Page 1

AS420

E1 Digital Loopback (EDL) Device

34-00294.2

May 2000

i

Page 2

RONT

F

M

ATTER

Copyright N otice

Trademarks

EU Declaration of

Conformity

Copyright © 2000 Verilink Corporation. All rights reserved.

This document does not create any express or implied warranty about Verilink or about its

products or services. Verilink’s sole warranty is contained in its product warranty. The

end-user documentation is shipped with Verilink’s products and constitutes the sole specifications re ferred to in th e pr od u c t wa r ranty. Verili nk h as m a de re a so n ab le efforts t o ve r ify th at the

information contained herein is accurate, but Verilink assumes no responsibility for its use or

for any infringem ent of patents or other rights of third parties that may result. The customer is

solely responsible for verifying the suitability of Verilink’s products for its use. Specifications

are subj ect to change without notice.

Manual reorder # 34-00294

2nd Edition, May 2000

Verilink™ and the Verilink logo are registered trademarks of Verilink Corporation. All other

trademarks or registe red trademarks are the property of th eir respectiv e ow ners.

Model Number: AS420

Manufacturer’s Name: Verilink Corporation

Manufacturer’s Address: 127 Jetplex Circle

Madison, Ala bama 35758

USA

Telephone: (256) 772-3770

Facsimile: (256) 774-2277

The before me ntioned products comp ly with the following EU directive:

89 / 336 / EEC, “Council Directive of 3 M ay 1989 on the approximation of the

laws of Mem be r Sta tes relati ng to ele ct ro m a gn e tic compatibility”

The com pliance o f the above mention ed produc ts with th e Directives and with th e followin g

essent ial requirements is hereby confirmed:

Emissions Immunity Safety

EN 55022, Class A , 1995 EN 50082-1, 1992 EN 60950: 1992 / A1 + A2: 1993 /

A3: 1995 / A4: 1997

The technical files and other documentation are on file with Mr. Ron Hillis, Certification Manager.

As the manufacturer we declare under our sole responsibility that the above mentioned products compl y w ith the above named di rectives.

Ron Hillis,

Certification Manager, Verilink Corporation

Madison Ala bama, 6 May 1999

Canadian Emissions

Requirements

ii AS420 Reference Manual

This digital apparatu s d oe s not exceed the Class A limits for radio noise emissions from dig ital

apparatus set out in the Radio Interference Regulations of the Canadian Department of Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites

applicables aux appareils numériques (de la class A) prescrites dans le Règlement sur le

brouillage radioélectrique édicté par le ministère des Communications du Canada.

Users should ensure for their own protection that the electrical ground connections of the

power utility, telephone lines and internal metal lic water pipe system, if present, are connected

together. This precaution may be particular ly important in rural areas.

Page 3

Caution: Users should not attempt to make such connections themselves, but

should contact the appropriate electric inspection authority, or

elect rician, as appropriate.

Warranty

Customer Service

Returning P roducts

Verilink's product warranty covers repair or replacement of all equipment under normal use for

a five-year period from date of shipment. Replacement product s may be new or reconditioned.

Any replaced or repaired product or part has a ninety (90) day warranty or the remainder of the

initial warranty period, whichever is longer. Our in-house Repair Center services on a standard

10-workday-turnaround basis.

Verilink offers the following services:

Customer support is available by telephone 24 hours a day, 7 days a week. To speak

•

directly with a Verilink customer service representative, you may dial one of the

followin g numbe rs:

Technical Support: 800- 285 -2755 (toll-free)

•

256-772 - 3770 (local)

Sales and Marketing: 800-VERILINK (837-4546)

•

You can request sales and marketing information or pose a technical support question

•

about your Verilink product by contacting us at the e-mail addresses provided below.

Verilink will respond to e- mailed requests for support during regular business hours

(8–5 CST, M onday–Friday).

Sales and Marketing: info@verilink.com

•

Technical Support: support@verilink.com

•

Access the latest information about Verilink products, customer service, technical

•

support, latest news releases and more by visiting Verilink’s Internet Web site:

www.verilink.com.

A product must be assigned a Return Materials Authorization (RMA) number before it is sent

to Verilink for repair. An RMA number is issued by Verilink Customer Service at (800)

926-0085 , ext. 2282.

Safety Precautions

When handling this equipment, follow these basic safety precautions to reduce the risk of electric shock and injury:

Follow all warnings and instructions marked on the product and in the manual.

•

Unplug the hardware from the wall outlet before cleaning. Do not use liquid cleaners or

•

aeros ol clea ners. Use a sl ight ly dam p clot h for cl eani ng.

