Page 1

1.0 SCOPE

These instructions provide procedures for installing the

V150 Verabar flow sensor. Procedures are given for all

industrial flow measurement applications including

liquid, steam and gas service for both horizontal and

vertical piping configurations.

2.0 RECEIVING INSPECTION

The following tasks should be performed as part of the

receiving inspection procedure:

• Check items received against the packing list.

• Check sensor nameplate for proper model num-

ber, serial number and customer number.

• Verify that the actual pipe diameter matches the

ID stated on the sensor nameplate.

• Check the bullet shaped sensor tube for any

signs of damage. Damage to the sensor tube

may result in erroneous flow readings.

• Check the round cover tube for any damage.

Damage to the cover tube may prevent the

packing from sealing properly.

3.0 SAFETY PRECAUTIONS

The following tasks should be conducted prior to installing the Verabar flow sensor:

• Check maximum operating conditions on the

flow sensor nameplate and verify that they

exceed the maximum conditions of the

installation. If any pressure, temperature or

flow limits will be exceeded, consult the factory

before proceeding.

Verabar V150

INSTALLATION INSTRUCTIONS

• Check that the pipe is depressurized and drained

prior to installation.

• The Spring-Lock Model V150 is designed for

carbon and stainless steel pipes with a schedule

10 or heavier wall thickness. The V150 should

be used with PVC, copper, aluminum, cast

not

iron or thin-walled pipes or ducts. If there is any

question as to the proper application for a model

V150, consult the factory.

