Page 1

VH7200 Humidistat Series

For Humidification & Dehumidification Control

For Commercial HVAC Applications

(Issue Date September 29, 2008 – 028-0208 R4)

Product overview

The VH7200 humidity controller family is specifically designed for control of

humidification and dehumidification equipment such as steam header direct

injection, desiccant wheel, or stand alone humidification / dehumidification

equipment. The product features a complete embedded humidity control

solution with an intuitive backlit LCD display that walks the installer through the

configuration steps, making the process extremely simple. Accurate relative

humidity control is achieved due to the product’s unique PI time proportional

control algorithm, which virtually eliminates humidity offset associated with

traditional, differential-based humidity controllers.

All models contain a binary input, which can be set by the user to monitor an

electrode humidifier canister service status or may be used as a general

purpose service indicator. Models are available which contain more advanced

features such as discharge humidity proportional high limit, and indoor humidity

setpoint reset based upon outdoor air temperature to conserve energy and

eliminate condensation on windows and structure.

The additional following documents are available at:

• Information on the BACnet models (VH72xxX1000B), is available on document ITG-VH7200-BAC-Exx

www.viconics.com

Models available

Model with Outdoor reset & Proportional High Limit VH7270K1000 (X)

Application Model Number

Humidification

On/Off 24 Vac

Fig.1 VH7200 series humidistats

Dehumidification

Output(s)

0-10 Vdc &

On-Off 24 Vac

Output

Model with Outdoor reset & Proportional High Limit VH7270F1000 (X) 0-10 Vdc On-Off 24 Vac

Models with outdoor reset only VH7200A1000 (X) On/Off 24 Vac On-Off 24 Vac

* NEW * Duct Mount Model with Outdoor reset &

Proportional High Limit

(X) model number represents available communication options: X=none for Stand-alone and X=B for BACnet MS-TP.

VH7270D1000 (X) 0-10 Vdc On-Off 24 Vac

Features and benefits

Features Benefits

• Embedded humidification and dehumidification

sequences

⇒ Simplifies installation and reduce installation

costs

• Embedded internal RH sensor ⇒ Eliminates components

• Proportional high limit override

• (VH7270 Models Only)

• Humidity setpoint reset based on outdoor

temperature

⇒ Prevents costly damage due supply humidity

condensation

⇒ Saves energy and prevents window

condensation in colder climates

• Sensor failure protection ⇒ Prevents water damage

• PI time proportioning algorithm ⇒ Increased comfort, accuracy, and energy savings

• Binary input ⇒ Adds functionality (Trigger service alarms )

• Unique configuration menu routine ⇒ Minimizes parameter tampering

• Lockable keypad ⇒ Tamper proof, no need for humidistat guards

• EEPROM memory ⇒ No loss configuration parameters

• Optional remote humidity sensors ⇒ Increase flexibility and functionality

028-0208 R4_LIT-VH72x0-E14.doc

www.viconics.com / sales@viconics.com

Page 2

Features overview

• Internal RH sensor and optional remote RH input with embedded humidification and dehumidification sequence

of operation.

• Humidity set point reset based upon outdoor temperature sensing for added flexibility.

• Proportional high limit input to prevent over-humidification due to supply humidity condensation.

• Lockable keypads for tamper proofing. No need for extra humidistat guard.

• Programmable binary input for added flexibility. The input can be programmed as the following:

- None: No function will be associated with the input

- Service: a backlit flashing Service alarm will be displayed on the humidistat LCD screen when the input is energized. It can be tied in to the AC unit control card, which provides an alarm in case of malfunction.

- Canister: a backlit flashing Canister alarm will be displayed on the humidistat LCD screen when the input is energized. It can be tied to a Dry contact output supplied by others.

