Page 1

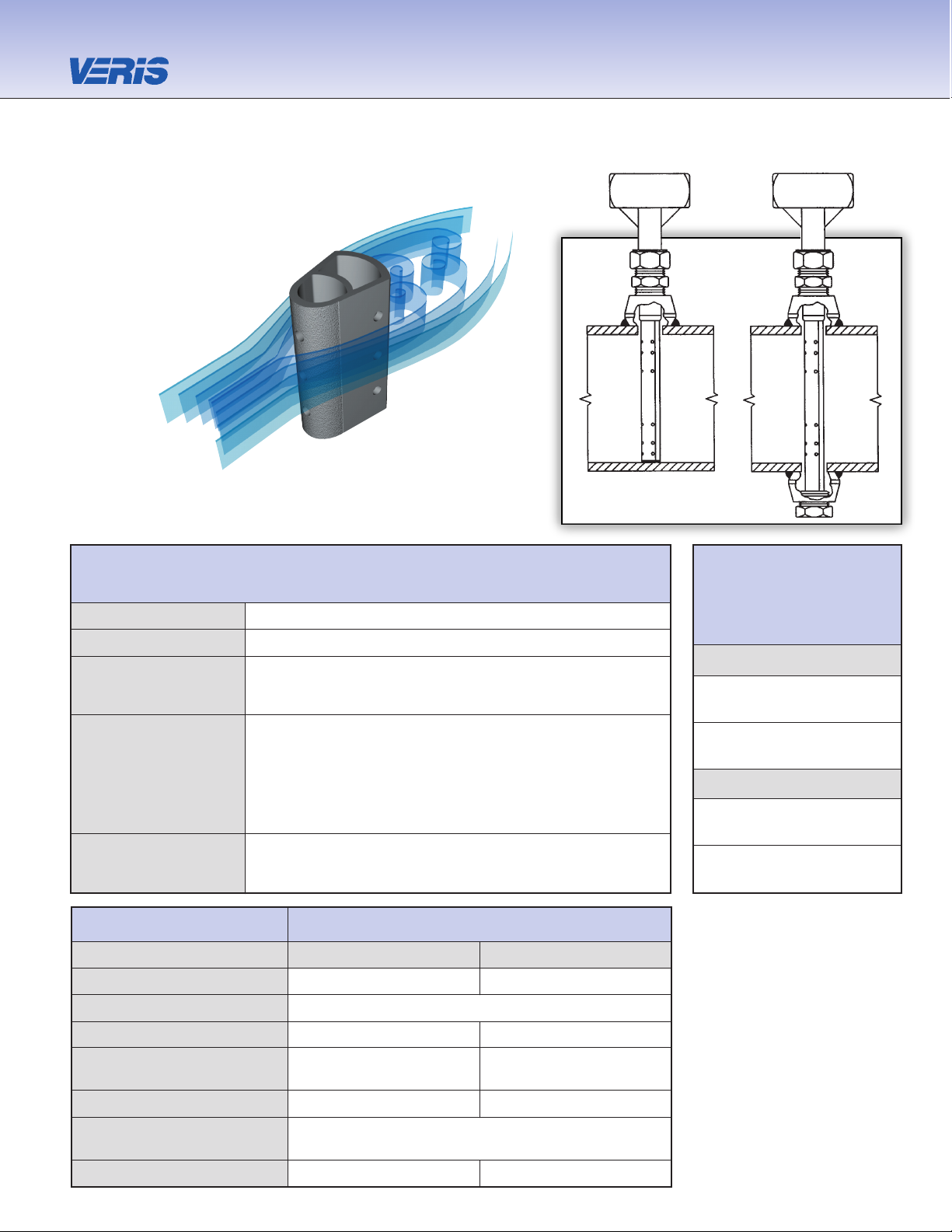

The Most Accurate and Reliable Technology

for Measuring Gas, Liquid and Steam…

Developed from aerospace technology,

the Verabar® averaging pitot flow

sensor provides unsurpassed

accuracy and reliability.

With its solid, one-piece

construction and bullet

shape, the Verabar

makes flow

measurement

leak proof

and precise.

The unique

sensor shape

reduces drag and flow induced vibration. The location

of the low-pressure ports eliminates the potential for

clogging and improves signal stability.

