Page 1

Differential Pressure Flow Sensors

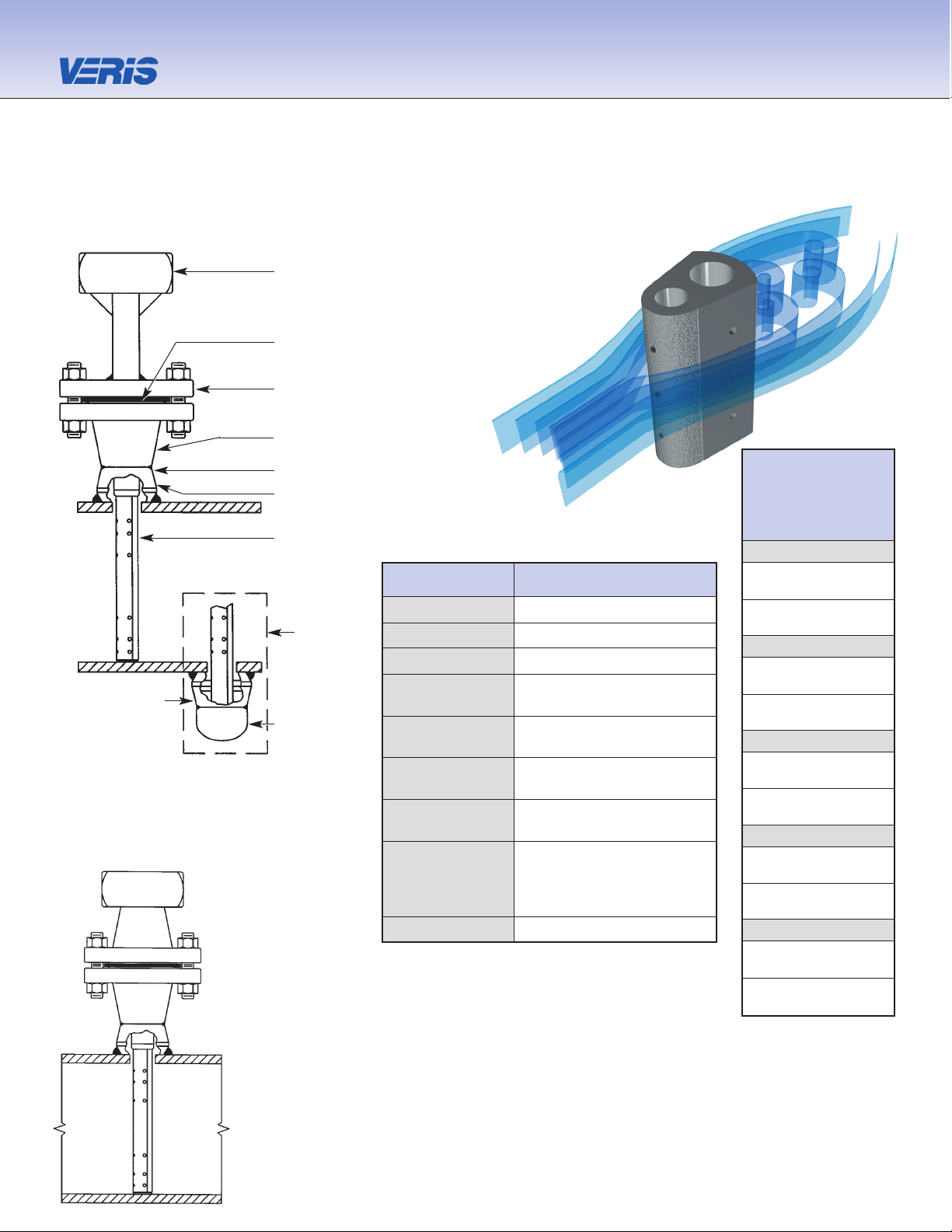

Verabar

®

Temperature

Pressure

Limits

(ANSI Class)*

150 #

275 psig @ 100°F

(19 Bars @ 38°C)

80 psig @ 800°F

(5.5 Bars @ 426°C)

300#

720 psig @ 100°F

(49.6 Bars @ 38°C)

410 psig @ 800°F

(28.3 Bars @ 426°C)

600#

1440 psig @ 100°F

(99.3 Bars @ 38°C)

825 psig @ 800°F

(56.9 Bars @ 426°C)

