Page 1

OM17-P4000VIS-NIR

Operating Instructions

VIS/NIR Spectrophotometer Probe

Table of Contents

Section 1

1-1 Warranty & Safety

Section 2

2-1 System Overview

Section 3

3-1 Software Installation Guide

3-7 Ocean Optics Spectrometer Configuration

3-11 Setting Port Order

3-12 Setting Integration Time

Section 4

4-1 Field Operations - Electronics

4-12 Importing sample locations for Interpolation

4-15 Bench Top Usage

4-15 Test/Example data

Section 5

5-1 Probe Platform Installation

5-3 Platform Operation

5-4 VIS/NIR Probe Operation

5-6 Soil Coring

5-8 Probe Rotation

5-10 Soil Anchoring System

5-12 Probe Removal and Tractor Installation

Section 6

6-1 Maintenance and Lubrication

6-4 EC Point Replacement

6-9 Probe Removal

6-5 Case Removal

Section 7

7-1 Troubleshooting

Section 8

8-1 Glossary

8-5 Appendix

1-1

Page 2

OM17-P4000VIS-NIR

Warranty

Veris Technologies warrants this product to be free of defects in materials and

workmanship for a period of one (1) year from the date of delivery to the purchaser.

Veris Technologies will repair or replace any product returned to Salina, Kansas, which

appears upon inspection to be defective in materials or workmanship. Veris

Technologies will have shall have no obligation under this warranty for the cost of labor,

down-time, transportation charges, or for the repair or replacement of any product that

has been misused, carelessly handled, modified, or altered.

ALL OTHER WARRANTIES OF ANY KIND, WHETHER EXPRESSED OR IMPLIED,

INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF

MERCHANTABILITY OR OF FITNESS FOR A PARTICULAR PURPOSE AND ALL

CLAIMS FOR CONSEQUENTIAL DAMAGES, ARE SPECIFICALLY DISCLAIMED AND

EXCLUDED.

Safety

1-2

Page 3

OM17-P4000VIS-NIR

Important! Read the following SAFETY PROCEDURES before operating the Veris

MSP

• Escaping fluid under pressure can penetrate the skin causing serious injury. Avoid

the hazard by relieving pressure before disconnecting hydraulic lines. Use a piece of

• Use paper or cardboard, NOT BODY PARTS, to check for suspected leaks.

• Wear protective gloves and safety glasses or goggles when working with hydraulic and

high-pressure wash systems.

• If an accident occurs, see a doctor immediately. Any fluid injected into the skin must

be surgically removed within a few hours or gangrene may result.

• Pinch point hazard: to prevent injury, stand clear when raising

or lowering any part of the Veris P4000.

• Install all transport locks before transporting or working underneath.

• Detach and store implements in an area where children normally do not play. Secure

implement by using blocks and supports.

• Keep feet clear of foot and probe when lowering.

• Do not probe where utility lines may be present. Use ‘Call Before You Dig’ services.

• Use paper or cardboard, NOT BODY PARTS, to check for suspected leaks.

• Wear protective gloves and safety glasses or goggles when working with hydraulic and

high-pressure wash systems.

• If an accident occurs, see a doctor immediately. Any fluid injected into the skin must

be surgically removed within a few hours or gangrene may result.

• Read Operations Manual before operating machine

• Review safety instructions with operators before operating machine and at least

annually

• Riders obstruct the operator’s view. They could be struck by foreign objects or

thrown from the machine.

• Never allow children to operate equipment.

• To prevent possible electrical shock, or damage to the instrument, do not connect to

any power source greater than twelve (12) volts DC.

• Do not grease or oil implement while it is in operation.

• Disconnect battery ground cable (-) before servicing or adjusting electrical systems or

before welding on implement.

• Remove buildup of mud, oil or debris.

• Be prepared if a fire starts

• Keep a first aid kit and fire extinguisher handy.

• Be careful when touching the probe after use, the sapphire window gets hot.

1-3

Page 4

OM17-P4000VIS-NIR

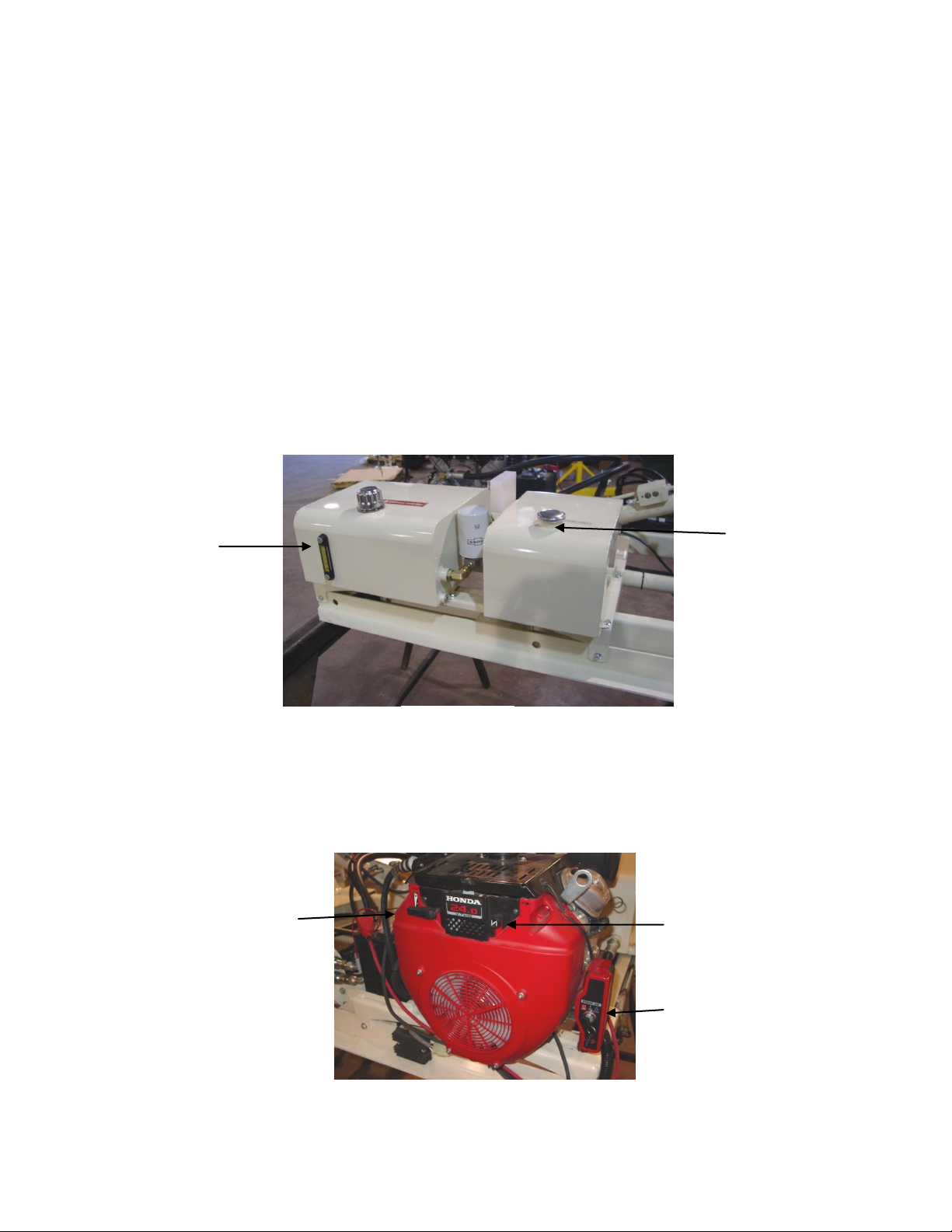

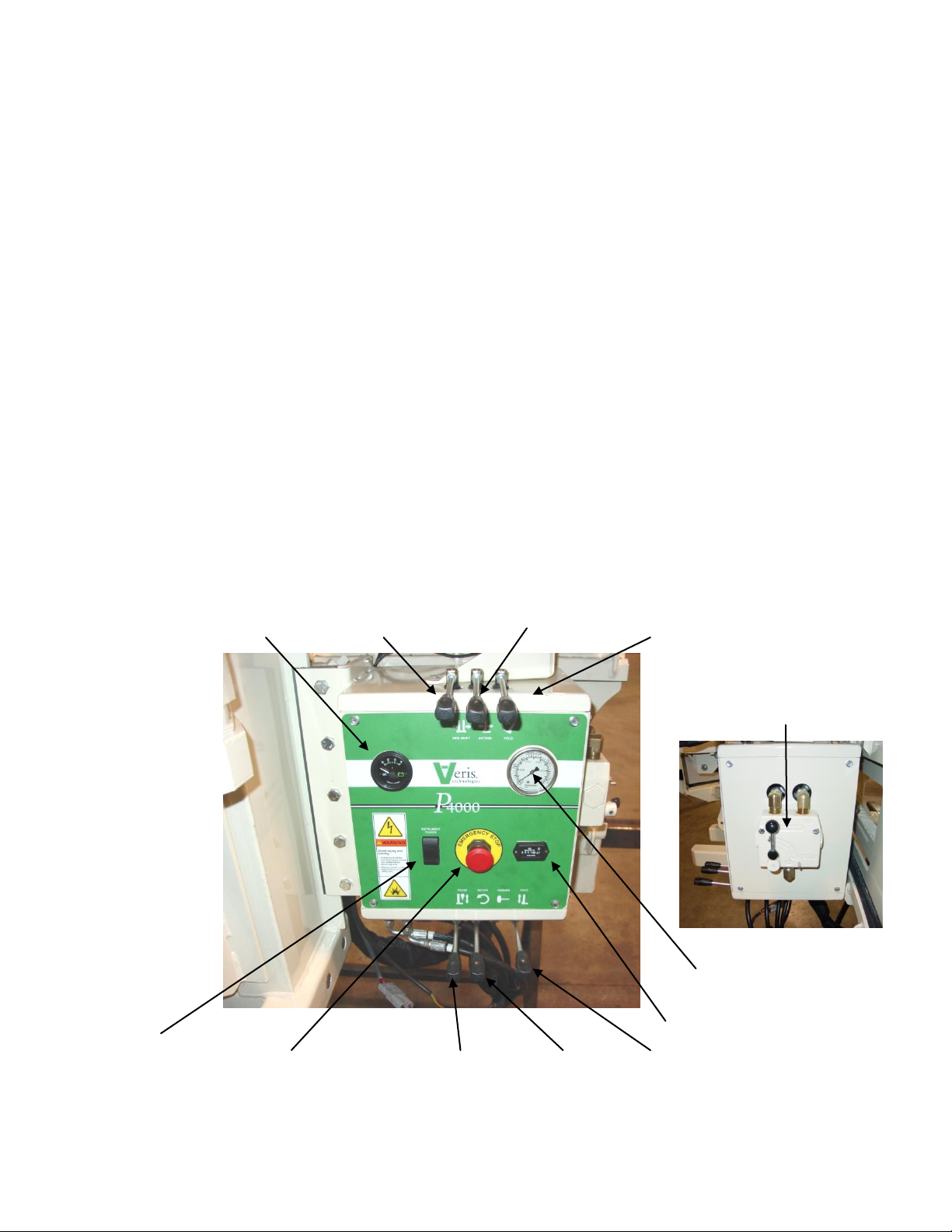

Hyd sight

gauge

Fuel Tank

Figure 1

Starter Switch

Choke

Throttle

Figure 2

Section 2

VERIS P4000 Probe Platform

System Overview

Before you begin using your P4000, it’s important to familiarize yourself with the basic

components and controls

Pre-operation checks:

1) Engine oil Level – refer to Honda GX 670 engine manual

2) Hydraulic fluid -- fluid level should be at or near upper black line on sight gauge

of hydraulic reservoir. (Figure 1). If not add suitable ISO 32 hydraulic fluid with a

viscosity index of 95- 140. Unit is filled at factory with Mobilfluid 424.

3) Check gas level – unleaded gasoline only

4) Check for any loose fasteners or hydraulic leaks.

Controls:

1) Engine controls are located on the engine itself. (figure 2) . Refer to Honda

engine manual for detailed information.

2-1

Page 5

Hydraulic Controls

Figure 3

Figure 4

Voltage meter Side Shift control Extension control Fold control

Probe speed

Flow control

12v power switch Engine emergency stop Probe control Rotation control Foot control

Hyd pressure gauge

Engine hour meter

All system monitoring and probe control functions are contained on the

console mounted to the right of the probe, referred to as the “foot”. (Figures 3,4)

a) Voltage meter – monitors battery voltage

b) Side shift control – allows lateral movement of probe for multiple insertions at

a given location.

c) Extension control -- used to extend probe from transport to field use position

d) Fold control – folds probe from transport to use position

e) Probe speed flow control – controls insertion speed of NIR/EC Force Probe to

operator preference

f) Hydraulic pressure gauge – monitors system pressure during hydraulic

cycling

g) Hour meter—monitors engine operation for routine maintenance

h) Foot Control – Raises and lowers foot

i) Rotation control – aids in soil core insertion in tough soils. Down is clockwise-

direction required for coring.

j) Probe control – Raises and lowers probe assembly

k) Engine emergency stop – immediately shuts down engine if need arises.

l) 12VDC power switch for auxiliary and spectrometer power.

