Page 1

TM

the user will be required to correct the interference at his own expense.

ENERCEPT ™ H8035/H8036

Networked Power Transducer (Modbus RTU)

Installer’s Specifications

Measurement A ccuracy:

Syste m Accuracy ±1% of reading from 10% to 100% of the rated current *

Type of Measurement One or three phase AC system

Input Voltage Characteristics:

Measured AC Voltage 208-480 VAC

POWER MONITORING

US Patent No. 6,373,238

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Follow safe electrical work practices. See NFPA 70E in the USA, or applicable local codes.

• This equipment must only be installed and serviced by qualified electrical personnel.

• Read, understand and follow the instructions before installing this product.

• Turn off all power supplying equipment before working on or inside the equipment.

• Use a properly rated voltage sensing device to confirm power is off.

DO NOT DEPEND ON THIS PRODUCT FOR VOLTAGE INDICATION

• Only install this product on insulated conductors.

Failure to follow these instructions will result in death or serious injury.

A qualied person is one who has skills and knowledge related to the construction and

operation of this electrical equipment and the installation, and has received safety

training to recognize and avoid the hazards involved. NEC2009 Article 100

No responsibility is assumed by Veris Industries for any consequences arising out of the

use of this material.

CAUTION

RISK OF EQUIPMENT DAMAGE

• Enercept meters are rated for use at 50-60Hz. Do not connect this product to circuits with

high harmonic energy, such as Variable Speed Drives (a.k.a. Variable Frequency Drives,

Adjustable Frequency Drives) or similar sources, as these may permanently damage the

product.

Failure to follow these instructions can result in overheating and permanent

equipment damage.

Frequency Range 50/60 Hz

Fuses 1/2A, 600VAC, 200 kAIC

Input Current Characteristics:

Maximum Primary Current 100, 300, 400, 800, 1600, or 2400 A, continuous p er phase**

Meter Current Draw:

Maximum 60 mA AC

Output:

Modbus RTU Protocol RS-485, 2-wire plus common

Baud Rate 9600

Mechanical Conditions:

CT Case Iso lation 600 VAC

Internal Isolation 2000 VAC RMS

Terminal Block Screw Torque 0.37 ft-lb (0.5 N·m) min.; 0.44 ft-lb (0.6 N·m) max.

Environmental Conditions:

Operating Temperature Range 2400 A model only: 0° to 50°C (32° to 122°F)

all other models: 0° to 60°C (32° to 140°F)

Storage Temperature Range -40° to 70°C (-40° to 15 8°F)

Operating Humidity Range <95% RH non-condensing

Agency Approvals:

US and Canada (cULus) UL508 (open ty pe device)

* Meter accuracy specied with conduc tors centered in the CT window.

** For amperages greater than 2400A, see App Note VN19, www.veris.com/applicationnotes.aspx

QUICK INSTALL

Disconnect and lock out power before installation.

1. Set the address switches located on the bottom of the CT.

2. Connect the voltage leads to the source to be monitored.

3. Snap the CT onto the conductor (observe color matching).

4. Connect the Modbus wires (observe polarity).

INSTALLATION GUIDE

NOTICE

• This product is not intended for life or safety applications.

• Do not install this product in hazardous or classified locations.

• The installer is responsible for conformance to all applicable codes.

• Mount this product inside a suitable fire and electrical enclosure.

FCC PART 15 INFORMATION

NOTE: This equipment has been tested by the manufacturer and found

to comply with the limits for a class A digital device, pursuant to part

15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and

used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in

a residential area is likely to cause harmful interference in which case

Modifications to this product without the express authorization of

Veris Industries nullify this statement.

For use in a Pollu tion Degree 2 or bet ter environment only. A Pollut ion Degree 2 environme nt must

control conductive pollution and the possibility of condensation or high humidity. Consider the

enclosure, t he correct use of ven tilation, thermal pro perties of the equ ipment, and the relatio nship

with the env ironment. Installat ion category: CAT II or C AT III

Z201686-0N PAGE 1 ©2012 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 08122

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other count ries.