Installation

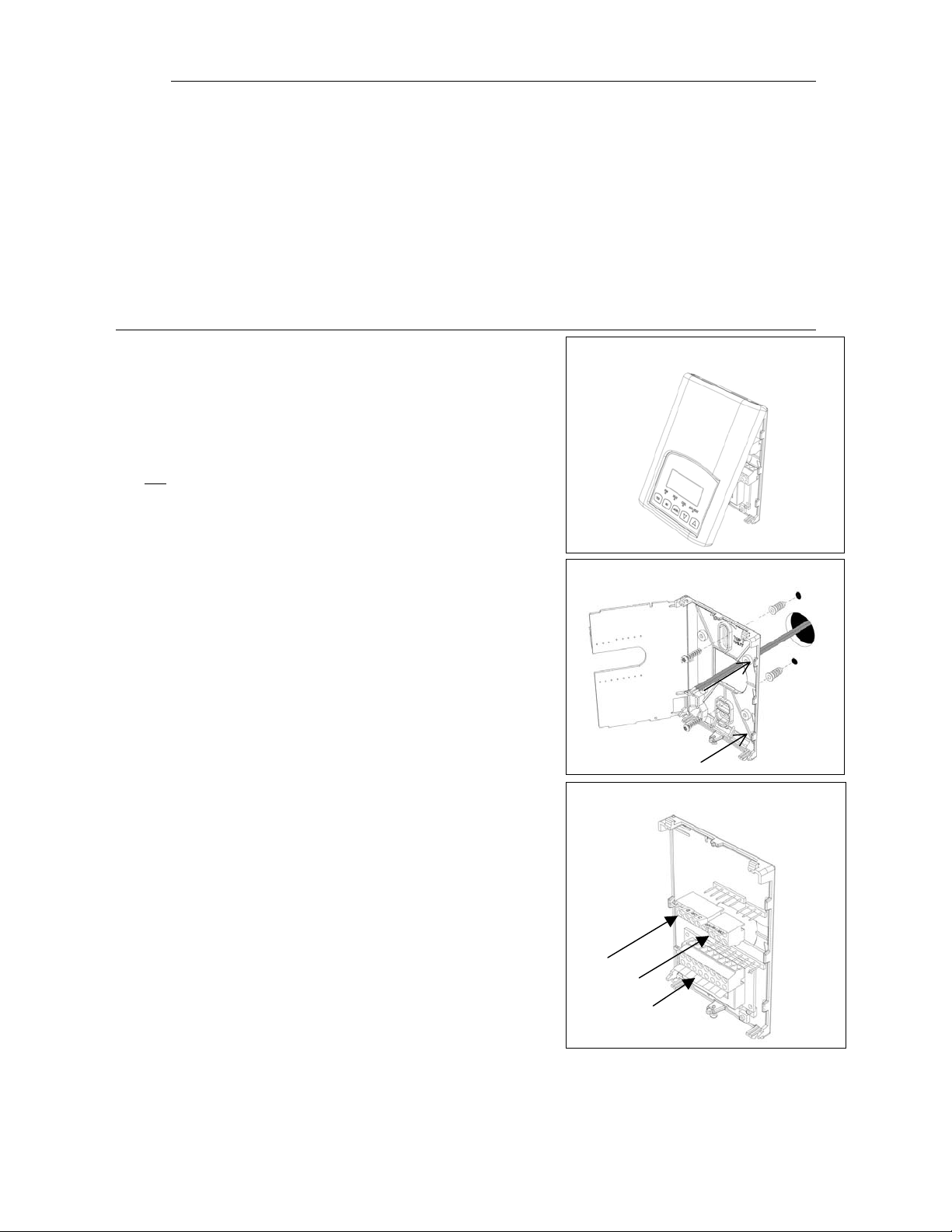

• Remove security screw on the bottom of humidistat cover.

• Open up by pulling on the bottom side of humidistat.

• Remove Assembly and remove wiring terminals from sticker.

(Fig. 2)

A) Location:

1- Should

not be installed on an outside wall.

2- Must be installed away from any heat source.

3- Should not be installed near an air discharge grill.

4- Should not be affected by direct sun radiation.

Fig.2

5- Nothing must restrain vertical air circulation to the

humidistat.

B) Installation:

1- Swing open the humidistat PCB to the left by pressing the

PCB locking tabs. (Fig. 3)

2- Pull out cables 6” out of the wall.

3- Wall surface must be flat and clean.

4- Insert cable in the central hole of the base.

5- Align the base and mark the location of the two mounting

holes on the wall. Install proper side of base up.

Fig.3

6- Install anchors in the wall.

7- Insert screws in mounting holes on each side of the base.

(Fig. 3)

8- Gently swing back the circuit board on the base and push

on it until the tabs lock it.

10- Strip each wire 1/4 inch.

11- Insert each wire according to wiring diagram.

13- Gently push back into hole excess wring (Fig. 4)

14- Re-Install wiring terminals in correct location. (Fig. 4)

15- Reinstall the cover (top side first) and gently push back

extra wire length into the hole in the wall.

16- Install security screw.

Fig.4

For VH7270D1000 duct-mount model only:

1- Make 1” diameter hole in duct wall

2- Insert the duct sensor and fix the electrical box to the

duct wall in the vertical position (respect airflow

direction).

3- Install the humidistat to the electrical box using the

supplied screws (2).

4- Follow steps 1-16 above.

