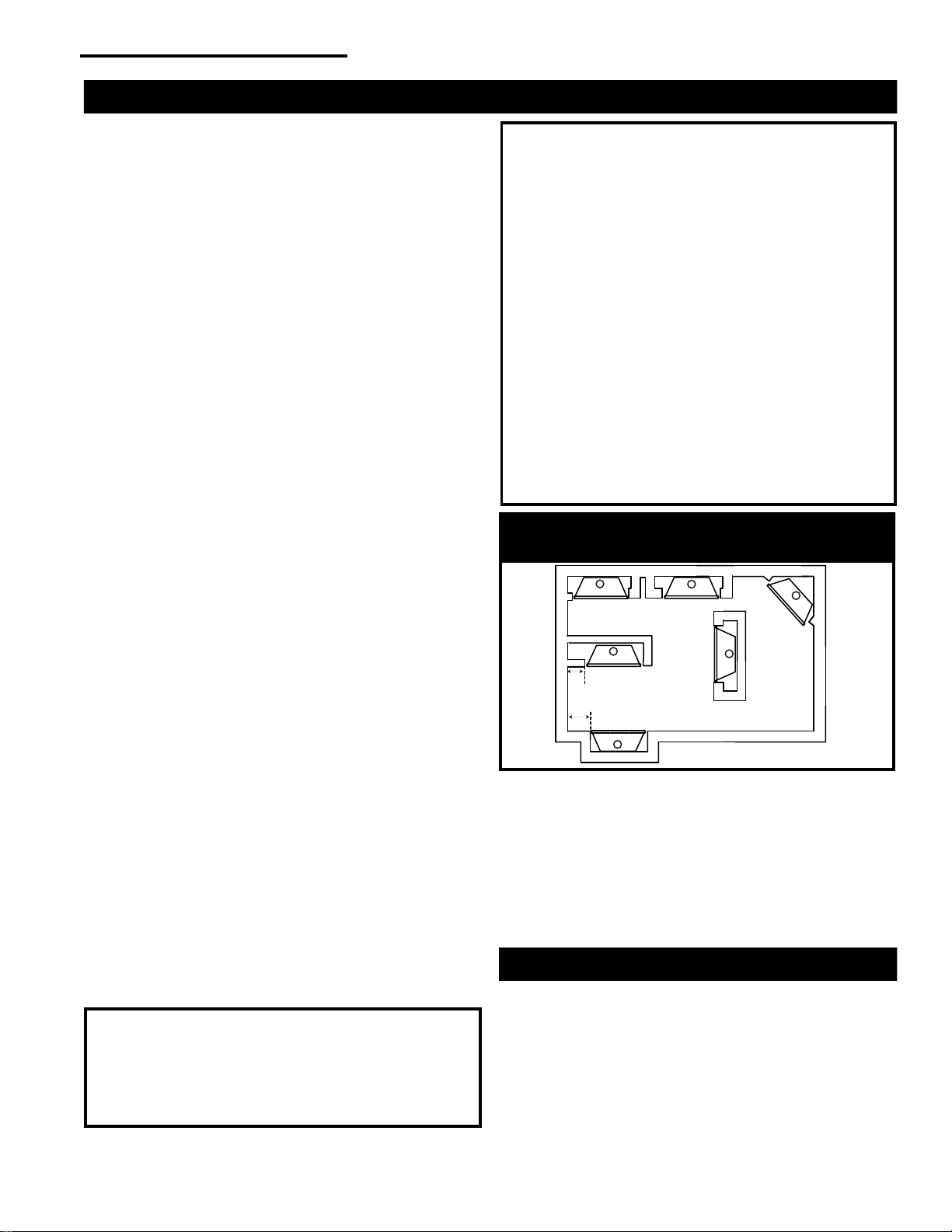

Locating Your Gas Fireplace Insert with

Zero Clearance Kit

X

E

D

X

X

F

Fig 1. Locating unit with zero clearance kit.

A) Flat on wall B) Cross corner

C) Island D) *Room divider

E) *Flat on wall corner F) Chase installation

NOTE: (Fig. 1)

* When you install your Majestic fireplace in (D) Room divider

or (E) Flat on wall corner positions, a minimum of 6" (X)

(153mm) clearance must be maintained from the perpendicular wall and the outer edge of the trim.

A

C

B

FP1249

Insert Applications

Before installing the gas fireplace insert, consideration

must be given to the functioning needs of the fireplace.

The size of the fireplace cavity, the design of the chimney

for effective venting should be determined. The

availability of the gas supply as well as electricity for the

insert fan must be confirmed.

10000836

3

Vermont Castings, Majestic Products RHE Natural Vent Insert

Fireplace Dimensions

B

D

F

A

Maintain 1"

C

Minimum Fireplace

Insert Opening

U

Q

V

Q - Fireplace Opening Height T - Firebox Width at Insert Depth(s)

R - Fireplace Opening Width U - Firebox Depth at Insert Back Height (V)

S - Depth of Insert V - Insert Back Height

T

R

I

M

F

I

R

E

P

L

A

C

E

M

O

I

P

N

E

I

N

M

I

U

N

M

G

A-1 26³⁄₄" (680mm) 26³⁄₈" (676mm) 30³⁄₄" (781mm)

B-1 38¹⁄₂" (978mm) 38³⁄₈" (975mm) 43¹⁄₈" (1095mm)

A-2 29¹⁄₄" (743mm) 29" (737mm) 33³⁄₈" (848mm)

B-2 43¹⁄₂" (1105mm) 41¹⁵⁄₁₆" (1065mm) 48¹⁄₄" (1225mm)

A-3 -- 33" (838mm) - B-3 -- 44" (1118mm) - A-4 -- 28" (712mm) - B-4 -- 40⁷⁄₈" (1041mm) - -

A-5 -- 30¹⁄₂" (775mm) - -

B-5 -- 46" (1171mm) - -

C 25¹⁄₄" (641mm) 28³⁄₄" (730mm) 31" (787mm)

D 17" (432mm) 17¹⁄₄" (438mm) 20¹⁄₈" (511mm)

E 13³⁄₄" (349mm) 15⁵⁄₈" (397mm) 17³⁄₄" (451mm)

F 15" (381mm) 17¹⁄₈" (435mm) 21" (533m)

G 19¹⁄₄" (489mm) 20¹⁄₂" (521mm) 23¹⁄₄" (590mm)

H 17¹⁄₂" (445mm) 20" (508mm) 22³⁄₄" (578mm)

K 35" (889mm) 35" (889mm) 39¹⁄₄" (1000mm)

L 26⁵⁄₈" (676mm) 26⁵⁄₈" (676mm) 31¹⁄₈" (790mm)

M 8¹⁄₂" (216mm) 8¹⁄₂" (216mm) 8¹⁄₂" (216mm)

N 37¹⁄₂" (952mm) 37¹⁄₂" (952mm) 37¹⁄₂" (954mm)

O 19¹⁄₈" (486mm) 19¹⁄₈" (486mm) 21³⁄₄" (553mm)