Do not place t his product on an unstable cart, stand, or table. It may fall, causing serious

•

damage to the product.

This product should be operated only from the type of power source indicated on the

•

marking l abel and manual. If you are unsure of the type of power supply you are using,

consult your dealer or local power company.

Do not allow anything to rest on the power cord. Do not locate this product where the

•

cord in terf eres w ith th e free moveme nt of people .

Do not overload wall outlets and ext ension cords, as this can result in fire or electric

•

shock.

Never push objects of any kind into the unit. They may touch dangerous voltage points

•

or short out parts that could result in fire or electric shock. Never spill liquid of any kind

on this equipment.

Unplug the equipment from the wall outlet and refer servicing to qualified service

•

personnel under the following conditions:

When the power supply cord or plug is dama ged or frayed.

•

If liquid has been spill ed into the product.

•

If the product has been exposed to rain or water.

•

If the product has been dr opped or if the housing has been damaged.

•

iii

Page 4

iv AS420 Reference Manual

Page 5

Table of Cont ents

Copyright Notice ................................................................................................................................... ii

Trademarks ............................................................................................................................................ ii

EU Declaration of Conformity .............................................................................................................. ii

Canadian Emissions Requirements ........................................................................................................ ii

Warranty ............................................................................................................................................... iii

Customer Service .................................................................................................................................. iii

Returning Products ............................................................................................................................... iii

Safety Precautions ................................................................................................................................ iii

About This Manual

What is a Reference Manual? .................................................................................................................1

Where to go for Information ...................................................................................................................1

Conventions ............................................................................................................................................1

Chapter 1 General

Introduction .............................................................................................................................................3

Features ...................................................................................................................................................3

Specifications ..........................................................................................................................................4

Generic Interface Requirements (120 W and 75 W) .......................................................................4

E1 Interface ...............................................................................................................................4

T1 Interface ................................................................................................................................4

120 W Termination ....................................................................................................................4

75 W Termination ......................................................................................................................4

E1 Equipment Interface ....................................................................................................................4

120 W Termination ....................................................................................................................4

75 W Termination ......................................................................................................................5

Timing ..............................................................................................................................................5

Network .....................................................................................................................................5

Internal .......................................................................................................................................5

Management .....................................................................................................................................5

Mechanical .......................................................................................................................................5

Power Source ...................................................................................................................................5

Industry Standards ............................................................................................................................5

Europe ........................................................................................................................................5

Canada .......................................................................................................................................6

US ..............................................................................................................................................6

Environmental ..................................................................................................................................6

v

Page 6

Chapter 2 Installation and Configuration

Introduction .............................................................................................................................................7

Safety Summary ......................................................................................................................................7

Unpacking and Inspection ......................................................................................................................7

Supplied Materials ..................................................................................................................................8

Connections ............................................................................................................................................8

DTE and Network Connections .....................................................................................................8

User Interface Port Connection ........................................................................................................8

Power ................................................................................................................................................9

Configuration ..........................................................................................................................................9

Configuration Switch S1 ................................................................................................................9

E1 Mode Settings .......................................................................................................................9

Framed E1 ...........................................................................................................................9

CRC-4 .................................................................................................................................9

CAS Signalling ...................................................................................................................9

Timing Mode .......................................................................................................................9

Front Panel Rocker ..............................................................................................................9

Not Used .............................................................................................................................9

T1 Mode Settings .....................................................................................................................10

Framing T1 ........................................................................................................................10

CRC-4 ...............................................................................................................................10

Signalling ..........................................................................................................................10

Timing Source ...................................................................................................................10

Network Mode ..................................................................................................................10

Front Panel Rocker ............................................................................................................10

Not Used ...........................................................................................................................10

Supervisory (SUPV) Port ........................................................................................................10

Firmware Download Procedure ...............................................................................................11

Reloading Previous Firmware .................................................................................................11

Power Bypass .................................................................................................................................11

Chapter 3 Testing

Introduction ...........................................................................................................................................13

Indicators ..............................................................................................................................................13

Loopbacks .............................................................................................................................................14

Front Panel Rocker Switch ...................................................................................................................14

Network ..........................................................................................................................................15

Equipment ......................................................................................................................................15

Chapter 4 Terminal Operation

Terminal Interface ................................................................................................................................17

Screen Components ........................................................................................................................17

Header ......................................................................................................................................17

vi AS420 Reference Manual

Page 7

Main Title ................................................................................................................................18

Cursor Controls ........................................................................................................................18

Field Types ..............................................................................................................................18

vii

Page 8

viii AS420 Reference Manual

Page 9

A

C

0

HAPTER

What is a Reference Manual?

