Page 1

Installation and Operating

Instructions for

Vented Gas Log Sets

LISTED BY

Models R18CFL, R24CFL, R30CFL

LISTING NO. 1254

Decorative Gas Appliance for Installation in Solid Fuel Burning Fireplaces

WARNING

If the information in this manual is not followed exactly, a fire or explosion may result, causing property

damage, injury, or loss of life.

—Do not store gasoline or other flammable

vapors or liquids near this or any other

appliance.

—WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do

not use any phone in your b uilding.

• Immediately call your gas supplier from

a neighbor’s phone. Follow the gas

supplier’s instructions.

• If you cannot reach your gas supplier,

call the fire department.

Installation, service and repair of this

appliance must be performed by a qualified installer, service agency, company or

gas supplier experienced with this type of

gas appliance.

Installer:

Read this instructions completely and carefully prior to beginning installation. After

installation, leave these instructions with the

owner.

Owner:

ATTENTION

Read these instructions and follow the warnings. Save this manual for future reference.

Department of Building and Safety, Rule of General Application No. RGA2-72,

“Standard for Decorative Log Sets for Installation in Wood Burning Fireplaces”.

Decorative Gas Appliances for Installation in Solid-Fuel Burning Fireplaces.

CFM Specialty Home Products

410 Admiral Blvd. • Mississauga, Ontario, Canada L5T 2N6 • 905-670-7777

www.majesticproducts.com • www.vermontcastings.com

SAVE THIS MANUAL FOR FUTURE REFERENCE

20003889 12/04 Rev. 1

Page 2

WARNING

Improper installation, adjustment, alteration, service or maintenance can cause injury or property

damage. Read these directions thoroughly before installation. For assistance or additional information, consult your gas log dealer, qualified installer, service agency or

gas supplier.

WARNING

Do not use this appliance or any part that has

been under water. Immediately call a qualified

service technician to inspect the appliance and

to replace any part of the control system and

any gas control which has been under water.

If not installed, operated, and maintained in

accordance with the manufacturer’s instructions, this product could expose you to substances in fuel or fuel combustion which are

known to the state of California to cause

cancer, birth defects, or other reproductive

harm.

WARNING

WARNING

A properly sized, unobstructed chimney will normally vent all fumes and products of combustion.

Any odor or smoke detected in the room is an indication that the flue is not properly removing the

combustion products. Turn off the gas supply valve immediately! The cause of the venting problem must be discovered and corrected before using this gas log set. Disregarding this warning

can cause illness as well as soot damage to your fireplace, room, and furnishings.

WARNING

Young children are not allowed to operate this unit and must be supervised when they are in the

same room as the appliance.

INSTALLATION PRECAUTIONS

Fireplace damper MUST be locked fully open when operating the gas log set.

If the fireplace has glass doors, operate gas log set only with doors fully opened. The fire-

place screen must be in place when the appliance is operating and, unless other provisions for

combustion air are provided, the screen shall have an opening(s) for introduction of

combustion air.

The log set and its individual shut-off valve MUST be isolated from the gas supply piping system

by closing its individual shut-off valve during any pressure testing of gas supply at test pressures

equal to or less than 1/2 psig.

The log set and its individual shut-off valve MUST be disconnected from the gas supply piping

system during any pressure testing of that system at test pressures in excess of 1/2 psig.

Keep the gas log set clear and free from combustible materials, gasoline and other flammable

vapors and liquids.

2

20003889

Page 3

General Information

In order to assure a safe and effective installation, only a qualified service person who is

familiar with the building codes and installation techniques appropriate to your area may

install and service this appliance.

The Logsets have been designed and tested to

operate safely when installed according to the

installation instructions contained in this manual.

Read all instructions before starting the installation.

• The logset should be inspected before use and at

least annually thereafter. More frequent cleaning

may be necessary because of excessive lint from

carpeting or bedding material.

• In the United States, the installation and operation

must conform to local codes or, in the absence of

local codes, with the National Fuel Gas Code,

ANSI Z223.1/NFPA 54, latest edition, CSA-B149

Installation Code, and with the National Electrical

Code, ANSI/NFPA70 (latest edition).

• The gas logset and its individual shutoff valve

must be disconnected from the gas supply piping

system during any pressure testing of that system

at test pressures in excess of 1/2 p.s.i.g. (3.5 kPa)

The gas logset must be isolated from the gas

supply piping system by closing its individual

manual shutoff valve during any pressure testing

of the gas supply piping system at test pressures

equal to or less than 1/2 p.s.i.g. (3.5 kPa)

• Do not, under any circumstances, burn solid fuel

(wood, paper, coal) in the fireplace where you

have installed your logset. Do not use it for

cooking. Put nothing on top of the logs.

• The logset must be compatible with its fuel.

Natural gas requires different hardware than

propane. Never attempt to use natural gas with a

propane logset or vice versa.

