Page 1

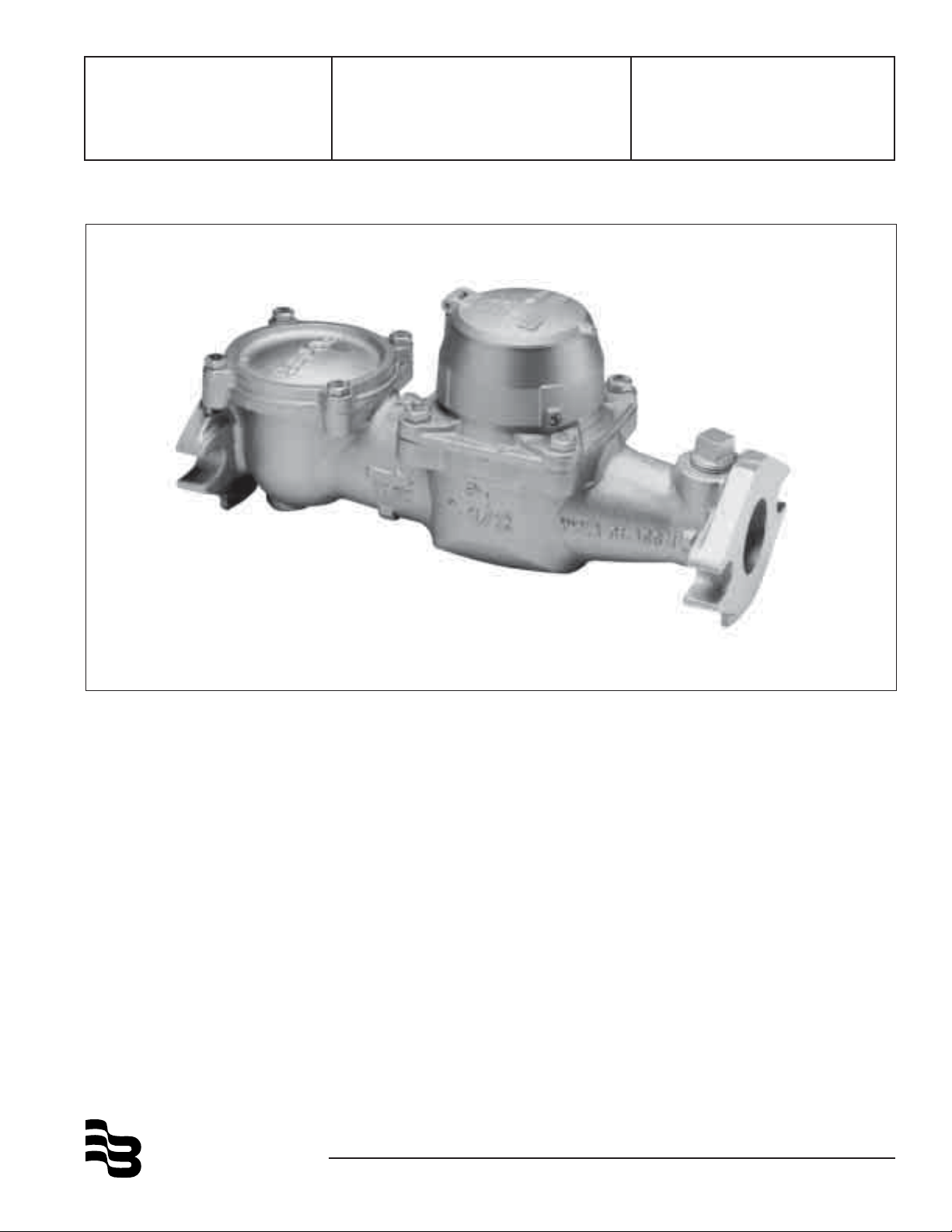

Recordall® Turbo

Series Meters

Sizes 1 ½", 2", 3", 4", 6", 8",

10", 12", 16" and 20"

Installation &

Operation Manual

RTS-IOM-5

BadgerMeter,Inc.

®

P/N: 53407-004 Rev. 6

10-03

Page 2

PREFACE

SCOPE OF MANUAL

This manual contains information concerning the installation, operation and maintenance of Recordall® Turbo Series meters with magnetic drive.

To ensure efficient operation of the meters, the instructions in this manual should be thoroughly read and understood. Retain this manual in a

location where it is readily available for reference.

Section I

GENERAL INFORMATION

1-1. DESCRIPTION

Recordall® Turbo Series meters utilize proven design features such

as thrust compensated rotor geometry, direct drive magnetic coupling

and dual outboard rotor bearings to achieve high accuracy over a broad

flow range. Extended product service life is achieved at higher levels

of accuracy, in addition to lower meter maintenance costs. Recordall

Turbo Series meters are available in 1 1/2", 2", 3", 4", 6", 8", 10", 12",

16" and 20" sizes.

Incorporating unitized construction with corrosion-resistant assemblies, the basic components of the Recordall Turbo Series consist of

the housing and completely removable measuring element. Permanently sealed for greater product reliability, the straight-reading local

register and Recordall Transmitter Register (RTR®) allow in-line

servicing. The meter housing and cover plate are bronze (1 1/2" - 10").

