Page 1

Trouble-shooting

(Refer to Operations Manual for complete

instructions, including software installation, safety,

maintenance, and troubleshooting.)

2000 XA, 3100, 3150

Soil EC Mapping System

Table of Contents

Procedure #1: EC Surveyor Instrument Signal Testing

Procedure #2: Testing Electrical Continuity

Procedure #3: Diagnosing and Correcting EC Signal Problems.

Procedure #4 Spring Plunger adjustment and replacement

Procedure #5: Diagnosing GPS-related problems

Page 2

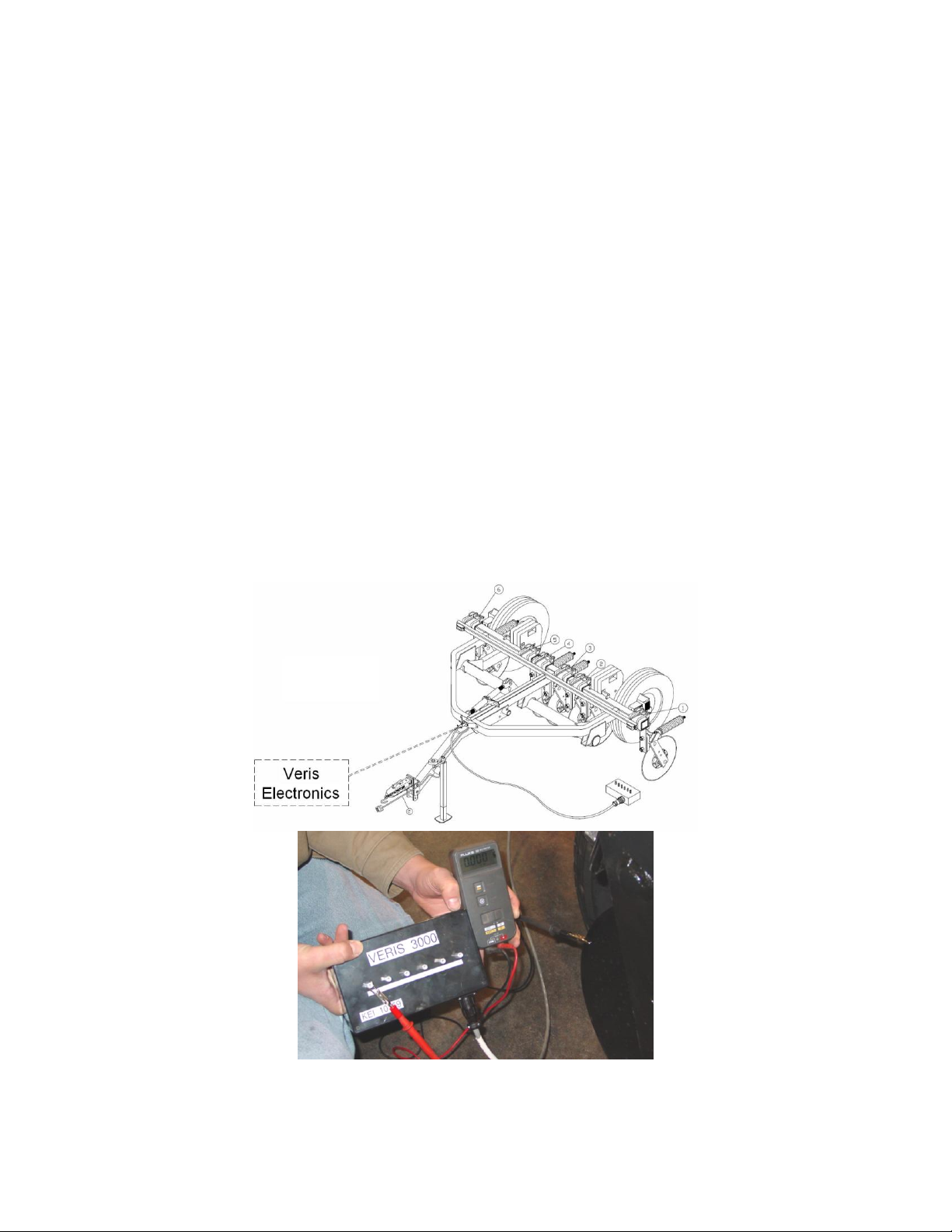

Procedure #1: EC Surveyor Instrument Signal Testing

Signal Test Load

Perform this test daily or every 10 hours of data collection to ensure you are obtaining

reliable data, and whenever EC data is questionable. The purpose of this test is to insure

that the instrument is performing properly.