2

Page 3

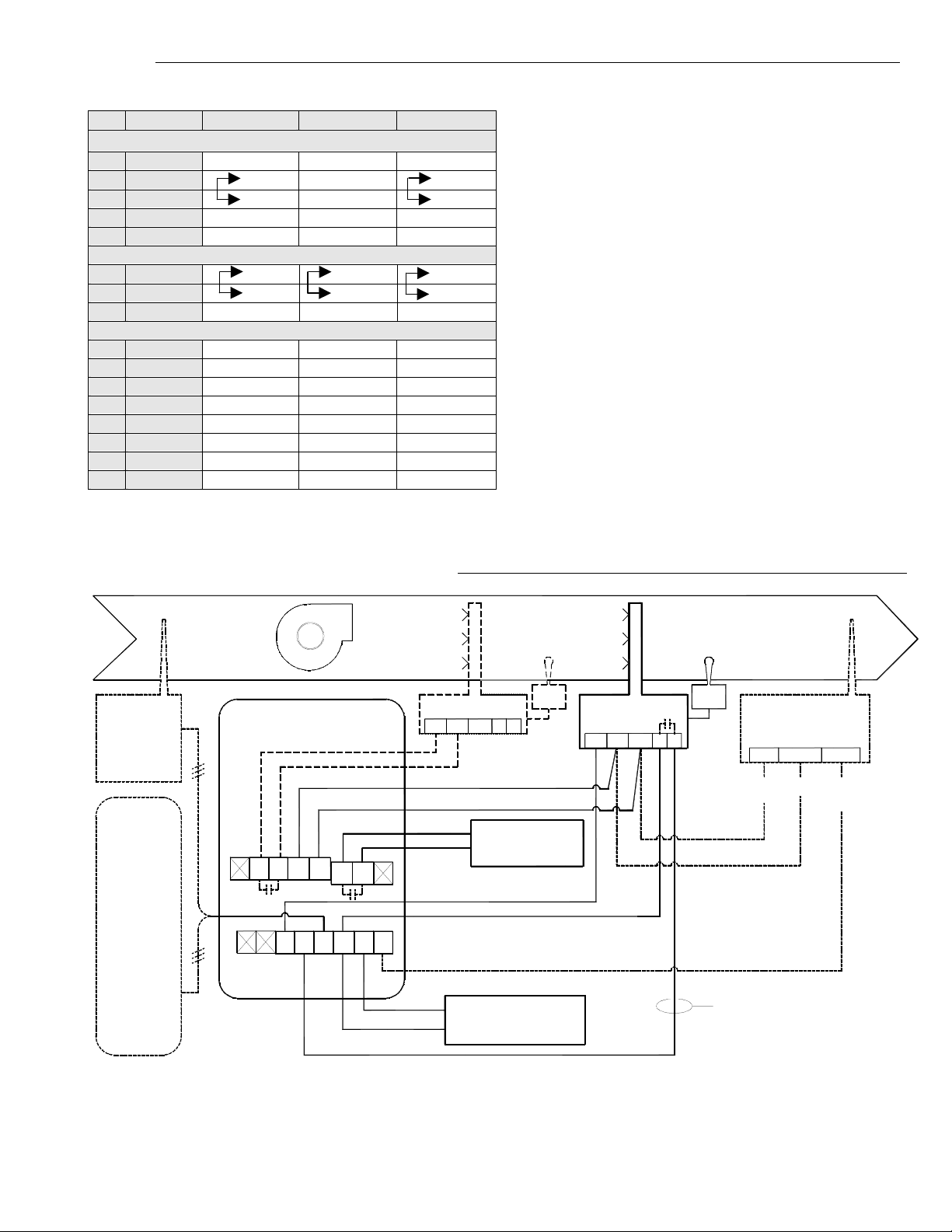

Wiring

3

Terminal identification & screw terminal arrangement

Part Number VH7270K VH7270D/F VH7200A

Top left terminal block

1 Not used Not used Not used

2 HUM

3 HUM

4 R

5 C

X

X

X X X

X X X

Not used

Not used

X

X

Top right terminal block

6 DEH

7 DEH

X X X

X X X

8 Not used Not used Not used

Bottom terminal block

9 Not used Not used Not used

10 Not used Not used Not used

11 HUM 0-10

12 DI1

13 HS

14 SCOM

15 OS

16 HL

X X

X X X

X X X

X X X

X X X

X X

Fig.5 : VH7200’s wiring terminals

Not used

Not used

Wiring notes:

Note 1:

Reference of the analog 0-10 Vdc control signal

is the common of the power supply of the

humidistat. (terminal C)

Note 2:

Electromechanical dry contact is to be used with

the binary input. Electronic triacs cannot be used

as mean of switching for the input. The switched

leg to the input for the input to activate is

terminal Scom

Note 3:

The transformer of the unit provides power to

the humidistat and any additional loads wired

to the humidistat.

Note 4:

Both the remote humidity sensors ( HS & HL

terminals ) use 0 to 10 Vdc type humidity

sensors.

Detailed wiring diagram for model VH7270K1000

R.A. S.A.

HumidificationOutput :

( On/Off ) or ( 0- 10 Vdc )

Refer to parameter:

"SeqOpera"

VH2030D1000

OPTIONAL

DUCT

MOUNTED

HUMIDITY

TRANSMITTER

VH2030W1000

OPTIONAL

WALL

MOUNTED

HUMIDITY

TRANSMITTER

Note:

Whenaremote

humidity

transmitter

is connected to

the VH7200,

it's internal

humidity

sensor is

au

tomatically

disabled.

VH7270K1000

HUMIDITY CONTROLLER

HUM

HUM

or

HUM

0-10

R C

DEH

DEH

Scom

HSDI1 OS

FLOW

(On/Off) HUMIDIFIER

H

H

Dry contact

Dry contact

HL

S202 00

0E1000 or S2000D10

OP

TIONAL OUTDOOR

TE R

MPERATURE SENSO

SWITCH

Dehumidification

air exchanger

and/or

(0-10 Vdc)

HUMIDIFIER

Com

0-10

24V

FLOW

SWITCH

XX

Binary Input "Di1" Set

for "SER VICE" alarm

VH2030D1000

HUMIDITY TRANSMITTER

(OPTIONALHIGH LIMIT)

