Page 1

REL AY S

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Follow safe electrical work practices.

See NFPA 70E in the USA, or applicable local codes.

• This equipment must only be installed and serviced by qualied electrical personnel.

• Read, understand and follow the instructions before installing this product.

• Turn o all power supplying equipment before working on or inside the equipment.

• Use a properly rated voltage sensing device to conrm power is o.

DO NOT DEPEND ON THIS PRODUCT FOR VOLTAGE INDICATION

Failure to follow these instructions will result in death or serious injury.

DANGER

TM

INSTALLATION GUIDE

V220

V220

20A SPDT Enclosed Relay

Installer’s Specifications

Operating Temperature -34°C to 55°C (-29° to 131° F)

Operating Humidity 10-90% non condensing

Expected Relay Life Electrical (at rated current): 100,000 cycles

Mechanical (unpowered): 10,000,000 cycles

Relay Status LED ON=energized

Wire Specications:

Lead Length 14” (356mm) min.

Gauge UL1015; Coil: 18AWG; Contacts: 16AWG

Insulation Class 600VAC RMS

Agency Approvals UL508 enclosed device listing, pollution degree 2

INSTALLATION

Disconnect and lock out all power sources before beginning the

installation.

1. Using the threaded nipple, connect the relay to the desired enclosure through a

knock out hole.

2. Secure with the conduit nut provided.

3. Connect coil wires:

• Choose the coil common lead (white with yellow stripe) and connect it to

the common (-) source termination point.

• Choose either the low voltage (10-30VAC/DC, white with blue stripe) or

high voltage (208-277VAC, white with brown stripe) lead, depending

NOTICE

• This product is not intended for life or safety applications.

• Do not install this product in hazardous or classified locations.

• The installer is responsible for conformance to all applicable codes.

• Mount this product inside a suitable fire and electrical enclosure.

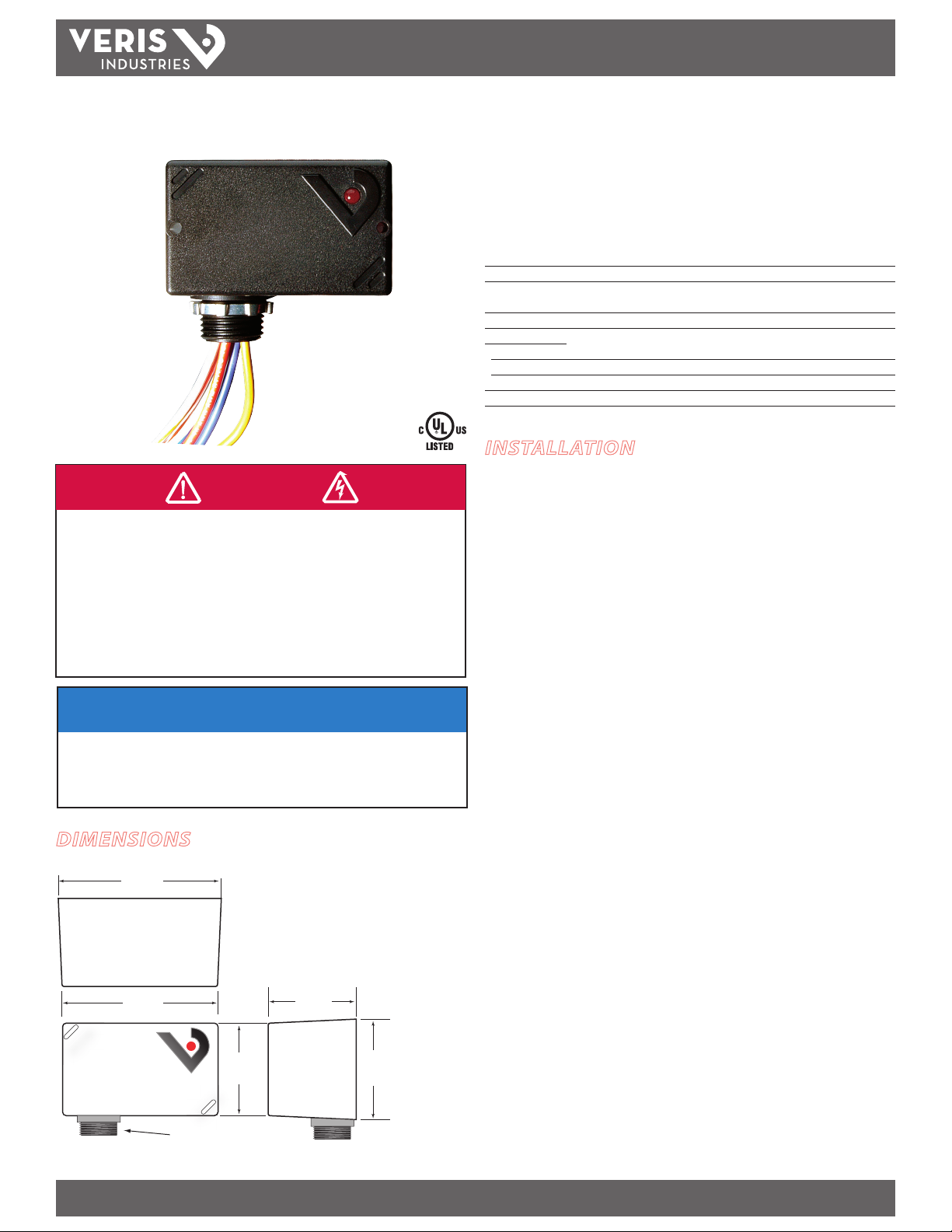

DIMENSIONS

2.9"

(74 mm)

2.8"

(71 mm)

1.6"

(41 mm)

4. Connect relay contacts:

5. Secure the enclosure and reconnect power.

* Isolate or insulate all non-terminated wires according to local electrical code requirements, i.e.

wire nut.

on the application requirements, and connect it to the (+) source

termination point.*

• Choose the relay common wire (yellow) and connect to the switched load.