• For a propane burning logset, the supply tank

must include a high to low gas pressure regulator.

The tank must be outdoors. Do not, under any

circumstances, locate supply tanks inside any

structure.

• The fireplace must include a screen made of

chain mesh or a similar material. You must keep

the screen closed at all times during the operation

of the logset; it will protect you in the event of an

explosion.

• WARNING: If the fireplace contains glass doors,

they must remain open at all times during the

operation of the logset, allowing combustion air to

circulate.

• In order to avoid any possible gas leaks, apply

pipe joint compound to all non-flared threaded

connections involved in this installation. For

propane, the joint compound must be resistant to

the corrosive action of propane.

• To check for leaks, always use a soapy water

solution or a sniffer. Never test by using an open

flame.

• The area around the gas logset must be free of all

combustible materials, especially gasoline or other

highly flammable, vapor producing liquids.

• Due to high temperatures, locate this logset away

from both high traffic areas and furniture and

draperies.

• Children and adults alike should be aware of the

high surface temperatures; to avoid the risk of

burns or ignition of clothing they should stay away.

• Do not touch any part of the logset other than the

controls while it is operating or immediately after

you turn it off.

• Supervise young children and pets carefully when

they are in the room where the logset is operating.

• Do not place clothing or other flammable material

on or near the logset.

• Make sure that any safety screen or guard,

removed during servicing, has been replaced

before you use the logset.

• Do not, under any circumstances, install the logset

in any bedroom, bathroom, other small, enclosed

room, mobile home or recreational vehicle.

• Do not install the logset in a drafty area or use it

with any aftermarket blower system that may

cause drafting and consequently alter the flame

pattern.

• It is imperative that you keep clear all burner

areas, control compartments and passageways for

circulating air.

• Do not move the logset in any way that might

dislodge the logs from their fixed positions. If you

bump the logset check to see if you have dislodged anything.

• Provide adequate clearances around air openings

into the combustion chamber and adequate

accessibility clearance for servicing and proper

operation. NEVER obstruct the front opening of

the fireplace.