4.0 INSTALLATION PREPARATIONS

4.1 Location

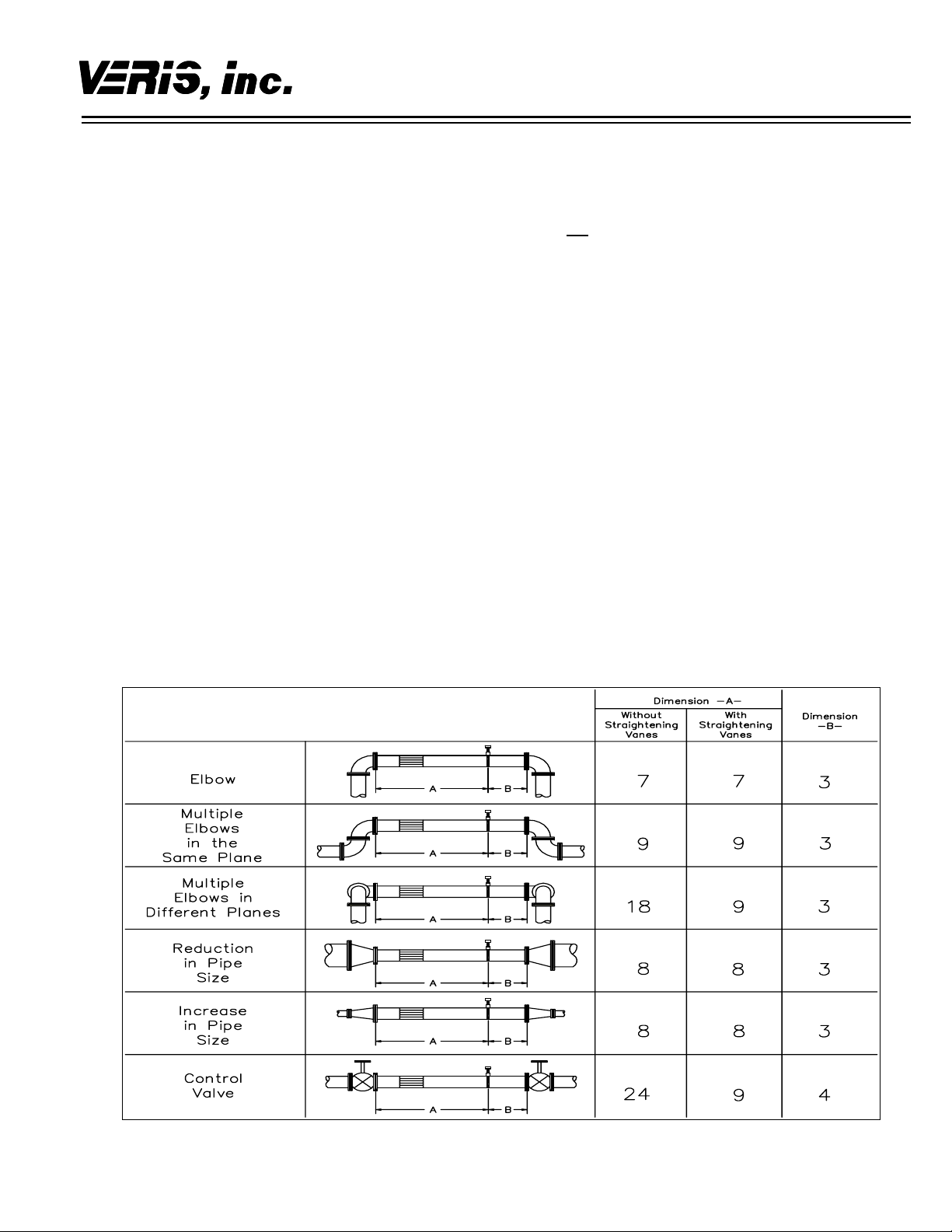

For the most accurate flow measurement, a minimum

straight run of pipe is required. Table 1 shows the

minimum straight run requirements.

If longer straight runs are available, position the

Verabar such that the ratio of upstream straight run to

downstream straight run is approximately 4 to 1. If

straight run lengths are less than the values stated in

Table 1, consult the factory for additional accuracy and

location information.

Position straightening vanes such that the end closest

to the Verabar is half way between the Verabar and the

closest upstream configuration. For elbow installations,

mount the Verabar in the same plane as the closest

upstream elbow.

Piping Configuration

Table 1. Straight Run Requirements

Page 2

4.2 Orientation

Verify the proper sensor orientation by checking for an

“-H” (horizontal piping) or a “-V” (vertical piping) in the

model number on the Verabar name plate.

