Page 1

TM

operated in a residential environment. This equipment generates, uses,

Power MoNITorING

INSTALLATIoN GUIDe

E31

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Follow safe electrical work practices. See NFPA 70E in the USA, or applicable local codes.

• This equipment must only be installed and serviced by qualified electrical personnel.

• Read, understand and follow the instructions before installing this product.

• Turn off all power supplying equipment before working on or inside the equipment.

• Use a properly rated voltage sensing device to confirm power is off.

DO NOT DEPEND ON THIS PRODUCT FOR VOLTAGE INDICATION

• Only install this product on insulated conductors.

Failure to follow these instructions will result in death or serious injury.

E31

Panelboard Monitoring System

Installer’s Specifications

Inputs:

Input Power 90-277VAC, 50/60 Hz

Accurac y:

Power/Energy IEC 62053-21 Class 1, ANSI C12.1-2008

Volt age ±0.5% of reading 90-277V line-to-neutral

Operation:

Sampling Frequency 2560 Hz

Update Rate 1.8 seconds (both panels)

Overload Capability 22 kAIC

Outputs:

Type Modbus RTU

Connection DIP switch-selectable 2-wire or 4 -wire, RS-485

Address DIP switch-selectable address 1 to 247 (in pairs of 2)*

Baud Rate DIP switch-selectable 9600, 19200, 38400

Parity DIP switch-selectable NONE, ODD, EVEN

Communication Format 8-data-bits, 1-start-bit, 1-stop-bit

Termination 5-position depluggable connector

(TX+ TX- SHIELD TX+/RX+ TX-/RX-)

Mechanical:

Ribbon Cable Suppor t 4 ft. (0.9 m) at ribbon cable ships standard;

up to 20 ft. (6 m) available

Environmental:

Operating Temperature Range 0° to 60°C (32° to 140°F) (<95% RH noncondensing)

Storage Temperature Range -40° to 70°C (-4 0° to 158°F)

Altitude of Operation 3000 m

Agency Approvals UL508, EN61010

* See Conguration section for de tails.

NOTICE

• This product is not intended for life or safety applications.

• Do not install this product in hazardous or classified locations.

• The installer is responsible for conformance to all applicable codes.

• Mount this product inside a suitable fire and electrical enclosure.

FCC PART 15 INFORMATION

NOTE: This equipment has been tested by the manufacturer and found

to comply with the limits for a class B digital device, pursuant to part

15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is

and can radiate radio frequency energy and, if not installed and used

in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in

a residential area may cause harmful interference in which case the

user will be required to correct the interference at his own expense.

Modifications to this product without the express authorization of

Veris Industries nullify this statement.

Product IdentIfIcatIon

Description

E31

A = Advanced b oard

B = Interme diate board

C = Basic boa rd

# of CTs

002 = 2 adapter b oards, no CTs, no cable s

004 = 4 adap ter boards, no CTs, no cab les

42 = 2 adapter boa rds, 42 50A CTs, 4 ft. round r ibbon cables

84 = 4 adapter b oards, 84 50A CTs, 4 ft . round ribbon ca bles

table of contents

Quick Install 2

Operation 2

Dimensions 2

Product Diagram 3

Data Output 3

Blink Codes for Status LED 4

Solid-Core CT Accuracy 4

Installation 4

Wiring 8

Conguration 9

Default DIP Switch Settings 9

Address Setup 10

Commissioning 11

Recommended Accessories 11

Safety 11

Troubleshooting 12

China RoHS Compliance Information IEFUP Table) 12

Z205667-0E PAGE 1 ©2012 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 07121

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other coun tries.

Page 2

e31

TM

INSTALLATIoN GUIDe

quIck Install

Observe precautions for handling static sensitive

devices to avoid damage to the circuitry that

is not covered under the factory warranty.

1. Disconnect and lock out power. Use a properly rated voltage sensing device to

conrm power is o.

2. Mount the main acquisition board in the electrical enclosure.

3. Mount adapter boards to either DIN Rail or SNAPTRACK™.

4. Connect adapter boards to the main board via ribbon cable (sold separately).

5. Connect current transducers to the adapter boards.

6. Snap current sensors onto the conductors to be monitored. Note: ensure that

each split-core CT is closed and firmly seated.

7. Secure wires using strain relief cable ties.

8. Congure communication and addressing parameters using DIP switches.

9. Wire RS-485 communications.

10. Connect CTs to the auxiliary inputs and connect them onto the main conductors

in the enclosure (optional).

11. Wire control power and voltage taps (E31A and E31B only).

12. Download the free E3x conguration tool from www.veris.com to commission the

device for operation.