20003889

3

Page 4

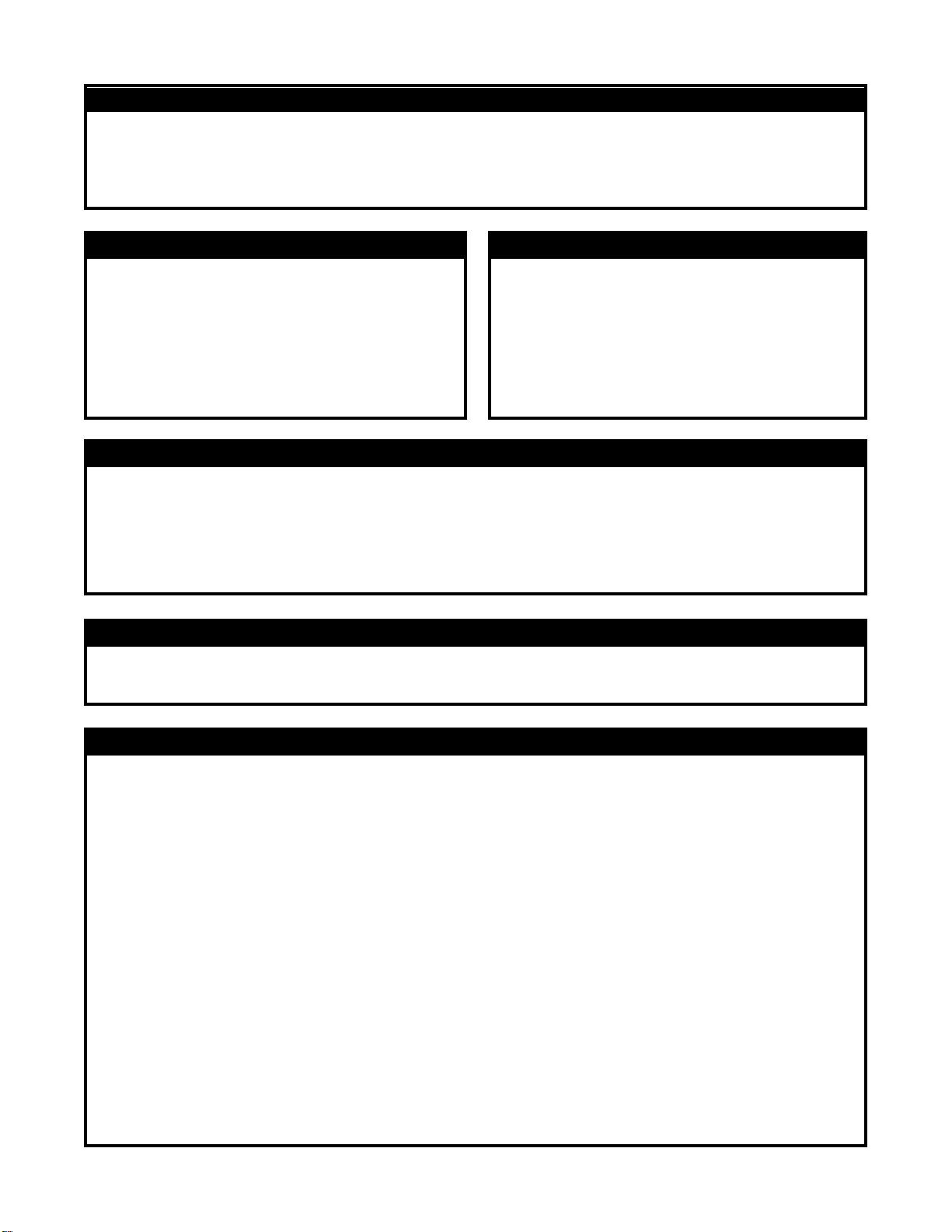

Pre-Installation Checklist Yes No

Are you burning Natural Gas? If you have Propane Gas, you need to purchase a

factory authorized safety pilot kit (see below).

Is the gas supply inlet pressure correct?NG: Min. 3.5” w.c./Max. 7.0” w.c.

Does the firebox meet the minimum size dimensions below?

Is your fireplace plumbed with gas on the right side (facing) of the fireplace?

If not, see Page 4.

Is the gas supply line sized properly (Minimum 1/2” iron pipe)?

Do you have a solid fuel (wood burning) fireplace with a vented flue?

Do you have a manual gas supply valve installed at your fireplace? If not, a licensed

plumber, gas company technician or other qualified installer must install one.

Have you checked local building codes? (Check with your local building department)

Does your fireplace have a wire mesh screen in place?

CAUTION: If you answered “NO” to any item, or have any questions regarding your installation, please

contact your dealer/distributor for assistance.

Minimum Clearances & Specifications

Natural Gas Units

Minimum Firebox Dimensions Minimum Gas Fuel Line

Set Input Width Flue Pressure

Size Btu/hr Back Front Depth Height Size Minimum Maximum

18” 54,000 16” 24” 15” 18” 51 sq.in. 3.5” w.c. 7.0” w.c.

24” 90,000 20” 30” 15” 18” 79 sq.in. 3.5” w.c. 7.0” w.c.

30” 90,000 27” 36” 18” 18” 79 sq.in. 3.5” w.c. 7.0” w.c.

NOTE: Use of a Pilot or LP Conversion Kit will add 3” to the minimum width requirements.

Refer to the pilot kit’s installation instructions.

Propane (LP) Conversion

USE OF THIS SET WITH LP OR PROPANE FUEL REQUIRES THE INSTALLATION OF ONE

OF OUR FACTORY AUTHORIZED SAFETY PILOT KITS:

MODEL SPK P - Pilot Kit with Piezo Spark Ignition

MODEL RVKRP - Millivolt Pilot Kit with Remote Control Capabilities

4

20003889

Page 5

Tools Required

8” adjustable crescent wrench; Pipe thread sealant compound or teflon tape; 12” pipe wrench or channel lock pliers.

Gas Plumbed on Left Hand Side of Fireplace

NOTE: Your gas log set is assembled at the factory to be installed in a fireplace plumbed with the gas

on the right side (facing). If your fireplace is plumbed with the gas on the left side remove fittings on

right and left side of straight burner tube and switch sides, at the same time put front burner tube on

right side with the elbow fitting. (Fig. 5a and 5b)

You may also run a flexible connector (or as per local codes) along the back wall of the fireplace to

bring your gas line to the right hand side. You can then place the set in front of the flexible connector.

(Fig. 5c)