The 12" - 20" meter housings are cast iron with a heat fused epoxy

coating. The measuring element is constructed of high-impact

strength thermoplastics. Recordall Turbo Series meters are also

equipped with an integral calibration mechanism for in-line accuracy

calibration.

In the operation of a turbo meter, water flows through the straightening

vanes and a nose cone at the inlet side of the meter so that the swirling

effect of upstream piping is minimized. The water then strikes the rotor

blades, causing the rotor to turn. A downstream nose cone includes

straightening vanes to limit the downstream effects of flow profile

distortions. Optional NPT test ports are provided for field performance

testing.

Motion of the rotor is transferred by means of a worm drive to a vertical

shaft driving a gear set, which transmits the rotation to the meter's

registration device. The direct drive magnetic coupling provides

accurate flow registration during line surges, and allows the permanently sealed register to be easily removed to facilitate in-line service.

A pictorial description of the meter's components and location can be

found in the illustrated parts list RTS-P-1 which is provided as a

supplement to this manual. Each assembly or part has an item number

that is cross-referenced to an associated parts list which consists of

the service assemblies and parts shown in the exploded illustration.

The list provides the following information:

a. Item number

b. Name of part

c. Part number

1-2. CONFIGURATIONS AND SPECIFICATIONS

A descriptive brochure, exploded parts list, pressure loss and accuracy

charts are available and show the available sizes, flow range, head

loss, laying length and weight for Recordall Turbo Series meters. The

difference between various meter configurations relate primarily to

flange connections and options for units of registration, i.e., U.S.

gallons, cubic feet, etc. Materials used in the construction of the

meters are also described in the accompanying literature.

1-3. ACCESSORIES

Badger's Recordall Transmitter Register (RTR) is available as an

option for Recordall Turbo Series meters. The RTR provides system

connectivity to the Itron® ERT®, ORION® and TRACE® meter reading

systems.

Badger Plate Strainers 2" - 20" are also available. Recommended for

use with all turbo meters, Badger Plate Strainers provide exceptional

meter protection while improving meter accuracy and reliability. The

1 1/2" - 4" Turbo Series meters are available with integral stainless

steel plate strainers.

Section II

INSTALLATION

2-1. UNPACKING AND INSPECTION

To avoid damage in transit, Badger® Recordall Turbo Series meters

are shipped to the customer in special shipping containers. Upon

receipt of shipment, be sure to follow these unpacking and inspection

procedures:

NOTE

If damage to a shipping container is evident upon receipt

of a meter, request that a representative of the carrier be

present when the meter is unpacked.

a. Carefully open the shipping container, following any instructions

that may be marked on the container. Remove all cushioning material

surrounding the meter and carefully lift the meter from the container.

Keep the container and all packing material for possible use in

reshipment or storage.

b. Visually inspect the meter and applicable accessory devices for

any signs of damage such as scratches, loose or broken parts or other

physical damage that may have occurred during shipment.

NOTE

If damage is found, request an inspection by the carrier's

agent within 48 hours of delivery. Then file a claim with

the carrier. A claim for equipment damaged in transit is

the responsibility of the customer.