P 27¹⁄₄" (692mm) 27¹⁄₄" (692mm) 25³⁄₄" (654mm)

Q 17³⁄₄" (451mm) 21" (533mm) 23¹⁄₄" (591mm)

R 25" (635mm) 28" (711mm) 29" 737mm)

S 13³⁄₄" (349mm) 16" (407mm) 18" (457mm)

T 17¹⁄₂" (445mm) 17³⁄₄" (451mm) 20⁵⁄₈" (524mm)

U 14" (356mm) 16¹⁄₂" (419mm) 21" (533mm)

V 17³⁄₄" (451mm) 20¹⁄₄" (514mm) 23" (584mm)

T

S

R

RHE25 RHE32 RHE42

(25mm) Clearance

to B-Vent

1"

(25mm)

E

Air Inlet Channel

1 = SS or SSD Trim

2 = SL or SLD Trim

3 = SXL Trim

4 = BSL Trim

5 = BXL Trim

Zero Clearance Kit

M

L

K

Gas Inlet Knock-out

O

G

H

P

N

4

10000836

Vermont Castings, Majestic Products RHE Natural Vent Insert

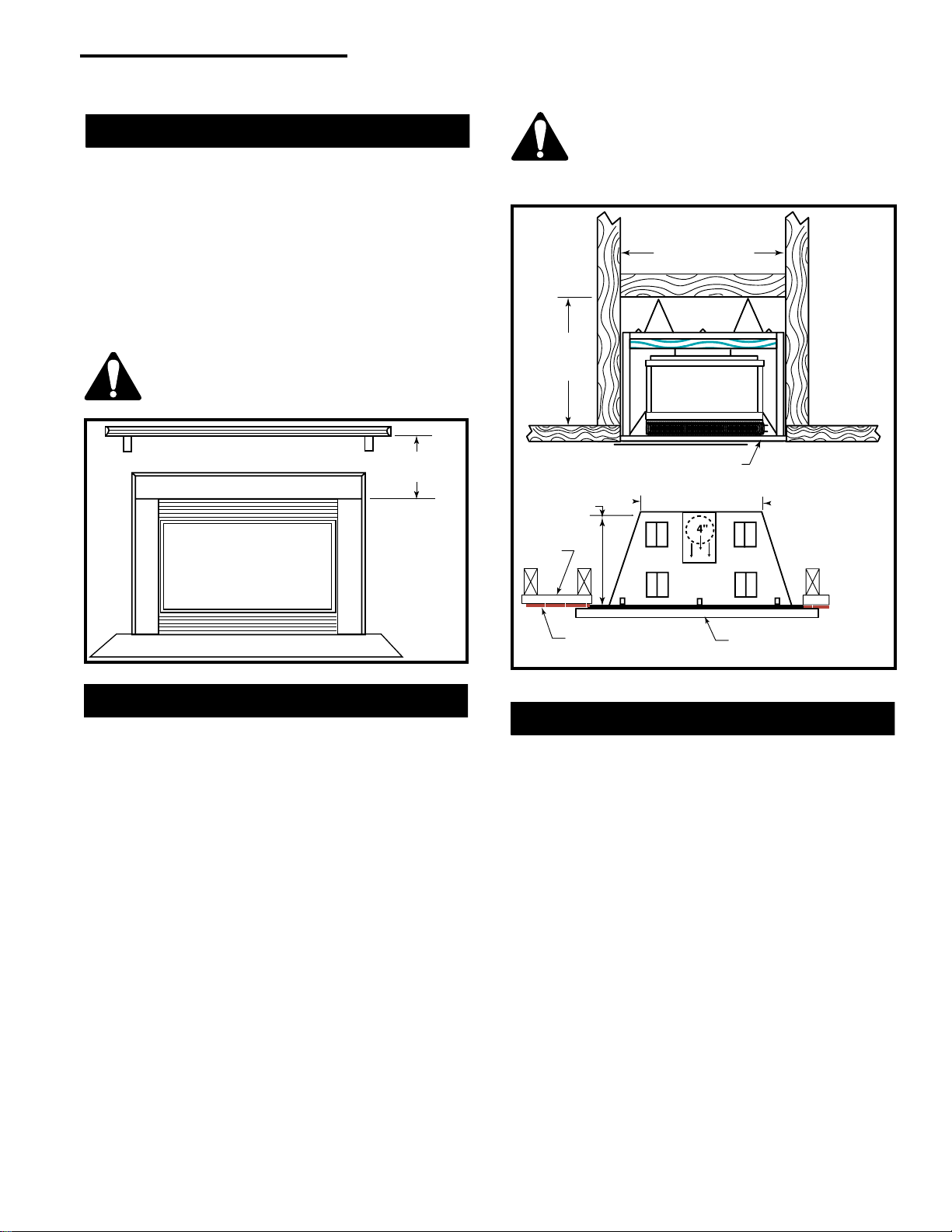

Mantels

When the insert is being installed into a woodburning

fireplace the minimum the mantel can be above the

fireplace is governed by local building codes applicable

to woodburning fireplaces. Consult local authorities

having jurisdiction for these clearances.

For applications requiring the use of a Zero Clearance

Kit, the minimum a mantel can protrude above the

fireplace is 24" (610mm) from the top of the upper

louvres. The maximum mantel depth is 8" (200mm).

(Fig. 2)

The underside of the mantel will get quite

warm. Use only finishes which are heat

resistant and do not discolour.

24" Min.

(610mm)

35"

(889mm)

19¹⁄₈" (486mm)

(RHE25/32)

21³⁄₄" (553mm)

(RHE42)

Dry

Wall

The use of wallpaper adjacent to this

fireplace is not recommended, as the

high heat given off by this fireplace may

adversely effect the binders in the adhesive used to apply the wallpaper.

37¹⁄₄" (946mm)

Air Inlet Channel

27¹⁄₄" (692mm) (RHE25/32)

25³⁄₄" (654mm) (RHE42)

FP1325

Fig. 2 Minimum mantel height above fireplace.

Framing & Finishing

For Zero Clearance Kit applications it is important to

determine the finished facing material before beginning

to frame. This will allow for the thickness of the

finishing material between the frame and the fireplace

trim.

Similarily, consideration must be given to the 1"

(25mm) depth of the air inlet channel sitting on the

fireplace base. Finishing material for the hearth should

be flush with the top of the air inlet channel.

If the fireplace is installed at floor level a noncombustible hearth must extend a minimum 12"

(305mm) in front of the fireplace.

If the fireplace is recessed into the wall and at least 12"

(305mm) above floor level, no hearth is required.

A (3" for RHE25, 4" for RHE32 and RHE42) diameter

Class "B" vent must be used when installing the

fireplace insert along with the Zero Clearance Kit. The

vent system must be a minimum height of 12' (3.7m).

Finish Wall

Fig. 3 RHE insert framing dimensions.

Decorative Trim Kit

FP1351a

Combustion Air

It is very important that an adequate air supply is

available when the unit is being operated. Since most

homes of today are tightly sealed and insulated,

additional make-up air is usually necessary.