24 Vac

COM. 0-10Vdc

K

C

A

L

B

E

D

E

G

R

N

A

R

O

Fig.6 : VH7270F1000 wiring diagram

Page 4

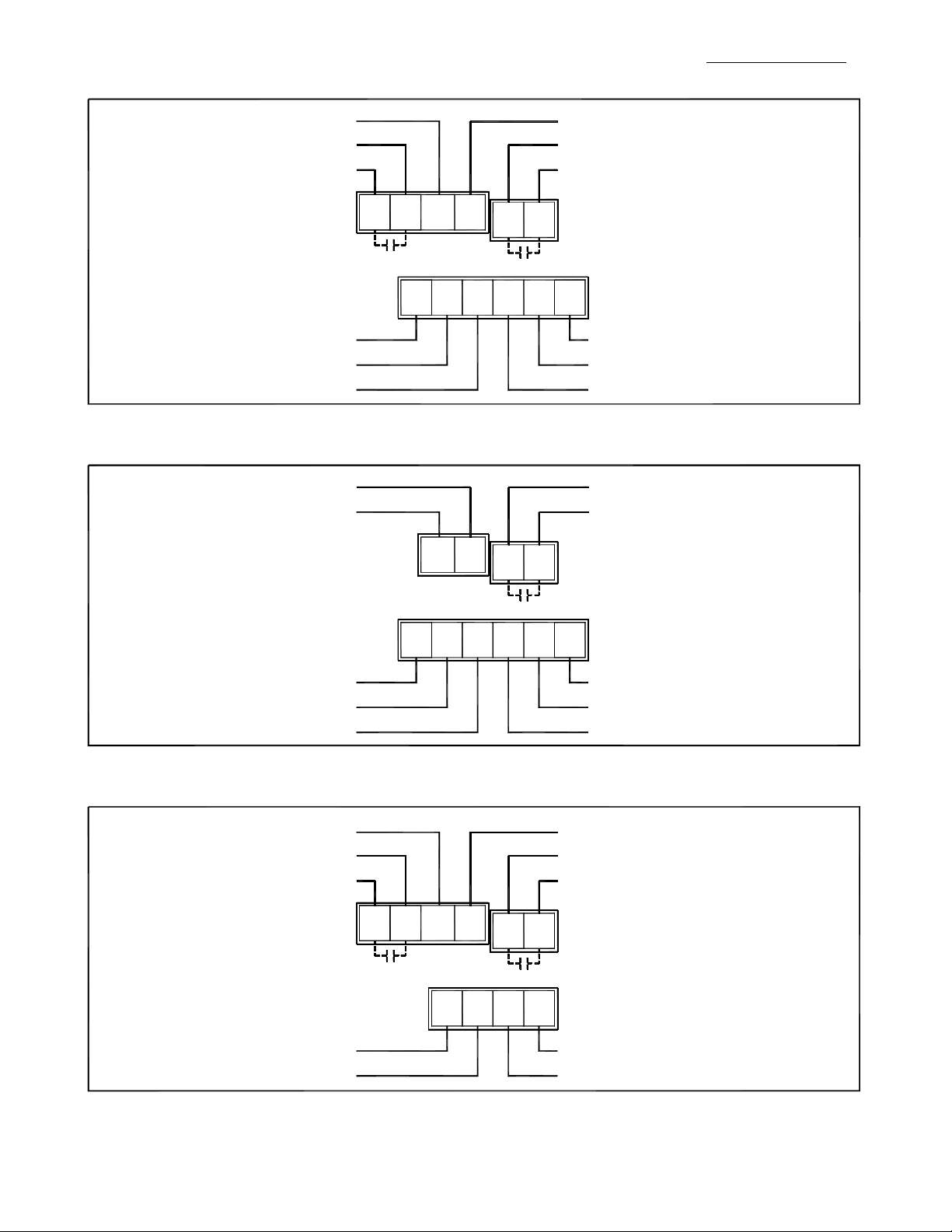

Specific wiring diagrams for all models VH7200A1000, VH7270F1000, VH7270K1000

4

24 VacHot

On/Off Humidification

On/Off Humidification

VH7270K1000 Universal

Analog 0-10 Vdc Humidification

Digital input, dry contact to "Scom"

Remote humidity sensor (opt.)

24 Vac Com.

24 VacHot

HUMRHUM

HUM

0-10

C

DI1 OSHS

CR

DEH

Scom

DEH

24 Vac Com.

On/Off Dehumidification

On/Off Dehumidification

DEH

HL

Supply Humidity High Limit Sensor (opt.)

Outside air temperaturesensor (opt.)

Sensor(s) andBI inputcommon

On/Off Dehumidification

On/Off Dehumidification

DEH

VH7270F1000 Analog

VH7270D1000 Analog

Analog 0-10 Vdc Humidification

Digital input, dry contact to "Scom"

Remote humidity sensor (opt.)

24 VacHot

On/Off Humidification

On/Off Humidification

VH7200A1000 On/Off

Digital input, dry contact to "Scom"

Optional remotehumidity sensor

HUM

0-10

HUMHUM

DI1

R C

DI1

HS

HS

Scom

OS

DEH DEH

Scom

OS

HL

Supply Humidity High Limit Sensor (opt.)

Outside air temperaturesensor (opt.)

Sensor(s) andBI inputcommon

24 Vac Com.

On/Off Dehumidification

On/Off Dehumidification

Outside air temperaturesensor (opt.)

Sensor(s) andBI input common

Page 5

g.9–

p

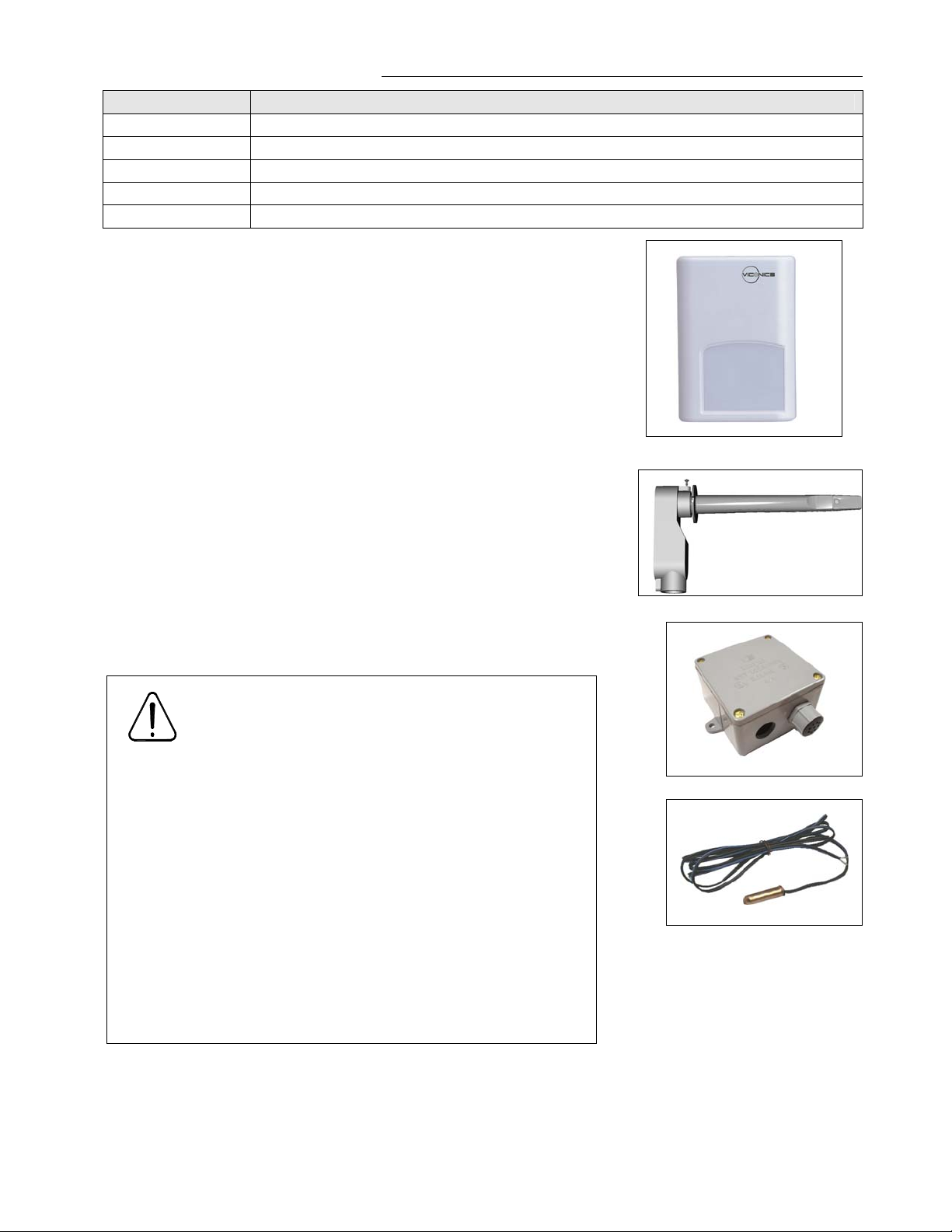

Remote humidity sensor accessories

Model number Description:

VH2020W1000

VH2020D10000

S2000D1000

S2020E1000

S1010E1000

VH2020W1000, remote wall mounted room humidity sensor.