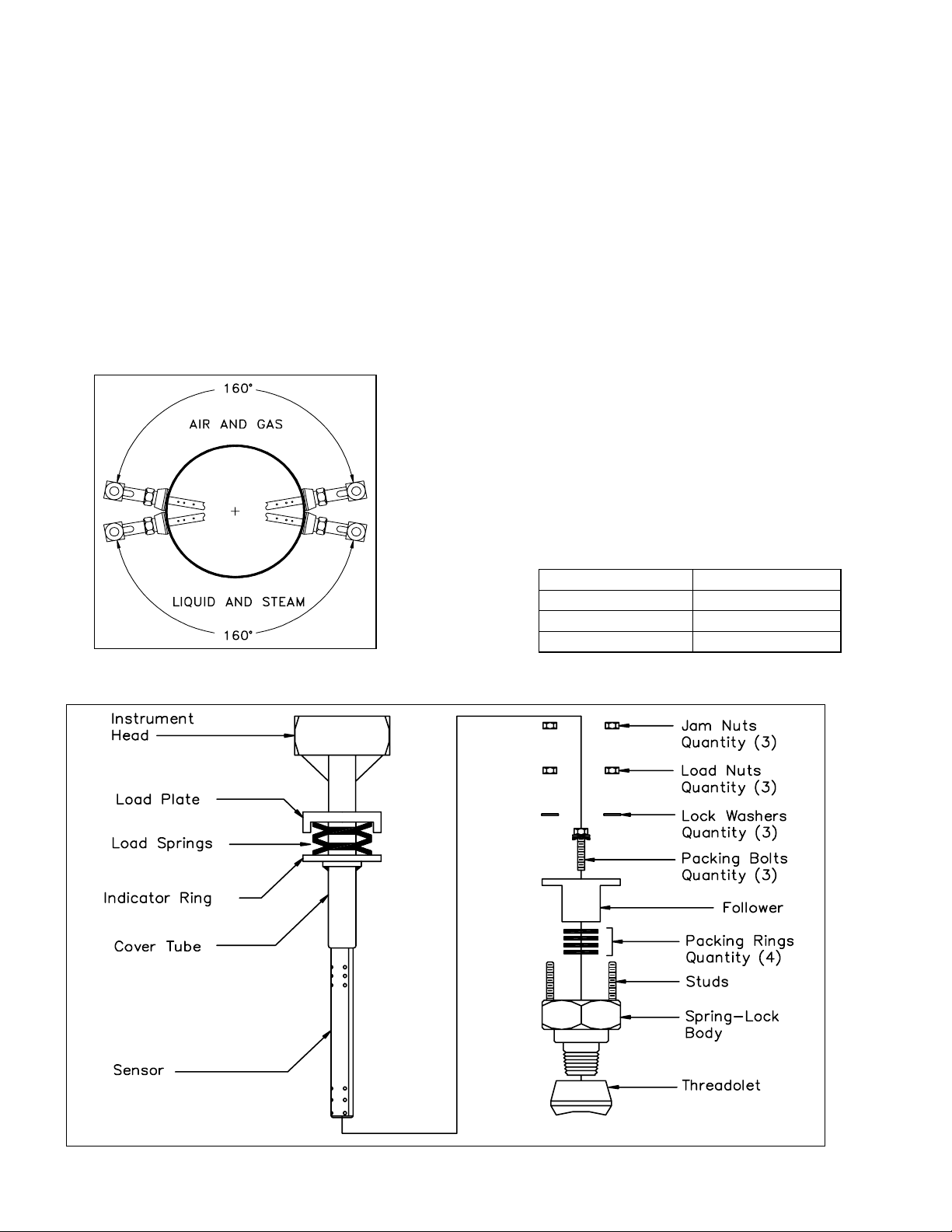

4.2.1 Horizontal Piping

For air or gas installations, mount the Verabar in the

upper 160° of the pipe to allow any condensate to drain

into the pipe (Figure 1). For liquid or steam installations, mount the Verabar in the lower 160° of the pipe.

This allows any entrained air to bleed back into the pipe

for liquid applications and allows condensate to collect

in the instrument piping for steam applications.

4.2.2 Vertical Piping

The Verabar may be mounted in any location around

the circumference of the pipe for vertical piping

applications.

Figure 1. Verabar Orientation in Horizontal Pipe

Figure 2. Verabar Model V150

4.3 DP Transmitter/Local Indicator

Location

When choosing a Verabar location, consider the DP

transmitter/local indicator location:

• The transmitter must be mounted below the

Verabar for liquid and steam applications.

• The transmitter must be mounted above the

Verabar for air and gas applications.

4.4 Installation Drawings and Bill of

Materials

Additional information is available in the Installation

Drawings and Bill of Materials VB-7061 (also on the

VeraData CD). It contains standard and alternate

transmitter locations and a complete bill of materials

based on the fluid type and sensor orientation on the

pipe.

5.0 INSTALLATION PROCEDURE

5.1 Drill Hole in Pipe

• Completely depressurize and drain the pipe prior

to installation of the Verabar.

• Mark the location of the hole through which the

Verabar will be mounted. Use a center punch to

mark the hole to prevent the drill bit from walking

on the pipe.

• Drill the pipe with the proper sized hole per the

following table:

Sensor Size Hole Dia

V150-05 1/2" (13mm)

V150-10 1” (25mm)

V150-15 1-1/2” (38mm)

• Deburr the hole on the inside of the pipe.