2-2. INSTALLATION

Procedures for installing Badger Turbo Series meters are essentially

the same for all meter sizes. Any special instructions required for the

installation or connection of accessory devices such as strainers will

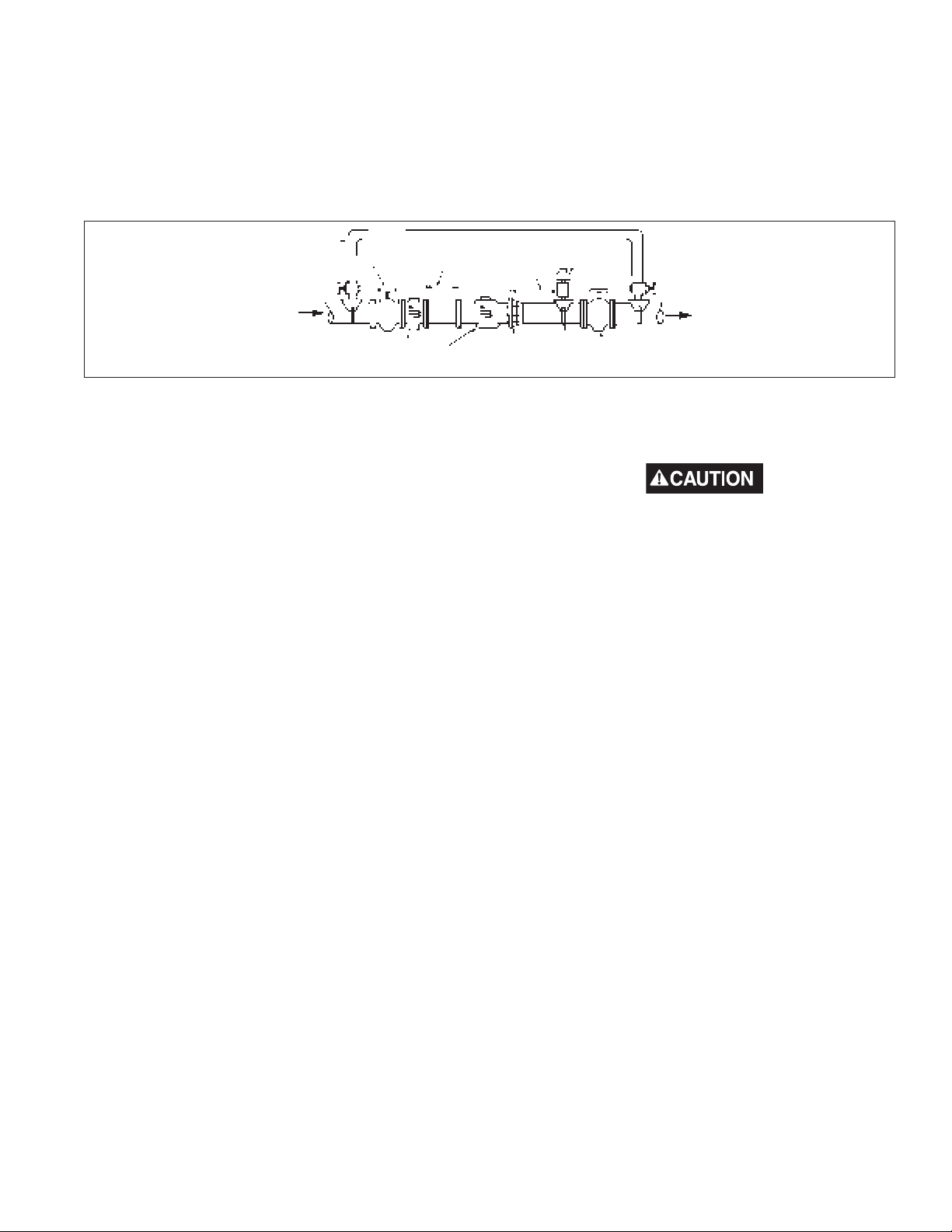

be provided as supplements to this manual. Figure 1 outlines a

recommended meter installation.

A. PRELIMINARY CONSIDERATIONS. Before proceeding any further with the installation, first read the instructions in the paragraphs

immediately following to become familiar with the requirements and

procedures involved.

NOTE

Badger Recordall Turbo Series meters are designed for

operation in HORIZONTAL piping arrangements.

1. Be sure that the meter flow range and size of the meter coincide

with the intended service and demand for water.

The life of the turbo meter will be curtailed if operated at

flow rates higher than specified. (Reference Technical

Briefs).

2. The meters are designed for use in cold water service (up to

120°F or 49°C) within the applicable flow requirements for turbo

Page 2

Page 3

meters. For use with water at higher temperatures, consult your

Badger Meter representative or nearest Badger regional sales office.

3. Installation of a strainer is recommended upstream of the meter.

The strainer, in addition to protecting the meter from debris in the line,

minimizes the effect of velocity profile distortions or turbulence caused

by changes in pipe direction or valving resulting in more accurate

registration. Contact your Badger Meter representative for information on Badger® Plate Strainers.

4. Avoid locating the meter in close quarters. Allow sufficient

space to permit access for meter reading, testing, and maintenance.

BY-PASS

(PERMANENT OR

TEMPORARY)

VALVE

(open)

MINIMUM OF FIVE

DIAMETERS OF

STRAIGHT PIPE

B. INSTALLING THE METER. Overall dimensions and laying lengths

of each meter size are shown on the Technical Briefs. After reviewing

the applicable dimensional requirements, choose an appropriate installation point in the piping and proceed as follows:

1. Measure precisely the overall length of the meter with gaskets

attached to the inlet and outlet flange connections.

2. Provide proper gap length in service piping.

3. Install meter in the pipeline so that the flow arrow on the meter

housing points in the same direction as water flow.

MINIMUM TWO

PIPE DIAMETERS

DOWNSTREAM

OF TURBO

METER

TEST TEE

UPSTREAM

BADGER PLATE

STRAINER AND TURBO

SERIES METERS

Figure 1. Recommended Meter Installation

5. Because of the need to test large meters periodically to verify

their performance, it is recommended that a bypass system be

incorporated into the piping arrangement. This will also provide a

means of performing periodic cleanout and routine maintenance

without interrupting service to the customer. A test tee can be installed

downstream of the meter for field accuracy testing.

6. The Recordall® Turbo Series is accuracy and pressure tested

prior to shipment, therefore no field adjustments are required. As

turbine performance is directly related to the flow conditions of the

water stream entering the meter, upstream fittings and piping changes

can adversely affect flow registration. To insure valid registration and

proper performance, the following factors should be considered when

installing Recordall Turbo Series meters and Turbo Series meters with

integral strainers.

a. When installing the meter with a separate Badger Plate

Strainer or integral strainer, a minimum of five (5) pipe diameters of

straight, unobstructed pipe is recommended upstream of the meter.

