Page 1

MultiPro

Verilink Corporation

127 Jetplex Circle

Madison, AL 35758

1.800.VERILINK

Platform

Series

i

34-00271

September 1998

Page 2

ii

✍

Copyright

Documentation

Disclaimer

Trademarks

©1998 TXPORT. All rights reserved. No part of this publication may be reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any language in any form by any means without

the written permission of TXPORT.

Reorder # 34-00271

rd

Edition, September 1998

3

TXPORT shall not be liable f or errors con tained herein or for incident al or consequ ential damages in

connection with the furnishing, performance, or use of this material. TXPORT reserves the right to

revise this publication from time to time and make changes in content without obligation to notify any

person of such revision changes.

Contents of this publication may be preliminary and/or may be changed at any time without notice and

shall not be regarded as a warranty.

TXPORT makes no representation or warranties of any kind whatsoever with respect to the contents

hereof and specifically disclaims any implied warranties of merchantability or fitness for any particular

purpose.

NetWare and Novell are registered trademarks of Novell, Inc.

Xerox is a registered trademark of Xerox Corporation.

NCR is a registered trademark of National Cash Register Corporation

Sperry is a registered trademark of Sperry Rand Corporation.

Uniscope is a registered trademark registered by Sperry Rand Corporation and owned by Unisys.

Windows is registered trademark of Microsoft Corporation.

AppleTalk is a registered trademark of Apple Computer, Inc.

OpenView is a registered trademark of Hewlett-Packard Company.

CROSSTALK is a registered trademark of Attachmate Corporation.

PROCOMM is a registered trademark of DATASTORM TECHNOLOGIES, INC.

Any other named products herein are trademarks of their respective companies.

Acknowledgment

The software used in the SNMP function of this product contains material derived from the following

source:

Copyright © 1989 by the Regents of the University of California. All rights reserved.

Redistributions in binary form must reproduce the above copyright notice, this list of conditions, and

the following disclaimer in the documentation and /or other materials provided with the distribution.

All advertising materials mentioning features or use of this software must display the following

acknowledgment:

This product includes software developed by the University of California, Berkeley and its contributors.

Neither the name of the University nor the names of its contributors may be used to endorse or

promote products derived from this software without specific prior written permission.

This software is provided by the regents and contributors ‘as is’ and any express or implied warranties,

including, but not limited to, the implied warranties of merchantability and fitness for a particular purpose are disclaimed. In no event shall the regents or contributors be liable for any direct, indirect, incidental, special, exemplary, or consequ ential damages (including, but not limited to, procurement of

substitute goods or serv ices; loss of use, data, or profits; or business interrupt ion) however caused and

on any theory of liability, whether in contract, strict liability, or tort (including negligence or otherwise)

arising in any way out of the use of this softw are , even if advised of the possibility of such damage .

Page 3

FCC Requirements

iii

FCC Requirements

This equipment (9000, 9101, 9111 , and 9211) has been te sted and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of FCC Rules. These limits are designed to provide reasonable protection against harmfu l interference when the equi pment is operated in a commercial environment. This equipment ge nerates, uses, and can radiate radio frequency energy and if no t installed and

used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in which

case the user is req uired to correct the interfe rence at his own expense. Th is device must also accept

any interference received, including i nterference tha t may cause unde sired operation. Shielded cables

must be used to ensure compliance with the Class A FCC limits.

Changes or modifications to this unit not expressly approved by the party responsible for

compliance could void the user’s authority to operate the equipment.

This equipment complies with Part 68 of the FCC Rules. On the rear or bottom of the unit is a label

that contains the FCC registration number and other information. If requested, provide this information

to the telephone company.

All direct connections to the network lines must be made using stan dard plugs and jacks (co mpliant

1

with Part 68). The tables below present a list of applicable registration jack USOCs, facility interface

codes (FICs), and service order codes (SOCs). These are req uired to order service from the telco.

9101

Port ID REN/SOC FIC USOC

56 kbps 6.0F 04DU5 - 56 RJ-48S jack

9111 Port 1 T1 Option

Port ID REN/SOC FIC USOC

1.544 Mbps SF

1.544 Mbps SF, B8ZS

1.544 Mbps ANSI ESF

1.544 Mbps ANSI ESF, B8ZS

6.0N 04DU9-BN

RJ-48C jack

04DU9-DN

04DU9-1KN

04DU9-1SN

9111 Port 1 DDS Option

Port ID REN/SOC FIC USOC

56 kbps 6.0F 04DU5-56 RJ-48S jack

If the unit appears to be malfunctioning, it should be disconnected from the network lines until the

2

source of trouble is deter mined to be your equip ment or the telephon e line. If your equipme nt needs

repair, it should not be reconnected until it is repaired.

The unit has been designed to prevent harm to the network. If the telephone company finds that the

3

equipment is exceeding tolerable parame ters, it can tempo rarily disconnec t service. In this case, the

telephone company will give you advance notice, if possible.

No customer is authorized to repair this equipment, regardless of warranty status.

4

If the telephone company alters its equipment in a manner that will affect the use of this device, it

5

must give you warning so that you have the opportunit y for uninterrupt ed service. You will be

advised of your right to file a complaint with the FCC.

In the event of equipment malfunction, all repairs should be performed by our company or an

6

authorized agent. It is the responsibility of users requiring service to report the need for service to our

company or to one of our authorized agen ts.

The affadavit at the end manu al must be co mpleted by the installer.

7

Page 4

iv

Canadian

Emissions

Requirements

Warranty

This digital apparatus does n ot exceed the Class A li mits for radi o nois e emis sions from di gi tal app aratus set out in the Radio Interference Regulations of the Canadian Department of Communications.

Le présent appare il numérique n’émet pas de brui ts radioélect riques dépassant les limites appl icables

aux appareils numérique s (de la clas s A) pres crites dan s le Règl ement sur le b rouillag e radio électriqu e

édicté par le mini stère des Communications du Canada.

Notice: The Industry Canada label identifies certified equipment. This certification means that the

equipment meets certain tel ecommunications network p rotective, operational and safety requirement s.

The Industry Canada does not guarantee the equipment will operate to the user’s satisfaction.

Before installing this equipment, users should ensure that it is permissible to be connected to the facilities of the local teleco mmunications company. The equipment must also be installed using an acceptable method of connection. In some cases, the company’s inside wiring associated with a single lin e

individual service may be extend ed by means of a certified connector assemb ly (telephone extension

cord). The customer should be aware that co mpliance with the above conditions may not p r event degradation of service in some situations.

Repairs to certified equipment should be made by an authorized Canadian maintenance facility designated by the supplier. Any repairs or alterations made by the user to this equipment, or equipment malfunctions, may give the telecommunications company cause to request the user to disconnect the

equipment.

Users should ensure for their own protection that the electrical ground connections of the power utility,

telephone lines and internal metallic water pipe system, if present, are connected together. This precaution may be particularly important in rural areas.

Caution: Users should not attempt to make such connections themselves, but should contact the appropriate electric inspection authority, or electrician, as appropriate.

TXPORT warrants each unit against d efects in material and work manship for a period of five years

from the date the unit was shipped to the customer. If the unit malfunctions at any time during the warranty period, TX PORT will repair, or at TXPORT’s option, replace the unit free of charge.

The remedies listed herein are the users sole and exclusive remedies. TXPORT shall not be liable for

any indirect, direct, incidental or consequential damages. The owner must return the unit to the factory,

shipping prepaid and pa ckaged to the best commercial standard fo r electronic equipment. TXPORT

will pay shipping charges for delivery on return. The customer is responsible for mode and cost of

shipment to TXPORT. This warranty does not apply if the unit has been damaged by accident, misuse

or as a result of service o r modification by other than TXP O RT personnel.

Hardware

Warranty

TXPORT warrants its hardware products to be free from defects in workmanship and materials, under

normal use and service, for five years from the date of purchase from TXPORT or its Authorized

Reseller:

If a product does not operate as warranted above during the applicable warranty perio d, TXPORT shall,

at its option and expens e, repair the defe ctive product or part, d eliver to Customer an equivalent product or part to replace the defective item, or refund to Customer the purchase price paid for the defective

product. All products that are replaced will become th e property of TXPORT. Replacement product s

may be new or reconditioned. Any replaced or repaired prod uct or part has a n inety (90) d ay warranty

or the remainder of the initial warranty period, whichever is longer.

TXPORT shall not be responsible for any software, firmware, information, or memory data of Customer contained in, stored on, or integrated with any products returned to TXPORT for repair, whether

under warranty or not.

Page 5

Software Warranty

v

Software

War ran ty

Standard

Warranty

Service

Warranties

Exclusive

TXPORT warrants that the software programs licensed from it will perform in substantial conformance

to the program specifications therefor for a period of ninety (90) days from the date of purchase from

TXPORT or its Authorized Reseller. TXPORT warrants the media containing software against failure

during the warran ty period. No updates a re provided. TXPORT's sole obligatio n with respect to this

express warranty shall be ( at TXPORT's discretion) to r efund the purchase p rice pa id by Customer for

any defective software products, or to replace any defective media with software which substantially

conforms to TXPORT's applicable published specifications. Customer assumes responsibility for the

selection of the appr opriate applicat ions program and a ssociated reference materials. TXPORT makes

no warranty or representation that its software products will work in combination with any hardware or

applications software products provided by third parties, that the operation of the software products

will be uninterrupted or error free, or that all defects in the software products will be corrected. For any

third party products listed in the TXPORT software product documentation or specifications as being

compatible, TXPORT will make reasonable efforts to provide compatibility, except where the

non-compatibility is caused by a bug or defect in the third party's product.

Standard warranty ser vice for hardwa re products may be obtained by delivering the d efective product,

accompanied by a copy of the dated proof of purchase, to TXPORT's Corporate Service Center or to an

Authorized TXPORT Service Center during the applicable warranty period. Standard warranty service

for software products may be obtained by telephoning TXPORT's Corporate Service Center or an

Authorized TXPORT Service Center, within the warranty period. Products returned to TXPORT's Corporate Service Center must be pre-authorized by TXPORT with a Return Material Authorization

(RMA) number marked on the outside of the package, and sent pre paid, insured, and packag ed appropriately for safe shipment. The repaired or replaced item will be shipped to Customer, at TXPORT's

expense, not later than thirty (30 ) day s after recei pt of the de fective product by TXPORT.

If a TXPORT product does not operate as warranted above, customer’s sole remedy for breach of that

warranty shall be repair, replacement, or refund of the purchase price paid, at TXPORT’s option. To the

full extent allowed by law, the foregoing warranties and remedies are exclusive and are in lieu of all

other warranties, ter ms, or conditions, express or i mplied, either in fact or by operation of law, statutory

or otherwise, including warranties, terms, or conditions of merchantability, fitness for a particular purpose, and satisfactor y qual ity. TXPORT neither assumes nor authori zes any othe r pers on to assume for

it any other liability in connection with the sale, installation, maintenance or use of its products.