Page 3

5.2 Weld Threadolet to Pipe

• With the follower and packing rings already in

place, loosely insert the sensor into the SpringLock body (see Figure 2). Thread the SpringLock body into the threadolet (hand tight), then

insert the complete assembly into the pipe. This

will assure proper alignment of the threadolet to

the hole already drilled in the pipe.

• Using the appropriate weld gap (1/16” [1.5mm]

typical), tack weld the threadolet into position,

then remove the sensor and Spring-Lock body.

Protect threads on the threadolet and finish

welding the threadolet to the pipe per applicable

codes (see Figure 3).

Figure 3. Weld Gap

5.3 Thread Packing Body into Threadolet

Using appropriate pipe thread sealant, thread the

Spring-Lock body into the threadolet.

5.4 Insert Sensor

• With the follower and packing rings already in

place (factory assembled), insert the sensor into

the Spring-Lock body until the tip of the sensor

hits the opposite side of the pipe. Note, the three

studs must pass through the indicator ring and

the load plate.

• Align the head of the sensor so that the arrow

labeled “flow” on the head is in the direction of

the flow in the pipe to within 3° (Figure 4).

Maintain the head in this position for the

remainder of the installation.

• Place the three lock washers and the three load

nuts on the studs and tighten. Tighten the load

nuts until the load plate is 0.050” (1.3mm) from

the indicator ring for –05 and –10 sensors. For

–15 sensors, the load plate should be 0.063”

(1.6mm) from the indicator ring (Figure 6). For

–05 sensors, this can be done by tightening all

the load nuts until the load plate just touches the

indicator ring and then backing off all the load

nuts one complete turn. For –10 and –15

sensors, this can be done by tightening all the

load nuts until the load plate just touches the

indicator ring and then backing off all the load

nuts ¾ of a turn. The load springs are now

properly set.

• Thread on the three jam nuts and tighten until

they are resting hand-tight against the lock nuts.

Place a backup wrench on the load nut to

prevent it from rotating. While not allowing the

load nut to rotate, tighten the jam nuts 1/8 turn

beyond hand tight.

Figure 4. Orientation of Flow Arrow

Page 4

• Using a torque wrench, tighten the three packing

bolts to the appropriate torque value listed in the

table below.

Sensor Size Packing Bolt

Torque (in-lbs)

–05 50 4.2

–10 100 8.3

–15 170 14.1

Note: The weld on the weld ring (Figure 6) should

not contact the top surface of the follower. If the weld

on the weld ring comes into contact with the follower,

the sensor will not be properly bottomed in the pipe.

If this occurs, consult the factory before proceeding.

Figure 5. Spring-Lock Cut Away

Packing Bolt

Torque (ft-lbs)

5.5.2 Manifold

If the Verabar has a direct or integral manifold, be sure

the high and low-pressure block valves are shut off

prior to repressurizing the pipe.

5.6 Pressurize Pipe and Retighten Bolts

Pressurize the pipe and check for leaks. If leaks are

present, retighten the packing bolts until leaking is

eliminated. Verify that the distance between the load

plate and the indicator ring is approximately 0.050”

(1.3mm) for –05 and –10 sensors and 0.063” (1.6mm)

for –15 sensors; make adjustments as required.

The Verabar is now properly installed (Figure 7).

Figure 7. Installed V150

Periodic Maintenance

The assembly should be periodically checked. Verify

Figure 6. Proper Spring Compression

that no leaks are present. Tighten the packing bolts if

necessary.

5.5 Install Instrument Valves or Manifold

5.5.1 Valves

If the Verabar does not have a valve head, install

instrument valves using proper thread sealant. Be sure

instrument shut-off valves are installed and shut prior to

repressurizing the pipe.

6315 Monarch Park Place • Niwot, CO 80503 USA • Phone: (303) 652-8550 IO-150-VWI-CS-022 REV B (6/08)

Fax: (303) 652-8552 • Email: contact@veris-inc.com • Website: www.veris-inc.com Printed in USA

Loading...

Loading...