OM17-P4000VIS-NIR

2-2

Page 6

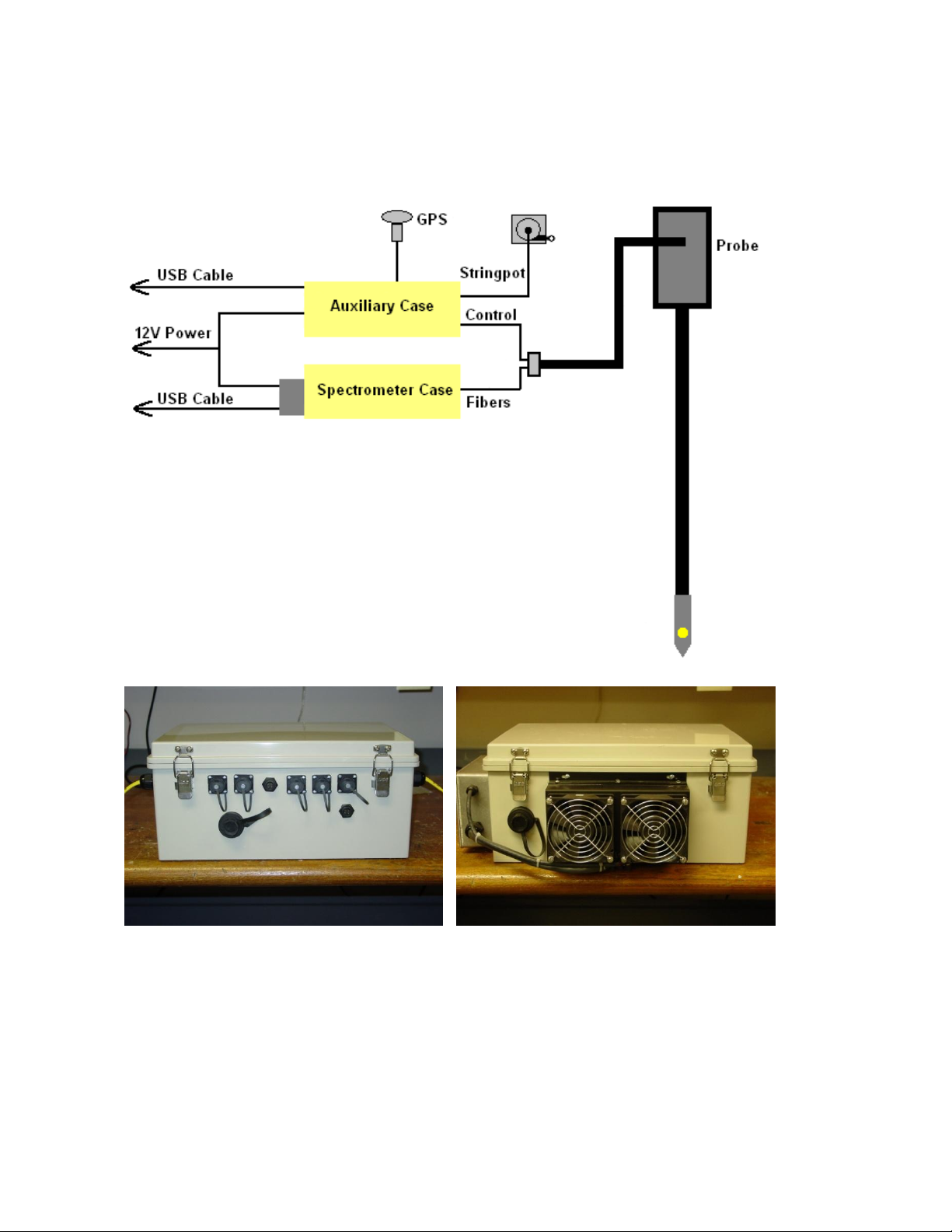

System diagram

OM17-P4000VIS-NIR

Electronics

Figure 5

Figures 6 and 7

2-3

Page 7

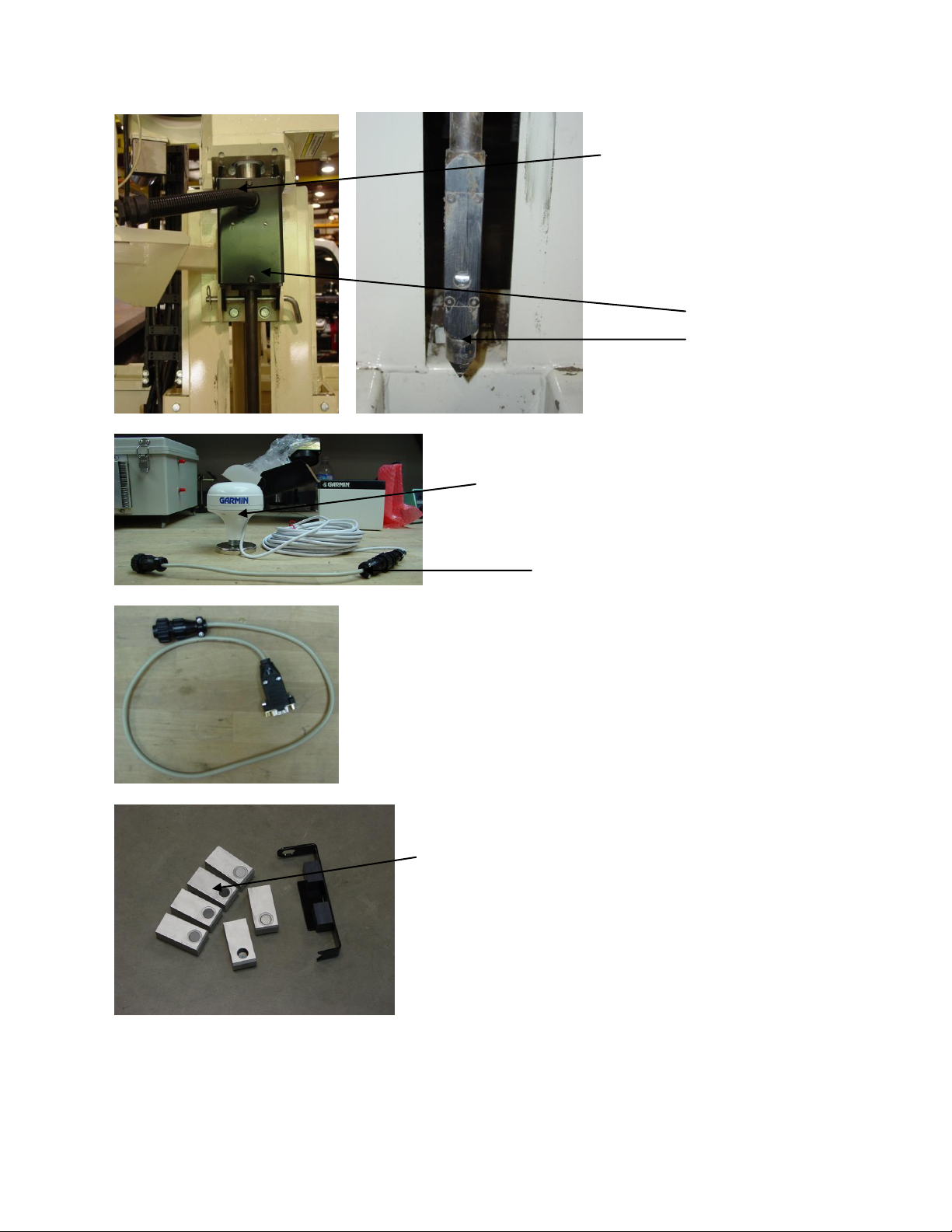

Figure 8&9

Probe module

#34848

Cable that includes fiber, motor

control and lamp power

Garmin GPS

# 21221 – for U.S. customers only

GPS adaptor cable #30727

Note: This adaptor cable is

required in order for

compatibility with the provided

Garmin GPS.

GPS serial adaptor cable

#35482

This will connect the serial port of a GPS to the

GPS port on the auxiliary case, for using an

alternate GPS to the Garmin. External power is

required for the GPS to function.

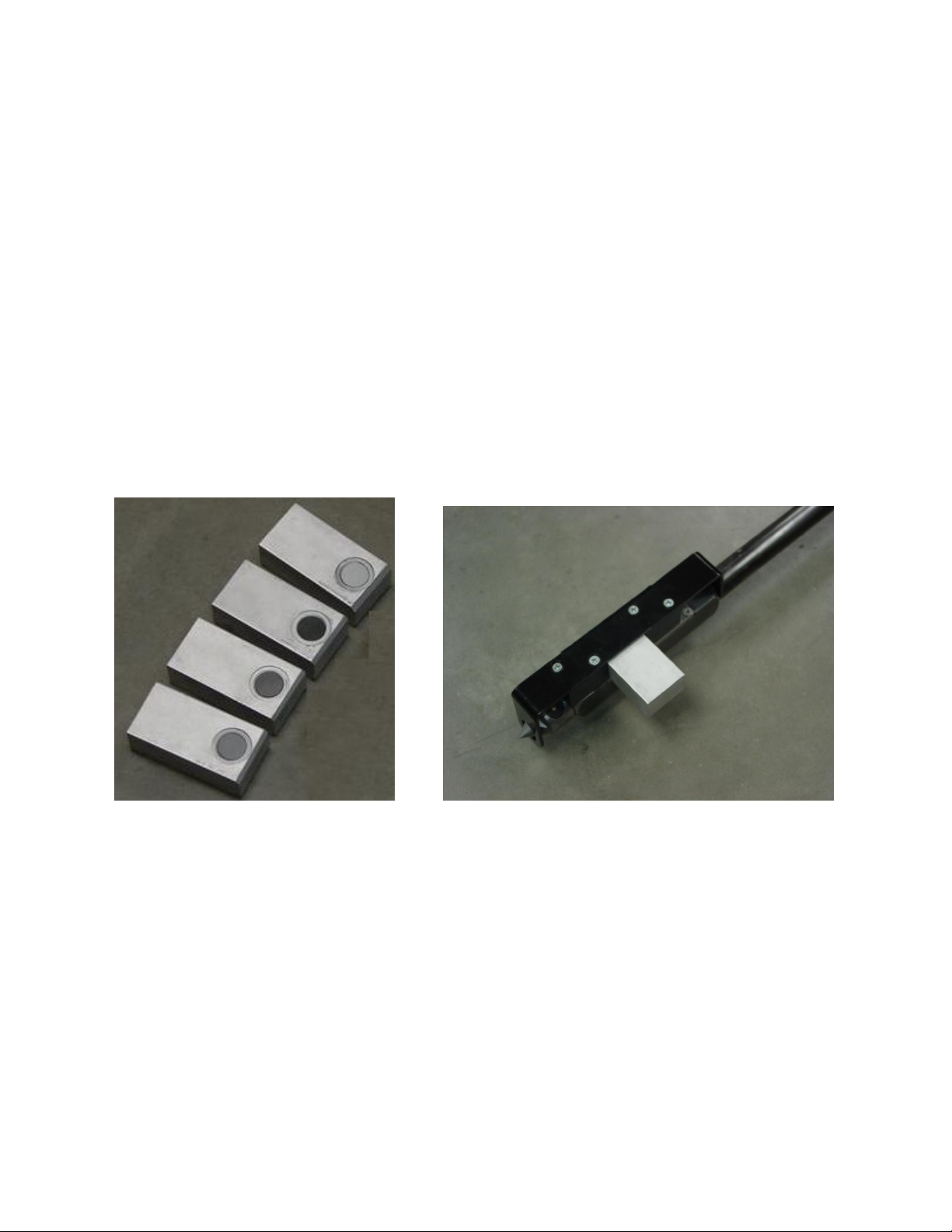

External reference blocks

which are used to calibrate

instrument during the system

check. (Labeled ER1 – ER4)

OM17-P4000VIS-NIR

Figure 10

Figure 11

Figure 12

2-4

Page 8

Figure 13

Reference block to be used for the manual

reference check, which needs to be taken every

10 mins or after every samples.

#38841

5-meter USB cables

#30281

Power cable

#39985

This is used to power the

instrument from a vehicle (for

field use).

Note: Only use 15-amp fuse

OM17-P4000VIS-NIR

Figure 14

Figure 15

2-5

Page 9

Figure 16

Probe Wear plate assembly

#38847

String Pot #SC160

String Pot Cable #38866

OM17-P4000VIS-NIR

Figure 17

2-6

Page 10

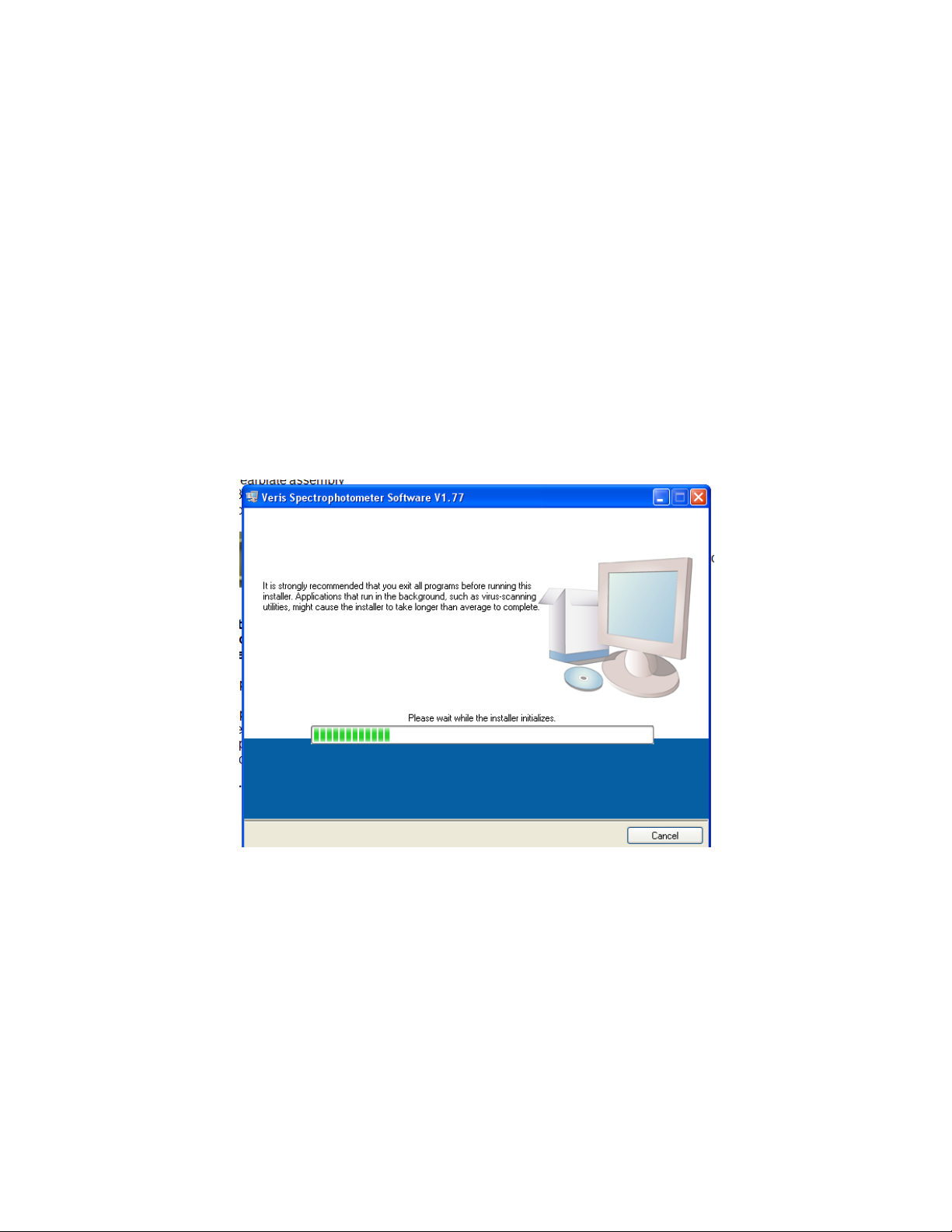

OM17-P4000VIS-NIR

The Veris

Spectrophotometer

Software installer will

guide the user through

installation of the Veris

operating software and

the necessary drivers

needed to run the

spectrometers. Note:

Do not plug in USB

cables for cases at

this time.

Section 3

Software Installation and Setup

Software Installation

Note: For computers outside the United States of America, please make the following

change to the computer’s regional settings before installing the Veris

Spectrophotometer Software.

Step 1: Open control panel and double click on Regional and Language Options

Step 2: Click on Customize, the following screen will appear. The Decimal symbol

needs to be a “.” while the Digit grouping symbol needs to be a “,”. The will ensure

proper operation of the software. Once the changes have been made click OK and

proceed with installation.