For optimum protection and accuracy, this straight pipe spool piece

should be installed between the separate strainer and meter as

illustrated in Figure 1. (A minimum of ten (10) pipe diameters (minimum

of 25 pipe diameters for smallest size) of straight unobstructed pipe

is recommended upstream of a meter installed without a plate strainer.

The deletion of a strainer, however, is not recommended.) This allows

for dampening of velocity profile distortions caused by elbows, pumps,

dirt traps, etc., prior to the meter. Where spiral flows are created by

three dimensional elbows or rotary pumps, additional distance to

dampen the effect is beneficial. If a basket or Y-type strainer is utilized,

it is recommended that it be placed five (5) to ten (10) pipe diameters

prior to the meter to dampen velocity profile distortions created by this

design.

b. Do not install check valves or pressure reducing devices

upstream of the meter.

c. Valves immediately upstream of the meter should only be

fully-open gate valves. Butterfly valves are acceptable if they are five

(5) pipe diameters or more upstream from the meter. Downstream,

fully open gate or butterfly valves can be used.

d. The service saddle (or reducing tee) which is used for field

accuracy testing should be at least two (2) pipe diameters downstream

of the meter's outlet flange.

e. Unweighted check valves should not be located closer than

three (3) pipe diameters downstream of the meter.

f. Externally weighted check valves and pressure reducing

devices should not be located closer than five (5) pipe diameters of the

meter.

g. When installing a turbo meter and plate strainer of a size

smaller than the pipe installation, to reduce the effect of jetting caused

by the increase in flow velocity, a minimum of five (5) pipe diameters

is recommended upstream of the meter. Additional length is recommended if a sharp contraction or an eccentric reducer, rather than a

concentric, tapered reducer is used.

DOWNSTREAM

COUPLING

ADAPTOR

SERVICE

SADDLE

SHUT-OFF

VALVE

4. With meter and gaskets in place, tighten flange connection bolts.

5. To relieve possible strain on the piping, it is recommended that

a meter support be used under the meter housing where appropriate.

Turbine meters must operate in a completely filled line

at all times. The downstream piping must always be

arranged to provide sufficient back pressure to maintain

a full line at the meter. By eliminating air in the line, as

well as sudden flow surges, inaccurate registration and

damage to the turbine mechanism can be avoided.

2-3. RECORDALL TRANSMITTER REGISTER OPTION

Badger Meter Recordall Transmitter Registers are designed for use

with the Recordall Turbo Series. If the meter has been purchased with

a RTR®, the installation guidelines as outlined in the Installation Data

Sheet should be followed.

Before proceeding with the installation, be sure that the Recordall

Transmitter Register corresponds to the meter size, and unit of

measure.

2-4. PERFORMANCE CHECKS

Any valves or devices controlling the flow of water through a turbo

meter must always be opened and closed SLOWLY to prevent shock

loads that may damage the meter's rotor assembly.

Complete the following checks to ensure that a turbo meter is properly

installed and operational:

a. Slowly open upstream valve to apply water pressure to the meter

and check to see if there are any leaks. Tighten flange bolts as

required.

b. Perform a functional test of the meter. Slowly open valve on

downstream (consumer) side of the meter to evacuate any air that may

have been trapped in the service line. When air has been eliminated,

increase demand flow rate by further opening of downstream valve or

valves. Observe register for correct direction of flow. The large test

pointer will now move in the proper direction. Now open all applicable

service valves.

c. Adjust rate of flow by throttling with the downstream valve so the

flow does not exceed the maximum continuous duty specification as

defined in the Technical Briefs. The rate of flow can be quickly checked

by timing the quantity registered through the meter in one minute.

2-5. SHUTDOWN INSTRUCTIONS

If the turbo meter is to be shut down for an extended period of time or

if it is being removed from service, Badger recommends that the meter

and measuring components be thoroughly flushed to prevent the

settling out of undissolved solids or the accumulation of corrosive

deposits. If there is an upstream strainer in the line, it also should be

flushed at this time.

Page 3

Page 4

Section III

MAINTENANCE

3-1. GENERAL

This section is limited to information about general preventative

maintenance and calibration procedures for Badger® Recordall® Turbo

Series meters, whereas instructions for disassembling the meters for

servicing can be found in Section IV. A repair parts list, exploded views

and other illustrations are provided as a supplement to this manual.

3-2. MAINTENANCE EQUIPMENT

The tools and equipment recommended for servicing and maintenance of Recordall Turbo Series meters consist of the usual complement of hand tools used by plumbers and mechanics.

3-3. PREVENTATIVE MAINTENANCE

The purpose of preventative maintenance is to ensure efficient

operation and long life by detecting and correcting any condition that

may damage the meter or cause it to fail. Maintenance intervals are

a function of the water quality and operating flows experienced by the

meter. Preventative maintenance includes periodic inspection, accuracy testing and cleaning procedures.

a. PERIODIC INSPECTION

1. Visually inspect the meter for missing hardware, loose screws,

broken or scratched register lens or any other signs of wear or

deterioration. Replace worn parts as required.