Regular Models

V100 & V110 Compression Fitting

Differential Pressure Flow Sensors

Verabar

®

Model

V110

Model

V100

V100 Single Support

V110 Opposite Support

Pipe Connection Threaded (NPT)

Mounting Type Tube fitting

Features and

• Most cost effective model

Benefits

• Installed in less than one hour

• Low and medium pressures

• Pipes (steel, PVC, FRP, copper)

• Air (compressed, combustion)

• Natural gas

Applications • Stack/flue gas

• Water (raw, cooling, feedwater)

• Low pressure steam

• Non-hazardous fluids

Special Designs—

• Custom mounting, lengths, materials,

Consult Factory

instrument connections, etc.

• Short straight run

Temperature

Pressure

Limits

(ANSI Class)*

300#

740 psig @ 100°F

(51.0 Bars @ 38°C)

410 psig @ 800°F

(28.3 Bars @ 426°C)

600#

1440 psig @ 100°F

(99.3 Bars @ 38°C)

825 psig @ 800°F

(56.9 Bars @ 426°C)

* DIN and JIS flanges available. Consult factory.

Model Specifications V100 and V110

Sensor Code 05 10

Sensor Diameter 7/16” (11mm) 7/8” (22mm)

Accuracy ±1% of flow rate; ±0.5% if calibrated

ANSI Class* 600# 300#

Pipe Size

2”- 6” 6”- 48”

(50mm-150mm) (150mm-1200mm)

Instrument Connection 1/2” NPT 1/2” NPT or Direct Mount

Components Furnished

Weld coupling, tube fitting;