Veris Spectrophotometer Software Installation

Figure 1

Veris Spectrophotometer Software V1.77 and up will run on either Windows XP,

Vista or 7—32 bit operating systems only

3-1

Page 11

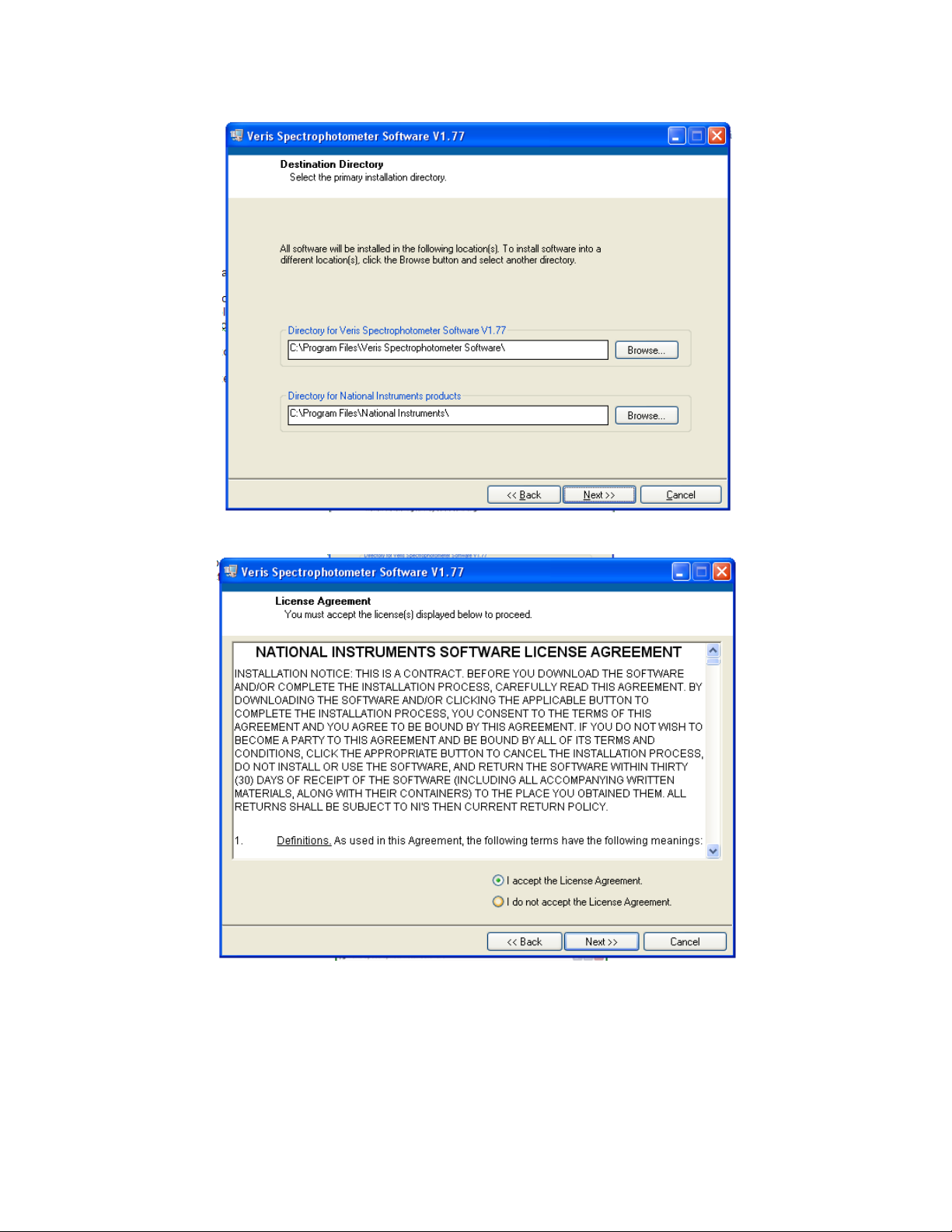

Figure 2

Keep the default

directory and click next

OM17-P4000VIS-NIR

Figure 3

3-2

Page 12

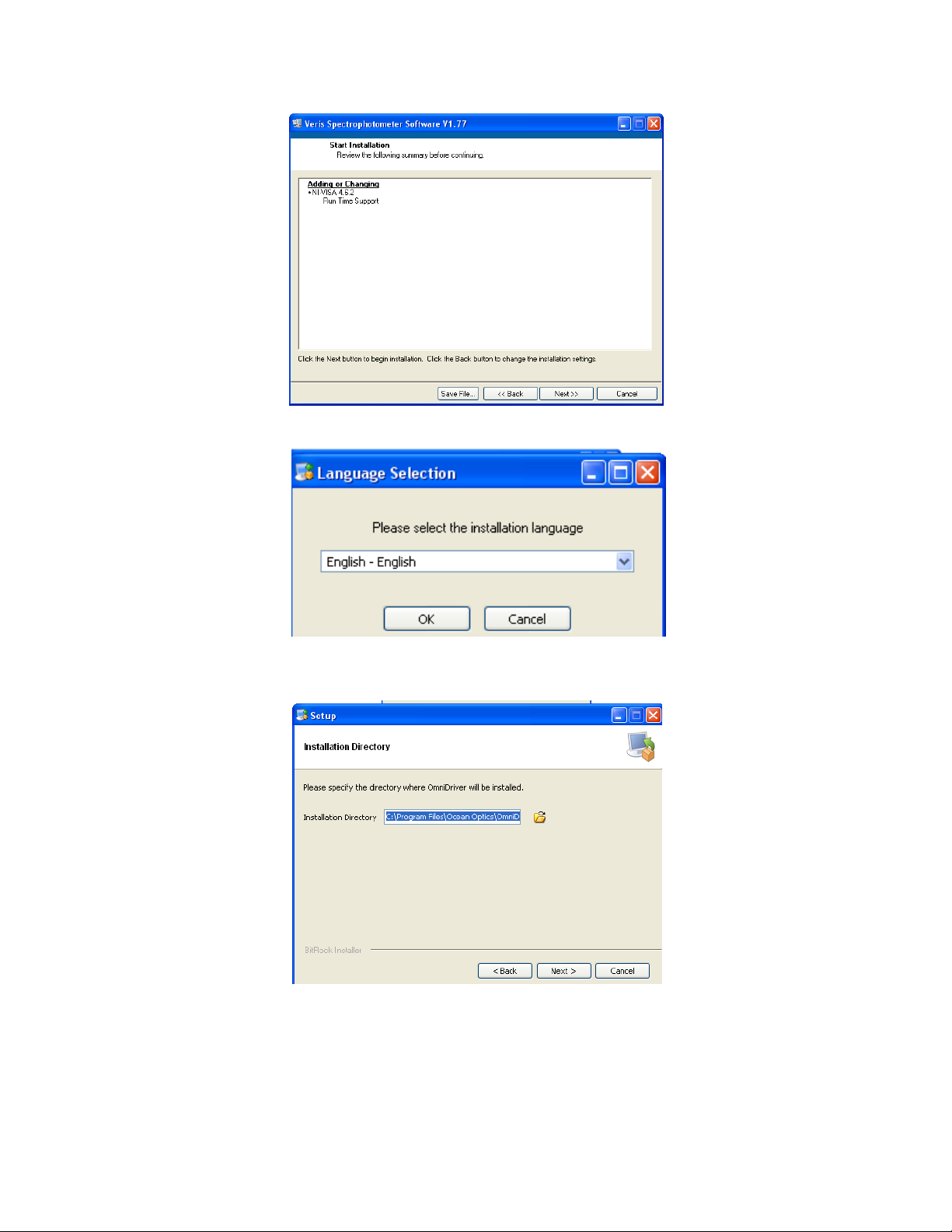

Figure 4

Select next to

complete install

Now the ocean optics

drivers will be installed.

Select language and

continue.

Leave the default

directory and click next

OM17-P4000VIS-NIR

Figure 5

Figure 6

3-3

Page 13

OM17-P4000VIS-NIR

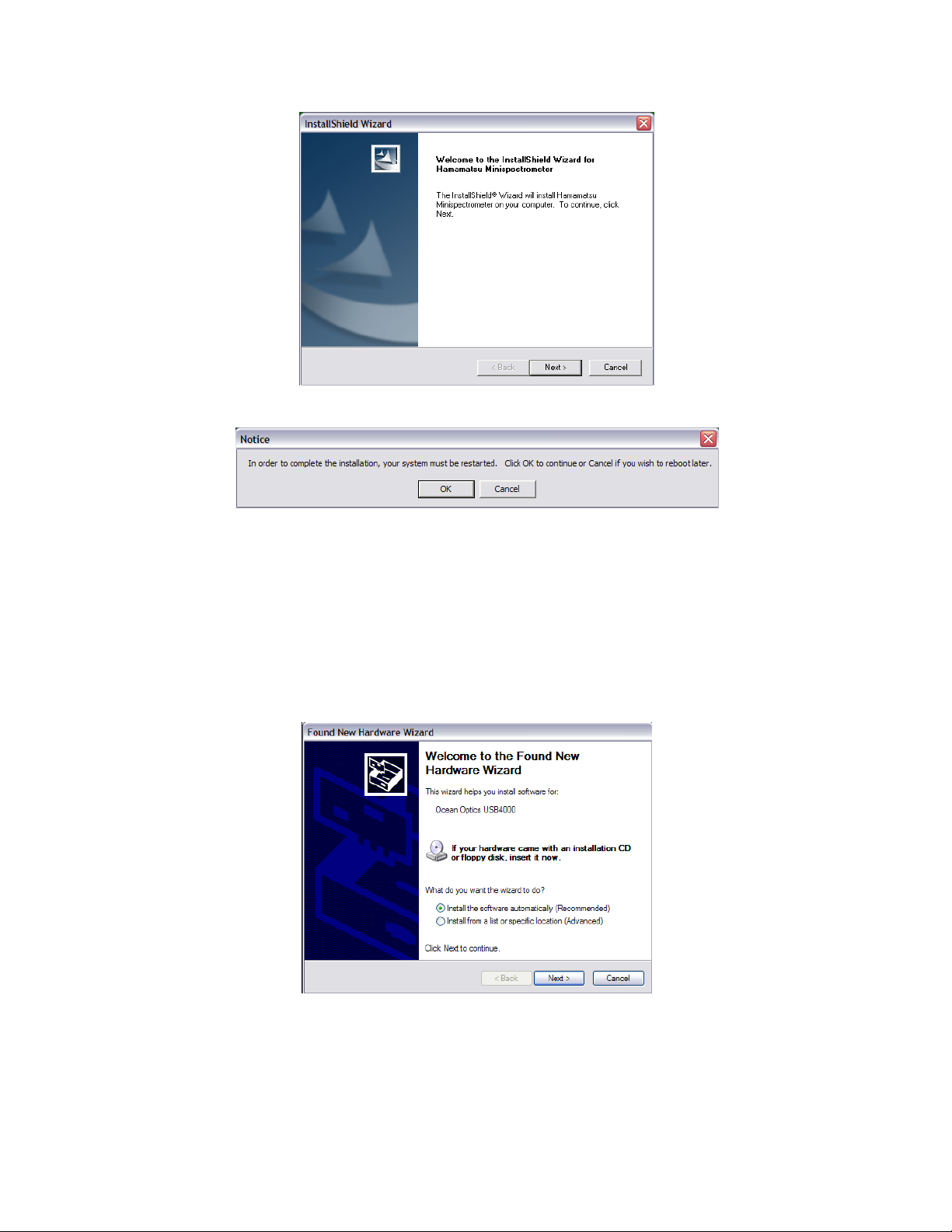

Next the Hamamatsu

Minispectrometer

installation guide will

appear. Click next two

process through the

installer

At this point it is

OK to restart the

computer

Select Install the

software automatically,

then click Next to

complete the hardware

installation.

Figure 7

Figure 8

Once the restart is complete, plug in the USB cables for the auxiliary and spectrometer

cases

MS Windows may then bring up the following screens about the Ocean Optics

spectrometer and the Hamamatsu spectrometer.

Figure 9

3-4

Page 14

OM17-P4000VIS-NIR

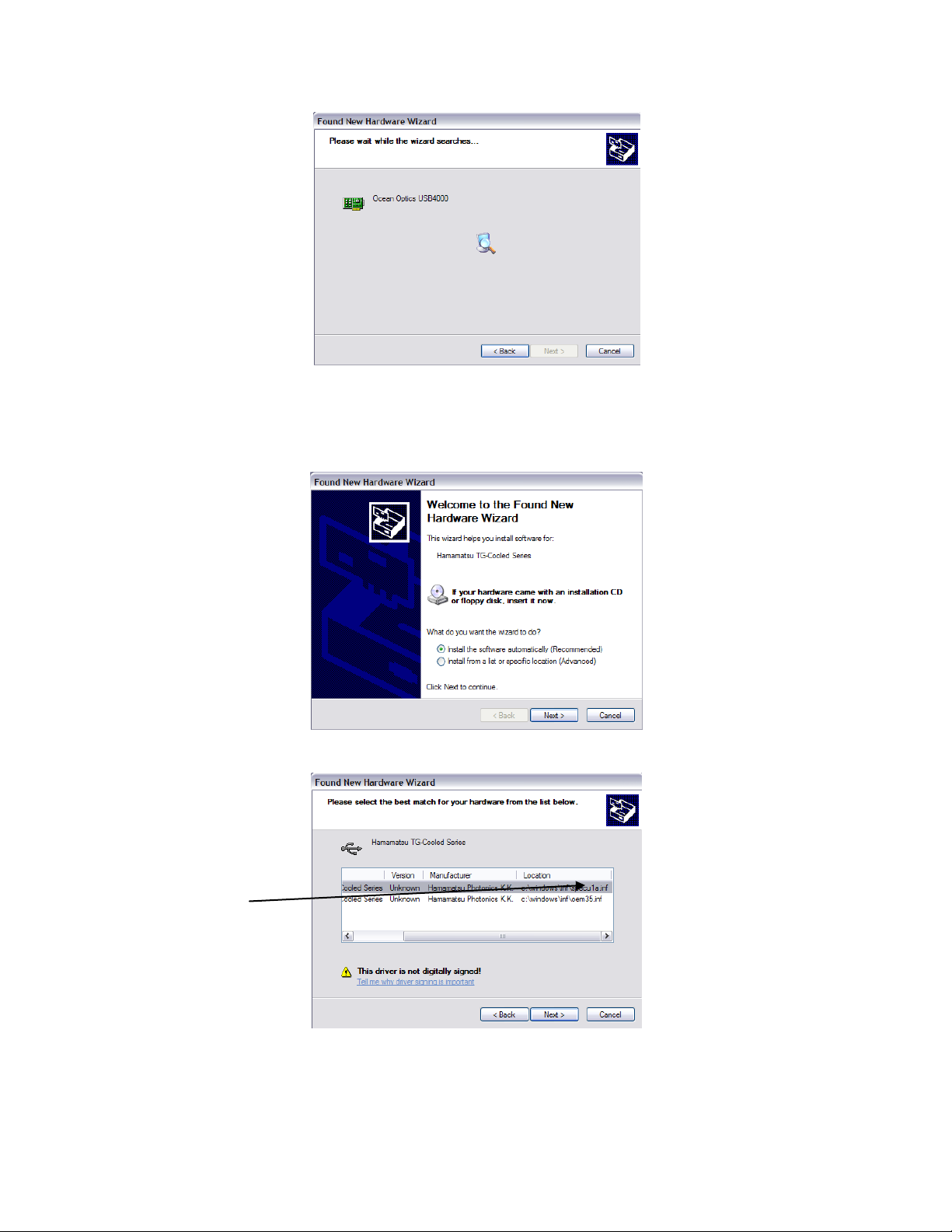

Windows will

automatically find the

correct drivers for the

Ocean Optics USB4000.

For the Hamamatsu

installation select Install

the software

automatically then Next

to complete installation.

If this screen appears

asking for the driver

version to be installed

always use the

specu1a.inf, then

select Next.

Figure 10

After completing the Ocean Optics MS Windows installer, the Hamamatsu installer may

appear. Note: These installers may appear in any order.

Figure 11

Figure 12

3-5

Page 15

OM17-P4000VIS-NIR

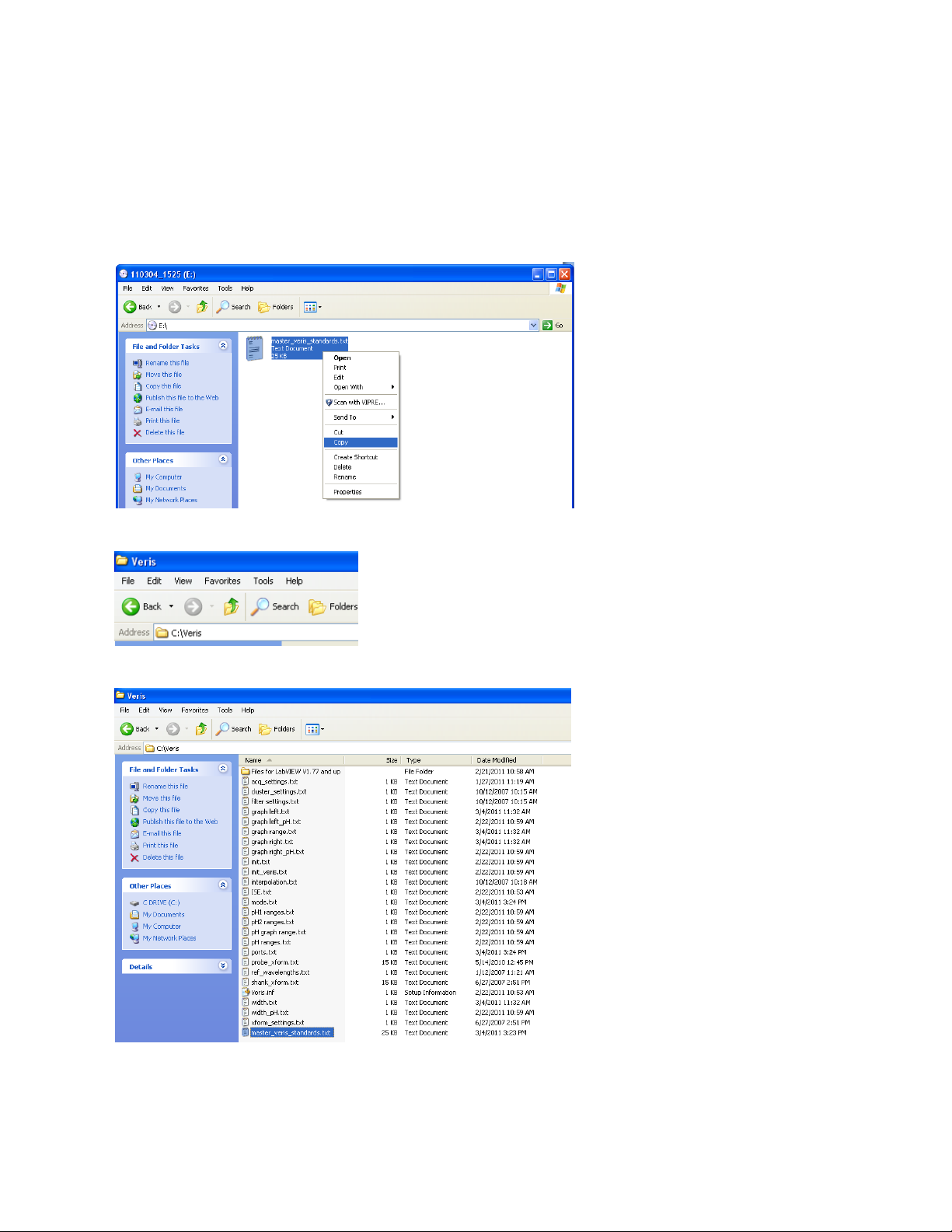

The master_veris_standards

file is specific to your external

references and is provided by

Veris.