TXPORT shall not be liable under this warranty if its testing and examination disclose that the alleged

defect in the product d oes not exist or was caused by customer’s or any third person’s misuse, neglect,

improper install ation or testing , unauthorized attempts to r epair or modify, or any other ca use beyond

the range of the intended use, or by accident, fire, lightning, or other hazard.

Limitation

of Liability

Governing

Law

To the full extent allowed by law TXPORT also excludes for itself and its suppliers any liability,

whether based in contra ct or tort (includi ng n egligence), for in ciden tal , conse qu ential, indi rect, sp ecial,

or punitive damages of any kind, o r for loss of revenue or profits, loss of busi ness, loss of i nformation

or data, or other financial loss arising out of or in connection with the sale, installation, maintenance,

use, performance, failure, or interruption of its products, even if TXPORT or its authorized reseller has

been advised of the possibility of such damages, and limits its liability to repair, replacement, or refund

of the purchase price paid, at TXPORT’s option. this disclaimer of liability for damages will not be

affected if any remedy pro vi ded here in shall fail of its essential purpo se.

Some countries, states, or provinces do not allow the exclusion or limitation of implied warranties or

the limitation of incidental or consequential dama ges for certain prod ucts supplied to consumers, so the

above limitations and exclusions may be limited in their application to you. This warranty gives you

specific legal rights which may vary depending on local law.

This Limited Warranty shall be governed by the laws of the state of Alabama.

TXPORT,Inc.

, 127 Jetplex Circle, Madison, AL 35758 ( 256) 772-3770

Page 6

vi

Page 7

Table of Contents

Copyright. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Documentation Disclaimer . . . . . . . . . . . . . . . . . . . . . ii

Trademarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Acknowledgment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

FCC Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

Canadian Emissions Requirements . . . . . . . . . . . . . . . iv

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Hardware Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Software Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . .v

Standard Warranty Service . . . . . . . . . . . . . . . . . . . . . .v

Warranties Exclusive. . . . . . . . . . . . . . . . . . . . . . . . . . .v

Limitation of Liability. . . . . . . . . . . . . . . . . . . . . . . . . .v

Governing Law . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .v

1 General

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Principles and Concepts. . . . . . . . . . . . . . . . . . . . . . . . .2