• Choose the relay N.O. (orange) and/or* N.C. (blue) lead and connect to the

switched load.

1.7"

Z203096-0C PAGE 1 ©2012 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 04121

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other count ries.

1/2" NPT Nipple

(43 mm)

1.8"

(46 mm)

Page 2

V220

To Load

To Controls

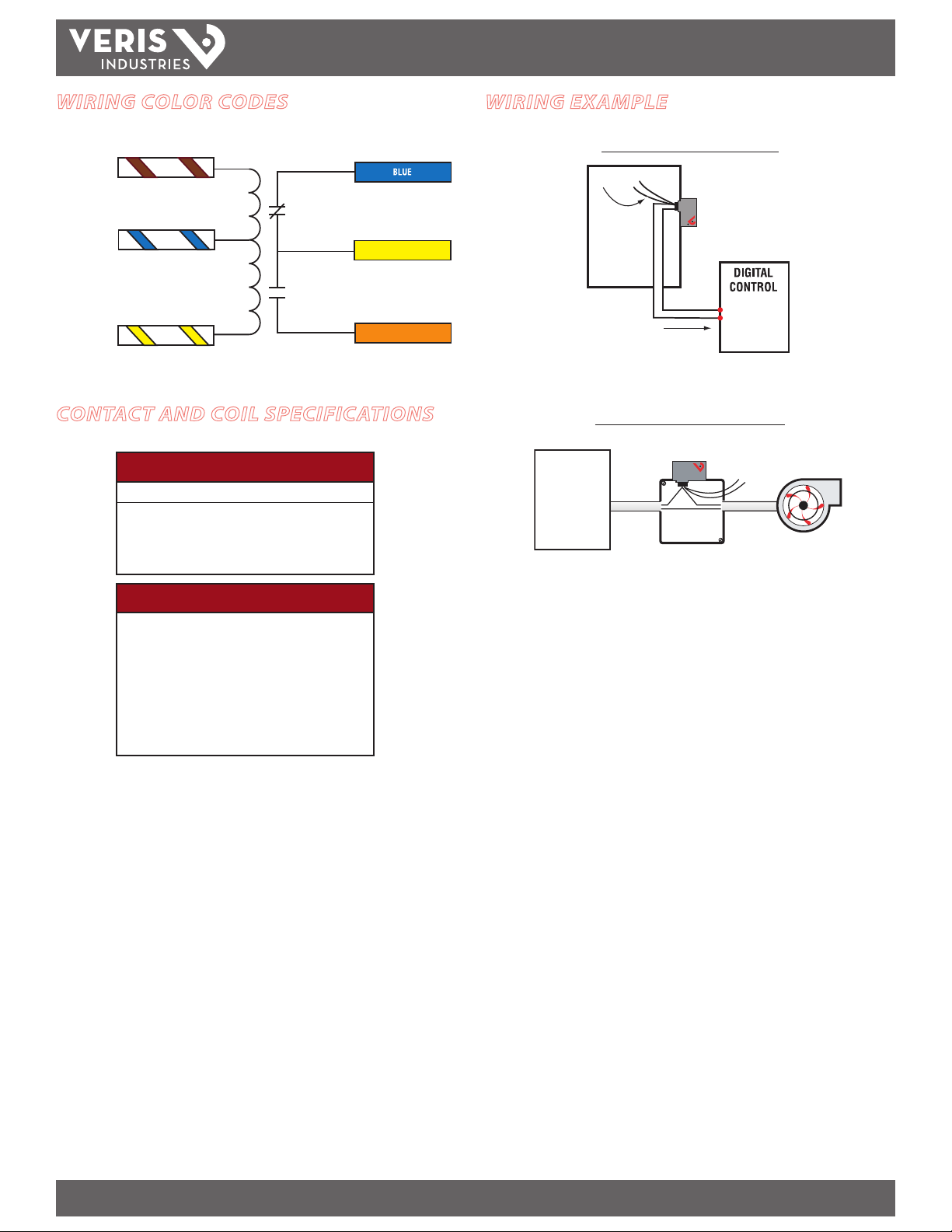

COIL

CONTACTS

Voltage Coil Current

AC DC

24V.......................................... 75mA 32mA

208V........................................ 36mA -

277V........................................ 49mA -

TYPICAL COIL PERFORMANCE

CONTACT RATINGS

Resistive.............. 20A@277VAC, 28VDC

Motor.................... 120VAC, 1HP

277VAC, 2HP

Pilot Duty............. A300

Ballast.................. 277VAC, 20A N.O.

277VAC, 10A N.C.

Tungsten............... 120VAC, 10A N.O.

120VAC, 2A N.C.

N.C.

Common

24VAC/DC

LOW

wht/blue

COMM

wht/yellow

Common

N.O.

CONTACT OUTPUTCONTROL SYSTEM INPUT

White

YELLOW

White

ORANGE

b

l

ue

b

l

ue

y

e

ll

o

w

y

e

ll

o

w

208-277VAC

HI

wht/brown

White

br

o

w

n

br

o

w

n

TM

INSTALLATION GUIDE

WIRING COLOR CODES

CONTACT AND COIL SPECIFICATIONS

WIRING EXAMPLE

Nipple mount directly to a panel

Nipple mount to a 4x electrical box

POWER

SOURCE

To Controls

Fractional

HP Motor

Z203096-0C PAGE 2 ©2012 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 04121

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other count ries.

Loading...

Loading...