Page 1

Verilink Access System 2000

The Basics

October 1999

P/N 880-502981-001-H

Page 2

Copyright Notice

Copyright 1999 Verilink Corporation. All rights reserved.

This document does not create any express or implied warranty about Verilink or

about its products or services. Verilink’s sole warranty is contained in its product

warranty. The end-user documentation is shipped with Verilink’s products and

constitutes the sole specifications referred to in the product warranty. Verilink has

made reasonable efforts to verify that the information contain ed h erein is accurate,

but Verilink assumes no responsibility for its use or for any infringement of patents

or other rights of third parties that may result. The customer is solely responsible

for verifying the suitability of Verilink’s pro ducts for its use. Specifications are

subject to change without notice.

Trademarks

FCC Requirements

Lithium Battery

English

Verilink is a registered trademark of Verilink Corporation. Access System 2000,

WANscope, VeriStats, and FrameStart are trademarks of Verilink Corporation.

Any named prod ucts herein are trademarks of their respective companies.

This equipment has been tested and found to comply within the limits for a Class A

digital device pursuant to Par t 15 of the Federa l Communic ations C ommissio n (FCC)

rules. These limits are designed to pro vide protection against harmful interference

in a commercial environment.

This equipment generates, uses, an d can radiate radio frequency energy and, if not

installed and used in accordance with the user manual, can cause harmful

interference t o radio communications.

There is no guarantee that interference will not occur in a p articular installation. If

this equipment causes harmful interference to radio or television reception—which

can be determined by turning the equipment off and on—try to correct the

interference by one or more of the following measures:

Reorient or relocate the receiving antenna.

•

Increase the separation between the equipment and receiver.

•

Connect the equipment into an outlet on a circuit different from that to whi c h

•

the receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

•

The lithium battery referred to in the following notices is contained inside the clock

chip.

DANGER!

The battery can explode if incorrectly replaced! Replace only with the same or

equivalent type recommended by the manufacturer. Dispose of used batteries

according to the manufacturer’s instructions.

DANGER!

To avoid electrical shock in case of failure, the power supply must be installed

by a professional installer. The terminal labeled with the ground symbol ( )

on the power supply must be connected to a permanent earth ground.

CAUTION!

Interconnecting circuits must comply with the requirements of

EN60950:1992/A2:1933 Section 6.2 for telecommunications network voltages

(TNV) circuits.

Français

Une explosion peut se produire si la batterie est remplacée d’ une façon incorrecte! Remplacez-la seulement avec le même modêle de batterie ou un modèle

équivalent selon les recommendations de manufacture. Disposez de les batteries usées selon les instructions de manufacture.

ATTENTION!

ATTENTION!

Pour éviter choc électrique en cas de insuccès, la provision de pouvoir doit êtré

installé par un installeur professionnel. Le terminal de la provision de pouvoir,

marqué du symbol de terre, ( ) doit connecté à un circuit de terre permanent.

ii Verilink Access Sy stem 2000: The Basics

Page 3

ATTENTION!

Les circuits doivent êtré interconnectés de manière à ce que l’ équipement

continue a êtré en agrément avec “EN60950:1992/A2:1933, Section 6.2, pour les

circuits de voltage de liaisons d’ échanges (réseau) par les télécommunications

(TNV),” après les connections de circuits.

Españole

Deutsch

PELIGRO!

La bateria puede exp lotar si s e reempla za incorr ectamente. Reemp lace la bateri a

con el mismo tipo de bateria ó una equivalente recomendada por el manufacturero. Disponga de las baterias de acuerdo con las instrucciones del manufacturero.

PELIGRO!

Para evitar contacto con circuitos que electrocutan, la fuente de alimentación

debe ser instalada por un técnico profesional. La terminal de la fuente de al imentación marcada con el símbolo de tierra ( ) debe ser conectada a un circuito de vuelta por tierra permanente.

CIRCUITOS A INTERCONECTARSE

Circuitos que se int erc on ecta n a la re d de telecomunicaciones deben h ace r se de

tal manera que cumplan con los requisitos estipulados en las especificaciones

“EN60950:1992/A2:1933, Sección 6.2, para los voltages de circuitos

interconnectados a la Red de Telecomunicaciones (TNV),” despues de terminar

las connecciones entre los circuitos.

VORSICHT!

Explosionsgefahr bei unsachgemäßem Ersetzen der Batterie! Batterie gleichen

Typs und gleicher Qua lität ben utzen, wie v om Hersteller empfohlen. Entsor gung

der Batterie nach Anweisung des Herstellers!

VORSICHT, GEFAHR!

Um keinen Schlag zu erhalten beim Versagen der electrischen Anlage, muss der

Stromanschluss von einem Elektriker vorgenommen werden. Der elektrische

Pol, versehen mit dem Erdsymbol ( ) muss am Stromanschluss permanent

geerdet sein.

VORSICHT!

Schaltungen, die in den Geräten zusammengeschaltet sind, müssen weiterhin

den Vorschriften EN60950:1992/A2:1933, Absatz 6.2 für Telecommun ications

Netz Spannung (TNV) Schaltkreize entsprechen.

Canadian

Requirements

Safety Precautions

This digital apparatus does not exceed the Class A limits for radio noise emissions

from digital apparatus set out in the Radio Interference Regulations of the Canadian

Department of Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les

limites applicables aux app a reils numériques (de la class A) prescrites dans le

Règlement sur le brouillage radioélectrique édicté par le ministère des

Communications du Canada.

This equipment is intended to be insta ll ed o nly in a Restricted Access Location that

meets the following criteria:

Access can only be gained by service personnel or users who have been

•

instructed about the reasons for the restrictions applied to the location and

about any precautions that must be taken.

Access can only be gai ned th rough th e use of a lock a nd ke y or ot her mea ns of

•

security, and is controlled by the autho r ity responsible for the location.

When handling this equipment, follow these basic safety precautions to reduce the

risk of electric shock and injury:

Verilink Access Sy stem 2000: The Basics iii

Page 4

Follow all wa rnings and inst ructions marked on the product and in the

•

manual.

Unplug the hardware from the w all outlet before cleaning. Do not use liquid

•

cleaners or aerosol cleaners. Use a cloth slightly dampened with water.

Do not place this product on an u nstable cart, stand, or table. It may fall,

•

causing serious damage to the product.

Slots and openings in the shelves are prov ide d for ve nti latio n to prote c t them

•

from overheating. These openings must not be blocked or covered. Never

place this product near a radiator or heat register.

This product should be op erated onl y from the t ype of power sou rce indicate d

•

on the marking label and manual. If you are unsure of the type of power

supply you are using, consult your dealer or local power company.

Do not allow anything to rest on the power cord. Do not locate this product

•

where the cord will interfere with the free movement of people.

Do not overload wall outlets and extension cords, as this can result in fire or

•

electric shock.

Never push objects of any kind into the sh elves. They may touch dangerous

•

voltage points or short out parts that could result in fire or electric shock.

Never spill liquid of any kind on this equipment.

Unplug the equipment from the wall outlet and refer servicing to qualified

•

service personnel under the following co nditions:

a. When the power supply cord or plug is damaged or frayed.

b. If liquid has been spilled into the product.

c. If the product has been exposed to rain or water.

d. If the product has been dropped or if the cabinet has been damaged.

Product Warranty

Customer Service

Publications Staff

Verilink’s product warranty covers re pair or replacement of all equipment under

normal use for a five-year period from date of shipment. Our in-house Repair Center

services returns within ten working days.

Verilink offers the following services:

System Engineers at regional sales offices for network design and planning

•

assistance (800.837.4546)

Technical Assistance Center for free 24x7 telephone support during

•

installation, maintenance, and troubleshooting (800.837.4546 x333,

support@verilink.com)

Return Materials Authorization (RMA) (800.837.4546 x332)

•

Maintenance contracts and leasing plans (800.837.4546. x206)

•

Technical Training on network concepts and Verilink products (800.837.4546

•

x346, training@verilink.com)

Web site (www.verilink.com)

•

FAX-On-Demand (800.957.5465)

•

This manual was written and illustrated by David Fradelis and Barbara Termaat.