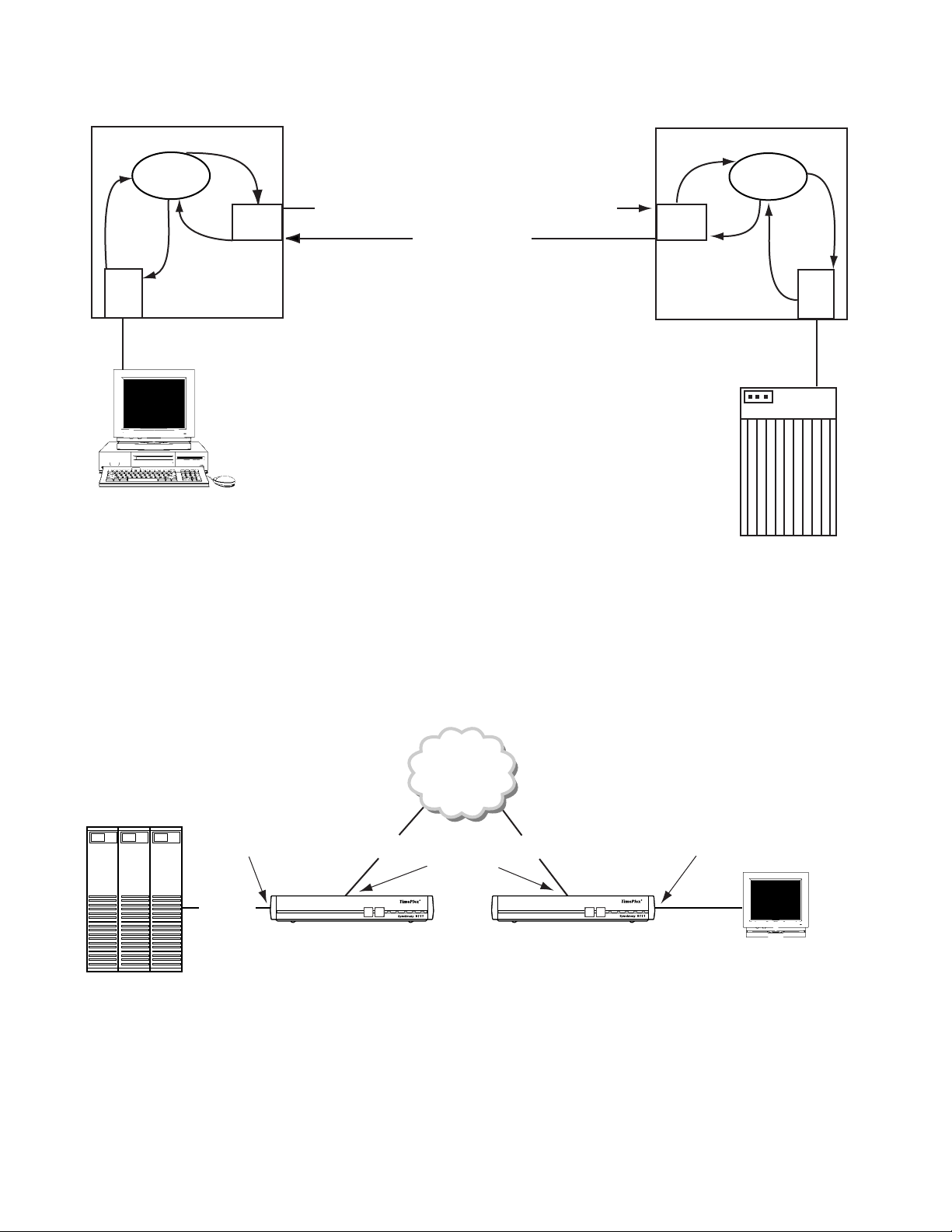

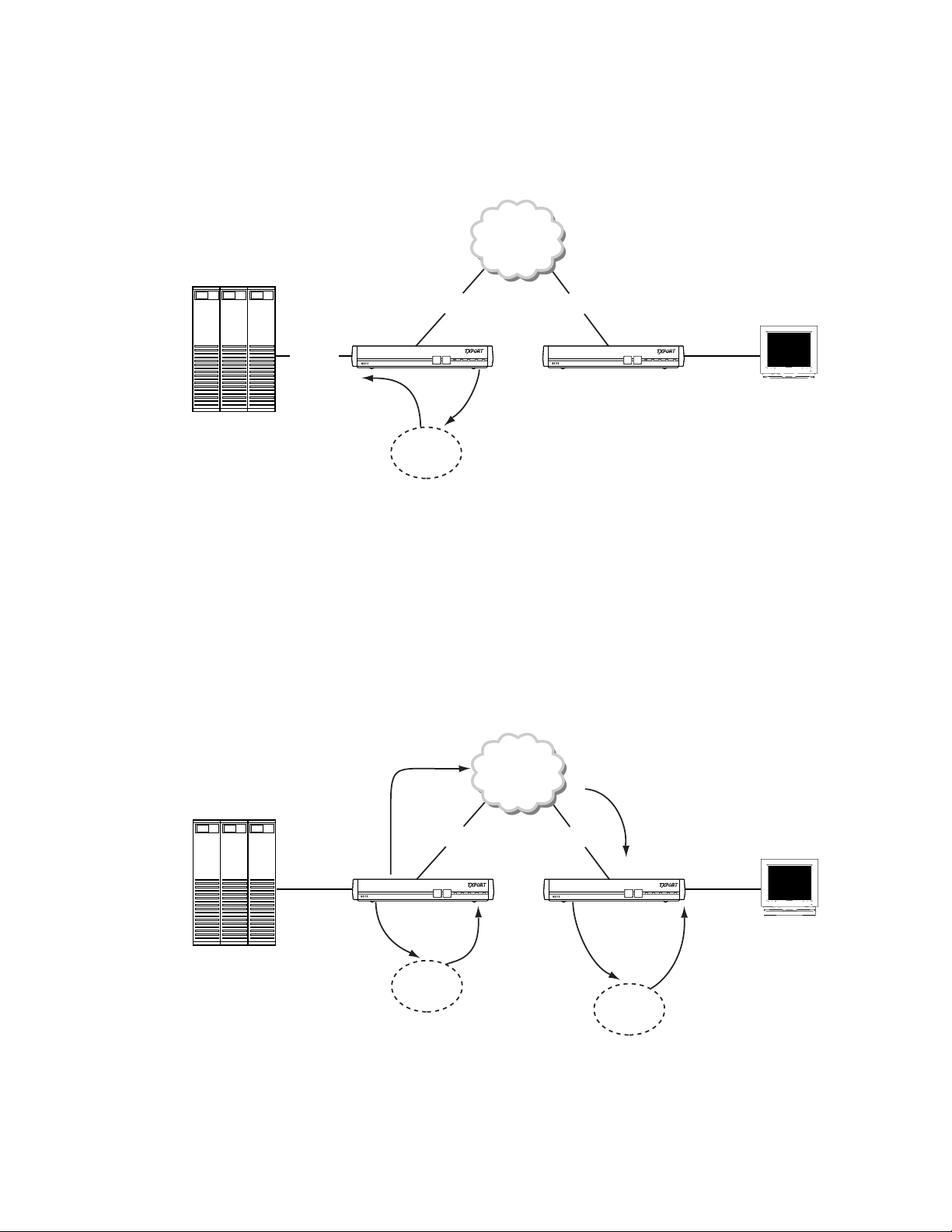

Message Delivery System . . . . . . . . . . . . . . . . . . .2

Endpoint-to- Endpoint Connectivity

and Station Level Routing . . . . . . . . . . . . . . . . . . .2

Data Integrity . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

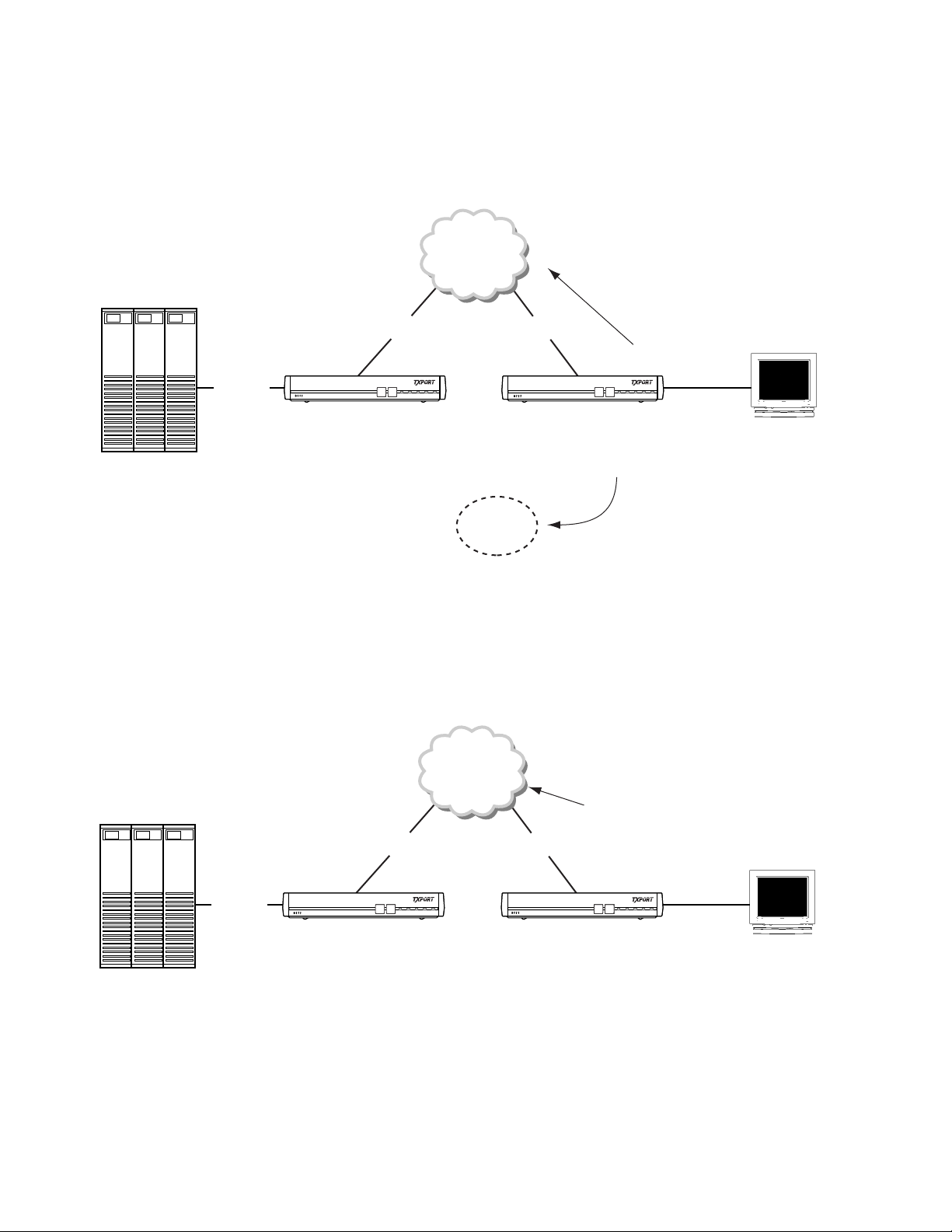

Establishing a Connection . . . . . . . . . . . . . . . . . . .3

A Connection Example. . . . . . . . . . . . . . . . . . . . . .4

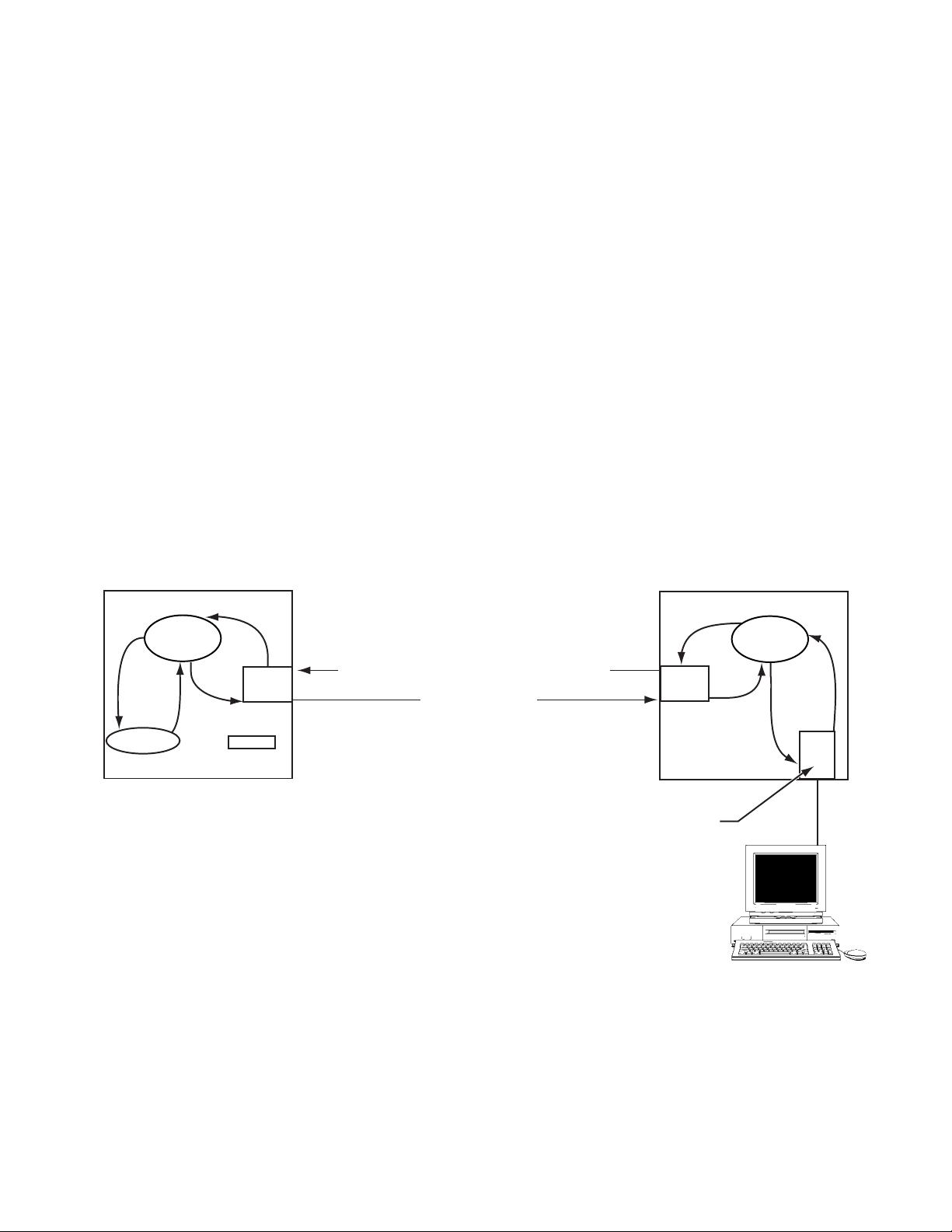

Connecting for Network Management. . . . . . . . . .7

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Serial Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . .8

9111 Port 1 DDS Option . . . . . . . . . . . . . . . . . . . .9

Network Interface . . . . . . . . . . . . . . . . . .9

Industry Standards. . . . . . . . . . . . . . . . . .9

9111 T1 Port 1 Option . . . . . . . . . . . . . . . . . . . . . .9

Network Interface . . . . . . . . . . . . . . . . . .9

Industry Standards. . . . . . . . . . . . . . . . .10

LAN Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Protocols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Management. . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Ordering Numbers. . . . . . . . . . . . . . . . . . . . . . . . . . . .12

TXPORT Customer Service . . . . . . . . . . . . . . . . . . . .16

Support from Your Network Supplier. . . . . . . . . . . . .16

Support from TXPORT. . . . . . . . . . . . . . . . . . . . . . . .16

Telephone. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

E-mail. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

World Wide Web . . . . . . . . . . . . . . . . . . . . . . . . .16

Returning Products . . . . . . . . . . . . . . . . . . . . . . . . . . .17

2Installation

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Safety Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Unpacking and Inspection. . . . . . . . . . . . . . . . . . . . . . 19

Supplied Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

9101 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

AC Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

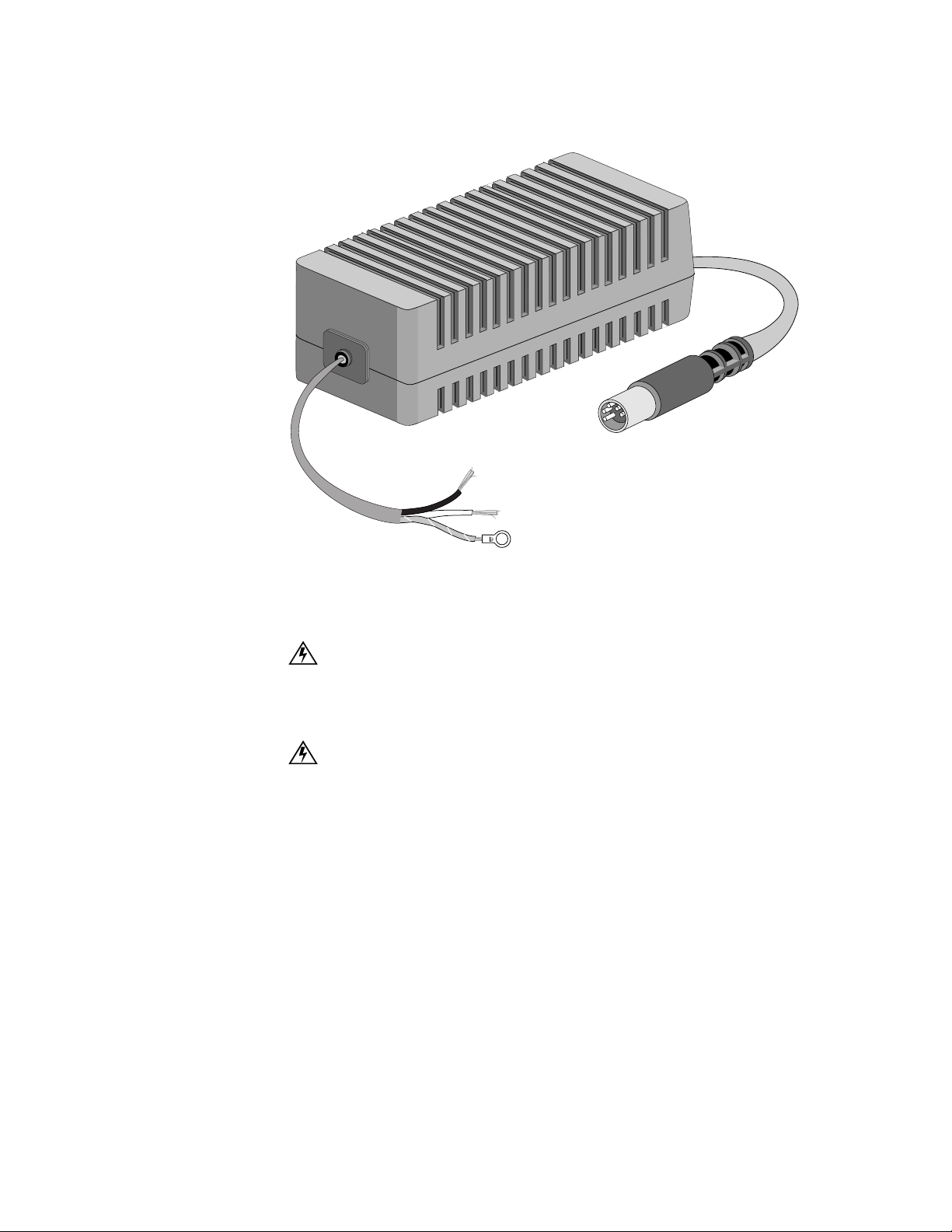

DC Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Connecting the DC Power Supply . . . . . . . . 21