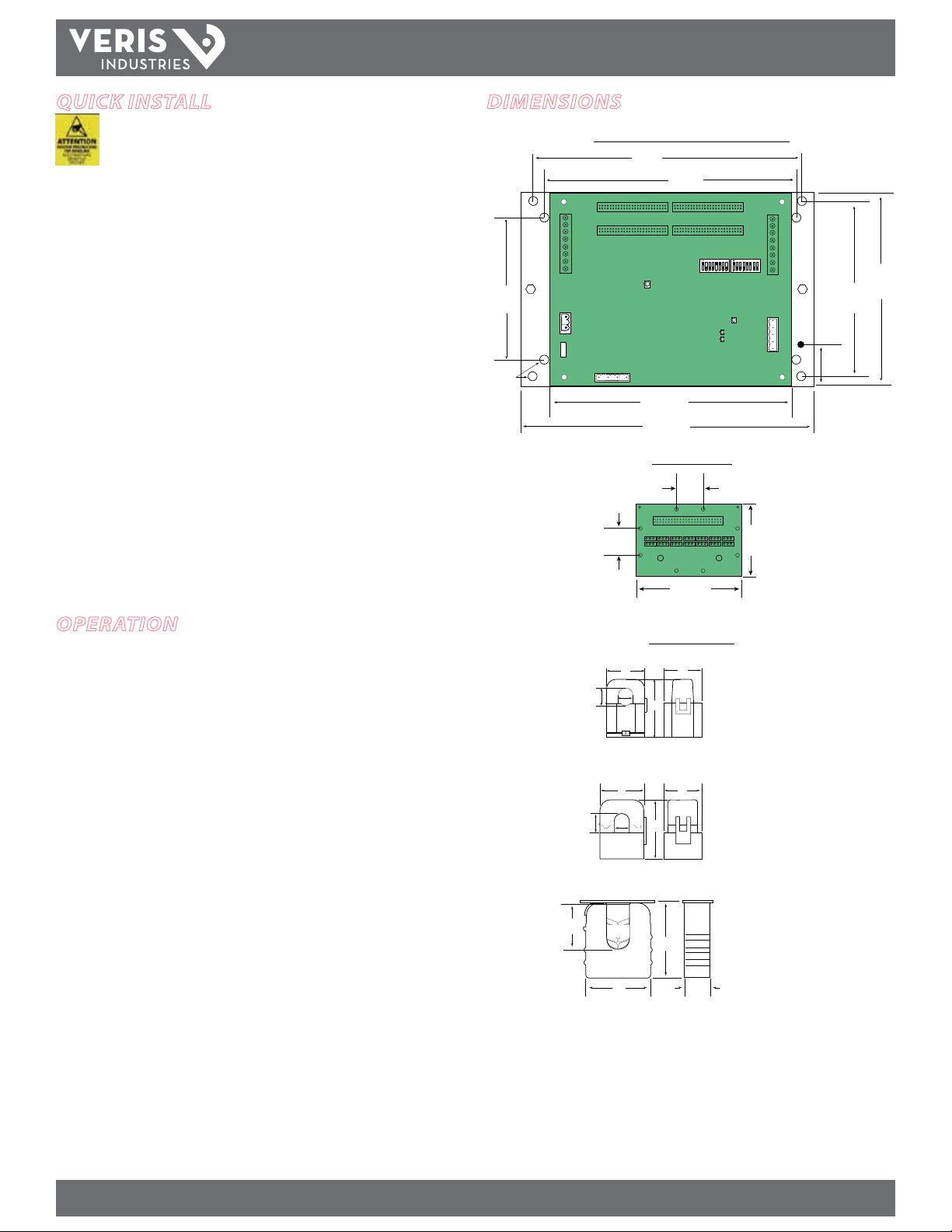

dImensIons

Circuit Board and Mounting Bracket

3.9”

(100 mm)

Ø = 0.2”

(5 mm)

1.00”

(26 mm)

8.3”

(211 mm)

7.3”

(184 mm)

8.9”

(288 mm)

7.9”

(200 mm)

Adapter Board

(26 mm)

(117 mm)

1.00”

4.6”

2.75”

(70 mm)

1.75”

(45 mm)

4.8”

(122 mm)

5.8”

(146 mm)

oPeratIon

The E31 Series Branch Current Monitor is designed to measure the current, voltage,

and energy consumption of up to 92 circuits (84 branch circuits, 2 3-phase mains, 2

neutrals) on a single board. One E31 can monitor up to two panels.

The E31 consists of a data acquisition board and up to 84 split-core current sensors

(50A, 100A, or 200A), with eight auxiliary inputs. Each conductor passes through a

current sensor and terminates at the breaker. Each sensor transmits the current data

to the data acquisition board.

Data is transmitted using an RS-485 Modbus protocol. Each data acquisition board

requires two addresses, one for each set of 42 current sensors and four auxiliary

inputs. Data is updated roughly every two seconds. As a circuit approaches the userdened threshold, the E31 activates the alarm indicators.

