Page 1

Verilink APS 2000

User Manual

August 1999

P/N 880-502411-001-D

Page 2

Copyright Notice

Copyright 1999 Verilink Corporation. All rights reserved.

This document does not create any express or implied warranty about Verilink or

about its products or services. Verilink’s sole warranty is contained in its product

warranty. The end-user documentation is shipped with Verilink’s products and

constitutes the sole specifications referred to in the product warranty. Verilink has

made reasonable efforts to verify that the information contain ed h erein is accurate,

but Verilink assumes no responsibility for its use or for any infringement of patents

or other rights of third parties that may result. The customer is solely responsible

for verifying the suitability of Verilink’s pro ducts for its use. Specifications are

subject to change without notice.

Trademarks

FCC Requirements

Verilink is a registered trademark of Verilink Corporation. Access System 2000,

WANscope, VeriStats, and FrameStart are trademarks of Verilink Corporation.

Any named prod ucts herein are trademarks of their respective companies.

This equipment has been tested and found to comply within the limits for a Class A

digital device pursuant to Par t 15 of the Federa l Communic ations C ommissio n (FCC)

rules. These limits are designed to pro vide protection against harmful interference

in a commercial environment.

This equipment generates, uses, an d can radiate radio frequency energy and, if not

installed and used in accord ance with the user manual, can cause harmful

interference t o radio communications.

There is no guarantee that interference will not occur in a particular installation. If

this equipment causes harmful interference to radio or television reception—which

can be determined by turning the equipment off and on—try to correct the

interference by one or more of the following measures:

Reorient or relocate the receiving antenna.

•

Increase the separation between the equipment and receiver.

•

Connect the equipment into an outlet on a circuit different from that to whi c h

•

the receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

•

This equipment complies with Part 68 of the FCC Rules. On the rear, side or bottom

of the unit is a label that contains the FCC registration number and other

information. If requested, provide this information to the telephone company.

All direct connecti ons to the ne twork lines m ust be made usi ng standard plugs

•

and jacks (compliant with Part 68). The following tables list the applicable

registration jack universal order codes (USOCs), facility interface codes (FICs),

and service order codes (SOC s). These are required to order service from the

telco.

For T1 interfaces:

Port ID REN/SO C FIC USOC

1.544 Mbit/s SF

1.544 Mbit/s SF, B8ZS

1.544 Mbit/s ANSI ESF

1.544 Mbit/s ANSI ESF, B8ZS

For DDS interfaces:

Port ID REN/SO C FIC USOC

56 kbit/s

64 kbit/s

If the unit appears to be malfunctioning, inform the telco and disconnect it

•

from the network lines until the source of trouble is determined to be your

equipment or the telephone line . If your equipment needs repair, it should

not be reconnected until it is repaired.

ii Verilink APS 2000 User Ma nual

6.0N 04DU9 -BN

6.0N 04DU5 -56

04DU9 -DN

04DU9 -1KN

04DU9 -1SN

04DU5 - 64

RJ-48C jack

RJ-48S jack

Page 3

The unit has been designed to prevent harm to the network. If the telephone

•

company finds that the equipment is exceeding tolerable parameters, it can

temporarily disconnect service. In this case, the telephone company will

provide you advance notice if possible.

If the telephone company alters its equipment in a manner that can affect the

•

use of this device, it must give you warning so that you have the opportunity

to maintain uninterrupted service. You will be advised of your right to file a

complaint with the FCC.

No customer is authorized to repair this equipment, regardless of warranty

•

status. All repairs must be performed by Verilink or an authorized agent. It is

the responsibility of users requiring service to report the nee d for service to

Verilink or to one of our authorized agents.

Lithium Battery

English

Français

The lithium battery referred to in the following notices is contained inside the clock

chip.

DANGER!

The battery can explode if incorrectly replaced! Replace only with the same or

equivalent type recommended by the manufacturer. Dispose of used batteries

according to the manufacturer’s instructions.

DANGER!

To avoid electrical shock in case of failure, the power supply must be installed

by a professional installer. The terminal labeled with the ground symbo l ( )

on the power supply must be connected to a permanent earth ground.

CAUTION!

Interconnecting circuits must comply with the requirements of

EN60950:1992/A2:1933 Section 6.2 for telecommunications network voltages

(TNV) circuits.

ATTENTION!

Une explosion peut se produire si la batterie est remplacée d’ une façon incorrecte! Remplacez-la seulement avec le même modêle de batterie ou un modèle

équivalent selon les recommendations de manufacture. Disposez de les batteries usées selon les instructions de manufacture.

ATTENTION!

Pour éviter choc électrique en cas de insuccès, la provision de pouvoir doit êtré

installé par un installeur professionnel. Le terminal de la provision de pouvoir,

marqué du symbol de terre, ( ) doit connecté à un circuit de terre permanent.

ATTENTION!

Les circuits doivent êtré interconnectés de manière à ce que l’ équipement

continue a êtré en agrément avec “EN60950:1992/A2:1933, Section 6.2, pour les

circuits de voltage de liaisons d’ échanges (réseau) par les télécommunications

(TNV),” après les connections de circuits.

Españole

PELIGRO!

La bateria puede exp lotar si s e reempla za incorr ectamente. Reemp lace la bateri a

con el mismo tipo de bateria ó una equivalente recomendada por el manufacturero. Disponga de las baterias de acuerdo con las instrucciones del manufacturero.

PELIGRO!

Para evitar contacto con circuitos que electrocutan, la fuente de alimentación

debe ser instalada por un técnico profesional. La terminal de la fuente de alimentación marcada con el símbolo de tierra ( ) debe ser con ectada a un cir-

Verilink APS 2000 User Manual iii

Page 4

cuito de vuelta por tierra permanente.

CIRCUITOS A INTERCONECTARSE

Circuitos que se int erc on ecta n a la re d de telecomunicaciones deben h acer se d e

tal manera que cumplan con los requisitos estipulados en las especificaciones

“EN60950:1992/A2:1933, Sección 6.2, para los voltages de circuitos

interconnectados a la Red de Telecomunicaciones (TNV),” despues de terminar

las connecciones entre los circuitos.

Deutsch

Canadian

Requirements

VORSICHT!

Explosionsgefahr bei unsachgemäßem Ersetzen der Batterie! Batterie gleichen

Typs und gleicher Qua lität ben utzen, wie v om Hersteller empfohlen. Entsor gung

der Batterie nach Anweisung des Herstellers!

VORSICHT, GEFAHR!

Um keinen Schlag zu erhalten beim Versagen der electrischen Anlage, muss der

Stromanschluss von einem Elektriker vorgenommen werden. Der elektrische

Pol, versehen mit dem Erdsymbol ( ) muss am Stromanschluss permanent

geerdet sein.

VORSICHT!

Schaltungen, die in den Geräten zusammengeschaltet sind, müssen weiterhin

den Vorschriften EN60950:1992/A2:1933, Absatz 6.2 für Telecommun ications

Netz Spannung (TNV) Schaltkreize entsprechen.

This digital apparatus does not exceed the Class A limits for radio noise emissions

from digital apparatus set out in the Radio Interference Regulations of the Canadian

Department of Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les

limites applicables aux appareils numé riques (de la cl ass A) prescrit es dans le

Règlement sur le brouillage radioélectrique édicté par le ministère des

Communications du Canada.

The Industry Canada label indentifies CS-03 certified equipment. This certification

means that the equipment meets certain telecommunications network protective,

operational and safety requirements. Industry Canada does not guarantee the

equipment will operate to the user’s satisfaction.

Before installing this equipment, users should ensure that it is permissible to be

connected to the facilities of the local telecommunications company. The equipment

must also be instal led usin g an acce ptab le method of conn ecti on. In some cas es, the

company’s inside wiring associated with a single line individual service may be

extended by means of a certified connector assembly (telephone extension cord).

The customer should be aware that compliance with the above conditions may not

prevent degradation of service in some situations.

Repairs to certified equipment should be made by an authorized Canadian

maintenance facility designated by the supplier. Any repairs or alterations made by

the user to this equipment, or equipment malfunctions, may give the

telecommunications company cause to request the user to disconnect the

equipment.

Users should ensure for their own protection that the electrical ground connections

of the power utility, telephone lines and internal metallic water pipe system, if

present, are connected together. This precaution may be particularly important in

rural areas.

Caution:

should contact the appropriate electric inspection authority, or electrician, as

appropriate.

Users should not attempt to make such connections themselves, but

Safety Precautions

This equipment is intended to be insta ll ed o nly in a Restricted Access Location that

meets the following criteria:

Access can only be gained by service personnel or users who have been

•

instructed about the reasons for the restri ctions applied to the location and

about any precautions that must be taken.

iv Verilink APS 2000 User Manual

Page 5

Access can only be gai ned th rough th e use of a lock a nd ke y or ot her mea ns of

•

security, and is controlled by the authority responsible for the location.

When handling this equipment, follow these basic safety precautions to reduce the

risk of electric shock and injury:

Follow all wa rnings and ins tructions marked on the pr oduct and in the

•

manual.

Unplug the hardware from the w all outlet before cleaning. Do not use liquid

•

cleaners or aerosol cleaners. Use a cloth slightly dampened with water.

Do not place this product on an u nstable cart, stand, or table. It may fall,

•

causing serious damage to the product.