This is a reference manual. It provides information about unit installation,

configuration, testing and troubleshooting on a function-by-function basis. It

is not a user’s guide containing step-by-step procedures. This manual contains

specific information about a command, menu field, port, etc. Unless otherwise

noted, the information in this manual applies only to the Verilink AS420 (also

referred to as “the unit.”)

Where to go for Information

The chapters and appendices in this manual are arranged for quick reference.

It is not necessary to read previous chapters to understand the subsequent

chapters.

Chapter 1, General -- Introduces the unit, lists the features, and provides

•

specifications.

Chapter 2, Installation and Configuration -- Describes unit installation, port

•

and power connections, switch settings, and firmware upload procedures.

BOUT

T

HIS

M

ANUAL

Conventions

Chapter 3, Testing -- Describes the indicators, test switch, and loopbacks.

•

Chapter 4, Terminal Operation -- Describes the terminal interface’s screen

•

structure and menu controls.

The following table lists the conventions used throughout this manual.

Convention Description

Notices call attention to important features or instructions.

Cautions alert you to personal safety risk, system damage, or data loss.

Warnings alert you to the risk of severe personal injury.

italics Italics denote new terms or emphasis.

underline Default settings are underlined.

About This Manual 1

Page 10

2 AS420 Reference Manual

Page 11

Introduction

HAPTER

C

1

G

C

1

HAPTER

The AS420 is an E1 Digital Loopback device (EDL). This device allows

network management centers to remotely activate an E1 signal payload

loopback to facilitate installation and troubleshooting of the E1 circuit. This

EDL device responds to proprietary codes, transmitted by remote test

equipment, which does not interfere with network maintenance elements that

belong to local postal telegraph (PTT) authorities.

ENERAL

Features

Table top packaging

•

100–240 VAC autoranging power supply

•

BNC (75 ohm) and RJ-48C (120 ohm) NET and EQUIP connectors

•

Compatible with fractional, full, or unframed E1 services

•

LED status indicators

•

DIP switch configurable

•

Provides payload maintenance loop-back, towards network, on demand

•

Provides DTE line loopback on demand

•

Power bypass relays on EDL device to maintain E1 service to customer if the

•

EDL device loses power. Automatically terminates bypass mode when power

is restored to unit.

SUPV port for local firmware upgrades

•

General 3

Page 12

Specifications

Generic Interface Requirements (120 Ω

Ω and 75 ΩΩΩΩ)

Ω Ω

E1 Interface

Line Rate: 2.048 Mbps (± 32 ppm)

Framing: ITU-T G.704 (with or without CRC-4) G.703

Line Code: HDB3

Input Level: E1 to 6 decibels

Pulse Width: 244 (± 41) nanoseconds at half amplitude

Pulse Afterkick: 10 to 30 percent of pulse peak

T1 Interface

Line Rate: 1.544 Mbps (± 32 ppm)

Framing: D4 or ESF

Line Code: AMI or B8ZS

Input Level: 0 to -36 decibels

Pulse Width: 344 (± 45) nanoseconds at half amplitude

Pulse Afterkick: 10 to 30 percent of pulse peak

120 Ω

Ω Termination

Ω Ω

Interface: RJ-48C

Impedance: 120 Ω, balanced

Output Level: 3.0 (± 0.3) volts (base- to- peak)

75 Ω

Ω Termination

Ω Ω

Interface: BNC - coax

Impedance: 75 Ω, unbalanced

Output Level: 2.37 (± 0.24) volts (base- to -peak)

E1 Equipment Interface

N×64 kbps rate... for unframed E1: N= 32;

120 Ω

Ω Termination

Ω Ω

Interface: RJ-48C

Impedance: 120 Ω, balanced

for framed E1 without CAS: N= 1 to 31;

for framed E1 with CAS: N=1 to 15 and 17 to 31

4 AS420 Reference Manual

Page 13

Timing

Management

75 Ω

Ω Termination

Ω Ω

Interface: BNC - coax

Impedance: 75 Ω, unbalanced

Network

E1: 2.048 Mbps (±50ppm)

T1: 1.544 Mbps (±50ppm)

Internal

E1: 2.048 Mbps (±32ppm)

T1: 1.544 Mbps (±32ppm)