TABLE OF CONTENTS

Quick Install 1

Operation 2

Product Identication 2

Dimensions 2

Product Diagram 2

Installation 3

Wiring 4

Data Outputs 4

Address Setup 5

Modbus Register Addressing 6

Using Integer Data Types 8

Notes 10

Troubleshooting 10

Page 2

H8035/H8036

TM

INSTALLATION GUIDE

OPERATION

The H8035 and H8036 three-phase power transducers monitor energy parameters

from aggregate kW (real power) and kWh (consumption) to power factor per phase.

Integration of electronics lowers hardware and installation costs. The sensors

automatically detect phase reversal, so CT load orientation is not a concern. The CTs

and electronics are calibrated as a set, so it is necessary to color-match the CTs and

voltage leads when installing. These devices monitor up to 63 loads at a time on a

single RS-485 drop.

With two platforms to choose from (H8035 Basic/Energy Only or H8036 Enhanced

Data Stream), the applications for these devices are diverse, including aggregate

billing, tenant monitoring, energy management, performance contracting, demand

limiting and cooling plant optimization.

PRODUCT IDENTIFICATION

Modbus Enhanced Data Stream Power Transducers*

MODEL MAX. AMPS CT SIZE

H8036-0100-2 100 SMALL

H8036-0300-2 300 SMALL

H8036-0400-3 400 MEDIUM

H8036-0800-3 800 MEDIUM

H8036-0800-4 800 LARGE

H8036-1600-4 1600 LARGE

H8036-2400-4 2400 LARGE

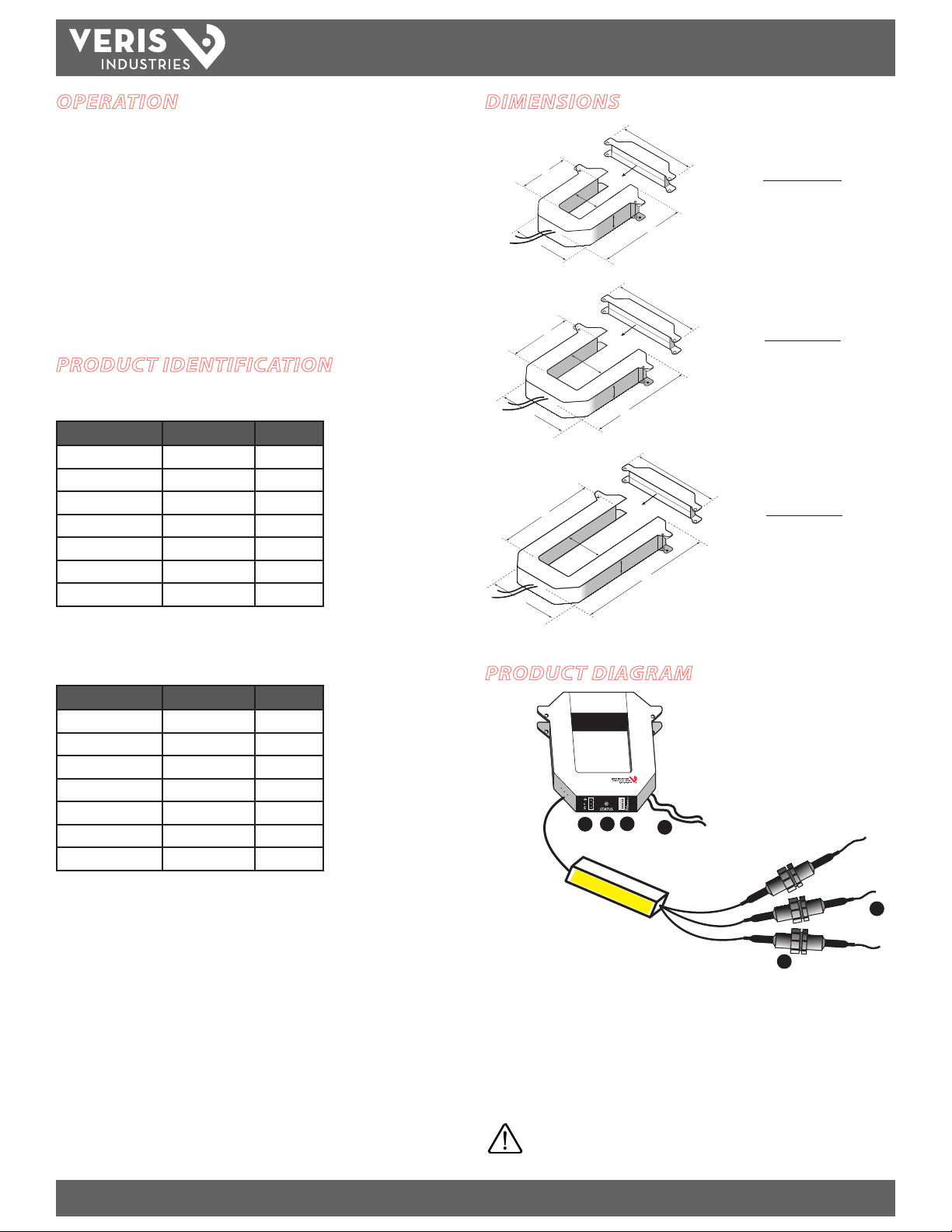

DIMENSIONS

B

C

A