Slots and openings in the shelves are prov ide d for ve nti latio n to prote c t them

•

from overheating. These openings must not be blocked or covered. Never

place this product near a radiator o r heat register.

This product should be op erated onl y from the t ype of power sou rce indicate d

•

on the marking label and manual. If you are unsure of the type of power

supply you are using, consult your dealer or local power company.

Do not allow anything to rest on the power cord. Do not locate this product

•

where the cord will interfere with the free moveme nt of people.

Do not overload wall outlets and extension cords, as this can result in fire or

•

electric shock.

Never push objects of any kind into the shelves. They may touch dangerous

•

voltage points or short out parts that could result in fire or electric shock.

Never spil l liquid of any kind on this equipment.

Unplug the equipment from the wall outlet and refer servicing to qualified

•

service personnel under the following conditions:

a. When the power supply cord or plug is damaged or frayed.

b. If liquid has been spilled into the product.

c. If the product has been exposed to rain or water.

d.If the product has been dropped or if the cabinet has been damaged.

Product Warranty

Customer Service

Publications Staff

Verilink’s product warranty covers re pair or replacement of all equipment under

normal use for a five-year period from date of shipment. Our in-house Repair Center

services returns within ten working days.

Verilink offers the following services:

• System Engineers at regional sales offices for network design and planning

assistance (800) 837-4546

• Technical Assistance Center for free 24x7 telephone support during install ation,

maintenance, and troubleshooting (800) 285-2755 and support@verilink.com)

• To return a product, it must be assigned a Return Materials Authorization (RMA)

number before sending it to Veril i nk for repa ir (800) 92 6- 0085 , ext. 228 2

• Maintenance contracts and leasing plans (800) 837-4546

• Technical Training on network concepts and Verilink products (800) 282-2755

and training@verilink.com

• Web site (www.verilink.com)

This manual was written and illustrated by Steve Rider. Contributing writers

include: Marie Metivier, Theresa Lau, and Barbara Termaat.

Verilink APS 2000 User Ma nual v

Page 6

vi Verilink APS 2000 User Manual

Page 7

Table of Contents

Overview

................................................................................................................................. 1-1

Purpose and Use.................................. ..................... ..................... ..................... ...............1-1

Scope.................................................................................................................................1-1

Theory of Operation................... ... ..................... ..................... ..................... .....................1-2

Protection Groups........................ ..................... ... ..................... ... ..................... ......... 1-2

T1 Prioritization.............................. ... ..................... ... ..................... ..................... ...... 1-2

Switching Criteria....................................................................................................... 1-2

V.54 Channel Loopback and Test ............................................................................... 1-5

User Interfaces........................................................................................................... 1-5

System Hardware............................................................................................................... 1-6

MLS 2200 Shelf....................... ... ..................... ..................... ..................... .................. 1-6

Channel Service Unit s ........................... ... ..................... ..................... ..................... ...1-7

Node Controller Functions......................................................................................... 1-7

CSU Functions............................................................................................................ 1-7

Connector Interface Module.......................................................................................1-9

Controls and indicator s ................................. ..................... ... ..................... ............... 1-9

System Cabling Requirements......................................................................................... 1-10

Required Cables....................................................................................................... 1-10

Cable Distance Limitations ...................................................................................... 1-11

Cable Schematics...................................................................................................... 1-12

CSU Configuration Options...................................................................................... 1-15

Quick Setup

Installation Procedure....................................................................................................... 2-1

Connecting the CIMs....................................... ..................... ..................... ..................... ...2-4

Configuration

Configuring the system..................................................................................................... 3-1

Node Administration......................................................................................................... 3-3

Configuration Menu ........................................................................................................ 3-12

............................................................................................................................ 2-1

Step by Step................ ... ..................... ... ..................... ..................... ..................... ...... 2-1

........................................................................................................................ 3-1

Important notes ......................................................................................................... 3-1

Logging on.................................................................................................................. 3-1

Node Administration Menu........................................................................................ 3-3

Modem Configuration ................................................................................................ 3-6

Configuration procedure............................................................................................ 3-8

Configuration Menu Commands .............................................................................. 3-12

APS Control Modes................................................................................................... 3-15

Switching Priority..................................................................................................... 3-17

Initializing the AP S 20 0 0............................. ... ..................... ..................................... 3-17

Verilink APS 2000 User Manua l vii

Page 8

Initializing the sy ste m......................................... ..................... ..................... .......... 3-17

Important Do’s and Don’ts....................................................................................... 3-20

Firmware Upgrade Procedures................................. ..................... ... ..................... ... ....... 3-20

Upgrading SCC Modules.................. ..................... ..................... ... ..................... ....... 3-20

Upgrading Flashba nk B..... ... ..................... ..................... ..................... ..................... . 3-21

Element Download................................................................................................... 3-23

Performance Monitoring

Performance Menu ............................................................................................................4-1

Performance Menu Display ........................................................................................ 4-1

One Hour Network......................................................................................................4-2

24-hour Errored Seconds........... ..................... ... ..................... ... ..................... ............ 4-3

24-Hour Bursty Errored Seconds................................................................................ 4-4

24-Hour Severely Errored Seconds............................................................................. 4-5

24-Hour Unavailable Seconds..................................................................................... 4-6

24-Hour Loss of Frame Count..................... ... ... ..................... ..................... ............... 4-7

Reset Registers........................................................................................................... 4-7

Error Event Monitoring ............................................................................................... 4-8

Performance Data Registers..................................................................................... 4-10

Performance data processing................................................................................... 4-11

Diagnostics

What tools are available.................................................................................................... 5-1

Using Diagnostics.............................................................................................................. 5-3

T1 and DSO Loopback and Test Functions........................................................................ 5-9

CSU alarms ............................. ... ..................... ... ..................... ..................... .................. .5-12

............................................................................................................................ 5-1

CSU LEDs.................................................................................................................... 5-2

Alarm Status...............................................................................................................5-3

Diagnostics Menu................ ... ..................... ..................... ..................... .....................5-3

Status Messages.......................................................................................................... 5-5

Diagnostic Commands ............................................................................................... 5-6

Signal Access Jacks .................................................................................................... 5-7

Local Loopbacks............................................. ... ..................... ..................... ... ............ 5-9

Remote Loopbacks................................................................................................... 5-10

Loss of Signal......................... ..................... ..................... ..................... ... ................ 5-12

Out-of-frame and Loss of Signal............................................................................... 5-12

Loss-of-frame........................................................................................................... 5-12

AIS Alarm.................................................................................................................. 5-13

Keep-alive Signal............................. ... ..................... ..................... ..................... ....... 5-13

.................................................................................................... 4-1

Specifications

SCC 2120 and TAC 2110....................................................................................................A-1

System shelves and heat baffles.......................................................................................A-2

viii Verilink APS 2000 User Ma nual

............................................................................................................ A-1

Page 9

Chapter

1

Purpose and Use

Overview

This manual describes the Verilink Automatic Protection Switch

(APS 2000), a fully automatic, 1 for n, T1 protection switch

component of the Verilink Access System 2000 (AS2000) product

family.

The APS 2000 system automatically senses degrading or failed T1

lines and restores service to a protection line.

When the trouble clears, the system returns service to th e original

working line, either automatically or manually. The protection line

can carry low priority traffic which will be bumped if another T1

fails.

Alarms and control are provided both locally and remotely via

SNMP or Telnet. APS 2000 consists of a software addition to

Verilink’s T1 Access Cards (TACs) and software enhancements to

the Verilink SNMP MIB.

Scope

•

This chapter presents an overview with theory of operation

and illustrations of front and rear modules.

•

Chapter 2, "Quick Setup" presents a sample configuration

procedure, as a guide to configuring the APS2000.

•

Chapter 3, "Configuration" presents a detailed listing of all

configuration options.

•

Chapter 4, "Performance Monitoring" describes the

Performance Menu functions.

•

Chapter 5, "Diagnostics" details the Diagnostics Menu

functions.

•

Appendix A, "Specifications" lists technical details of the APS

2000 products.

Verilink APS 2000 User Manual

1

-1

Page 10

Overview

Theory of Operation

Protection Groups

T1 Prioritization

An APS Protection Group is comprised of a T1 protection line and n

working T1 lines.

To eliminate the possibility of cross switches, switching priority is

built into the APS 2000 system.

Prioritization ensures that, during multiple line failures, both ends

of the same line switch to the protection line. That line will be the

failed line with the highest priority, as determined at the time of

installation.

If a lower priority line has switched to the protection line and,

subsequently, a higher priority line fails, the lower priority line is

“bumped” back onto its original line, which is forced to carry

service as best it can. By definition, the protection line has the

lowest priority and cannot be switched if it has failed.

Figure 1-1 Prioritized sequence of CPEs = 1, 2, 3, 4

APS 2000

Switch Circuit

CPE 4

CPE 3

#4

in

#3

in

out

out

CSU 4

CSU 3

T1 #4

T1 #3

Switching Criteria

CPE 2

CPE 1

Low Priority

CPE

#2

in

#1

in

Protection

Circuit

out

out

CSU 2

CSU 1

Protection

CSU

T1 #2

T1 #1

T1 Protection Line

The priority system may also be overridden for maintenance

purposes by placing higher priority lines in the

Inhibit

control

mode. Then lower priority lines can access the protection line.