The EC Surveyor is shipped with an Instrument Test Load (Part No. 10447) that will

enable you to quickly check the instrument to ensure that it is functioning properly. To

perform this test:

1) Disconnect the signal cable from the signal terminal on the EC Surveyor.

2) Connect the test load to the signal terminal.

3) Switch on the EC Surveyor and view display.

4) The display should show:

Shallow: (2000XA and 3100) 14 (3150) 11

Deep: (2000XA and 3100) 21 (3150) 40

5) If the readings vary significantly (more than one whole number) contact Veris

service department.

6) Once the test is complete, remove the test load and reinstall the implement

signal cable.

Figure 1.1 Signal Test Load installed (display showing proper EC readings for 2000XA and

3100)

Page 3

Procedure #2: Testing Electrical Continuity

Perform this test daily or every 10 hours of data collection to ensure you are obtaining

reliable data, and whenever EC data is questionable.

The purpose of this test is to insure that each coulter-electrode has an uninterrupted signal

path from the EC Surveyor to the disk blade. Think of each coulter-electrode and its wire

path as a ‗channel‘. On a 3100 and 3150, there are 6 signal channels that must be clear

and isolated from each other (4 on a 2000XA). You will first test the complete pathway for

each channel—each coulter-electrode. One easy-to-take reading for each channel tests

the cable, wiring harness, and each coulter-electrode and disk blade. If no problems

surface during this test, there is no need to test individual components. This test should

take only a couple of minutes to perform.

To perform this test, you will need the EC Signal Test Box (part #10759) and an ohmmeter

(sometimes referred to as a multi-meter or voltmeter). Make sure the meter is set to ohms,

Ω. If a range of ohms is available, choose the lowest setting--ohms rather than kilo or

mega ohms. If unfamiliar with ‗ohming-out‘ or resistance testing, make a few trial tests

before performing the Veris signal test procedure. Touching the meter leads together will

display a zero resistance reading, touching two places on the same piece of metal will

produce a nearly zero reading, touching nothing will produce an OL (overload or over limit)

reading—meaning complete resistance, and no continuity.

Figure 2.1

Page 4

Remove the signal cable from the EC Surveyor and connect it to the terminal on the test

Connect to coulter

blade

Ohmmeter

Connect one lead to Signal Test

Box terminal (corresponding to

each coulter)

Signal extension cable

(from implement)

box. If you have hard-wired the signal cable extension into the cab, making it difficult to

reach the implement with the cable end, you may want to purchase an extension cable

from Veris (part #12269). This cable attaches to the signal cable end and allows you to

position the Signal Test Box in close proximity to the coulter-electrodes.

Figure 2.2

Firmly press one lead of the ohmmeter to the #1 coulter blade edge (left hand, standing

behind the unit) and the other lead to the #1 terminal on the test box. Maintain firm

pressure on the ohmmeter lead touching the disk blade. A reading of less than 2 ohms is

normal. Rotate blade ¼ of a turn back and forth as you view the ohmmeter. Any jump in

the readings above 2 ohms indicates a problem.

Figure 2.3

Continue to check each coulter electrode in succession, left to right.

If any coulter electrode exhibits no continuity or resistance higher than 2 ohms, refer to

Procedure #3 Diagnosing EC Signal Problems.