(see Fig.8) (wiring diagram next page)

VH2020D1000, remote duct mounted humidity sensor c/w junction box.

(see Fig.9) (wiring diagram next page)

This sensor can be used for:

• Remote return air humidity sensing with the sensor mounted on the

return air duct.

• Supply air humidity sensor used as a high limit protection.

S2020E1000, commercial style outside air temperature sensor in a

NEMA 4 enclosure. (see Fig.10) (wiring diagram next page)

S1010E1000, residential style outside air temperature sensor, capsule

type. (see Fig.11) (wiring diagram next page)

• These sensors are used for the humidity setpoint reset function

based on outdoor temperature.

INSTALLATION NOTICE !

• If replacing an old humidistat, label the wires

• Electronic controls are static sensitive devices.

• Short circuit or wrong wiring may permanently

• Anti-short cycling can be set to 0 minutes for

•

Wall mounted humidity transmitter 2% R.H.

Duct mounted humidity sensor 2% R.H.

Duct mounted outside air temperature sensor

Outside air temperature sensor in a NEMA 4 enclosure

Outside air temperature sensor, capsule type ( ¼” dia., 1” long )

before removal of the old humidistat.

Discharge yourself properly before manipulation

and installing the humidistat.

damage the humidistat or the equipment.

equipment that posses their own anti cycling

timer. Do not use that value unless the

equipment is equipped with such internal timer.

Failure to do so can damage the equipment.

All VH7200 series humidistat are to be used only as

operating controls. Whenever a control failure could

lead to personal injury and/or loss of property, it

becomes the responsibility of

the user to add safety

devices and/or alarm system to protect against such

catastro

hic fa

ilures.

Fig.10 – VH2020D1000 / S2000D1000

VH2020W1000

Fi

Fig.11 – S2020E1000

Fig.12 – S1010E1000

5

Page 6

Wiring of humidity and temperature sensors

Wiring example of the High-Limit humidity sensor

powered by the same transformer as the VH7200 humidistat

VH7200 SER IES

HUMIDITY

CONTROLLER

C

RC

HL

6

VH20 SERIES

HUMIDITY TRANSMTTERS

OS

S

COM

HS

BLACK (1)

RED (2)

ORANGE (3)

COMMON

POWER

0-10 Vdc

Wiring example of the main remote humidity sensor

powered by the same transformer as the VH7200 humidistat

VH7200 SERIES

HUMIDITY

CONTROLLER

C

R

HL

OS

S

COM

HS

VH20 SERIES

HUMIDITY TRANSMTTERS

BLACK (1)

RED (2)

ORANGE (3)

COMMON

POWER

0-10 Vdc

Wiring example of the outside air temperature sensor

VH7200 SERIES

HUMIDITY

CONTROLLE R

OS

S

COM

S2020E1000 o r S1 010E1000

TEMPERATURE SENSOR

OUTSIDE AIR

Page 7

Programming and status display instructions

Status display

The Humidistat features a two-line, eight-character display. There is a low level back-light level that is always

active and can only be seen at night.

When left unattended, the Humidistat has an auto scrolling display that shows the actual status of the system.

There is an option in the configuration menu to lockout the scrolling display and to only present the room humidity

and conditional outdoor humidity to the user. With this option enabled, no local status is given of mode, schedule

and relative humidity.

Each item is scrolled one by one with the back lighting off. Pressing any key will cause the back light to come on.

When left unattended for 10 seconds after changes are made, the display will resume automatic status display

scrolling.

To turn on the back light, press any key on the front panel. The back lit display will turn off when the humidistat is

left unattended for 45 seconds.

Sequence of auto-scroll status display:

Humidity Effective RH Setpoint System Mode Outdoor Temperature Alarms

Humidity RH reset Sys mode Outdoor Service

xx %RH xx %RH off x.x °C or°F

Sys mode

auto

Sys mode

Humid

Sys mode

Dehumid

Canister

Humidity

Displayed value is either the internal humidity sensor or will automatically switch to display the value of a remote

sensor if one is connected on terminal HS

Effective RH Setpoint

This conditional display prompt will show the actual reset value of the humidification setpoint if:

• The humidistat is not in dehumidification

• The outdoor temperature sensor is connected

• The outdoor temperature humidification setpoint reset function is used

• The outdoor temperature value is below the reset RH higher outside humidity setpoint

parameter

System Mode

Displayed and available system modes are dependent on the configured sequence of operation parameter.

Selected sequence of operation Modes available

0 = Ahu

1 = 2Phu

2 = 2Pdh

3 = Ahu 2Pdh

4 = 2Phu2Pdh

0-10V Analog humidification only Off - Humid Humid

2 position On-Off humidification Off - Humid Humid

2 position On-Off dehumid only Off - Dehumid Dehumid

Analog humidification & 2 position On-Off dehumidification Off – Humid – Dehumid - Auto Auto

2 position On-Off humidification & 2 position On-Off

dehumidification

Off – Humid – Dehumid - Auto Auto

Outdoor Temperature

Is displayed only when an outdoor temperature sensor is connected or a valid network value is received.

Alarms

This conditional prompt will display alarms when they are detected

• Alarms will automatically be displayed at the end of the status display scroll.