DIP switches and LEDs

Mechanical

Mounting: desktop

Dimensions: 1.3" H, 8.0" W, 8.0" D

Weight: 1 pound

Power Source

External: Input: 100 –240 VAC autoranging

Industry Standards

Europe

ITU-T G.703

ITU-T G.704

ITU-T G.706

ITU-T G.821

ITU-T G.823

Output: 24 VDC, 500 mA

Directive 89/ 336 /EEC

Directive 73/ 23 /EEC

Directive 98/ 13 /EEC

General 5

Page 14

Environmental

Canada

Canadian Safety CSA C22.2, No. 950-95

US

FCC Compliance Part 15, Class A

rd

US Safety UL 1950, 3

Operating Temp: 0° to 40°C (32° to 104°F)

Storage Temp: −20° to 70°C (−4° to 158°F)

Humidity: 95% maximum (non- condensing)

Edition

6 AS420 Reference Manual

Page 15

Introduction

HAPTER

C

2

I

C

2

HAPTER

NSTALLATION AND

C

ONFIGURATION

This chapter contains information and instructions required to prepare the

Verilink AS420 for use. Included are initial inspection procedures,

configuration guidelines, connection, and powering information.

Safety Summary

This manual contains information and warnings that must be followed to

ensure safe operation and retain the equipment in a safe condition.

This WARNING sign denotes a potential hazard to the operator. It calls attention

to a procedure or practice that, if not correctly performed or adhered to, could

result in injury or loss of life. Do not proceed beyond a WARNING sign until the

indicated conditions are fully understood and met.

Unpacking and Inspection

This unit is carefully packaged to prevent damage in shipment. Upon receipt,

inspect the shipping container for damage. If the shipping container or

cushioning material is damaged, notify the carrier immediately and make a

notation on the delivery receipt that the container was damaged (if possible,

obtain the signature and name of the person making delivery). Retain the

packaging material until verifying the contents of the shipment are complete

and the unit has been checked both mechanically and electrically.

If the contents of the shipment are incomplete or, if there is mechanical

damage or defect, notify Verilink. If the shipping container is also damaged,

or the cushioning material shows signs of stress, notify the carrier of the

damage as well as Verilink. Keep the shipping materials for the carrier’s

inspection. Verilink will arrange for repair or replacement without waiting for

claim settlement.

Installation and Configuration 7

Page 16

Supplied Materials

The AS420 is shipped from the factory with the following standard

equipment.

external AC power supply

•

reference manual

•

RJ-48 to RJ-48 cables

•

RJ-48 to DB-15 adapters

•

Connections

The AS420 has BNC and RJ-48C connectors for the network and equipment

interfaces, a supervisory port and a power connector. The following

paragraphs describe these connections.

DTE and Network Connections

Table 2.1 shows the pinout for the RJ-48C NET and EQUIP connectors.