Installation of Calibration Files

This must be complete for the software to be operational

Copy the master_veris_standards.txt file from the calibration CD into the C:\Veris

directory

Figure 13

Figure 14

Figure 15

3-6

Page 16

OM17-P4000VIS-NIR

Ocean Optics Spectrometer Configuration

Only necessary for Veris Spectrophotometer Software V1.76 and below

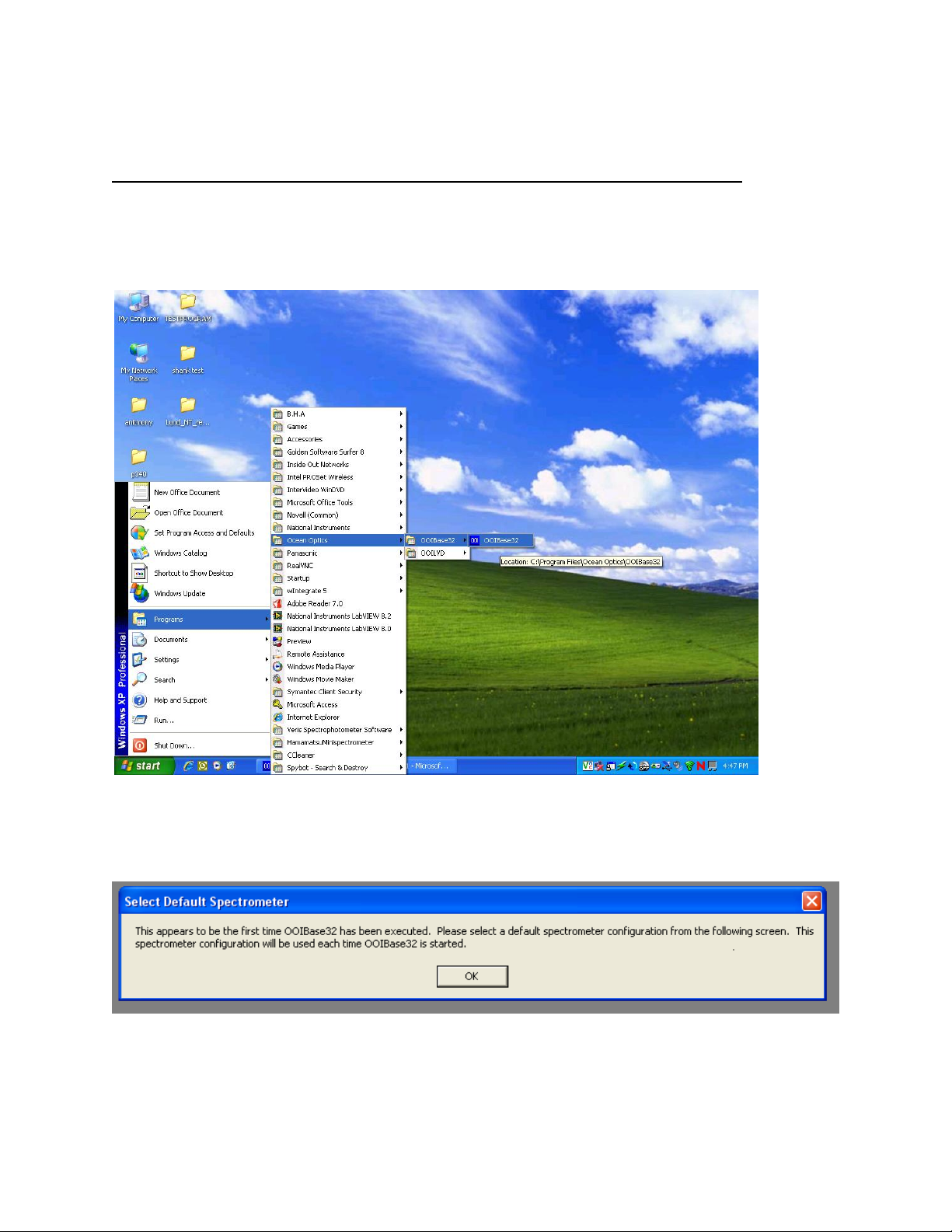

Step 1: Open OOIBase32 Software

Start Ocean Optics software (Start programs Ocean Optics OOIBase32)

a. If software asks for a default spectrometer file click cancel

Figure 16

If it asks for a spectrometer configuration click, OK

Figure 17

3-7

Page 17

OM17-P4000VIS-NIR

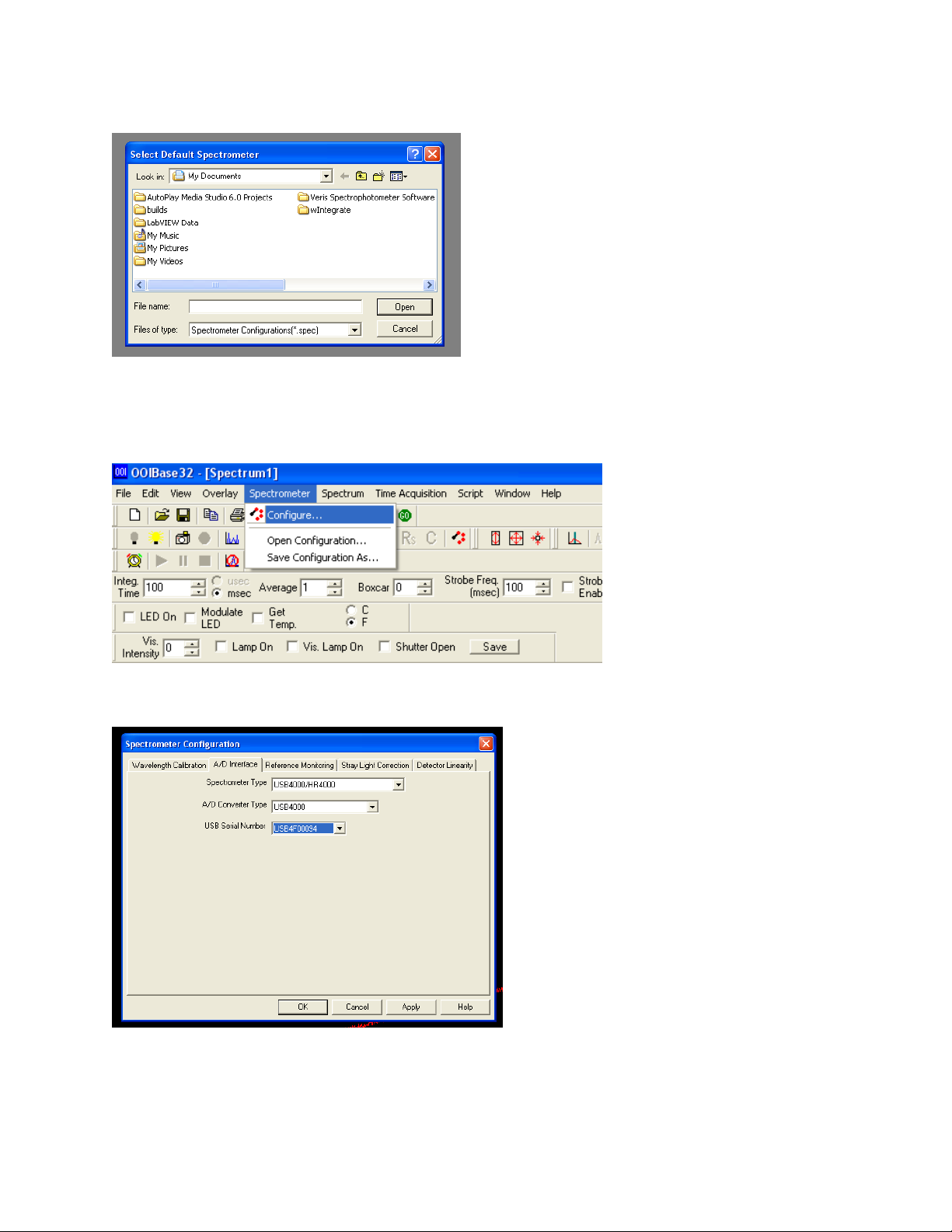

If software asks for a default spectrometer file click Cancel

Figure 18

Step 2: Open Configuration

Click on Spectrometer in the toolbar at the top and then select Configure

Figure 19

On the configuration screen select the A/D Interface tab

Figure 20

Note: Under Spectrometer Type if USB4000/HR4000 is not available select S4000

3-8

Page 18

OM17-P4000VIS-NIR

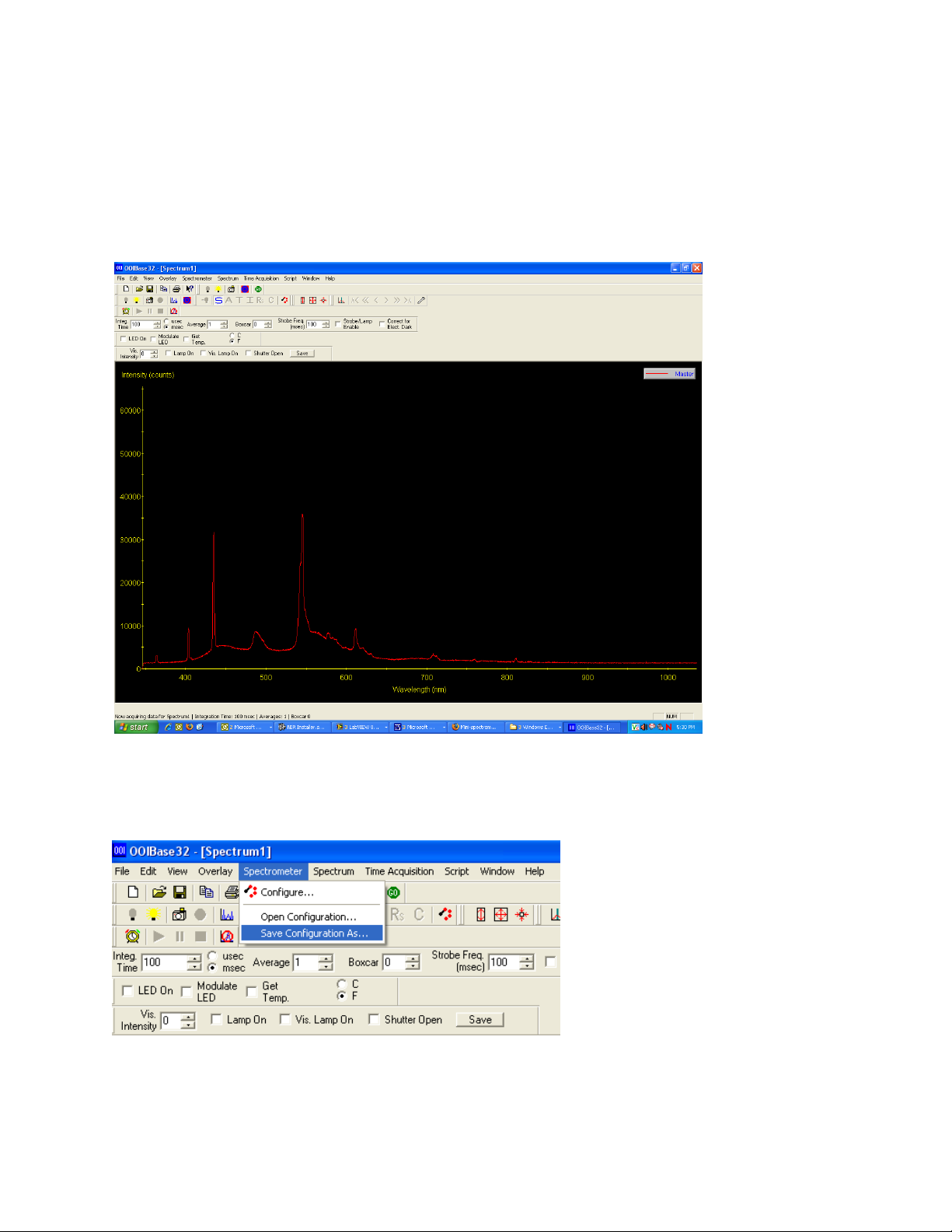

Under serial # only one spectrometer number should be present. If no serial number is

present close out of the software, unplug the USB cable and reinsert the USB cable,

wait to see if windows recognizes a new device, then proceed to the open the Ocean

Optics software and try again.

Click OK and a spectrum will be present on the screen.

Figure 21

Example of spectrum that should be shown on screen (when light is on at probe).

Step 3: Save Configuration

Figure 22

3-9

Page 19

OM17-P4000VIS-NIR

Click on Spectrometer then Save Configuration As.

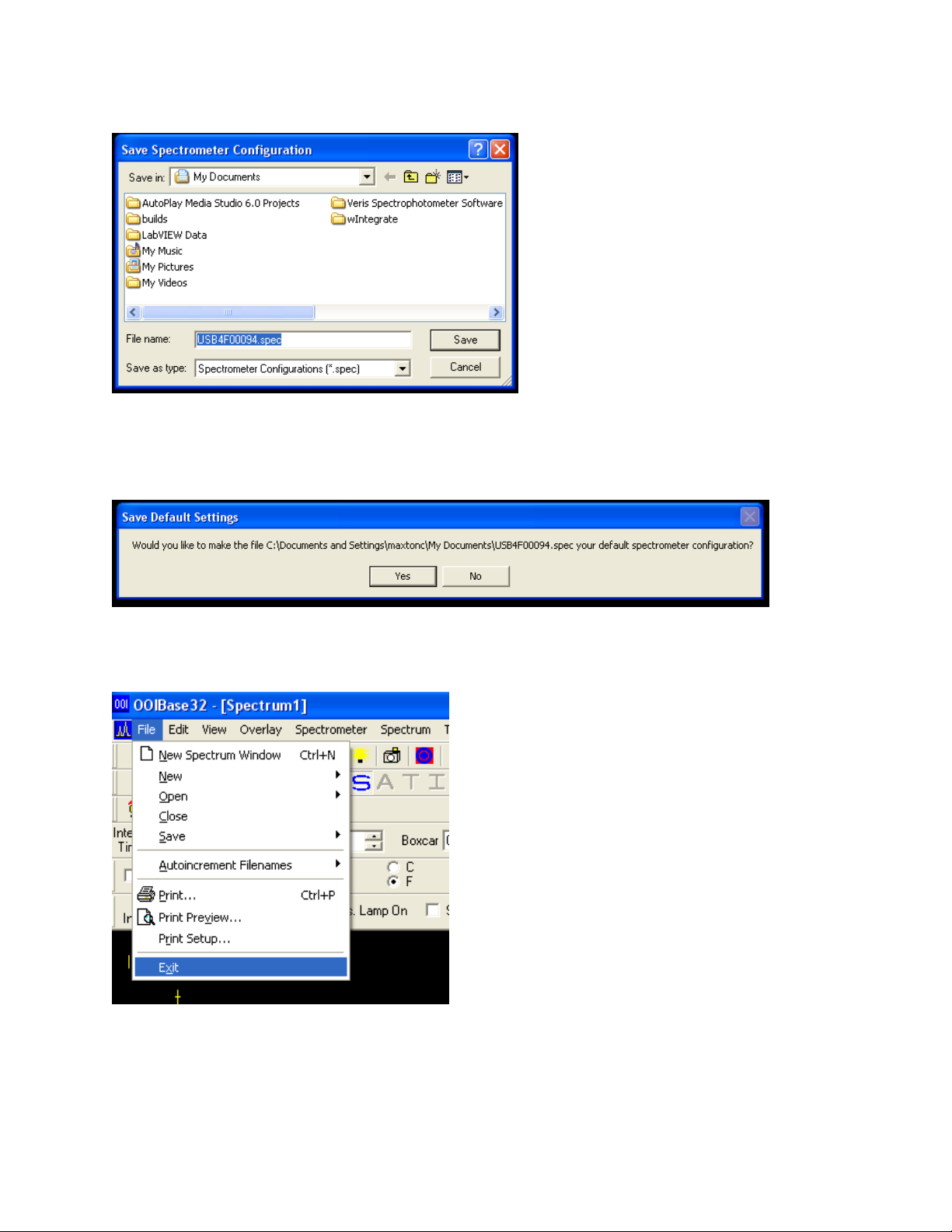

Figure 23

The Save Spectrometer Configuration should automatically fill in the file name with the

serial number. Click Save.

Figure 24

Choose yes to make the spectrometer configuration the default settings.

The spectrometer has now been configured.

Figure 25

Exit the software.

3-10

Page 20

OM17-P4000VIS-NIR

Auxiliary case ports

Spectrometer case ports

The software could increment the

number of the ports by one

depending on the computer. For

example, the device manager

shows ports 20,21,22,23,9 but the

software shows 21,22,23,24,10.

Just use the incremented numbers

if this situation occurs.