Contributing writers include: Steve Rider, Marie Metivier, and Theresa Lau.

iv Verilink Access Sy stem 2000: The Basics

Page 5

Table of Contents

About this Manual

Access System 2000 Overview

AS2000 Concept.................................................................................................. 1-1

AS2000 System ................................................................................................... 1-2

Shelf Units.................................................................................................... 1-2

AS2000 Design.................................................................................................... 1-3

Advanced Communications Engine (ACE) .................................................... 1-3

AS2000 Management Options............................................................................. 1-4

Craft (ASCII) Interface................................................................................... 1-4

Node Manager............................................................................................... 1-5

SNMP............................................................................................................. 1-5

Management Support Cross-Reference ........................................................ 1-5

Access Manager 2000................................................................................... 1-6

Thumbwheel Switches.................................................................................. 1-6

Performance Monitoring..................................................................................... 1-6

System Information

Shelf Units .......................................................................................................... 2-1

Multi-line Shelf..................................................................................... 2-1

Quint-line Shelf .............................. ...................... ...................... ... ....... 2-1

Dual-line Shelf...................................................................................... 2-1

Data Bus Structure........................................................................................ 2-2

ACP Data Bus Structure ........................................................................ 2-3

ACP Controller Bus Structure ....................................................................... 2-4

Shelf and Node Masters....................................................................... 2-4

Types of Modules ............................................................................................... 2-5

Channel Service Unit Modules (CSU) .................................................... 2-5

Data Service Unit (DSU) Modules.......................................................... 2-6

Integrated DSU/CSU Modules............................................................... 2-7

Connector Interface Modules (CIMs) .................................................... 2-7

Controller Modules............................................................................... 2-7

AS2000 Modules ................................................................................................. 2-8

TABS-Based Application Modu le s.................................... ... ... ...................... . 2-8

TABS-Based Controller Module s .............................. ... ...................... ... . 2-8

ACP-Based Application Modules................................................................... 2-9

Node Controller Module....................................................................... 2-9

Timing .............................................................................................................. 2-10

Timing Source ............................................................................................ 2-10

CSU Timing......................................................................................... 2-10

DCE to DTE Timing......... ...................... ...................... ... ..................... 2 -11

Crossover Connection................. ...................... ... ...................... ........ 2-12

Tail Circuit Timing ............................................................................. 2-13

.......................................................................................................ix

................................................................................ 1-1

................................................................................................. 2-1

Verilink Access System 2000: The Basics v

Page 6

TABS-Based Timing Option s...................... ... ... ...................... ..................... 2- 13

ACP-Based Timing Options........................................................................ 2-13

Shelf vs. Card Timing......................................................................... 2-13

Timing Source .................................................................................... 2-14

Shelf Sync Master ............................................................................... 2-14

Site Planning

............................................................................................................. 3-1

Installation Planning........................................................................................... 3-1

Module Installation ...................................................................................... 3-1

TABS-Based Nodes................................................ ... ...................... ... .... 3-1

ACP-Based Nodes.................................................................................. 3-2

System Cabling Considerations.................................................................... 3-2

T1 Network Interface ........................................................................... 3-3

External Clock Source............... ... ...................... ... ...................... ... ....... 3-3

DTE Interface........................................................................................ 3-3

System Power Requirements ........................................................................ 3-3

Hardware Dimensions.................................................................................. 3-4

Heat Dissipation............................ ... ...................... ... ...................... ... .......... 3-5

Heat Baffles................................. ... ...................... ... ...................... ... .... 3-5

Fan Shelf............................................................................................... 3-5

Preparation Guidelines ....................................................................................... 3-7

FCC Part 68 (or Equivalent) C ompliance Statement ........... ... ... .................... 3-7

Configuration Worksh eet s ............ .... ..................... ...................... ... .................... 3-8

Pre-installation Que stionnaire.......... ... ... ...................... ... ...................... ....... 3-8

Node Summary Worksheets.......................................................................... 3-8

SNMP Node Planning Worksheet........................................................... 3-8

Shelf Planning Worksheets for TABs Modules.............................................. 3-9

Shelf Planning Worksheets for ACP Modules ............................................. 3-11

Hardware Installation

.............................................................................................. 4-1

Required Hardware and Tools ............................................................................ 4-1

Equipment Inspec tion.......... ...................... ...................... ... ...................... .......... 4-1

Wiring for DC Power Installation ......... ... ...................... ... ...................... ... .......... 4-2

Shelf Mounting.................................................................................................... 4-2

Mounting Brackets........................................................................................ 4-2

Installing and Groundi ng Pow er Supp lie s ............. ...................... ... .................... 4-4

Shelf Grounding ........................................................................................... 4-4

Quint-line Shelf Groundin g ............................... ... ... ...................... ... .... 4-5

AC Power Connections........................................................................................ 4-5

Multi-line and Quint-Line Shelves ................................................................ 4-5

Dual-line Shelf.............................................................................................. 4-5

DC Power Connections ..... ...................... ...................... ... ...................... ............. 4-6

Multi-line DC Power Connections................................................................. 4-6

Quint-line DC Power Connections...................................... ... ...................... . 4-7

Dual-line Shelf PWR 2940 and 2950 DC Power Connections........................ 4-7

Connect the Power Supply Alarm................................................................. 4-8

Fan Shelves................................................................................................... 4-9

AC Power Fan Shelf Connections.......................................................... 4-9

DC Power Fan Shelf Connection s ......... ... .... ..................... .................. 4-10

vi Verilink Access System 2000: The Basics

Page 7

Fan Alarm............................................................................................4-11

Installing the Rear Connector Module...............................................................4-12

Installing the Application Module ..............................................................4-12

TIU Installation ...........................................................................................4-13

TIU Connections .................................................................................4-13

System Power Application and Verification................................................ 4-14

Applying Multi-line Shel f DC Pow e r.............................. ...................... 4-14

Applying AC Power to 115 VAC Power Supplies (PAC 2910) ..............4-15

AS2000 Cabling ... .... ... ...................... ..................... ...................... ... ...................4-17

Setting the Shelf Address....................................................................4-18

Extending the TABs Node Controller Bus ...........................................4-19

Daisy-Chaining for the NCM ............ ... ...................... ...................... ............4-19

Data Bus Expansion.....................................................................................4-20

Connecting the Rear Connector Modules ...................................................4-20

ASCII Terminal Connection.........................................................................4-20

Monitoring and Troubleshooting

............................................................................5-1

Front Panel LED Indic ato r s.................. ...................... ...................... ... ...........5-1

Test Equipment ...................................................................................................5-1

System Failure.....................................................................................................5-2

Alarms.................................................................................................................5-2

Interpreting Alarms ......................................................................................5-3

Alarm Description.................................................................................5-3

Alarm Classification .............................................................................5-3

Problem Types ......................................................................................5-3

What To Do About Alarms ............................................................................5-4

Alarm List......................................................................................................5-4

Configuration Problems......................................................................................5-7

T1 Line Coding and Density Enforcement ....................................................5-7

AMI Coding and Pulse Stuffing .............................................................5-7

B8ZS Coding....... ...................... ... ...................... ...................... ... ...........5-7

Loopbacks and Test Patterns ..............................................................................5-8

Repeater Loopback (RLB) ..............................................................................5-9

Line Loopback (LLB) ......................................................................................5-9

Payload Loopback (PL B) ......... .... ..................... .... ..................... .....................5-9

Equipment Loopback (ELB)............................................................................5-9

Data Port Loopback (DPLB)..........................................................................5-10

Test Patterns...............................................................................................5-10

Performance Monitoring Registers.................................................................... 5-11

Performance Register Definitions...............................................................5-11

Performance Data Processing ..................................................................... 5-15

AT&T TR 54016 Performance Data Processing............. ... .... ...............5-15

ANSI TIM1.3 Performance Data Processing.........................................5-15

Verilink Performance Data Processing................................................5-16

Equipment Signal Performance Data Processing ................................5-16

Power Failure.............. ...................... ... ...................... ..................... ...................5-16

DC Power..................................................................................................... 5-16

AC Power.....................................................................................................5-17

System Fault Isolation ................................................................................5-19

Verilink Access System 2000: The Basics

vii

Page 8

Check System Power .......... ..................... .... ..................... .................. 5-19

Verify Self Test................................................................................... 5-19

Check System Configura tio n....................... ... ...................... ... ........... 5-19

NET Loopback.. ...................... ...................... ..................... .................. 5-19

Perform Application Equipment Loopback ........................................ 5-20

CSU Mode Troubleshooting................................................................ 5-20

Compliance Statements

........................................................................................... A-1

Line Aggregate Compliance ................................................................................ A-1

Data Interface Specifications ....................................................................... A-2

Mean Time Between Failure.......................................................................... A-2

British Approvals Board of Telecommunications (BABT) ................................... A-2

Cabling ......................................................................................................... A-3

Required Information for Instructions and Testing..................................... A-3

Tolerance to Wander .................................................................................... A-4

Certifications and Compliance ........................................................................... A-4

System Cables

............................................................................................................B-1

Acronyms.............................................................................................................B-1

Illustrated Parts List ............................................................................................B-2

T1/E1 Line Interface Cables...............................................................................B-22

Acronyms and Definitions

............................................................................ glossary-1

viii Verilink Access Sy stem 2000: The Basics

Page 9

Preface

About this Manual

This manual is the foundational documentation for Verilink’s

Access System 2000. It provides general information for the

modular equipment used within the Access System 2000.

