Page 1

Differential Pressure Flow Sensors

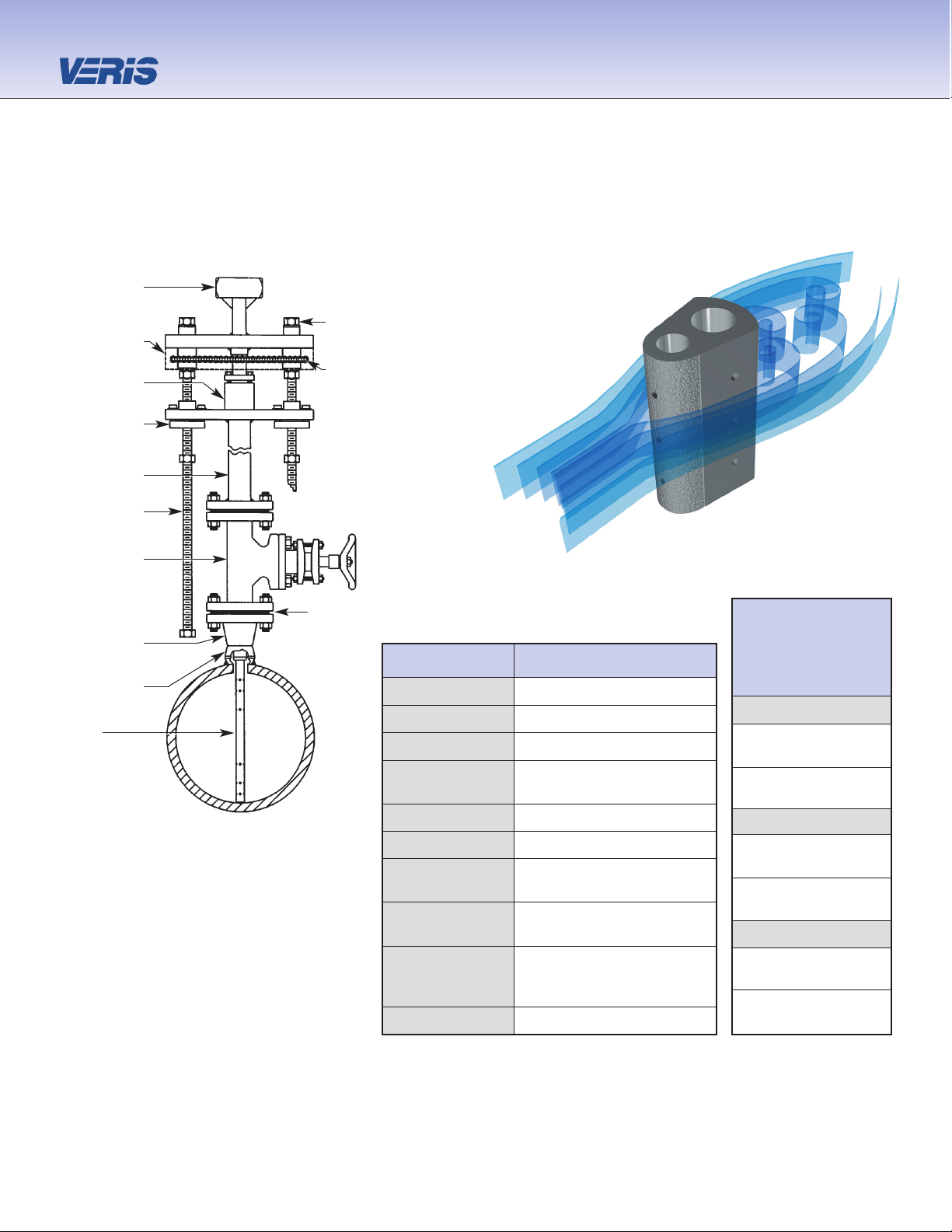

Verabar

®

Model Specs V400D

Pipe Connection Flanged

Sensor Code 20

Sensor Diameter 2” (51mm)

Accuracy

±1% of flow rate;

±0.5% if calibrated

ANSI Class* 150#, 300#, 600#

Drive Rods 2

Pipe Size

12”-60”

(300mm -1524mm)

Instrument

Connection

1/2” NPT

Components Weld coupling, weld neck

Furnished flange, gaskets,

studs & nuts

Flange Size 3”

The Most Accurate and Reliable Technology

for Measuring Gas, Liquid and Steam…

The extended range Verabar® is engineered

for liquid, steam and high velocity gas

flow measurement in larger pipe

sizes, up to 60” (1524mm). With

its solid, one-piece construction

and bullet shape, the Verabar

makes flow measurement

leak proof and precise.

