VERDER Verderflex Vantage 5000 Series Original Operating Manual

Peristaltic Cased Tube Pump

Original Operating Manual Vantage 5000

Version 1.4v-09/2019

Print-No. 01

Version 1.4v-09/2019

Print-No. 01

Vantage 5000

The information in this document is essential for the safe operation and servicing of Verderex

Vantage 5000 family of pumps. This document must be read and understood thoroughly prior to

installation of unit, electrical connection and commissioning.

Vantage 5000 1.4v-09.2019 2 | Page

®

Table of Contents

1 About this Document

1.1 Target Groups

1.2 Warnings and Symbols used in the Manual

1.3 Warnings and Symbols used on the Pump

2 Safety

2.1 Intended Use

2.2 General Safety Instructions

2.2.1 Product Safety

2.2.2 Obligation of the Operating Company

2.3 Specic Hazards

2.3.1 Hazardous Pumped Liquids

3 Transport, Storage and Disposal

3.1 Transport

3.1.1 Unpacking and Inspection on Delivery

3.1.2 Lifting

3.2 Storage Conditions

3.3 Interim Storage After Using the Pump

3.4 Interim Storage Before Using the Pump

3.5 Disposal

4 Layout and Function

4.1 Design Details of Vantage 5000

4.2 Vantage 5000 - an overview

4.3 Layout

4.3.1 Vantage 5000 Exploded View - Continuous

Tube

4.3.2 Vantage 5000 Exploded View - Tube

Element

5 Installation and Connection

5.1 Electrical Installation

5.1.1 Preparing for Installation

5.1.1.1 Checking the Ambient Conditions

5.1.2 Connecting to a Power Supply

5.1.3 Protective Earthing/Grounding

5.1.4 Electrical Isolation

5.2 Installing the Tube

5.2.1 Vantage 5000 - Tube Options

5.2.2 Installing the Continuous Tube

5.2.3 Installing the Tube Element

6 User Interface - an overview

7.7 Users / Passcodes

7.7.1 Users / Passcodes - an Overview

7.7.2 Users / Passcodes Setup

7.7.3 Passcode Request ON

7.7.4 Users/Passcodes

7.8 Remote Control

7.9. Logs / History

8 Operational Modes

8.1 Flow Mode

8.1.1 Select the Flow Mode

8.2 Batch Mode

8.2.1 Select the Batch Mode

8.3 Dose Mode

8.3.1 Select the Dose Mode

8.3.2 Memory Dose

9 Vantage 5000 Software Update Process

10 System Reset Procedure

11 Vantage 5000 Screen Calibration

12 Inspections, Maintenance and Repairs

12.1 Inspections

12.2 Maintenance

12.2.1 Cleaning the Pump Head

12.2.2 Maintenance Schedule

12.3 Repairs

12.3.1 Returning the Pump to the Service Centre

12.4 Ordering Spare Parts

13 Troubleshooting

13.1 Pump malfunctions

14 List of Figures and Tables

14.1 List of Figures

14.2 List of Tables

15 Declaration of Conformity

16 Declaration of Incorporation

7 Screen Layout

7.1 Home Screen

7.2 Main Menu

7.3 Job Files

7.4 Edit Job Files

7.4.1 Delivery Setup

7.4.2 Pump Setup

7.4.3 Mode Setup (Batch/Dose Mode)

7.4.4 Real Time Clock Mode (RTC) Setup

7.4.5 Log Setup

7.5 Calibration

7.5.1 Calibration Procedure

7.6 Settings

7.6.1 General

7.6.2 Outputs

Vantage 5000 1.4v-09.2019 3 | Page

Table of Contents (continued)

1 Appendix A

Pump Specication

2 Appendix B

Spare Parts Replacement

3 Appendix C

Ordering Information

4 Appendix D

Analogue Remote Control Options

5 Appendix E

25 WAY Remote I/O Connector

6 Appendix F

Breakout Box

7 Appendix G

Error Codes and Description

8 Appendix H

Formatting the USB drive

9 Appendix I

Standards

10 Appendix J

Modbus® RTU

Vantage 5000 1.4v-09.2019 4 | Page

1 About this Document

The Verderex Vantage 5000 range of peristaltic pumps have been developed according to the latest technology and subject to

continuous quality control. These operating instructions are intended to facilitate familiarisation with the pump and its designed

use. This manual will act as a guide for operating the pump. You are advised to follow these guidelines to operate the pump correctly. These operating instructions do not take local regulations into account; the operator must ensure that such regulations are

strictly observed by all, including the personnel responsible for installation.

1.1 Target Groups

Target Groups Duty

Operating Company

Qualied personnel, tter u Read, observe and follow this manual and the other applicable

Table 1 Target Groups

u Keep this manual available at the operating site of the pump.

u Ensure that personnel read and follow the instructions in this

manual and any other applicable documents, especially all safety

instructions and warnings.

u Observe any additional rules and regulations referring to the system.

documents, especially all safety instructions and warnings.