Organized for first- time installation and set -u p o f Access 2000

equipment, this manual contains the following chapters:

Chapter 1: Access System 2000 Overview

Chapter 2: System Information

Chapter 3: Site Planning

Chapter 4: Hardware Install ation

Chapter 5: Fault Isolation

Appendix A: Compliancy Statements

Appendix B: System Cables

Glossary

Index

Verilink Access Sy stem 2000: The Basics ix

Page 10

About this Manual

x Verilink Access System 2000: The Basics

Page 11

Chapter

1

AS2000 Concept

Access System 2000 Overview

Access System 2000 (AS2000) is a uniform system that provides

multiple access interfaces to network services for voice, data, and

video applications. The AS2000 is a bandwidth manager of Level 1

digital services. The Advanced Communications Engine (ACE)

architecture brings the bandwidth management capabilities of the

AS2000 to Level 0 channels (DS0 and E0) and Level 3 channels

(DS3).

The AS2000 system is modular by design, providing different types

of data, network, and mana gement ports. The syst em’s applic ation

components can be managed individually or through a controller

card, locally or remotely. End-user applications include Local Area

Networks (LANs), video conferencing and imaging, digital voice,

and remote terminal-to-mainframe connections.

An AS2000 system consi sts o f one o r more nod es. An AS2000 node

is a combination of up to four shelf units, providing network

support for private networks, virtual private networks, FT1, T1,

FE1, E1, T3, and ISDN PRI. For network ma nagement, the Access

System 2000:

•

Generates and stores non-service-affecting T1/E1 circuit

performance data for circuit analysis and maintenance.

•

Generates alarms for fault conditions from incoming

network/equipment signals, and reports the alarms to th e

AS2000 applicatio n.

•

Stores operator-defined configuration settings required for

network and equipment interfaces.

The AS2000 Advanced Programmable Architec ture (APA) enables

new features and firmware upgrades through local or remote

downloads. The download process uses File Transfer Protocol

(FTP) or the Access Manager 2000 prog ram, depending on the

controller module used. Figure 1-1 illustrates the flexibility of the

AS2000 platform.

Verilink Access Sy stem 2000: The Basics 1-1

Page 12

Access System 2000 Overview

Figure 1-1 AS2000 System

User

300 bit/s to 19.2 Kbit/s

Low

Speed

Carrier

Frame Relay

ATM

User

HSSI

Router

56K

Router

Nx56K

Video

Host/FEP

Channel

Extension

PBX

NxT1/E1

T1

AS2000 System

V.35

RS-449

EIA 530

Router

Video

Channel

Extension

AS2000

NxT1/E1

PRI

T1/E1

ISDN

Private

T3/E3

PRI

AS2000

FE1/FT1

Network

Services

SNMP

Manager

The AS2000 system consists of application modules and mating

connector interface modules (CIMs). Application modules fit into

the front shelf slots and house the processors required for the

designated application . The fr ont panels contain status LEDs and

management ports.

X.21/RS-232

Router

Network and information ports reside on the rear connector

interface modules, which slide into a corresponding slot on the

back of the shelf. These ports are available with different types of

physical and electrical i nterfaces. The shelf unit contains a

controller bus and data bus for module recognition and data

transfer. Controller modu les interface the entire node t o sof tware

management applicatio ns.

Shelf Units

AS2000 shelf units house the network access modules, and can be

mounted in 19– or 23–inch equipment racks. The shelf units

contain the buses and power connections for the AS2000. There

are five types of shelf units available:

•

Multi-line Shelves (MLS 2000, MLS 2200, and MLS 2200-4i)

•

Quint-line Shelf 2500 (QLS 2500)

•

Dual-line Shelf 2100 ( DLS 2100)

1-2 Verilink Access System 2000: The Basics

Page 13

AS2000 Design

Access System 2000 Overview

The AS2000 system is designed to operate under the Telemetry

Asynchronous Bit Serial Protocol (TABS protocol) and the Advanced

Communication Protocol (ACP). TABS is an industry-wide

controller protocol. Verilink’s ACP is a faster and more powerful

protocol developed as a part of the Advanced Communication

Engine (ACE) architecture. AS2000 provides same-shelf integration

of TABS and AC P-based modules through the us e of the Node

Controller Module (NCM 2000).

Advanced Communications Engine (ACE)

Verilink’s Advanced Communications Engine (ACE) architecture

supports international carrier channel standards, including E1, T1,

DS3, and ISDN Primary Rate Interface (PRI). The ACE architecture

uses the Advanced Communication Protocol (ACP) to communicate

between modules. The ACE architecture adds a cross-conne ct

switch, enabling individual Level 0 channels to be directed to a port

within a module, or to the port of another module within the node.

The ACE architecture transforms a shelf of individual modules into

a bandwidth manager.

Verilink Access Sy stem 2000: The Basics 1-3

Page 14

Access System 2000 Overview

AS2000 Management Options

There are five methods of node management for AS2000. The five

management options are:

Craft (ASCII) Interface

•

Craft or L

•

Node Manager program (a GUI interface that can manage an

OCAL

port (ASCII) interface.

entire AS2000 network) .

•

SNMP interface, using Manager of Managers (MOM).

•

Access Manager 2000, a screen-based software product that

manages NCC controller modules. (Not Y2K ready).

•

Thumbwheel switches, a mechanical way to configure certain

TABS-based modules.

The Craft interface is accessed by connecting directly to the port

labelled C

RAFT

or L

OCAL

on the front panel of a node controller

module. This interface can configure any module in the local node.

A Craft cable connects the mod ule to a pe r s ona l com pu t er in

terminal mode, providing a direct connection to the firmware

within the module. A node containg an SCC or NCM control ler

module can be managed remotel y using a personal computer,

Telnet, and the IP address of the remote node controller. Figure 1-2

is an example of an ASCII screen.

NOTE:

The NCC 2020 and NCC 213 0 node control ler modu les do not

support remote man agement by Telnet.

Figure 1-2 Example Craft Interface Menu

-- VERILINK NCM CONTROLLER : FW Rev 4.33, Sep 10 1999 15:06:43 --

-- VERILINK NCM CONTROLLER : FW Rev 4.33, Sep 10 1999 15:06:43 --

-- VERILINK NCM CONTROLLER : FW Rev 4.33, Sep 10 1999 15:06:43 ---- VERILINK NCM CONTROLLER : FW Rev 4.33, Sep 10 1999 15:06:43 - Site Name: Tech Pubs Access Level: 2

Site Name: Tech Pubs Access Level: 2

Site Name: Tech Pubs Access Level: 2 Site Name: Tech Pubs Access Level: 2

Managing at NEAR end node [127.255.255.0] Node ID: 64352

Managing at NEAR end node [127.255.255.0] Node ID: 64352

Managing at NEAR end node [127.255.255.0] Node ID: 64352 Managing at NEAR end node [127.255.255.0] Node ID: 64352