Disconnecting the DC Power Supply. . . . . .22

Supervisory Port . . . . . . . . . . . . . . . . . . . . . . . . .22

Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 2

Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Port 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Port 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

9111 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 4

Supervisory Port . . . . . . . . . . . . . . . . . . . . . . . . .24

Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 4

Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . .24

9111 Port 1 T1 Option. . . . . . . . . . . . . . . . . . . . .25

Switch S1.. . . . . . . . . . . . . . . . . . . . . . . . . . .25

T1 Connection . . . . . . . . . . . . . . . . . . . . . . . 26

9111 Port 1 T1 Option Testing . . . . . . . . . . . . . .27

CSU Line Loop. . . . . . . . . . . . . . . . . . . . . . . 27

9111 Port 1 DDS Option . . . . . . . . . . . . . . . . . . . 27

Switch SW1 . . . . . . . . . . . . . . . . . . . . . . . . .27

DDS Network Connection . . . . . . . . . . . . . .27

9111 Port 1 DDS Option Testing. . . . . . . . . . . . .28

Remote Channel Loop . . . . . . . . . . . . . . . . . 28

Port 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Changing the Interface on Port 2 . . . . . . . . . 29

Port 3 and Port 4 . . . . . . . . . . . . . . . . . . . . . . . . . 30

9111 Dual RS-232 Expansion Option Module . .30

Port 5 and Port 6 Pinouts . . . . . . . . . . . . . . .31

9211 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 2

Supervisory Port . . . . . . . . . . . . . . . . . . . . . . . . .32

Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

UTP Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

AUI Port . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Ports 1, 2, 3, and 4. . . . . . . . . . . . . . . . . . . . . . . . 33

9000 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 4

Console Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

AUI Port . . . . . . . . . . . . . . . . . . . . . . . . . . .34

UTP Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Ports 1, 2, 3, and 4. . . . . . . . . . . . . . . . . . . . . . . . 35

Page 8

viii

3 Hardware Operation

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

9101, 9111, and 9211 Front Panel Operation . . . . . .37

Configuration Mode. . . . . . . . . . . . . . . . . . . . . . .37

Download Mode. . . . . . . . . . . . . . . . . . . . . . . . . .38

9000 Front Panel Operation . . . . . . . . . . . . . . . . . . . .38

Run/Config Switch . . . . . . . . . . . . . . . . . . . . . . .38

Port Select Switch . . . . . . . . . . . . . . . . . . . . . . . .38

Reset Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Signal Indicators . . . . . . . . . . . . . . . . . . . . . . . . .38

System Indicators. . . . . . . . . . . . . . . . . . . . . . . . .39

LAN Indicators . . . . . . . . . . . . . . . . . . . . . . . . . .39

Download Mode. . . . . . . . . . . . . . . . . . . . . . . . . .40

Configuration Mode. . . . . . . . . . . . . . . . . . . . . . .40

4NMCS

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Installing NMCS . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Starting NMCS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Connecting the PC to the MultiPro Unit . . . . . . . . . . .41

Configuration/Operation. . . . . . . . . . . . . . . . . . . . . . .42

Navigating the Basic NMCS Screens . . . . . . . . .42

Main Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Change Configuration Number. . . . . . . . . . .43

Configuration Name . . . . . . . . . . . . . . . . . . .43

Copy Configuration From/To . . . . . . . . . . .43

Create Configuration. . . . . . . . . . . . . . . . . . .44

Delete Configuration. . . . . . . . . . . . . . . . . . .44

Create Down Load File. . . . . . . . . . . . . . . . .44

Down Load Configuration . . . . . . . . . . . . . .44

LM Start and Stop . . . . . . . . . . . . . . . . .44

As Unit. . . . . . . . . . . . . . . . . . . . . . . . . .44

Reset?. . . . . . . . . . . . . . . . . . . . . . . . . . .44

Reset Unit . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Print Configuration. . . . . . . . . . . . . . . . . . . .45

Upgrade Software (Shift+F10) . . . . . . . . . . .46

Configuration Number. . . . . . . . . . . . . .46

Configuration Name . . . . . . . . . . . . . . .46

Line Module. . . . . . . . . . . . . . . . . . . . . .46

Upgrade File Name . . . . . . . . . . . . . . . .46

Cancel Software Upgrade . . . . . . . . . . .46

Get Software version. . . . . . . . . . . . . . .46

Function Keys for Upgrade Software. . . . . .46

ESC=Main. . . . . . . . . . . . . . . . . . . . . . .46

F1=Help . . . . . . . . . . . . . . . . . . . . . . . .46

F10=Send . . . . . . . . . . . . . . . . . . . . . . .46

Function Keys for Main Menu . . . . . . . . . . .47

ESC=Quit . . . . . . . . . . . . . . . . . . . . . . .47

F1=Help . . . . . . . . . . . . . . . . . . . . . . . .47

F2=Status . . . . . . . . . . . . . . . . . . . . . . .47

F3=DLM. . . . . . . . . . . . . . . . . . . . . . . .47

F4=Stats . . . . . . . . . . . . . . . . . . . . . . . .47

F6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

F7=AlmMod . . . . . . . . . . . . . . . . . . . . .47

F8=Xref . . . . . . . . . . . . . . . . . . . . . . . . 47

F10=Next . . . . . . . . . . . . . . . . . . . . . . . 47

SHIFT+F6 . . . . . . . . . . . . . . . . . . . . . . 47

System Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Foreground. . . . . . . . . . . . . . . . . . . . . . . . . . 47

Background . . . . . . . . . . . . . . . . . . . . . . . . . 47

Memory Use . . . . . . . . . . . . . . . . . . . . . . . . . 48

Prog Key (Key Redefinition). . . . . . . . . . . . 48

F2=Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Configuration Number. . . . . . . . . . . . . . . . . 49

Configuration Name. . . . . . . . . . . . . . . . . . . 49

Status Type. . . . . . . . . . . . . . . . . . . . . . . . . . 49

WAN Status . . . . . . . . . . . . . . . . . . . . . 49

LAN Status . . . . . . . . . . . . . . . . . . . . . . 50

Line Module. . . . . . . . . . . . . . . . . . . . . . . . . 50

Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Station Name . . . . . . . . . . . . . . . . . . . . . . . . 51

Address. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

SNA PU . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

SNA LU . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Function Keys . . . . . . . . . . . . . . . . . . . . . . . 51

ESC=MAIN . . . . . . . . . . . . . . . . . . . . . 51

F1=Help . . . . . . . . . . . . . . . . . . . . . . . . 51

F10=Send . . . . . . . . . . . . . . . . . . . . . . . 51

F3=DLM (Data Line Monitor Menu). . . . . . . . . 52

Configuration Number. . . . . . . . . . . . . . . . . 52

Configuration Name. . . . . . . . . . . . . . . . . . . 52

Line Module. . . . . . . . . . . . . . . . . . . . . . . . . 52

Log To . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

View Log File . . . . . . . . . . . . . . . . . . . . . . . 53

Display LCN/SNA Address. . . . . . . . . . . . . 53

Delete Log File. . . . . . . . . . . . . . . . . . . . . . . 53

Send END MONITOR Request. . . . . . . . . . 53

Condensed Mode . . . . . . . . . . . . . . . . . . . . . 53

Function Keys . . . . . . . . . . . . . . . . . . . . . . . 53

ESC=MAIN . . . . . . . . . . . . . . . . . . . . . 53

F1=Help . . . . . . . . . . . . . . . . . . . . . . . . 53

F10=Send . . . . . . . . . . . . . . . . . . . . . . . 53

F4=Statistics . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Configuration Number. . . . . . . . . . . . . . . . . 54

Configuration Name. . . . . . . . . . . . . . . . . . . 54

Statistic Type . . . . . . . . . . . . . . . . . . . . . . . . 54

WAN Statistics . . . . . . . . . . . . . . . . . . . 54

LAN Statistics. . . . . . . . . . . . . . . . . . . . 55

Line Module. . . . . . . . . . . . . . . . . . . . . . . . . 55

Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Station Name . . . . . . . . . . . . . . . . . . . . . . . . 55

Function Keys . . . . . . . . . . . . . . . . . . . . . . . 55

ESC=MAIN . . . . . . . . . . . . . . . . . . . . . 55

F1=Help . . . . . . . . . . . . . . . . . . . . . . . . 55

F10=Send . . . . . . . . . . . . . . . . . . . . . . . 56

F8=Xref (Configuration Modification). . . . . . . . 57

Configuration Number. . . . . . . . . . . . . . . . . 57

Description. . . . . . . . . . . . . . . . . . . . . . . . . . 57

Page 9

Last Modified . . . . . . . . . . . . . . . . . . . . . . . .57

Last Download . . . . . . . . . . . . . . . . . . . . . . .57

F/W . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

F10=Next (Port List) . . . . . . . . . . . . . . . . . . . . . .58

Global . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Line Module 1. . . . . . . . . . . . . . . . . . . . . . . .58

Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Port 1-4 Parameters. . . . . . . . . . . . . . . . . . . .58

Port 1-4 Address Table. . . . . . . . . . . . . . . . .58

Port D Parameters . . . . . . . . . . . . . . . . . . . . .58

Port D Address Table . . . . . . . . . . . . . . . . . .59

Port L Parameters . . . . . . . . . . . . . . . . . . . . .59

Port L Address Table. . . . . . . . . . . . . . . . . . .59

Internetwork Applications. . . . . . . . . . . . . . .59

Global Parameters . . . . . . . . . . . . . . . . . . . . . . . .60

Configuration Title . . . . . . . . . . . . . . . . . . . .60

Down Load Station Address . . . . . . . . . . . . .60

Com Port Speed. . . . . . . . . . . . . . . . . . . . . . .60

TXPORT Model . . . . . . . . . . . . . . . . . . . . . .60

Number of Ports on Unit. . . . . . . . . . . . . . . .61

Firmware Version . . . . . . . . . . . . . . . . . . . . .61

Network Unit Number. . . . . . . . . . . . . . . . . .61

Power Supply Serial Number . . . . . . . . . . . .61

Chassis Serial Number . . . . . . . . . . . . . . . . .61

Console Password . . . . . . . . . . . . . . . . . . . . .61

COM Port . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Function Keys . . . . . . . . . . . . . . . . . . . . . . . .61