This fireplace has been designed to operate by

drawing air in from the front and outer perimeters of

the fireplace. The air provides combustion air ensuring

a clean burning flame, dilution air for proper venting, as

well as, the air which the fan circulates over the

firebox/heat exchanger system.

Insulating around the fireplace will result in overheating

and possible malfunctioning of the circulating fan.

10000836

5

Vermont Castings, Majestic Products RHE Natural Vent Insert

Zero Clearance Applications

An alternate air supply is recommended

with this component.

For installations other than in existing woodburning

fireplaces such as new construction or renovation

projects, a Zero Clearance Kit must be used. The kit

enables these inserts to be installed in combustible

environments. It is recommended that an Air Kit

(AKZC) be installed whenever using a Zero Clearance

Kit. Consideration must be given to the dimensions of

the Zero Clearance Kit and the requirements of the Air

Kit when planning the installation.

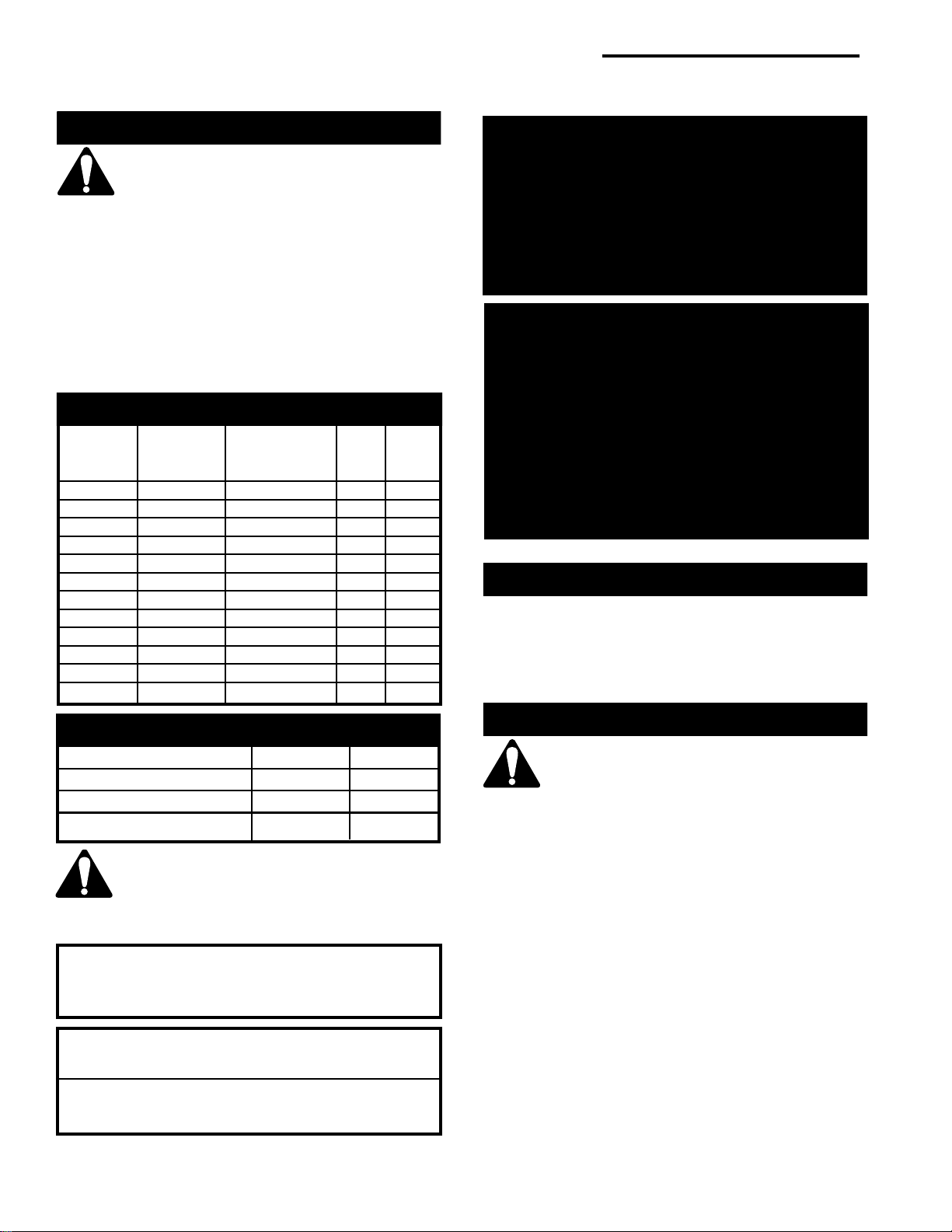

Gas Specifications

Max. Min.

Input Input

Model Fuel Gas Control Btu/h Btu/h

RHE25RN Natural Gas Millivolt HI/LO 22,000 15,400

RHE25RP Propane Gas Millivolt HI/LO 22,000 16,500

RHE25MN Natural Gas Manual HI/LO 22,000 15,400

RHE25MP Propane Gas Manual HI/LO 22,000 16,500

RHE3RN Natural Gas Millivolt HI/LO 30,000 21,000

RHE32RP Propane Gas Millivolt HI/LO 30,000 22,500

RHE32TN Natural Gas Thermostat HI/LO 30,000 21,000

RHE32TP Propane Gas Thermostat HI/LO 30,000 22,500

RHE42RN Natural Gas Millivolt HI/LO 40,000 28,000

RHE42RP Propane Gas Millivolt HI/LO 37,000 27,750

RHE42TN Natural Gas Thermostat HI/LO 40,000 28,000

RHE42TP Propane Gas Thermostat HI/LO 37,000 27,750

Gas Inlet & Manifold Pressures

Natural LP

Minimum Inlet Pressure 5.5" W.C.11.0" W.C.

Maximum Inlet Pressure 14.0" W.C. 14.0" W.C.

Manifold Pressure 3.5" W.C. 10.0" W.C.

Do not use this appliance if any part of it

has been under water. Immediately call a

qualified service technician to inspect the

unit and replace any part of the control

which has been under water.

These gas inserts are approved for installation in

solid fuel burning masonry or zero clearance

fireplaces.

RHE25 / RHE32 / RHE42

Certified To

ANSI Z 21.88-2002 / CSA 2.33-2002

Vented Gas Fireplace Heaters

The installation of your Majestic Fireplace

must conform with local codes, or in the

absence of local codes, with National Fuel Gas

Code, ANSI Z223.1 latest edition, or CSAB149.1 Installation Code. (EXCEPTION: Do

not derate this appliance for elevations up to

4,500 ft (1,370m). Maintain the manifold

pressure at 3.5" w.c. for Natural Gas and 10.0"

w.c. for LP gas.)

High Elevations

Input ratings are shown in BTU per hour and are

certified without deration for elevations up to

4,500 feet (1,370m) above sea level.

For elevations above 4,500 feet (1,370m) in USA,

installations must be in accordance with the

current ANSI Z223.1 and/or local codes having

jurisdiction.