1500#

3600 psig @ 100°F

(248.2 Bars @ 38°C)

190 psig @ 1500°F

(13.1 Bars @ 815°C)

2500#

6000 psig @ 100°F

(419.6 Bars @ 38°C)

315 psig @ 1500°F

(21.7 Bars @ 815°C)

Model Specs V500 & V510

Pipe Connection Flanged

Sensor Code 20

Sensor Diameter 2” (51mm)

Accuracy

±1% of flow rate;

±0.5% if calibrated

ANSI Class*

150#, 300#, 600#,

1500#, 2500#

Pipe Size

12”-72”

(300mm -1829mm)

Instrument

Connection

1/2” NPT

Weld coupling, weldneck

Components flange, gaskets, studs & nuts

Furnished V510 includes additional

weld coupling and pipe cap.

Flange Size 3”

The Most Accurate and Reliable Technology

for Measuring Gas, Liquid and Steam…

The extended range Verabar® is engineered

for liquid, steam and high velocity gas

flow measurement in larger pipe

sizes, up to 72” (1829mm). With

its solid, one-piece construction

and bullet shape, the Verabar

makes flow measurement

leak proof and precise.

The unique

sensor shape

reduces drag

and flow induced

vibration. The location

of the low-pressure

ports eliminates the potential for

clogging and improves signal stability.

Extended Range

Flanged Models

V500 Single Support

V510 Double Support

Flanged Components

Unique Design Features

High Pressure Threaded (HPT) and High

Pressure Socket (HPS) designs offer the

highest possible pressure and temperature capabilities. When pressure containment and safety are primary concerns,

the HPT/HPS has the strongest and

safest design in the industry.

As with all Veris designs, it meets

ANSI/ASME B31.1 and can be

supplied with code welding (ASME

Section IX), hydrostatic testing, N.A.C.E.

and material traceability.

Applications

Main Header Steam Lines

Used for high pressure and

temperature applications

such as main header steam lines.

For these applications, pipe mounting assemblies

are available in chrome-moly material (ASTM A182

F11, F22 & F91).

Other Applications

• High pressure and temperature gasses and liquids

• Natural gas transmission lines

• Boiler feed water lines

• Oil well injection lines

Applications

up to ANSI Class 2500#

High Pressure and

Temperature

V500 (Single Support)

V510 (Double Support)

Instrument head

(SS)

Sensor flange

(SS)

Spiral-wound

gasket

Weld coupling

(CS or SS)

Sensor (316SS)

Optional:

Monel 400

Hastelloy C-276

Inconel 800H

316HSS

Weld cap

(CS) (SS-opt)

Factory weld

Weld neck flange

(CS or SS)

Model

V510 only

Weld coupling

(CS) (SS-opt)

* DIS and JIS flanges available. Consult factory.