ESC=Main Menu. . . . . . . . . . . . . . . . . .61

F1=Help. . . . . . . . . . . . . . . . . . . . . . . . .61

F5=Clear . . . . . . . . . . . . . . . . . . . . . . . .61

F7=Redisplay. . . . . . . . . . . . . . . . . . . . .61

F8=Jump . . . . . . . . . . . . . . . . . . . . . . . .61

F9=Previous. . . . . . . . . . . . . . . . . . . . . .61

F10=Next. . . . . . . . . . . . . . . . . . . . . . . .61

Line Module Parameters. . . . . . . . . . . . . . . . . . . .62

Line Module . . . . . . . . . . . . . . . . . . . . . . . . .62

Copy Line Module Parameters

from Configuration . . . . . . . . . . . . . . . . . . . .62

Serial number . . . . . . . . . . . . . . . . . . . . . . . .62

Network Host . . . . . . . . . . . . . . . . . . . . . . . .62

Connect Timeout. . . . . . . . . . . . . . . . . . . . . .62

Task-to-Task Timeout. . . . . . . . . . . . . . . . . .63

Task to Terminal/Host Timeout . . . . . . . . . .63

Connect Command . . . . . . . . . . . . . . . . . . . .63

Disconnect Command. . . . . . . . . . . . . . . . . .63

Send Command. . . . . . . . . . . . . . . . . . . . . . .63

Reserve Command . . . . . . . . . . . . . . . . . . . .63

Disconnect Message . . . . . . . . . . . . . . . . . . .63

Port Type. . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Line Module Type . . . . . . . . . . . . . . . . . . . . .64

Firmware Version . . . . . . . . . . . . . . . . . . . . .64

Function Keys . . . . . . . . . . . . . . . . . . . . . . . .64

ESC=Main Menu. . . . . . . . . . . . . . . . . .64

F1=Help. . . . . . . . . . . . . . . . . . . . . . . . .64

F5=Clear . . . . . . . . . . . . . . . . . . . . . . . .64

F7=Redisplay . . . . . . . . . . . . . . . . . . . . 64

F8=Jump. . . . . . . . . . . . . . . . . . . . . . . . 64

F9=Previous . . . . . . . . . . . . . . . . . . . . .65

F10=Next . . . . . . . . . . . . . . . . . . . . . . .65

Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Line Module . . . . . . . . . . . . . . . . . . . . . . . . .6 5

Greeting Message. . . . . . . . . . . . . . . . . . . . . 65

Connected. . . . . . . . . . . . . . . . . . . . . . . . . . .66

Message Lost . . . . . . . . . . . . . . . . . . . . . . . .66

Host Offline . . . . . . . . . . . . . . . . . . . . . . . . .66

Disconnect Message. . . . . . . . . . . . . . . . . . . 66

Message from Host. . . . . . . . . . . . . . . . . . . .66

Send Confirmed . . . . . . . . . . . . . . . . . . . . . .66

Send Refused . . . . . . . . . . . . . . . . . . . . . . . .66

Function Keys. . . . . . . . . . . . . . . . . . . . . . . .66

ESC=Main Menu . . . . . . . . . . . . . . . . .66

F1=Help . . . . . . . . . . . . . . . . . . . . . . . .66

F5=Clear. . . . . . . . . . . . . . . . . . . . . . . . 66

F7=Redisplay . . . . . . . . . . . . . . . . . . . . 66

F8=Jump. . . . . . . . . . . . . . . . . . . . . . . . 66

F9=Previous . . . . . . . . . . . . . . . . . . . . .67

F10=Next . . . . . . . . . . . . . . . . . . . . . . .67

Port 1-4 Parameters. . . . . . . . . . . . . . . . . . . . . . . 67

Port 1-4 Address Table . . . . . . . . . . . . . . . . . . . .67

Port D Parameters . . . . . . . . . . . . . . . . . . . . . . . .68

Line Module . . . . . . . . . . . . . . . . . . . . . . . . .6 8

Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 8

Description . . . . . . . . . . . . . . . . . . . . . . . . . .68

Copy Port Parameters. . . . . . . . . . . . . . . . . .6 8

Configuration. . . . . . . . . . . . . . . . . . . . . 68

Line Module . . . . . . . . . . . . . . . . . . . . . 68

Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Baud Rate . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Bits Per Character. . . . . . . . . . . . . . . . . . . . .69

Termination . . . . . . . . . . . . . . . . . . . . . . . . .69

RTS/CTS Control. . . . . . . . . . . . . . . . . . . . .69

Parity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Full Duplex. . . . . . . . . . . . . . . . . . . . . . . . . . 69

Flow Control. . . . . . . . . . . . . . . . . . . . . . . . . 70

Function Keys. . . . . . . . . . . . . . . . . . . . . . . .70

ESC=Main Menu . . . . . . . . . . . . . . . . .70

F1=Help . . . . . . . . . . . . . . . . . . . . . . . .70

F5=Clear. . . . . . . . . . . . . . . . . . . . . . . . 70

F7=Redisplay . . . . . . . . . . . . . . . . . . . . 70

F8=Jump. . . . . . . . . . . . . . . . . . . . . . . . 70

F9=Previous . . . . . . . . . . . . . . . . . . . . .70

F10=Next . . . . . . . . . . . . . . . . . . . . . . .70

Port L Parameters (Ethernet). . . . . . . . . . . . . . . .71

Line Module . . . . . . . . . . . . . . . . . . . . . . . . .7 1

Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 1

Description . . . . . . . . . . . . . . . . . . . . . . . . . .71

Copy Port Parameters. . . . . . . . . . . . . . . . . .7 1

Configuration. . . . . . . . . . . . . . . . . . . . . 71

Line Module . . . . . . . . . . . . . . . . . . . . . 71

Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Page 10

x

LAN Speed . . . . . . . . . . . . . . . . . . . . . . . . . .72

Physical Port selection . . . . . . . . . . . . . . . . .72

Link Test Enabled. . . . . . . . . . . . . . . . . . . . .72

Squelch Threshold . . . . . . . . . . . . . . . . . . . .72

Function Keys. . . . . . . . . . . . . . . . . . . . . . . . 72

ESC=Main Menu . . . . . . . . . . . . . . . . .72

F1=Help . . . . . . . . . . . . . . . . . . . . . . . .72

F5=Clear . . . . . . . . . . . . . . . . . . . . . . . .72

F7=Redisplay . . . . . . . . . . . . . . . . . . . .72

F8=Jump . . . . . . . . . . . . . . . . . . . . . . . .72

F9=Previous . . . . . . . . . . . . . . . . . . . . .72

F10=Next . . . . . . . . . . . . . . . . . . . . . . .72

Internetworking Applications . . . . . . . . . . . . . . .73

Line Module . . . . . . . . . . . . . . . . . . . . . . . . .73

Application . . . . . . . . . . . . . . . . . . . . . . . . . .73

Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Modify . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Function Keys. . . . . . . . . . . . . . . . . . . . . . . . 73

ESC=Main Menu . . . . . . . . . . . . . . . . .73

F1=Help . . . . . . . . . . . . . . . . . . . . . . . .73

F5=Clear . . . . . . . . . . . . . . . . . . . . . . . .73

F7=Redisplay . . . . . . . . . . . . . . . . . . . .73

F8=Jump . . . . . . . . . . . . . . . . . . . . . . . .74

F9=Previous . . . . . . . . . . . . . . . . . . . . .74

F10=Next . . . . . . . . . . . . . . . . . . . . . . .74

Downloading Firmware for the MultiPro Unit . . . . . .74

Establishing NMCS Connections. . . . . . . . . . . . .75

Using NMCS to Download Firmware . . . . . . . . .76

Required Equipment for Downloading . . . . . . . .77

Software Requirements. . . . . . . . . . . . . . . . .77

Hardware Requirements . . . . . . . . . . . . . . . .77

9101-, 9111-, and 9211-Specific Core

Download Procedure . . . . . . . . . . . . . . . . . . . . . .77

9101-, 9111-, and 9211-Specific Task

Download Procedure . . . . . . . . . . . . . . . . . . . . . .78

Creating A Unit Configuration File . . . . . . .78

Downloading the Specific Task Software . . 79

9000-Specific Core Download Procedure . . . . . .79

9000-Specific Task Download Procedure . . . . . .80

Creating A Unit Configuration File . . . . . . .80

Downloading the Specific Task Software . . 81

Displaying Software Versions . . . . . . . . . . . . . . .82

5 Unisys Poll/Select

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Poll/Select Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Configuration/Operation. . . . . . . . . . . . . . . . . . . . . . .87

Unisys Poll /S elect Terminal . . . . . . . . . . . . . . . .87

Line Module . . . . . . . . . . . . . . . . . . . . . . . . .87

Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

Description . . . . . . . . . . . . . . . . . . . . . . . . . .87

Copy Port Parameters . . . . . . . . . . . . . . . . . .87

Configuration. . . . . . . . . . . . . . . . . . . . .87

Module. . . . . . . . . . . . . . . . . . . . . . . . . .88

Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

Baud Rate. . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Bits per Character. . . . . . . . . . . . . . . . . . . . . 88

Parity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Message Buffer . . . . . . . . . . . . . . . . . . . . . . 88

Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Algorithm. . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Termination . . . . . . . . . . . . . . . . . . . . . . . . . 88

Contention Frequency . . . . . . . . . . . . . . . . . 89

Trailing Pad Characters . . . . . . . . . . . . . . . . 89

Turnaround Delay . . . . . . . . . . . . . . . . . . . . 89

Consecutive Contention Poll . . . . . . . . . . . . 89

RTS/CTS Control . . . . . . . . . . . . . . . . . . . . 89

Timeouts to Mark Offline . . . . . . . . . . . . . . 89

Drop DTR If DCD Drops. . . . . . . . . . . . . . . 90

Offline Delay Retry . . . . . . . . . . . . . . . . . . . 90

Message Timeout. . . . . . . . . . . . . . . . . . . . . 90

Maximum Select Before Poll. . . . . . . . . . . . 90

Active If DSR/DCD. . . . . . . . . . . . . . . . . . . 90

Select Retry Delay . . . . . . . . . . . . . . . . . . . . 91

Poll And Select Timeout . . . . . . . . . . . . . . . 91

Downline Controller. . . . . . . . . . . . . . . . . . . 91

Activity Timer . . . . . . . . . . . . . . . . . . . . . . . 91

Unisys Poll/Select Terminal Addresses . . . . . . . 92

Line Module. . . . . . . . . . . . . . . . . . . . . . . . . 92

Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Description. . . . . . . . . . . . . . . . . . . . . . . . . . 92

Copy Stations. . . . . . . . . . . . . . . . . . . . . . . . 92

Configuration . . . . . . . . . . . . . . . . . . . . 92

Module . . . . . . . . . . . . . . . . . . . . . . . . . 92

Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Terminal Address. . . . . . . . . . . . . . . . . . . . . 93