Page 5

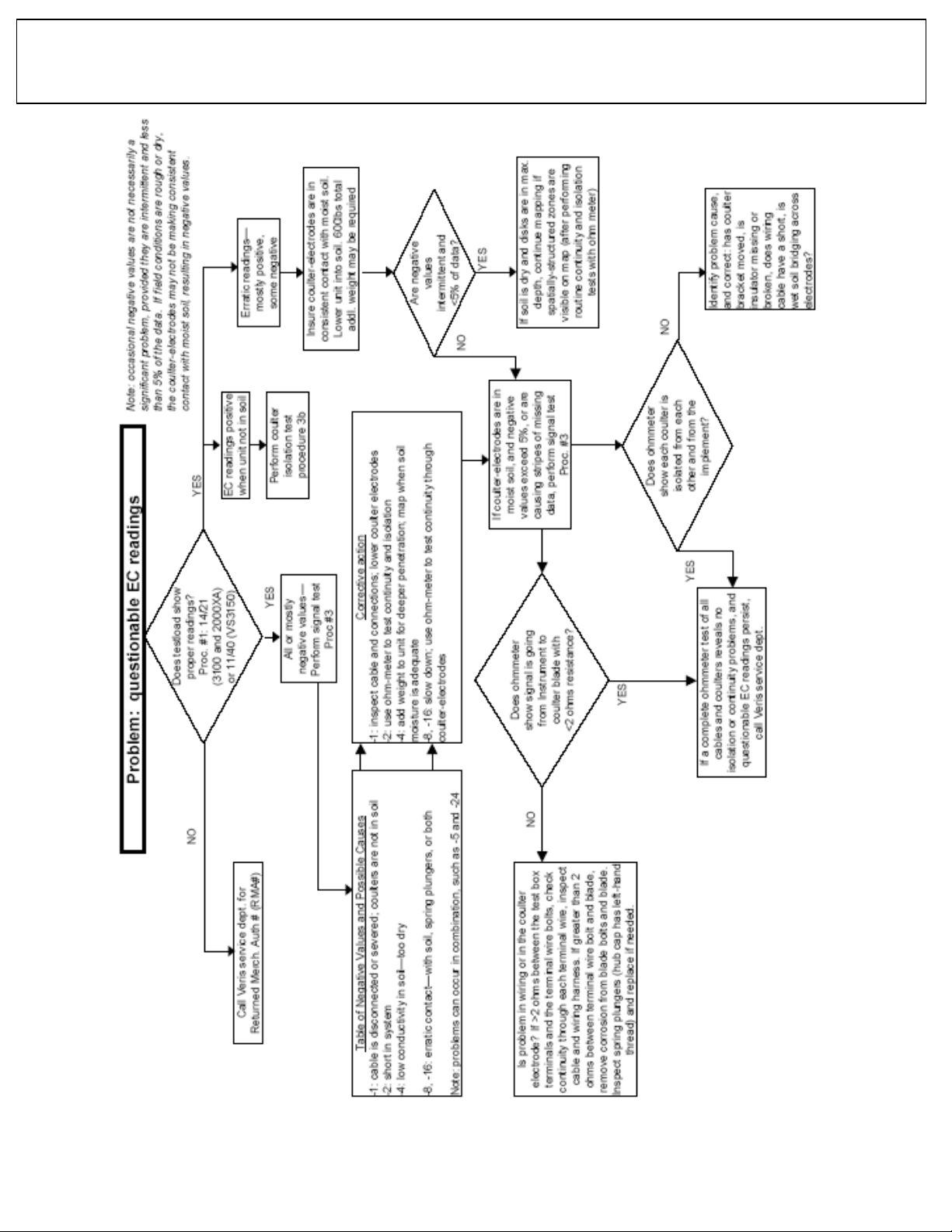

Procedure #3: Diagnosing and Correcting EC Signal Problems.

Use this Troubleshooting tree to work through the system, locate the problem, and take corrective action.

Figure 3.1

Page 6

Coulter Electrode Functions-

Each coulter electrode on the implement is part of a pair, and each pair has a distinct

function.

a) Coulters 1 & 6 are the Deep EC receptors. If you are seeing problems only with the

―Deep‖ readings, focus on testing continuity on these two coulter-electrodes.

b) Coulters 2 & 5 are the ―charged‖ coulters that inject the voltage into the soil. If you

are getting no (or intermittent) readings on both the ―Shallow‖ and the ―Deep‖ -continuity to one of these two coulter-electrodes is likely the cause.

c) Coulters 3 & 4 are the ―Shallow EC‖ receptors. Focus on this pair if you see

problems in the ―Shallow‖ reading.