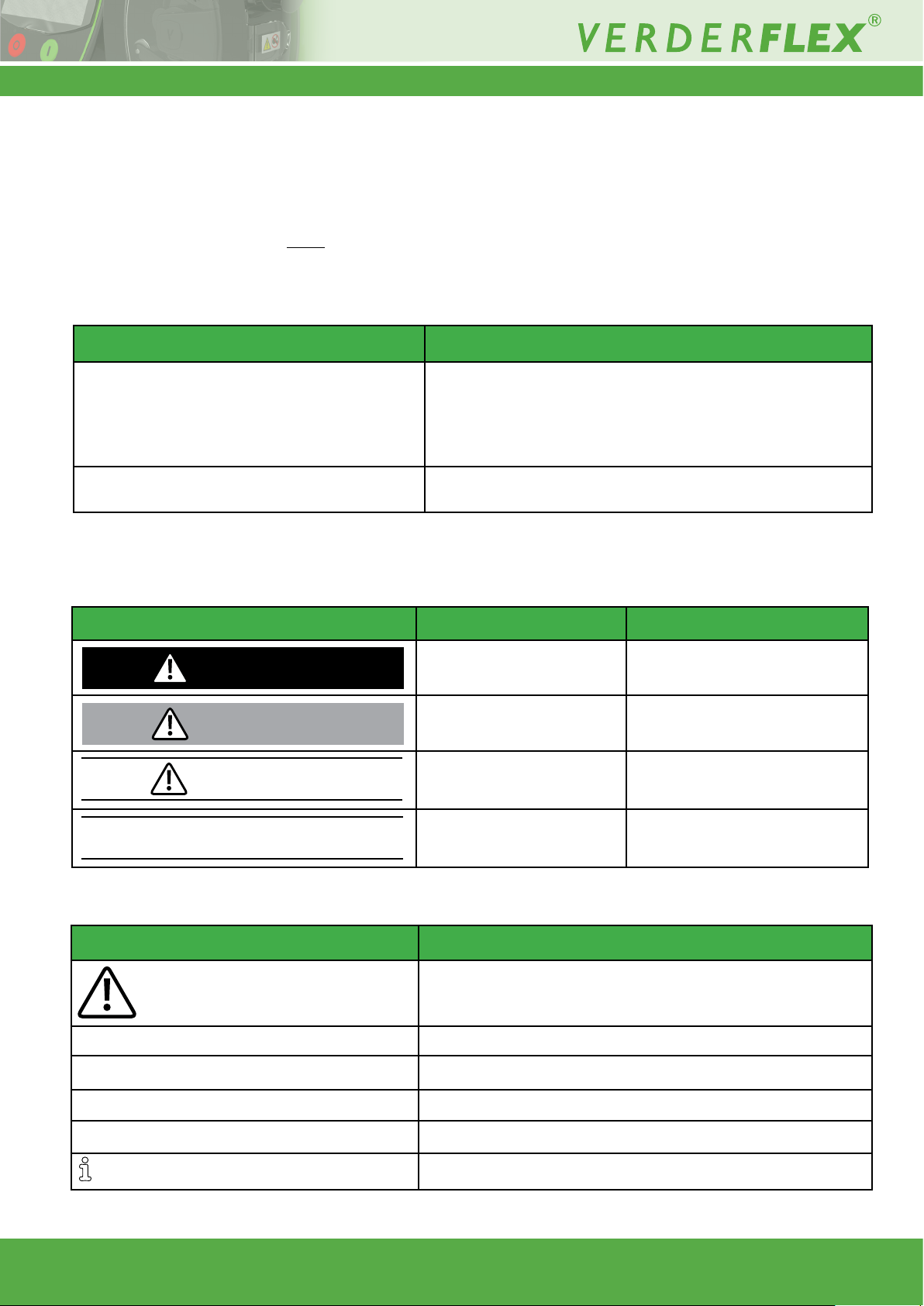

1.2 Warnings and Symbols Used in the Manual

Warning Risk Level Consequences of disregard

DANGER

WARNING

CAUTION

Immediate risk Death, serious bodily harm

Potential acute risk Death, serious bodily harm

Potential hazardous situation Potential damage to the pump

Note

Table 2 Warnings Used in the Manual

For information

Possible incorrect use / maintenance

of pump

Symbol Meaning

Safety warning sign in accordance with DIN 4844 - W9

u Take note of all information highlighted by the safety warning sign

and follow the instructions to avoid injury or death.