<- SLOT ->

<- SLOT ->

<- SLOT -> <- SLOT ->

SHELF 1 2 3 4 5 6 7 8 9 10 11 12 13

SHELF 1 2 3 4 5 6 7 8 9 10 11 12 13

SHELF 1 2 3 4 5 6 7 8 9 10 11 12 13 SHELF 1 2 3 4 5 6 7 8 9 10 11 12 13

0 - - - - - - - - - - - - -

0 - - - - - - - - - - - - -

0 - - - - - - - - - - - - - 0 - - - - - - - - - - - - 1 M [*N] - Q M P - P L A D - T G

1 M [*N] - Q M P - P L A D - T G

1 M [*N] - Q M P - P L A D - T G 1 M [*N] - Q M P - P L A D - T G

2 - - - - - - - - - - - - -

2 - - - - - - - - - - - - -

2 - - - - - - - - - - - - - 2 - - - - - - - - - - - - 3 - - - - - - - - - - - - -

3 - - - - - - - - - - - - -

3 - - - - - - - - - - - - - 3 - - - - - - - - - - - - 4 - - - - - - - - - - - - -

4 - - - - - - - - - - - - -

4 - - - - - - - - - - - - - 4 - - - - - - - - - - - - KEY: A=didcsu B=diu/dbu C=csu D=diu E=sdiu F=diu/dds G=dhdm

KEY: A=didcsu B=diu/dbu C=csu D=diu E=sdiu F=diu/dds G=dhdm

KEY: A=didcsu B=diu/dbu C=csu D=diu E=sdiu F=diu/dds G=dhdmKEY: A=didcsu B=diu/dbu C=csu D=diu E=sdiu F=diu/dds G=dhdm

H=atm/imux I=idcsu J=pep K=dac L=hlm M=imux N=ncm

H=atm/imux I=idcsu J=pep K=dac L=hlm M=imux N=ncm

H=atm/imux I=idcsu J=pep K=dac L=hlm M=imux N=ncm H=atm/imux I=idcsu J=pep K=dac L=hlm M=imux N=ncm

P=dpri Q=quad R=subrate S=hsm T=hdm U=dcsu

P=dpri Q=quad R=subrate S=hsm T=hdm U=dcsu

P=dpri Q=quad R=subrate S=hsm T=hdm U=dcsu P=dpri Q=quad R=subrate S=hsm T=hdm U=dcsu

V=vcu X=qpri W=dhdm_poet ?=unknown

V=vcu X=qpri W=dhdm_poet ?=unknown

V=vcu X=qpri W=dhdm_poet ?=unknown V=vcu X=qpri W=dhdm_poet ?=unknown

S) shelf/slot O) administration

S) shelf/slot O) administration

S) shelf/slot O) administrationS) shelf/slot O) administration

C) configuration D) diagnostics

C) configuration D) diagnostics

C) configuration D) diagnosticsC) configuration D) diagnostics

P) performance/status A) alarm

P) performance/status A) alarm

P) performance/status A) alarmP) performance/status A) alarm

B) circuit manager I) manufacturing info

B) circuit manager I) manufacturing info

B) circuit manager I) manufacturing infoB) circuit manager I) manufacturing info

X) exit this screen

X) exit this screen

X) exit this screenX) exit this screen

A [127.255.255.0] [1,1] NCM 2000 >

A [127.255.255.0] [1,1] NCM 2000 >

A [127.255.255.0] [1,1] NCM 2000 >A [127.255.255.0] [1,1] NCM 2000 >

1-4 Verilink Access System 2000: The Basics

Page 15

Access System 2000 Overview

Node Manager

Node Manager is a PC program that supports a graphical user

interface (GUI) for managing all AS2000 nodes. The monitor

display shows the AS2000 shelf units with all modules in their

assigned slots. When a module is selected, a drawing of its CIM is

displayed. To configure a port, click on the desired port.

When used to manage ACP-based modules, Node Manager guides

the circuit-building process, and the database tracks all circuits

within the network.

Node Manager supports Simple Network Management Protocol

(SNMP), Advanced Communications Protocol (ACP), and Telemetry

Asynchronous Block Serial (TABS) node managemen t protoc ols.

Figure 1-3 shows a Node Manager window.

Figure 1-3 Node Manager Window

SNMP

Management

Support CrossReference

The SCC 2020, SCC 2130, NCM 2000, QUAD 2164, HDM 2180, and

the HDM 2182 modules have embedded SNMP agents for use with

an SNMP Managment Program.

Depending on the module type, the communica tion link may be a

direct Ethernet connection at 10 Mbit/s or a SLIP connection at 9.6

kbit/s.

Figure 1-4 lists the various modu le types which may be used to

control a shelf or node of Verilink products. For each module

listed, the supported management option types are listed.

Verilink Access Sy stem 2000: The Basics 1-5

Page 16

Access System 2000 Overview

Figure 1-4 Management Support Cross Reference

Module Verilink Node

NCC 2020 Yes No No No Yes

NCC 2130 Yes No No No Yes

NCM 2000 Yes Yes Yes Yes Yes

SCC 2020 Yes Yes Yes Yes Yes

SCC 2130 Yes Yes Yes Yes Yes

HDM 2180 via NCM only Yes Yes No Yes

HDM 2182 via NCM only Yes Yes No Yes

QUAD 2164 via NCM only Yes Yes No Yes

DIDCSU 2912 via NCM only via NCM only No No Yes

Access Manager 2000

Manager

Support

Access Manager 2000 (AM2000) is a sc reen-based network

management program, operating in a Windows

SNMP

Manager

Support

10BaseT

Ethernet

Support

SLIP via Modem or

Terminal Server

Support

®

(Version 3.x only)

Verilink Craft

Interface

Support

environment. Because of Year 2000 considerations, AM2000 will

not be supported a fter Ja nuar y 1, 2 000. Co ntact you r Veri li nk sa le s

representative if you need assistance upgrading from AM2000.

Thumbwheel Switches

The NCC and SCC controller cards have thumbwheel switches for

manual configuration of the first 30 modules in a node.

Thumbwheels are used when there is no terminal or Craft cable

available. See the product manual for the specific NCC or SCC

controller for details on the thumbwheel switch commands.

Performance Monitoring

Performance monitoring tracks format and logic al errors found in

the data stream. The number and type of errors found aids with

fault isolation. The AS2000 performance registers track the type

and number of errors occurring within a 24-hour period. If the

number of errors exceeds a predefined threshold, or a severe fault

disrupts service, an alarm report is generated in the alarm buffer,

and the appropriate LED lights red.

Verilink supports AT&T TR 54016, ANSI T1.403, and ITU-T

performance data processing standards. Addition al data and signal

registers not required by standards are provided by Verilink to aid

in troubleshooting. Refer to the documentation for the individual

module for more informati o n about registers.

1-6 Verilink Access System 2000: The Basics

Page 17

Chapter

2

Shelf Units

Multi-line Shelf

Quint-line Shelf

System Information

This chapter provides system information for AS2000, including

shelf buses, application module descriptions and clock timing

considerations..

AS2000 has three different types of shelves, described below:

Multi-line Shelf units (MLS 2000 and 2200 series) hold 13

application modules and 2 modular power supplies (AC or DC).

The difference between the MLS 2000 and MLS 2200 series shelf

units is the structure of Data Bus A on the backplane of the shelf.

The Quint-line Shelf (QLS 2500) holds 5 modules and cont ains an

internal AC or DC power supply. This shelf is a standalone unit.

Dual-line Shelf

The Dual-line Shelf (D LS 2100) holds 2 modules and is po wered by

external power supplies. Verilink offers a universal AC/DC power

supply. Figure 2-1 illustrates the Multi-line, Quint-line, and Dualline shelf units.

NOTE:

NOTE:

the PWR 2940 power supply for the Dual-line Sh elf operates

only with 110VAC or 48VDC inputs. Some units may indi cate

they support 240V AC operation, but this is not correct. Us e

the newer PWR 2950 power supply where 240 VAC power

input is required.

When an HDM 2180 or HDM 2182 i s used i n a Dua l-line shelf,

the use of two external power supplies is suggested. If an

NCM 2000 is added, the use of two power supplies is

required.

Verilink Access Sy stem 2000: The Basics 2-1

Page 18

System Information

Figure 2-1 AS2000 Shelf Units

Multi-line Shelf

Dual-line Shelf

Data Bus Structure

Quint-line Shelf

ACCESS SYSTEM 2000

The MLS and DLS shelf units have three data buses: A, B, and C.

These data buses are used for:

•

Transferring data between Data Service Units (DSUs) and

Channel Service Units (CSUs).

•

Operating in drop-and-insert mode (data from different DTE

are multiplexed into a T1, FT1, E1, T3, etc.).