In Canada, please consult provincial and/or local

authorities having jurisdiction for installations at

elevations above 4,500 feet (1,370m).

Preparation

Before beginning, remove the glass frame from the

fireplace. Also check to make sure there is no hidden

damage to the fireplace. Take a minute and plan out

the gas, vent and electrical supply. Refer to Glass

Frame Removal section.

Gas Line Installation

When purging the gas line, the front

glass must be removed.

The gas pipeline can be brought into the fireplace base

from the right side. It is most convenient to install it

from the right side into the gas fittings provided.

When using copper or flex connector use only

approved fittings. Always provide a union when using

black iron pipe so that gas line can be easily

disconnected for burner or fan servicing. Refer to gas

specifications for pressure details and ratings.

The gas line connection can be made of either properly

tinned 3/8" copper pipe, 3/8" rigid pipe or an approved

flex connector.

The gas control inlet is 3/8" N.P.T. therefore the 1/2"

rigid gas line must be reduced to 3/8" N.P.T. Typical

installation layout for rigid pipe is shown following. (Fig.

4)

6

10000836

Vermont Castings, Majestic Products RHE Natural Vent Insert

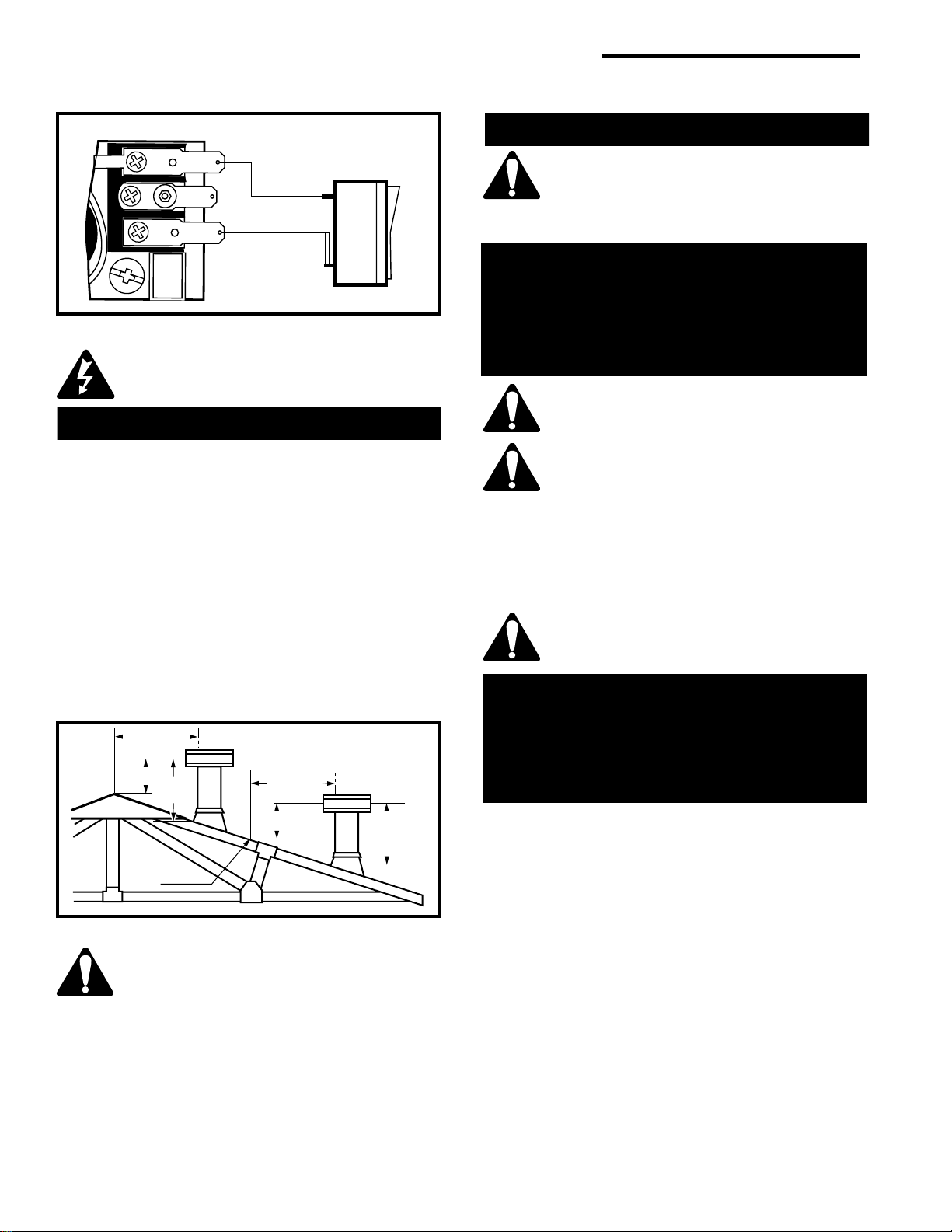

1/2" Gas Supply

1/2" x 3/8" Reducer

3/8" x 3/8" Shut Off

Valve

3/8" Union

3/8" Nipple

FP1278

Fig. 4 Typical gas supply installation.

During any pressure testing of the gas line system,

when the test pressures are to exceed 1/2 psi (3.5 kpa)

the fireplace and its gas valve must not be connected

to that system.

At test pressures equal to or less than 1/2 psi, the gas

valve of the fireplace may be connected to the gas line,

but must be in the closed position.

Some municipalities have additional local codes, it is

always best to consult the local authority and the CSAB149.1 installation code in Canada.

FOR U.S.A Installations consult the current National

Fuel Gas Code, ANSI Z223.1

Always check for gas leaks with a mild soap

and water solution. Do not use an open

flame for leak testing.

Manifold Gas

Outlet

Thermostat

Bulb

Gas Inlet

Thermocouple Inlet

Brass

Plug

Brass Plug

Pressure

Regulator

Installation of Remote Switch

for RN/RP Gas Valves

1. Thread wire through gas inlet opening on the right

side of fireplace. Do not cut wire or insulation on

metal edges.

2. Slide switch assembly from the back, between

subframe and trim, then fasten the screw. (Fig. 6)

3. For left side installation reverse switch position in

bracket and repeat Step 2. (Fig. 7)

4. Connect wiring to gas valve (Fig. 8a & b) and switch.

Right Side Installation

Trim Right

Side

Trim

Screw

ON/OFF Switch

Assembly

ON/OFF Switch Assembly

Fig. 6 Slide switch assembly between subframe and trim.

Left Side Installation

Trim Top

Wiring from

Millivolt Gas

Valve

Trim Left

Side

Trim

Screw

FP1253

Bracket Switch

Pilot Tube Entry

Pilot

Adjustment

Screw

LO

Minimum Rate Screw

(Nonadjustable)

it

PILOT

HI

OFF

Control Knob

Control Knob

HV118

Fig. 5 On fireplaces equipped with the Eurosit 630 gas

valves, there are brass plugs in two of the holes. These

plugs are not to be removed. The gas inlet hole has a plastic

cap in it. Remove the plastic cap and connect your gas

supply line at this point.