The E31A measures both current and power for the mains and branch circuits. The

E31B measures both current and power for the mains, and current only in each circuit.

The E31C measures current only for the mains and branch circuits.

Current Sensors

D

C

B

D

C

B

B

C

A

A

E

A

E

E

D

50 Amp

A = 1.0” (26 mm)

B = 0.5” (11 mm)

C = 0.4” (10 mm)

D = 0.9” (23 mm)

E = 1.6” (40 mm)

100 Amp

A = 1.2” (29 mm)

B = 0.8” (20 mm)

C = 0.7” (16 mm)

D = 1.6” (40 mm)

E = 2.1” (53 mm)

200 Amp

A = 2.6” (66 mm)

B = 1.1” (28 mm)

C = 0.8” (19 mm)

D = 2.9” (74 mm)

E = 3.5” (90 mm)

Z205667-0E PAGE 2 ©2012 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 07121

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other coun tries.

Page 3

e31

TM

INSTALLATIoN GUIDe

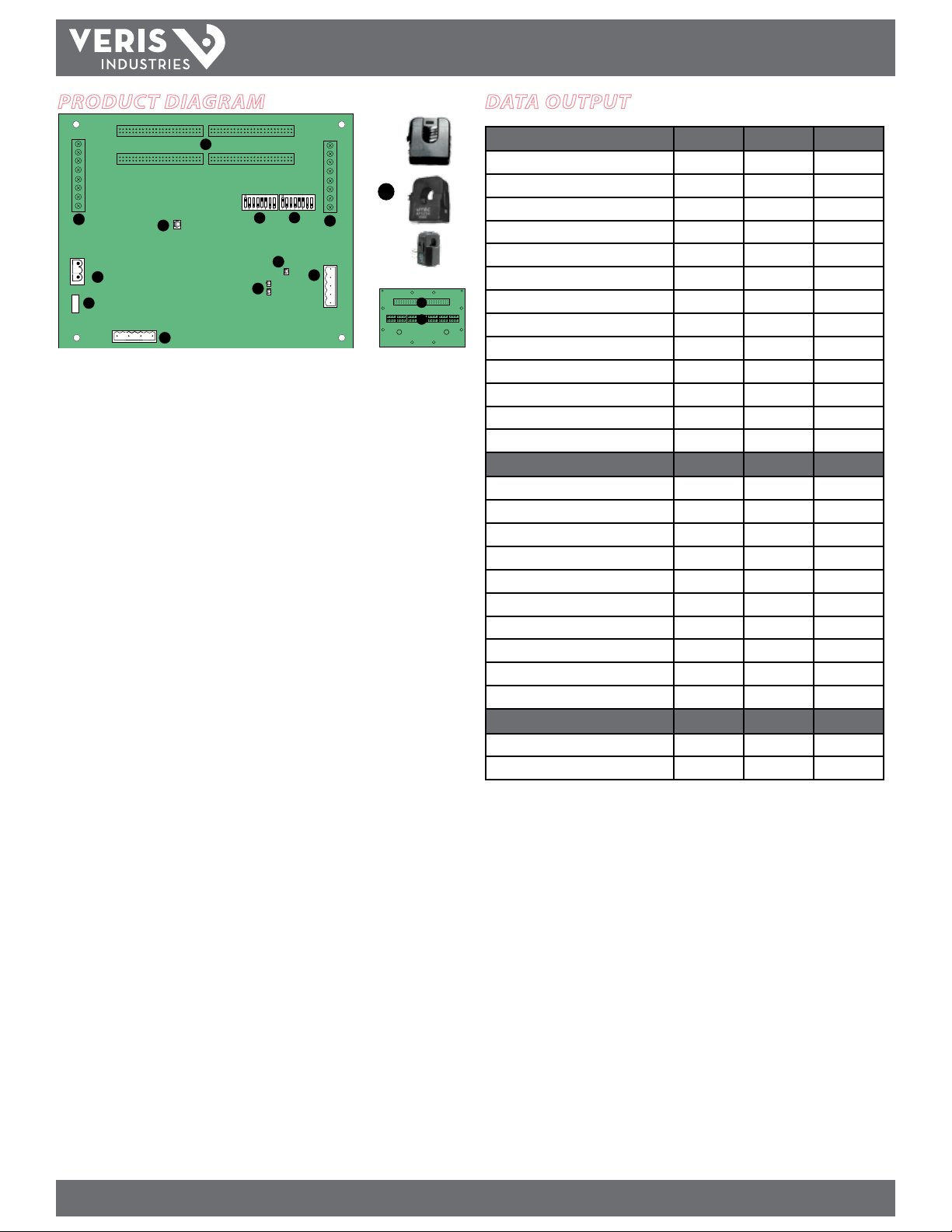

Product dIagram

A A

1

B B

12

8

2

3

4

5

6

1. 50-Pin Ribbon Cable Connectors: Ribbon cables attach here for easy

connection of adapter boards to the data acquisition board. The two connectors

on the left are for panelboard 1; the two on the right are for panelboard 2.