2. Verify that the meter operates at the proper flow rate and

pressure. A loss in pressure coupled with a decrease in flow rate may

indicate that the screen in the upstream strainer or the meter itself is

clogged and needs cleaning.

b. CLEANING

1. Clean all dirt, grease, moisture or other foreign material from

the exterior of the meter. Use a cleaning solvent or volatile mineral

spirits to remove grease or oil. To clean the measuring element, soak

for 12 hours in a mild soap-based cleaner or detergent, and then use

a stiff nylon bristle brush to remove any deposits. After cleaning, rinse

thoroughly with water and dry.

2. In the event that the system pressure has been reduced and the

upstream strainer or meter is clogged, the foreign material must be

flushed out. To flush the strainer, open the cleanout plug and purge the

foreign material with fresh water from the service line. After the strainer

has been cleaned, purge the meter with fresh water and run discharge

out the nearest downstream outlet.

3. Integral Strainer Units. Before attempting service/maintenance of strainer section, system pressure must be removed. See

Section 4-2 to prepare meter for service. After system pressure is

removed, remove cover bolts and cover. Clean out/flush strainer

section of all loose particles/debris. After cleaning is complete,

reinstall screen and reassemble. See Section 2-4 and follow instructions to return meter to normal service.

3-4. CALIBRATION CHECK AND ADJUSTMENT

The accuracy of Badger Recordall Turbo Series meters is tested at the

factory before shipment. However, after a long period of service, it may

be necessary to recalibrate a meter. The meter can be tested for

accuracy using appropriate connections with either a test tank of

known volume or a test meter. The meter can be tested in the setting

by running output flow through the optional test port, if so equipped.

The Recordall Turbo Series integral calibration mechanism can be

adjusted under line pressure, simplifying and reducing calibration time.

The following instructions are provided to assist in performing a

calibration check and adjustment.

a. ACCURACY TEST

If the optional test port is to be used, upstream and

downstream valves must be closed prior to removing

plug and installing appropriate connections. Failure to

do so can lead to plug being ejected from housing,

causing personal injury and/or property damage. Wherever an installation is equipped with a drain valve for

meter flushing, open the drain valve to relieve pressure

within the meter. If the installation does not have a drain

valve, carefully loosen test plug until it begins leaking.

Stop and wait for pressure to bleed down, then continue

to slowly loosen, making certain pressure is completely

bled off before removing.

1. After installing appropriate connections, meter can be tested

by leaving setting downstream valve closed (if using integral test port),

and slowly opening upstream valve. Finally, the test circuit downstream valve can be slowly opened and used to throttle flow for test

purposes.

2. Place a test tank of known volume at the output of the meter.

(An alternative is to connect a calibrated test meter to the output.)

Accuracy testing requires test volumes at least as large as the register

test circle.

3. As in testing the accuracy of any meter, the Recordall Turbo

Series meter must first be purged of air by running water through the

meter.

NOTE

Good test practices are required to perform reliable field

accuracy tests such as those outlined in the AWWA M6

manual. Register "jump" can occur in some instances if

valves are abruptly opened or closed. While this jump is

not accumulative (no affects in service billing), it can

affect accuracy results (1% per division on a one test

circle volumetric test). Care during tests must be taken

to insure this does not occur.

LOCK SCREW

CALIBRATION

SHAFT O-RING

CALIBRATION

SHAFT SEAL

PLUG

CALIBRATION

SHAFT

Figure 2. Calibrating Recordall Turbo Series Meters, shown with

Optional Test Plug

4. Operate the meter until the test tank is filled to the calibrated

level or the predetermined quantity has registered on the calibrated

test meter. Because accuracy may vary slightly with flow rate, it is

recommended that the meter be tested at low, intermediate and high

flows.

5. Record the quantity registered on the meter during the test.

6. Perform the following calculations to determine meter accuracy:

Quantity Registered on Meter

Test Tank or Test Meter Quantity

x 100 = Meter Accuracy

b. CALIBRATION. The meter's calibration ring is preset at the

factory and sealed. In normal service, it should not have to be reset.

If a retest is required in which a calibrated test stand reveals that the

meter needs recalibration, proceed as follows (see Figure 2):

Page 4

COVER

SCREEN

Page 5

1. Remove calibration shaft seal plug by puncturing plug in slot

provided and twist/pry plug from hole.

2. Loosen calibration shaft lock screw.

3. Adjust calibration ring with screw driver as follows:

TO INCREASE REGISTRATION. Turn the calibration shaft

clockwise. This will speed up the rotor, increasing registration.

TO DECREASE REGISTRATION. Turn the calibration shaft

counter clockwise. This slows down the rotor, decreasing registration.

NOTE

The total range of the calibration adjustment is about

10%. Tested and calibrated at the factory, the calibration mechanism will allow for a ±5% adjustment in the

field.