There are four types of abnormalities which may cause a working

line to switch to the protection line. These criteria are:

•

Errors and alarms

•

Abnormal network codes

•

Switch code

•

Removal of the CSU module

1

-2 Verilink APS 2000 User Manual

Page 11

Overview

Errors and Alarms

Abnormal Network

Codes

Switch Code

The errors and alarms which activate switching are loss of frame

(LOF), Loss of Signal (LOS), high Bit Error Rate (BER), and high

Bipolar Violations (BPV)s.

In addition to errors or degraded/failed T1 signals, APS 2000

specifically recognizes other service-affecting conditions which

appear as clean T1 signals. These include loopbacks and injected

test signals.

A loopback condition in the middle or far end of a circuit would

appear to the near end as a clean si gn al . However, service is

interrupted when loopbacks are present. Similarly, if a clean signal

(from a test set, for example) was inje cted into one or both

directions of transmission from the middle of a circuit, no alarms

would be generated.

APS 2000 transparently sends a unique “network code” from each

end of the system. The near-end and far-end codes are different

and are automatically selected when the APS is in operation. If

either end receives its own network code (indicating a loopback is

present) or no network code (indicating “foreign signal” injection),

the system will switch as if errors had been received.

All 1-for-n automatic protection switching systems must switch

both ends of a circuit when a failure occurs in one or both

directions of transmission. If the failure is in one direction only,

the failed end must commu ni cate with the remote end to tell it to

switch.

The APS 2000 system provides for two different selectable methods

of communicating this “switch code” (and the unique Network

Codes discussed above) to the far end to ensure end-to-end

operability. This end-to-end operability is assured regardless of

network topology or carrier-based transmission equipment. The

methods are ESF Facility Data Link (FDL) and density bit. ESF FDL is

the default and density bit is an option.

ESF Facility Data Link (FDL)

ESF FDL signalling is the normal (default) method of

communicating switch code.

It sends a priority bit-oriented protocol (BOP) message (as defined

in ANSI T1.403) to inform the far end when to switch and when to

restore.

Using the FDL offers a number of advantages:

•

The messages are reserved for APS usage so the detection time

may be kept short.

•

Payload loopback may be asserted without risk of single-ended

restoration (“half switch”) due to a switched unit receiving its

own clean signal.

Verilink APS 2000 User Manual

1

-3

Page 12

Overview

APS uses a standards-based (non-proprietary) method of

controlling switching events.

The potential disadvantage is that some network-based DACS

systems do not provide end-to-end connectivity of the FDL. If the

carrier’s network includes a DACS, the DACS must either be

optioned for “through” FDL usage or the T1 must be routed around

the DACS. If these options are not available, another method must

be selected to communicate switch code.

56kb Density Bit signalling

This method relies on the fact that if one or more of the DS0

channels in a T1 system contain data at 56kbs, the eighth bit

of the DS0 byte may be used as a communications channel.

Normally, the eighth bit is forced to a “1” to ensure proper

ones-density on the T1 signal, but this requirement may be

waived under either of the following scenarios:

• If the network T1 is optioned for B8ZS, density is assured.

• If the network cannot be B8ZS for some reason, and only a

single DS0 is used for the 56kbs + signalling bit, density

can still be maintained by using the bit during frames

where the frame bit is a “1.” The extra “1” in the frame bit

allows one DS0 to be all zeros without violating the density

rules as defined by ATT PUB 62411 and ECSA T1.403.

CSU Removal

The ESF FDL signalling method is the preferred method of

communicating “switch code” and is se t by default. Density bit

signalling may be selected if the system either does not use ESF

lines, or if an older DACS system prevents ESF FDL continuity.

APS 2000 does not use, nor require , any form of “ common cont rol.”

Each APS/CSU module is independent of other modules and its

actions are independent of the actions of other modules (wit hin the

scope of the priority system discussed above).

Even physical removal of a module does not affect the switching

and restoral process. In the unlikely event of a failed module, the

module may be removed and replaced without disrupting service

to the effected DTE. If the module to be removed is associated with

a working line, a normal switch to the protection line will occur at

both ends. Once the module is reinstalled, a normal reset is

allowed.

NOTE:

The far end module should not be in the

INHIBIT

control

mode when removing a near-end module. When a module is

removed at either end, the empty slot appears to the priority

system as a failed line requesting to switch to the spare and

is still part of the priority system. Make sure the spare is not

being used by a higher priority line (or

INHIBIT

higher

priority lines) before removing a module.

1

-4 Verilink APS 2000 User Manual

Page 13

Overview

V.54 Channel Loopback and Test

T1 CSUs and APS systems normally process an entire T1 bitstream.

Drop-and-insert DSU/CS Us however, are channelized and capable

of loopback testing on just a portion of the T1 signal (one or more

DS0 channels). Drop and insert devices contain multiplex logic and

dataport interfaces and are, therefore, more costly than T1 CSUs.

Many systems utilize both T1 CSUs and drop and insert CSUs in the

same circuit. For example, when physical access to a DS0 data

signal is not required be tween two intermediate locati ons, the

signal may still be dropped and inserted at the ends. Standar d CSUs

may then be deployed at the intermediate locations, effect ing a

cost savings. The drop-and-insert CSUs or routers at the circuit

end-points usually provide for DS0 loopback testing (built into the

port circuitry) to test a specific portion of the signal without

disrupting the rest of the signal (other DS0s). However, without

special circuitry, DS0 testing could not be initiated from an

intermediate location where there was no drop and insert CSU .

The V.54 loopback option (V54LB) adds this special circuitry to an

APS CSU. V54LB provides the required V.54 loop-up, loop-down,

and channel test signal capabilities to initiate loopback and test of

a user-selected DS0 channel or FT1 bundle, using drop-and-insert

without requiring physical data port access. The V54LB option

bridges the gap between a full drop-and-insert DSU/CSU and a

standard T1 CSU by providing both T1 loopback/test and DS0

loopback/test.

User Interfaces

Craft / Telnet

APS 2000 includes standard T1 CSU functionality as well as

protection switching functionality. A connection to one end of a

system provides status and control of both ends of the circuit via

the ESF FDL or density bit as discussed above.

APS 2000 provides both local and remote status indications and

control capability. Front panel LEDs indicate status.

The SCC 2120 front panel port lab e l led

driven ASCII interface (called the Craft interface).

Detailed status, alarm information and control, requires access to

either the Craft interface or the embedded SNMP agent via the

node’s SNMP Controlle r and Channel Service Unit (SCC 21 20).

The Craft interface is accessible by direct connection of a terminal

emulator to th e

session over a SLIP or Ethernet interface.

An automatic log-off function logs the operator off the node if no

input command is entered within 15 minutes. The Craft inter f ace

data rate is 19.2 Kbit/s.

RAFT

port on the SCC front panel or via a Telnet

C

RAFT

provides a menu

C

Verilink APS 2000 User Manual

1

-5

Page 14

Overview

SNMP

System Hardware

Alternatively, the operator can use an SNMP manager (such as

SunNet Manager or HP OpenView) via either a SLIP or Ethernet

connection. Verilink’ s prop riet ary MIB augmen ts the stan dar d MIBs

to provide the same management capabilities as Verilink’s Craft

interface.

The SLIP and Ethernet connec tors are located on the CIM 2022 APS,

which mounts to the back of the SCC 212 0, against the shelf

midplane.

The SLIP connection runs at 9600Kbit/s and the Ethernet

connection at 10 Mbit/s .

Every APS 2000 system node with full T1 protection switching

consists of at least a shelf, a power supply, and modules with the

appropriate cabling.

The APS 2000 Line Protection System works with either Multi-line

or Dual-line shelves.

MLS 2200 Shelf

The MLS 2200 has 13 plug-in module slots. The two redundant

power supplies provide power to all of the plug-in modules.

Figure 1-2 Multi-line Shelf (front view)

SCC 2120

With cabling, the control bus can be expanded to additional shelves

for increased node capacity.

TAC 2110

(12 slots)

Power Supplies

Mounting Ear

(each side of shelf)

More Information

For more information on power supplies and shelves, see the

manual AS2000: The Basics.

1

-6 Verilink APS 2000 User Manual

Page 15

Overview

Channel Service Units

Node Controller Functions

Verilink offers two Channel Service Units (CSUs) for use with the T1

protection line application — the SCC 2120 and t he TAC 2110. The

SCC 2120 provides node controller functionality in addition to all

of the CSU functionality of the TAC 2110. Each node must have

only one SCC 2120 module.

Connector Interface Modules (CIMs) provide network and DSX-1

equipment (EQUIP) connectivity to the SCC and TAC. The SCC 2120

uses the CIM 2022 APS, and the TAC 2110 uses the CIM 2010 APS.

NOTE:

Although the CSUs have additional functions related to

channel distribution, use, and management, only those

functions which are applicable to ful l T1 line protection

switching will be discussed.

Each APS 2000 node consists of an SCC 2120 and all the associated

circuit elements it controls. In the case of T1 line protection

switching, all of these circuit elements are CSUs.

The SCC 2120 is typically located in the first slot of the first shelf

of each node, and is also known as the “node controller.” The node

controller provides the operator interface for each node. Using

either the ASCII terminal or SNMP Manager, an operator can acc e ss

the modules in the APS 2000 node for T1 network administratio n

and maintenance. This is illustrated in Figure 1-3.