Note: Connect Adapter Boards A and B to the correct ribbon cable connectors

for each panel. The top connec tor is for Adapter Board A, and the bottom

connector is for Adapter Board B.

Note: Ribbon Cable is not included with all E31 models. For ribbon cable

options, see Recommended Accessories on page 11.

2. Auxiliary Inputs: These 0.333VAC inputs are used for monitoring the main

breaker or other high amperage source. Inputs on the lef t are for panelboard 1;

inputs on the right are for panelboard 2.

3. Control (Mains) Power Connection: Easy 2-wire 90-277 VAC 50/60 Hz

connection.

4. Control Power Fuse: 600VAC, 500mA time lag, factory-replaceable.

5. Alive LED: Red/green/amber LEDs. Blink codes are on page 3.

6. Voltage Taps: 1, 2, or 3 phase plus neutral connections. For voltage sensing and

power calculations (no voltage taps on the E31C). Voltage taps are shared by both

panels.

7. Communications Address DIP Switch: Each Modbus device must have a unique

address. Switches are binar y weighted. Left-most switch has a value of 1; rightmost switch has a value of 128. Note: switches set the address for panel 1; panel 2

is automatically set to (Panel 1 address + 1). See Conguration section for details.

7

11

10

2

9

13

14

data outPut

Monitoring at Mains E31A E31B E31C

Current per phase

Max. current per phase

Current demand per phase

Max. current demand per phase

Energy (kWh), total

Real Power (kW) per phase

Apparent Power (kVA)

Power factor, total *

Power factor, per phase

Voltage, L-L and average of 3 phases

Voltage, L-N and average of 3 phases

Voltage, L-N and per phase

Frequency (phase A)

Monitoring at Branch Circuit

Current

Max. current

Current demand

Max. current demand

Real power (kW)

Real power (kW) demand

Real power (kW) demand max.

Energy (kWh) per circuit

Power factor

Apparent Power (kVA)

Modbus Alarms

Voltage over/under

Current over/under

* Based on a 3-phase breaker rotation.

8. Communications Settings DIP Switch: Congures baud rate, parity, 2- or

4-wire communications.

9. RS-485 Connection: Used for Modbus serial communications. The Universal plug

accomodates 2 or 4 wire connections.

10. RS-485 LEDs: The RX LED (closest to DIP switches) indicates the RS-485 is

receiving information; the TX LED indicates transmission of information.

11. Power LED: Indicates power to main board

12. Branch Current Sensors: Each split-core current sensor is capable of monitoring

conductors rated up to a maximum of 50, 100, or 200 amps. Up to 84 sensors can

be purchased with the E31 (see Recommended Accessories on page 10). One of

each style is pic tured here.

13. Ribbon Cable Connection

14. CT Terminal Connections

Z205667-0E PAGE 3 ©2012 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 07121

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other coun tries.