u

1., 2., Multiple-step instructions

p

g

Table 3 Symbols Used in the Manual

Vantage 5000 1.4v-09.2019 5 | Page

Instruction

Precondition

Cross-reference

Information

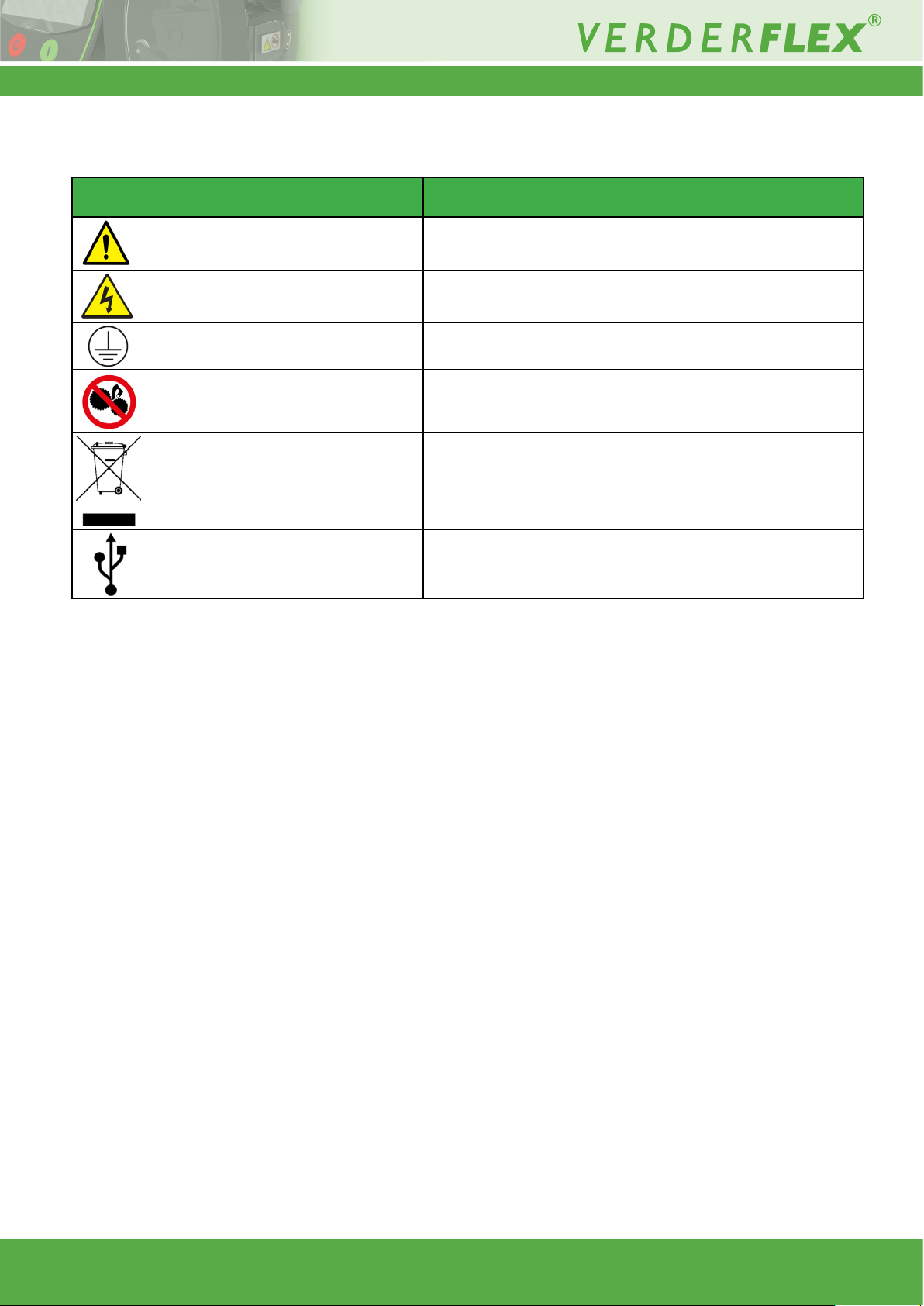

1.3 Warnings and Symbols Used on the Pump

Warnings and Symbols Meaning

Safety Warning

Warning of Dangerous Electrical Voltage

Protective Earth (Ground)

Pinch Point/Entanglement Hazard

Waste Electronic and Electrical Equipment (WEEE)

USB 2.0

Table 4 Warning and Symbols Used on the Pump

Vantage 5000 1.4v-09.2019 6 | Page

2 Safety

2.2.2 Obligation of the Operating Company

The manufacturer does not accept any liability for damage

resulting from disregard of this documentation.

2.1 Intended Use

u Only use the pump to handle uids compatible with the

tted tube (g Appendix A)

u Adhere to the operating limits

u Consult the manufacturer regarding any other use of the

pump.

Prevention of misuse (examples)

u Note the operating limits of the pump with regard to

temperature, pressure, ow rate and motor speed

(g Appendix A)

u Do not operate the pump with any inlet/outlet valves closed

u

Only install the pump as recommended in this manual.

For example, the following are not allowed:

– Running the pump with tube that is not compatible

with the tted rotor

– Insert any items into contact with moving parts

– Installation in the immediate vicinity of extreme hot or

cold sources (g Appendix A)

– Running pump in explosive atmosphere

2.2 General Safety Instructions

Observe the following instructions before carrying out any

work.

2.2.1 Product Safety

• These operating instructions contain fundamental infor-

mation which must be complied with during installation,

operation and maintenance. Therefore this o p e ra t in g

manu a l m us t be re a d a n d understood both by the

installing personnel and the responsible trained personnel

/ operators prior to installation and commissioning, and it

must always be kept easily accessible within the operating

premises of the machine.

Not only must the general safety instructions laid down

in this chapter on “Safety” be complied with, but also the

safety instructions outlined under specic headings.

• Operate the pump only if it and all associated systems are

in good functional condition.

• Only use the pump as intended, be fully aware of safety

and risk factors involved and the instructions in this

manual.

• Keep this manual and all other applicable documents

complete, legible and accessible to personnel at all times.

• Refrain from any procedure or action that would pose a

risk to personnel or third parties.

• In the event of any safety-relevant faults, shut down the

pump immediately and have the malfunction corrected by

qualied personnel.

• The installation of the pump must comply with the require-

ments of installation given in this manual and any local,

national or regional health and safety regulations.

Safety-conscious operation

• Ensure that the following safety aspects are

observed and monitored:

– Adherence to intended use

– Statutory or other safety and accident-prevention

regulations

– Safety regulations governing the handling of

hazardous substances if applicable

– Applicable standards and guidelines in the country

where the pump is operated

• Make personal protective equipment available

pertinent to operation of the pump.

Qualied personnel

• Ensure that all personnel tasked with work on the pump

have read and understood this manual and all other

applicable documents, including the safety,

maintenance and repair information, prior to use or

installation of the pump.

• Organize responsibilities, areas of competence and

the supervision of personnel.

• Have all work carried out by specialist technicians

only.

• Ensure that trainee personnel are under the

supervision of specialist technicians at all times when

working with the pump.