Setting Port Order

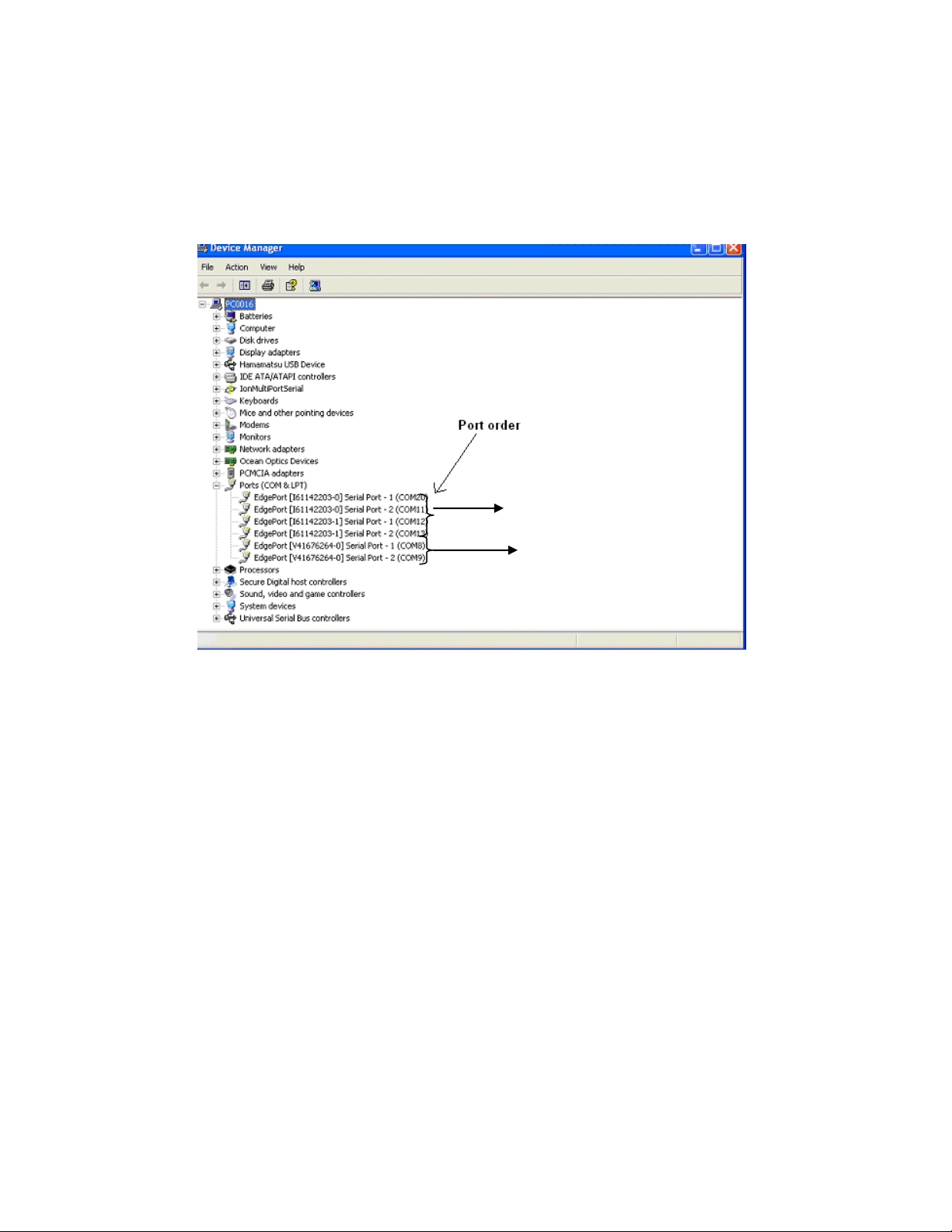

1. Check Device Manager for port order (Start settings control panel system

hardware tab device manager double click ports)

2. Ports will be listed in order, as they should be set in software.

Figure 26

In this example the order to set the ports would be as follows: (see Figure 25.) Different

computers will have the ports in different orders; however if the software is used on one

computer only, the ports will never change. The ports will always be in the order of

spare, GPS, temp, control, and spectrometer. For future reference, make note of the

com port order your computer is using.

Spare: COM20

GPS: COM11

Temp: COM12

Control: COM13

Spectrometer: COM8

The last port (COM9) will not be used.

3-11

Page 21

OM17-P4000VIS-NIR

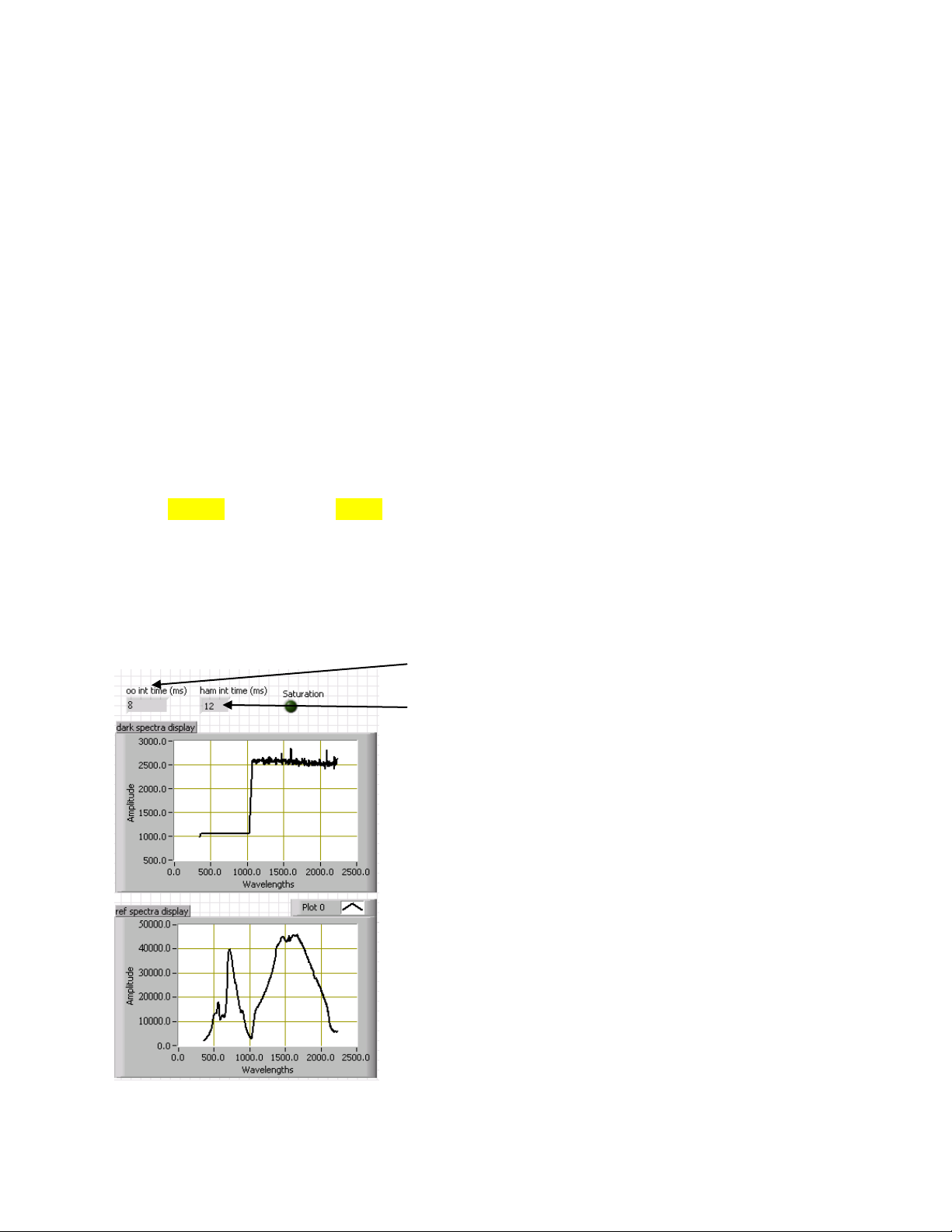

Example of ref spectra shown

in system check and acquisition

with correct integration time set.

Figure 27

Make sure to check the integration

time while going through the initial

setup of the instrument.

Ocean Optics Integration time

Hamamatsu Integration time

Setting Integration Time:

The integration time is the amount of time the spectrometers collect the spectral data for

averaging. It is important to have this set correctly because too much light will saturate

the spectrometer, while too little light won’t allow the full range of the detector to be

used. The integration time needs to be set before acquiring spectral data. This is

especially important for users switching between probe and shank modules as

the optics are different and the amount of light seen between each device varies.

Step 1: Open the Veris Spectrophotometer Software and start the system check. After

the first Dark and Reference measurements are stored, check the ref spectra display

(example shown below). The two peaks shown should be around 40000.00 counts.

The first peak is controlled by the oo int time, while the second peak is controlled by the

ham int time. If peaks are too high, then lower the integration time. If peaks are too low

then raise the integration time.

Step 2: Once it has been determined which way to move the integration time, exit the

software and open the acq_settings.txt file located in the C:\Veris directory.

0.010 12.000 5.000 8.000 0.150 0.150 0.300 0.150 2.000

Example of data stored in acq_settings.txt

The second value represents the ham int time,while the third value represents the oo int

time. Raise or lower these values then save the file, open the Veris Spectrophotometer

Software, run a dark and reference measurement, and then check these values again to

see how the peaks changed.

3-12

Page 22

OM17-P4000VIS-NIR

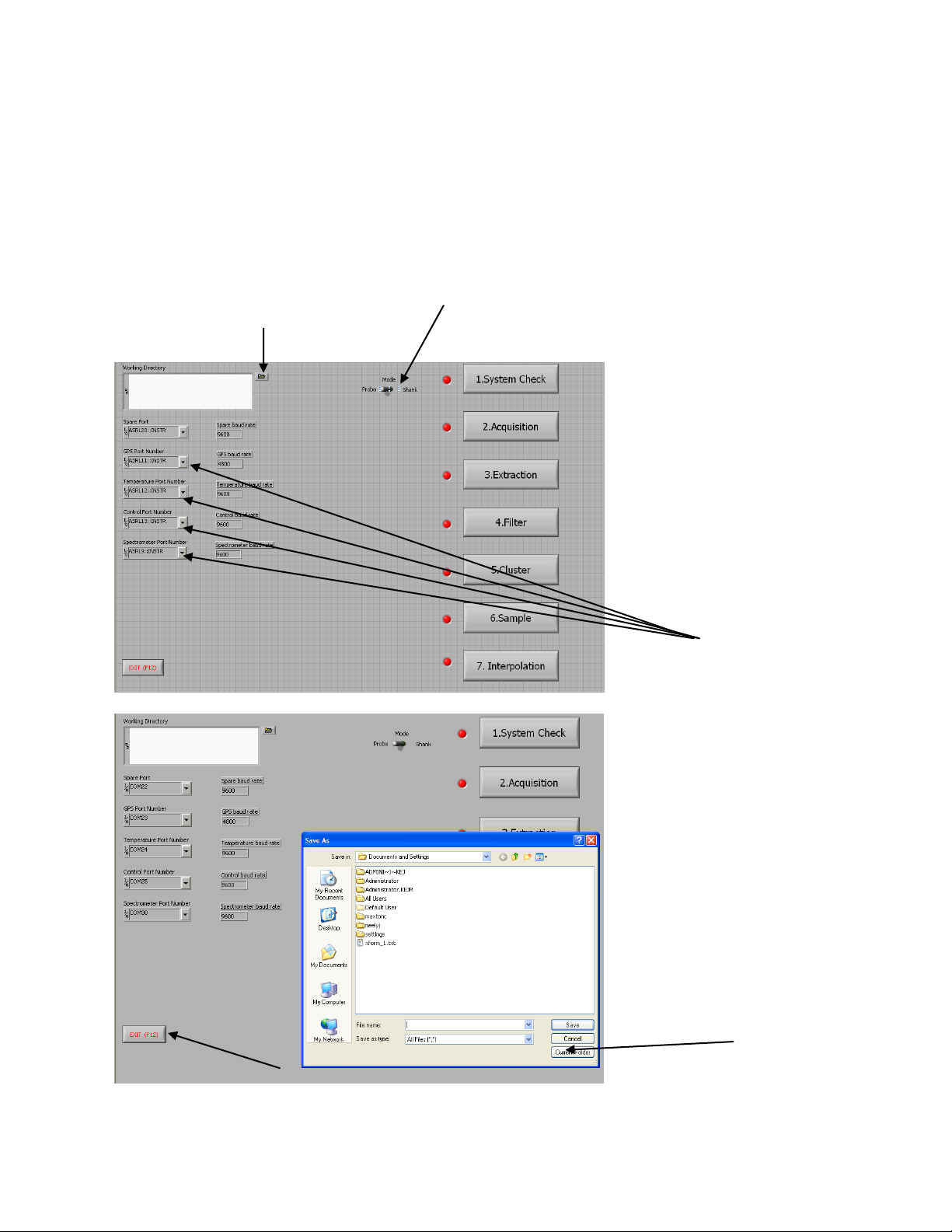

Folder icon to select working directory.

A field folder must be selected before

any steps can be completed. Note:

Each field or site must have its own

Once the desired

directory is found,

click on current folder.

BEFORE STARTING:

1. Before taking any

data let system run

for 20 minutes to

allow the

spectrometers to

stabilize.

2. Connect

spectrometers to

PC.

3. Open Veris software

4. The port order must

be set (see Setting

Port Order). This

needs to be done

the first time the

software is run on a

machine, after that

the port order will be

stored for future use.

Port terminology

may be labeled

COM or ASRL.

Both are acceptable

if port number is

correct.

Press EXIT or F12 when ready to quit the software; this will

ensure the port order will be saved.

Set software for either probe or shank mode. If the

incorrect mode is selected and system check or

acquisition entered, then the auxiliary case will need

to be reset by shutting off power and turning back on

before entering software again.

Section 4

Field Operation - Electronics

Operating software - This will need to be completed every time the software is started.

Open Veris operating software:

Figure 1

Figure 2

4-1

Page 23

OM17-P4000VIS-NIR

Example of what screen will

look like when manual

reference needs to be taken.

First place the reference block

holder on the end of the probe

as shown

Then slide references in front of

window. Be sure reference

material is facing the window

How to take Manual Reference

In order to calculate reflectance a dark and reference measurement must be taken

initially when the software starts, and then every 10 minutes to ensure all

measurements are accurate and to compensate for any discrepancies in the

spectrometer or light source due to temperature. The software will alert the user when

these conditions occur by displaying Take manual reference in the system message as

well as the ref check light flashing.

Figure 3

Before placing the reference block on top of the wear plate window wipe the wear

plate window clean of any debris.

Figure 4

Reference block to be used for dark/ref measurements. This is the block stamped

dark/ref.

Figure 5A & 5B

4-2

Page 24

OM17-P4000VIS-NIR

1. System Check – This step calibrates the spectra data to known standards to ensure

data integrity. This is accomplished by: A) manually placing four external reference

standards against the window and collecting spectra measurements for each standard;

and B) transforming the data to a master set of data provided by Veris.

A) Before running the external references make sure the window on the probe and the

window on the reference are clean. When program state reads REST and controller is

in neutral (N), place the correct external reference adjacent the probe window and then

press the corresponding external reference button. If the External Reference (ER)

failure light is yellow, check to make sure the correct external reference was placed

adjacent wear plate and that the correct external reference button was pressed, and

then run the external reference again. Once ER light illuminates, proceed to next

reference, after taking a manual reference. Once each external reference has been

run at least once, press end or F12. This will exit this program and initiate the create

transform program, which will take the data just acquired and compare it to the master

data to create a current transform. If the transform is created successfully, then that

transform will be applied to all spectra data acquired during the acquisition.

External References External References securely in place

Figure 6A & 6B

Place the ER securely onto the probe wear-plate. Make sure to align the window on the

ER to the window on the probe, and magnets hold the ER firmly in place. The reference

material goes towards the ground and lines up directly adjacent the sapphire window on

the wear-plate.