Figure 1-3 SCC Node Controller with Operator Interfaces

SNMP

Network Manager

(MOM)

CSU Functions

Local

ASCII

Terminal

SLIP

Ethernet

LAN

IP over T1

The CSU provides T1 circuit termination at the customer premises

RS-232D

Node

Controller

circuits

CSU

circuits

SCC 2120

and connects the customer’s DS X-1 equipment to the network,

regenerating the data received from the line.

Operator Interface

RS-485 Controller Bus

TAC

TAC

2110

2110

Other units in nod

TAC

2110

RS-485 bus

expansion to

other shelves

in node

Verilink APS 2000 User Manual

1

-7

Page 16

Overview

Each CSU can be configured for the desired mode of operation. The

configuration data is stored in each module and can be retrieved or

edited.

Network

Management

The Access System 2000 performs the fol l owing network

management-related functi o ns:

Performance Data

Generates and stores T1 circu it perf ormanc e data. An oper ator ca n

retrieve this data for circuit analysis and maintenance.

•

Generates non-service-affectin g T1 performan ce data requi red

by AT&T TR-54016 and ANSI T1M1 .3 .

•

Generates non-service-affecting performance report messages

consistent with ANSI T1.403-1989.

Network Transmission Functions

The CSU performs network transmission functions such as:

• T1 signal framing and encoding

• Line coding conversion

• Network density enforcement

• Performanc e data processing and storage

Circuit

Maintenance

• CSU status and alarm rep orting

• T1 test signals and loopbacks for circuit diagnostics and

maintenance

Access System 2000 equipment provides several built-in features

that make circuit maintenance, diagnostics, and testing possib l e:

Loopbacks

Four different signal loopbacks are av ailable for rapid T1 circuit

trouble isolation. Each of these loopbacks can be activated or

deactivated by an operator.

Test signa ls

Each CSU is capable of applying one of four test signals to the

circuit through operator-issued commands.

•

Service-affecting diagnostics, testing, and maintenance in

accordance with AT&T Publication 54016.

1

-8 Verilink APS 2000 User Manual

Page 17

Overview

Connector Interface Module

Controls and indicators

The SCC 2120 uses a CIM 2 022 APS to make its connections to the

network, equipment, netwo rk management, timing, and alarm

signalling cables.

The CIM 2022 APS modules is mounted from the back of the shelf.

The CIM 2022 APS provides the following major functions for its

SCC:

•

CSU to Network connection (RJ-48C connecto r)

•

CSU to Equipment connection (RJ-48C connector)

•

APS IN

•

APS OUT

•

ASCII, SLIP, and Ethernet Interfaces

connection

connection

The SCC has three LEDs, three pairs of bantam jacks, a 6-pin

modular jack, two thumb whee l switch es, and a push- but ton swi tch.

NOTE:

The 6-pin modular jack on the TAC 2110 is not used. This

jack is only functional for an ASCII terminal interface on the

SCC 2120.

Figure 1-4 SCC 2120 and TAC 2110 Controls and Indicators

SCC

2120

EXE

0

2

FUNCTION

EQPT

STAT

NET

CRAFT

IN

OUT

IN

OUT

NET

EQPT

EQPT

NET

MON

Thumbwheel Switches

and Command

Execution

Push button

Equipment, CSU

Status and

Network LEDs

Modular Jack

for

ASCII Terminal

Connection

Signal Access

Jacks (Bantam)

NOT

USED

OUT

OUT

NET

EQPT

TAC

2110

EQPT

STAT

NET

IN

IN

EQPT

NET

MON

Verilink APS 2000 User Manual

1

-9

Page 18

Overview

System Cabling Requirements

This section describes the various cables used to connect all the

components of the Automatic Protection Switch application. These

are shown in Figure 1-5.

Required Cables

The tables and figures below describe types of cables, indicate

cable connections and give pinou t infor m ation f or re q uire d ca ble s.

Table 1-1 Cables Used with APS 2000

Cable Description

T1 network interface cable

Priority cable

Controller bus expansion

cable

Customer Premises

Equipment cable

Craft interface cable

SLIP cable

These T1-grade transmission cables connect the SCC 2120 (via the

CIM 2022 APS ) or TAC 2110 (via the CIM 2010 APS) to the T1 network.

This cable goes from the APS OUT po rt of one CIM to the APS I N port of

the next lower priority CIM. Additionally, for the CIM 2022 APS in the

first shelf’s slot, it connects the EQPT port and the APS IN port on that

CIM.

The controller bus expansion cable has a 6-pin, mini-modular male

connector (RJ-11) on each end. This cable extends network

management from Shelf 1 (the SC C 2120 CSU/Contro ller) to other

shelves in the node.

This cable connects the DSX-1 equipment to the CIM 2010 APS

connector.

This cable connects an ASCII terminal or a PC to the Craft interface port

on the SCC 2120.

This cable connects from the CIM 2022 APS

terminal server or modem, providing a SLIP interface.

connector to the

SLIP

EQPT

Ethernet transceiver

Ethernet cable

Cable Type Part Number Description

T1 Network Interface 458-501767-xxx RJ-48C (male) to Open Wire

458-501768-xxx RJ-48C (male) to DA-15 (male)

458-501769-xxx RJ-48C (male) to RJ-48C (m ale)

Controller Bus

Expansion

1

-10 Verilink APS 2000 User Manual

458-501761-002 RS-485, 20-inch, RJ-11 male connectors

458-501761-004 RS-485, 40-inch, RJ-11 male connectors

458-501761-006 RS-485, 60-inch, RJ-11 male connectors

This adapter connects the CIM 2022 APS

cable via 10BaseT or 10Base2.

This cable connects the Ethernet transceiver to the LAN.

Table 1-2 Cables Available from Verilink

THERNET

E

port to the Ethernet

Page 19

Cable Type Part Number Description

APS Priority 458-502572-001 RJ-48C (male) to RJ-48C (male), 18 inches

Overview

Ethernet Transceiver 591-502386-001 Ethernet transceiver, in cl ud ed with eac h SCC

2120. Identical to those used with Apple

Macintosh® computers.

Craft Interface 458-501788-008 Craft MiniMod to DB-25 (Female), 8 foot

458-102119-008 Craft MiniMod to DB-9 (Female), 8 foot

Figure 1-5 APS 2000 Cable Connections

This figure shows the cables required to set up this application in a hypothetical two-shelf node. Numbered cables are

identified and detailed in Figure 1-6.

Customer Premise

Equipment (CPE)

T1 Service

Provider

Protection Line

Customer Premise

Equipment (CPE)

Low Priority

3

1

CIM

TAC 2110

MLS 2200 #1

3

1

CIM

SCC 2120

Shelf 1, Slot 1

Operator interface options

LAN

Router

7

5

6

2

Ethernet

10 Mbps

SLIP

19.2 kbps

4

19.2 kbps

Terminal

Server

ASCII Terminal

SNMP

Manager

Customer P r emise

Equipment (CPE)

KEY:

Cable Distance Limitations

TAC 2110

CIM

MLS 2200 #2

1

3

Pinouts for these connectors are detailed in this chapter

Indicates connection for the T1 protection line

P

Each number indicates a specific cable type

1

All shelves in the same Access System 2000 node must be within 12

cabling feet of each other.

Verilink APS 2000 User Manual

1

-11

Page 20

Overview

Each CSU must be within the following cable distances from the

connected equipment at the customer premises:

CSU attached to: Distance from CSU

DSX-1 equip ment 655 feet, maximum

First network repeater 3000 feet, maximum

ASCII terminal

(RS-232D)

These distances are critical for accurate system operation.

Cable Schematics

The following cable schematics will provide you with the

information to assemble any of the shelf interconnection cables.

T1 network

interface cable

Figure 1-6 Network Interface Cable Schematics

RJ-48C to RJ-48C

(PN: 458-501769-xxx)

The network interface cables are used to connect the SCC 2120 via

the CIM 2022 APS to the T1 network.

To/From

CSU

50 feet, nominal

RJ-48C

Male

4

5

7

1

2

8

Ring

Tip

Ring 1

Tip 1

Twisted

Pairs

RJ-48C

Male

4

5

7

1

2

8

To/From

Networ

RJ-48

Male

4

RJ-48C to DA-15 (15-Pin

(PN: 458-501768-xxx)

RJ-48C to Open Wires

(PN: 458-501767-xxx)

1

-12 Verilink APS 2000 User Manual

To/From

CSU

To/From

CSU

5

7

1

2

8

RJ-48C

Male

4

5

7

1

2

8

Twisted

Ring

Tip

Ring 1

Tip 1

Pairs

Blue (R)

Wht/Blue (T

Orn (R1)

Wht/Orn (T1)

DA-1

Male

Twisted

Pairs

9

1

To/From

Networ

11

3

To Networ

From Networ

Page 21

Overview

Controller Bus

Expansion Cable

Craft Interface

Cable

The Controller Bus Expansion Cabl e extends network management

from shelf to shelf. Figure 1-7 illustrates where the cable leads

attach to the 6-pin mi ni-modular (RJ-11) connectors.

Figure 1-7 Controller Bus Expansion Cable Schematic

RJ-11 Male RJ-11 Male

From the

current shelf in

the node

2

5

6

5

To the next

shelf in the

2

node

1

The Craft interface cable is used to connect the ASCII terminal or

emulator to the 6-pin modular connector, labelled

C

RAFT

, on the

front of the SCC 2120.