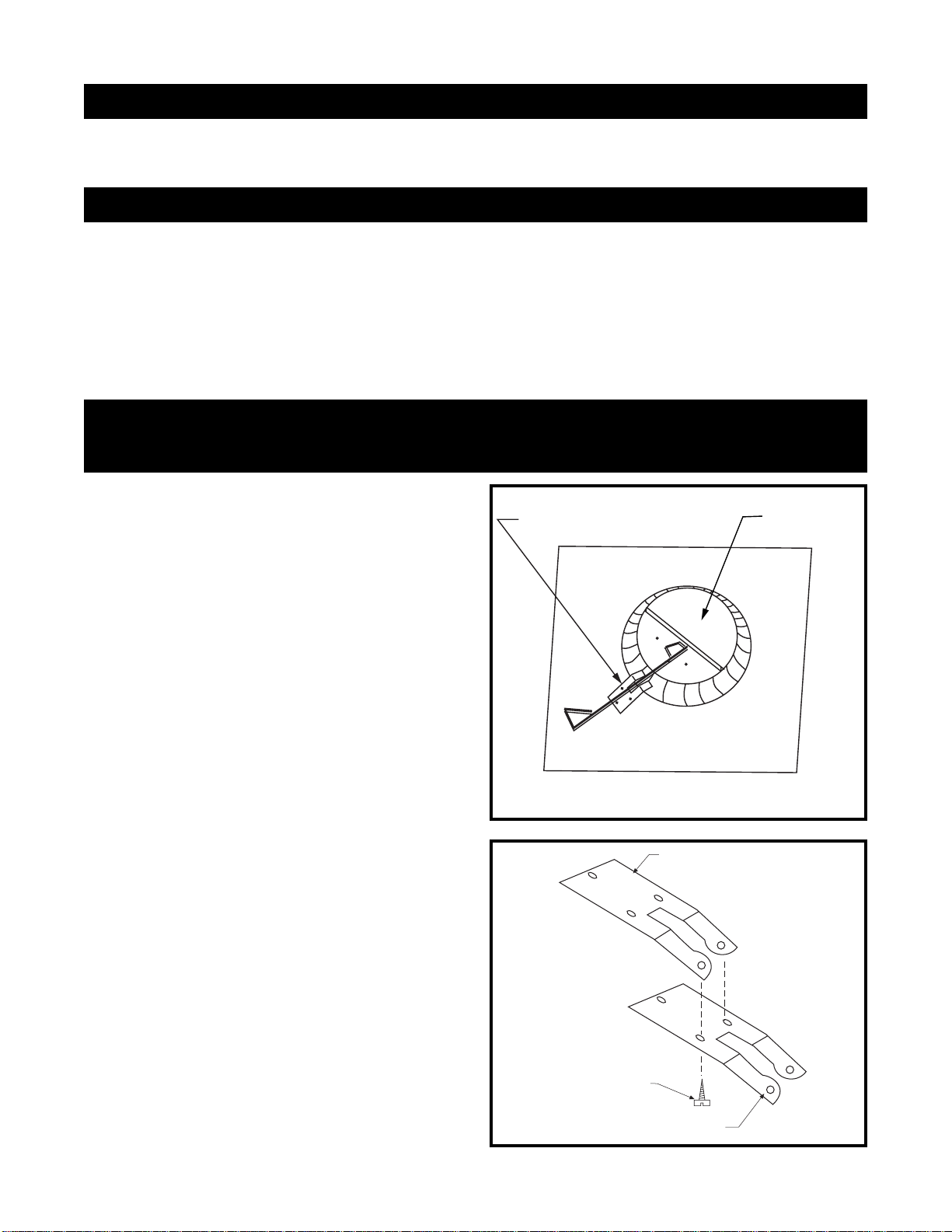

Damper Stop Installation:

For Use with BR, BC, SR, SC, TF and TL Series

CFM Specialty Home Products Fireplaces

This Damper Stop is designed to work on all CFM

Specialty Home Products BR, BC, SR, SC, TF

and TL series fireplaces. For all other fireplaces,

refer to Page 6.

When installing a decorative gas appliance in a

fireplace, some local codes require this Damper

Stop to be used so the Damper will not close

completely. To install the Damper Stop:

The Damper Locking Bracket is already installed

on all BR, BC, SR, SC, TF and TL fireplaces.

Locate the Damper Locking Bracket on the left

side of the fireplace’s Combustion Dome. (Fig. 1)

Damper Locking Bracket

Damper Plate

With the Damper open, align the two slots on

either side of the cut-out on the Damper Stop with

the two small holes on the angled portion of the

Damper Locking Bracket. Attach the Damper

Stop with the Screws provided, as shown in

Figure 2.

NOTE: Some of the early fireplace units may not

have the holes in the end of the Damper Locking

Bracket. If this is the case, use the Damper Stop

as a template to drill two (2) 1/8” holes in the

Damper Locking Bracket to mount the Damper

Stop.

20003889

Figure 1

Damper Stop Screw

Figure 2

Damper Locking

Bracket

Damper Stop

DP100

DP101

5

Page 6

Damper Stop Installation:

For Use With All Other Fireplaces

The Damper Stop provided keeps your damper

from accidentally closing during operation of your

set. This Damper Stop must be installed onto

your Damper at all times. NOTE: The damper

clamp is designed to hold the damper plate

open 3 inches. However, the damper must be

fully open when the log set is in operation.

Install the Damper Stop onto the edge of the

damper plate. Attach by securing the bolt provided to the damper plate with an adjustable

wrench. (Fig. 3)

If the Damper Stop does not fit, drill a 1/4” hole

into the damper plate and install an

anchor bolt with nut, at a 90 degree angle, so that

the damper plate will remain fully open.

The proper finished installation of the Damper

Stop is shown in Figure 4. If the bolt fails to block

the damper in an open position, the damper

should be removed from the chimney.