Section IV

SERVICING

4-1. GENERAL

When the performance of the meter indicates a need for servicing,

refer to the following instructions pertaining to removal, inspection and

installation of service parts and assemblies. With the Recordall® Turbo

Series unitized construction, service is simplified with a reduction in

required product maintenance training. Also refer to the illustrated

repair parts list RTS-P-1 for part numbers of replaceable components

for ordering information. If satisfactory repair cannot be achieved,

contact the Utility Division of Badger Meter, Inc.

4-2. REMOVAL OF METER HEAD

Recordall Turbo Series meters can be serviced without removing them

from the line. A typical installation would be equipped with drain and

piping valves. To inspect or replace components of the head assembly, close the upstream and downstream valves. However, if the

installation does not have a drain valve, proceed as follows to relieve

pressure:

Due to the floating rotor design principle, the calibration

mechanism contains some clearance for proper part fit

resulting in some hysterisis or "deadband" when changing

directions with calibration shaft. Adjustments should be

made in small increments in one direction to avoid need for

counter rotation. If desired setting is exceeded, counter

rotations in small increments should be made, even though

first reverse setting may result in no apparent change.

This is normal, and subsequent changes will cause reverse accuracy curve shift.

4. With the calibration shaft turned to the desired setting, tighten the

lock screw while maintaining the calibration shaft position.

5. Retest the meter to confirm the accuracy of the calibration

setting. If the meter is still out of calibration, repeat the procedure.

6. Replace the calibration shaft seal plug with a new one.

SEAL

SCREW

SEAL

SCREW

Upstream and downstream valves must be closed before

attempting to remove meter head from housing. Failure

to do so can lead to head being "ejected" from housing,

causing personal injury and/or property damage!

a. Loosen each of the head bolts about one and one-half turns.

Do not completely remove the bolts.

b. If the O-ring between the meter head and the housing is secure

and not leaking, pry the measuring element assembly loose by

inserting a screwdriver blade where the head and housing join together.

Be sure that any water coming out of the meter head

does not spray onto electrical equipment to create a

shock hazard.

c. Allow the meter to drain and relieve internal pressure.

d. When pressure is relieved, remove the head bolts. Lift the

measuring element assembly from the housing.

NOTE

A dummy cover plate is available to close the meter in

the line and continue service while the measuring ele-

ment assembly is being inspected or serviced. (See

illustrated repair parts list RTS-P-1.)

4-3. LOCAL REGISTER AND RTR REMOVAL

The Recordall Turbo Series meter register is easily removable to

facilitate in-line service. Remove the register lid and shroud by

removing the seal screw. The shroud is removed by rotating the

register assembly counter clockwise until it stops. This provides

clearance so it can be lifted off the measuring element assembly (see

Figure 3a and 3b). To reinstall the register, follow the above procedure

in reverse order.

Page 5

COVER PLATE

HOLD DOWN

STRAP

TRANSMISSION

SHAFT GEAR

TRANSMISSION

STRAIGHTENING

VANE ASSEMBLY (2)

PROTECTION

SHAFT

BOTTOM

BEARING

NOSE CONE/

NOSE CONE

SET SCREW (2)

CALIBRATION

CALIBRATION

SHAFT O-RING

TUBE

MAGNET

CARRIER

ASSEMBLY

CAGE

INSERT

TRANSMISSION

SHAFT

ASSEMBLY

SHAFT SEAL

PLUG

ROTOR

CALIBRATION

SHAFT LOCK

THRUST WASHER

CALIBRATION

CAGE SET

SCREW

CAGE SEAL

Figure 3a. Register and Measuring

Element Assembly, 1 1/2" - 4"

SCREW

SHAFT

HEAD

O-RING

CALIBRATION

LINKAGE

CALIBRATION

RING

Page 6

EYEBOLTS

TRANSMISSION

SHAFT GEAR

NOSE CONE

SETSCREW

TRANSMISSION

SHAFT ASSEMBLY

NOSE CONE/

STRAIGHTENING

VANE ASSEMBLY (2)

COVER

RETAINING

LOCK SCREW

CALIBRATION GEAR

PLATE

RING

CALIBRATION

DRIVE PLATE

PROTECTION

TUBE

ROTOR

CALIBRATION

RING (REAR)

BEARING

CAGE SEAL

O-RING

SEAL PLUG

THRUST WASHER

CALIBRATION

SHAFT

MAGNET

CARRIER

CAGE

INSERT

HEAD BOLT

HEAD

O-RING

CALIBRATION

RING (FRONT)

CAGE

SETSCREW (4)

WASHER (4)

Figure 3b. Register and Measuring

Element Assembly, 6"

4-4. MEASURING ELEMENT ASSEMBLY

Remove the O-ring and cage seal. Check for damage and clean or

replace prior to reassembly.

NOTE

A cage seal is installed in the 1 1/2" - 6" Recordall® Turbo

Series so that the entire water volume flows through the

measuring element.

To remove measuring element from cover, remove calibration shaft

seal plug and lock screw (see Figures 3a and 3b). Place cover register

side down on table or flat surface. Lightly tap or press calibration shaft

from wet side out of bore in cover (1 1/2" - 4" only). Care should be

taken not to strike or bend the calibration linkage.