V110 includes additional weld coupling and plug

Weld Coupling Size 3/4” NPT 1” NPT

Page 2

Verabar

®

Verabar

F

lo

w

C

a

lc

u

la

tio

n

P

ro

g

ra

m

F

lo

w

C

a

lcu

la

tio

n

P

ro

g

ra

m

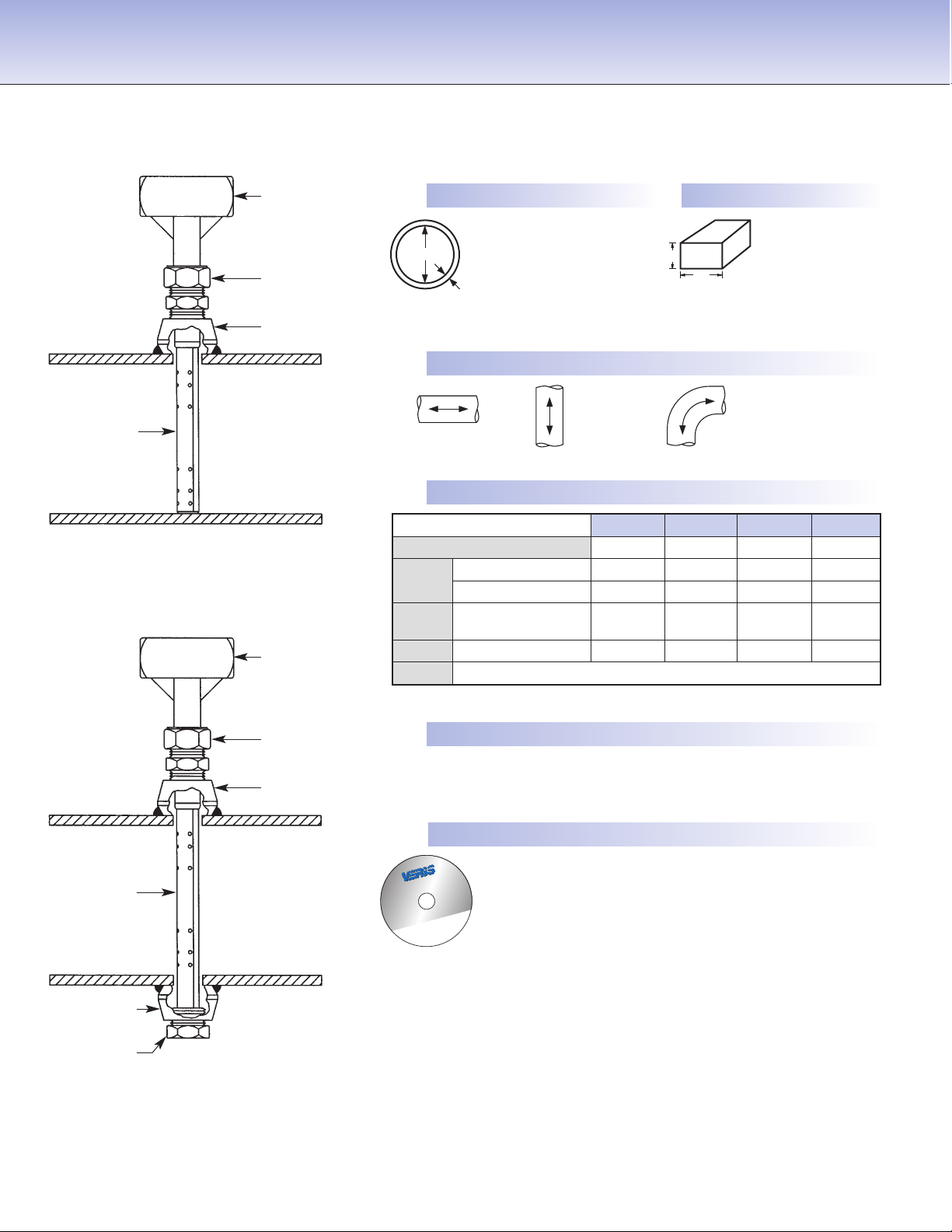

5.

Flow Calculation

All Verabar applications require a flow calculation to verify

the DP, pressure and temperature limits, structural limits

and to size the transmitter. The Veracalc PC Program

is for use by representatives and end users. It is easy

to operate and includes steam tables.

V100 (Single Support)

V110 (Double Support)

Verabar®Regular Models

Instrument

head (SS)

Tube fitting

(SS)

Weld coupling

(CS) (SS-opt)

Sensor (316SS)

Sensor (316SS)

4.

Select Model from Page 3

Use the Ordering Information table on Page 3 to determine your

model number.

Short

Straight Run

Consult Factory

(V) Vertical

(H) Horizontal

Pipe Size _____ Sch _____

Pipe ID _____ and

Wall _____ Pipe Mat’l _____

Wall

Height (H) _____

Width (W) _____

Wall _____

Duct Mat’l _____

Dimension

Verabar spans

(H) or (W)

Fluid Name: Maximum Normal Minimum Units

Flow Rate

All

Temperature @ Flow

Fluids

Pressure @ Flow

Gas

Specific Gravity, or

Molecular Weight

Liquid Specific Gravity

Steam Veracalc Program can calculate Density from Temperature and Pressure

ID

W

H

2.

Pipe or Duct Orientation

3.

Enter Flow Conditions

1.

Enter Pipe Dimensions or Duct Dimensions

Furnish the following information:

Weld coupling

(CS) (SS-opt)

Instrument

head (SS)

Tube fitting

(SS)

Weld coupling

(CS) (SS-opt)

Plug (CS)

(SS-opt)

Page 3

Model Regular

V100 Compression Fitting (Single Support)

V110 Compression Fitting (Double Support)

Pipe Size and Schedule or Exact ID and Wall Thickness

Code Sensor Pipe Size Range

05 2” to 6” (50mm to 150mm)

10 6” to 48” (150mm to 1200mm)

Code Pipe Orientation

H Horizontal

V Vertical

Instrument Connections

(Select Remote or Direct Mount)

(Transmitter sold separately)

Remote Mount Transmitter Direct Mount Transmitter

(1/2” NPT) (Flanged 450°F/232°C Max.)†

Parallel Regular RTD

*

Valve Transmount Mass Transmount

*

Manifold

PR D T F G E M

Code Options

For stainless steel pipes.

WNS

For V100, furnished with one SS weld coupling.

For V110, furnished with two SS weld couplings and

one SS plug.

V100 8”sch40 10 H R C2NC Typical Model Number

Ordering Information

*

For high pressure (>500psig) or high temperature (>500°F), remote mount RTD in a thermowell is preferred.

† Assuming adequate heat dissipation for transmitter.

Instrument Valves (Opt.) Manifolds (Optional)

Remote Mount Direct Mount

Needle Gate 3-Valve 5-Valve

C2NC (CS) C2GC (CS) F3SC(CS) F3HC (CS) F5SC (CS) F5HC(CS)

C2NS (SS) C2GS (SS) F3SS (SS) F3HS (SS) F5SS (SS) F5HS (SS)

1/2” NPT Soft Seat Hard Seat Soft Seat Hard Seat1/2” NPT

Explsn. Proof

Remote

RTD

Integral

RTD

Integral

Integral

Optional

Page 4

6315 Monarch Park Place •Niwot, CO 80503 USA •Phone: 303-652-8550 •Fax: 303-652-8552

E-Mail: contact@veris-inc.com

•

Website: www.veris-inc.com

True Performance in DP Flow Measurement

PSS-100 (1/07)

Printed in USA

ISO 9001 Certified

Loading...

Loading...