Figure 1-8 Craft Interface Cable (DB-25) Schematic

6-Pin

Mini-Mod

Male

3

4

5

To Craft port on

SCC 2120 front

panel

To ASCII

terminal

DB-25

Female or Male

2

3

7

Figure 1-9 Craft Interface Cable (DB-9) Schematic

DB-9

Female or Male

To PC COM

portl

3

2

5

6-Pin

Mini-Mod

Male

3

4

5

To Craft port on

SCC 2120 front

panel

Verilink APS 2000 User Manual

1

-13

Page 22

Overview

DSX-1 Equipment

Cable

This cable connects the DSX-1 equipment to th e connector labelled,

EQPT.

Figure 1-10 DSX-1 Equipment Cable Schematics

RJ-48C to RJ-48C

(PN: 458-501766-xxx)

RJ-48C to DA-15 (15-Pin

(PN: 458-501765-xxx)

RJ-48C to Open Wires

(PN: 458-501767-xxx)

To/From

CSU

To/From

CSU

To/From

CSU

RJ-48C

Male

4

5

7

1

2

8

RJ-48

Male

4

5

7

1

2

8

RJ-48C

Male

4

5

7

1

2

8

Twisted

Pairs

Ring

Tip

Ring 1

Tip 1

Twisted

Ring

Tip

Ring 1

Tip 1

Pairs

Blue (R)

Wht/Blue (T

Orn (R1)

Wht/Orn (T1)

RJ-48C

Male

DB-15

Male

Twisted

Pairs

1

2

8

4

5

7

11

3

2

9

1

To/From

Equipment

To/From

Equipment

To Equipment

From Equipment

1

-14 Verilink APS 2000 User Manual

Page 23

Overview

NMS Cable

The Network Management System (NMS) cable connects a terminal

server or modem to the Management Port (IN) connector on the

CIM 2022 APS to provide a SLIP interface.

Figure 1-11 Network Management Interface (for SLIP) Cable Schematic

P1, DB-25

Female

RD

TD

CTS

RTS

DTR

SG

DSR

DCD

PC

3

2

5

20

7

6

8

1

Chassis

Ground

To

PN: 458-501772-008

P2, DB-9

Female

3 TD

2RD

7RTS

8CTS

6DSR

5SG

1DGD

4DTR

(Case)

APS Priority Cable

CSU Configuration Options

The APS priority cables connect the APS OUT port on a CIM to the

APS in port of the next lower priority line’s CIM. All APS CIMs are

daisy-chained in this manner.

Figure 1-12

APS Priority Cable Schematic

RJ-48C

Male

1

To/From

CIM

2

7

4

5

8

RJ-48C to RJ-48C

(PN: 458-502572-001)

Ring

Tip

Ring 1

Tip 1

Twisted

Pairs

RJ-48C

Male

1

2

8

4

5

7

To/From

CIM

The SCC and TAC contain numerous software-programmable CSU

configuration options. These options are set by an ASCII terminal

operator or using SNMP.

The most recent CSU configuration option settings of an SCC or

TAC are saved in nonvolatile storage. If the SCC or TAC is stored

off-line (not powered up), option storage is maintained by a RAM

backup battery for at le ast 3 months.

Verilink APS 2000 User Manual

1

-15

Page 24

Overview

1

-16 Verilink APS 2000 User Manual

Page 25

Chapter

2

Quick Setup

This chapter provides a step-by-step procedure for installing the

minimum configuratio n required to begin using the APS 2000.

Complete details on all configuration options are provided in

Chapter 3, "Configuration".

Installation Procedure

For each node, follow the procedure below.

Step by Step

1. Make sure you have completed all the physical installation

2. If the node has more than one shelf, extend the TABS

procedures described in the manual AS2000: The Ba sics.

controller bus. See the manual AS2000: The Basics.

3. Make the connections for each CSU. (See Connecting the CIM s).

a. Connect the T1 lines to the CIM

b. Connect the customer equipment to the CIM EQPT port.

c. Connect the APS priority cable(s).

4. Connect the SLIP and /o r Ethern et net work mana gement ca bl es

to the CIM 2022 APS in Shelf 1 Slot 1 of the node. (See

Figure 2-2, “Rear view of CIM interconnections”.)

5. Apply system power.

6. Connect a terminal or PC to the port labelled

of the SCC 2120 module. Use one of the two types of Craft

cable:

a. P/N 458-102119-008, DB-9 to RJ-11—(Figure 1-9) used with

notebook or other computers which present a DB-9 COM

port.

b. P/N 458- 501788- 001, D B-25 to RJ-1 1—(Figure 1-8) used with

terminals or computers which present a DB-25 RS-232

connector.

7. Configure your terminal or terminal program for:

a. A data rate of 19.2Kbit/s

NETWORK

port.

RAFT

C

on the front

b. N o parity

c. One stop bit

Verilink APS 2000 User Manual

2

-1

Page 26

Quick Setu p

d. No flow control (both hardware flow control and X-on/X-off

flow control must be di sabled).

NTER

8. Press the

key. The prompt

E

9. Log on to the ASCII inter face by typing "craft" at th e

prompt and pressing

NTER

E

to get the

pSH+>

is displayed.

YOUR PASSWORD?

pSH+>

prompt. If you’re accessing the node for the first time, press

NTER

(initially there is no passwo rd). The SCC 2120

E

Menu

is displayed.

10. Use the "O" command to access the

11. Use the "E" command to access the

Administration Menu

Ethernet Configuration

Main

.

submenu.

12. Set the node’s Ethernet IP address, and subnet mask as

required for your local LAN segment. Use

Ethernet type. Return to the

Administr a tion Menu

Ethernet/DIX

using the

for the

"X" command.

13. Reboot the SCC 2120 using the "B" command. Then repeat

steps 8 and 9 to return to the

14. Use the "C" command to access the

Main Menu

.

Configuration Menu

.

15. Use the "W" command to set the correct framing type for your

DSX-1 equipment (first of two choices) and T1 facility (second

choice). For this example we will assume you wish to connect a

D4/AMI PBX port to an ESF/B8ZS line. Select

3(SF,ESF)

.

16. Use the "F" command to select the format (line coding), for this

example select

2(AMI,B8ZS)

.

17. Document your installation, you may use th e worksheet in

Figure 2-1.

18. Perform the initialization procedure described in Initializing

the APS 2000 in Chapter 3.