B

C

A

B

C

A

F

SMALL

100/300 Amp

A = 3.8" (96 mm)

D

E

F

B = 1.2" (30 mm)

C = 1.3" (31 mm)

D = 1.2" (30 mm)

E = 4.0" (100 mm)

F = 4.8" (121 mm)

MEDIUM

400/800 Amp

A = 4.9" (125 mm)

D

E

F

B = 2.9" (73 mm)

C = 2.5" (62 mm)

D = 1.2" (30 mm)

E = 5.2" (132 mm)

F = 6.0" (151 mm)

LARGE

800/1600/2400 Amp

A = 4.9" (125 mm)

D

E

B = 5.5" (139 mm)

C = 2.5" (62 mm)

D = 1.2" (30 mm)

E = 7.9" (201 mm)

F = 6.0" (151 mm)

*H8036 models work with H8920-1 LON nodes

Modbus Basic Power Transducers*

MODEL MAX. AMPS CT SIZE

H8035-0100-2 100 SMALL

H8035-0300-2 300 SMALL

H8035-0400-3 400 MEDIUM

H8035-0800-3 800 MEDIUM

H8035-0800-4 800 LARGE

H8035-1600-4 1600 LARGE

H8035-2400-4 2400 LARGE

*H8035 models work with H8920-5 LON nodes

PRODUCT DIAGRAM

®

Enercept

5

4

3

1. Voltage leads

2. Fuses

3. Modbus connector

4. Status LED: Blink codes: slow green for normal operation; slow red for incorrect

wiring or low power factor (less than 0.5); fast red for maximum current exceeded.

5. Modbus address switches

6

2

1

6. External CTs: Permanently attached; do not disconnect or use with other power

transducers.

Color match CTs and voltage leads! Example: clamp the

red labeled CT around the power conductor connected to

the red voltage wire.

Z201686-0N PAGE 2 ©2012 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 08122

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other count ries.