Warranty

The warranty is void if the customer fails to follow any

Instruction, Warning or Caution in this document. Verder

has made every effort to illustrate and describe the product in this document. Such illustrations and descriptions

are however, for the sole purpose of identication and do

not express or imply a warranty that the products are mer-

chantable or t for a particular purpose, or that the products will necessarily conform to the illustration or descriptions.

Obtain the manufacturer’s approval prior to carrying out

any modications, repairs or alterations during the warranty period. Only use genuine parts or parts that have

been approved by the manufacturer.

For further details regarding warranty, refer to terms and

conditions.

2.3 Specic Hazards

2.3.1 Hazardous Pumped Liquids

Follow the statutory safety regulations when handling haz-

ardous pumped liquids (e.g. hot, ammable, poisonous or

potentially harmful).

Use appropriate Personal Protective Equipment when car-

rying out any work on the pump.

Vantage 5000 1.4v-09.2019 7 | Page

3 Transport, Storage and

Disposal

3.3 Interim Storage After Using the

Pump

3.1 Transport

Always transport the pump in a horizontal position and

ensure that the pump is securely packed in the box.

3.1.1 Unpacking and Inspection on

Delivery

1. Report any transport damage to the manufacturer/

distributor immediately.

2. Retain the packing if any further transport is required.

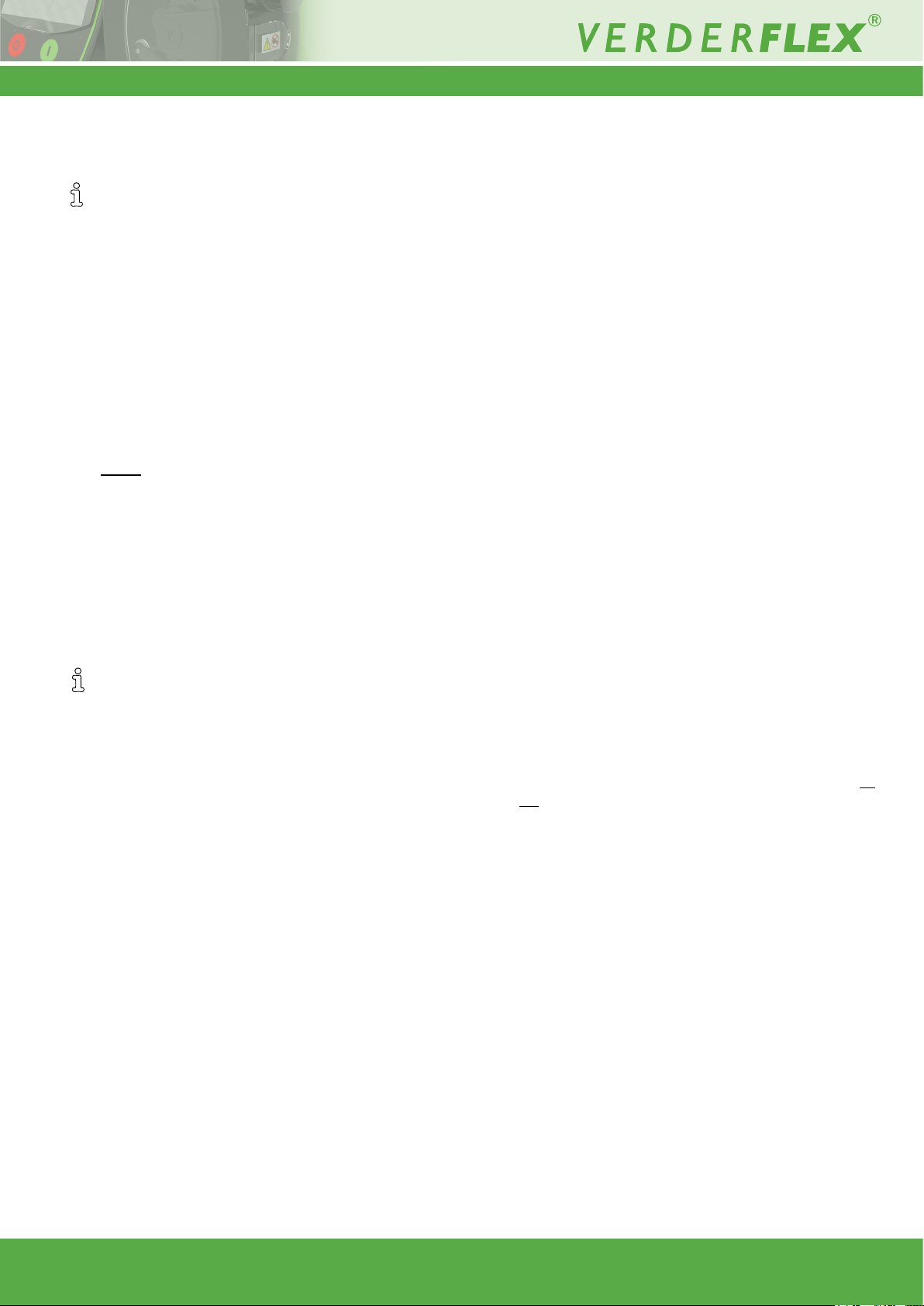

3.1.2 Lifting

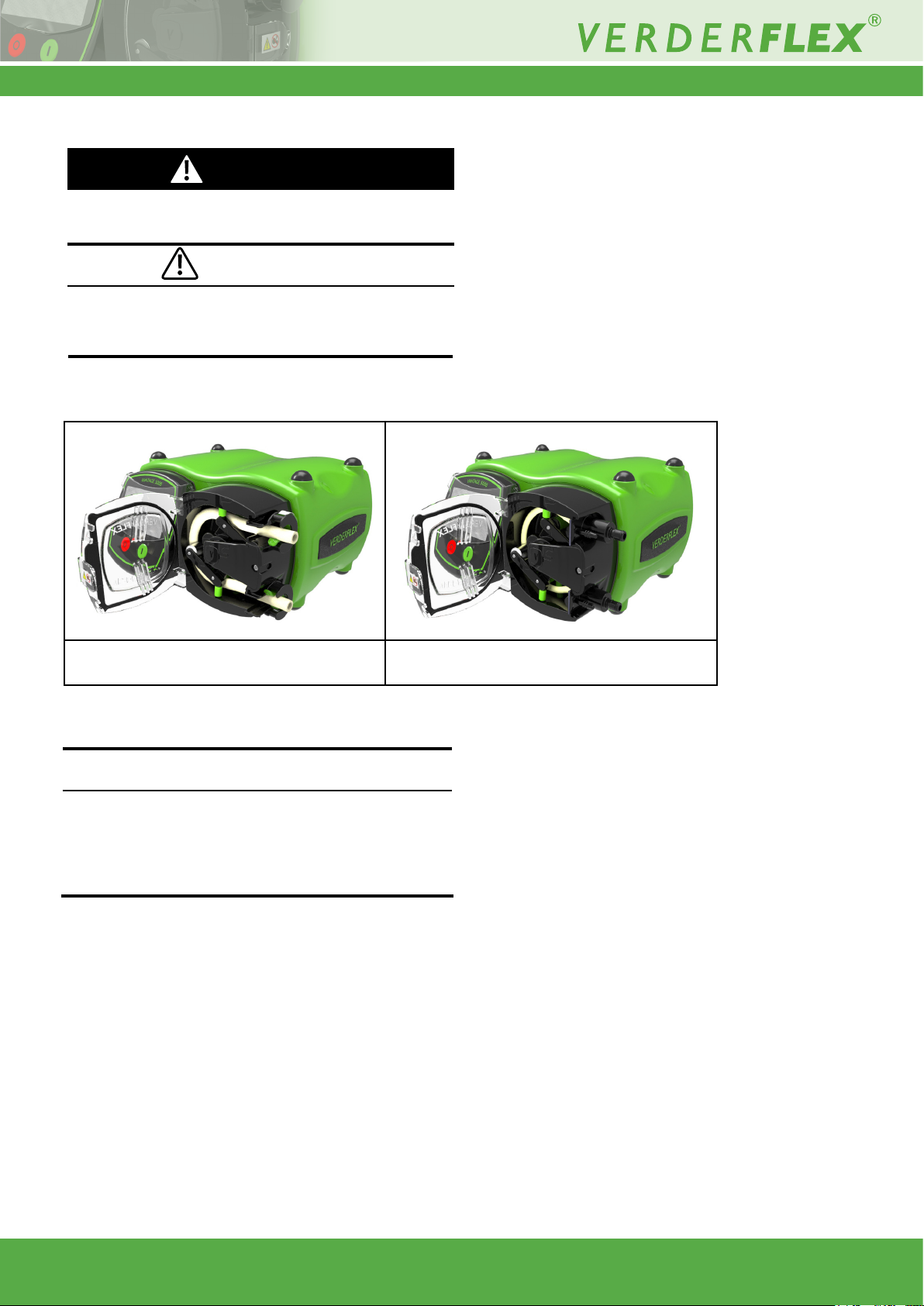

CAUTION

Pump damage caused by lifting

u Do not lift the pump by the Screen Module or the Pump

Head as shown in the following illustration.

u The tube should be removed from the pump.

u The pumphead should be washed out, allowed to dry and

any external build up of product removed.

3.4 Interim Storage Before Using