2

-2 Verilink APS 2000 User Manual

Page 27

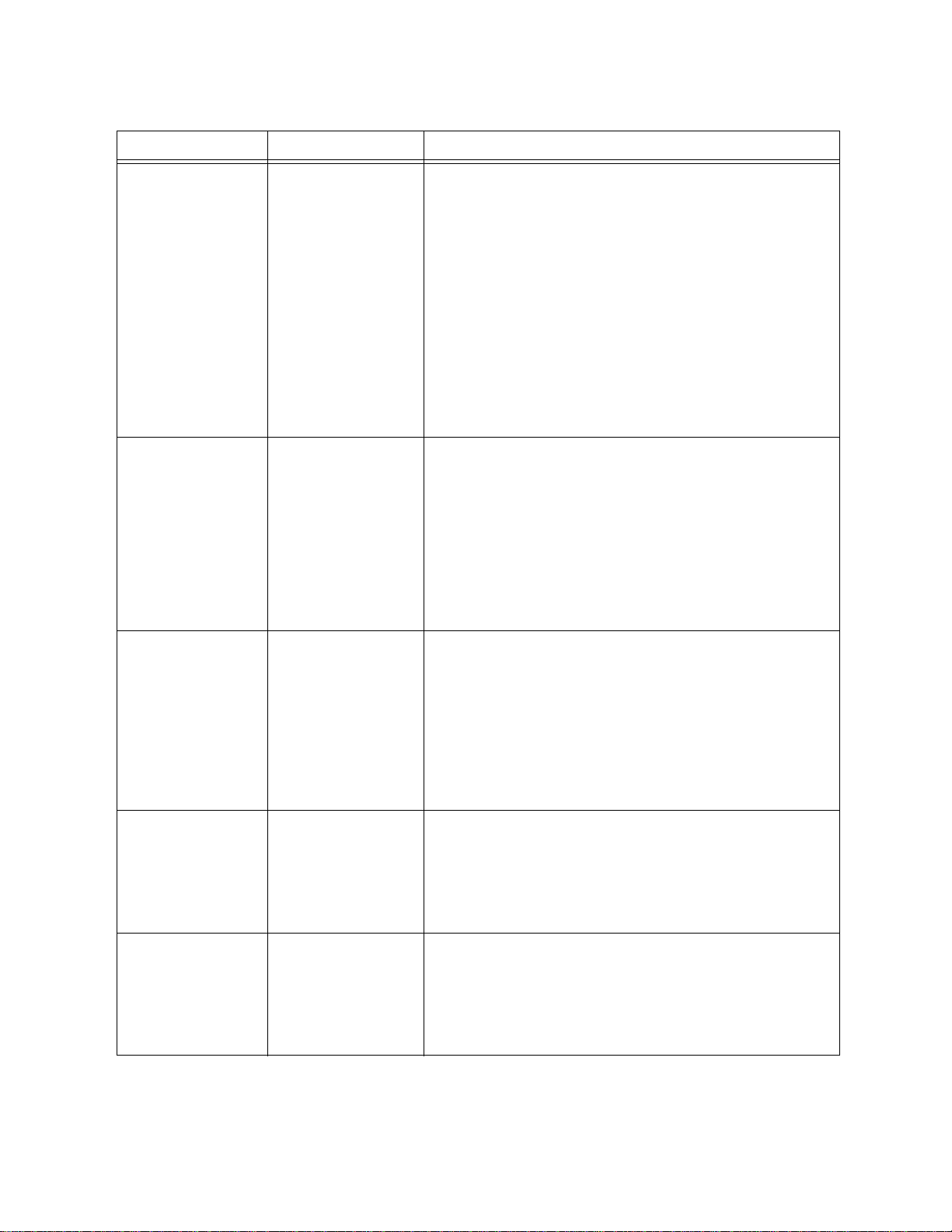

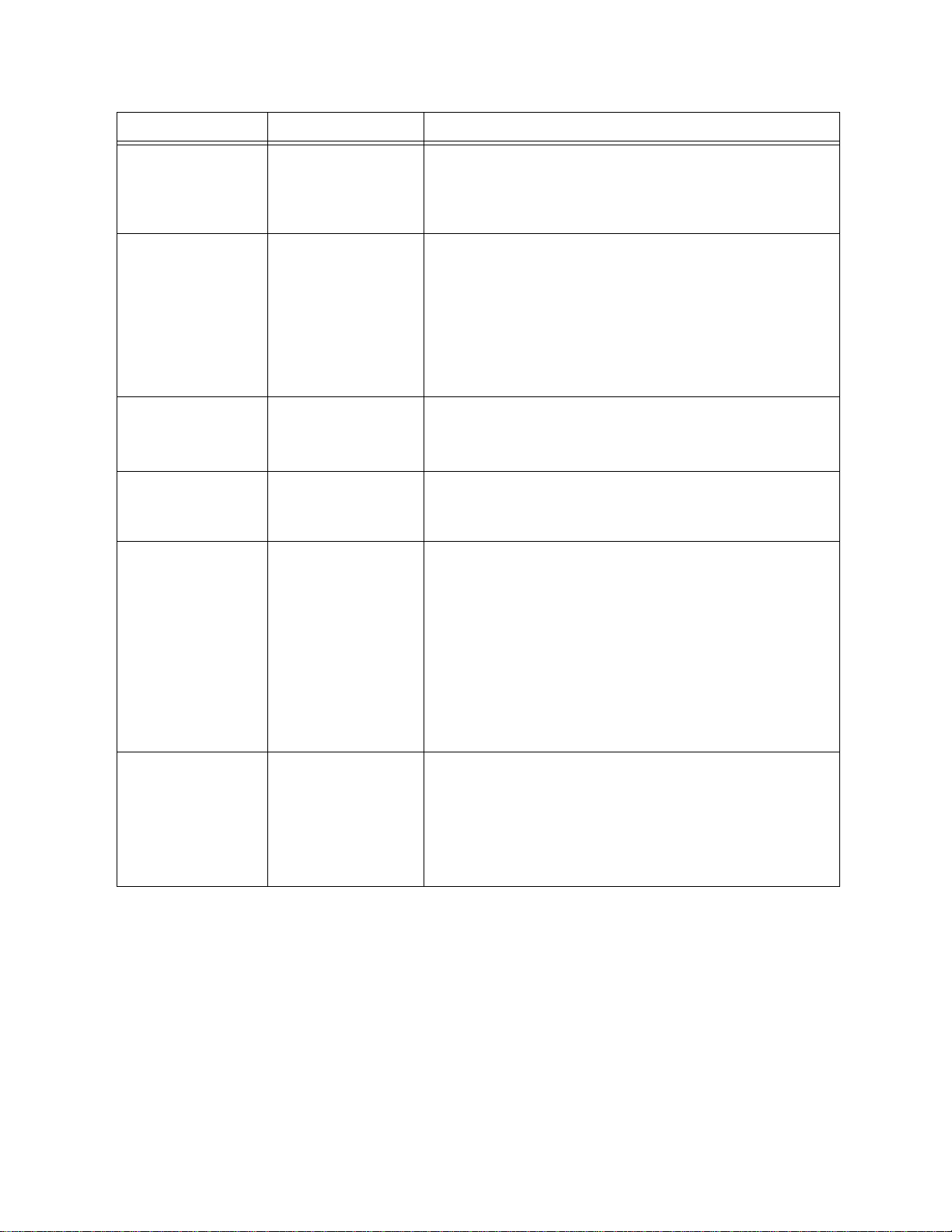

Figure 2-1 Multi-Line Shelf Worksheet

T1 Line Protection Switch: Multi-Line Shelf Worksheet

Node ID ______________

Shelf Number ____of ____

Operator interface (circle): SLIP / Ethernet / ASCII terminal

Quick Setu p

Slot

1

2

3

4

5

6

7

8

9

10

11

Module

Type

SCC NA P 2022 APS

TAC W 2010 APS

Priority

(1-N)

Line

Type

CIM/DIM

Type

Circuit

Name/

Number

Cables required

Type Length

APS

Control

Mode

12

13

14 Power Supply

15 Power Supply

AC slot B

breaker#_____________

AC slot A

breaker#_____________

DC slot B

fuse #_________

DC slot A

fuse #__________

Verilink APS 2000 User Manual

2

-3

Page 28

Quick Setu p

Connecting the CIMs

After installing the CSUs into the shelves, connect each module to

the external customer premise equipment. These connections are

made at the associated CIM 2022 A PS or CIM 2010 APS in back of

the shelf.

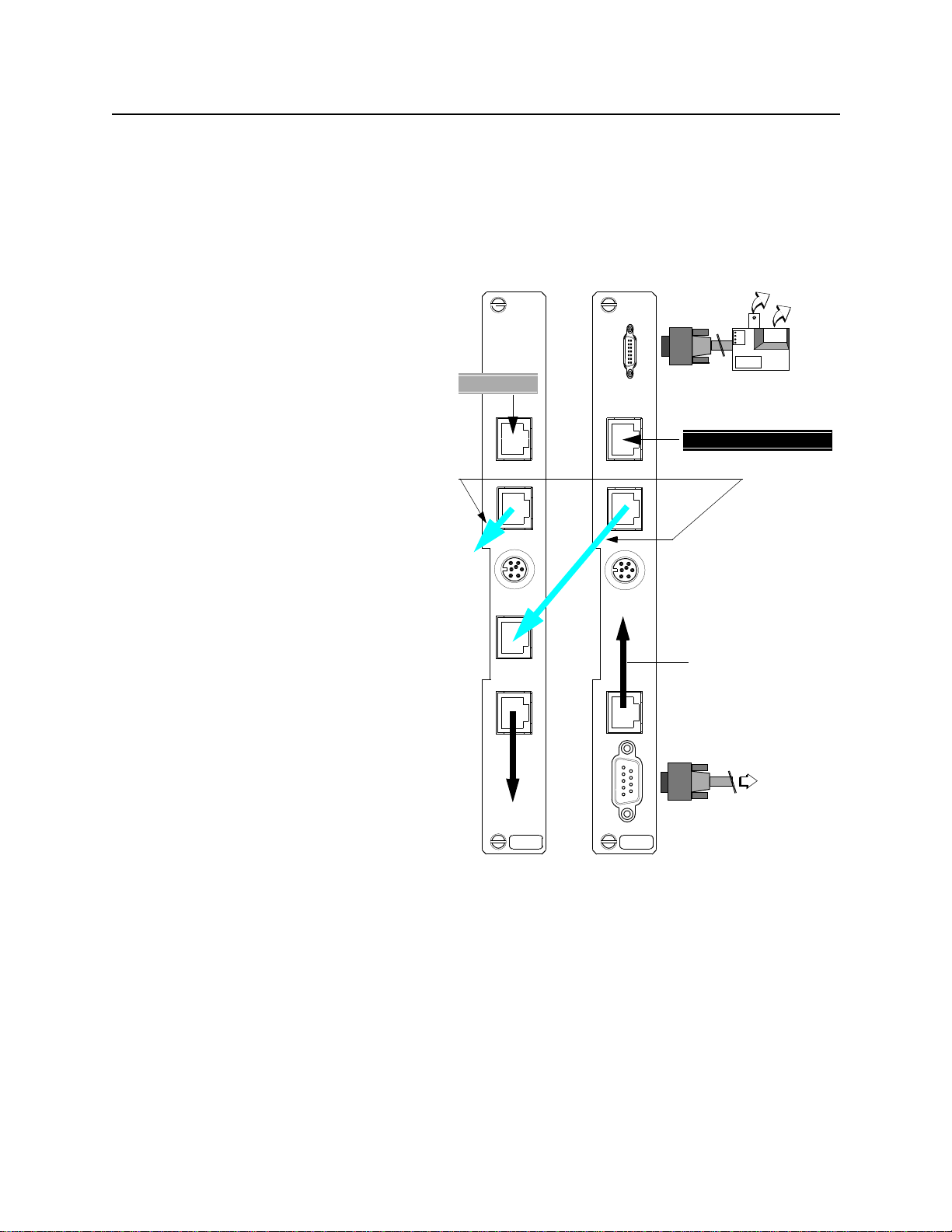

Figure 2-2 Rear view of CIM interconnections

CIM

2010

APS

CIM

2022

APS

To

Ethernet

Installing the Protection Line (Slot 1):

1.