•

Operating in mini-digital cross-connect switch mode (data

switches between DTE and network ports on channel level 0

basis).

All three data buses on the MLS and DLS shelves ca n be expanded to

another shelf using a data bus extension cable. When using the

MLS 2200 and MLS 2200-4i, only the last data bus segment (A4 or

2-2 Verilink Access System 2000: The Basics

Page 19

System Information

A5) is expanded to another shelf. Data bus extensions are only

supported by (non-IMUX) TABs -based modules, i.e. TAC 2010 a n d

DIU modules.

NOTE:

The NCM does not support data bus extension.

Figure 2-2 illustrates the data bus configuration using the MLS 2000

and MLS 2200 series shelves.

Figure 2-2 AS2000 Data Bus Example

4

5

7

6

8 9 10 11 12 131

MLS2000

7

6

8 9 10 11 12 131

A4

A5

MLS2200

Power

Supply

Power

Supply

AB

Power

Supply

Data Bus

Expansion

Cable

AB

Power

Supply

A1

23

23

A2

4

Data Bus A

Data Bus B

Data Bus C

5

A3

Data Bus B

Data Bus C

ACP Data Bus

Structure

4

5

7

6

A1

23

A2

Data Bus B

Data Bus C

8 9 10 11 12 131

A3

MLS2200-4i

AB

Power

Power

Supply

Supply

A4

The ACE architecture includes expanded data bus bandwidth,

enabling greater switching capacity between ACP modules. While

TABS-based modules have three 1. 544 M bit/s dat a buses—A, B, and

C—with ACE architecture, the B and C buses are 2.048 Mbit/s, and

the Bus A bandwidth is increased to 16.384 Mbit/s (8 E1 lines). The

total bandwidth availab le is 20.48 0 Mbit/s. Timesl ot 0 of each ACP

bus A is used for framing. Bus A is divided into two sections,

designated as the low A bus and the high A bus. The low bus data

is sampled on the down stroke of the receive clock, and the high

bus data is sampled on the up stroke of the same clock.

Verilink Access Sy stem 2000: The Basics 2-3

Page 20

System Information

ACP Controller Bus Structure

The ACP can operate on either Data Bus A or C. The MLS 2200

provides up to five islands using bus segments A1-A5, or full shelf

control using bus C. Additionally, you can set up one or two selfcontrolled islands on the MLS 2200 A bus, and have the remaining

segments under common control using the C bus. Refer to Figure

2-3.

The MLS 2000, QLS 2500, and DLS 2100 can use Bus A or C to

control all the ACP-based modules in the shelf. The ACP controller

bus can be expanded to other shelves with a daisy-chain cable

between the primary and expansion management ports.

Figure 2-3 MLS 2200 Controller Bus Usage

Shelf and Node

Masters

2-4 Verilink Access System 2000: The Basics

In an ACP-based node, a shelf master uses t he ACP controller bus to

poll the other modules in the shelf for configuration and

performance status information. A redundant NCM in the same

shelf becomes the shelf master if the current shelf master fails. If

there is no redundant NCM in the shelf, an ACP application module

in the shelf becomes the shelf master if the NCM fails.

In a multi-shelf node, when the shelf master is polled by the node

master, it transfers the information from its shelf modules to the

node master. If the node master fails, the shelf master with the

Page 21

Types of Modules

System Information

longest uptime becomes the new node master. In a node conta ining

a single shelf, an NCM module is usually both the node and shelf

master.

The shelf and node ACP masters can be determined by the status of

the LEDs. See the section “Front Panel LE D Indicators“ in Chapter 4

for more information.

Application modules contain the hardware and firmware to

construct different service roles. There are three functions the

AS2000 system applicati on modules can perform. Channel Service

Units (CSUs), Data Service Units (DSUs) and Node Controller Units

(NCM, NCC, etc.). An application module’s port configuration is

determined by selecting the appropriate Connector Interface

Module (CIM). The configuration data is stored within each

module, and can be retrieved or edited.

Channel Service

Unit Modules (CSU)

The CSU terminates network services at the customer premises,

and connects a Wide Area Network (WAN) to application equipment.

Each CSU can be configured for a desired mode of operation. The

CSU can connect directly to DS1 or CEPT-1 equipment, to one or

more DSUs (if MUX mode is available), or both.

CSU Operating Modes

CSUs can operate in one or two of three possible modes: CSU mode,

multiplexer mode (MUX), and drop-and-insert mode (D&I). All CSUs

interface to the Network Service Provider (NSP) ports. The

configuration on the Equipment side of the CSU in each mode is

described in Table 2-1. Figure 2-4 provides a graphic view of the

three CSU modes.

Verilink Access Sy stem 2000: The Basics 2-5

Page 22

System Information

Table 2-1 CSU Operating Modes

Mode Definition

Figure 2-4 CSU Modes

CSU Mode

MUX Mode

Drop and

Insert Mod e

The CSU connects directly to Level 1 equipment. It

ensures the channel carrier signals meet network

standards before passing the signals to the

network port.

In MUX mode, the CSU conne cts to a DSU, or

includes an integrated DSU. The DSU converts

synchronous serial data to a channel carr ier signal.

Some DSUs are dua l port and c an rec eive da ta fr om

multiple sources. The information from these

ports is multiplexed into Level 0 chann els and

transmitted to the CSU. The CSU multiplexes data

from one or more DSU ports, up to the maximum

number of Level 0 channel s (T1 = 24, E1 = 31). The

CSU transmits all-ones in any unused Level 0

channel to keep the Level 1 channel in service.

The CSU multiplexes information from Level 1

equipment and DTE (insert), enabling digital voice,

data, and video applications to share the same

T1/E1. At the far end, the channels are redirected

to either the Level 1 equipment or DTE (drop).

CSU Mode

Level 1

Equipment

Data Service Unit

(DSU) Modules

CSU

Drop & Insert Mode

Drop and Insert Mode

Level 1

Equipment

DSU

Additional Data

Equipment

CSU

MUX

NSP

Additional Data

Equipment

NSP

MUX Mode

CSU

NSP

MUX

DSU

Data Service Units (DSUs) convert synchronous serial data to a

standard network format signal. When accessing a T1/E1 line, a

CSU is required. Newer technologies such as DS3 include CSU and

DSU functions but are ca lled DSUs. Verilin k DSUs are often referr ed

to as Data Interface Units ( DIUs).

2-6 Verilink Access System 2000: The Basics

Page 23

System Information

Integrated

DSU/CSU Modules

Connector

Interface Modules

(CIMs)

Controller Modules

Integrated DSU/CSU modul es (IDCSUs) work only with the DSU

located on the module. Data from a standalone DSU cannot be

multiplexed into the same data stream with an IDCSU.

Connector Interface Modules (CIMs or rear connector modul es)

provide different physical port configurations for the AS2000. The

CIM plugs into the back of a shelf unit and mates with the

application module. If port requirements change, only the CIM

requires replacement. The CIMs provide the following major

functions:

•

CSU to network and equipment connection

•

SLIP and Ethernet interfaces

•

External timing interface

Controller modules provide a single access point for configuring

and monitoring all node modules. All controller modules have a

Craft port (ASCII interface) to manage module configurations.

Verilink’s Node Manager software can operate with any controller

module. The SCC and NCM modules include an embedded SNMP

agent. Figure 2-5 illustrates the role of a node controller within a

multi-node environment.

Figure 2-5 Multinode Management

System Node 1

Node Manager or

SNMP Mgr (MOM) or

AM2000

ASCII Terminal

Node

Controller

NCM

or

SCC

or

NCC

Node

Controller

NCM

or

SCC

or

NCC

TAC

or

~

DIU

System Node 2

TAC

or

~

DIU

ACP-based

(NCM Only)

RS-232 Daisychain Cable

ACP-based

(NCM Only)

Up to 52 Units

(30 with NCC)

Up to 52 Units

(30 with NCC)

Verilink Access Sy stem 2000: The Basics 2-7

Page 24

System Information

AS2000 Modules

Through its modular design, the AS2000 hosts a variety of

applications. Application modules use TABS or Verilink’s ACPbased protocol. The application modules plug into the front of a

shelf unit and mate with the CIM. In the following sections, the

available operating modes for each CSU are shown in parentheses.