Page 3

H8035/H8036

Wire tie

SHIELD

SHIELD

S

S

SHIELD

120Ω

Terminator

TM

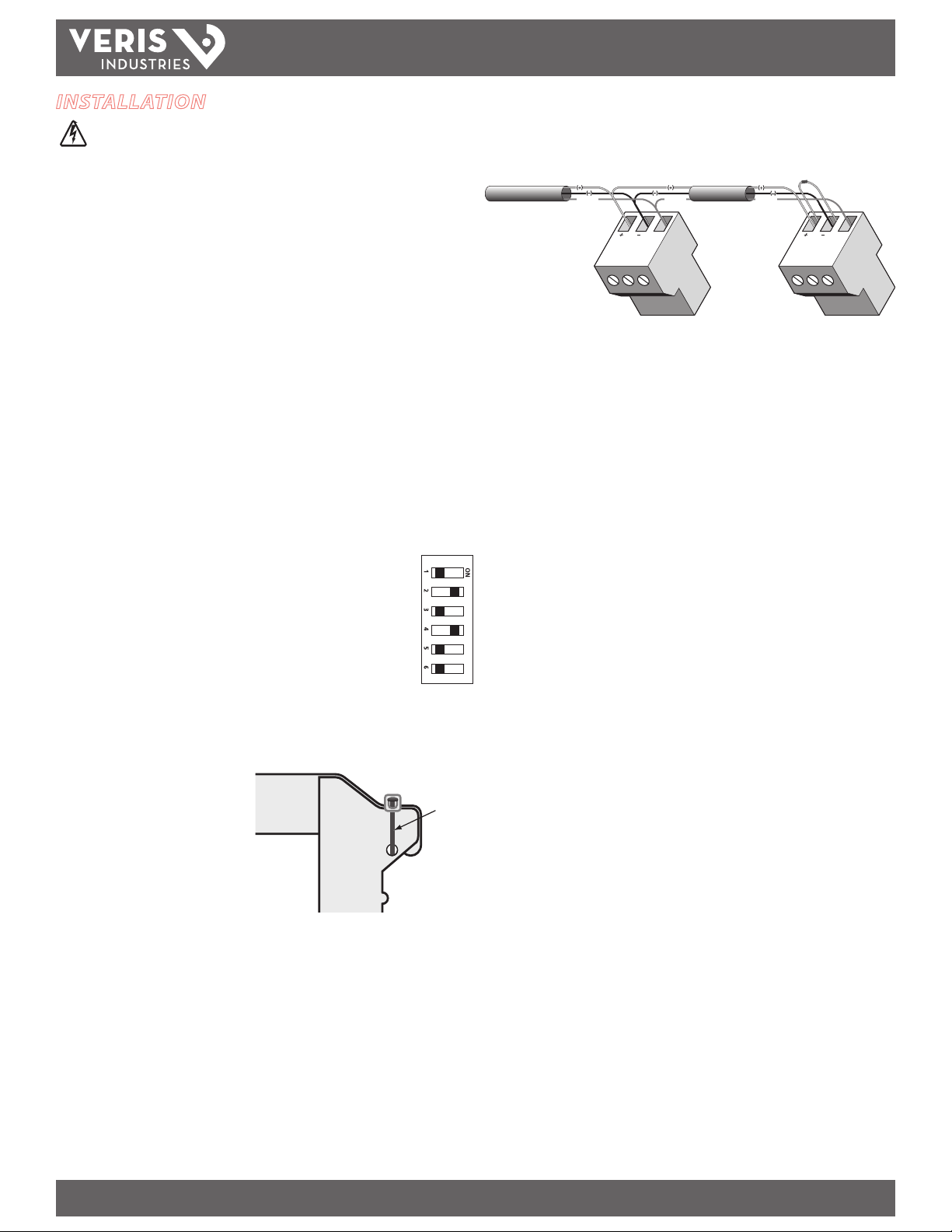

INSTALLATION

Disconnect and lock out power before installation.

The Enercept meter, including the current transformers (CTs), voltage connection

fuses, and fuse pack, is permitted within electrical distribution equipment

including but not limited to panelboards, switchboards, motor control centers, and

transformers. Carefully review the equipment in which the Enercept meter will

be installed. Consider the following installation conditions during the installation

process:

• Review the equipment enclosure for ventilation openings. Wires will cross

many of these openings in a normal installation, however, do not install

the Enercept where it will substantially block ventilation openings in the

enclosure.