The measuring element insert can be removed from the cover plate for

service or replacement by removing the cage set screw (see Figures

3a and 3b, quantity 4 for 6" size. Holding the cover plate in one hand,

rotate the thermoplastic element counter clockwise until the bayonettelike tabs are aligned with open areas of the cover plate (1 1/2" - 4" only).

Remove element from cover plate.

4-5. STRAIGHTENING VANES/NOSE CONE

The straightening vanes are an integral part of the upstream and

downstream nose cone assemblies (see Figures 3a and 3b). To gain

access, the measuring element must be removed from cover as

outlined in Section 4-4 above.

Removal of upstream nose cone provides access to rotor, calibration

ring and transmission assembly. To remove nose cone, unscrew the

upstream nose cone setscrew. For 1 1/2" - 4", slide calibration linkage

into cage insert stop. Take hold of the nose cone/straightening vanes

and turn clockwise, thereby disengaging the calibration linkage from

the tab on the calibration ring and unlocking bayonettes of nose cones

from cage (see Figure 4a). If tab of calibration ring has not disengaged

linkage, rotate ring carefully by pushing struts at interior of element

(between straightening vanes and rotor). Pull the nose cone assembly

out from the measuring element insert. For 6", remove transmission

gear by lifting off shaft, noting alignment of "D" shaped bore with flat

on shaft (required to align for assembly). Next remove retaining ring

that holds down calibration drive plate, located under magnet carrier

magnet (see Figures 3b and 4b). Remove drive plate. Rotate

calibration ring until pin clears slot of cage. Take hold of the nose cone/

straightening vanes and turn clockwise. Pull the nosecone assembly

out from the measuring element insert. Remove rotor assembly.

Rear nose cone removal requires transmission shaft removal (see

Figures 3a, 3b, 4a and 4b). First, remove strap over gear (1 1/2" - 4"

only). Gear is removed from shaft by simply lifting off. Note shaft has

a flat that matches with "D" shaped bore in gear (required to align for

assembly). Remove nose cone set screw. Remove protection tube by

carefully pressing (with flat surface of blade screwdriver) on bottom of

tube located inside rear nose cone. Press to release detent lock,

approximately 1/4" vertical travel, then lift tube out from top of cage

insert. Lift transmission shaft assembly up and out of bottom bearing,

then slide shaft downward and diagonally out (towards you) to remove

from nose cone/cage assembly. Finally, holding cage firmly with one

hand, rotate nose cone clockwise with other hand, then carefully lift off

cage. Reinstallation is reverse of removal.

Refer to Section 4-8 of this manual to correctly reassemble components.

4-6. CALIBRATION MECHANISM

To disassemble the calibration ring assembly, the following procedures are required (see Figures 3a and 3b). Refer to Sections 4-2

through 4-5 above. Remove the calibration shaft seal plug and

unscrew the calibration shaft lock screw from the cover plate. Remove

the calibration shaft thrust washer and calibration shaft. The calibration shaft can be pressed out of the cover plate from below. The

calibration shaft O-ring may be removed if a leak exists at this point in

the disassembly of the meter. If replaced, the O-ring should be coated

slightly with a silicon grease before insertion. Clean all parts as

required.

To gain access to the calibration ring, the straightening vane/nose

cone must be removed. See Section 4-5 to remove. To remove

calibration ring from nose cone assembly, align the ring slots with

bayonettes of nose cone assembly located on inner ring of calibration

ring. To remove, carefully lift the calibration ring from the nose cone

assembly. Reinstallation is the reverse of this procedure.

CALIBRATION

CAGE

INSERT

CALIBRATION

LINKAGE

SMALL HOLE

WITH

CHAMFER UP

RING

TOP SIDE

PIN

NOSE

CONE

LARGE HOLE

WITH

CHAMFER

DOWN

Figure 4a. Calibration Ring/Linkage Assembly, 1 1/2" - 4"

Page 6

ARROW

TIP

INTO CAGE

THIS END

Page 7

CAGE INSERT

(TOP VIEW)

TRANSMISSION

GEAR

CALIBRATION DRIVE

PIN OF

CALIBRATION

RING

RETAINING RING

PLATE

Figure 4b. Calibration Ring/Linkage Assembly, 6"

NOTE

When reassembling, the pin on the perimeter of the

calibration ring must be aligned with the arrow tip located

on the nose cone assembly (see Figure 4a). For 1 1/2"4" sizes, the calibration linkage is to be installed into cage

with larger hole to engage calibration ring tab, and side of

chamfered edge of hole towards nose cone assembly

(see Figure 4a). With calibration linkage fully inserted to

cage stop, install nose cone onto cage and rotate counterclockwise. This rotation engages pin of ring to calibration

linkage. The hole of the calibration linkage has to be

aligned onto the calibration shaft, engaging it fully so that

the calibration ring cannot vibrate during operation. The

calibration shaft lock screw should also be tightened

securely to hold the calibration ring in its desired position.

After the calibration mechanism is serviced or replaced, be sure to check

the accuracy and calibration in accordance with the instructions in

section 3-4 of this manual.