Connecting Address. . . . . . . . . . . . . . . . . . . 93

Station Name . . . . . . . . . . . . . . . . . . . . . . . . 93

Default Host. . . . . . . . . . . . . . . . . . . . . . . . . 93

Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

A - Auto Connect On Power Up. . . . . . 93

B - Don’t Send Status Message. . . . . . . 93

C - Reserved Channel. . . . . . . . . . . . . . 93

D - Device Is Sharable . . . . . . . . . . . . . 93

E - Send Carriage Return . . . . . . . . . . . 93

F - Output Only. . . . . . . . . . . . . . . . . . . 93

G - Group Address . . . . . . . . . . . . . . . . 93

H - Keep Message. . . . . . . . . . . . . . . . . 93

I - Wait for Host Connection. . . . . . . . . 94

J - Virtual Address . . . . . . . . . . . . . . . . 94

K - Send CR Only. . . . . . . . . . . . . . . . . 94

L - Spool printer . . . . . . . . . . . . . . . . . . 94

M - Flush input For Unknown Address 94

XN Type (Transmission Number) . . . . . . . . 94

Unisys Poll/Select Host . . . . . . . . . . . . . . . . . . . 95

Line Module. . . . . . . . . . . . . . . . . . . . . . . . . 95

Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Description. . . . . . . . . . . . . . . . . . . . . . . . . . 95

Copy Port Parameters. . . . . . . . . . . . . . . . . . 95

Configuration . . . . . . . . . . . . . . . . . . . . 95

Page 11

Module. . . . . . . . . . . . . . . . . . . . . . . . . .95

Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

Baud Rate . . . . . . . . . . . . . . . . . . . . . . . . . . .96

Bits per Character . . . . . . . . . . . . . . . . . . . . .96

Parity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

Message Buffer . . . . . . . . . . . . . . . . . . . . . . .96

Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

Termination. . . . . . . . . . . . . . . . . . . . . . . . . .96

Trailing Pad Characters. . . . . . . . . . . . . . . . .96

Turnaround Delay . . . . . . . . . . . . . . . . . . . . .97

RTS/CTS Control. . . . . . . . . . . . . . . . . . . . .97

Messages per Group Poll. . . . . . . . . . . . . . . .97

Offline Timeout. . . . . . . . . . . . . . . . . . . . . . .97

Upline Controller. . . . . . . . . . . . . . . . . . . . . .98

Host Name. . . . . . . . . . . . . . . . . . . . . . . . . . .98

Backup Host Name . . . . . . . . . . . . . . . . . . . .98

Unisys Poll/ Select Host Addresses . . . . . . . . . . .98

Line Module . . . . . . . . . . . . . . . . . . . . . . . . .98

Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

Description . . . . . . . . . . . . . . . . . . . . . . . . . .99

Host Address. . . . . . . . . . . . . . . . . . . . . . . . .99

Group Address. . . . . . . . . . . . . . . . . . . . . . . .99

Auto Connect Station Name . . . . . . . . . . . . .99

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

A - Timeout For Offline Device . . . . . . 99

B - Flush Data For Offline Device. . . . .99

C - Auto Connect On Select. . . . . . . . . .99

D - Group Address. . . . . . . . . . . . . . . . .99

E - Virtual Address . . . . . . . . . . . . . . .100

F - Auto Connect On Link Active . . . .100

G - Send Disconnect Message . . . . . . .100

H - Shared Device Timeout . . . . . . . . .100

I - 15 Minute Connect Retry . . . . . . . .100

XN Type (Transmission Number). . . . . . . .100

6 Asynchronous Host and

Terminal Protocol Parameter s

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

Asynchronous Host and Terminal Port Parameters. .101

Asynchronous Terminal Parameters . . . . . . . . . . . . .102

Line Module . . . . . . . . . . . . . . . . . . . . . . . . . . . .102

Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .102

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . .102

Copy Port Parameters. . . . . . . . . . . . . . . . . . . . .102

Configuration . . . . . . . . . . . . . . . . . . . . . . .102

Line Module . . . . . . . . . . . . . . . . . . . . . . . .102

Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

Baud Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

Bits per Character. . . . . . . . . . . . . . . . . . . . . . . .103

Parity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

Message Buffer. . . . . . . . . . . . . . . . . . . . . . . . . .103

Transparent Mode. . . . . . . . . . . . . . . . . . . . . . . .103

Host Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .104

RTS/CTS Control . . . . . . . . . . . . . . . . . . . . . . .104

Terminal Type . . . . . . . . . . . . . . . . . . . . . . . . . .104

Drop DTR If DCD Drops . . . . . . . . . . . . . . . . .104

Device Type. . . . . . . . . . . . . . . . . . . . . . . . . . . .104

Active If DSR/DCD. . . . . . . . . . . . . . . . . . . . . .105

Alternate Port. . . . . . . . . . . . . . . . . . . . . . . . . . .105

Full Duplex . . . . . . . . . . . . . . . . . . . . . . . . . . . .105

User Field Length . . . . . . . . . . . . . . . . . . . . . . . 105

Flow Control . . . . . . . . . . . . . . . . . . . . . . . . . . .105

Suppress Trailing Blanks. . . . . . . . . . . . . . . . . .105

Input Terminator . . . . . . . . . . . . . . . . . . . . . . . . 105

End of User Field. . . . . . . . . . . . . . . . . . . . . . . .106

User Terminator. . . . . . . . . . . . . . . . . . . . . . . . .106

Output Terminator. . . . . . . . . . . . . . . . . . . . . . . 106

Include Terminator . . . . . . . . . . . . . . . . . . . . . .106

Inactivity Timer . . . . . . . . . . . . . . . . . . . . . . . . . 106

Input Terminator Timeout. . . . . . . . . . . . . . . . .106

Control Characters . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Line Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Control Character Mapping. . . . . . . . . . . . . . . . 107

TTY Terminal Addresses . . . . . . . . . . . . . . . . . . . . .108

Line Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Terminal Address. . . . . . . . . . . . . . . . . . . . . . . . 108

Connecting Address. . . . . . . . . . . . . . . . . . . . . .108

Station Name . . . . . . . . . . . . . . . . . . . . . . . . . . .109

Default Host. . . . . . . . . . . . . . . . . . . . . . . . . . . .109

Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Option A - Automatic connection on

power on. . . . . . . . . . . . . . . . . . . . . . . . . . .109

Option B - Don't send status message . . . . 109

Option C - Reserved channel . . . . . . . . . . .109

Option D - Sharable . . . . . . . . . . . . . . . . . . 109

Option E - Send CR on input . . . . . . . . . . .109

Option F - Keep message . . . . . . . . . . . . . . 109

Option G - Spool output. . . . . . . . . . . . . . .110

Option H - Output only. . . . . . . . . . . . . . . .110

XN Type (Transmission Number). . . . . . . . . . .110

Console Port Parameters. . . . . . . . . . . . . . . . . . . . . .111

Line Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

Copy Port Parameters . . . . . . . . . . . . . . . . . . . .111

Configuration . . . . . . . . . . . . . . . . . . . . . . .111

Line Module . . . . . . . . . . . . . . . . . . . . . . . .112

Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .112

Baud Rate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .112

Bits per Character . . . . . . . . . . . . . . . . . . . . . . . 112

Termination . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

RTS/CTS Control . . . . . . . . . . . . . . . . . . . . . . .112

Parity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .112

Full Duplex . . . . . . . . . . . . . . . . . . . . . . . . . . . .112

Flow Control . . . . . . . . . . . . . . . . . . . . . . . . . . .112

Page 12

xii

7 Bisync 2780/3780 and 3270

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

Bisync Principles and Concepts . . . . . . . . . . . . . . . .113

Configuration/Operation. . . . . . . . . . . . . . . . . . . . . .115

Bisync Terminal. . . . . . . . . . . . . . . . . . . . . . . . .115

Line Module . . . . . . . . . . . . . . . . . . . . . . . .115

Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

Description . . . . . . . . . . . . . . . . . . . . . . . . .115

Copy Port Parameters . . . . . . . . . . . . . . . . .115

Configuration. . . . . . . . . . . . . . . . . . . .115

Line Module. . . . . . . . . . . . . . . . . . . . .115

Port. . . . . . . . . . . . . . . . . . . . . . . . . . . .116

Baud Rate . . . . . . . . . . . . . . . . . . . . . . . . . .116

Bits per Character . . . . . . . . . . . . . . . . . . . .116

Parity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

Message Buffer. . . . . . . . . . . . . . . . . . . . . .116

Interface . . . . . . . . . . . . . . . . . . . . . . . . . . .116

Maximum Messages Queued . . . . . . . . . . .116

Termination. . . . . . . . . . . . . . . . . . . . . . . . . 1 17

Timeouts to Mark Offline. . . . . . . . . . . . . .117

Trailing Pad Characters . . . . . . . . . . . . . . .117

Offline Delay Retry . . . . . . . . . . . . . . . . . .117

Turnaround Delay. . . . . . . . . . . . . . . . . . . .117

Maximum Select before Poll . . . . . . . . . . .117

RTS/CTS Control. . . . . . . . . . . . . . . . . . . .117

Select Retry Delay . . . . . . . . . . . . . . . . . . .118

Drop DTR if DCD Drops . . . . . . . . . . . . . . 1 18

Active if DSR/DCD . . . . . . . . . . . . . . . . . .118

Message Timeout . . . . . . . . . . . . . . . . . . . .118

Activity Timer. . . . . . . . . . . . . . . . . . . . . . .118

Poll and Select Timeout . . . . . . . . . . . . . . .119

End-to-End Protocol Conversion . . . . . . . .119

End-to-End Flow Control. . . . . . . . . . . . . .119

Bisync Terminal Station Parameters . . . . . . . . .120

Line Module . . . . . . . . . . . . . . . . . . . . . . . .120

Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120

Copy Stations . . . . . . . . . . . . . . . . . . . . . . .120

Configuration. . . . . . . . . . . . . . . . . . . .120

Module. . . . . . . . . . . . . . . . . . . . . . . . .120

Port. . . . . . . . . . . . . . . . . . . . . . . . . . . .120

CU Address. . . . . . . . . . . . . . . . . . . . . . . . .121

Device Address. . . . . . . . . . . . . . . . . . . . . .121

Connection Address . . . . . . . . . . . . . . . . . .121

Station Name. . . . . . . . . . . . . . . . . . . . . . . .121

Default Host . . . . . . . . . . . . . . . . . . . . . . . .121

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . .121

A. Auto Connect on Power up. . . . . . .121

B. Don't Send Status Message. . . . . . .121

C. Reserved Channel . . . . . . . . . . . . . .121

D. Device is sharable. . . . . . . . . . . . . .121

E. Output Only. . . . . . . . . . . . . . . . . . .122

F. Keep Message . . . . . . . . . . . . . . . . .122

G. Wait for Host Connection. . . . . . . .122

H. Flush Data if Offline. . . . . . . . . . . .122

CU Type. . . . . . . . . . . . . . . . . . . . . . . . . . . 122

0 - RMBCS Switch . . . . . . . . . . . . . . . 122

1 - IBM 3274. . . . . . . . . . . . . . . . . . . . 122

2 - IBM 3275. . . . . . . . . . . . . . . . . . . . 122

3 - IBM 2780. . . . . . . . . . . . . . . . . . . . 122

4 - IBM 3780. . . . . . . . . . . . . . . . . . . . 122

5 - 3270 LAN Gateway. . . . . . . . . . . . 122

Bisync Host Port Parameters. . . . . . . . . . . . . . . 123

Line Module. . . . . . . . . . . . . . . . . . . . . . . . 123

Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Description. . . . . . . . . . . . . . . . . . . . . . . . . 123