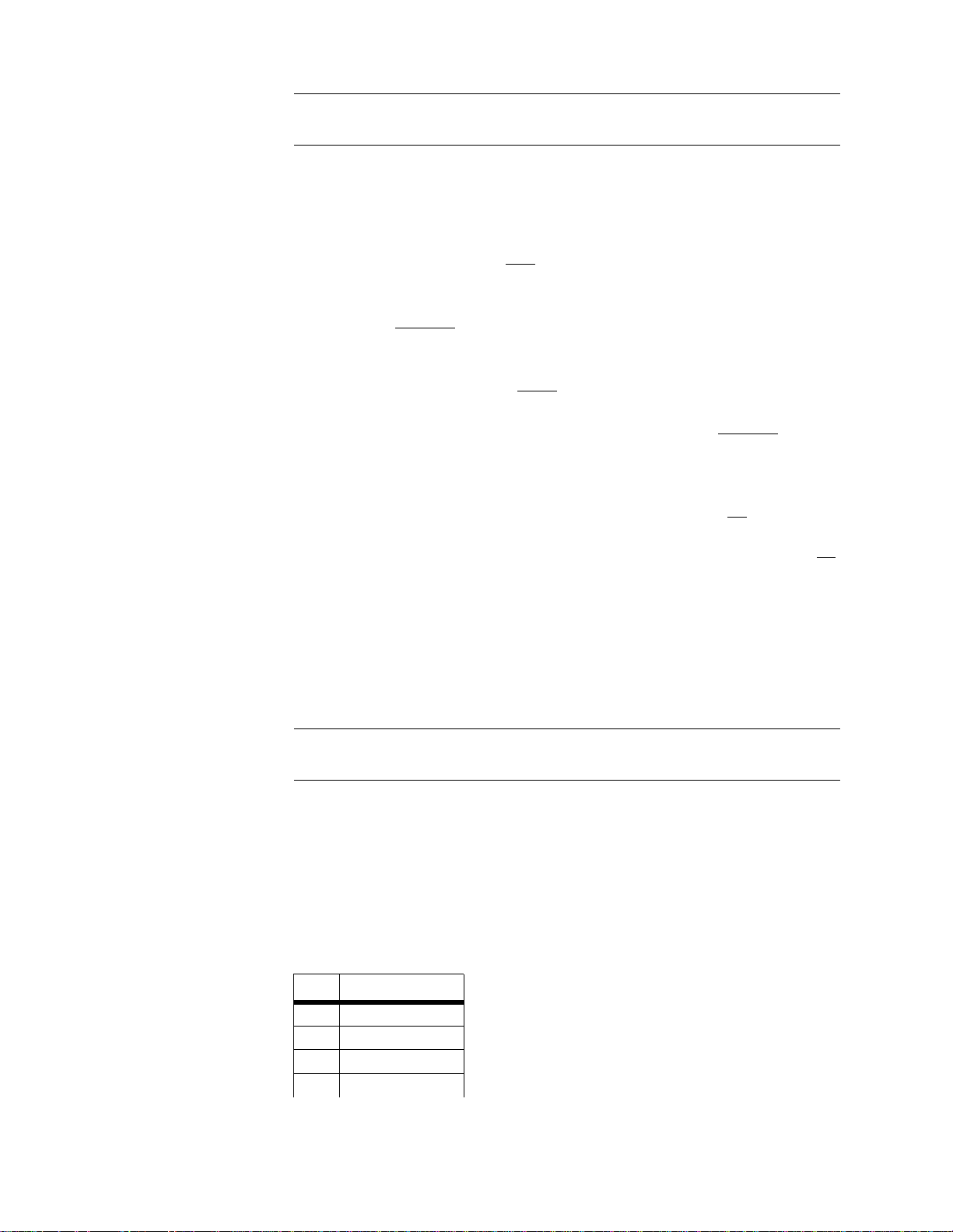

Table 2.1

Pin NET EQUIP

1 Tip In Tip Output

2 Ring In Ring Output

4 Tip Out Tip Input

5 Ring Out Ring Input

3, 6–8 not used not used

RJ-48C Equipment and Network Connector Pinout

User Interface Port Connection

Table 2.2 shows the pinout for the RJ- 48C User Interface port.

Table 2.2

Pin User Interface Port

1 Not used

2RTS*

3 Chassis Ground

4TXD

5RXD

6 Ground

7CTS*

8 not used

RJ-48C User Interface Port Pinout

8 AS420 Reference Manual

Page 17

Power

Configuration

Plug the connector from the power supply into the unit. Plug the transformer

into an appropriate outlet. This applies power to the unit.

This section describes the configuration of the AS420. This unit is configured

using the rear panel DIP switches. Refer to Figure 2.1 for switch locations.

Figure 2.1

The switches are read every two seconds. Any change in the DIP switch

configuration takes effect within a four-second period.

Configuration Switch S1

Switch S1 is located on the rear panel. This switch provides the following

configuration parameters.

E1 Mode Settings

Framed E1.

unframed signals. The default is Framed (Down).

CRC-4.

The default is Disabled (Down).

CAS Signalling.

signalling in frame 16 of a framed E1 signal. The default is Disabled (Down).

Timing Mode.

timing is selected, the unit recovers timing from the network signal. Internal

timing recovers the clock from the unit’s internal circuitry.

Position S1-2 is used to enable or disable CRC4 for the equipment.

Verilink AS420

Position S1-1 sets the unit to receive and transmit framed or

Position S1-3 sets the unit to receive and transmit CAS

Position S1-4 sets the timing mode. When Network (Down)

Front Panel Rocker.

rocker switch to prevent inadvertent loopbacks. The default is Enabled

(Down).

Not Used.

Positions S1-5, S1 -7, and S1 -8 are reserved for future use.

Position S1-6 enables and disables the front panel

Installation and Configuration 9

Page 18

✍

NOTICE:

Switch positions 5, 7, and 8 must remain in the default (Down)

position for normal operation.

T1 Mode Settings

Framing T1.

framed signals. The default is ESF (Down).

CRC-4.

The default is Disabled

Signalling.

B8ZS signalling. The default is B8ZS (Down).

Timing Source.

timing is selected, the unit recovers timing from the network signal. Internal

timing recovers the clock from the unit’s internal circuitry.

Network Mode.

mode is selected, the unit receives and transmits E1 signals. When T1 (Up)

mode is selected, the unit receives and transmits T1 signals. The default is E1

(Down).

Front Panel Rocker.

rocker switch to prevent inadvertent loopbacks. The default is

Enabled(Down).

Position S1-1 sets the unit to receive and transmit D4 and ESF

Position S1-2 is used to enable or disable CRC4 for the equipment.

(Down).