• During an alarm message display, the back lit screen will light up at the same time as the message and shut

off during the rest of the status display scroll.

• Two alarms maximum can appear at any given time. The priority for the alarms is as follows:

Service

Canister

Indicates that there is a service alarm as per one of the programmable binary input ( BI)

Indicates that the canister is dirty as per one of the programmable binary input ( BI)

7

Default

mode

Page 8

8

Two status LED’s on the humidistat cover are used to indicate if Humidification or Dehumidification is active.

• When Humidity output is active the “Hum” LED will luminate.

• When Dehumidification sequence is active, the “Dehum” LED will luminate.

Installer configuration parameter menu

Fig.13 – User interface

Configuration can be done through the network or locally at the Humidistat.

• To enter configuration, press and hold the Mode button for 8 seconds

• Press again the mode button repetitively to scroll between all the available parameters

• Use the up and down key to change the parameter to the desired value.

• To acknowledge and save the new value, press the mode button again.

• The next listed parameter is now displayed

Configuration interface

Mode

Enters the configuration mode. Press and hold for 8 seconds

Pressing repetitively will scroll all available parameters one by one. Concurrently, the mode button

is used to toggle between Humidify and dehumify set points

Down

Up

User interface:

Adjust / rotate parameter value down

Adjust / rotate parameter value up

The user may choose to scroll between mode of the humidistat. By depressing on the mode button the user may

manually toggle between the following modes of operation;

Off

Auto

Humidification

Dehumidification

Keypad interface:

System is disabled

System will satisfy both Humidification and Dehumidification setpoints

System will satisfy the Humidification setpoint only

System will satisfy Dehumidification setpoint only

The user may choose to scroll between mode of the humidistat. By depressing on the mode

Mode

button the user may manually toggle between the following modes of operation; While making

changes to setpoints in “Auto Mode” the mode button is utilized to toggle between humidify and

dehumidify setpoints

Adjust the setpoints down

Down

In Humidification mode only the humidification setpoint is displayed,

In Dehumidifcation mode only the Dehumidification setpoint displayed

In auto mode, (See below)

Adjust the setpoints up

Up

In Humidification mode only the humidification setpoint is displayed,

In Dehumidifcation mode only the Dehumidification setpoint displayed

In auto mode, (See below)

1. Lockouts of access to certain functions is made with configuration parameter (lockout)

2. If the supply humidity sensor is used, press both the mode button and the up arrow button simultaneously to

momentarily display the supply humidity

High limit display:

Valid only if a high limit 0 to 10 Vdc humidity sensor is used and wired at terminal ( HL ). The actual value “Duct

HL” read by the sensor can be displayed by pressing both the mode and down arrow button simultaneously for a

few seconds.

Page 9

Set point Adjustments

Humidification

Mode

Dehumidification

Mode

Off Mode Auto Mode

• Set point presented to user is the set point

from the last action taken by the humidistat

or the one currently in use.

• Humidify and Dehumify set points are

changed independently by using the toggle

function associated with the mode button.

Hum XX % and Dehum XX %

Both Hum and Dehum set point are changed

independently utilizing the mode button to

toggle between the two. A fixed dead band of

5% RH is present.

HumXX % Dehum XX %

Acess to setpoint

adjusment

Installer configuration parameter menu

Configuration can be done through the network or locally at the humidistat.

• To enter configuration, press and hold the mode button for 8 seconds

• Press the same mode button repetitively to scroll between all the available parameters

• Use the up and down key to change the parameter to the desired value.

• To acknowledge and save the new value, press the mode button again.

• The next listed parameter is now displayed

Config.

parameters

Com Addr

PAN ID

Significance

Default value

Humidistat networking

address

Default value = 4

Range is: 0 to 254

Personal Area Network

Identification

Default value = 0

Range is: 0 to 500

Adjustments

Conditional parameter to BACnet MS-TP models (VH72xxX1000B)

Conditional parameter to Wireless models (VH72xxX1000W)

This parameter will only appear when a BACnet or wireless network adapter

is present. If the humidistat is installed as a stand-alone unit or with an

Echelon adapter, this parameter will not be used or displayed

• For BACnet MS-TP models valid range to use is from 1 to 127

• For wireless models valid range is 0 to 254 with a maximum of 30

thermostat per VGG

Conditional parameter to Wireless models (VH720xxX1000W)

This parameter will only appear when a wireless network adapter is present. If

the humidistat is installed as a stand-alone unit or with a BACnet or Echelon

adapter, this parameter will not be used or displayed

This parameter (Personal Area Network Identification) is used to link specific

humidistat to a single specific Viconics wireless gateway ( VWG ) For every

humidistat reporting to a gateway ( maximum of 30 device per gateway ), be

sure you set the SAME PAN ID value both at the gateway and the

humidistat(s).

9

Channel

Channel selection

Default value = 10

Range is: 10 to 26

The default value of 0 is NOT a valid PAN ID. The valid range of available

PAN ID is from 1 to 500

Conditional parameter to Wireless models (VT720xx0X1000W)

This parameter will only appear when a wireless network adapter is present. If

the humidistat is installed as a stand-alone unit or with a BACnet or Echelon

adapter, this parameter will not be used or displayed

This parameter (Channel) is used to link specific humidistat to specific

Viconics wireless gateway(s) ( VWG ) For every humidistat reporting to a

gateway ( maximum of 30 device per gateway ), be sure you set the SAME

channel value both at the gateway and the thermostat(s).