Page 4

e31

TM

INSTALLATIoN GUIDe

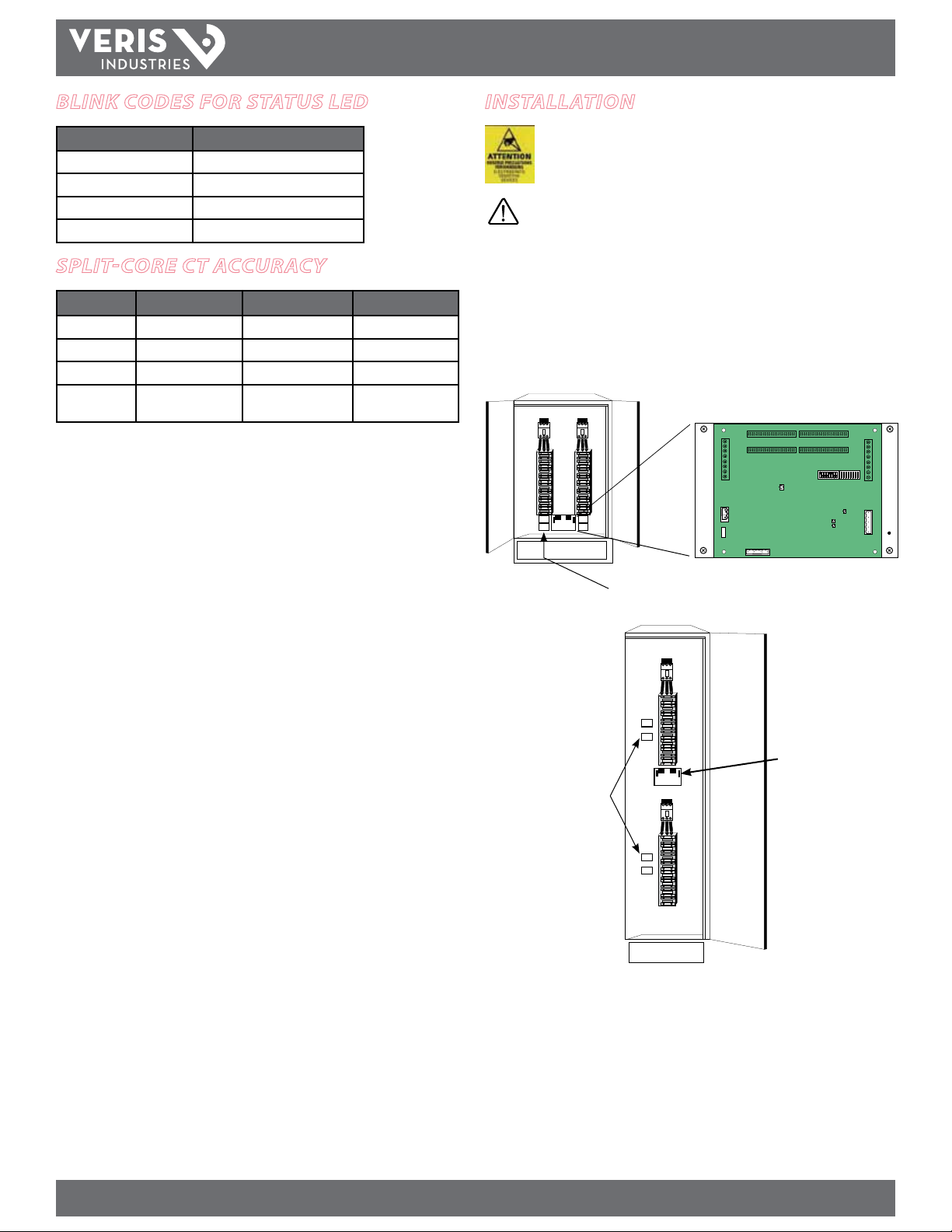

blInk codes for status led

Color and Pattern Status Description

Green, once per second Normal operation

Amber, once per second Volts or Amps clipping

Amber, twice per second Invalid rmware image

Red, solid or blink Diagnostic event detected

sPlIt-core ct accuracy

50A Split-Core CT 100A Split-Core CT 200A Split-Core CT

Voltage Rating 300VAC 600VAC 600VAC

Accuracy ±1% ±0.5% ±1%

Temperature 0° to 60°C 0° to 60°C 0° to 60°C

Agency UL508 recognized,

EN61010

UL508 recognized,

EN61010

UL508 recognized,

EN61010

InstallatIon

Observe precautions for handling static sensitive

devices to avoid damage to the circuitry that

is not covered under the factory warranty.

Disconnect power to the electrical panel and lock it out.

1. Install the acquisition board mounting bracket in the panel using screws and bolts

provided Panels can be oriented side-by-side (Figure 1A) or vertically (Figure

1B). A grounding connection is located on the mounting bracket, near the lower

right corner. Use this stud to ground the bracket when mounting on a nonconductivesurface.

Fi gure 1A

Panel 1 Panel 2

Fig ure 1B

Adapter boards

Adapter boards

Panel 1

Main Circuit Board

Panel 2

Z205667-0E PAGE 4 ©2012 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 07121

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other coun tries.

Page 5

e31

TM

2. Mount the adapter boards to either DIN rail or SNAPTRACK.

A. DIN Rail: Use the supplied screws to secure the plastic DIN clip to the

adapter board. Ax the clip to the DIN rail (Figure 2).

B. SNAPTRACK: Secure the SNAPTRACK to the mounting surface. Click the

adapter board into place (Figure 3).

Figure 2 Figure 3

DIN Option 1: Vertical Mount

DIN Option 1: Horizontal Mount

INSTALLATIoN GUIDe

3. Connect adapter boards to the main board using ribbon cable (Figure 4). Ribbon

cables are keyed to ensure proper installation. Orient cables so that the red

stripe is on the left.

Note: Flat and round ribbon cable are available from Veris. See

Recommended Accessories (page 10)

4. Connect current sensors to the terminals on the adapter boards (Figure 4).

Figure 4

Red Stripe

Red Stripe

Red Stripe

Align ribbo n cable key with

connector keyhole.

Orient ribb on cable so that

the red stripe is o n the left

side of the connector.

A A

Pane l 2Pane l 1

B B

Note: Current sensor

orientation does NOT

aect meter accuracy.

Z205667-0E PAGE 5 ©2012 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 07121

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other coun tries.

Page 6

e31

TM

INSTALLATIoN GUIDe

5. Install the current sensors onto the conductors to be monitored (Figure 5).

Sensors can be mounted facing either direction; orientation does not aec t meter

accuracy. Note: Clean split-core contacts before closing. The hinge can detach,

allowing the base and the top to separate for easier cleaning and installation.