Position S1-3 sets the unit to receive and transmit AMI and

Position S1-4 sets the timing source. When Network (Down)

Position S1-5 sets the network mode. When E1 (Down)

Position S1-6 enables and disables the front panel

Positions S1-7 and S1-8 are reserved for future use.

Switch positions 5, 7, and 8 must remain in the default (Down)

position for normal operation.

✍

Not Used.

NOTICE:

Supervisory (SUPV) Port

The front panel supervisory port is used for local downloading of firmware

updates.

The physical connection is an RJ-48 jack (electrically RS-232). The pinout is

shown in Table 2.3.

Table 2.3

Pin Description

1 Not Connected

2RTS*

3 Chassis Ground

4TXD

Supervisory Port Pinouts

10 AS420 Reference Manual

Page 19

Table 2.3

Pin Description

5RXD

6 Ground

7CTS*

8 Not Connected

Supervisory Port Pinouts

Firmware Download Procedure

This port is accessed through a direct connection. Configure the terminal for

VT100 emulation, 115200 bps, 8 bits, no parity, 1 stop bit.

✍

✍

NOTICE:

Begin the procedure by entering AT . The unit returns “OK.”.

1

NOTICE:

Put the unit into download mode by entering

2

“

Initiate the download or file transfer utility in your communication’s

3

package.

Enter the desired binary file name (.BIN extension) to download. The

4

transfer can take one or two minutes. After the unit successfully receives the

file, the display will read, “

After successfully downloading the binary file, reset the unit by

5

disconnecting and reconnecting the power.

After the unit has reset, enter

6

Commands to the unit are not case sensitive. When the word “enter”

is used in this manual, it means to press the Return or Enter key.

The unit does not echo the typed characters.

Ready for Flash download.

Reloading Previous Firmware

To reload the previous version of the firmware, enter

1

will read, “

Processing Previous Firmware.

. The display will return

AT$Y

”

Flash download was successful.

to verify the new software version.

ATI

. The display

AT$P

”

”

Power Bypass

After the firmware successfully loads, the unit returns “OK”.

2

After successfully downloading the binary file, reset the unit by

3

disconnecting and reconnecting the power.

To verify software, type

4

The AS420 can operate in a power bypass mode where the AS420 passes the

signal from the network to the equipment and vice versa whether in a

powered state or not.

.

ATI

Installation and Configuration 11

Page 20

The power bypass mode is done using relays that switch the network and

equipment connections. When the unit is powered and stable, the relays have

the network and equipment connections switched into the AS420’s internal

circuitry. When the unit loses power, the relays switch the network connection

to a direct connection path to the equipment connection. When power is

reestablished and the unit passes self test, the relays switch the network and

equipment connections back into the AS420’s internal circuitry.

The AS420 powers up and remains in the power bypass mode for two

minutes. This delay allows for any power glitches that may occur as power

resumes after an outage. This minimizes the unit switching from power

bypass to normal operation.

12 AS420 Reference Manual

Page 21

Introduction

HAPTER

C

3

T

C

3

HAPTER

ESTING

This chapter describes the diagnostic and test features of the AS420. The unit

is controlled manually using rear panel DIP switches (the DIP switches are

discussed on page 9). The front panel indicators and switch are shown in

Figure 3.1 and described below.

Indicators

Figure 3.1

The front panel indicators shown in Figure 3.1 convey major alarm conditions

and looping status.

Table 3.1

LED Condition Description

PWR Off

BPV Off

CRC Off

AS420 Front Panel

AS420 Front Panel Indicators

Power off.

Solid

Flashing Red

Solid Red

Flashing Red

Solid Red

Power is applied to the unit.

No errors.

Intermittent BPV errors.

Continuous BPV errors.

No errors.

Intermittent CRC-4 errors.

Continuous CRC-4 errors.

Testing 13

Page 22

Table 3.1

LED Condition Description

AS420 Front Panel Indicators

Loopbacks

NET Off

Flashing Red

Solid Red

LPBK Off

Flashing Yellow

Solid Yellow

No errors.

RAI/AIS detected.

Loss of signal.

No loopback active.

Equipment loopback active.

Payload loopback active.

The AS420 responds to remote loopup and loopdown codes from any channel

in the framed E1 data stream. The resulting payload loopback occurs on all

channels in the framed E1 data stream. Loopbacks are initiated after receiving

the loopback code for five seconds and remain until the time limit expires or

the loopdown code is received.

Loopback commands received from the far end must be initiated from test

equipment that sends data without packet protocols. This allows the AS420 to

detect loop-up and loop-down streams without stripping headers, footers, or

flags. The loop codes with their descriptions are provided in Table 3.2.