If the continuity ohm test indicates a problem on a channel, you will need to determine

where the interruption is located. Listed below are detailed instructions on how to

determine exactly where a continuity or isolation problem is located:

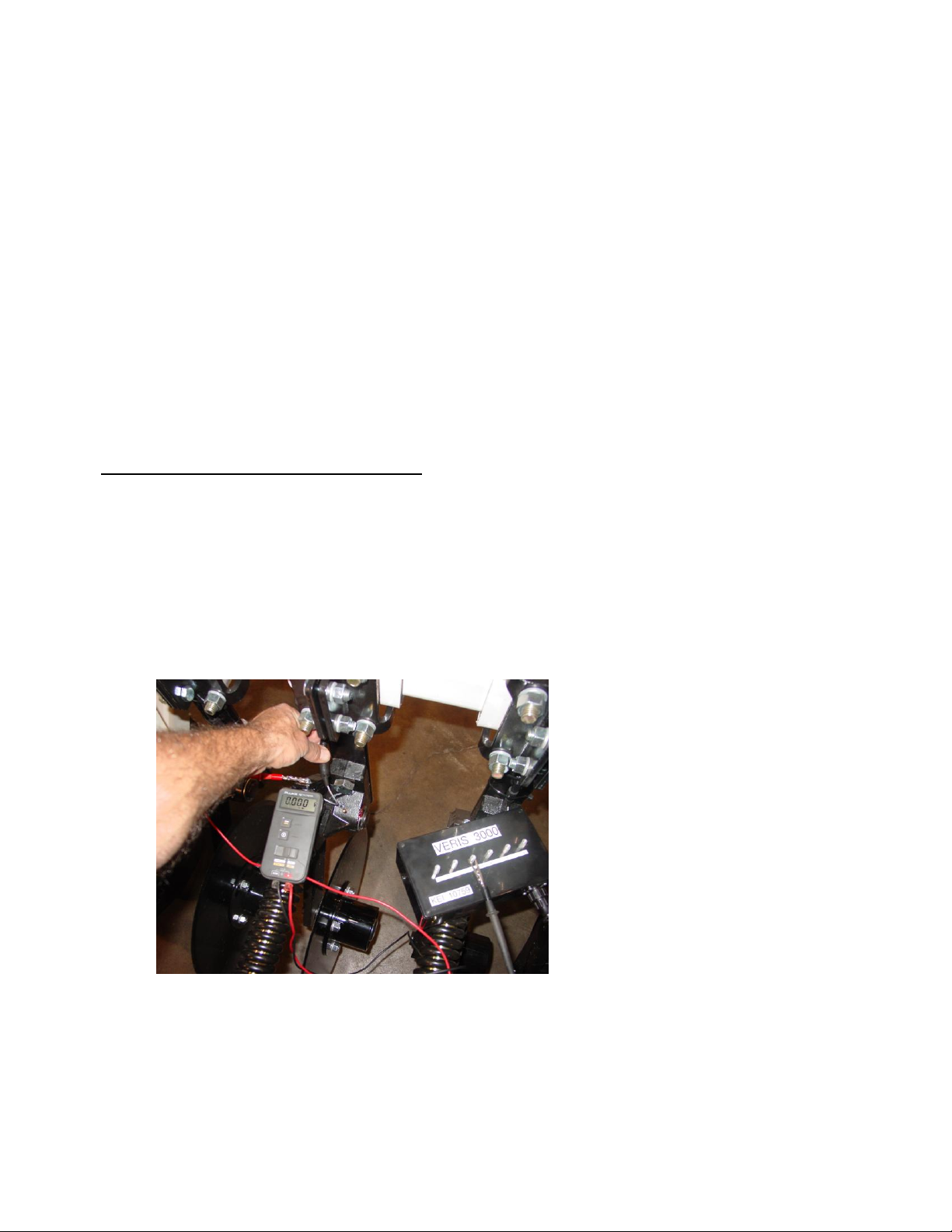

A. Testing Cable and Wiring continuity:

1. Once a high resistance reading on a channel is confirmed, determine whether the

problem is in the wiring or in the coulter-electrode. To test all cable and wiring, place

one ohmmeter lead in the Test Box terminal pin for that channel and the other on

the corresponding coulter wire terminal bolt. Grasp sure-seal connector and move

back and forth during this test – vibration from rough fields can weaken the contacts

on the sure seal, causing breaks in continuity during operation that might no show

up in a static test. Repeat process on all coulter-electrodes.