• The Enercept meter and the wiring installed within a wiring space

or gutter should not exceed 75 percent cross sectional ll at the

Enercept meter parts as addressed in the NEC. Improper installation of

Enercept meter in the wire gut ter of equipment may aect the thermal

performance of the equipment.

• Consider the arrangement of CTs within the equipment to ensure the

correct bending radius of conductors.

• Review the arrangement and location of the CTs within the equipment.

Use appropriate support for the CT to prevent undue strain on the

conductor.

ADDRESS

1. Choose a unique address and set the switches for that address as

shown in the Address Selec tion Switches section. Only addresses 1

to 63 can be used.

2. Connect the voltage leads to the phase conductors at a location that

is not normally turned o. Connect voltage leads on the Line side

of the conductor to ensure constant power to the Enercept. For a

3-phase system, connect the red lead to phase A, black to phase B, and yellow to

phase C. See the Wiring section on the following page.

1

2

4

8

16

32

INSTALLATION GUIDE

4. Remove the terminal block and attach the RS-485 wires. Observe (+), (-), and

Shield polarity. Insulate any exposed wiring.

5. For information regarding software setup, see the Modbus protocol specications

available at www.veris.com/Modbus/.

6. Check power reading (these calculations are approximations only).

Expected power:

kW = Volts x Amps x 1.732 x PF / 1000

kW = Horsepower x 0.746

3. Snap the CT onto the conductor.

Connect CTs to the correspondingly

colored voltage leads. If the

application can exceed 20 times the

rated CT current, use wire ties to

secure the I-bar to the CT housing.

This CT automatically detects phase

reversal, so CT load orientation is not

important.

Z201686-0N PAGE 3 ©2012 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 08122

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other count ries.

Page 4

H8035/H8036

TM

INSTALLATION GUIDE

WIRING

ØB

ØA

ØC

120

ØB

Neutral

120

ØA

Typical 208/480 VAC 3Ø, 3- or 4- Wire Installation

Typical 240/120 VAC 1Ø, 3-Wire Installation

MODBUS RS-485 LINE

MODBUS RS-485 LINE

DATA OUTPUTS

H8035

kWh, consumption

Reset kWh

kW, demand

H8036

kWh, consumption

kW, real power

kVAR, reactive power

kVA, apparent power

Power fac tor

Average real power

Minimum real power

Maximum real power

Voltage, line-to-line

Voltage, line-to-neutral

Amps, average current

kW, real power ØA

kW, real power ØB

kW, real power ØC

Power factor ØA

Power factor ØB

Power factor ØC

Voltage, ØA to ØB

Voltage, ØB to ØC

Voltage, ØAto ØC

Voltage, ØA to Neutral

Voltage, ØB to Neutral

Voltage, ØC to Neutral

Amps, Current ØA

Amps, Current ØB

Amps, Current ØC

To additional MODBUS Devices

Typical 277 VAC 1Ø, 2-Wire Installation

Neutral

277

ØA

MODBUS RS-485 LINE

To additional MODBUS Devices

Note: The Enercept cannot communicate on the net work bus without power.

Therefore, it is best to connect the voltage lea ds ahead of switching devices.

Z201686-0N PAGE 4 ©2012 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 08122

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other count ries.

Page 5

H8035/H8036

TM

INSTALLATION GUIDE

ADDRESS SETUP

Set these switches to assign a unique address before connecting the device to the Modbus RS-485 line. Each Modbus device must have a unique address. If two devices are

given the same address, neither device will be able to communicate.

Z201686-0N PAGE 5 ©2012 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 08122

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other count ries.

Page 6

H8035/H8036

TM

INSTALLATION GUIDE

MODBUS REGISTER ADDRESSING

This table lists the addressed assigned to each data point. Registers are read MostSignicant Byte (MSB) rst. 32 bit oating point values are encoded per IEEE Standard 754.

For oating point format variables, each data point appears twice because two 16-bit addresses are required to hold a 32-bit oat value. The 16 bit Most Signicant Word

(MSW) is in the lower address of the register pair, while the least Signicant Word (LSW) is in the upper address.