To check your vent for proper drafting: Light a

tightly rolled newspaper on one end and place it

at the inside front edge of the fireplace. Observe

the smoke and be sure the vent is properly

drawing it up the chimney. If the smoke is drawn

back into the room, extinguish the flame and

Connection to Gas Supply

Figure 3

Damper

Clamp

Figure 4

Damper Plate

Damper Stop

DP104

Damper

DP103

1. Place the burner pan in the fireplace. The

burner pan should be located several inches

from the back wall, centered from right to left.

NOTE: This is for burner connection purposes

only. Exact burner placement will be covered

on page 8, after all connections have been

made.

2. Attach the Gas Supply Fitting onto your

fireplace’s gas supply pipe, as shown in Figure

5.

3. Attach one end of the Flexible Gas Connector

to the brass Burner Inlet Fitting which has

been factory installed into the burner.

4. Attach the other end of the Gas Connector to

the flared side of the Gas Supply Fitting.

Remember to use pipe thread sealant or teflon

tape only on the

straight pipe threads. Do not

use on any flared ends.

6

Figure 5a

CFM149

20003889

Page 7

Figure 5b

CFM159

Figure 5c

CFM150

Leak T est Procedures

Create a mixture of equal parts soap and water. Apply to all the joints of the pipe fittings from the gas

supply pipe to the burner. Turn on the gas supply valve for no longer than 3-5 seconds. If bubbles

appear in the soap solution applied to the joints, there is a leak. Turn off the gas supply valve and

tighten those fittings. Repeat the above procedure until no bubbles appear in the soap solution.

Remember to test all joints.

WARNING: Do not use an open flame to test for leaks!

NOTE: Always perform a leak test any time the appliance has been moved or disconnected from

the gas supply line.

Adding Pan Material

1. Open the bag of Silica Sand and spread it

evenly across the Burner Pan, to the top, as

shown in Figure 6. You may overflow the front

and sides of the pan to cover the entire pan

and connecting hardware. NOTE: Sand is for

use with Natural Gas ONLY! Vermiculite or

Lava Rock must be used in place of Sand for

Propane Gas. See Propane Conversion Kit

Manual for details.

Glowing

Embers

2. Next, open the bag of Glowing Embers and

place them on top of the Silica Sand, evenly

across the Burner Pan. Be sure to separate

the Glowing Embers into very small pieces

before placing them onto the Silica Sand.

20003889

Figure 6

Silica

Sand

Glowing

Embers

Lava Rock

LG370

7

Page 8

Grate and Log Placement

1. Place the Elevated Grate Steps onto the back

of the Grate and attach the Fettel to front of

Grate as shown in Figure 7.

2. Place the Grate over the Burner Pan so the

front legs of the Grate are 1” behind the front

edge of the Pan, as shown in Figure 8.

3. Place the larger bottom logs (longer log in

back, shorter (2) in front) onto the grate,

leaving as much space between themas

possible. (Fig. 8) When burning, the flames

should come up directly between these two

logs.

4. Next, place the smaller top logs diagonally

onto the bottom logs. The top logs can be

arranged to achieve your desired flame pattern. Refer to Figures 9, 10, and 11 (R18CFL,

R24CFL, and R30CRL). Be sure you leave as

much open space between the logs as possible to minimize flame impingement and

sooting.

5. Open the bag of Lava Rock and spread the

rocks onto the fireplace floor around the burner

pan for decorative purposes. (Fig. 6)

Figure 7

Fettel Cast

Front Grate

Figure 8

1"

Grate Steps

Grate

Front (2)

Shorter Logs

Grate

Clip

Long

Log

CFM130

Figure 9

Figure 10

R18CFL, R24CFL and R30CFL Log Sets

R18CFL Log Set

LG371

Figure 11

R30CFL Log Set

LG373

R24CFL Log Set

8

LG372

20003889

Page 9

For Your Safety Read Before Lighting

WARNING: If you do not follow these directions exactly, a fire or explosion may result

causing property damage, personal injury, or loss of life.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch, do not use any phone in your building.

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

Lighting Instructions

1. Turn the gas shut-off valve to OFF.

2. Wait five (5) minutes to clear out any gas.

Figure 12

If you then smell gas STOP! Follow the safety

information above. If you don’t smell gas, go

on to the next step.

3. Light a match and lay it on top of the pan

material, about 2” from the end of the supply

side of the pan. (Fig. 12)

4. Slowly turn the gas shut-off valve ON until the

burner ignites. If the burner doesn’t ignite

within ten (10) seconds with the match burning, turn the shut-off valve OFF and repeat

Match

steps 1 through 4 again.

WARNING: Flame may flare up when ignited. Keep hands and face away from firebox.

Operation and Maintenance

To Adjust the Flame:

Adjust the flame to the desired level by rotating the gas valve counterclockwise to open or

clockwise

to close.