TABS-Based Application Modules

TABS-Based

Controller Modules

The following TABS-based application modules are used in the

AS2000 system:

Table 2-2 TABS-based Application Modules

Module Function

DIU 2130

DIU 2131

DIU 2140

TAC 2010

TAC 2130

TIU 2850

A high-speed T1 DSU with two ports, each carrying 1 to 24

DS0s. Multiple DIU 2130s can be configured to one CSU ,

maximizing T1 timeslot usage.

This DSU multiplexes a high-speed V.35 application with a

low-speed RS-232 application (up to 64 kbit/s on T1).

A sub-rate data multiplexer low-speed T1 DSU, with fiv e RS 232 ports operating from 300 bit/s to 19. 2 kbit/s. Data can

be synchronous or asynchronous.

A T1 CSU, 1 to 24 channels (CSU , D&I, MUX).

An integrated T1 CSU/DSU with standard network and DSU

ports (MUX).

The Timing Interface Unit connects an external reference

clock signal to a CSU, synchronizing it with the associated

DSUs. This module only works with TABS-based CSUs,

including NCC, SCC, TAC.

The following TABS-based application modules are controller

modules. They reside in shelf 1, slot 1 of a TABS-based node.

Table 2-3 TABs-based Controller Modules

Module Ability

NCC 2020

NCC 2130

2-8 Verilink Access System 2000: The Basics

A node controller and CSU module that includes a T1 CSU.

This unit can manage up to 30 modules in a node (CSU, D&I,

MUX).

This node controller includes an integrated T1 CSU/DSU and

can manage up to 30 modu les in a no d e (MUX).

Page 25

System Information

ACP-Based Application Modules

SCC 2020

SCC 2130

SCC 2120

This unit is an SNMP controlle r with a management interface

that includes a T1 CSU. This unit can manage up to 52

modules in a single node (CSU, D&I, MUX).

This SNMP controller includes an integrated T1 C SU / DSU and

can manage up to 52 modu les in a no d e (MUX).

This SNMP contro lle r includes an adva nced protection switch,

providing manual or automatic 1-for-n T1 line protection.

This unit can manage up to 52 modules in a node (CSU).

ACP-based modules provide increased functionality over TABSbased modules. ACP-based modules can operate independently, as

shelf controllers, or controlled by an NCM. The following ACPbased application modules are used in the AS2000 system:

Table 2-4 ACP Application Modules

Module Function

DCSU 2911

DIDCSU 2912

A dual-port CSU with two complete T1 or E1 CSUs. (CSU)

Dual Integrated DSU/CSU with two data ports and two

network ports. Circuits are used to direct links between

the four ports. Used with the NCM, circuits can be built

between modules. (CSU, D&I, MUX)

Node Controller

Module

DPRI 2922

QUAD/IMUX

HDM 2180

HDM 2182

QPRI 2921

The Dual Primary Rate Interfac e (ISDN) provides a T1 dialbackup system for the network. It has the same circuitbuild features and modes as the DIDCSU 2912.

An inverse multiplexing syst em with au toma tic rate

adaption for up to eight T1/E1 lines. Consists of one

IMUX 2160 module and one or two QUAD 2164 modules.

SNMP over 10BaseT is supported by the QUAD 2164

A high speed digital interface module, con verts very high

bandwidth data into DS3 framing format. The 2180 has a

single data port.

The HDM 2182 multiplexes two high-bandwidth data

applications into the DS3 framing format.

CSU module with two PRI ISDN ports and 2 T1 ports. The

QPRI provides an alternate ISDN route when regular T1

lines are unavailable. The QPRI 2921 can also be used to

designate a reserv e leased T1 as a backup.

The Node Control Module (NCM) communicates in both the ACP and

TABS protocol. The NCM works with all AS2000 products (except

TIU 2850 or the DIU 2140), and includes an embedd e d SNMP

management agent. The NCM is not an application module, but a

dedicated c ontroller module.

The NCM integrates TABS and ACP- based modules into the same

shelf unit. The NCM can manage up to 51 application modules in a

node. This is the only AS2000 controller used in the E1 and high

bandwidth environment.

Verilink Access Sy stem 2000: The Basics 2-9

Page 26

System Information

Timing

The NCM stores circuit information for the entire node, enables the

creation of inter-module circuits, and ensures all circuits are viable

from port to port. The NCM stores the configuration of all the

modules in the node for restoration tasks, and provides a single IP

address for the entire node.

Redundant NCMs

An ACP-based node can have more than one NCM. If the additional

NCM is located in the same shelf, it is called a redundant NCM. The

ALM LED is not lit on a redundant NCM.

Proper operation of a carri e r channel network depends on ti ming.

All of the equipment in a poi nt-to-point network must refer to a

single digital master clock.

In AS2000, timing is handled differently between TABS-based

nodes (NCC and SCC) and ACP-based nodes (NCM). This section

describes the general timing configuration for each type of node.

Timing Source

CSU Timing

The CSU uses a master clock to synchronize DSU timing (in MUX or

drop-and-insert modes) and to transmit signals to the network.

The following options inform the CSU where to look for the master

clock signal. Since the options are not relevant to all CSU modes,

applicable modes are shown in parentheses.

Figure 2-6 CSU Timing Options

CSU

Level 1

Equipment

Clock

DSU

External

422

NSP

TIU

Receive Clock

Transmit Clock

Terminal Timing

External

TTL

2-10 Verilink Access Sy stem 2000: The Basics

Page 27

Table 2-5 CSU Timing

Options Definition

System Information

Through

Equipment

Internal

External 422

External TTL

Network

TIU

DIU

The DS1 or CEPT-1 equipment at this node provides clock.

(CSU, D&I)

DS1 or CEPT-1 equipment provides clock. (D&I)

The CSU itself provides clock. (MUX, D&I)

The CSU is connected to an external RS-422 clocking device.

Network Service Provid er (NSP) equipment (digital access

cross-connect switch or DACS) provides a balanced +/- signal

to the external clock. (MUX, D&I)

The CSU connects to an external TTL (transistor-to-transistor

logic) clocking device. NSP equipment (DACS) provides an

unbalanced 0/+5 V signal to the external clock. (MUX, D&I)

A DACS inside the NSP cloud, or the DCE or DTE at the far

end, provides the master cl ock. The CSU reco vers clock from

the incoming network signal. Network timing is also

referred to as “recovered” or “slave” timing. (MUX, D&I)

A timing module (TIU 2850) within the node passes on the

clock signal it receives from another source. TIU supports

MUX, D&I modes for other products. (MUX, D&I)

The DIU passes the mast er clock, received from the d a ta

equipment, to the CSU. Used with the Terminal Timing (TT)

setting (see “DCE to DTE Timing” in this chapter).

DCE to DTE Timing

The DSU provides transmit clock to the data equipment (f or

example, the router), which present the next data bit to be sent.

DSUs have timing settings at their port s, and determine which part

of the clock pulse should be used when sampling received data

from the DTE. These choices are:

Table 2-6 DCE to DTE Timing Options

Options Definitions

Send Timing

(ST)

Inverted ST

(INV ST)

Terminal

Timing (TT)

The DSU samples the transmit data on the downward

(negative-going) edge of the transmit clock pulse.

The DSU samples the transmit data on the upward (positivegoing) edge of the transmit clock pulse.

Used when the DTE has the capability to use the clocking

from the DSU signal and loop it around onto an optional

third clock pair. The third pair of wires is in addition to the

transmit clock and receive clock pairs. This clock may be

labeled TT, SCTE (Ser ial Clock Transmit External), or XTC

(eXternal Transmit Clock). The Terminal Timing option is the

preferred choice, because the clock is transmitted in phase

with the data, ensuring that samples are taken in the middle

of each bit.

ST or inverted ST is det ermined by the data rate an d length of

cabling between the DTE and DSU. Less than 1.3 Mbit/s generally

requires ST (fractional Level 1 service). Da ta rates greater than 1.3

Mbit/s usually require inverted ST. See Figure 2-7.

Verilink Access Sy stem 2000: The Basics 2-11

Page 28

System Information

Figure 2-7 DCE to DTE Timing

Clock

Signal

ST

ST

TT

Crossover

Connection

Use a crossover connection whenever transmit and receive signals

go to the opposite leads for an appl ication, such as tail circu its.

The receive data from device A becomes the transmit data to device

B. The receive data from device B becomes the transmit data to

device A.