Modbus RTU function codes suppor ted: 3=read holding registers; 6=preset single register; 17=report Slave I.D.

Quick Reference of the Most Common Data Points

Address Typical

Offset

40001 0 kWh Energy Consumption, LSW X

40002 1 kWh Energy Consumption, MSW X

40003 2 kW Real Power X

40257 --- kWh Energy Consumption X

40258 kWh Energy Consumption X

40259 0 kWh Energy Consumption (same 40257) X

40260 kWh Energy Consumption (same 40258) X

40261 2 kW Real Power X

40262 kW Real Power X

Units Description Integer:

multiplier required

Float:

upper 16 bits

Complete Listing of Data Points

Address Typical

Offset

40001 0 kWh Energy Consumption, LSW X

40002 1 kWh Energy Consumption, MSW X

40003 2 kW Real Power X

40004 3 kVAR Reactive Power X

40005 4 kVA Apparent Power X

40006 5 --- Power Factor X

40007 6 Volts Voltage, line to line X

40008 7 Volts Voltage, line to neutral X

40009 8 Amps Current X

40010 9 kW Real Power, Phase A X

40011 10 kW Real Power, Phase B X

40012 11 kW Real Power, Phase C X

40013 12 --- Power Factor, phase A X

40014 13 --- Power Factor, phase B X

40015 14 --- Power Factor, phase C X

40016 15 Volts Voltage, phase A-B X

40017 16 Volts Voltage, phase B-C X

40018 17 Volts Voltage, phase A-C X

40019 18 Volts Voltage, phase A-N X

40020 19 Volts Voltage, phase B-N X

40021 20 Volts Voltage, phase C-N X

40022 21 Amps Current, phase A X

40023 22 Amps Current, phase B X

40024 23 Amps Current, phase C X

40025 24 kW Average Real Power X

40026 25 kW Minimum Real Power X

40027 26 kW Maximum Real Power X

Units Description Integer:

multiplier required

Float:

upper 16 bits

Float:

lower 16 bits

Float:

lower 16 bits

40257 --- kWh Energy Consumption X

40258 kWh Energy Consumption X

40259 0 kWh Energy Consumption (same 40257) X

40260 kWh Energy Consumption (same 40258) X

40261 2 kW Real Power X

40262 kW Real Power X

Z201686-0N PAGE 6 ©2012 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 08122

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other count ries.