Figure 3.2 Testing cable at coulter electrode #3 terminal

2. If you see <2 ohms on all, test the coulter electrodes as explained in B below.

3. If you see a > 2ohms reading on any channel, separate sure-seal connector and

insert one ohmmeter lead in the end of wiring harness and the other lead in the

corresponding terminal on the Test Box. If reading is < 2 ohms at that point, the

Page 7

problem is not with the wiring harness or signal cable extension. It is most likely in

the terminal connector wire. Check resistance in it by placing one ohmmeter lead

on the coulter wire terminal bolt and the other lead in the end of the terminal wire

socket. Replace connector wire (PN 14226) as necessary.

Figure 3.3 Testing cable at end of signal cable wiring harness

Figures 3.4 ab. a. Separating sure-seal connector b. Testing terminal connector wire

4. If there is a >2 ohm reading in the signal cable harness or signal extension cable,

visually inspect the wiring harness and cable extension for damage. If a visual

inspection doesn‘t reveal a problem, you will need to test continuity of the wiring

harness and cable. You will need to ohm these cables out individually. Disconnect

signal extension cable from implement and insert ohmmeter leads into sockets as

shown below.

Page 8

Figures 3.5 a and b. Checking

continuity of signal extension

cable with one ohmmeter lead

contacting pins in extension

cable end, and other lead

contacting corresponding test

box terminal.

5. To ohm out the wiring harness, disconnect the serial cable extension from the

implement and check continuity through the harness as shown in Figures 10a and

10b. While doing so, check the pins and the sockets of the 6-pin connector for

corrosion and fit. If necessary spread the pins with a small screwdriver to tighten fit

in sockets.

Figures 3.6 a and b. Checking continuity of signal harness, with one ohmmeter lead

contacting pins in connector and other lead contacting corresponding coulter-electrode.

Note: intermittent electrical problems are difficult to diagnose. Flex wiring and

connectors while checking continuity.

Page 9

B. Testing Coulter-Electrode continuity

hubcap

commutator

coulter spindle

1. Place ohmmeter lead on terminal wire bolt and other lead on disk blade. Rotate

blade ¼ turn. If readings are consistently above 2 ohms, check for excessive

corrosion at the coulter blade mounting bolts, or the terminal located near the

coulter pivot. Make sure that high ohm readings are not due to poor contact

between blade and ohmmeter lead. Re-test holding lead firmly against edge of

blade, removing rust or paint if necessary.

2. If ohms jump over 2 ohms when the blade is rotated, and you were careful to

maintain good contact between the lead and the blade, the problem is likely inside

the hub. Because electrical signals cannot be sent consistently through the coulter

bearing, Veris has designed a more reliable path for the EC signal to travel. A

special hub with a spring plunger presses against the spindle of the coulter, serving

as a commutator. Shown below is a cut-away view of the hubcap and plunger

assembly. When ohm readings jump during blade rotation, it is due to the greased

rollers on the bearing making intermittent and inconsistent contact. See

Maintenance and Service procedure #4: Spring Plunger adjustment and

replacement on adjusting and replacing spring plungers.

Figure 3.7

C. Testing Coulter-Electrode isolation

If continuity tests show no excessive resistance on any channel, yet erratic soil EC

readings continue, or if EC readings do not drop to –1 when unit is out of the soil, it is

possible that the channels are not isolated. This could be the result of a pinched wiring

Page 10

cable, causing channels to short out. Or, one of the coulter-electrodes is no longer

insulated properly from the frame or adjacent coulter-electrodes.