To Turn the Appliance Off:

Rotate the gas shut-off valve clockwise

to off.

Proper Maintenance:

• Keep the area around the log set clean and clear of debris.

• Occasionally, you may use a soft bristle brush to clean logs.

• Once every year, a qualified agency or certified chimney sweep should examine and clean the

venting system of the fireplace in which the log set is installed.

LG176

Appliance Break-In

During the 2-3 hour appliance break-in period, you may detect an odor from the appliance as the

various water-based paints used in the manufacture of this log set cure. This is a normal and temporary situation that is not a cause for alarm. However, you may want to provide extra ventilation to the

room during this time.

To ensure proper curing of the logs:

1) Ignite a 2” flame and maintain it for 1/2 hour.

2) Burn the logs in consecutive 1/2 hour periods, raising the flame an additional 2” to full flame

height for a total of three hours.

20003889

9

Page 10

Troubleshooting

Log Set is Smoking/Sooting Excessively

It is natural and unavoidable for vented gas log sets to produce moderate levels of carbon (soot)

where flame contacts the logs. The logs can be cleaned using a soft-bristle brush. However, if

soot is produced where there is no flame impingement, one of the following may be the cause:

Fireplace venting system not drafting properly: Make sure the damper is wide open at all times.

Preheat the flue in very cold weather by burning the log set at a very low level, then slowly increasing the flame height over a matter of hours. Have the fireplace and the venting system professionally cleaned.

Excessive flame impingement or blockage: Make sure there is proper spacing between the

logs so they are not smothering the flame. Rearrange the logs so they are touched less by the

flames.

Excessive gas supply/pressure: Make sure the gas pressure coming into the fireplace does not

exceed the maximum pressure allowed with this gas set (refer to tables on page 4). If you are

using the gas logs with a safety pilot kit, make sure you installed the correct orifice into the set.

Burner is Excessively Noisy

Please note: The movement and combustion of gas will create low, unavoidable levels of noise.

Excessive gas pressure: Make sure the gas pressure coming into the fireplace does not exceed

the maximum pressure allowed with this gas set (refer to tables on page 4). If you are using the

gas logs with a safety pilot kit, make sure you installed the correct orifice into the set.

Passage of air/gas across irregular surfaces: There may be burrs, paint, or other blockages on

the burner bar ports. Check these ports and remove any blockage.

Gas Connector: Relieve any tight bends or kinks in the Flexible Gas Connector. Switch to a

smooth aluminum gas connector, which can be purchased at any hardware or home improvement

store.

Burner Flame is Too High (8-12” Above Top Logs) or Too Low

(Below T op Logs)

Incorrect gas supply, pressure, or burner orifice used: Make sure the gas pressure coming

into the fireplace falls between the minimum and maximum pressures allowed with this gas set

(refer to tables on page 4). If you are using the gas logs with a safety pilot kit, make sure you

installed the correct orifice into the set.

Blocked ports (low flame only): Free the main burner orifice and burner bar ports of any burrs,

paint, or other blockage.

10

20003889

Page 11

1

b

a

g

c

f

h

d

e

2

3

4

6

10

9

11

13

12

CFM Specialty Home Products reserves the right to make changes in design, materials, specifications, prices and discontinue colors and products at any

time, without notice.