Copy Port Parameters. . . . . . . . . . . . . . . . . 123

Configuration . . . . . . . . . . . . . . . . . . . 123

Line Module . . . . . . . . . . . . . . . . . . . . 123

Port . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Baud RATE . . . . . . . . . . . . . . . . . . . . . . . . 124

Bits per Character. . . . . . . . . . . . . . . . . . . . 124

Parity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Message Buffer . . . . . . . . . . . . . . . . . . . . . 124

Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Offline Timeout . . . . . . . . . . . . . . . . . . . . . 124

Termination . . . . . . . . . . . . . . . . . . . . . . . . 124

Trailing Pad Characters . . . . . . . . . . . . . . . 125

Host Response Timeout. . . . . . . . . . . . . . . 125

Turnaround Delay . . . . . . . . . . . . . . . . . . . 125

Maximum Messages Queued. . . . . . . . . . . 125

RTS/CTS Control . . . . . . . . . . . . . . . . . . . 125

Messages per Group Poll . . . . . . . . . . . . . . 126

Host Name . . . . . . . . . . . . . . . . . . . . . . . . . 126

Backup Host Name . . . . . . . . . . . . . . . . . . 126

End-to-End Flow Control. . . . . . . . . . . . . . 126

End-to-End Protocol Conversion. . . . . . . . 126

Bisync Host Station Parameters . . . . . . . . . . . . 127

Line Module. . . . . . . . . . . . . . . . . . . . . . . . 127

Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Copy Stations. . . . . . . . . . . . . . . . . . . . . . . 127

Configuration . . . . . . . . . . . . . . . . . . . 127

Module . . . . . . . . . . . . . . . . . . . . . . . . 127

Port . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

CU Address . . . . . . . . . . . . . . . . . . . . . . . . 128

Device Address . . . . . . . . . . . . . . . . . . . . . 128

Auto Connect Station Name. . . . . . . . . . . . 128

Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

A. Timeout for Offline Device . . . . . . 128

B. Flush Data for Offline Device . . . . 128

C. Auto Connect Upon Select. . . . . . . 128

D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

F. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

G. Auto Connect on Link Active . . . . 128

H.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

I. Flush Output Data for Offline Device128

J. Do Not Send Device Status. . . . . . . 129

CU Type. . . . . . . . . . . . . . . . . . . . . . . . . . . 129

0 - RMBCS Switch . . . . . . . . . . . . . . . 129

Page 13

1 - IBM 3274 . . . . . . . . . . . . . . . . . . . .129

2 - IBM 3275 . . . . . . . . . . . . . . . . . . . .129

5 - 3270 LAN Gateway . . . . . . . . . . . .129

8NCR

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .131

Poll/Select Basics . . . . . . . . . . . . . . . . . . . . . . . . . . .131

Configuration/Operation . . . . . . . . . . . . . . . . . . . . . .133

NCR Terminal . . . . . . . . . . . . . . . . . . . . . . . . . .133

Line Module . . . . . . . . . . . . . . . . . . . . . . . .133

Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .133

Description . . . . . . . . . . . . . . . . . . . . . . . . .133

Copy Port Parameters . . . . . . . . . . . . . . . . .133

Configuration. . . . . . . . . . . . . . . . . . . .133

Module. . . . . . . . . . . . . . . . . . . . . . . . .133

Port. . . . . . . . . . . . . . . . . . . . . . . . . . . .133

Baud Rate . . . . . . . . . . . . . . . . . . . . . . . . . .134

Bits per Character . . . . . . . . . . . . . . . . . . . .134

Parity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .134

Message Buffer . . . . . . . . . . . . . . . . . . . . . .134

Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . .134

Timeouts to Mark Offline . . . . . . . . . . . . . .134

Termination. . . . . . . . . . . . . . . . . . . . . . . . .134

Trailing Pad Characters. . . . . . . . . . . . . . . .135

Offline Delay Retry. . . . . . . . . . . . . . . . . . .135

Turnaround Delay . . . . . . . . . . . . . . . . . . . .135

Maximum Select before Poll. . . . . . . . . . . .135

RTS/CTS Control. . . . . . . . . . . . . . . . . . . .135

Select Retry Delay. . . . . . . . . . . . . . . . . . . .135

Drop DTR If DCD Drops . . . . . . . . . . . . . .136

Message Timeout . . . . . . . . . . . . . . . . . . . .136

Active If DSR/DCD . . . . . . . . . . . . . . . . . .136

Poll and Select Timeout . . . . . . . . . . . . . . .137

Activity Timer. . . . . . . . . . . . . . . . . . . . . . .137

Limited Select Count. . . . . . . . . . . . . . . . . .137

NCR Terminal Addresses. . . . . . . . . . . . . . . . . .138

Line Module . . . . . . . . . . . . . . . . . . . . . . . .138

Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .138

Description . . . . . . . . . . . . . . . . . . . . . . . . .138

Copy Port Parameters . . . . . . . . . . . . . . . . .138

Configuration. . . . . . . . . . . . . . . . . . . .138

Module. . . . . . . . . . . . . . . . . . . . . . . . .138

Port. . . . . . . . . . . . . . . . . . . . . . . . . . . .138

Terminal Address . . . . . . . . . . . . . . . . . . . .139

Connecting Address . . . . . . . . . . . . . . . . . .139

Station Name. . . . . . . . . . . . . . . . . . . . . . . .139

Default Host . . . . . . . . . . . . . . . . . . . . . . . .139

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . .139

A. Auto Connect on Power up. . . . . . .139

B. Don't Send Status Message . . . . . . .139

C. Reserved Channel . . . . . . . . . . . . . .139

D. Device is sharable . . . . . . . . . . . . . .139

E. Non-SMF. . . . . . . . . . . . . . . . . . . . .139

F. Non-NCR. . . . . . . . . . . . . . . . . . . . .139

G. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .140

H. Keep Message. . . . . . . . . . . . . . . . .140

I. Wait for Host Connection . . . . . . . . 140

J. Limited select. . . . . . . . . . . . . . . . . .140

K. No Retransmission . . . . . . . . . . . . .140

L. Spool Option. . . . . . . . . . . . . . . . . .140

M. Wait for EOT. . . . . . . . . . . . . . . . .140

Poll Code . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Device Type . . . . . . . . . . . . . . . . . . . . . . . . 141

NCR Host. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .142

Line Module . . . . . . . . . . . . . . . . . . . . . . . .142

Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .142

Description . . . . . . . . . . . . . . . . . . . . . . . . .142

Copy Port Parameters. . . . . . . . . . . . . . . . .142

Configuration. . . . . . . . . . . . . . . . . . . . 142

Module. . . . . . . . . . . . . . . . . . . . . . . . . 142

Port . . . . . . . . . . . . . . . . . . . . . . . . . . .142

Baud Rate . . . . . . . . . . . . . . . . . . . . . . . . . .143

Bits per Character. . . . . . . . . . . . . . . . . . . .143

Parity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Message Buffer. . . . . . . . . . . . . . . . . . . . . .143

Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Termination . . . . . . . . . . . . . . . . . . . . . . . .143

Trailing Pad Characters . . . . . . . . . . . . . . .143

Turnaround Delay. . . . . . . . . . . . . . . . . . . .144

RTS/CTS Control. . . . . . . . . . . . . . . . . . . . 144

Poll Timer. . . . . . . . . . . . . . . . . . . . . . . . . . 144

Input Timer. . . . . . . . . . . . . . . . . . . . . . . . . 144

Host Name . . . . . . . . . . . . . . . . . . . . . . . . .144

Backup Host Name. . . . . . . . . . . . . . . . . . . 144

NCR Host Addresses. . . . . . . . . . . . . . . . . . . . .145

Line Module . . . . . . . . . . . . . . . . . . . . . . . .145

Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .145

Description . . . . . . . . . . . . . . . . . . . . . . . . .145

Copy Port Parameters. . . . . . . . . . . . . . . . .145

Configuration. . . . . . . . . . . . . . . . . . . . 145

Module. . . . . . . . . . . . . . . . . . . . . . . . . 145

Port . . . . . . . . . . . . . . . . . . . . . . . . . . .145

Host Address. . . . . . . . . . . . . . . . . . . . . . . . 146

Auto Connect Station Name. . . . . . . . . . . .146

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . .146

A. Timeout for Offline Device . . . . . .146

B. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .146

C. Auto Connect upon Select . . . . . . . 146

D . . . . . . . . . . . . . . . . . . . . . . . . . . . . .146

E. Non-SMF . . . . . . . . . . . . . . . . . . . .146

F. Non-NCR . . . . . . . . . . . . . . . . . . . .146

G. Auto Connect on Link Active. . . . .146

Poll Code . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Device Type . . . . . . . . . . . . . . . . . . . . . . . . 147

9 Unisys Uniscope

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Poll/Select Basics. . . . . . . . . . . . . . . . . . . . . . . . . . .149