Plug the T1 protection line (P1) into the

Network Port of the CIM 2022 APS in Slot

1.

2.

Run an RJ-48 cable from the

EQPT

Port of

the CIM 2022 APS to its APS IN port.

3.

Connect the APS CIMs in your shelf by

cabling the APS OUT port on the Slot 1

CIM to the APS IN port on the next APS

CIM. Continue daisy-chaining APS OUT

ports to APS IN ports for all the TACs on

your shelf. Leave the APS OUT port on the

lowest priority CIM empty.

NOTE: Both ends of the T1 protection group

must have the same priority cabling

sequence.

Making the network management connections

Use

1.

Management Port (IN)

for SLIP con-

nection.

Use the

2.

Management Extension

port for

Ethernet connection.

3.

Use the Craft interface to configure IP

addresses.

T1 Line (L2)

REV *

APS OUT

APS IN

EQPT EXT TIMING NETWORK

REV *

T1 Protection Line (P1)

NETWORK

APS OUT

To Low Priority CPE

EQPT ETHERNETEXT TIMING

SLIP connection

SLIP

9-pin

connector

Ethernet adapter

(10BaseT and 10Base2

connections)

APS priority

cables

part numbe

458-502572-001

To

SLIP peer

2

-4 Verilink APS 2000 User Manual

Slot 1Slot 2

Page 29

Chapter

3

Configuration

You can configure the node using either SNMP or the Craft

interface. You can access the Craft interface by telnettin g over a

SLIP or Ethernet interface. You can also access the Craft interface

locally by direct connection to a terminal or a PC running a

terminal program.

Configuring the system

Configure the SCC 2120 using the Craft interface. This interface

presents identical menus via direct connection or a Telnet session.

Important notes

When you first install the card, you must configure certain IP

address and related param e ters via the Craft port on the SCC 2120

front panel. These steps are listed in the section "Logging on"

below.

Logging on

Once you configure the IP address, you can access the Craft

interface to make subsequent configuration changes, using either a

direct connection or a Telnet session.

1. Ensure that your entries are spelled correctly and that the

options you choose are consistent with the application you are

setting up.

2. The screens do not refresh automatically after you enter a

command. To view the revised screen, you must press

refresh. Once you enter a command, the word

appears at the end of the prompt time to remind you to

refresh the screen for updated feedback.

To access the APS 2000 node from the

follows:

1. Configure your terminal or terminal program f or:

a. A data rate of 19.2 Kbit/s

b. N o parity

c. One stop bit

RAFT

port, proceed as

C

(UPDATE)

NTER

E

to

d. No flow control (both hardware flow control and X-on/X-off

flow control must be disabled)

Verilink APS 2000 User Manual

3

-1

Page 30

Configuration

RAFT

2. Connect the terminal or PC to the port labe l le d

C

on the

front of the SCC 2120 module. Use one of the two types of

Craft cable:

a. P/N 458-102119-008, DB-9 t o RJ-11—used with notebook or

other computers which present a DB-9 COM port.

b. P/N 458-501788-001, DB- 25 to RJ-11—used with terminals

or computers which present a DB- 25 R S-232 connector.

3. Press the

NTER

key. The prompt

E

4. Log on to the Craft interface by typing "craft" at the

prompt and pressing

NTER

E

to get the

prompt.

If you’re accessing the node for the first time, press

Initially there is no password.

5. If you have set a password, then type the correct password (up

to 6 characters, including spaces). The screen will display

placeholders (

Main Menu

The

Table 3-1 SCC 2120 Main Menu

-- VERILINK SCC NODE CONTROLLER at[1,1]: FW Rev 3.05, May 26, 1999. --

-- VERILINK SCC NODE CONTROLLER at[1,1]: FW Rev 3.05, May 26, 1999. --

-- VERILINK SCC NODE CONTROLLER at[1,1]: FW Rev 3.05, May 26, 1999. -- -- VERILINK SCC NODE CONTROLLER at[1,1]: FW Rev 3.05, May 26, 1999. -FLASH BANK: A Serial Number: 00520710

FLASH BANK: A Serial Number: 00520710

FLASH BANK: A Serial Number: 00520710FLASH BANK: A Serial Number: 00520710

Ethernet Address: A0:6A:00:07:F2:06:

Ethernet Address: A0:6A:00:07:F2:06:

Ethernet Address: A0:6A:00:07:F2:06:Ethernet Address: A0:6A:00:07:F2:06:

Slip Local IP Address: 0.0.0.0, Subnet Mask: 0.0.0.0

Slip Local IP Address: 0.0.0.0, Subnet Mask: 0.0.0.0

Slip Local IP Address: 0.0.0.0, Subnet Mask: 0.0.0.0Slip Local IP Address: 0.0.0.0, Subnet Mask: 0.0.0.0

Ethernet Local IP Address: 192.94.45.242, Subnet Mask: 255.255.255.0

Ethernet Local IP Address: 192.94.45.242, Subnet Mask: 255.255.255.0

Ethernet Local IP Address: 192.94.45.242, Subnet Mask: 255.255.255.0Ethernet Local IP Address: 192.94.45.242, Subnet Mask: 255.255.255.0

SITE NAME: SCC NODE ID: 372

SITE NAME: SCC NODE ID: 372

SITE NAME: SCC NODE ID: 372SITE NAME: SCC NODE ID: 372

<- SLOT ->

<- SLOT ->

<- SLOT -> <- SLOT ->

SHELF 1 2 3 4 5 6 7 8 9 10 11 12 13

SHELF 1 2 3 4 5 6 7 8 9 10 11 12 13

SHELF 1 2 3 4 5 6 7 8 9 10 11 12 13 SHELF 1 2 3 4 5 6 7 8 9 10 11 12 13

1 DL [A] A

1 DL [A] A

1 DL [A] A 1 DL [A] A

2

2

2 2

3

3

3 3

4

4

4 4

KEY: C = CSU, D = DIU, F = DIU/DDS, R = SRD, I = IDCSU, T = TU, A = APS,

KEY: C = CSU, D = DIU, F = DIU/DDS, R = SRD, I = IDCSU, T = TU, A = APS,

KEY: C = CSU, D = DIU, F = DIU/DDS, R = SRD, I = IDCSU, T = TU, A = APS, KEY: C = CSU, D = DIU, F = DIU/DDS, R = SRD, I = IDCSU, T = TU, A = APS,

B = DIU/DBU, S = SMDS, L = HLM

B = DIU/DBU, S = SMDS, L = HLM

B = DIU/DBU, S = SMDS, L = HLM B = DIU/DBU, S = SMDS, L = HLM

will appear.

******

) as you type the password. Press

pSH+>

is displayed.

YOUR PASSWORD?

pSH+>

NTER

E

E

NTER

.

.

S) shelf/slot D) diagnostics

S) shelf/slot D) diagnostics

S) shelf/slot D) diagnosticsS) shelf/slot D) diagnostics

N) near element O) node administration

N) near element O) node administration

N) near element O) node administrationN) near element O) node administration

F) far element M) monitor alarms (OFF)

F) far element M) monitor alarms (OFF)

F) far element M) monitor alarms (OFF)F) far element M) monitor alarms (OFF)

C) configuration A) view alarm buffer

C) configuration A) view alarm buffer

C) configuration A) view alarm bufferC) configuration A) view alarm buffer

P) performance X) log off

P) performance X) log off

P) performance X) log offP) performance X) log off

[1,1] NEAR TAC 2110 >

[1,1] NEAR TAC 2110 >

[1,1] NEAR TAC 2110 >[1,1] NEAR TAC 2110 >

3

-2 Verilink APS 2000 User Manual

Page 31

Table 3-2 SCC 2120 Main Menu Commands

Menu Option Description Instructions

Configuration

S) shelf/slot Used to navigate from module

N) near element Selects the local node. Used to return from a far element session.

F) far element Selects the node at the remote

C) configuration Selects the

P) performance Selects the

D) diagnostics Selects the

O) node

administration

M) monitor alarms

(OFF)

A) view alarm buffer Displays alarm buffer. A history of recent alarms is displayed.

X) log off Exits the

to module within a node.

end of the T1 circuit connected

to the current module, functions

only if ESF FDL has continuity.

Configuration

Menu

.

Performance Menu

Diagnostics Menu

Selects the

Administration Menu

Toggles on/off the monitor

alarms function.

Node

Main Menu

.

. Returns to

Enter the shelf number and slot number of the

desired module, use a comma delimiter (1,2).

With version 3.02 or higher SCC firmware, you

can navigate from module to module in the

remote node, earlier firmware versions only

allowed access to the remote CSU module. The

password required for this access is "800far".

See Figure 3-7 and Table 3-5 below.

.See Chapter 4 of this manual.

.See Chapter 5 of this manual.

See Figure 3-1 and Table 3-3 below.

If monitor alarms is ON, alarm messages are

displayed on the Craft interface as they occur.

No alarm messages are displayed if monitor

alarms is OFF.

pSH+>

pSH+>

pSH+>pSH+>

prompt, the TCP/IP shell.

Node Administration

In addition to the T1 CSU and Automatic Protection Switch

functions, the SCC 2120 i s also an SNMP nod e con troll er. T he

Administration Menu

configure site, Ethernet and SLIP address information.

Some functions on the

firmware upgrade procedures.