15

14

5

7

17

18

16

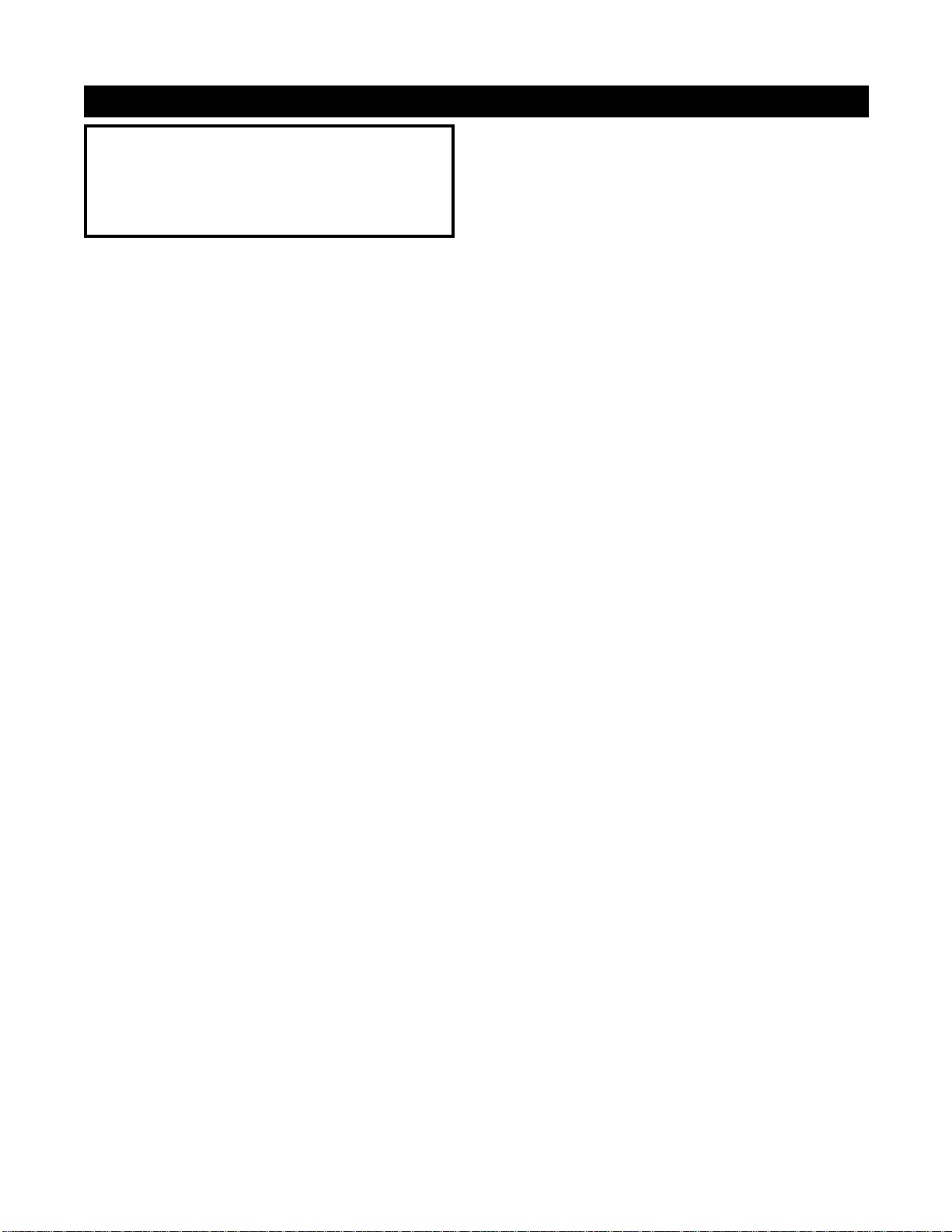

R18/24/30CFL Vented Gas Logs

Ref. Description R18CFL R24CFL R30CFL

1. Complete Log Set 20003915 20003916 20003917

1a. Outside Left Cross Log (NNS2) n/a n/a 4312778

1b. Left Cross Log (NNS4) n/a 4312780 4312780

1c. Center Left Cross Log (NEW-2) 4312847 4312847 4312847

1d. Center Right Cross Log (NNO-3) 4312848 4312848 4312848

1e. Outside Right Cross Log (NNS-3) 4312779 4312779 4312779

1f. Back Log (NNS18B), (NNS24B), (NNS30B) 4312776 4312788 4312814

1g. Front Left Log (KO-18L), (KO-24L), (KO-30L) 4312855 4312845 4312857

1h. Front Right Log (KO-18L), (KO-24L) 4312856 4312844 4312844

2. Bag of Lava Rock 4310010 4310010 4310010

3. Bag of Silica Sand 4310006 4310006 4310006

4. Bag of Glowing Embers 4310001 4310001 4310001

5. Damper Stop (for use with CFM Specialty Home Products Fireplaces

3030167 3030167 3030167

6. Damper Stop Screws 7521901 7521901 7521901

7. Damper Stop (for use with all other fireplaces) 20002632 20002629 20002575

8. Screen Mesh 20001419 20001419 20001419

9. Grate Clip - Fettel 3304311 3304311 3304311

10. Screw - Grate Clip 3309078 3309078 3309078

8

19

20003889

11

Page 12

R18/24/30CFL Vented Gas Logs (continued)

Ref. Description R18CFL R24CFL R30CFL

11. Cast Front Grate w/Clips CIGF18 CIGF24 CIGF30

12. Grate 20000924 20000925 20000926

13. Grate Step 20000955 20000955 20000955

14. Pan & Extension Assembly 20003840 20003841 20003842

15. Burner Tube - 3/8” 20003826 20003827 20003828

16. Orifice - Natural (installed into Part #17) 20000960 20000961 20000961

17. Burner Inlet Fitting (installed into Part #18) 20000958 20000958 20000958

18. Flexible Gas Connector 3304176 3304176 3304176

19. Gas Supply Fitting - Elbow 3304145 3304145 3304145

12

20003889

Page 13

LIMITED 2/20 YEAR WARRANTY

For VERMONT CASTINGS Decorative Gas Appliances

CFM Specialty Home Products extends the warranties

specified in paragraphs A and B below with respect to its

Vermont Castings Decorative Gas Appliances (the “Gas

Appliance”), including CFM Specialty Home Products

supplied accessories and components referred to in those

paragraphs, subject to the following conditions and

limitations:

(1) These warranties are extended only to the Gas

Appliance installed in the continental United States,

including Alaska, and Canada; only if and so long as the

accordance with the installation and operating instructions

furnished therewith; and only if and so long as Gas

Appliance is not removed from its original installation.