Page 7

H8035/H8036

TM

INSTALLATION GUIDE

Address Typical

Offset

40263 4 kVAR Reactive Power X

40264 kVAR Reactive Power X

40265 6 kVA Apparent Power X

40266 kVA Apparent Power X

40267 8 --- Power Factor X

40268 --- Power Factor X

40269 10 Volts Voltage, line to line X

40270 Volts Voltage, line to line X

40271 12 Volts Voltage, line to neutral X

40272 Volts Voltage, line to neutral X

40273 14 Amps Current X

40274 Amps Current X

40275 16 kW Real Power, phase A X

40276 kW Real Power, phase A X

40277 18 kW Real Power, phase B X

40278 kW Real Power, phase B X

40279 20 kW Real Power, phase C X

40280 kW Real Power, phase C X

40281 22 --- Power Factor, phase A X

40282 --- Power Factor, phase A X

40283 24 --- Power Factor, phase B X

40284 --- Power Factor, phase B X

40285 26 --- Power Factor, phase C X

40286 --- Power Factor, phase C X

40287 28 Volts Voltage, phase A-B X

40288 Volts Voltage, phase A-B X

40289 30 Volts Voltage, phase B-C X

40290 Volts Voltage, phase B-C X

40291 32 Volts Voltage, phase A-C X

40292 Volts Voltage, phase A-C X

40293 34 Volts Voltage, phase A-N X

40294 Volts Voltage, phase A-N X

40295 36 Volts Voltage, phase B-N X

40296 Volts Voltage, phase B-N X

40297 38 Volts Voltage, phase C-N X

40298 Volts Voltage, phase C-N X

40299 40 Amps Current, phase A X

40300 Amps Current, phase A X

40301 42 Amps Current, phase B X

40302 Amps Current, phase B X

40303 44 Amps Current, phase C X

40304 Amps Current, phase C X

40305 46 kW Average Real Power X

40306 kW Average Real Power X

40307 48 kW Minimum Real Power X

40308 kW Minimum Real Power X

40309 50 kW Maximum Real Power X

40310 kW Maximum Real Power X

Units Description Integer:

multiplier required

Float:

upper 16 bits

lower 16 bits

Float:

Modbus addresses in the 4xxx x format follow the Modicon protocol specication for point addressing. The actual address sent is the value shown, minus 40001. In other words,

the leading “4” is omitted, and the remaining 4-digit number is decremented so that point 40001 is requested with a value of zero in the actual Modbus communication. Some

Modbus implementations require point addresses to be specied beginning at zero or 40000, instead of 40001. Programming code may also require addresses that correspond

to actual values transmitted, so a value of zero is used to request data beginning at Modbus address 40001.

Many applications use a single Modbus command to read all of the data available from the Enercept. For integers, the beginning address is 40001 (or zero in the actual Modbus

command), and for oating points the rst address used is typically 40259 (or 258 in the actual Modbus command). Although the rst oating point appears at address 40257,

it is not necessary to read this value because it is a duplicate copy of the kWh value (required by the product rmware). When reading a block of data, the “typical oset ” values

index to the data within the block.

“Multiplier required” indicates that multiplication is required to properly scale the integer value. See Using Integer Data Types section.

Z201686-0N PAGE 7 ©2012 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 08122

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other count ries.

Page 8

H8035/H8036

TM

INSTALLATION GUIDE

USING INTEGER DATA TYPES

Unlike the oating-point data type, the integer data type can only represent whole numbers between zero and 65535. To convert a data point value into the number it

represents, multiply the value by a constant, as indicated in the table below.

Some data points require dierent multipliers for each amperage range, while others (e.g. volts and power factor) use the same multiplier regardless of the amperage range of

the product. The latter are indicated by single row values.

Addr Units 100A 300/400A 800A 1600A 2400A

40001 kWh 7.81E-03 0.03125 0.0625 0.125 0.25

40002 kWh 512 2048 4096 8192 16384

40003 kW 0.004 0.016 0.032 0.064 0.128

40004 kVAR 0.004 0.016 0.032 0.064 0.128

40005 kVAR 0.004 0.016 0.032 0.064 0.128

40006 --- 3.0518E-5

40007 Volts 0.03125

40008 Volts 0.015625

40009 Amps 3.906E-03 0.015625 0.03125 0.0625 0.1250

40010 kW 0.001 0.004 0.008 0.016 0.032

40011 kW 0.001 0.004 0.008 0.016 0.032

40012 kW 0.001 0.004 0.008 0.016 0.032

40013 --- 3.0518E-5

40014 --- 3.0518E-5

40015 --- 3.0518E-5

40016 Volts 0.03125

40017 Volts 0.03125

40018 Volts 0.03125

40019 Volts 0.015625

40020 Volts 0.015625

40021 Volts 0.015625

40022 Amps 3.906E-03 0.015625 0.03125 0.0625 0.1250

40023 Amps 3.906E-03 0.015625 0.03125 0.0625 0.1250

40024 Amps 3.906E-03 0.015625 0.03125 0.0625 0.1250

40025 kW 0.004 0.016 0.032 0.064 0.128

40026 kW 0.004 0.016 0.032 0.064 0.128

40027 kW 0.004 0.016 0.032 0.064 0.128

Z201686-0N PAGE 8 ©2012 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 08122

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other count ries.

Page 9

H8035/H8036

TM

INSTALLATION GUIDE

As an alternative to the table on the previous page, invert the values for use as divisors, in which the integer value returned by the Enercept is divided by a number from the

table below. In most cases, the divisors are a more compact number.