Viconics recommends using only the 2 last channels ( 25-2575MHz and 26-2580MHz )

The default value of 10 is NOT a valid channel. The valid range of available

channel is from 11 to 26

Page 10

Config.

parameters

Significance

Default value

Get From Get From Reference

address

Default value=255

BI 1

Binary input no.1

configuration

Default value = None

Lockout

Keypad lockout levels

Default value = 0 No lock

Sys Mode Setpoints

0

1

Yes access Yes access

No access No Access

SeqOpera Sequence of operation

Default value is = 2

2 position On-Off

dehumid

Units

Sets the display scale of

the thermostat

Default value = °F

Humi max Maximum humidify set

point limit

Default value = 90 %

Dehu min Minimum dehumidify set

point limit

Default value = 15%

MenuScro

Menu Scroll

Default value = On

10

Adjustments

Conditional parameter to Wireless models (VH72xxX1000W)

This parameter / function is not currently supported by the wireless humidistat

None, No function will be associated with the input

Canister, a back-lit flashing Canister alarm will be displayed on the humidistat

LCD screen when the input is energized

Service, a back-lit flashing Service alarm will be displayed on the humidistat

LCD screen when the input is energized

• Open contact input = function not energized

• Closed contact input = function energized

0 = No lock

1 = Low level lock

Level

Sets the desired control operation of the humidistat

Available sequence of operation is dependent on humidistat model

0 = Ahu - 0-10V Analog humidification only

1 = 2Phu - 2 position On-Off humidification

2 = 2Pdh - 2 position On-Off dehumid only

3 = Ahu 2Pdh - Analog humidification & 2 position On-Off dehumidification

4 = 2Phu2Pdh - On-Off humidification & 2 position On-Off dehumidification

°F for Fahrenheit scale

°C for Celsius scale

Maximum humidity set point adjustment. Humidity set point range is:

10% to 90 %

Minimum Dehumidification set point adjustment. Cooling setpoint range is:

15% to 95%

This parameter allow the user to select from scrolling system mode, room

humidity level. Disabling the scrolling function will render the display with the

Room humidity only.

Hum cph On/Off humidification

devices cycles per hour

setting:

Default value = 4 C.P.H.

Dhu cph On/Off dehumidification

devices cycles per hour

setting:

Default value = 4 C.P.H.

hum lock Humidification outside air

temperature lockout

Default value = 120 °F ( 49

°C )

Will set the maximum number cycles per hour under normal control operation

for the relay humidification output. It represents the maximum number of cycles

that the equipment will turn ON and OFF in one hour.

Note that a higher C.P.H will represent a higher accuracy of control at the

expense of wearing mechanical components faster. 3, 4, 5, 6,7 & 8 C.P.H.

Will set the maximum number cycles per hour under normal control operation

for the relay dehumidification output. It represents the maximum number of

cycles that the equipment will turn ON and OFF in one hour.

Note that a higher C.P.H will represent a higher accuracy of control at the

expense of wearing mechanical components faster. 3, 4, 5, 6,7 & 8 C.P.H.

Disables Humidification operation based on outdoor air humidity.

Function will only be enabled if OS (outside air humidity sensor) is connected.

From -15 °F up to 120 °F ( -26 °C up to 49 °C )

Page 11

11

Config.

parameters

Dhu OALK Dehumidification outside air

HL Hyst High Limit hysterisys

cal RH Humidity sensor calibration

cal OS Outside air temperature

sensor calibration

Default value = 0.0 °F or °C

RH LT

RH HT Reset RH higher outside

RE Sp Reset humidity setpoint

HL Sp RH High limit setpoint

Significance

Default value

temperature lockout

Default value = -40°F (-

40°C)

Default value = 5% RH

Default value = 0 %RH

Reset RH lower outside

temperature setpoint

Default value = -20°F (-

29°C)

humidity setpoint

Default value = 32°F (0°C)

Default value = 20% RH

Default value = 85% RH

Adjustments

Outside air temperature under which the dehumidification sequence is

disabled.

Only valid if an outdoor air sensor is connected at the humidistat or a network

value is transmitted to the humidistat.

From –40°F up to 122°F (-40°C to 50°C)

High Limit control hysterisys.

Used only if sequence uses 2 position humidity controle

2 = 2Pdh and 4 = 2Phu2Pdh

From 2% RH up to 20% RH

Offset that can be added/subtracted to actual displayed humidity by ± 15.0

%RH.

This calibration applies to the internal humidity sensor if no remote humidity

sensor is connected. This calibration applies to the remote humidity sensor

when one is connected.

From –15% RH up to 15% RH

Offset that can be added/subtracted to the displayed outside air temperature

± 5.0 °F ( ± 2.5 °C )

Minimum outside air temperature for RH setpoint reset.

Only valid if an outdoor air sensor is connected at the humidistat or a network

value is transmitted to the humidistat. See RH HT & RE Sp.

From –40°F up to 15°F (-40°C to –9.5°C)

Maximum outdoor air temperature for RH setpoint reset.

Only valid if an outdoor air sensor is connected at the humidistat or a network

value is transmitted to the humidistat. See RH LT & RE Sp

From 20°F up to 55°F (-6.5°C to 12.5°C)

The RH setpoint will be reset from the user setpoint to this value when the RH

LT outside air humidity value is reached.

Only valid if an outdoor air sensor is connected at the humidistat or a network

value is transmitted to the humidistat. See RH LT & RE HT.

From 10% RH up to 90% RH

High humidity limit in the supply.

Only valid if a 0-5 Vdc sensor is connected at the humidistat – otherwise this

feature is disabled automatically.

From 50% RH up to 90% RH

Page 12

Humidity setpoint reset by outside air temperature

If an outdoor air sensor is connected at the thermostat

45%

RH Set = 45%

or a value is received from the network, it can be used

to reset the humidity setpoint during the cold season to

40%

minimize condensation on windows and building

structures.

%RH Setpoint

35%

30%

25%

20%

RH HT = 32°F

RE Sp = 20%

RH LT = -20°F

When the outdoor temperature falls below the selected

high temperature, parameter RH HT (32°F in the

example Figure 8), the humidity setpoint will start to

decrease. The lowest humidity setpoint will be reached

at selected low temperature, parameter RH LT (-20°F).

The setpoint decrease from original setpoint to the

lowest setpoint determined by the parameter RE Sp. In

the example, Figure 8, RE Sp was set to 20%, therefore

-40°F

-20°F 0°F 20°F 40°F

Outside Air Temp.

the humidity setpoint dropped from 45% to 20%.

If you don’t want to use this feature, set the RE Sp

parameter to 90% RH.