The MN/MP valve control used on the

RHE25 does not include the thermostat

bullb as shown in Figure 5.

10000836

ON/OFF

Switch

FP1254

Fig. 7 For left side installation, reverse switch position in

bracket.

Valve

THTP

Thermopile

TP

TH

P

I

L

T

O

FP382a

Fig. 8a ON/OFF switch or millivolt thermostat.

7

Vermont Castings, Majestic Products RHE Natural Vent Insert

Venting and Installation

TH

TP

TPTH

FP1218a

Fig. 8b ON/OFF switch wiring.

If a remote wall switch is required for this

fireplace installation, do not wire wall

switch to 120V power supply.

Venting Instructions

Canadian Installations:

The venting system must be installed in accordance

with the current CSA-B149.1 installation code, and the

authority having jurisdiction.

U.S.A. Installations:

The venting system must be installed in accordance

with the current National Fuel Gas Code, ANSI Z223.1.

Minimum clearances to combustible materials is 1"

(25mm) for B Vent (use of single wall vent is not

allowed).

As with any natural draft appliances, the vent cap must

always extend a minimum of 2' (610mm) above any

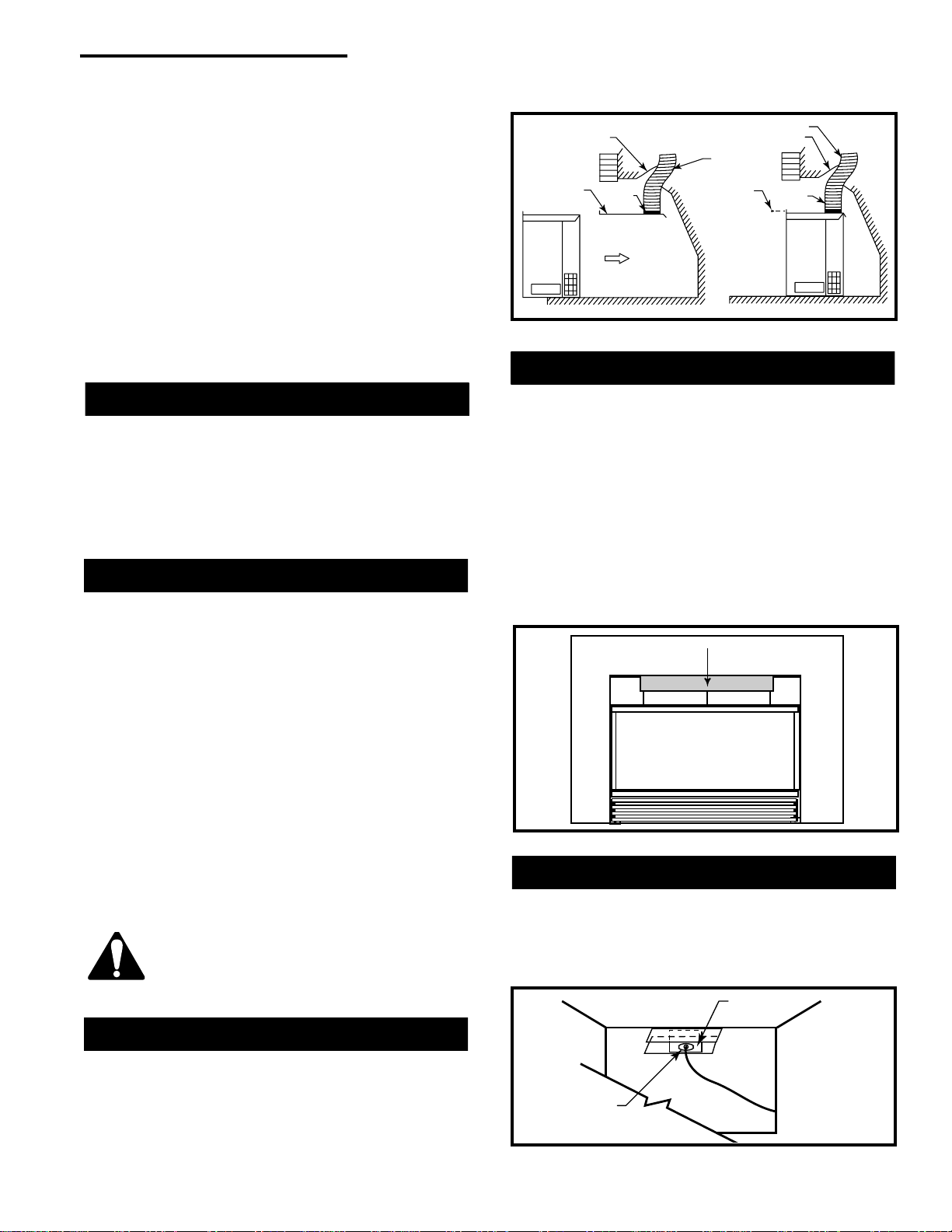

structure within a 10' (3m) horizontal plane. (Fig. 9)

0 To 10’

2’ Min.

3’

Min.

Reference

Point

Fig. 9 Example of the 2', 3', 10' rule.

A minimum 12' (3.7m) vent height is

required to effectively vent this fireplace.

0 To 10’

(3m)

2’

(610mm)

Min.

3’

(914mm)

Min.

AC246a

This fireplace has been converted for use with

gas only and cannot be used for burning wood

or solid fuels unless all original parts have been

replaced and the fireplace has been re-approved

by the authority having jurisdiction.

Some factory built fireplaces have air passages

on face of fireplace for zero clearance capabilities. All trim kits are designed so as to allow

airflow to these passages. Under no circumstances should these passages be blocked.

1. The Majestic gas inserts are designed for recessed

installations into solid fuel Masonry or Factory Built

Noncombustible fireplaces that have been installed

in accordance with the National, Provincial, State

and local building codes.

2. Measure for minimum fireplace opening requirement

on Page 4 of this installation manual. (If firebrick

[refractory] is removed from a factory built

fireplace in order to gain minimum gas fireplace

insert opening requirements, a minimum of 1/4"

(6.4mm) air space is required between the gas

insert fireplace's outer casing and the inner wall

of the factory built fireplace).

3. To assure top performance, safety and efficiency, all

inserts must be installed with an approved 4"

diameter flue liner, with exception of RHE25, which

should be installed with an approved 3" liner,as per

CSA-B.149 or National Fuel Code ANSI Z223.

Installer must attach red warning plate

with screws supplied with the gas fireplace insert to the inside of the firebox of

the fireplace into which the gas fireplace

insert is installed.

Cutting any sheet metal parts of the

fireplace, in which the gas fireplace insert

is to be installed, is prohibited.

If the factory-built fireplace has no gas

access hole(s) provided, an access hole

of 1¹⁄₂" (37.5mm) or less may be drilled

through the lower sides or bottom of the

firebox in a proper workmanship like

manner. This access hole must be

plugged with a noncombustible insulation

after the gas supply line has been

installed.