Page 2

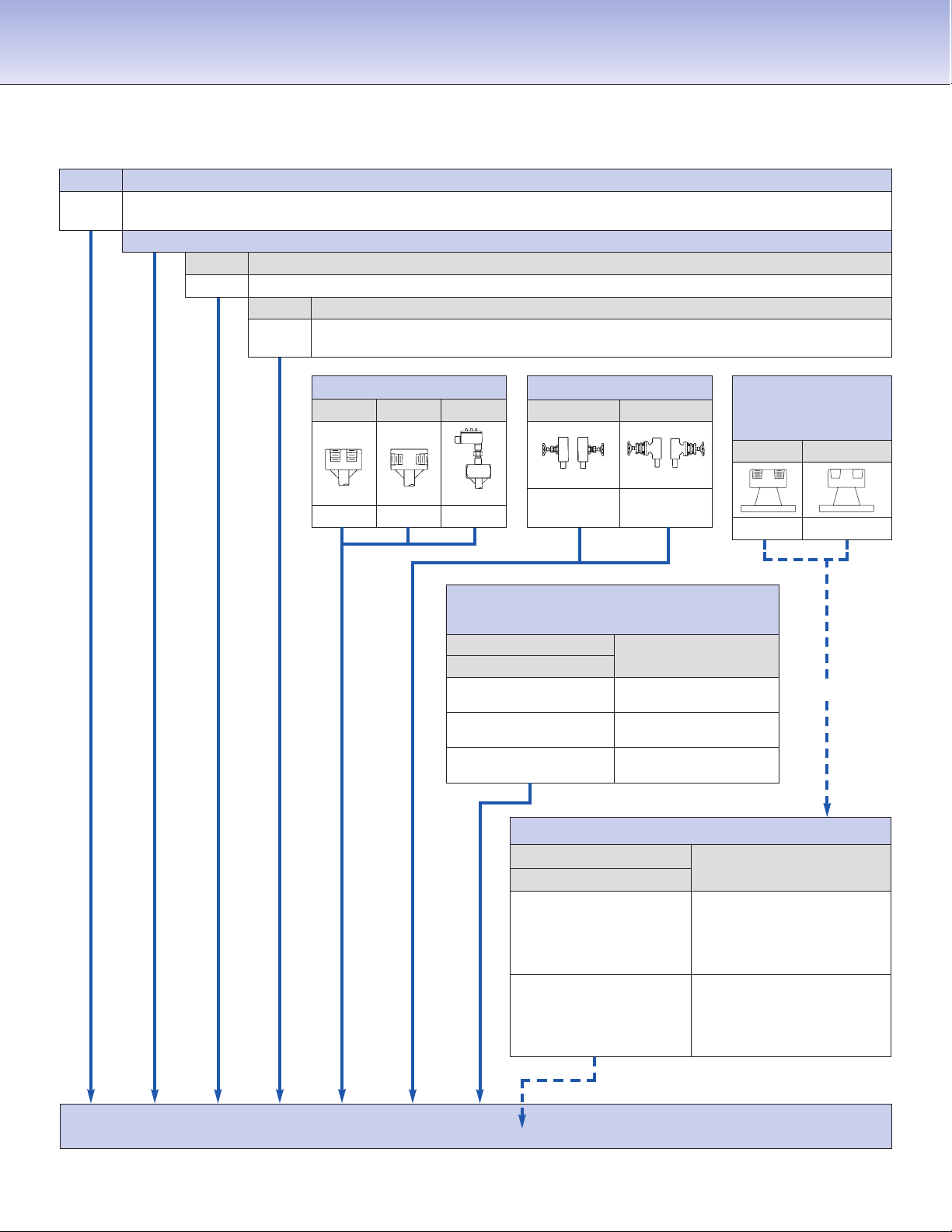

Ordering Information

Model Extended Range Flanged

V500 Single Support

V510 Double Support

Pipe Size and Schedule or Exact ID and Wall Thickness

Code Sensor Pipe Size Range

20 12” to 72” (300mm to 1829mm)

Code Pipe Orientation

H Horizontal

V Vertical

Instrument Connections

Parallel Regular RTD*

PR D

Mounting Assembly — Select Material & Rating

(Includes SS sensor flange, WN flange,

weld coupling, spiral-wound gaskets, studs & nuts)

Sensor 20 (Flange Size 3”)

Mating Flange Material

Code

& ANSI Class

F1215C CS

150#

F1215S SS

F1230C CS

300#

F1230S SS

F1260C CS

600#

F1260S SS

Explsn. Proof

V500 20”schstd 20 H R C2NC F1215C Typical Model Number

V500 20”schstd 20 H HPT F12150F11 Typical High Pressure Model Number

High Pressure

Instrument Head

(ANSI Class

1500# & 2500# only)

1/2” NPT Socket Weld

HPT HPS

Instrument Valves (Optional)

Needle Gate

C2NC (CS) C2GC (CS)

C2NS (SS) C2GS (SS)

1/2” NPT 1/2” NPT

Optional

*

For high pressure (>500psig) or high temperature (>500°F), remote mount RTD in a thermowell is preferred.

High Pressure Mounting Assembly (HPT & HPS Connections)

Sensor 20 (Flange Size 3”)

Mating Flange Material

Code

& ANSI Class

F12150C CS

F12150S SS

F12150F11 F11 1500#

F12150F22 F22

F12150F91 F91

F12250C CS

F12250S SS

F12250F11 F11 2500#

F12250F22 F22

F12250F91 F91

Page 3

Page 4

6315 Monarch Park Place •Niwot, CO 80503 USA •Phone: 303-652-8550 •Fax: 303-652-8552

E-Mail: contact@veris-inc.com

•

Website: www.veris-inc.com

True Performance in DP Flow Measurement

PSS-500X (1/07)

Printed in USA

Veris, Inc. is in compliance with this standard to ensure

that our customers are receiving the highest

quality products available.

ISO 9001 Certified

Loading...

Loading...