Table 3.2

Framed E1 Loops and Loop Codes

Description Code

Loop network traffic for 30 minutes. 00000111

Loop network traffic for 60 minutes. 00111000

Loop network traffic for 72 hours. 00010100

Cancel loop in progress. 00110010

For unframed E1 data, the unit responds to five seconds of a 1-in-5 (10000)

pattern by looping the entire E1 datastream until receiving a 1-in-3 (100)

pattern for three seconds.

In both framed and unframed E1 data payload loopback, the equipment

receives an all 1’s pattern.

Front Panel Rocker Switch

The front panel switch activates and deactivates a network or equipment

payload loopback. This switch can be overriden by disabling its functionality

with position S1-6. The loops requested default to a 72-hour loop and remain

in loopback until meeting one of three conditions: the switch is moved to the

middle position, the 72-hour clock expires, or a loopdown code is received

from the network.

14 AS420 Reference Manual

Page 23

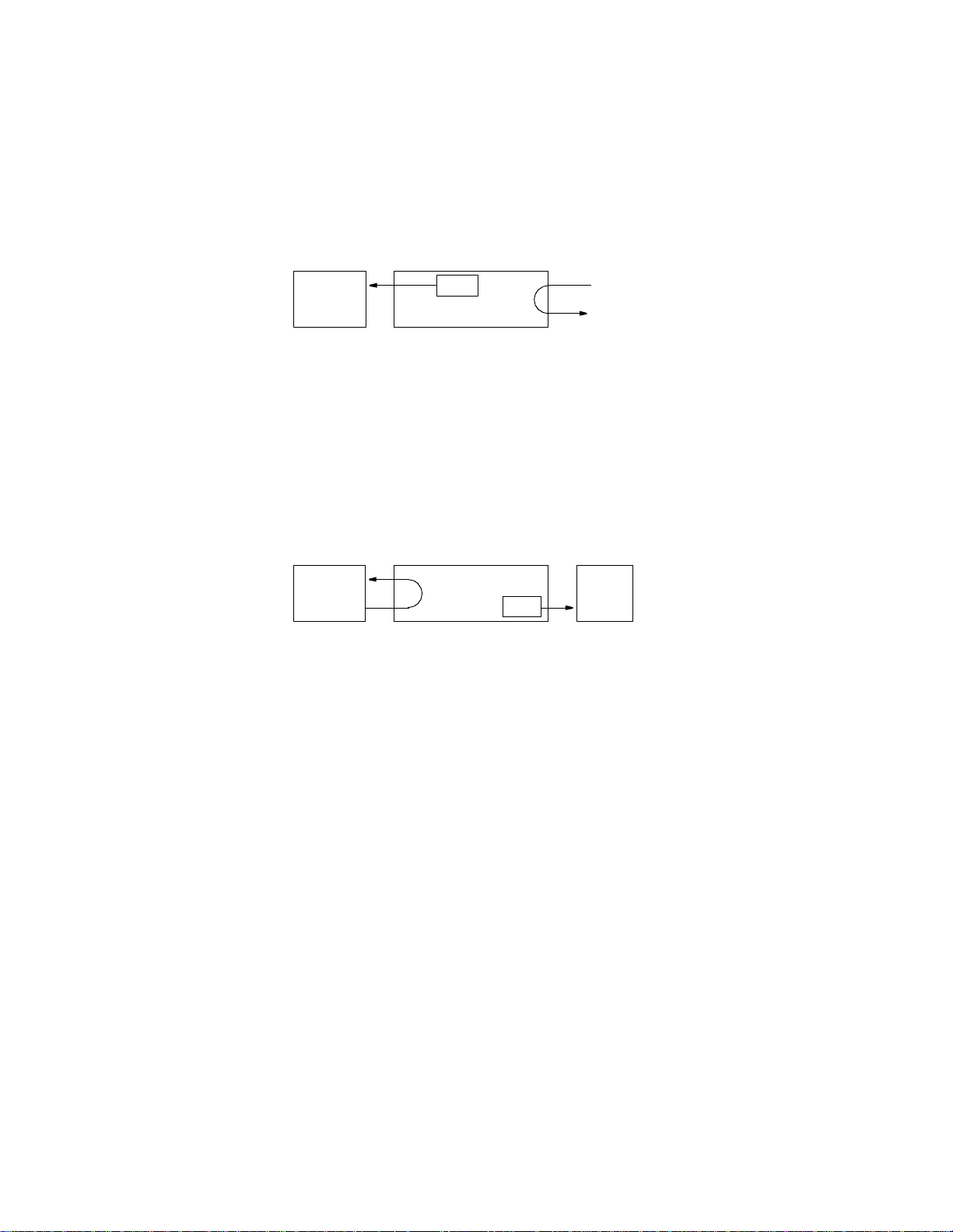

Network

Setting the front panel rocker switch to NET activates a payload loopback

where every frame of the E1 datastream received is looped back to the

network. The equipment receives unframed 1’s.