Figure 5

The 50 A CT accepts a maximum #2 AWG

(0.384” O.D.) wire with THHN insulation.

The 100A CT accepts a maximum 3/0 AWG

(0.584” O.D.) wire with THHN insulation.

The 200A CT accepts a maximum of 350 MCM

wire with THHN insulation.

Use this gauge wire or smaller for each ci rcuit.

Close CTs until the clasp cl icks

into place to ensur e that contact

surfaces are fi rmly seated.

✓

7. The adapter boards are silk screened with two rows of numbers. For applications

that require odd/even branch circuit numbering, use the row designated ODD or

EVEN. For applications that require sequential numbering, use the number row

marked SEQ (Figure 7).

Figure 7

BLACK

WHITE

41

39

37

35

33

31

29

27

25

23

21

19

17

15

13

11

9

7

ODD

SEQ

531

456

10

11

12

13

14

15

16

17

18

19

20

21

789

123

Adapter Board A numbering:

ODD 1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39 41

SEQ 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

BLACK

WHITE

42

40

38

36

34

32

30

28

26

24

22

20

18

16

14

12

10

8

EVEN

SEQ

642

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

24

24

23

22

Adapter Board B numbering:

6. Plastic cable ties are included with the product for strain relief. Insert the strain

relief device into one of the available holes on the adapter board (Figure 6A).

Gather all current sensor wires connected to that adapter board and secure the

cable tie around them (Figure 6B).

Figure 6

(A) (B)

EVEN 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 40 42

SEQ 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42

Figure 8

A

Pane l 2Pane l 1

B

Panel 1

Mains

Voltage taps are

shared by both panels

Panel 1 uses base Modbus address as set by DI P switches.

Panel 2 uses base + 1 Modbus address as set by DI P switches.

A

B

Panel 2

Mains

Z205667-0E PAGE 6 ©2012 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 07121

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other coun tries.

Page 7

e31

I1

I2

I3

IN

I1

I2

I3

IN

±

±

±

±

±

±

±

±

TM

8. Congure communication and addressing parameters using DIP switches. The E31

requires two addresses, one for each set of 42 current sensors and four auxiliary

inputs. See the Conguration section for more information.

9. Wire RS-485 communications (see diagrams in Wiring section).

10. Connect 0.333VAC current transducers (CTs) to the main conductors by snapping

CTs around lines, observing local codes regarding bending radius (optional;

Figures 9, 10).

INSTALLATIoN GUIDe

Figure 9

Panel 1 Panel 2

Recommended CT:

Veris Industries H6810, H6811, H6812 Series with 0.333VAC output.

Available in 100A max. to 2400A max.

Call a Veris sales rep if higher amperages a re required.

Fig ure 10

CT Input

(0 -0.333 VAC)

Set up Modbus registers 115-118 for CT scaling.

Use base + 1 address for Panel 2 setup.

Note: (+) represents black, (-) represents white

11. Connect 2-wire 90-277VAC power to main power terminals. Observe polarity. For

the E31A and E31B, connect voltage lines to the voltage taps (Figure 11). Equip

voltage lines with fuses.

Pane l 2Pane l 1

CT Input

(0 -0.333 VAC)

Fi gu re 11

V2/N

90 -277 VAC

V1

V1 V2 V3 N

Z205667-0E PAGE 7 ©2012 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 07121

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other coun tries.

L - L L - N

Line to Line (L-L) Voltage: 150 to 480 VAC

Line to Neutral (L-N) voltage: 90 to 277 VAC

Voltage taps are shared by both panels.

Page 8

e31

+

TM

WIrIng

Power must be disconnected and locked out before making any wiring connections.

1. Connect 2-wire or 4-wire Modbus RS-485 daisy chain network (Figures 12 and 13).

INSTALLATIoN GUIDe

Fi gu re 12

SHIELD

RX- TX-

RX+ TX+

TXTX+

Fi gu re 13

2-Wire 4-Wire

Master or Slave

TX+

TX-

RX+

TX+

SHIELD

RX-

TX–

SHLD

SHIELD

2. Mechanically secure the RS-485 cable where it enters the electrical panel.

3. Connect all RS-485 devices in a daisy-chain fashion, and properly terminate the

chain (Figure 14).

4. Shield the RS-485 cable using twisted-pair wire, such as Belden 1120A. The cable

must be voltage-rated for the installation.

Fi gur e 14

TX+

Master

TX+

TX-

TX–

RX+

SHLD

RX-

SHIELD

TX+

Slave

TX+

TX-

TX–

RX+

SHLD

RX-

SHIELD

2-Wire Example

Belden 1120A or

equivalent

120 Ω terminator

on last device of

daisy chain

5. When tightening terminals, ensure that the correct torque is applied: 0.5 to 0.6

N·m (0.37 to 0.44 ft·lb ) for connectors on main board, 0.22 to 0.26 N·m (0.16 to

0.19 ft·lb) for connectors on adapter boards (Figure 15).