4-3

Page 25

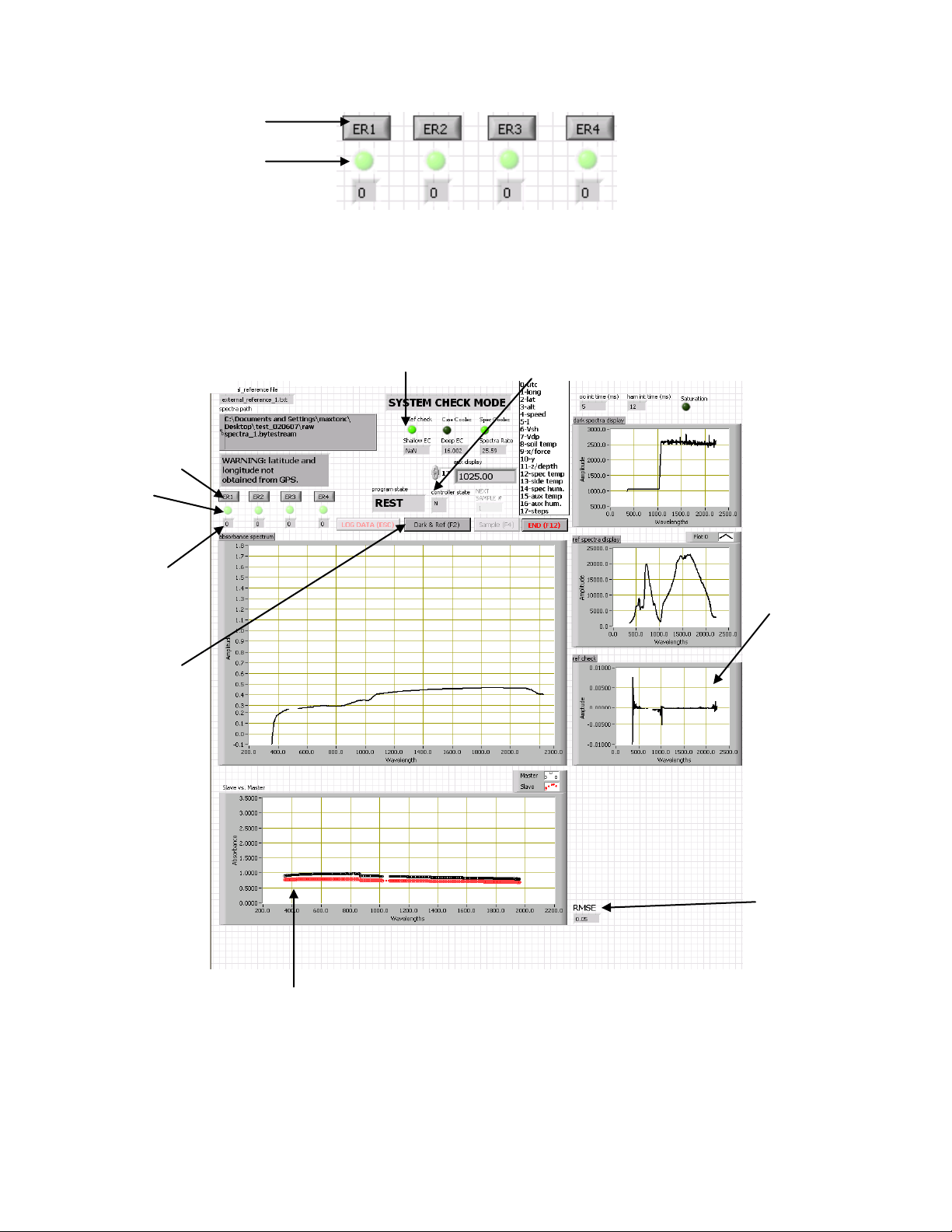

Figure 7

External

Reference buttons

Failure light

Number of times

each reference

has been ran,

since system

check was

opened.

Manually stores

dark/reference

data. This should

be done if there is

a failed reference

check. This could

be caused by the

shank steps not

being within

specification, or

one of the

spectrometers is

not running. Try to

clear out the

reference by

pressing F2. If

problem persists

shut down system

and restart.

Auxiliary data can be scrolled through by the up and

down arrows on the left of the indicator. Data

corresponds to chart listed on the right of indicator.

Note: a reading of –1.50 indicates failure of that

component or communication problem. See

Glossary for Auxiliary data information table.

Ref check graph:

This should be close to

a straight line except

for the edges and the

center. The reference

check light will indicate

if this is an acceptable

reference check.

Root mean squared

error of current

external reference.

By default the RMSE

should be within .10

for references 1,2,& 4

and within .15 for

reference 3.

Reference check light is

green for good references

and red for a failed

reference. If a reference

fails, press F2 to store a

new dark and reference.

Ref check light

This compares the slope

of the previous transform

to the current transform

Graph that compares current

external reference to master

reference. These should

correlate to one another if

system check has been

completed before.

A yellow ER light

indicates possible

problem. Regard as a

good reference unless

transform step fails.

ER buttons

Indicator light will be

yellow or green

OM17-P4000VIS-NIR

Figure 8

4-4

Page 26

OM17-P4000VIS-NIR

Raw master and

slave data

(external

reference). The

master is black

and the slave is

grey.

Master and slave

data with

transform applied

master is black

and slave is grey.

Root mean

squared error for

current transform.

Maximum allowed

RMSE for a good

transform.

Compares the

offset of the

previous transform

the current

transform

Indicates when transform is

complete. READY TO

MOVE TO NEXT STEP—

DATA ACQUISITION.

Previous transform will

be a straight line the first

time system is ran.

External

reference data

that was just

taken.

Master data file, which

will be used to transform

slave (master file

provided by Veris)

Indicates if transform is

Figure 9

Once the transform is complete press close window or F12. If the transform was

successful, the software will inform the user and continue on to acquisition. If the

transform failed, the program will enter the system check again so the references can

be ran once more. If the transform fails again, either there is a system problem

(spectrometer malfunction, window is dirty, or references not taken properly) or the

tolerance for the maximum allowed RMSE could be set too low; see program

modifications to change this.

4-5

Page 27

OM17-P4000VIS-NIR

Before mapping complete the following:

Start system at least 20 minutes before starting to map to ensure the spectrometers

have stabilized

Make sure auxiliary sensor data is coming in (see Glossary for auxiliary sensor data

definition).

Make sure all auxiliary lights are green.

Complete all steps above. Make sure Reference Check (Ref Check) light is green, and

GPS data are being received.

2. Data Acquisition – The collection of spectral and auxiliary data in the field. Data is

streamed to a file in a compact format.

Pressing the PROBE button stores spectrum data as absorbance and auxiliary data,

which includes EC data, the PROBE button key has been pressed again or the probe

pulled out of the ground. No data can be logged if there is no GPS signal or there is a

bad ref check. No data, including EC data, will be stored unless the program is in LOG

mode.

System will alert the user to take a dark and reference every 10 minutes—the next time

the PROBE button is pressed after a 10-minute period.

If an extra dark and reference is desired, pressing F2 or Dark & Ref stores a new

reference and dark spectrum. Pressing F4 or sample will store transformed spectrum

data as absorbance into the acquisition_samples file located in the field directory.

Once all data has been acquired press F12 or End to return to the main interface.

Soil EC is recorded simultaneously with NIR data. When EC is being collected, EC

value will appear in the shallow window. The deep will be a -1 because it is not used

with the probe. Note: unit must be in Log mode for EC to be recorded. Also, see

Maintenance section for information on testing EC system output.

4-6

Page 28

Ref check light This

green light indicates a

good reference

These indicate the temperatures and the

humidity of the system. If they are not

within range (see specifications) the

indicator light will be red, if this occurs

the system should be shut down.

Dark spectrum

that was stored

when program

state was in dark

mode

Reference

spectrum that

was stored when

program state

was in reference

mode.

Ref check

compares the

previous

reference data

to current

reference.

As in system check, this should be close to a straight line

except for the edges and the center. Since this is a bad

reference it is indicated by the ref check light at the top of the

screen. In this situation press F2 to store a new reference.

Pressing

PROBE stores

spectrum data

as absorbance

and auxiliary

data, which

includes EC

data, until

probe has

been hit again

or logging

stops

automatically

when probe

pulled out of

ground. No

data can be

logged if there

is no GPS

signal or there

is a bad ref

check. Use

PROBE to

store data

while mapping

a field. No

data, including

EC data, will

be stored

unless it

program is in

LOG mode.

Auxiliary data indicator

Auxiliary data can

be scrolled

through by

pressing the up or

down arrow to the

left of the indicator.

The auxiliary data

corresponds to the

chart listed on the

right of the

indicator.

Figure 10

EC indicators

Log and GPS

lights—must be

green for data to

be recorded

Note: Make sure to run through the setting the

integration time procedure after starting up

system for the first time or after switching

between probe and shank mode

OM17-P4000VIS-NIR

As long as the acquisition software is closed properly using F12, all data is saved and

the acquisition can be opened at a later time with new data being appended to the data

taken previously.

4-7

Page 29

OM17-P4000VIS-NIR

Transform which

will be applied to

field files created

in the acquisition

(bytestream

files).

Spectrum

acquired using

LOG mode

during

acquisition.

Reference check

spectrum

acquired during

acquisition.

Number of

references and dark

spectra taken during

acquisition.

All reference

spectrum taken

during acquisition.

All dark spectrum

taken during

acquisition.

Output file that contains

transformed field absorbance

spectrum taken during LOG

mode of acquisition.

Figure 11

How to know you’re collecting high quality NIR measurements:

a) Log light and GPS lights are both green

b) Ref check light is green

c) Spectrum absorbance doesn’t jump as the probe is pushed down

d) Absorbance spectrum shows a typical soil spectra pattern (Figure

52), and is changing slightly as the data is collected.

e) External references can be attached to probe at any time in Data

Acquisition mode. Absorbance should be highest for ER3 and

lowest for ER4.

f) Wear plate window is not broken, or cracked. This is caused by

excess wear, or rocky fields. Be sure to check window during

these situations and replace probe wear plate if necessary.

3. Data Extraction – The spectra and auxiliary data are read out of the compact format

(bytestream) file and averaged, then the output is stored in an ASCII format. EC data is

extracted into file named ec.txt. The extraction program will extract all the bytestream

files and apply the appropriate transform, then output the data into a single text file.

Once all the data has been processed, indicated by a green complete light, click on

close window or F12 to return to main interface.

4. Filtering -The spectra are compressed using principal components compression, and

outliers are removed. Maps of each principal component (up to 10) are displayed, and

the results of the PC analysis and filtering are output to ASCII formatted files.

4-8

Page 30

Score plots of

spectrum data that

indicate grouping of

spectra.

Number of outlying

spectra removed

during filtering.

Total number of

spectra.

Wavelengths used by

the spectrometers.

There are 384 total

wavelengths.

Graphs of each

principal component;

this is an ASCII text

file and may be

imported into other

mapping software.

The PC data are in the

field folder, and are

named PC scores.txt

Loadings of each

principal component.

Once all the data

has been filtered and

the complete light is

green press close

window or F12 to

return to main

interface.

OM17-P4000VIS-NIR

Figure 12

4-9

Page 31

OM17-P4000VIS-NIR

Map of proposed sample locations

based on clustering. Each circle

PC scores file to be clustered. represents a sample location.

File where GPS

locations of

proposed

sample locations

is stored.

Number of

points in each

cluster.

The number of

clusters should

be equal to the

number of

desired sample

locations.

This indicates

the status of the

program. First

the program will

space the

spectra evenly,

then cluster the

spectra.

Each plot

represents a

cluster.

Map of all data

with each color

representing a

different cluster.

Figure 13

5. Clustering – Clusters the principal components (PC's) of the spectra into the same

number of clusters as desired sample points. When the clustering program opens it will

ask if the settings are correct. The settings this refers to are the number of clusters or

sample locations, and the number of PC’s to use for clustering. By default there will be

3 PC’s used and 15 locations to sample. If more sample locations are desired, then this

can be changed at this time. Up to 10 PC’s can be chosen, however 95% of the data is

contained within the first 3 PC’s. If these settings are acceptable, then select YES or, to

update the settings press NO. If NO was selected, update the settings and press

continue to begin clustering the data. Once the data has been clustered, the program

status will say done and the complete light will be lit. Press close window or F12 to

return to the main interface.

For Probe mode the program will suggest which GPS locations along with which 10cm

increment of soil will provide optimal calibration based on the spectral variability.

4-10

Page 32

OM17-P4000VIS-NIR

Map of the proposed locations (black circles) and

the actual locations (black squares). The cursor

(not shown) will show the user their current location

when the cursor is over the proposed location or

the location desired to be sampled, then press OK

or enter to store that location as an actual location

that was sampled and take a sample of the soil.

Number of

next actual

locations to be

sampled.

When the

cursor is over

the desired

sample

location press

OK or enter.

File where the

GPS of the

actual

locations is

stored.

Current auxiliary data

that corresponds to the

chart on the right.

Figure 14

6. Soil Sampling – Allows the user to navigate to the GPS coordinates of desired

sample locations (from Step 5), and record actual sample locations. The actual

locations that are saved during sampling program will be used for the interpolation of

the spectra in the next step.

Once all the desired sampled locations have been stored, press close window or F12 to

return to the main interface.

4-11

Page 33

OM17-P4000VIS-NIR

Input

sampled

locations to

interpolate

Input field

data

Output file

with data at

each

sampled

location

Number of

spectra at

each

location

Distance in meters to search

through spectra in the x direction

Distance in meters to search

through spectra in the y direction

Distance in meters to search for

spectra in the z direction. This is

half of the distance of the depth

increments. This is only used

for the probe mode.

Increments in meters to space out the

1 meter of depth for the probe data.

This is only used in probe mode.

Spectral

data is

graphed as

it is found in

the

interpolation

program.

7. Interpolation – Uses a Gaussian weighting to average spectra near a sampled

location, so the data can be matched up with properties of interest for calibration.

Spectra near to the location are weighted higher than spectra far away. Also, this will

interpolate several probes into one value if desired. Outputs a file named

spectra@locations.txt to the working directory. This file contains the spectra and

auxiliary data for each sampled GPS location.

Once the interpolation begins it will ask if the settings are correct. The settings this

refers to are a, b, and the depth increments. By default a and b will be 3 meters, if a

larger search area is desired then these can be updated. If the settings are fine press

YES, if the settings need to be updated select NO. After selecting NO and updating the

settings then press continue to begin the interpolation. After the interpolation is done the

complete light will be green, then press close window or F12 to return to the main

interface.

For Probe mode the depth increments determine how to split up the data taken. If .1 is

chosen then that data will be split up into 10cm increments and the output file will show

depths of .05, .15. .25…95. This is because the interpolation searches half of the depth

increment in each direction so the .05 measurement is from data at 0-10cm in depth

and the .15 measurement is from 0-20cm in depth and so on. The output file will

include data from the whole core profile, not just the specific depth suggested from the

clustering. See examples on next page.

Figure 15

Note: always use exit button or press F12 to close out of Veris NIR software.

4-12

Page 34

OM17-P4000VIS-NIR

The example on the left illustrates how

the interpolation can use multiple cores

to obtain one value. If the a distance

was equal to 3m and the b distance

equal to 3m, then all three probes would

be interpolated into one to obtain the

value for the 10cm sample. If this is not

desired then make sure that a and b are

less than the actual probe spacing.

Figure 16

Figure 17

Interpolation (continued)

This example on the left shows the interpolated output vs. the sampling depth

increments. If a core was taken and cut into 10 cm depth increments the output file will

show 05 cm thru 95 cm, but the 05 cm data corresponds to the interpolated value using

0-10 cm data, not the data at precisely 05 cm. This continues down the probe until

through the 95 cm measurement. Likewise, in the example on the right a 20 cm depth

increment was used and the output file shows depths from 10 cm thru 90 cm. The 10

cm measurement corresponds to the interpolated data found between 0 – 20 cm. This

continues for every 20 cm increment of soil.

4-13

Page 35

OM17-P4000VIS-NIR

Importing sample locations for interpolation

Versions 1.4 and later.

This is only to be used when sampling is not completed in the Veris software. By

following these steps the user could map a field and then flag the GPS locations where

samples were collected and use those locations to get the interpolated values from the

Veris software.

Step 1: Collect field data, then extract and filter the data. Exit the Veris

Spectrophotometer Software once these steps have been completed.

Step 2: Create a file of the GPS coordinates of the sampled locations. The file should

be created in the following format. Column A is the sample number, column B is the

longitude, and column C is the latitude. Save the file as actual locations.txt in the

working directory, where the field data has been stored.

Figure 18

Example of actual locations.txt file

Step 3: Open the Veris Spectrophotometer Software and chose interpolation. The

software will use the locations stored in the actual locations.txt file, and give an

interpolated spectra, and auxiliary data for each location. The output will be a file called

spectra@locations.txt, which will be created in the working directory.

4-14

Page 36

OM17-P4000VIS-NIR

Sample holders

with soil.

Make sure the

soil is level with

the top of the

sample holder to

ensure a tight fit

with the probe.

Bench top Usage

To use the spectrophotometer to obtain measurements in the a bench top setting, first

complete the system check as described in the field usage steps, then proceed to the

acquisition. Mount the probe on the probe bench top stand. Place a soil sample in the

sample holder and place the holder against the face of the probe window. Use the

sample button or F4 to store a dark, reference, and then a sample spectrum. These

transformed spectra are stored in the acquisition_samples.txt file located in the field

folder.

Figure 19

Figure 20

4-15

Page 37

OM17-P4000VIS-NIR

Working directory icon

Test/Example Data

In order to gain experience with the software before mapping, test/example datasets are

included with the Veris software. This allows the user to experiment with the system,

without logging data or having GPS signal.

1. Start Operating software (Start programs Veris Spectrophotometer

Software Veris Data Processing)

2. Select working directory by clicking on folder icon.

Figure 21

3. Set ports (see setting port order)

4. Click on system check (see system check for more information).

5. Close acquisition and exit Veris software.

6. Go to C:\Veris\test data probe copy all files into the directory that was setup in

7. Start software again and proceed through the extraction, filter, cluster, sample

a. Run through all four external references

b. Exit system check

c. Start acquisition

step 2.