Configuration/Operation . . . . . . . . . . . . . . . . . . . . .151

Uniscope Terminal. . . . . . . . . . . . . . . . . . . . . . . 151

Page 14

xiv

Line Module . . . . . . . . . . . . . . . . . . . . . . . .151

Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .151

Description . . . . . . . . . . . . . . . . . . . . . . . . .151

Copy Port Parameters . . . . . . . . . . . . . . . . .151

Configuration. . . . . . . . . . . . . . . . . . . .151

Module. . . . . . . . . . . . . . . . . . . . . . . . .151

Port. . . . . . . . . . . . . . . . . . . . . . . . . . . .152

Baud Rate . . . . . . . . . . . . . . . . . . . . . . . . . .152

Bits per Character . . . . . . . . . . . . . . . . . . . .152

Parity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .152

Message Buffer. . . . . . . . . . . . . . . . . . . . . .152

Interface . . . . . . . . . . . . . . . . . . . . . . . . . . .152

Algorithm . . . . . . . . . . . . . . . . . . . . . . . . . .152

Termination. . . . . . . . . . . . . . . . . . . . . . . . . 1 52

Trailing PAD Characters . . . . . . . . . . . . . .153

End to End Flow Control . . . . . . . . . . . . . .153

Turnaround Delay. . . . . . . . . . . . . . . . . . . .153

Peripheral Selection Timer . . . . . . . . . . . . .153

RTS/CTS CONTROL. . . . . . . . . . . . . . . . .153

Timeouts to Mark Offline. . . . . . . . . . . . . .153

Drop DTR If DCD Drops . . . . . . . . . . . . . .153

Offline Delay Retry . . . . . . . . . . . . . . . . . .154

End to End Protocol Conversion . . . . . . . .154

Maximum Select before Poll . . . . . . . . . . .154

Active If DSR/DCD. . . . . . . . . . . . . . . . . .154

Message to Poll Delay . . . . . . . . . . . . . . . .154

Poll And Select Timeout. . . . . . . . . . . . . . .154

Maximum Messages Queued . . . . . . . . . . .154

Activity Timer. . . . . . . . . . . . . . . . . . . . . . .154

Uniscope Terminal Addresses . . . . . . . . . . . . . .155

Line Module . . . . . . . . . . . . . . . . . . . . . . . .155

Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .155

Description . . . . . . . . . . . . . . . . . . . . . . . . .155

Copy Port Parameters . . . . . . . . . . . . . . . . .155

Configuration. . . . . . . . . . . . . . . . . . . .155

Module. . . . . . . . . . . . . . . . . . . . . . . . .155

Port. . . . . . . . . . . . . . . . . . . . . . . . . . . .155

Terminal Address . . . . . . . . . . . . . . . . . . . .156

Connecting Address . . . . . . . . . . . . . . . . . .156

Station Name. . . . . . . . . . . . . . . . . . . . . . . .156

Default Host . . . . . . . . . . . . . . . . . . . . . . . .156

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . .156

A. Auto Connect on Power Up . . . . . .156

B. Don't Send Status Message. . . . . . .156

C. Reserved Channel . . . . . . . . . . . . . .156

D. Device Is Sharable . . . . . . . . . . . . .156

E. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .156

F. Station Not Pollable. . . . . . . . . . . . .157

G. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .157

H. Keep Message. . . . . . . . . . . . . . . . .157

I. Wait for Host Connection. . . . . . . . .157

Uniscope Host . . . . . . . . . . . . . . . . . . . . . . . . . .158

Line Module . . . . . . . . . . . . . . . . . . . . . . . .158

Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .158

Description . . . . . . . . . . . . . . . . . . . . . . . . .158

Copy Port Parameters. . . . . . . . . . . . . . . . . 158

Configuration . . . . . . . . . . . . . . . . . . . 158

Module . . . . . . . . . . . . . . . . . . . . . . . . 158

Port . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Baud Rate. . . . . . . . . . . . . . . . . . . . . . . . . . 159

Bits per Character. . . . . . . . . . . . . . . . . . . . 159

Parity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Message Buffer . . . . . . . . . . . . . . . . . . . . . 159

Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Offline Timeout . . . . . . . . . . . . . . . . . . . . . 159

Termination . . . . . . . . . . . . . . . . . . . . . . . . 159

Trailing Pad Characters . . . . . . . . . . . . . . . 159

Host Response Timeout. . . . . . . . . . . . . . . 160

Turnaround Delay . . . . . . . . . . . . . . . . . . . 160

Maximum Messages Queued. . . . . . . . . . . 160

RTS/CTS Control . . . . . . . . . . . . . . . . . . . 160

Acknowledgment Passing . . . . . . . . . . . . . 160

Host Name . . . . . . . . . . . . . . . . . . . . . . . . . 161

Backup Host Name . . . . . . . . . . . . . . . . . . 161

End to End Protocol Conversion . . . . . . . . 161

End to End Flow Control. . . . . . . . . . . . . . 161

Uniscope Host Addresses . . . . . . . . . . . . . . . . . 161

Line Module. . . . . . . . . . . . . . . . . . . . . . . . 161

Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Description. . . . . . . . . . . . . . . . . . . . . . . . . 162

Copy Port Parameters. . . . . . . . . . . . . . . . . 162

Configuration . . . . . . . . . . . . . . . . . . . 162

Module . . . . . . . . . . . . . . . . . . . . . . . . 162

Port . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Host Address . . . . . . . . . . . . . . . . . . . . . . . 162

Auto Connect Station Name. . . . . . . . . . . . 162

Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

A. Timeout for Offline Device . . . . . . 162

B. Flush Data for Offline Device . . . . 162

C. Auto Connect upon Select . . . . . . . 162

D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

G. Auto Connect on Link Active . . . . 163

10 Legacy Options

Legacy Terminal Options. . . . . . . . . . . . . . . . . . . . . 165

A - Auto Connect On Power Up . . . . . . . . . . . . 165

B - Don’t Send Status Message. . . . . . . . . . . . . 167

C - Reserved Channel . . . . . . . . . . . . . . . . . . . . 168

D - Device Is Shareable. . . . . . . . . . . . . . . . . . . 168

F - Output Only . . . . . . . . . . . . . . . . . . . . . . . . . 170

G - Group Address . . . . . . . . . . . . . . . . . . . . . . 171

Using Group and Specific Polling

on the Same Port . . . . . . . . . . . . . . . . . . . . . . . . 171

H - Keep Message . . . . . . . . . . . . . . . . . . . . . . . 173

I - Wait For Host Connection . . . . . . . . . . . . . . 173

Spool Messages. . . . . . . . . . . . . . . . . . . . . . . . . 175

M - Flush Input For Unknown Address . . . . . . 176

Legacy Host Options . . . . . . . . . . . . . . . . . . . . . . . . 178

Page 15

A - Timeout For Offline Device. . . . . . . . . . . . .178

B - Flush Data For Offline Device. . . . . . . . . . .179

C - Auto Connect on Select . . . . . . . . . . . . . . . .179

D - Group Address . . . . . . . . . . . . . . . . . . . . . . .181

G - Auto Connect On Link Active . . . . . . . . . . .181

H - Send Disconnect Message . . . . . . . . . . . . . .183

11 DLP (Data Link Protocol)

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .185

DLP Principles and Concepts . . . . . . . . . . . . . . . . . .185

Configuration/Operation . . . . . . . . . . . . . . . . . . . . . .187

Data Link Protocol Parameters. . . . . . . . . . . . . .187

Line Module . . . . . . . . . . . . . . . . . . . . . . . .187

Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .187

Description . . . . . . . . . . . . . . . . . . . . . . . . .187

Copy Port Parameters . . . . . . . . . . . . . . . . .188

Configuration. . . . . . . . . . . . . . . . . . . .188

Line Module. . . . . . . . . . . . . . . . . . . . .188

Port. . . . . . . . . . . . . . . . . . . . . . . . . . . .188

Link Speed. . . . . . . . . . . . . . . . . . . . . . . . . .188

Link Interface . . . . . . . . . . . . . . . . . . . . . . .188

Link Termination. . . . . . . . . . . . . . . . . . . . .188

RTS/CTS Control. . . . . . . . . . . . . . . . . . . .188

Link Active . . . . . . . . . . . . . . . . . . . . . . . . .188

NRZI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .189

Data link type . . . . . . . . . . . . . . . . . . . . . . .189

Tunneling. . . . . . . . . . . . . . . . . . . . . . .189

SDLC . . . . . . . . . . . . . . . . . . . . . . . . . .189

LAPB . . . . . . . . . . . . . . . . . . . . . . . . . .189

Parameters List for SDLC . . . . . . . . . . . . . . . . .190

Line Module . . . . . . . . . . . . . . . . . . . . . . . .190

Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .190

Recovery Counter . . . . . . . . . . . . . . . . . . . .190

Retransmission Busy Counter. . . . . . . . . . .190

Modulo Type. . . . . . . . . . . . . . . . . . . . . . . .191

Window Size. . . . . . . . . . . . . . . . . . . . . . . .191

T1 Timer . . . . . . . . . . . . . . . . . . . . . . . . . . .191

Device type . . . . . . . . . . . . . . . . . . . . . . . . .191

Duplex Exchange . . . . . . . . . . . . . . . . . . . .191

Switched Link . . . . . . . . . . . . . . . . . . . . . . .191

Poll Timer . . . . . . . . . . . . . . . . . . . . . . . . . .191

Device Inoperational Timer . . . . . . . . . . . .192

Postpone Timer . . . . . . . . . . . . . . . . . . . . . .192

Keep Message . . . . . . . . . . . . . . . . . . . . . . .192

Parameters List for LAPB . . . . . . . . . . . . . . . . .193

Line Module . . . . . . . . . . . . . . . . . . . . . . . .193

Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .193

RC Counter . . . . . . . . . . . . . . . . . . . . . . . . .193

Retransmission Busy Counter. . . . . . . . . . .194

Modulo . . . . . . . . . . . . . . . . . . . . . . . . . . . .194

Window Size. . . . . . . . . . . . . . . . . . . . . . . .194

T1 Timer . . . . . . . . . . . . . . . . . . . . . . . . . . .194

T2 Timer . . . . . . . . . . . . . . . . . . . . . . . . . . .194

Type of Device . . . . . . . . . . . . . . . . . . . . . .194

Device Inoperational Timer . . . . . . . . . . . .195

Postpone Timer. . . . . . . . . . . . . . . . . . . . . .195

Keep Message. . . . . . . . . . . . . . . . . . . . . . .195

Device Parameters Menu. . . . . . . . . . . . . . . . . .196

Device Parameters Menu for SDLC. . . . . . 196

Address. . . . . . . . . . . . . . . . . . . . . . . . . . . .196

Name. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Connect address . . . . . . . . . . . . . . . . . . . . .197

Connect name. . . . . . . . . . . . . . . . . . . . . . . 197

Alternate name . . . . . . . . . . . . . . . . . . . . . .197

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . .197

Option A - Transparent Link Setup. . . 197

Device Parameters Menu for

LAPB and TUNNEL . . . . . . . . . . . . . . . . . . . . .198

Device name. . . . . . . . . . . . . . . . . . . . . . . . 198

Device connect address . . . . . . . . . . . . . . . 198

Device connect name . . . . . . . . . . . . . . . . .198

Device alternate name . . . . . . . . . . . . . . . . 198

Data Link Protocol in SDLC Mode . . . . . . . . . . . . .199

Data Link Protocol in LAPB Mode . . . . . . . . . . . . .201

Data Link Protocol in Tunnel Mode. . . . . . . . . . . . . 203

12 Frame Relay Protocol

Frame Relay Basics. . . . . . . . . . . . . . . . . . . . . . . . . . 205

Configuration/Operation . . . . . . . . . . . . . . . . . . . . .207

Level 1 and Level 2 Frame Relay

Port Parameters. . . . . . . . . . . . . . . . . . . . . . . . . 207

Line Module . . . . . . . . . . . . . . . . . . . . . . . .207

Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .207

Description . . . . . . . . . . . . . . . . . . . . . . . . .207

Copy Port Parameters. . . . . . . . . . . . . . . . .207

Configuration. . . . . . . . . . . . . . . . . . . . 207