WARNING: After wiring the RS-485 cable, remove all

scraps of wire or foil shield from the electrical panel.

Wire scraps coming into contact with high voltage

conductors could be DANGEROUS!

–

Not Used

Fi gur e 15

–

+

Z205667-0E PAGE 8 ©2012 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 07121

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other coun tries.

Page 9

e31

TM

confIguratIon

1. Communications Conguration: Communications parameters for the E31 series

are eld selectable for your convenience. Please see the Product Diagram section

(page 2) for selector location. The following parameters are congurable:

• Baud Rate: 9600, 19200, 38400

• Parity On or O

• Parity: odd or even

• Wiring: 2 or 4

Example: 2-wire 19200 Baud No Parity

Bø

B1

Off/

On

Parity

Odd/

Even

Parity

2/4

Wire

Reserved

INSTALLATIoN GUIDe

3. The E31 uses two logical addresses. Panel 1 uses the base address as set on the DIP

switches, and Panel 2 uses this base address + 1. Address the E31 as any whole

number between and including 1-246. Each unit is equipped with a set of 8 DIP

switches for addressing. See below.

=

1

LSB MSB

1 2 4 8 16 32 64 128

4. To determine an address, simply add the values of any switch that is on.

For example:

LSB

Switch number 4 has an ON Value of 8 and switch number 6 has an ON Value of 32.

(8 + 32 = 40). Therefore, the address for Panel 1 is 40, and the address for Panel 2 is

41.

DIP Switch Values

=

40

MSB

1 2 3 4 5 6 7 8

o o X X X 9600

on o X X X 19200

o on X X X 38400

on on X X X Reserved

o o X X X No Parity

on o X X X Odd Parity

o on X X X No Parity

on on X X X Even Parity

on X X X 4-wire RS-

485

o X X X 2-wire RS-

485

2. Address Conguration: Each Modbus device on a single network must have

a unique address. Set the switch block to assign a unique address before the

device is connected to the Modbus RS-485 network. If an address is selected that

conicts with another device, neither device will be able to communicate.

See the Address Setup section (page 9) for a pictorial listing of the rst 63 switch

positions.

default dIP sWItch settIngs

The E31 includes two DIP switches, as shown below. Switches are shown in their

default positions.

Comms Address Comms Settings

Z205667-0E PAGE 9 ©2012 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 07121

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other coun tries.

Page 10

address setuP

e31

TM

INSTALLATIoN GUIDe

DO NOT

USE ZERO

1 2 3 4 5 6 7 8 9 10

11 12 13 14 15 16 17 18 19 20 21

22 23 24 25 26 27 28 29 30 31 32

33 34 35 36 37 38 39 40 41 42 43

44 45 46 47 48 49 50 51 52 53 54

55 56 57 58 59 60 61 62 63 246

......

Z205667-0E PAGE 10 ©2012 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 07121

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other coun tries.

Page 11

e31

TM

INSTALLATIoN GUIDe

commIssIonIng

1. Reconnect power to the panel.

2. Congure installation mode using Modbus Register 6.

3. Congure CT scaling.

4. Congure alarms.

5. Congure demand.

Download the free E3x conguration tool from www.veris.com to commission the

device for operation.

recommended accessorIes

Part ID Description

CBL008 Flat ribbon cable, 50 x 28 AWG, 1.5 ft. (0.45 m)

CBL016 Flat ribbon cable, 50 x 28 AWG, 4 ft. (1.2 m)

CBL017 Flat ribbon cable, 50 x 28 AWG, 5 ft. (1.5 m)

CBL018 Flat ribbon cable, 50 x 28 AWG, 6 ft. (1.8 m)

CBL019 Flat ribbon cable, 50 x 28 AWG, 8 ft. (2.4 m)

CBL020 Flat ribbon cable, 50 x 28 AWG, 10 ft. (3.0 m)

CBL021 Flat ribbon cable, 50 x 28 AWG, 20 ft. (6.1 m)

CBL022 Round ribbon cable, 50 x 28 AWG, 4 ft. (1.2 m)

CBL023 Round ribbon cable, 50 x 28 AWG, 10 ft. (3 m)

CBL024 Round ribbon cable, 50 x 28 AWG, 20 ft. (6 m)

CBL025 Flat ribbon cable, 50 x 28 AWG, 2 m

CBL026 Flat ribbon cable, 50 x 28 AWG, 4 m

CBL027 Flat ribbon cable, 50 x 28 AWG, 6 m

CBL031 Round ribbon cable, 50 x 28 AWG, 1.5 ft. (0.45 m)

CBL032 Round ribbon cable, 50 x 28 AWG, 2.5 ft. (0.76 m)