(2). These warranties are limited to only the component

parts manufactured and supplied by CFM Specialty Home

Products. The use of components manufactured by others

with the Gas Appliance (except for a listed Type B venting

system as defined in the installation instructions) could

create serious safety hazard, may result in the denial of

certification by recognized national safety agencies, and

could be in violation of local building codes.

(3). The Gas Appliance must be operated at all times in

accordance with the operating instruction furnished

therewith. The Gas Appliance is designed to burn either

natural or propane gas only. Burning conventional

fireplace fuels such as wood, coal, or any other solid fuel

will cause damage to the Gas Appliance, will produce

excessive temperatures and will result in a fire hazard.

(4). These warranties are limited to repair, replacement

or furnishing a replacement for sale, as specified in

Paragraphs A and B, for a part found to CFM Specialty

Home Products satisfaction, after examination, to be

defective in materials or workmanship under normal

conditions, use and service.

(5). All obligations with respect to these warranties may

be fully discharged by CFM Specialty Home Products

refunding the wholesale price of a defective part.

(6) Except as otherwise expressly specified in Paragraphs A and B. NONE OF THESE WARRANTIES

COVER, AND CFM SPECIALTY HOME PRODUCTS

SHALL NOT BE RESPONSIBLE FOR, ANY CONSTRUCTION, INSTALLATION, LABOR, TRANSPORTATION OR

OTHER COSTS OR EXPENSES ARISING FROM A

DEFECTIVE PART, ITS REPAIR OR REPLACEMENT OR

OTHERWISE, NOR SHALL CFM SPECIALTY HOME

PRODUCTS IN ANY EVENT BE RESPONSIBLE FOR

ANY INDIRECT, INCIDENTAL OR CONSEQUENTIAL

DAMAGES. EXCEPT TO THE EXTENT PROVIDED BY

LAW, THERE ARE NO IMPLIED WARRANTIES WITH

RESPECT TO THE GAS APPLIANCE, ITS COMPONENTS AND ACCESSORIES (INCLUDING IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE), ALL OF WHICH ARE

HEREBY EXPRESSLY INCLUDED. IN NO EVENT

SHALL ANY IMPLIED WARRANTY PRESCRIBED BY

LAW (NOTWITHSTANDING THE FOREGOING EXPRESS EXCLUSION) REMAIN IN EFFECT AFTER

EXPIRATIONS OF THE WARRANTIES SET FORTH IN

PARAGRAPHS A AND B.

A. Gas Appliances, electrical and manual compo-

nents, glass panels, all sealants or adhesives and

optional accessories (exclusive of CFM Specialty Home

Products supplied decorative logs which are covered by a

separate warranty under paragraph B below):

Within two years from the date of manufacture of the

gas appliance, CFM Specialty Home Products will repair,

or replace (at our option) a defective part without charge.

B. Cement or ceramic fiber log components:

Within two years from the date of manufacture of the gas

appliance, CFM Specialty Home Products will replace a

defective part without charge. Within years three through

twenty from the date of manufacture of the gas appliance,

CFM Specialty Home Products will provide a replacement

for a defective part to the homeowner, but assumes no

liability for incurred labor cost.

The foregoing warranties gives you specific legal rights

and you may also have other rights which vary from state

to state. Some states do not allow limitations on how long

an implied warranty may last, so the limitation specified

above on the duration of any implied warranty prescribed

by law may not apply to you. Similarly, some states do not

permit the exclusion or limitation of incidental or consequential damages, so the above exclusion of such

damages may not apply to you.

In order to obtain performance of any of the above

warranty obligations, write to CFM Specialty Home

Products at this address:

CFM Specialty Home Products

410 Admiral Blvd

Mississauga, Ontario Canada L5T 2N6

Attention: Manager of Warranty Services

Since local building requirements may vary greatly

throughout the country, users of CFM Specialty Home

Products products should determine in advance whether

there are any building code restrictions on the use of a

specified product.

CFM SPECIALTY HOME PRODUCTS MAKES NO

REPRESENTATION OR WARRANTY REGARDING, AND

SHALL NOT BE RESPONSIBLE FOR, ANY BUILDING

CODE COMPLIANCE.

specific legal rights and you may also have other rights which vary

from state to state.

The foregoing warranties give you

20003889

13

Page 14

CFM Specialty Home Products

410 Admiral Blvd. • Mississauga, Ontario, Canada L5T 2N6 • 905-670-7777

www.majesticproducts.com • www.vermontcastings.com

Loading...

Loading...