In a crossover circuit, each DCE relinquishes control of the transmit

path to the other DCE. Clock signals are also cross-connected. The

DCE device outputs receive data at the rate which data is received.

See Figure 2-8.

Figure 2-8 Crossover Connection

DSU

rx rd tt td

rx rd tt td

DSU

Synchronous devices output a receive clock that is in phase with

receive data. Since receive data becomes transmit data to the tailcircuit DCE, it uses the receive clock from the main circuit DCE to

sample correctly. In most crossover connections, both devices are

configured to use the receive clock as the transmit clock. The CSU

and DSU timing settings depend on the location of the master

clock.

2-12 Verilink Access Sy stem 2000: The Basics

Page 29

System Information

Tail Circuit Timing

When two synchronous circuits are connected directly to each

other through a crossover connection, they must use a common

clock. In a network duet, one circuit must pass clock to the other.

The circuit which receives timing from another circuit is known as

a tail circuit. Figure 2-9 illustrates tail-circuit timing. The digital

and cross-connect switch in the main circuit provides clock for the

network in this example.

Figure 2-9 Tail Circuit Timing, Net 1 Source

DSU DSUCSU CSU

Tail

DSU CSU

Timing

CSU

Source

Timing

NET

Source

Node #1

Main

Circuit

Timing

P1

Source

Timing

NET

Source

Node #2

Timing

DIU

Source

Crossover Connection

DSUCSU

Timing

CSU

Source

Circuit

Timing

NET

Source

Timing

CSU

Source

Node #3

TABS-Based Timing Options

ACP-Based Timing Options

Shelf vs. Card

Timing

The TABS-based modules simply require the user to set the timing

source for each network and data port. If the selected timin g

source fails for any reason, the module will automatically use its

internal clock as a backup until the primary source becomes

available again.

In ACP or mixed ACP/TABS nodes, there are several timing

considerations:

•

shelf vs. card timing

•

timing source

•

shelf sync master

For each ACP module, the timing source can be derived from the

shelf timing table or one of its own ports. In either case, two

backup timing sources are available for each module. If one timing

source fails, the module will automatically select the secondary

and, if necessary, th en the tertiary (third) timing source.

Shelf timing provides a way for some or all of the modules within a

shelf to use the same clock timing source. It is required for all

modules exchanging data across the shelf midplane.

Verilink Access Sy stem 2000: The Basics 2-13

Page 30

System Information

Timing Source

Shelf Sync Master

NOTE:

Any ACP based AS2000 applica tion modu le which u ses a data

bus to pass data to another module must use shelf timing.

Table 2-7 ACP Timing Options

Timing Definition

Shelf

Timing

Card

Timing

Some ACP module within the shelf provides the timing for all

modules set for shelf timing.

The module uses its internal clock or synchronizes its internal

clock to the signal from the network, application equipment, or

external timing ports. Shelf settings are ignored.

The timing source can be any port on the module, the internal

clock on the module, or an external clock source connected to the

external timing input DIN connector on the module’s rear

connector (CIM).

The shelf sync master is the ACP module responsible for putting

the shelf timing table onto the clock timing bus. The sync master

cannot be an NCM module. If the sync master is removed from the

shelf, any ACP modules relying on the shelf timing table will

momentarily have performance interruptions until a new sync

master is selected.

2-14 Verilink Access Sy stem 2000: The Basics

Page 31

Chapter

3

Site Planning

This chapter provides general information for site planning.

Sections within this chapter provide general and detailed

information on the following topics:

Installation Planning

When planning a site or adding to an exi sting AS2000, several

factors require consideration:

•

Installation planning

•

FCC Part 68 Compliance Statement

•

Application requirements and ESD considerations

•

General rules for module installation

•

Cabling requirements

•

Mechanical and environmental considerations

Module Installation

TABS-Based Nodes

•

Node Configuration Plan

Access System 2000 modules within each system node have

explicit requirements for installation.

The following requirements are for TABS-based nodes.

•

The SCC or NCC and corresponding CIM usually resides in

Shelf 1, Slot 1.

•

DIUs follow the corresponding SCC, NCC, or TAC in successive

slots.

•

The TIU clock signal can be passed to other shelves in the

node using the data bus expansion cable.

•

All DIUs associated with an NCC, SCC, or TAC must be in the

same shelf when the data buses are not extended.

•

NCC, SCC, and TAC modules can use one data bus—A, B, or C—

to exchange data with their associated DIUs.

•

In drop-and-insert mode, only Bus A is used.

•

A node must not exceed four shelves (2 MLS and 2 DLS units

with an NCC, or 4 MLS units with an SCC or NCM).

•

Certain TABS-based modules cannot function in the Quint-line

shelf, such as the NCC and the SCC.

Verilink Access Sy stem 2000: The Basics 3-1

Page 32

Site Planning

ACP-Based Nodes

System Cabling Considerations

Figure 3-1 Maximum Cabling Distances for T1 Equipment

Network

Use the following guidelines when installing ACP-based nodes:

•

The NCM can reside in any shelf or slot, but operates most

efficiently in shelf 1, slot 1.

•

Maximum of 4 MLS shelves with up to 52 modules in a node.

•

TABS-based rules apply to any DI U/TAC in the node.

•

No TIUs or SCCs in the node.

•

The NCM cannot control some functions of a DIU 2140.

Connecting cables at customer premises must be within specified

distances between the Access System 2000 and external

equipment. These distances are critical for system operation.

Figure 3-1 shows the recommended maximum distances. Cables

available from Verilink are identified in Verilink’s Cable directory.

50 ft (15 meters)

RS-232D

NCM

Management

Interface

3000 ft (914 meters)

DSX-1

EQ

DTE

DTE

DTE

DTE

655 ft (199 meters)

150 ft (45 meters)

RS-422

250 ft (76 meters)

V.35

50 ft (15 meters)

HSSI

50 ft (15 meters)

RS-232D

Data

Port

Data

Port

Data

Port

Data

Port

CSU

DSU

Power

Supply

Net

INTF

8 ft (2.4 meters)

First Network

Repeater

DC

Power Source

3-2 Verilink Access System 2000: The Basics

Page 33

Site Planning

T1 Network

Interface

External Clock

Source

DTE Interface

Each NCC, SCC, and TAC must be within the following cable

distances from connected equipment:

•

655 feet (199 meters) maximum from DSX-1 equipment. This

distance determines the pre-equalization option setting

toward the equipment.

•

3000 feet (914 meter s) maximum fro m the first repea ter on the

network. This distance determines the network line build-out

option setting.

If an external clock is used to synchronize CSUs with DIUs. The

maximum permissible cabli ng di stances to the clock source are:

•

150 feet (45 meters) with an external clock in an RS-422

format.

•

5 feet (1.5 meters) with an external clock in a TTL signal

format.

If an external RS-422 or TTL clock is connected to a TIU 2850, the

maximum cabling distances are the same as the external clock.

The maximum cabling distance between an AS2000 dat a po rt and

your data terminal equipment depends on the type of interface.

System Power Requirements

•

250 feet (76 meters) for ITU-T V.35 operation.

•

200 feet (60 meters) ma ximum for EIA 530 or RS-422 operation

(decreases as data rate increase).

•

50 feet (15 meters) for HSSI.

NOTE:

For long cable runs to DTE, use of TT timing is recommended.

The AS2000 system uses a variety of power supplies that can

accommodate differe nt commerc ial power so urces. AS 2000 system

components require a commercial power source free of surges and

other transient voltages. Commercial power requirements for the

AS2000 are listed in Table 3-1 and Table 3-2.

Table 3-1 Multi-line Shelf Power Supplies

PAC 2910

PAC 2930

PDC 2920

110 Vac 50- to 60 HZ

110 to 240

Vac

48 Vdc

input

75 Watts

50 to 60 Hz

200 Watts

Separate fused

75 Watts

15-amp circuit; separate branch

circuit for each AC power supply

15-amp circuit; separate branch

circuit for each AC power supply

Associated battery return path for

each power supply; recommended

fuse size of 10-amp

PDC 2930

Verilink Access Sy stem 2000: The Basics 3-3

48 Vdc

input

Separate fused

200 Watts

Associated battery return path for

each power supply; recommended

fuse size of 10-amp

Page 34

Site Planning

Hardware Dimensions

NOTE:

To provide the highest level of redundancy, use a fuse panel

with redundant (A and B ) fuse positions or two separate fuse

panels for the A and B power supplies.