the Pump

CAUTION

Pump damage caused by interim storage

u Allow the pump to reach ambient temperature before

use.

u Please observe the storage recommendations and use-

by dates which apply to tubing you may wish to bring into

service after storage.

3.5 Disposal

With prolonged use, pump parts can be contaminated

by hazardous pumped liquids to such an extent that

cleaning may be insufcient.

WARNING

Do not lift the pump from the Screen Module

or the Pump Head

Figure 1 Lifting the pump

3.2 Storage Conditions

Make sure the storage location meets the following

conditions:

– Dry, humidity not to exceed 80%, non-condensing

– Out of direct sunlight

– Frost-free; temperature range -40° to +70°C

– Vibration-free

– Dust-free

Risk of poisoning and environmental damage by the

pumped liquid

u Use suitable personal protective equipment when carrying

out any work on the pump.

u Prior to disposal of the pump:

– Collect and dispose of any leaking pumped liquid in

accordance with local regulations.

– Neutralize residues of pumped liquid in the pump.

u Dispose of the pump and associated parts in accordance

with local regulations.

4 Layout and Function

The medium to be pumped does not come into contact

with any moving parts and is totally contained within the

tube. A roller passes along the length of the tube, compressing it. This motion forces the contents of the tube directly in front of the roller to move forward along the length

of the tube in a ‘positive displacement’ peristaltic movement. In the wake of the roller’s compressing action, the

natural elasticity of the tube material causes the tube to

recover and regain its round prole. This creates suction

pressure which rells the tube.

Tubing should be stored as supplied in their wrapper

and should be stored away from direct sunlight

and at room temperature.