(no locations can be stored without GPS), and interpolation. For more information

on each of these steps, see Field Operations.

4-16

Page 38

OM17-P4000VIS-NIR

14” from rear edge

to rear of bumper

Section 5

Field Operation

P4000-S

Installation

The P4000-S is designed to be installed in ¾ ton – 1 ton pickups and due to the wide

range of bed and frame dimensions on the market, there are no mounting holes in lower

frame flange. Some drilling and fabrication will be required. You may choose to

perform this on your own, or may wish to have a local welding or truck shop do this for

you.

Steps:

1) Properly lift probe assembly in folded position with a minimum of two nylon straps

and lower into pickup bed.

2) Center side-to-side in bed and so rear portion of skid frame rail is 14” forward of

farthest point on rear bumper (Figure 1). This will ensure that foot will not contact

bumper when the skid is in the retracted position.

3) Ideally 4 mounting bolts (½” Gr5) are adequate for fastening the probe skid to the

frame of the truck. Choose mounting location based on frame obstructions such

as spring hangers, fuel tank hoses, etc. This will take some time, measuring both

top and underneath the bed to make sure bolts will align with skid frame

4) Locate all four positions and fabricate “L” straps from at least 3/8” material and

bolt or weld to frame. Make sure that fuel tanks, fuel line, and brake lines are not

in danger of being drilled or welded. Drilling is preferable and two ½” bolts in the

vertical position are adequate. (Figure 2)

5-1

Page 39

OM17-P4000VIS-NIR

Figure 1

Figure 2A & B

Start out with ¼”

pilot hole for

drilling up through

Top View

Figure 3

Figure 4

Figure 1

5) Using the “L” straps as templates, you can drill the hole through the bottom side

of the skid frame rail. Tip: If you start out with small pilot holes (1/4”or less) it

takes less effort to drill through the bed and frame rail, then drill out to full

dimension from on top.

6) If for some reason you must locate one or two of lower “L” mounts ahead or

behind the skid frame rail, you can fabricate some clips to hold down in place.

Ideally at least two bolts should go through the skid frame to ensure that probe is

properly connected to bed (Figure 3)

7) Securely bolt down and connect power cable to battery of vehicle.

5-2

Page 40

OM17-P4000VIS-NIR

Figure 5

Figure 6

KEEP FEET CLEAR OF

FOOT AND PROBE

Field Operation

Probe Platform

- Start engine and allow it to warm a minute or two before cycling – a few minutes

if during cold weather.

- Extend to full rear position

- Fold into upright position (figure 5)

- Lower foot to soil

- Raise probe (figure 6)

- Install Probe or core sampling

components

Important! -- When folding and retracting the platform make sure that

probe mast clears engine muffler. This can be achieved by shifting left to right as

you fold the unit.

5-3

Page 41

OM17-P4000VIS-NIR

KEEP FEET CLEAR

OF FOOT AND

Figure 7

Figure 8

Field Operation

VIS/NIR Probe

Checking Electrical Signal Continuity and Electrode Isolation

It is recommended that you routinely check the EC signal to verify that all functions are

working properly. See Maintenance and Lubrication Section for a step-by-step

procedure. It is advisable to perform this test on a routine basis (weekly or every 20-25

hours of data collection) to ensure you are obtaining reliable data.

Operation

Before probing refer to Section 4 for electronics operation. Remove hairpin from string

pot piston (Figure 7). Set probe speed --- not recommended over 3cm/sec. This is

adjustable via the probe speed flow control on the side of the control panel. (Figure 9)

Begin probing: with probe mast vertical, insert probe into soil until top of window

is not visible. (Figure 8.) This starting position is recommended so ambient light

will not be collected.

Pressing Probe button begins storing spectrum data and auxiliary data until

probe is stopped or raised. Once insertion is initiated, do not stop or reverse

unless problem has occurred or desired depth is achieved. Data recording stops

when probe is raised. GPS and Log lights must be green for data to be recorded.

While probing monitor the following: Streaming spectra rate and Streaming Aux

Display. If either of these is not streaming, stop immediately and diagnose the

problem. See Section 7 Troubleshooting.

After 10 minutes the program will alert the user to take a manual reference. Several

manual references may be required.

5-4

Page 42

OM17-P4000VIS-NIR

Figure 9

Operational tip

Use side-shift function to move probe to adjacent probing locations.

Do not let stringpot cable snap back into spool; factory stringpot repair will be

required if cable retracts too rapidly.

For best results, clear plant residue from probe insertion area.

5-5

Page 43

OM17-P4000VIS-NIR

Figure 10

Figure 11

Figure 12

Field Operations

Soil Coring

Once you have competed probing, remove NIR/EC force probe as outlined in Section 6.

- Install drive coupler to rotating head by means of drive retainer (Figure 10)

- Install PETG liner onto cutting shoe and thread into sampling tube (Figure 11)

- Install sampling tube into drive coupler and push into soil.

Use slow and steady insertion speed and minimal

rotation to push core sampler into the soil. A brief

rotation at bottom of stroke will snap off the core in

tight clay, giving you a fuller core as you retract.

(Figure 12) Excessive rotation may affect the

condition of your cores.

5-6

Page 44

OM17-P4000VIS-NIR

Figure 13

Figure 14 Figure 15

Remove sampler tube and remove cutting shoe from sampling tube by tapping and

rotating, or by use of wrench (provided). (Figure 13)

Cap the lower end of core with black vinyl cap, and the top with red. (Figures 14-15)

5-7

Page 45

OM17-P4000VIS-NIR

Field Operations

Probe Rotation Option

An optional accessory for the P4000 is the Probe Inverter Option. This allows the

operator to quickly rotate the NIR/EC force probe upwards to allow access to the coring

tools without removal of the probe itself.

Below Figure 16 shows the NIR/EC force probe rotated down. To rotate upwards first

pull the quick latch as shown in Figure 16

Next rotate the probe to the up position as shown in Figure 17

Figure 16 Figure 17

5-8

Page 46

OM17-P4000VIS-NIR

Once in the up position (Figure 18) ensure the quick latch is locked as shown in Figure

19. If the latch is not locked the probe may rotate round and cause personal injury.

Figure 18 Figure 19

5-9

Page 47

OM17-P4000VIS-NIR

Figure 20

Figure 21

Field Operations

Optional Anchoring System

In some field conditions it may be necessary to drive soil anchors into the soil to obtain

adequate depth with probe or core sampler. If this is the case, you will need PN 40209

Anchoring Package.

Installation and Removal

- Retract probe until is in the most forward position.

- Side shift to the far right and lower foot.

- Place anchor in center of foot opening and lower probe drive until hex enters hex

drive on probe. (Figure 20)

- Drive in slowly using Probe and Rotation controls. Apply adequate force to push

as you rotate. If you rotate too rapidly, the anchor will simply auger a hole, and

will not anchor properly --- Drive in until all flighting is below ground level and

probe is at bottom of stroke.

- Raise foot, side shift to far left, and repeat this process. (Figure 21)

5-10

Page 48

1. Extend platform out to full extension

2. Attached chain binders on each side of probe

3. Slip anchor plates over anchors and bind down each side (figure 22)

OM17-P4000VIS-NIR

Figure 22

Anchoring will limit your side travel somewhat, but you should still be able to take

multiple cores with the anchors installed.

- Do not use extension control while anchors are connected

- Remove the anchors in reverse sequence.

- If anchors have shifted during use and you are unable to slide the hex head of

the anchor back into the hex drive – use the foot to gently nudge the anchor back

into re-alignment.

Note: Be careful when lowering the probe with the instrument cases in

place. Remove left hand anchor first – otherwise you might push the head

of the anchor into the instrument mount when lowering probe to remove

RH anchor.

5-11

Page 49

OM17-P4000VIS-NIR

Figure 23 P & T Hoses

Figure 24

Field Operations

P4000T Removal and Tractor installation

The P4000 is designed to work equally well on a tractor, or as a skid mount unit.

Removing probe from skid –

- Install three point stabilizer stands into probe and temporarily lock in mid position

with ¾” pinch bolt.

- Extend and unfold the probe.

- Lower foot to ground level.

- Remove fold cylinder pin, and carefully retract fold cylinder until it is fully

retracted. You may have to gently move fold control valve back and forth to

relieve pressure on pin for removal.(Figure 23)

- Carefully remove lower link pins and lower probe down by retracting foot cylinder

- Lower stabilizer stands and lock with ¾” bolt

- Retract probe platform and shut of engine. (Figure 23)

- Disconnect wiring and 4 hoses on bottom of console (Figure 24)

- Disconnect main Pressure and Tank hose from platform (Figure 25)

5-12

Page 50

OM17-P4000VIS-NIR

Figure 25

Fold and

Extend hoses

Disconnect

wiring

Figure 26

Stabilizer

link bushing

Installing on Tractor –

- All bushings and pins are provided for Category I and II three-point hitches.

- Connect lower links – make sure you include the stabilizer link bushings(Figure

26)

- Connect top link

- Raise three point to desired height and level with top link

- Install lower stabilizer mount on drawbar and tighten 5/8” bolts

- Connect LH and RH stabilizer to upper and lower points, adjust, and lock with

jam nut.

- Connect hydraulic hoses noting P and T

- Retract stabilizer stands and engage hydraulics -- locking valve into detent with

tarp strap or other device. Make sure that flow is correct or controls will be

backward.

5-13

Page 51

OM17-P4000VIS-NIR

Figure 1

Section 6

Maintenance and Lubrication

Proper maintenance and lubrication of the Veris P4000G will allow you to collect high

quality NIRS and EC data, and greatly extend the useful life of the unit. Veris

Technologies strongly suggests that you follow the following guidelines:

MAINTENANCE: Storage of Spectrophotometer

Spectrometer and Auxiliary cases are water resistant; store NIRS system indoors or

under roof. Water damage to spectrometers and electronic components is not covered

by warranty.

MAINTENANCE: Electrical Continuity and Isolation

It is advisable to perform this test on a routine basis (weekly or every 20-25 hours of

data collection) to ensure you are obtaining reliable data.

1) Probe electrode isolation – Check isolation of the dipole to the point with a

Digital Multi Meter if the coulter electrode is properly isolated, a reading of

12K ohm should be obtained.

6-1

Page 52

OM17-P4000VIS-NIR

Test Load

-1

3

LOG

Figure 3

Instrument Signal Testing – The Veris Auxiliary Instrument is shipped with an

Instrument Test Load (Part No. 10447) that will enable you to quickly check the

instrument to ensure that it is functioning properly. To perform this test, do the following:

1) Disconnect the signal cable from the amp pin (signal) terminal on the auxiliary

case.

2) Connect the test load to the signal terminal.

3) Switch on the unit and perform System Check and Data Acquisition.

4) The display should show: (See Figure 30)

Shallow 3 (approx.)

Deep -1 (Not used in Probe Mode)

5) If the readings vary significantly (more than one whole number) contact Veris

service department.

6) Once the test is complete, remove the test load and reinstall the implement

signal cable.

Figure 2

6-2

Page 53

OM17-P4000VIS-NIR

Figure 4

Figure 5

Maintenance: NIRS Wear-plate Replacement

Step 1:

With the probe out of the ground remove the wear-plate using a 3/32 hex wench.

Step 2:

Insert new O-ring into new shank wear-plate

Step 3:

Make sure both the surface of the wear plate and the surface of the probe are clean

before placing the new probe wear plate onto probe and securing with four new bolts.

Step 4:

Put the wear-plate back on and secure using a 3/32 hex wrench

6-3

Page 54

OM17-P4000VIS-NIR

EC Point Replacement Procedure

While replacing the EC point take extra care to not damage the fiber optic cable.

Figure 6

Remove window sheath by loosening the four hex screws.

Figure 7 Figure 8

Clean hex screw with some pointed tool. Then loosen the hex screw on the side of the

housing to release the reflection module.

6-4

Page 55

OM17-P4000VIS-NIR

Figure 9

Remove the bolts on the front cover to gain access the terminal block.

Figure 10

Now disconnect the EC Point wires from the terminal block. Use an ohm meter to check

witch wires to disconnect. The dipole on the EC point will be red 22ga wire. The case

of the EC point will be black 22ga wire.

6-5

Page 56

OM17-P4000VIS-NIR

Figure 11

Using two wrenches unscrew the EC point from the probe housing.

Figure 12

Once the EC point is unscrewed pull the wires out.

6-6

Page 57

OM17-P4000VIS-NIR

Figure 13

New replacement EC point.

Figure 14

Feed the wires of the new EC point down the probe. Using two wrenches tighten down

the EC point to the probe housing.

6-7

Page 58

OM17-P4000VIS-NIR

Figure 15

Make sure the o-ring is pressed in the groove all the way before installing the window

sheath. Now secure the window sheath using the four hex screws. Tighten down the

hex screw on the side of the window housing. Move up to the top and connect the EC

point wires to the terminal block. Be careful with the fiber optic cable when putting the

front cover back on. It can be pinched between cover and probe. Once cover is on

secure with the bolts.

6-8

Page 59

OM17-P4000VIS-NIR

Cables

Fibers

Loom

Clip

Mounting

Pin

Probe Removal

This procedure is needed when removing the probe for bench top use, road transport,

or for soil coring.

Step 1:

Disconnect the fibers from the spectrometer case, and the cables to the auxiliary case.

Step 2:

Remove loom from clip.

Step 3:

Figure 16

Step 3:

Firmly grasp probe, and remove the mounting pin holding the probe on the platform.

6-9

Page 60

OM17-P4000VIS-NIR

Auxiliary case

Spectrometer case

Mounting plates

Latches

Case Removal and Installation

When the spectrometer and auxiliary cases need to be removed for storage, repair, or

bench top use follow these instructions.

First disconnect all wires and the optical fibers connected to the auxiliary and

spectrometer cases.

Each case is secured with two latches, and case and latch assembly can be removed

as a unit.

Figure 17

Figure 18

6-10

Page 61

OM17-P4000VIS-NIR

Section 7

Troubleshooting

Troubleshooting EC module

Data missing from display reading –

1. Unit must be in contact with soil to record data points

2. Check GPS and DGPS signal; Veris instrument is programmed to eliminate all nonDGPS geo-referenced points.

3. Shut power off and restart

4. Check electrical continuity

5. Check input voltage, 12 v minimum required

Troubleshooting NIRS

No spectrum is present on graph or spectrum is not updating in Acquisition

1. Ensure USB cables are tightly connected

2. Shut down software and cases and restart system

3. Check port settings

4. Open each spectrometer individually in the manufactures software(procedure #7 & 8)

MS Windows brings up an new hardware found wizard when I plug in my cases

1. Select ‘Install software automatically’ and allow hardware wizard to configure device

Ports won’t save in Veris Spectrophotometer Software

1. Make sure the Exit button is being used to close out of the software, not the X in the

upper right hand corner.

No GPS data is coming in during acquisition

1. Check to ensure nothing is obstructing GPS signal (ex. buildings)

2. Is the GPS plugged into the correct port? (second one from the right on auxiliary

case)

3. Check to make sure GPS adaptor is in place

4. Follow the steps of the GPS troubleshooting guide to further diagnose problem

System check only allows one External Reference to be taken

1. Check to ensure the Ref Check light is green

2. Check the shutter movement distance (auxiliary indicator #17, should be 5.21 +/- .05

3. Check for green lights on the temperature and humidity indicators

Transform does not pass during System Check

1. Check to ensure the correct ER was placed under the shank and the correct ER

button was pressed during the system check.

2. Make sure instrument had a 20 minute warm up period

3. Make sure ER was pressed firmly in place, so little ambient light entered the shank

4. Run System Check again – run all four external references

7-1

Page 62

OM17-P4000VIS-NIR

Computer crashes or has been hard reset while acquiring data

1. Once computer has restarted open Veris Spectrophotometer Software again.

2. Step through software till clustering has been complete. The cluster program will

generate a map, which will let the user know the last point where data was stored.

Using the map as a guide open the acquisition and begin to store data again. The

acquisition will append the new data to the previous data stored.