The unique

sensor shape

reduces drag

and flow induced

vibration. The location

of the low-pressure ports

eliminates the potential for clogging

and improves signal stability.

Extended Range

Hot Tap Models

V400D Double Rod

Flanged Components

V400D Synchro-Drive

(Standard)

Instrument

head (SS)

Drive

nut

Drive

chain

Protective

chain shroud

Anti-seize

orbital bearing

Packing gland

(SS)

Access nipple

(SS)

Flanged

access valve

(CS) (SS-opt)

Weld coupling

(CS) (SS-opt)

Weld neck

flange

(CS) (SS-opt)

Spiralwound

gasket (2)

Sensor

(316SS)

Optional:

Monel 400

Hastelloy C-276

Inconel 800H

316HSS

Drive rod (SS)

Synchro-Drive Description

Synchro-Drive is standard on all – 20 sensors. Two drive

rods are coupled together by a protected chain drive

system. Turning either drive nut simultaneously rotates

both rods.

Synchro-Drive Benefits

• 95% faster and easier insertion and retraction

• Equal load distribution over both rods maintains sensor

alignment and eliminates binding

Temperature

Pressure

Limits

(ANSI Class)*

150 #

275 psig @ 100°F

(19 Bars @ 38°C)

80 psig @ 800°F

(5.5 Bars @ 426°C)

300#

720 psig @ 100°F

(49.6 Bars @ 38°C)

410 psig @ 800°F

(28.3 Bars @ 426°C)

600#

1440 psig @ 100°F

(99.3 Bars @ 38°C)

825 psig @ 800°F

(56.9 Bars @ 426°C)

* DIS and JIS flanges available. Consult factory.