Vantage 5000 1.4v-09.2019 8 | Page

4.1 Design Details of Vantage 5000

The Verderex Vantage 5000 range of tube pumps, provide a balanced selection of simple to operate peristaltic pumps.

The range offers the customer pump choices that are simple by design, with touchscreen interface and 4000:1 turndown

ratio with the stepper drive.

4.2 Vantage 5000 - an overview

A. SCREEN PROTECTOR

– Gently pull up the screen protector to touch the screen.

– Gently push the screen protector down after selecting the functions.

B. SCREEN MODULE

– Presents information to the user about the status of the pump.

– Accepts and implements the operators control instructions using the touchscreen.

– Use a suitable stylus or nger to select the functions. (g 6 User Interface - overview)

C. STOP BUTTON

– Stops the pump.

– RED LED illuminated when the pump is stopped

– FLASHING RED indicates an alarm or fault mode.

D. START BUTTON

– Starts the pump.

– GREEN LED illuminated when the pump is running.

– FLASHING GREEN LED indicates the pump is paused.

E. PUMP DOOR

– Must be closed for the pump to run.

– When opened during the operation, the pump will stop and the red led will ash.

F. CONTINUOUS TUBE CLAMP

– Clamps the loose tube in place or locate the tube assembly on xed element pumps.

G. CONTINUOUS TUBE

A

B

C

D

E

Figure 2 Key Parts of the Pump

Vantage 5000 1.4v-09.2019 9 | Page

F

G

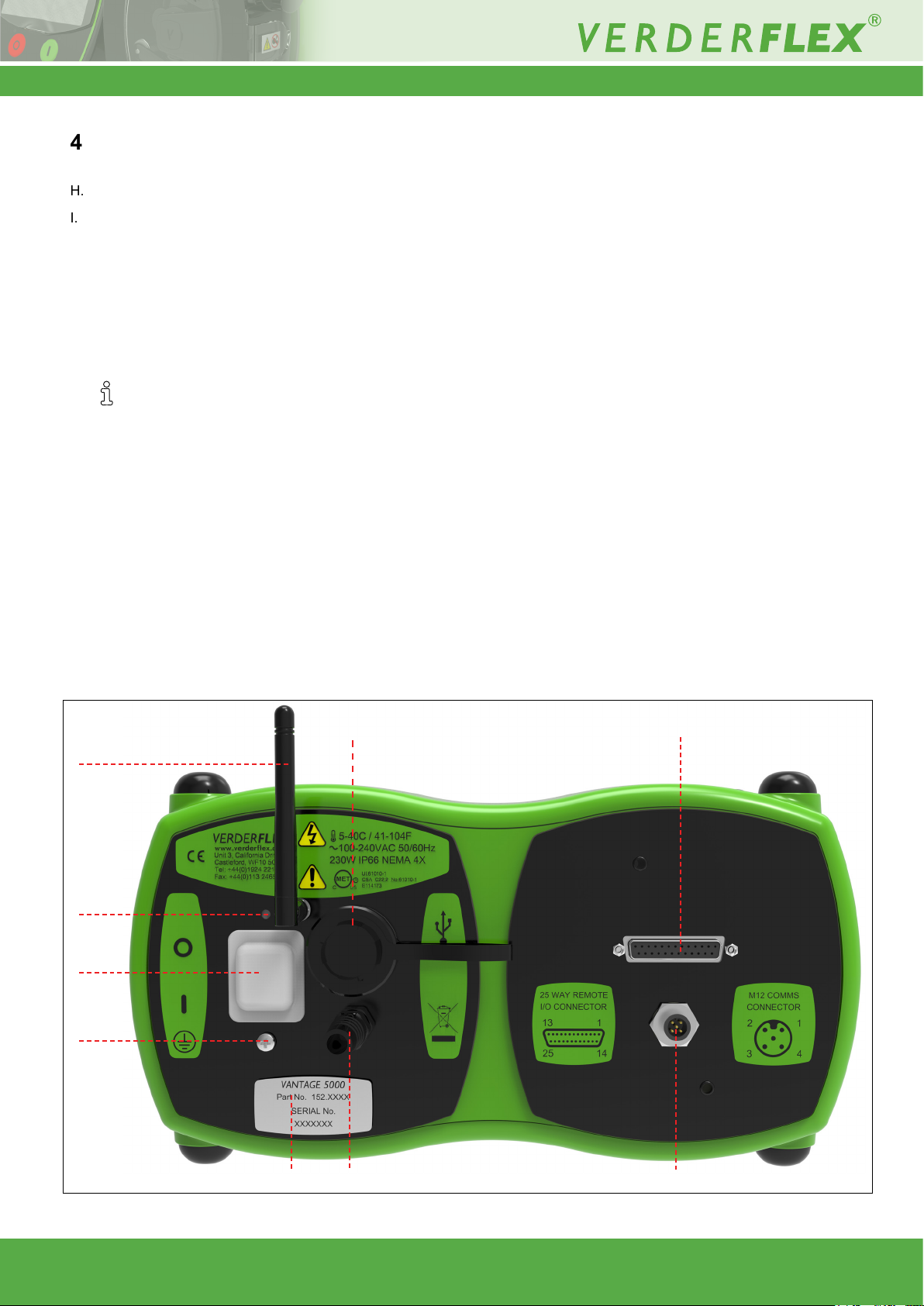

4.2 Vantage 5000 - an overview (continued)

H. BREATHER POINT (do not cover)

I. ON/OFF SWITCH

– Turns the pump ON or OFF.