Ensure there are no obstructions to side

air passages of decorative trim once

installed on insert.

WARNING

WARNING

8

10000836

Vermont Castings, Majestic Products RHE Natural Vent Insert

4. Flue damper must be fully blocked in the open

position or removed for installation.

5. The chimney must be clean and in good working

order and constructed of noncombustible materials.

6. Make sure that all chimney cleanouts fit properly so

air cannot leak into the chimney.

7. Glass door, screen kits and log grate may be

removed for installation of insert into factory built

fireplace.

8. Install the insert without the trim frame and make all

gas, venting and electrical connections.

9. Install decorative trim frame. Please refer to Frame

Assembly and Mounting instructions on this manual.

Common Flue Installations

In some areas it is possible to vent more than one gas

fireplace into the same flue. You must ensure the flue

being shared has the proper capacity to handle both

fireplaces. Check installation codes for venting capacity

information.

As always it is best to check with the authority having

jurisdiction prior to commencement of the installation.

Liner Installation

Insert liner from top of chimney through the damper

opening and attach to 3" flue collar (for RHE25); 4" flue

collar (for RHE32 & RHE42). For best results use

three (3) sheet metal screws and a hose clamp.

For natural draft inserts packing fibreglass insulation

around the liner in the damper area will isolate the

fireplace cavity from the chimney and prevent drafts

and noises during operation.

In case the fireplace opening is only minimum height

(17¹⁄₂" for RHE25) (20" for RHE32) (22³⁄₄" for RHE42)

and access from the front is not possible, remove the

flue collar plate - unscrew and slide out from the back

of the unit. Now attach the liner to the flue collar, lift up

and simply slide flue collar plate back onto the unit top.

It is important the plate is completely inserted and the

front screw is fastened again in order to line up the flue

outlet and the liner properly. (Fig. 10)

If fireplace lintel is wider than 8"

(205mm), the height of the fireplace

opening must be 25" (635mm) to allow

for a 90° offset elbow to be installed.

Damper

Flue

Collar Plate

Fig. 10 Remove flue collar plate and attach to flue collar.

Clamp

Chimney Liner

Damper

Chimney

Liner

Screw

Clamp

FP1354

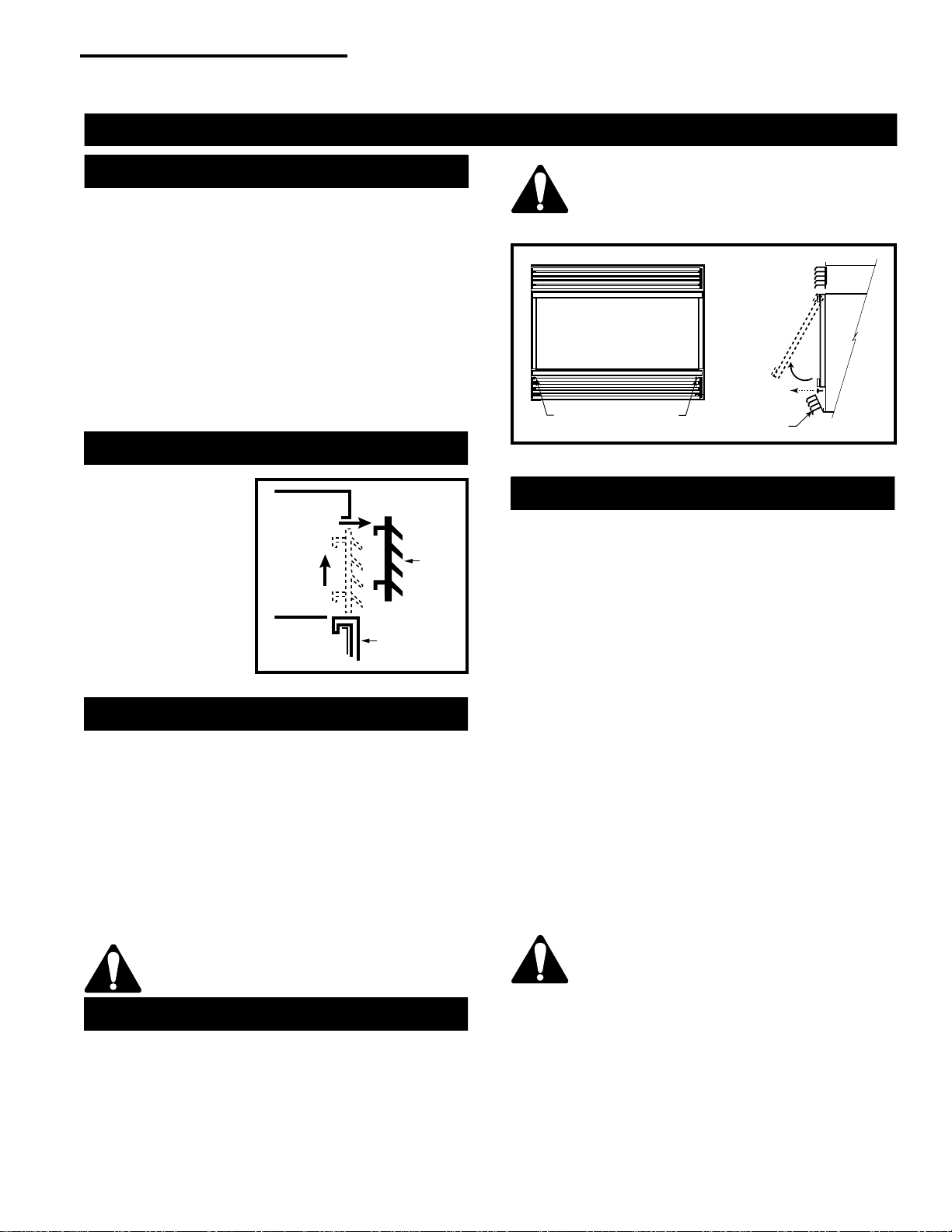

Test Chimney Draw

A "Chimney Draw" test must be made before the

installation is complete.

1. Close all doors and windows in the home and start

exhaust fans in the kitchen and bathroom.

2. Light unit and operate for 5 minutes.

3. Hold an ignited match or cigarette in front of the

unit. Refer to Figure 11 for the location of the draft

hood opening.

4. Check to make sure smoke from the match or

cigarette is drawn into the fireplace. If it is not, turn

the unit off and check for causes creating the lack of

adequate draft.

Test for Draft at This Location

FP1371

Fig. 11 Hold an ignited match in front of fireplace.

Vent Safety System

These inserts are equipped with a vent safety shut

down switch. This switch is factory installed, wired and

tested. Check and make sure the switch and wires are

in the proper position. The safety switch is heat activated and wired in series with the pilot system. (Fig. 12)

Bracket

Draft Relief Opening

This insert is equipped with a draft-relief opening which

receives its dilution air supply through the opening

behind the louvres. These openings must not be

obstructed or altered in any way. (Fig. 11)

10000836

Vent Safety

Switch

FP1372

Fig. 12 Vent safety switch.