1. If EC readings do not drop to –1 when unit is raised, disconnect signal cable

extension from implement. If readings don‘t drop to –1, the problem is with the

signal cable extension. If readings show -1, re-insert the signal cable extension into

the implement. Disconnect the sure-seal terminal connector wire from each coulter

electrode. If readings don‘t drop to –1, the problem is with the wiring harness. If this

is the case, you should replace the wiring harness. If readings do drop, re-insert the

signal cable extension into the implement. The problem is with one or more of the

coulter-electrodes. Proceed as follows:

sure-seal pin

sure seal socket

Figure 3.8

2. Inspect nylon insulation slides under coulter-electrode mounting brackets. These

nylon insulators may become worn or brittle, or may slip out from under mounting

bracket. Repair and replace as necessary. Make sure that all electrode coulter Ubolts are properly tightened to clamp mounting bracket and insulation tightly to

frame.

nylon insulation

Figure 3.9

3. Disconnect signal cable from instrument or front of frame. Check so see that no

metal part of the any coulter electrode is in contact with the implement frame. This

may be by visual inspection or by connecting one lead of an ohmmeter to the

Page 11

individual coulter electrode, and the other to a grounded fastener on the frame. If

no

continuity

grounded

bolt

coulter

terminal

the coulter electrode is properly isolated, no reading will be obtained. Make sure

that all electrode coulter clamp bolts are properly tightened to prevent lateral

movement of the coulter electrode.

Figures 3.10 a and b

4. Wet soil on the toolbar could be a pathway for the EC signal to short. Test coulterto-coulter and coulter-to-frame isolation by checking resistance between coulterelectrodes. Any continuity from one coulter to another is not acceptable. Remove

buildup of wet soil, especially if is bridges across insulation slides. It may be

necessary to remove coulter mounting brackets and clean toolbar, if problem

persists.

Figure 3.11 Wet soil buildup on toolbar may

cause EC signal to short.

Page 12

Procedure #4 Spring Plunger adjustment and replacement

The spring plungers are located in the center of each coulter electrode hub cap, and are

vital to maintain good continuity through the coulter hub bearings. They are factory

preset, and should not need routine adjustment. If a continuity test shows abnormally high

resistance, the plungers should be checked. This may be performed in the following

manner:

1) Check coulter hub bearing preload by grasping coulter blade and

pushing from side to side. If there is any noticeable movement,

bearing preload is incorrect, or bearings are failing --and this can

damage the spring plunger ; see procedure #8 for adjustment or

replacement.

2) Remove the 3/8‖ allen head set screw.

3) Remove the plunger by turning counter-clockwise.

4) Depress the spring loaded tip on a hard surface to determine if

plunger has adequate tension and can move freely.

5) If the plunger will not move freely, replace. Coat the threads with dielectric silicone grease before installation.

6) If the plunger appears to be in good working order, reinstall in the

hub, and adjust until it bottoms against the spindle end. Rotate 1/2

turn backward to allow adequate clearance. Improper adjustment

will result in premature failure (too little tolerance) or poor continuity

(too much tolerance). See Figure 3.12 below to view proper

clearance.

7) Reinstall locking set screw and tighten firmly on top of plunger. The

top of the setscrew should be even with the face of the hub. If not,

remove and adjust the plunger inward or outward as necessary.

8) Re-test coulter electrode continuity

Figure 3.12

In some cases, you may have to remove the hub cap to service the spring plunger, if the

plunger is rusted in the cap, or if the readings are still unsatisfactory with the new plunger

installed.

Page 13

Procedure:

1) Remove hub cap by turning clockwise with a pipe wrench or large

adjustable wrench – these caps have left hand thread to prevent

loosening during field rotation.

2) If plunger is frozen in cap, remove allen head set screw on top of

plunger and apply penetrating oil on both sides of plunger. Let this

stand for a few minutes and try to remove. If it will not back out

with allen wrench, lock vise grips on the inside portion and turn out

through inside of hub.

3) Clean all hub cap surfaces, install new o-ring, coat plunger and set

screw with di-electric grease and install as outlined above.