J. EARTH POINT (M4)

K. NAME PLATE

– Part Number

– Model of Pump

– Serial Number

When requesting spares, the part number

and serial number should always be quoted.

L. POWER CABLE

M. M12 COMMS CONNECTOR (where tted)

– For digital RS485 and MODBUS® communications.

N. 25WAY REMOTE I/O CONNECTOR (where tted)

– Connection for footswitches, 0-10V DC & 4-20 mA remote controls.

– Provides connection for opto isolated BREAKOUT BOX modules.

O. USB 2.0 SOCKET CONNECTOR

– Pump can be backed up to USB memory.

– Pump programs can be loaded.

– Pump rmware can be updated.

P. WiFi Antenna

P

H

I

J

O

N

K

Figure 3 Back of the Pump

Vantage 5000 1.4v-09.2019 10 | Page

L

M

4.3 Layout

4.3.1 Vantage 5000 Exploded View - Continuous Tube

4

5

3

2

1

6

7

8 9

3.3

3.2

3.1

Figure 4 Vantage 5000 Exploded View - Continuous Tube

1 Bearing Strut 3.2 Horizontal Guide Rollers 6 Pump Door

2 Continuous Tube 3.3 Main Rollers 7 Pump Head

3 Rotor Assembly 4 Screen Protector 8 Tube Clamp

3.1 Vertical Guide Rollers 5 Screen Module 9 Pump Body

Vantage 5000 1.4v-09.2019 11 | Page

4.3.2 Vantage 5000 Exploded View - Tube Element

4

5

3

2

1

6

7

8

3.3

3.2

3.1

2.1

Figure 5 Vantage 5000 Exploded View - Tube Element

1 Bearing Strut 3.1 Vertical Guide Rollers 5 Screen Module

2 Tube Element 3.2 Horizontal Guide Rollers 6 Pump Door

2.1 Drain Port 3.3 Main Rollers 7 Pump Head

3 Rotor Assembly 4 Screen Protector 8 Pump Body

Note

The tube element is supplied with the drain port as shown in

Figure 5.

In case of an accidental tube burst, the upper most drain port

can be cut and may be used to provide ushing / neutralizing

solution. The lower drain port can be used to drain this ushing

liquid out from the pump.

If the customer wishes to use this feature, then the tip of the top

and bottom drain port should be removed.

Cut 1-2 mm off with the tip to open the port and connect suitable

tubing to a bunded area.

Vantage 5000 1.4v-09.2019 12 | Page

5 Installation and Connection

Wire colours are shown in the following table:

CAUTION

Material damage due to unauthorized modication on

pump

u Unauthorized modication will invalidate the warranty.

Note

u A non-return valve must be installed between the pump

and the discharge pipework to prevent sudden release of

uid into the pump head in the event of tube failure.

5.1 Electrical Installation

CAUTION

Failure to follow safe and proper electrical installation

practices may result in pump malfunction or dangerous

operation

u Make sure the pump is installed correctly.

u The pump is supplied with a pre-tted mains lead which is

not a user-replaceable part.

u The mains lead may have a fuse tted (country

dependant)

u The fuse should be replaced with an identical fuse in the

event of the fuse blowing.

u The pump is protected by a mechanical overload switch

built into the power switch.

5.1.1 Checking the Ambient Conditions

Conductor Name European Colouring American Colouring

Live Brown Black

Neutral Blue White

Earth (Ground) Green/Yellow Green

Table 5 Conductor colour coding

Note

We advise customers to consider using a commercial surge

suppression system for installations where there is a risk of

excessive electrical noise.

5.1.3 Protective Earthing/Grounding

CAUTION

Failure to earth the pump correctly can result in hazardous

voltages being present on the pump body

u The pump is designed to be permanently earthed and

MUST be connected as such.

u By default, the earth connection is made through the earth

pin on the mains lead.

u If the mains lead is of a “bare end” type, the earth cable

(denoted by a Green/Yellow marking) must be wired to the

earth.

u If an Earth/Ground is unavailable from the mains plug,

there is an earthing stud provided on the back of the pump

(g Figure 3) and this should be used in place of the earth

from the mains plug.

1. Make sure that the operating conditions are as per pump

specications (g Appendix A).

2. Make sure the required ambient conditions are within limits

(g Appendix A).

5.1.2 Connecting to a Power Supply

DANGER

Isolate power supply from the pump before performing the

installation.

1. The pump must be installed by a qualied individual if it is

to be permanently wired in place.

2. The pump must not be used if there is visible damage to

the mains cable or plug.

3. The pump must be positioned so that the disconnect

device is easily accessible.

4. The pump cable must be free from strain and the pump

weight must not be supported by the mains cable.

5. All cabling used to connect to the pump must be 0.75mm

Cross Sectional Area (CSA) minimum.

Note

Make sure a ground loop is not created through using both a

cable earth and the earthing stud.

If in any doubt, please contact a qualied electrician.

5.1.4 Electrical Isolation

1. The mains plug is the disconnection point for the pump

and is used for isolation from the mains.

2. The mains plug should therefore be readily accessible in

order to use as a disconnection point.

3. To isolate the pump, the mains plug is to be removed from

the wall outlet.

2

Vantage 5000 1.4v-09.2019 13 | Page

5.2 Installing the Tube

DANGER

u Isolate power supply from the pump before opening the

pump head.

CAUTION

u Make sure the tube is compatible with the rotor assembly.

u Before using a new tube assembly, make sure the pump is

run in the counter-clockwise direction for 1 minute.