Reference check will not pass after several tries or steps are out of range

1. Close out of software

2. Shut down power/ restart power to cases

3. Check the port settings

4. Restart software and run dark/reference again

5. Complete procedure #9,on shutter movement.

Auxiliary data not updating or ports not setting up correctly

1. Shut down power, and restart cases

2. Ensure USB cables are secured tightly

3. Follow the steps outlined in procedure #10, to ensure data is present on the ports.

7-2

Page 63

OM17-P4000VIS-NIR

Problem: No response from Hamamatsu Spectrometer (1100-2200nm)

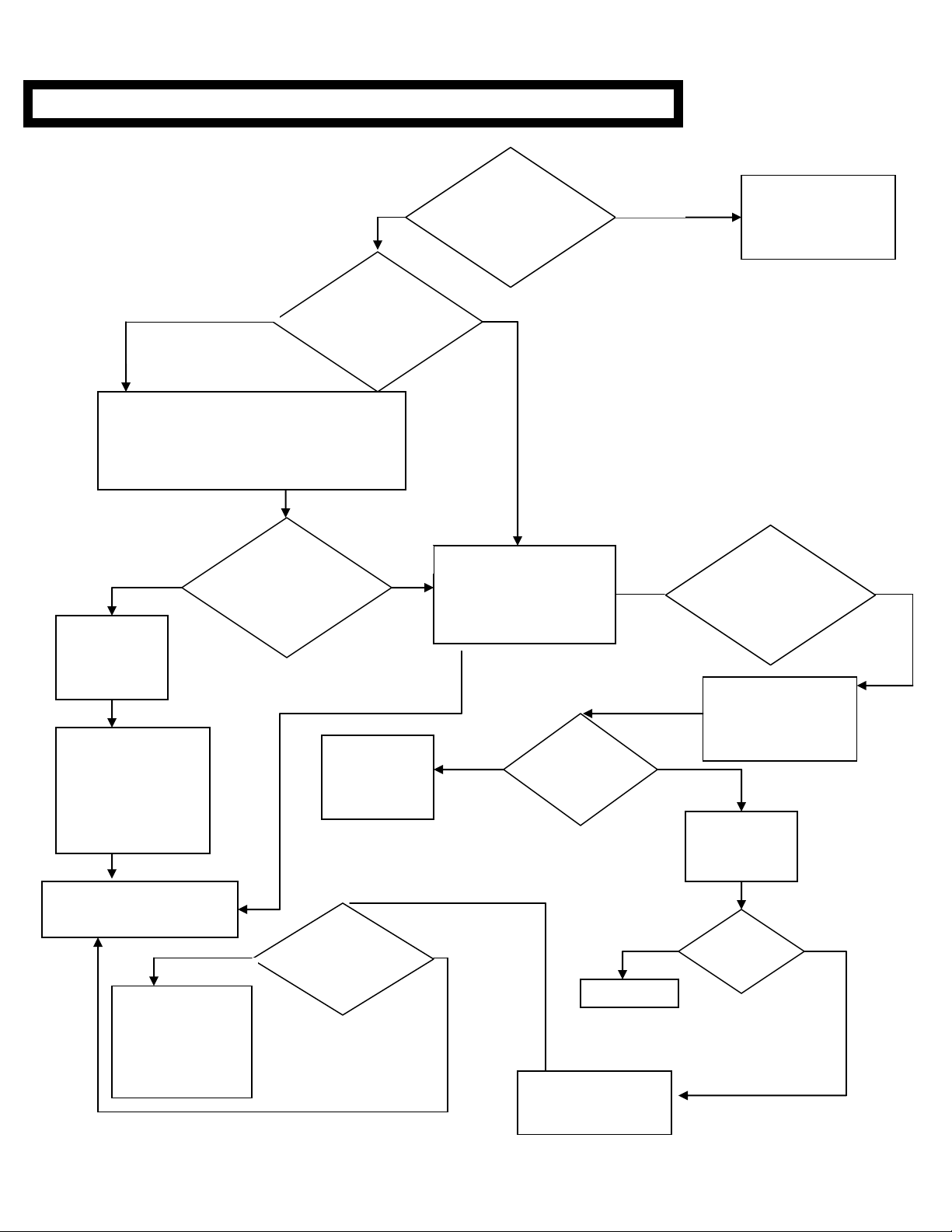

Does

Hamamatsu

software open?

(Proc. #7)

NO

Hamamatsu is

operating correctly.

Restart Veris

Spectrophotometer

Software and try again.

Does

Hamamatsu

report error

message?

Error stating temperature out of range

Error stating cannot find/open device

Check the device manager for Hamamatsu

hardware. To do so

Right click on the My Computer icon on the

desktop. Go to properties, click on the hardware

tab, then on the device manager button. Check to

see if Hamamatsu is listed in the alphabetical list.

Is Hamamatsu

present in

device

manager?

Shut down power to cases,

restart computer with cases

shut down. Once computer

comes back up, turn on

power and retry Hamamatsu

software.

YES

YES

NO

Does software

report

temperature still

out of range?

Open spectrometer

port in HyperTerminal

(Procedure #10) and

check the last digit of

string

YES

Check to

ensure case is

powered, USB

cables securely

connected.

Unplug and replug

USB cables. Wait to

see if a windows

installer comes up

asking to install

spectrometer software.

Afterwards reopen

software.

Last digit of

string = 1?

YES

Check fuse on

Hamamatsu

power supply

(Proc. #11)

Is fuse

good?

NO

Replace fuse

NO

Spectrometer

case is out of

temperature

range.

Check voltage to

Hamamatsu. (Proc.

#12)

Reinstall Hamamatsu software

using disk provided.

5V on

Hamamatsu?

Check for 12V at

power source (ex.

power supply,

battery), check

power connections.

Contact Veris

service department.

NO

YES

YES

Error stating temperature out of range

Software failed to open

7-3

Page 64

OM17-P4000VIS-NIR

GPS port open in

HyperTerminal

Check HyperTerminal port

settings and ensure port is

present in the device

manager (see port settings)

Ensure GPS adaptor is

in place and GPS is

plugged into correct

spot on Auxiliary Case

(see system overview).

Check Veris

Spectrophotometer Software

port settings

Reinstall Edgeport drivers

Power down cases and

restart computer, once

computer is back up turn

power on to cases and

check again

Check GPS quality factor. (see

program modifications under

acq_settings.txt)

Is data

streaming in

HyperTerminal

? (Proc. #9)

NO

YES

Is port present

in device

manager?

(Proc. #3)

YES

NO

Is USB cable

plugged in

securely?

Plug USB

cable in

NO

Is the power

turned on to

the auxiliary

case?

Turn on power

to case

NO

YES

YES

Troubleshooting GPS

If GPS fails to come in it could be for a variety of reasons. The easiest way to isolate

the problem is to open the GPS port in HyperTerminal (see troubleshooting with

HyperTerminal).

7-4

Page 65

OM17-P4000VIS-NIR

How to check Ocean Optics spectrometer

1) Click on start Programs Ocean Optics OOIBase32 Start OOIBase32

software

2) Check graph it see if spectrum is present (see figure below). The spectrum

should change as different objects are placed in front of the window on the

probe.

Figure 1

3) If there is no spectrum present or graph does not update as objects are placed

beneath the shank. Then the spectrometer needs to be configured. To

configure click on spectrometer configure A/D Interface tab

7-5

Page 66

OM17-P4000VIS-NIR

Figure 2

4) Under Spectrometer Type select S4000. For the A/D Converter Type select

USB4000. The USB Serial Number will have one serial number present, which is

unique to each spectrometer, select the available serial number.

5) Click OK to save the settings and return to the main screen. A spectrum should

now be present.

6) Close OOIBase32 software, restart computer, and open Veris

Spectrophotometer Software to begin mapping again.

7-6

Page 67

To open Hamamatsu spectrometer individually

Open spectrometer icon

1) Click on Start Programs HamamatsuMinispectrometer

EvaluationSoftware SpecEvaluation

2) Click on open spectrometer

Figure 3

3) Click on Open under Select Spectrometer

OM17-P4000VIS-NIR

Figure 4

4) Click on start and check to see if spectrum graph changes as different objects

are placed adjacent the probe window. This ensures the Hamamatsu

spectrometer is working properly. If this is not the case then close Hamamatsu

software, shut down power, restart computer and try Hamamatsu software again.

7-7

Page 68

Figure 5

Start

OM17-P4000VIS-NIR

7-8

Page 69

OM17-P4000VIS-NIR

Figure 7

Troubleshooting NIRS with HyperTerminal

If auxiliary data fails to come in properly, then the port and device can be verified

outside of the software by utilizing the HyperTerminal. If the port works properly here

then the data should be present in the Veris Operating software. If the ports fail to open

or does not have any data present then check the physical connections to the auxiliary

box, unplug the USB cords, shut down the system, and restart the computer, then check

for the auxiliary data again.

How to open HyperTerminal

o On MS Windows 2000 or XP machine

o Start Programs Accessories Communications HyperTerminal

o Enter name of connection ex. com3@9600

o Click OK

Figure 6

o Select the correct com port from the connect using option.

o Click OK

7-9

Page 70

OM17-P4000VIS-NIR

Enter com port properties for your device. See the Port Properties section for the

standard settings.

Figure 8

o Click OK

o HyperTerminal session now open and data should be present. See Port

Definitions for example HyperTerminal data.

.

Port Properties

o Temperature Port

Bits per second: 9600

Data bits: 8

Parity: None

Stop bits: 1

Flow control: None

o GPS

Bits per second: 4800

Data bits: 8

Parity: None

Stop bits: 1

Flow control: None

o Control Port

Bits per second: 9600

Data bits: 8

Parity: None

Stop bits: 1

Flow control: None

7-10

Page 71

o Spectrometer Port

Bits per second: 9600

Data bits: 8

Parity: None

Stop bits: 1

Flow control: none

Port Definitions

o Temperature Port – Reads in soil temperature.

o GPS Port – Reads in GPS coordinates.

OM17-P4000VIS-NIR

Example of temperature port connected in HyperTerminal

Example of GPS port connected in HyperTerminal.

o Control Port – Reads in EC, Auxiliary case temperature and humidity, and

shutter steps. After opening this port if no data is present type S for shank

mode or P for probe mode. The letter after E represents the shutter state.

In the case below the shutter is in neutral or rest. If the case reads R the

shutter is in reference or if there is a D the shutter is in dark. To manually

move the shutter type N for neutral, then R for reference, then D for dark.

Example of Control Port connected in HyperTerminal.

How to read control port data strings

Shank Mode

E shutter position, current, voltage deep, voltage shallow *

T temperature, humidity, shutter steps, 0, 0*

7-11

Page 72

OM17-P4000VIS-NIR

o Spectrometer Port – Reads in Spectrometer temperature and humidity,

side box temperature, cooler state, and spectrometer cooler state.

7-12

Page 73

OM17-P4000VIS-NIR

Use a flat head screwdriver to

remove fuse

Fuse replacement

There are two fuses inside the spectrometer case and one inside the auxiliary case. To

locate and replace these fuses, follow these steps. First remove the cases see the

following

Spectrometer case fuses

The first fuse is on the side control box. This is a four-amp fuse, which protects the

power to the Hamamatsu spectrometer as well as the internal microcontroller. To locate

this fuse take off the six screws securing the mounting plate on the side of the box.

Figure 9

Internal wiring of the spectrometer case control box

Figure 10

Fuse and fuse holder once removed

The other fuse is located inside the spectrometer case underneath the mounting shelf.

This fuse protects the power to the Edgeport hub, which sends data out through the

USB port.

7-13

Page 74

OM17-P4000VIS-NIR

Edgeport hub

Ocean Optics USB4000

spectrometer

Silica gel packet

used to remove

moisture in the air.

Note: If humidity in

spectrometer case

is above 90% this

packet needs to be

replaced.

Fiber optic cable

USB output cable

Figure 11

Inside view of spectrometer case mounting shelf

To reach the fuse for the Edgeport first disconnect the fiber optic cable to the USB4000,

then disconnect the USB output cable.

Figures 12 and 13

Once the fiber optic cable and the USB output cable have been disconnected, the shelf

can be tilted up and the case will be exposed.

7-14

Page 75

Figure 14

Edgeport hub

power board, also

the temperature

and humidity

readings are

monitored from

this board

Fuse can be removed using

screwdriver. Replace only with

3-amp fuse.

Spectrometer case mounting shelf tilted back.

OM17-P4000VIS-NIR

Figure 15

7-15

Page 76

OM17-P4000VIS-NIR

Fuse holder. Replace only with a

4-amp fuse.

Connect negative lead from

voltmeter here (brown wire)

Connect the positive

lead from the voltmeter

here (white wire)

Voltage should read 5V, as

long as spectrometer case is

within temperature range.

The fuse for the auxiliary case protects the voltage for the electrical conductivity board

and the lamp. To replace the fuse open the case and locate the black fuse holder

Figure 16

Checking Spectrometer Input Voltage and Hamamatsu Voltage

Figure 17

Internal wiring of auxiliary case

7-16

Page 77

OM17-P4000VIS-NIR

Number

Name

Description

0

UTC

Universal Time Coordinated hhmmss.cc

hh = hours, mm = minutes, ss = seconds,

cc = hundredths of seconds

1

Long

GPS Longitude

2

Lat

GPS Latitude

3

Alt

GPS Altitude

4

Speed

Speed (Km/h)

5 I Current used to calculate EC data

6

Vsh

Voltage shallow

7

Vdp

Voltage deep

8

Soil temp

Soil temp

9

X/force

Spare for Shank mode or force for probe mode

10 Y Spare

11

Z/depth

Spare for Shank mode or depth for probe mode

12

Spec temp

Spectrometer case temperature

13

Side temp

Side control box on spectrometer temperature

14

Spec hum.

Spectrometer case humidity

15

Aux temp

Auxiliary temperature

16

Aux hum.

Auxiliary humidity

17

Steps

Steps shank moves during dark/reference check

All temperatures are

in degrees C. If no

data is present for

an auxiliary data

item a –1.50 will be

output.

Section 8

Glossary

Spectrophotometer – A complete system for making spectral measurements. The

system includes a light source, means for collecting light that has interacted with the

material under test, and a spectrometer to measure the collected light.

Spectrometer – Instrument to measure the quantity of light over a spectrum of

wavelengths. The spectrometer is the "measurement engine" of the spectrophotometer.

Auxiliary Data (in system check and acquisition)

Field Auxiliary output definitions

EC_Sh – Electrical conductivity shallow.

EC_Dp - Electrical conductivity deep.

Temp – Soil temperature

Spec_T – Spectrometer case temperature

Ctrl_T – Control box temperature (this is the metal box on the side of the spectrometer

case)

Spec_H – Spectrometer case humidity

Aux_Te – Auxiliary case temperature

Aux_Hu – Auxiliary case humidity

8-1

Page 78

OM17-P4000VIS-NIR

Specifications

Max ambient temperature to operate system: 110 degrees F

Max spectrometer case temperature: 30 degrees C

Max spectrometer case humidity: 90% RH

If spectrometer case humidity reaches this point, the silica packet inside

spectrometer case needs to be replaced.

Max side case (control box) temperature: 65 degrees C

Max aux case temperature: 65 degrees C

Max aux case humidity: 90% RH

Field Files Description

acquisition_samples_*.txt Transformed samples in absorbance

taken during acquisition.

Figure 1

The first column represents the sample number, except for the first value of –4, which

indicates that the row is the spectrometer wavelength values. There will be a total of

384 wavelength values, which also represents the number of columns in each sample

file. In this example a total of three samples were taken, for each wavelength there is

an absorbance value, so for sample 1 at wavelength 348.84732 the absorbance was

.8793300.

master_veris_standards.txt External reference data in reflectance

standardized against Avian grayscales.

(provided by Veris)

external_reference_*.txt Untransformed external reference data

in reflectance taken during system

check.

xform_*.txt Transform created by comparing

master_veris_standards and latest

xternal_reference files.

raw_spectra_*.bytestream Field data taken in compact bytestream

format. Note: Each time system check

is ran a new .bytestream file and

xform.txt file will be created. Once

system check has been completed

8-2

Page 79

OM17-P4000VIS-NIR

Figure 3

successfully, then the .bytestream

file will automatically be appended to

if acquisition is stopped and started

again later.

field spectra.txt Auxiliary sensor data and field data in

absorbance extracted and transformed.

Figure 2

The first 17 columns of the field spectra file represent the auxiliary sensor data (see

glossary for definition), each is labeled by a header, following the header is the

wavelength values. The next 384 columns are the absorbance data at each wavelength.

A value of –1 represents no data was present at that time.

Probe field spectra.txt This is output after the extraction

is ran and has all the hole

data interpolated to the same

depth increments.

cleaned field spectra.txt Filtered field spectra can be used

for applying calibration.

loadings.txt Principal components loadings.

PC_scores.txt Principal component scores.

interp_PC scores.txt Interpolated PC scores.

proposed_locations.txt Proposed sample locations

based on clustering.

actual_locations.txt Actual locations stored during

sampling program.

spectra@locations.txt Interpolated spectra and auxiliary

data at actual locations.

8-3

Page 80

OM17-P4000VIS-NIR

The P_Sample, P_Long, P_Lat, P_Depth are the actual sample number, longitude,

latitude, and depth. The # Spec refers to the number of spectra found near each sample

location. These are the locations that were selected in the sampling program. The