4-7. MAGNET CARRIER/TOP GEAR SET

Remove the magnet carrier from the measuring element insert by lifting

it off the stainless steel pin (see Figures 3a and 3b). Check the

condition of the magnet and gear on the magnet carrier for damage or

wear. If significant wear or damage is present, replace the magnet

carrier.

Remove the hold down strap (see Figures 3a and 3b.) Check the

condition of the transmission shaft gear for damage or wear. If

significant wear or damage is present, replace the gear. Remove gear

by lifting off the shaft.

ROTOR

BEARINGS

ROTOR

WORM

NOSE CONE

ASSEMBLY

(2)

BEARING

(2)

PIN

Figure 5. Rotor and Nose Cone Assembly (1 1/2" - 6" Turbo

Meters)

4-8. ROTOR AND BEARINGS

The rotor can be inspected by removing the nose cone assembly from the

measuring element insert as outlined in section 4-5 of this manual.

Check the rotor worm and blades for signs of damage and wear. Also

inspect the bearing bushings in the front and rear shaft. If damage or

wear has occurred, replace the part (see Figure 5).

The rotor bearing pins in the straightening vane and nose cone

assembly should be inspected for signs of damage and wear (see

Figure 5). The spherical end of the bearing pin must not show any drag

lines and/or wear.

NOTE

Only highly-polished bearing pin ends insure a minimum

of friction and optimal meter performance. Bearing pins

are an integral part of the straightening vane and nose

cone assembly. Wear or damage would require the

replacement of this component.

To reassemble, the rear nose cone must be installed to cage. See

section 4-5. Now place the rotor assembly with worm gear side leading

through the cage, place on the rear rotor bearing pin, while tipping the

assembly back so that the opening is up. See section 4-6 to insure

calibration rings are properly assembled with nose cone assembly.

Insert the front nose cone assembly partially onto the cage insert,

engaging the bearing pin with the front bearing of the rotor. Tilt the

measuring element insert assembly forward and back to see that the

rotor now engages the bearing pins on the straightening vane/nose

cones and is free to rotate and slide fore and aft.

Page 7

Page 8

Be careful not to force the nose cone assembly into the

cage insert. Be sure that rotor engages both front and

rear rotor bearing pins prior to pressing the nose cone

assembly fully into the cage insert.

Press the nose cone assembly fully into the cage insert and turn it

counter clockwise catching the calibration linkage in the slot. Check

to see that the rotor spins freely. If not, remove the nose cone

assembly and repeat the procedure. Install and tighten nose cone

assembly setscrew.

Holding the cover plate in one hand, align the thermoplastic cage

bayonette-like tabs with the slots in the cover plate (1 1/2" - 4" only).

Rotate the element clockwise until the cage set screw hole is aligned.

Install the cage set screws (quantity 1 for 1 1/2" - 4", quantity 4 for 6")

and tighten.

4-9. REINSTALLING METER HEAD ASSEMBLY

Badger recommends that a new housing O-ring be used after each

teardown and reassembly of the Recordall

®

Turbo Series. To provide

a tight seal, make sure the surfaces of the housing and meter head are

clean and free of any old O-ring material. Be careful not to force the

measuring element insert into the meter housing. If you experience

any binding, do not force the element into the housing. Remove the

element from the housing and properly reinsert the unit.

NOTE

Head bolts should be tightened similar to that on car tire.

First insert the bolts and snug-fit each. Then using a

crisscross pattern, tighten the bolts down. Following this

pattern, the meter head will not turn allowing the rotor to

remain perpendicular to the flow and eliminating any

potential flow distortion. Head bolts should be tightened

to 10-11 ft. lbs. for 1 1/2" and 2" sizes, and 35-40 ft. lbs.

for 3" - 6" sizes.

The registration device should be reinstalled on the meter body.

To place the meter back in service, close the flushing system drain

valve. Open the upstream valve partially, then open the downstream

valve slightly to purge air from the service line. Then open both valves

completely.

ORDERING INFORMATION

Order replacement service parts for your Recordall Turbo Series

through your local Badger Meter sales representative. When placing

an order, please provide the following information:

a. Size of meter.

b. Registration units, i.e., U.S. gallons, cubic feet, etc.

c. Complete description of assembly or parts required.

d. Part number of item as shown in the repair parts list (RTS-P-1).

e. Quantity required.

f. Purchase order number, plus exact return and billing address.

Badger®, ORION®, Recordall® and RTR® are registered trademarks of Badger Meter, Inc.

TRACE® is a registered trademark of American Meter Company.

Itron® and ERT® are registered trademark s Itron, Inc.

Please see our website at

www.badgermeter.com

for specific contacts.

Copyright © Badger Meter, Inc. 2003. All rights reserved.

Due to continuous research, product improvements and enhancements,

Badger Meter reserves the right to change product or system specifications

without notice, except to the extent an outstanding bid obligation exists.

BadgerMeter,Inc.

P.O. Box 245036, Milwaukee, WI 53224-9536

(800) 876-3837 / Fax: (888) 371-5982

®

www.badgermeter.com

Loading...

Loading...