Table 3-2 Dual-line Shelf Power Supplies

PWR 2940

PWR 2950

NOTE:

When HDM 2180 or HDM 2182 mo dules are used in a Dual-

110 Vac 47 to 440 Hz 36 to 60 Vdc input

100 to 220 Vac 47 to 440 Hz 100 to 240 Vac input

line shelf, installation of two external power supplies is

recommended. If an NCM 2000 is added to a Dual-line shelf

with an HDM 218x module, the use of two power supplies is

required.

NOTE:

The PWR 2940 power supply is recommended fo r use

only

at

110 volts. The PWR 2950 power supply can be used wi th

voltages of 100 to 240 Vac.

AS2000 shelves require a mou nting surface that can suppo rt the

weight of the shelf and all associated plug–in modules. A 19–inch

(49 cm) or 23–inch (59 cm) equipment rack, cabinet, or desktop can

support the weight of Access System 2000 shelves. Multi-line,

Quint-line, and Dual-line shelves can be front or mid- mo unted into

a 19– or 23–inch (49 to 58.5 cm) rack.

Table 3-3 Approximate Weight and Height in Rack

Item Approximate Weight Height in Rack

Multi-line Shelf 14 lb (7 kilos) empty, 36

Quint-line Shelf 12 lb (5.5 kilos) empty,

Dual-line Shelf with

power supply

Desktop power supply 2 lb (0.908 kilos) 3.85 inches (9.6 cm)

Heat baffle 1.3 lb (0.504 kilos) 1.75 inches (4.5 cm)

Fan Shelf 1RU 5 lb (2.3 kilos) 1.75 inches (4.5 cm)

Fan Shelf 3RU 6 lb (2.7 kilos) 5.25 inches (13.4 cm)

NOTE:

Provide approximately 30 inches (77 cm) of clear space in

lb (16 kilos) fully

equipped

20 lb (9.2 kilos) fully

equipped

10 lb (4.6 kilos), fully

equipped

8.75 inches (23 cm)

5.25 inches (13.5 cm)

1.75 inches (4.5 cm)

front of and behind the equipment rack for installers to

maneuver during assembling and testing.

3-4 Verilink Access System 2000: The Basics

Page 35

Site Planning

Heat Dissipation

Heat Baffles

A fully loaded Multi-line Shelf with redundant power supplies

generates a maximum of 200 watt s (680 BTUs). However, a fu ll

shelf of DS3s may exceed this amount (dissipation must include

power supply losses.) A QLS generates 75 watts and a fully

assembled Dual-line Shelf with power supplies generates a

maximum of 22 watts (75 BTUs).

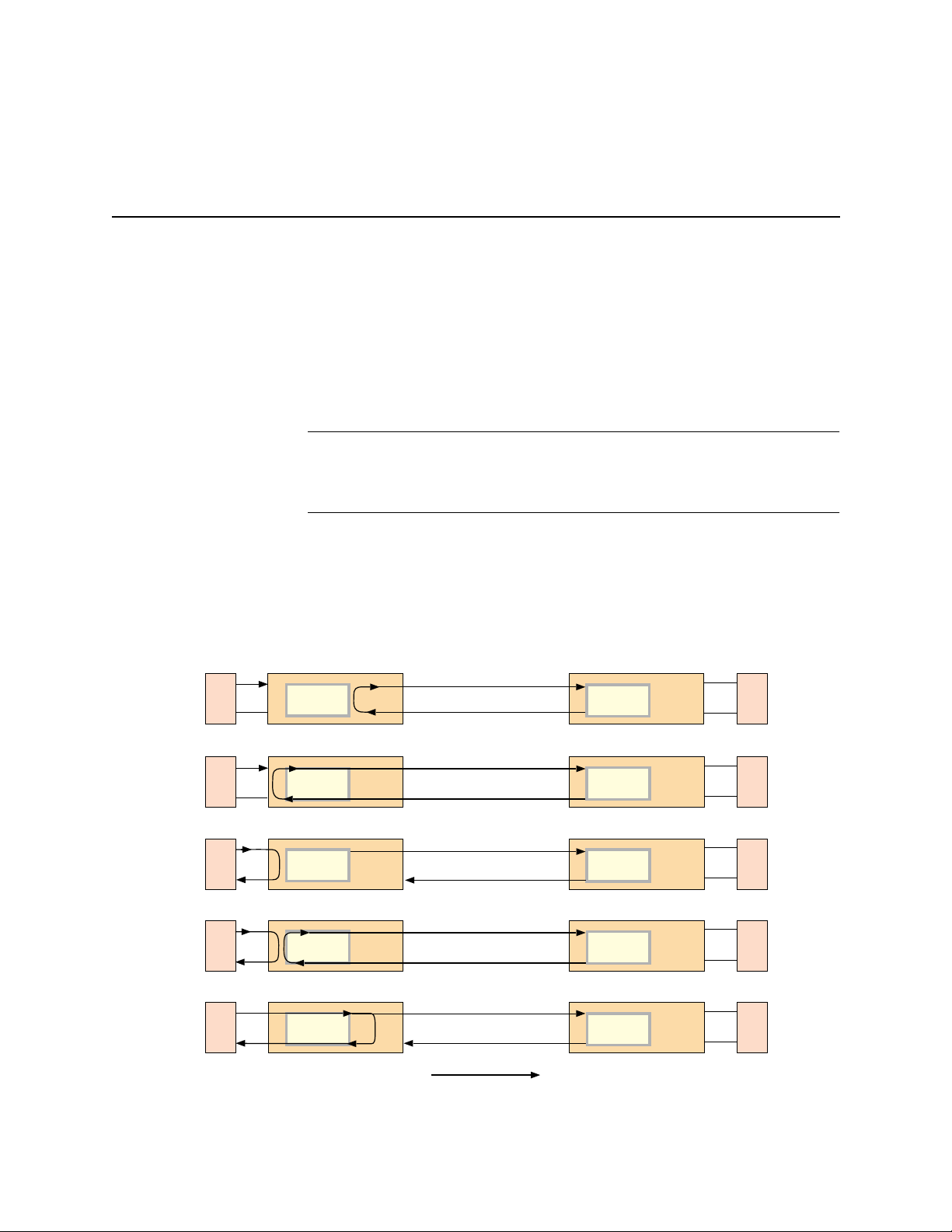

Figure 3-2 shows a variety of cooling options. Choose the option

that best fits your needs.

If you have an MLS shelf above and an MLS shelf unit below, use a

heat baffle in the center to deflect the convected heat (Figure 3-2,

A).

If you install (stack) two or more Quint-line or Dual-line shelf units,

Verilink recommends that you position a heat baffle between each

unit, or leave a space the size of a rack unit to dissipate the heat

(Figure 3-2, B).

CAUTION

The QLS and DLS do not have cooling vents at the bottom of their case,

and can overheat from a lack of cooling air if the top air vents are blocked.

Fan Shelf

Mount the heat baffle with the inter ior metal plate slopin g up to the

rear of the shelf. Cooling air and heat flows are directed upward.

A fan shelf is only required if you have an MLS populated with six

or more high-bandwidth modules (HDM 21 80/2182). Use a fan shelf

above a single MLS (Figure 3-2, F) or between every two MLS units

(Figure 3-2, C, D, E).

Shelf Cooling Limitations

If you do not have a cooling fan, provide an empty air space

between the component side of the HDM module (right side ), and

the next module in the MLS. Without a fan, this limits the number

of HDM modules to six in an MLS, even with an NCM in slot 1.

Since a QLS can not use a fan shelf, you are limited to two HDM

modules (slots 2 and 4 only). In the DLS, only one HDM module is

permitted because of the power supply limitation.

Verilink Access Sy stem 2000: The Basics 3-5

Page 36

Site Planning

Figure 3-2 Multiple Node Cooling Options

3-6 Verilink Access System 2000: The Basics

Page 37

Preparation Guidelines

This section provides the safety precautions and compliance

requirements for the Access System 2000 within the United States

operating environment. Other country requirements can vary.

Site Planning

FCC Part 68 (or Equivalent) Compliance Statement

CAUTION

Follow United States National Electrical Code and/or applicable

local codes for all safety requirements during equipment

installation.