Fig.11 – Humidity setpoint reset by outside air temperature

High limit humidity sensor (VH7270 Models Only)

The VH7270 models include a high limit sequence. This

100 %

allows the use of a remote 0 to 10 Vdc humidity sensor to

limit the humidity in the supply air. If no sensor is detected at

Control

Output

Level

50 %

0 %

85 %

Maximum Supply Humidity

the HL connector, this sequence is disabled at the

humidistat.

Note: this high limit function is not a safety device. For

critical situations, provide installation with normal protections

required to ensure a safe operation.

Fig.12 – High humidity limit vs Control output level curve

Troubleshooting guide

Symptom Possible Cause Corrective Action

Digital display

Defective display Replace humidistat

shows missing

digits or erratic

segments

12

Humidistat does

not call for

humidification.

(Hum LED is OFF)

RH sensor is out of range Verify the remote RH sensor or the internal RH sensor

System Mode in

Change the system mode parameter to Humidification

Dehumidification or Off

System Mode in Auto but there

is a Dehumidification demand

Wait: when a Humidification demand will occur at the

humidistat, humidification will resume

at the humidistat

High limit sensor is controlling

the humidifier output by forcing

Wait: when the supply humidity will drop below the high

limit setpoint, humidification will resume.

it to 0%

Page 13

Humidistat calls for

humidification.

(Hum LED is ON)

but the humidifier

does not operate

Humidistat does

not call for

dehumidification

(Dehum LED is

OFF)

Humidistat calls for

dehumidification

(Dehum LED is

ON) but the

dehumidifier does

not operate

Specifications

On a VH7270F1000,

disconnect the wire on the

“Hum” terminal measure the

voltage across terminals

“Hum” and “C” you should

read a dc voltage close to 10

Volts

If the “Hum” LED is ON and you measure a dc voltage

close to 10 Vdc, the humidistat is working fine. Look at

the wiring between the Humidistat and the Humidifier. If

the Humidistat is not powered by the Humidifier

(separate transformer) you may have a conflict with the

Common (signal reference)

If the “Hum” LED is ON and you don’t measure a dc

voltage, the humidistat is probably defective, contact

your distributor or Viconics technical support

department.

On a VH7200A1000,

disconnect the wire on the

“Hum” terminal measure the

voltage across terminals

“Hum” and “C” you should

read 24 Vac.

If the “Hum” LED is ON and you measure 24 Vac, the

humidistat is working fine. Look at the wiring between

the Humidistat and the Humidifier. If the Humidistat is

not powered by the Humidifier (separate transformer)

you may have a conflict with the Common (signal

reference)

If the “Hum” LED is ON and you don’t measure 24 Vac,

the humidistat is probably defective, contact your

distributor or Viconics technical support department.

RH sensor is out of range Verify the remote humidity sensor and it’s wiring or the

internal RH sensor

System Mode in Humidification

Change the system mode parameter to Dehumidification

or Off

System Mode in Auto but there

is a Humidification demand at

Wait: when a Dehumidification demand will occur at the

humidistat, dehumidification will resume.

the humidistat

Outside air humidity is below

the Dhu OALK parameter

On all models, take a wire

(jumper) and short across

“DEH” and “DEH” terminals.

Change the Dhu OALK parameter to a value that will

enable the dehumidification, if desired.

When you short across the two “DEH” terminals the unit

does not operate, the problem is related to wiring or to

the dehumidification device. Refer to wiring diagram.

If the system turns ON when you short across the two

“DEH” terminals the humidistat dehumidification contact

is probably defective, replace humidistat.

Humidistat power requirements: 19-30 Vac 50 or 60 Hz; 2 VA ( RC & C ) Class 2

Operating conditions: 0 °C to 50 °C ( 32 °F to 122 °F )

0% to 95% R.H. non-condensing

Storage conditions: -30 °C to 50 °C ( -22 °F to 122 °F )

0% to 95% R.H. non-condensing

Resolution: Temperature: ± 0.1 °C (± 0.2 °F)

Humidity: ± 0.1%

Control accuracy: Humidity: ± 5% RH from 20 to 100% RH at 50 to 90°F (10 to 32°C)

Humidification setpoint range: 10% RH to 90% RH

Dehumidification setpoint range: 15% RH to 95% RH

Outdoor air temperature range: -40 °C to 50 °C ( -40 °F to 122 °F )

Binary inputs: Relay dry contact only across “Scom” and “DI1” terminals

Contact output rating: Each relay output: 30 Vac, 1 Amp. Max. / 30 Vac, 3 Amp. in-rush

Analog output rating

Wire gauge 18 gauge maximum, 22 gauge recommended

Dimensions: 4.94” x 3.38” x 1.13”

Approximate shipping weight: 0.75 lb ( 0.34 kg )

Agency Approvals:

Industry Canada ICES-003 (Canada)

C-Tick AS/NZS CISPR 22 Compliant (Australia / New Zealand)

0 t0 10 Vdc into 2KΩ resistance minimum

UL UL 873 (US) and CSA C22.2 No. 24 (Canada), File E27734 with CCN

XAPX (US) and XAPX7 (Canada)

FCC Compliant to CFR 47, Part 15, Subpart B, Class A (US)

CE EMC Directive 89/336/EEC (Europe Union)

13

Page 14

Drawing & dimensions Important notice

verifications prior to shipment to ensure proper and

reliable operation in the field. Whenever a control

failure could lead to personal injury and/or loss of

property, it becomes the responsibility of the user /

installer / electrical system designer to incorporate

safety devices (such as relays, flow switch, thermal

protections, etc…) and/or alarm system to protect the

entire system against such catastrophic failures.

Tampering of the devices or miss application of the

device will void warranty.

All VH7200 series controls are for use

as operating controls only and are not

safety devices. These instruments have

undergone rigorous tests and

14

Fig.16 – Humidistat dimensions : VH7200A1000, VH7270F1000, VH7270K1000

Fig.17 – Humidistat dimensions : VH7270D1000

Loading...

Loading...