Page 2

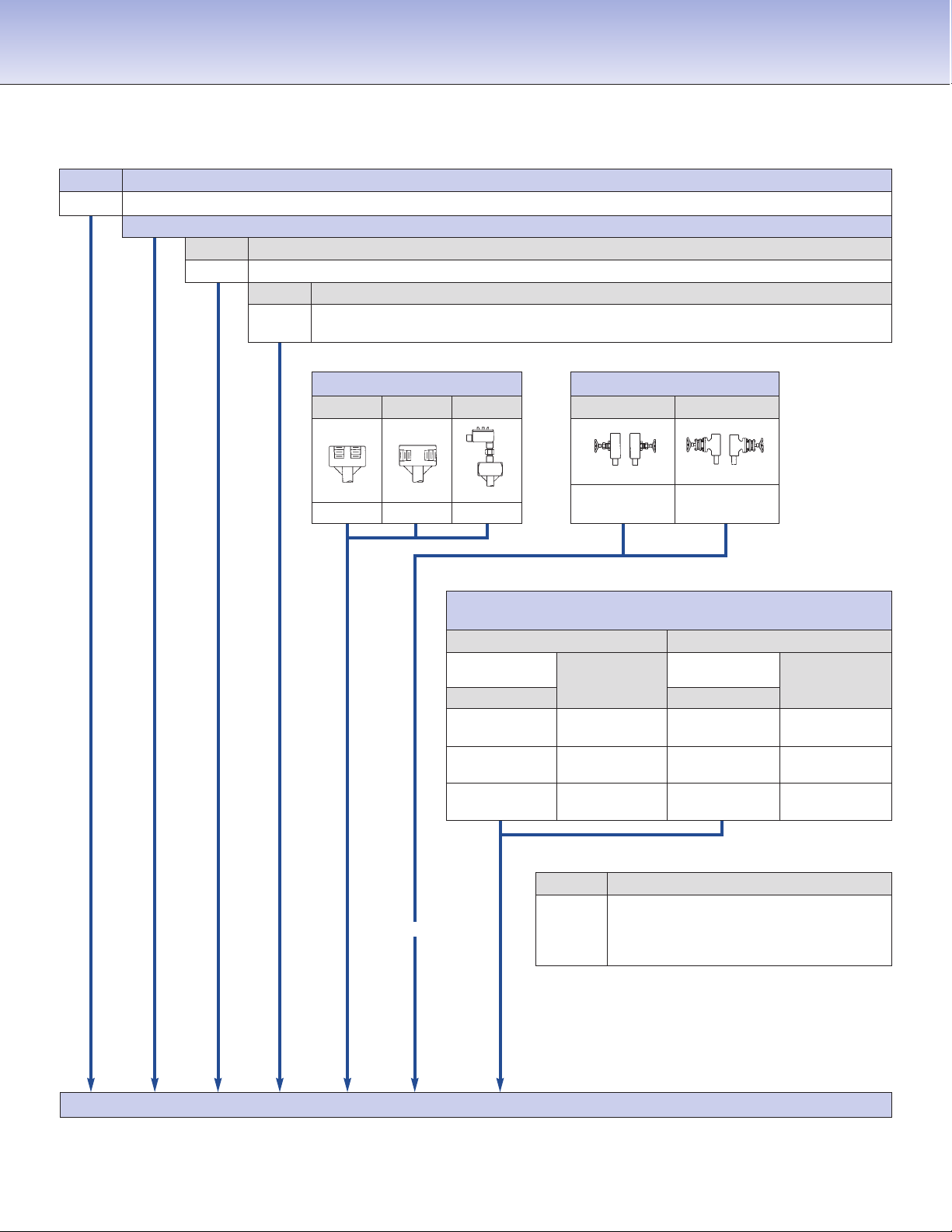

Ordering Information

Model Extended Range Hot Tap • Screw Drive

V400D Double Rod, Insert/Retract

Pipe Size and Schedule or Exact ID and Wall Thickness

Code Sensor Pipe Size Range

20 12” to 60” (300mm to 1524mm)

Code Pipe Orientation

H Horizontal

V Vertical

Instrument Connections

Parallel Regular RTD*

PR D

Mounting Assembly — Select Valve Type, Material & ANSI Class

(Includes valve, WN flange, weld coupling, spiral-wound gaskets, studs & nuts)

Ball Valve Flange Gate Valve Flange

Sensor 20 Sensor 20

(Valve Size 3”)

Material

(Valve Size 3”)

Material

Code

& ANSI Class

Code

& ANSI Class

B12CF15 CS 150# G12CF15 CS 150#

B12SF15 SS 150# G12SF15 SS 150#

B12CF3 0 CS 300# G12CF3 0 CS 300#

B12SF30 SS 300# G12SF30 SS 300#

B12CF6 0 CS 600# G12CF6 0 CS 600#

B12SF60 SS 600# G12SF60 SS 600#

Explsn. Proof

V400D 20”schstd 20 H R C2NC G12CF30 Typical Model Number

Instrument Valves (Optional)

Needle Gate

C2NC (CS) C2GC (CS)

C2NS (SS) C2GS (SS)

1/2” NPT 1/2” NPT

Optional

*

For high pressure (>500psig) or high temperature (>500°F), remote mount RTD in a thermowell is preferred.

Code Options

SS Wetted Components

WPS

(Furnished with SS weld coupling,

flanges & access nipple)

Must be ordered with SS access valve

Page 3

Page 4

6315 Monarch Park Place •Niwot, CO 80503 USA •Phone: 303-652-8550 •Fax: 303-652-8552

E-Mail: contact@veris-inc.com

•

Website: www.veris-inc.com

True Performance in DP Flow Measurement

PSS-400DX (1/07)

Printed in USA

Veris, Inc. is in compliance with this standard to ensure

that our customers are receiving the highest

quality products available.

ISO 9001 Certified

Loading...

Loading...