9

Vermont Castings, Majestic Products RHE Natural Vent Insert

Operation of this fireplace when not

connected to a properly installed and

maintained venting system or tampering

with the vent safety shutoff system can

result in carbon monoxide (CO)

poisoning and possibly death.

Thermal Sensor is

attached to burner

base

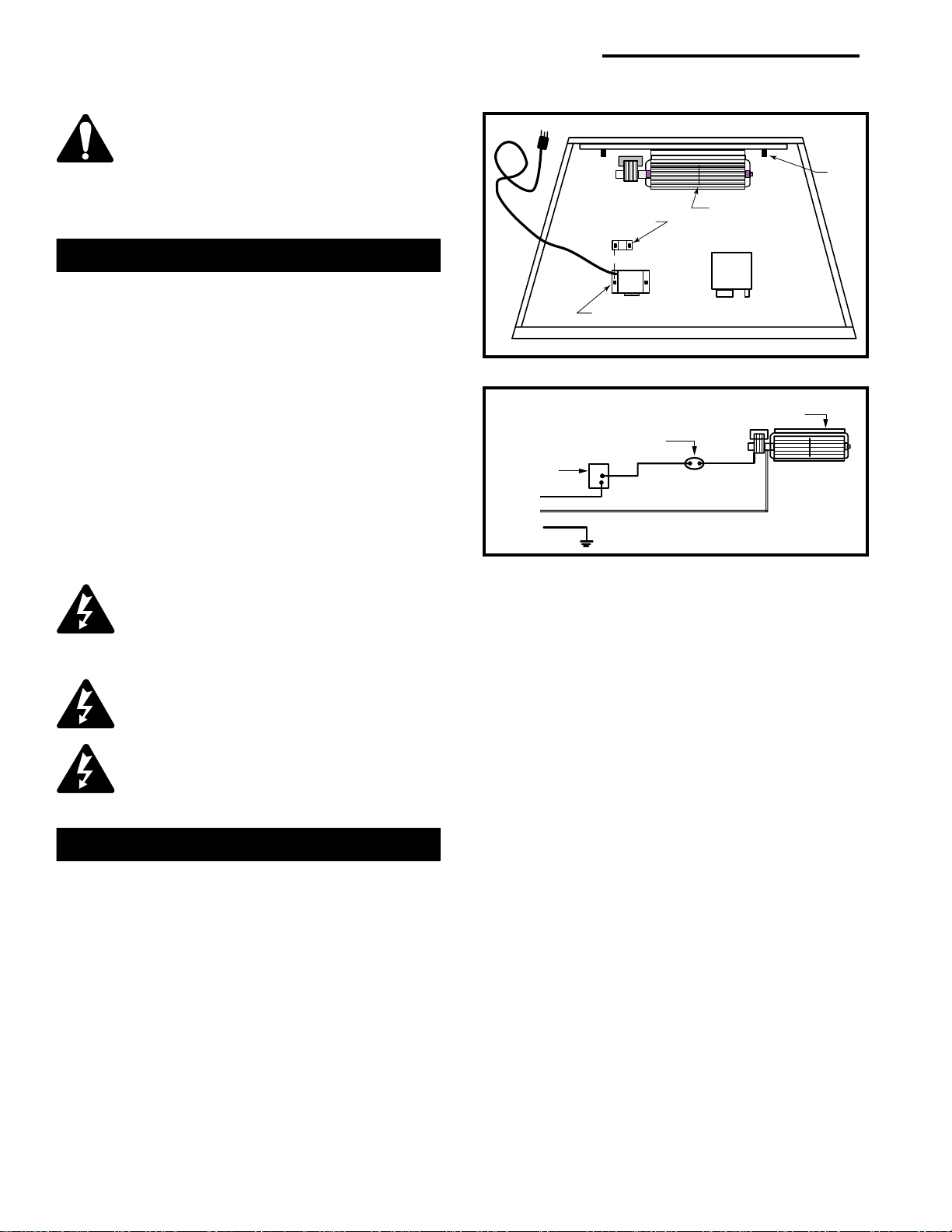

Fan Kit

115 Volt, 60 Hz. 56W

The fan kit includes the following: fan, temperature

sensor, speed control and a 6 ft. cord. The following

explains how to start and set the fan for automatic

operation.

1. Plug in the electrical cord.

2. Start gas fire - see lighting procedures.

3. Turn on fan speed control.

4. Wait until the unit has warmed up sufficiently to

activate the temperature sensor.

5. Once fan starts, adjust speed control to desired fan

speed. The fan will now automatically come on

every time the fireplace is in operation. Should the

fan not be needed simply turn off the speed control.

The appliance, when installed must be

electrically connected and grounded in

accordance with local codes or, in the

absence of local codes, with the current

CSA C22.1 Canadian Electrical Code.

For U.S.A. installations, follow local

codes and the national electrical code,

ANSI/NFPA No. 70.

Should this fan require servicing, the

power supply must be disconnected. For

rewiring of any replacement components refer to Figures 13 & 14.

Fig. 13 Fan location.

Temperature Sensor

Speed

Control

Black

White

Ground

Fig. 14 Wiring diagram RN/RP.

Fan is installed

at the back of

the air intake

box

Stud

Fan Speed Control/Junction Box

Valve

Stud

FP1252

Fan

FP394

Fan Removal Instructions

1. Turn off gas and electricity.

2. Remove the front glass.

3. Remove the logs.

4. Remove burner assembly and rear log support plate.

5. Remove the fan mounting nuts (2). (Fig. 13)

6. Slip off the electrical connector at the motor.

7. Lift out the fan.

8. To reinstall, reverse procedure.

10

10000836

Vermont Castings, Majestic Products RHE Natural Vent Insert

Operating Instructions

General Glass Information

Only ceramic glass approved for use in Majestic

fireplaces may be used for replacement on this

fireplace.

1. The use of substitute glass will void all product

warranties.

2. Care must be taken to avoid breakage of the glass.

3. Under no circumstances should this fireplace be

operated without front glass properly installed, or

with any cracked or broken glass. Replacement of

any glass assembly as supplied by the

manufacturer should be done by a licensed qualified

service person.

Louvre Removal

To remove top flat

louvre pull louvre up

and then lift out.

FP444

Fig. 15 Louvre removal.

2.

Glass

Panel

Louvre

1.

Glass Cleaning

It will be necessary to clean the glass periodically.

During start-up, condensation, which is normal, forms

on the inside of the glass and causes lint, dust and

other airborne particles to cling to the glass surface.

Also initial paint curing may deposit a slight film on the

glass. It is therefore recommended the glass be

cleaned two or three times with a non-ammonia

household cleaner and warm water (we recommend

gas fireplace glass cleaner). After that the glass should

be cleaned two or three times during each heating

season depending on the circumstances present.

Clean glass after first two weeks of

operation.

Before remounting glass frame, brass

trim must be installed. Refer to instructions in "Frame Mounting" section.

