2

No Straight Run Required

The Accelabar can be used in extremely limited straight

run piping configurations. The straight run is integral to

the meter. The stabilization and linearization of the velocity

profile within the throat of

the nozzle eliminates the

need for any upstream run.

Engineering

Specifications

• Low velocity flow rates

• High accuracy:

to ± 0.50%

• Repeatability: ±0.050%

• Verified flow coefficients

• No calibration required

• Extended turndown

• No straight run

requirements

• Low permanent

pressure loss

• Mass or volumetric flow

Actual Application (see data on page 4)

Application: 3” Sch 40 Natural Gas

Operating Pressure/

Temperature: 50 PSIG/70° F

Max/Min Flow Rate: 60,000 SCFH/1,000 SCFH

Flow Turndown: 60:1

Straight Run: 0”

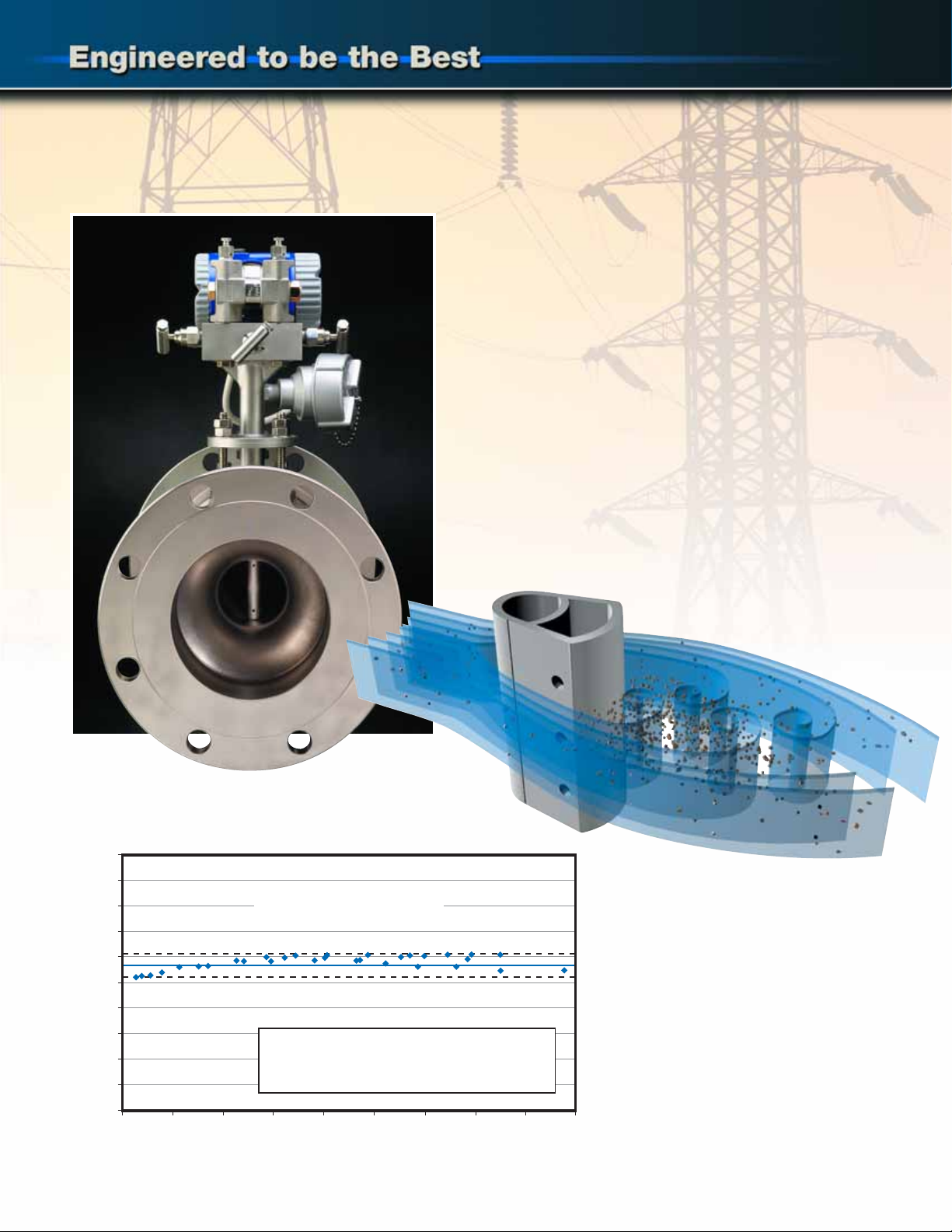

How the Accelabar Works

The Accelabar consists of a unique toroidal nozzle design

and a Verabar® averaging pitot. The nozzle has a patented

straight run “settling distance” that accelerates, linearizes

and stabilizes the velocity profile sensed by the Verabar.

The Verabar located within the nozzle accurately measures

and significantly increases the differential pressure output

to increase the operating range (turndown). The Accelabar

has a constant flow coefficient and produces an accuracy

of up to ±0.50%.

Other manufacturers claim high accuracy, but over

a limited turndown.

The Unique Accelabar Flow Meter

The Accelabar is a new and unique flow meter that combines two differential pressure

technologies to produce operating ranges never before attainable in a single flow meter.

It is capable of generating high differential pressures for

measuring gas, liquids and steam at turndowns previously

unattainable—with no straight run requirements.

Stabilizing &

linearization section

Toroidal

inlet

Accelabar

nozzle

RTD

(optional)

Verabar

Diffuser

cone

FLOW

US Patent No. 6,868,741B2 and various foreign patents pending.

3

Verabar Provides the Accuracy

The proven technology of the Verabar makes

the Accelabar work. It accurately measures the

flow rate within the nozzle. Its unique bullet shape,

constant flow coefficient, solid one-piece construction,

non-clog design and signal stability make it the

only design capable of producing the overall

performance.

Verified Accuracy and

Flow Coefficients

Empirical test data from independent

laboratories verified an analytical model

and flow coefficients as constant and

independent of Reynolds Number

and within ±0.75% of the predicted

value over a flow turndown of 65:1

(see actual test). This eliminates

the need for calibration.

0.500

0.490

0.480

0.470

0.460

0.450

0.440

0.430

0.420

0.410

0.400

Published Flow Coefficient: 0.4568

Reynolds Number Range: 6,517 to 438,160

Flow Turndown: 65 to 1

DP Turndown: 2,293 to 1 (0.111” H2O to 255.51” H2O)

Flow Coefficient (K)

Flow Test

Accelabar Flow Meter

Flow Coefficient vs. Reynolds Number

Date 8-21-02

Accuracy ± 0.75%

Flow Turndown 65:1

0 50 100 150 200 250 300 350 400 450

Reynolds Number ✕ 1,000

Loading...

Loading...