Addr Units 100A 300/400A 800A 1600A 2400A

40001 kWh 128 32 16 8 4

40002 kWh 1.9531E-3 4.8828E-4 2.4414E-4 1.2207E-4 6.1035E-5

40003 kW 250 62.5 31.25 15.625 7.8125

40004 kVAR 250 62.5 31.25 15.625 7.8125

40005 k VA 250 62.5 31.25 15.625 7.8125

40006 --- 32768

40007 Volts 32

40008 Volts 64

40009 Amps 256 64 32 16 8

40010 kW 1000 250 125 62.5 31.25

40011 kW 1000 250 125 62.5 31.25

40012 kW 1000 250 125 62.5 31.25

40013 --- 32768

40014 --- 32768

40015 --- 32768

40016 Volts 32

40017 Volts 32

40018 Volts 32

40019 Volts 64

40020 Volts 64

40021 Volts 64

40022 Amps 256 64 32 16 8

40023 Amps 256 64 32 16 8

40024 Amps 256 64 32 16 8

40025 kW 250 62.5 31.25 15.625 7.8125

40026 kW 250 62.5 31.25 15.625 7.8125

40027 kW 250 62.5 31.25 15.625 7.8125

Z201686-0N PAGE 9 ©2012 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 08122

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other count ries.

Page 10

H8035/H8036

TM

INSTALLATION GUIDE

NOTES

1. DO NOT GROUND THE SHIELD INSIDE THE ELECTRICAL PANEL. Insulate all Modbus

wires, including the shield, to prevent accidental contact with high voltage

conductors.

2. Mechanically secure the Modbus cable where it enters the elec trical panel.

3. Connect all Modbus devices in a daisy-chain fashion. Use a 120 Ω terminating

resistor between (+) and (-) on the rst and last devices in the chain.

4. Use shielded twisted pair wire BELDEN 1120A or similar for the Modbus cable.

WARNING: After wiring, remove all scraps of wire or foil

shield from the electrical panel. This could be DANGEROUS if wire scraps come into contact with high voltage

wires!

TROUBLESHOOTING

Problem Solution

Status LED does not blink Check fuses and voltage connections. Status LED should

Enercept interferes with another

device on the Modbus network

Readings seem highly inaccurate. •CheckthateachCTisinstalledontheconductorwith

Enercept goes oine when load is

switched o.

Status LED blinks red. •IftheLEDblinksquickly(i.e.,about5blinksintwo

blink regardless of CTs, Modbus connections, and DIP

switch setting.

Set DIP switches to a dierent Modbus address not in

use.

the corresponding color voltage input lead attached. In

most cases, incorrect wiring will cause the Status LED

to blink red (slowly). However, a power factor lower

than 0.5 could cause the LED to blink this way, even if

the unit is installed properly.

•ItdoesnotmatterwhichsideoftheCTfacestowards

the load.

•Ifcurrentisbelow7%offullscalemaximumforthe

CT, use a smaller CT or wrap each wire through the CT

multiple times

•Checkcurrentwithanamp-clamp.

Expected power:

kW = Volts x Amps x 1.732 x PF / 1000

kW = Horsepower x 0.746

PF is usually 0.7 to 0.95, depending on the load.

Connect voltage leads on the Line side of the conductor.

The Enercept cannot communicate on the Modbus

network without voltage.

seconds), then use a CT with a higher amp rating.

•IftheLEDblinksslowly(i.e.,about1blinkper

second), then the CTs are not installed on the correct

conductors or the power factor is less than 0.5. The

Enercept can accurately measure these low PFs, but

few loads operate normally at such a low power factor.

•IftheLEDblinksslowly(i.e.,about1blinkper

second), the monitored load might be less than 10%

of the CT maximum ratings.

Z201686-0N PAGE 10 ©2012 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 08122

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other count ries.

Loading...

Loading...