E31CT0 Six-pack 50 A CT, 6 ft. (1.8 m) lead

E31CT0R20 Six-pack 50 A CT, 20 ft. (6 m) lead

E31CT1 Six-pack 100 A CT, 6 ft. (1.8 m) lead

E31CT1R20 Six-pack 100 A CT, 20 ft. (6 m) lead

E31CT3 Single 200A CT, 6ft (1.8m) lead

E31CT3R20 Single 200A CT, 20ft (6m) lead

E31CTDB 2 E31 Adapter boards

AE001 E3x MCB Cover

AV01 Veris DIN Rail

safety

If Veris E31 products are used in installations with circuits higher than the product

ratings, the circuits must be kept segregated per UL508A Sec. 17.5.

Note: 277/480VAC Wye connected (center grounded) power systems operate

within the 300VAC line to neutral safety rating of the E3x series, and the

operational voltage limit (single-phase connection) as the line to neutral

voltage is 277VAC in such power systems. Corner-grounded delta 480VAC

systems would not qualif y, as the actual line to earth voltage is 480VAC on

each leg, exceeding the E3x ratings.

Note: E3x internal circuitr y (cables and CTs) are not circuits as dened by

UL508A, as they do not extend beyond the E3x itself without further safety/

re isolation.

UL listed under standard 508 as an “open type device.”

Maximum ambient air temperature for use is 60°C.

Installation categor y: CAT III

The E31 Series must be installed in an appropriate electrical and re enclosure per

local regulations.

For use in a Pollution Degree 2 or better environment only.

A Pollution Degree 2 environment must control conductive pollution and the

possibility of condensation or high humidit y. Consideration must be given to the

enclosure, the correct use of ventilation, thermal properties of the equipment and the

relationship with the environment.

If the equipment is used in a manner not specied by the manufacturer, the

protection provided by the device may be impaired.

IEC/EN 61010-1

This symbol indicates an electrical shock hazard exists.

Documentation must be consulted where this symbol is used on the

product.

Z205667-0E PAG E 11 ©2012 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 07121

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other coun tries.

Page 12

TM

troubleshootIng

Problem Solution

Product is not communicating over Modbus daisy chain

RX LED is solid

The main board has a fast ashing amber light

The main board has a slow ashing amber light

The main board has a ashing green light

The main board is a ashing or solid red light

Split-core product is reading zero for some values

Power factor reading is not as expected

Current reading is not as expected, or reading is on dierent CT

number than expected

Current is reading zero, even when small currents are still

owing through circuit

E3x Cong Tool returns Modbus error on read/write

e31

• Check the unit Modbus address to ensure that each device on the daisy chain has a unique address.

• Check Parity.

• Check the communications wiring.

• Check that the daisy chain is properly terminated.

• Check for reversed polarity on Modbus comms.

• Check for sucient biasing on the Modbus bus. Modbus physical specication calls for 450-650 Ω biasing. This is usually

provided by the master.

• Verify ribbon cable connectors are inserted in the correct orientation.

• If cables are correct, reset main board to re-initialize product.

• One or more channels is clipping. This can be caused by a signal greater than the split-core size or 277 V L-N, or by a signal

with high THD near the gain stage switching points (1.5 A and 10 A).

• Everything is wired properly and the main board has power.

• Light may be red briey while device powers up.

• If light is red for more the 60 sec. device has encountered a diagnostic event. Contact technical support.

• Device was unable to read split-core adapter boards on power up. Verify adapter boards are connected.

• Verify ribbon cable connectors are inserted in the correct orientation.

• Reset main board to re-initialize product.

• Verify voltage taps are connected in appropriate phase rotation.

• Verify phase rotation of breakers (rmware rev. 1.012 or higher allows for custom rotation if needed).

• Verify ribbon cable is fully seated and in the correct orientation.

• The product cuts o at 50 mA, and will set the reporting register to 0 mA for currents near or below this range.

• Verify using the latest release of E3x Cong Tool as older versions may not support all features in current product rmware.

Latest version is available on our website http://www.veris.com/modbus.aspx

INSTALLATIoN GUIDe

chIna rohs comPlIance InformatIon (efuP table)

产品中有毒有害物质或元素的名称及含量Substances

部件名称

铅 (Pb) 汞 (Hg) 镉 (Cd) 六价铬 (Cr(VI)) 多溴联苯(PBB) 多溴二苯醚(PBDE)

电子线路板 X O O O O O

O = 表示该有毒有害物质在该部件所有均质材料中的含量均在 SJ/T11363-2006 标准规定的限量要求以下.

X = 表示该有毒有害物质至少在该部件的某一均质材料中的含量超出SJ/T11363-2006标准规定的限量要求.

Z000057-0A

Z205667-0E PAGE 12 ©2012 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 07121

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other coun tries.

Loading...

Loading...