4) At the same time, inspect the end of the spindle. Over time the

plunger will wear a slight depression in the spindle face. This is

common, and more noticeable on high acreage units, or units that

have been operated at high field speeds. If the depression is 1/6‖

or more, carefully grind the face of the spindle. Cover the bearing

with a cloth or towel to prevent grinding dust from entering the hub

and bearings..

5) Re-install hub cap and tighten firmly. You may have to re-set the

plunger to compensate for the reduced length on the newly ground

spindle. Re-adjust as outlined above.

Note: If you are still unable to obtain favorable resistance readings, check for excessive

corrosion at the coulter blade mounting bolts, or the terminal located near the coulter pivot.

It may be necessary to grind the spindle end smooth, if a dimple has developed.

Page 14

Procedure #5: Diagnosing GPS-related problems

If you do not see a GPS, DGPS, or RTK in the upper left-hand corner of the EC Surveyor

screen, you do not have GPS coming in, and no data will be sent out the serial port for

logging.

Figure 5.1

Insure your GPS receiver is powered and outputting NMEA strings GGA, and either VTG

or RMC at a 1hz rate; 4800 baud, 8 data bits, no parity, 1 stop bit. Verify that your GPS

cable is sending GPS data through pin 2, pin 5 is ground, and no other pins have signal or

power on them. The most common issue is hz rate. If the GPS has been used for

lightbar guidance it may have been set to a 5 or 10 hz rate. It will need to be changed to 1

hz in order for the EC Surveyor to accept it.

Shown below is a Troubleshooting tree for diagnosing GPS signal problems. It is not

meant to replace your GPS receiver user manual—it merely shows how to determine if

your receiver is sending the GPS signal that the EC Surveyor needs.

Figure 5.2

Page 15

If it becomes necessary to send GPS data into your PC, you will use a program called

HyperTerminal. This program is in all Windows software. It is designed to record serial

data streaming into a serial or USB port on the computer. The purpose of this is two-fold:

1) it verifies whether your GPS and cables are delivering the proper messages, and 2) it

give Veris Technologies support personnel a GPS data file to test.

Here‘s how to use HyperTerminal

1. Plug the GPS output cable into the laptop serial input (or USB-serial hub); no null

modem is needed

2. Verify in Device Manager which Com port the GPS is connected to (Start-Settings—Control Panel—System—Hardware—Device Manager—Ports

3. Start the ―HyperTerminal‖ program under ―Accessories‖ in Windows.

Figure 5.3

4. Give your HyperTerminal session a name such as gps trial when the program

prompts you for the name of your connection and then hit ―OK‖.

Figure 5.4.

Page 16

5. The program will then ask you for a phone number. Instead of entering a phone

number, specify the proper serial port number. For example, if Com 1 of the laptop

is being used, specify ―Direct to Com 1‖ under ―connect using:‖ at the bottom of the

entry area.

Figure 5.5.

6. HyperTerminal will then display a configuration menu where you can specify 4800

bits per second, 8 data bits, no parity, 1 stop bit and no flow control.

Figure 5.6

Page 17

7. At this point, upon clicking ok, legible strings of GPS data should begin appearing

on the laptop screen. Here‘s an example of a typical set of strings:

$GPGGA,191528.00,3851.0333,N,09737.2342,W,2,08,1.3,372.7,M,27.3,M,10.0,0100*

69

$GPRMC,191528.00,A,3851.0333,N,09737.2342,W,0.1,0.0,090998,6.3,E*48

8. If GPS data doesn‘t appear, recheck the port and configuration settings to make

sure they are correct. If the data won‘t appear correctly in HyperTerminal, consult

your GPS supplier to see what adjustments (connectors or software) are necessary

to bring the signal into a computer.

9. If the signal appears correctly on HyperTerminal and it shows that the required

strings are being output, highlight a page of strings, copy and paste into Word or

Wordpad before exiting HyperTerminal.

10. Retry the unit with the Veris instrument. If it still doesn‘t work, please email the

page of GPS strings from HyperTerminal to Support@veristech.com, along with your

contact information.

Loading...

Loading...