Node Administration Menu

The

SCC 2120

Most of the commands on the

documented in Table 3-3 below.

Some of the menu options on the

produce submenus with detailed selections, for instance the

Modem Configuration Menu

, and submenus beneath it, are used to

Node Administration Menu

Node Administration Menu

Main Menu

. Figure 3-1 shows the options presented.

Node Administration Menu

is detailed in Table 3-4.

Node

support

is accessed by selecting O on the

are

Node Administration Menu

will

Verilink APS 2000 User Manual

3

-3

Page 32

Configuration

Figure 3-1 Node Administration Menu

--- NODE CONTROLLER MENU ---

--- NODE CONTROLLER MENU ---

--- NODE CONTROLLER MENU --- --- NODE CONTROLLER MENU ---

T) time

T) time

T) time T) time

D) date

D) date

D) date D) date

I) node id

I) node id

I) node id I) node id

N) site name

N) site name

N) site name N) site name

A) Slip Configuration

A) Slip Configuration

A) Slip Configuration A) Slip Configuration

E) Ethernet Configuration

E) Ethernet Configuration

E) Ethernet Configuration E) Ethernet Configuration

M) Modem Configuration

M) Modem Configuration

M) Modem Configuration M) Modem Configuration

O) IP Gateway

O) IP Gateway

O) IP Gateway O) IP Gateway

H) trap host ip address

H) trap host ip address

H) trap host ip address H) trap host ip address

C) community string (read)

C) community string (read)

C) community string (read) C) community string (read)

W) community string (write)

W) community string (write)

W) community string (write) W) community string (write)

F) flash download

F) flash download

F) flash download F) flash download

B) boot

B) boot

B) boot B) boot

R) reset com ports

R) reset com ports

R) reset com ports R) reset com ports

S) node controller status

S) node controller status

S) node controller status S) node controller status

P) set privileged password

P) set privileged password

P) set privileged password P) set privileged password

U) set unprivileged password

U) set unprivileged password

U) set unprivileged password U) set unprivileged password

Y) element download

Y) element download

Y) element download Y) element download

X) exit menu

X) exit menu

X) exit menu X) exit menu

[1,1] NEAR TAC 2110 >

[1,1] NEAR TAC 2110 >

[1,1] NEAR TAC 2110 >[1,1] NEAR TAC 2110 >

If any changes are made to the Ethernet or SLIP configurations,

those changes do not take effect until the module is rebooted.

Rebooting an SCC 2120 by using the boot command has no effect

on user data passing through the SCC 2120 module.

NOTE:

The SLIP IP address and the Ethernet IP address

must

different network segments in terms of the subnet masks in

use. If the SLIP and Eth ernet addresses are set to reflect the

same network segment an error message “Sendto: new socket

failed” will repeat constantly until the error is corrected and

the SCC 2120 is rebooted.

Table 3-3 Node Administration Commands

Menu Option Description Instructions

T) time Sets the time of

day.

D) date Sets the date. Enter new date (mm-dd-yy): — use format shown.

I) node id Sets a numeric

identifier.

Enter new time (hh:mm:ss): — use the format shown.

Maximum field length = ten digits, distinguishes one node

from another, each node in a network must have a unique

node id.

reflect

3

-4 Verilink APS 2000 User Manual

Page 33

Menu Option Description Instructions

Site Name: Tech Pubs SCC 2120 Change (Y/N)?

N) site name Sets an alpha-

numeric identifier

used to tell one

node from another.

A) Slip Configuration Calls a submenu

which is used to

configure the RS-

232 electrical, DB-9

physical, Serial Line

Internet Protocol

port on the rear

connector module.

Site Name: Tech Pubs SCC 2120 Change (Y/N)?

Site Name: Tech Pubs SCC 2120 Change (Y/N)?Site Name: Tech Pubs SCC 2120 Change (Y/N)?

selected, a second prompt appears:

New Site Name (40)

New Site Name (40)

New Site Name (40)New Site Name (40)

alpha-nume ri c characters.

---- host configuration for sli p ----

---- host configuration for sli p ----

---- host configuration for sli p ---- ---- host configuration for sli p ----

L) Slip Local ip address : 192.94.46.222

L) Slip Local ip address : 192.94.46.222

L) Slip Local ip address : 192.94.46.222 L) Slip Local ip address : 192.94.46.222

P) Slip Peer ip address : 192.94. 46.101

P) Slip Peer ip address : 192.94. 46.101

P) Slip Peer ip address : 192.94. 46.101 P) Slip Peer ip address : 192.94.46.101

S) Slip Subnet Mask : 255.255.255.0

S) Slip Subnet Mask : 255.255.255.0

S) Slip Subnet Mask : 255.255.255.0 S) Slip Subnet Mask : 255.255.255.0

X) exit

X) exit

X) exit X) exit

: — enter a site name using up to 40

Configuration

— if yes is

E) Ethernet

Configuration

M) Modem

Configuration

SLIP may be used in

lieu of or along with

the Ethernet

connectivity

described below.

If SLIP will not be

used, leave the SLIP

Local IP address set

to 0.0.0.0.

Calls a short

submenu which is

used to configure

the AAUI-14

Ethernet connector

on the rear

connector module.

An Ethernet

transceiver which

supports both

10BaseT and

10Base2 is pro vided

with each SCC

2120.

Calls the Modem

Configuration

Menu.

— the SLIP Local I P ad d ress is for this SCC 2120.

— the SLIP Peer address must be set for the trap host IP

address in curr ent SCC firmware .

— the SLIP Subnet mask shown is for a TCP/IP class C

address, use the normal subnet mask conventions.

---- host configur ation for Ethernet ----

---- host configur ation for Ethernet ----

---- host configur ation for Ethernet -------- host configur ation for Ethernet ----

L) Ethernet Local ip address : 192.94.45.242

L) Ethernet Local ip address : 192.94.45.242

L) Ethernet Local ip address : 192.94.45.242 L) Ethernet Local ip address : 192.94.45.242

S) Ethernet Subnet Mask : 255.255.255.0

S) Ethernet Subnet Mask : 255.255.255.0

S) Ethernet Subnet Mask : 255.255.255.0 S) Ethernet Subnet Mask : 255.255.255. 0

T) Ethernet Type : Ethernet/DIX

T) Ethernet Type : Ethernet/DIX

T) Ethernet Type : Ethernet/DIX T) Ethernet Type : Ethernet/DIX

X) exit

X) exit

X) exit X) exit

— the Ethernet local IP address is for this SCC 2120.

— the Ethernet subnet mask shown is for a TCP/IP class C

address, use normal subnet mask conve nti ons.

— the Ethernet type must be set to Ethernet/DIX.

Required only if SLIP will be used over a dial-up modem

connection, see the table below.

O) IP Gateway Sets the address for

a device, usually a

router, used to

reach IP addresses

on a different

network segment.

Verilink APS 2000 User Manual

---- Internet Gateway Configuration ----

---- Internet Gateway Configuration ----

---- Internet Gateway Configuration ---- ---- Internet Gateway Configuration ----

G) Internet Gateway IP address : 128.0.0.0

G) Internet Gateway IP address : 128.0.0.0

G) Internet Gateway IP address : 128.0.0.0 G) Internet Gateway IP address : 128.0.0.0

— if no IP gateway is used, leave the default value as

shown, if a gateway device is used, type “G” and enter the

IP address of the gateway.

3

-5

Page 34

Configuration

Menu Option Description Instructions

H) trap host ip

address

C) community string

(read)

W) community string

(write)

F) flash download Used to upgrade

B) boot Reboots (resets) the

Used to configure IP

addresses fo r up to

four SNMP

managers to which

alarm information

(trap messages) will

be sent.

Set number of trap

hosts equal to the

number of IP

addresse s us e d .

SNMP community

string, a

rudimentary

password.

SNMP community

string, a

rudimentary

password.

SCC firmware.

SCC 2120.

---- host configuration for traps ----

---- host configuration for traps ----

---- host configuration for traps ---- ---- host configuration for traps ----

N) Number of trap hosts : 1

N) Number of trap hosts : 1

N) Number of trap hosts : 1 N) Number of trap hosts : 1

1) host 1 ip address : 192.94.45.111

1) host 1 ip address : 192.94.45.111

1) host 1 ip address : 192.94.45.111 1) host 1 ip address : 192.94.45.11 1

2) host 2 ip address : 0.0.0.0

2) host 2 ip address : 0.0.0.0

2) host 2 ip address : 0.0.0.0 2) host 2 ip address : 0.0.0.0

3) host 3 ip address : 0.0.0.0

3) host 3 ip address : 0.0.0.0

3) host 3 ip address : 0.0.0.0 3) host 3 ip address : 0.0.0.0

4) host 4 ip address : 0.0.0.0

4) host 4 ip address : 0.0.0.0

4) host 4 ip address : 0.0.0.0 4) host 4 ip address : 0.0.0.0

X) exit

X) exit

X) exit X) exit

Community string (Read): public Change (Y/N)?

Community string (Read): public Change (Y/N)?

Community string (Read): public Change (Y/N)?Community string (Read): public Change (Y/N)?

Community string (64):

Community string (64):

Community string (64):Community string (64):

The current value for the read communi ty strin g is “pub lic”

and a string of up to 64 characters can be entered.

Community string (Write): Right Change (Y/N)?

Community string (Write): Right Change (Y/N)?