Glass Frame

Screws

Machine Screws

Fig. 16 Remove glass frame.

Open Access Door

FP1373

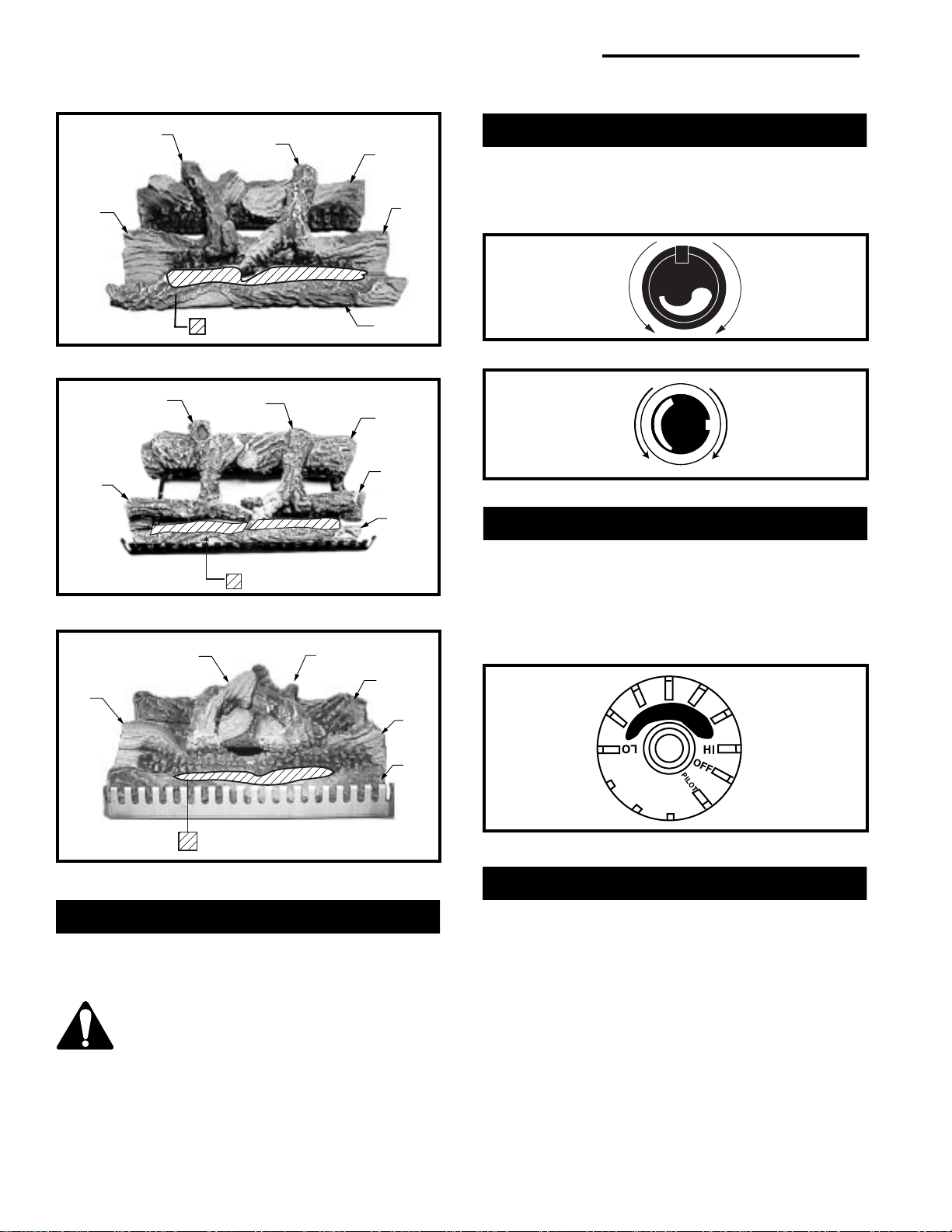

Installation of Logs

1 . Remove front glass. (Refer to "Glass Removal"

section)

2. Remove logs from packaging.

3. Place rear log (JR4/KR4 or SR4) on rear bracket

(ensure log is seated properly, leveled and

centered to the unit), so it will not move from side to

side and is firmly positioned on the bracket.

4. Slip front ember log (KR1or SR1) down in the front

deflector.

5. Place front left log (JR2/KR2 or SR2) on top

burner, left side. Use log's bottom holes to locate it

into the left bracket log locator studs.

6. Place front right log (JR3/KR3 or SR3) on top of

burner, right side. Use log's bottom holes to locate

it into the right bracket log locator studs.

7. Place burner lava rock material on top of burner.

(Refer to Figs. 17, 18 & 19 for proper location).

8. Place top left log (JR5/KR5 or SR5) onto locator

notches. Ensure log is secure.

9. Place top right log (JR6/KR6 or SR6) onto locator

notches. Ensure log is secure.

Top logs must be placed properly into

notches.

Glass Frame Removal

1. Remove the top louvre. (Refer to "Louvre Removal"

section)

2. Open the access door.

3. Remove two (2) machine screws from the bottom of

glass frame. (Fig. 16)

4. Lift up and unhook glass frame at the top.

10000836

11

Vermont Castings, Majestic Products RHE Natural Vent Insert

JR5

JR2

LG279

Fig. 17 RHE25 log and lava rock placement.

KR5

KR2

Fig. 18 RHE32 log and lava rock placement.

SR5

SR2

JR6

Burner Lava Rock

Placement

KR6

Burner Lava Rock

Placement

SR6

JR4

KR1

KR4

KR3

SR4

JR3

KR1

LG280

SR3

Flame Adjustment (RN/RP Models)

For fireplaces equipped with HI/LO valve, flame adjustment is accomplished by rotating the HI/LO adjustment

knob located near the center of the gas control.

(Figs. 20 & 21)

Turn

counterclockwise

to decrease

flame height

Fig. 20 Flame adjustment knob for Honeywell Valve.

Turn

counterclockwise

to increase

flame height

Fig. 21 Flame adjustment knob for SIT Valve.

LO

HI

Turn clockwise

to increase

flame height

I

H

Turn clockwise

to decrease

L

O

flame height

Temperature Adjustment (TN/TP Models)

The HI/LO reference on the control knob (Fig. 22) is to

indicate a higher or lower temperature setting. This

setting controls the heat by reducing then shutting off

the flame after the desired temperature is reached.

Position the control knob where it effectively maintains

a comfortable room temperature.

SR1

Burner Lava Rock

Placement

Fig. 19 RHE42 log and lava rock placement.

LG281

Large Lava Rock Placement

The large lava rock provided with this fireplace must be

placed on the firebox base on either side of the burner

assembly.

Under no circumstances should these

lava rock be placed on top of the burner

assembly.

12

Fig. 22 Temperature adjustment knob for TN/TP models.

Flame Characteristics

It is important to periodically perform a visual check of

the pilot and the burner flames. Compare them to

Figure 23 and Figure 24 or 25. If any of the flames

appear abnormal, call a service person.

10000836

Loading...

Loading...