Deactivate the loopback one of three ways: setting the rocker switch to the

middle position, allowing the 72-hour timer to expire, or receiving a

loopdown code from the network.

Equipment

Equipment

Figure 3.2

Payload Loopback

AIS

AS420

Network

Setting the front panel rocker switch to EQ activates an equipment loopback

where every frame received of the E1 datastream is looped back to the device.

The network receives all 1’s.

Deactivate the loopback one of three ways: setting the rocker switch to the

middle position, allowing the 72-hour timer to expire, or receiving a

loopdown code from the network.

Equipment

Figure 3.3

Equipment Loopback

AS420 Network

AIS

Testing 15

Page 24

16 AS420 Reference Manual

Page 25

HAPTER

C

4

Terminal Interface

This chapter describes the screens structure and menu controls for the

Verilink AS420 terminal interface. The interface is a firmware application

embedded inside the unit.

It requires an ANSI-compatible VT100 terminal (ASCII), or a computer

running an ANSI terminal emulation program. The terminal interface uses

ASCII break and escape functions, which are implemented differently with

the various terminal emulation programs.

Screen Components

Terminal interface screens have components common to all screens (Figure

4.1).

T

C

4

HAPTER

ERMINAL

Header

----- --------------- ------------------ Men u Ti tle ------ --------------------------- ---

O

PERATION

Figure 4.1

Header

The header contains the name of the device, which is “AS420.”

Figure 4-1 Terminal Interface Layout

Terminal Operation 17

Page 26

Main Title

The main title (third line, center) denotes the general classification of

functions currently accessible by the user (such as MAIN or

PERFORMANCE).

Cursor Controls

The terminal interface utilizes a highlighted cursor to make selections from

menus and select fields within the screens to be operated on. The cursor is

moved in different ways, depending on the terminal emulation program used.

Most programs allow use of the TAB and SHIFT+TAB keys. Others allow

use of the arrow keys. Once a field is highlighted, it is manipulated as

described in the section Field Types.

For keyboards that do not have these standard keys or have only some of

them, an alternate set if cursor commands is provided. Each command is

performed by pressing a letter key while holding down the CONTROL key.

Alternate commands may be freely mixed with the keyboard commands at

your discretion. Table 4-A shows the keyboard and equivalent commands.

Table 4.1

Keyboard

Command

left arrow CONTROL+S

right arrow CONTROL+D

up arrow CONTROL+E

down arrow CONTROL+X

backspace CONTROL+H

delete CONTROL+Z

Keyboard and Alternate Commands

Alternate

Command

Field Types

Each screen is made up of fields. The two basic types are user-selectable and

display-only. If the highlighted cursor can be moved to a field, it is a userselectable field. All other fields are for display only. User-selectable fields

allow for changes to be made or commands to be executed.

Fields without brackets or parenthesis are display-only. They cannot be

changed on the screen. Most user-selectable fields are enclosed in brackets or

parenthesis and are described in the following paragraphs.

Fields enclosed in brackets [ ] offer a list of selections from which to choose.

The selections may be toggled by pressing the spacebar. Each time it is

pressed, a new item appears. When the appropriate choice is displayed, press

ENTER to select it.

Fields enclosed in parenthesis ( ) are manipulated by one of the following

methods:

18 AS420 Reference Manual

Page 27

1 Pressing ENTER on such fields as (Reset) and (Start Test) simply executes

the function.

The most common type of field in parenthesis accepts typed input in the

2

form of letters and/or numbers. Typing characters when the field is

highlighted causes the current entry to be replaced with the new characters.

To edit an existing entry rather than replace it, press the right arrow key to

move the cursor to the point that needs editing. Characters may then be

inserted or deleted. Typed data is always inserted rather than typed over. If

the field is full, though, at least one character must be deleted to add

another.

Many fields of this type may also be toggled by pressing the spacebar.

3

Other fields are range checked, where the user is not allowed to exit with an

illegal value set.

✍

NOTICE:

Any screen may be redisplayed or refreshed by pressing

CONTROL+U. Any changes to fields on a screen that has not

been activated by pressing ENTER are discarded.

Terminal Operation 19

Page 28

20 AS420 Reference Manual

Loading...

Loading...