5.2.1 Vantage 5000 Pump Tube Options

1. Continuous Tube 2. Tube Element

Figure 6 Vantage 5000 Pump Tube Options

Note

The tube element incorporates a drain port as show in Figure 6

(2. Tube Element) which must be utilised to prevent build-up of

pressurised uid in the pump head in the event of tube failure.

Cut 1-2mm from the tip of the drain port and attach a sufcient

length of tubing into a bunded area or collection vessel.

Vantage 5000 1.4v-09.2019 14 | Page

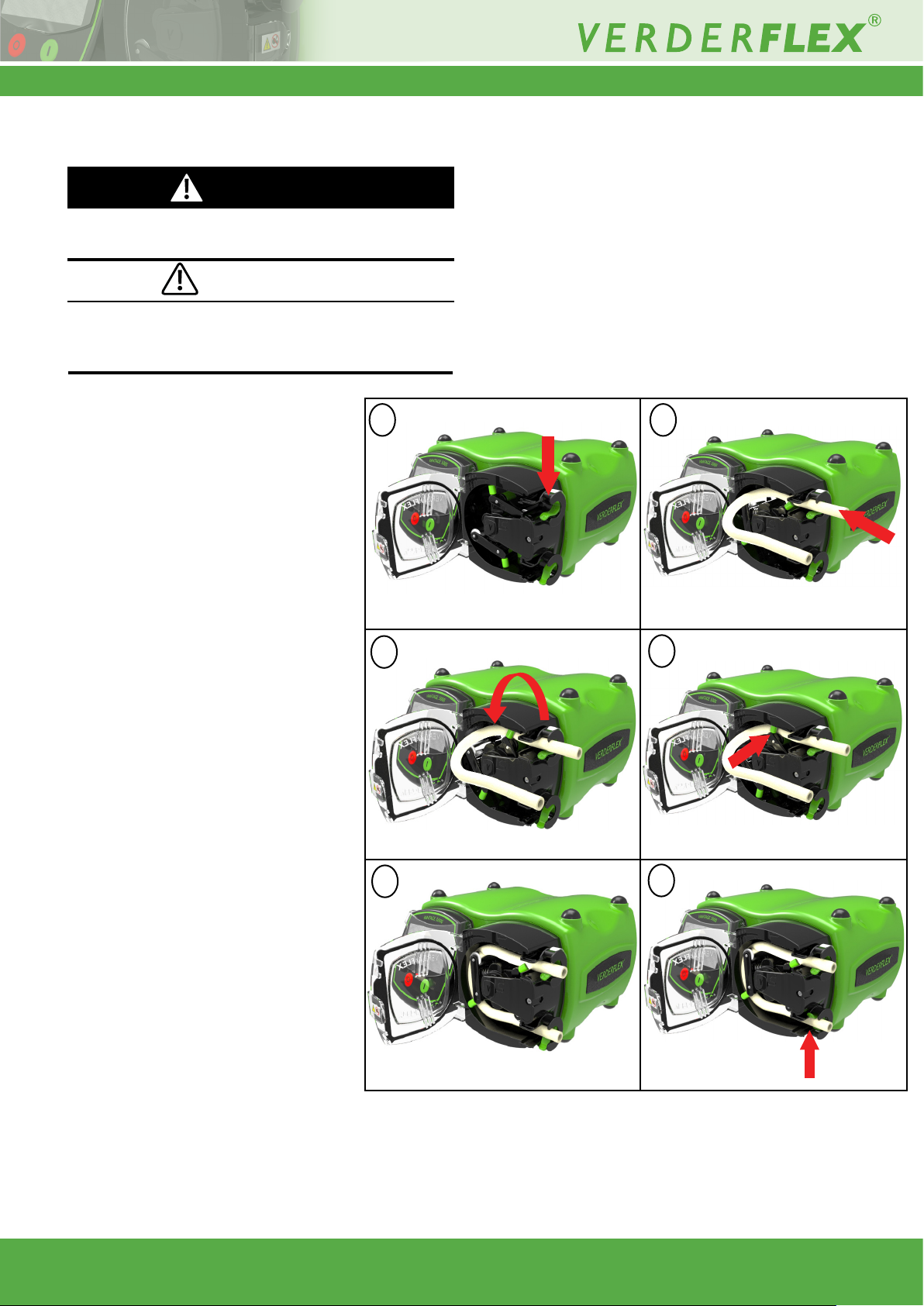

5.2.2 Installing Continuous Tube

DANGER

u Isolate power supply from the pump before opening the

pump head.

CAUTION

u Make sure the tube is compatible with the rotor assembly.

u Before using a new tube assembly, make sure the pump is

run in the counter-clockwise direction for 1 minute.

[ Ensure the Vantage 5000 pump is turned

off using the ON/OFF switch on the back

of the pump, if not, the rotor cannot be

turned by hand.

1. Open the pump door and push down the

tube clamp.

2. Insert the tube.

3. Rotate the rotor assembly using the vertical guide rollers in a counter-clockwise

direction.

3. Place the tube behind the vertical guide

rollers and continue to turn the rotor assembly in a counter-clockwise direction.

4. When performed correctly the main

rollers will compress the tube.

5. Release the tube clamp to lock the tube.

1 2

3

4

6. Push up the lower tube clamp and insert

the tube.

7. Once the tube is in place, close the pump

door before switching on the power sup-

ply.

Vantage 5000 1.4v-09.2019 15 | Page

5

Figure 6.1 Installing Continuous Tube

6

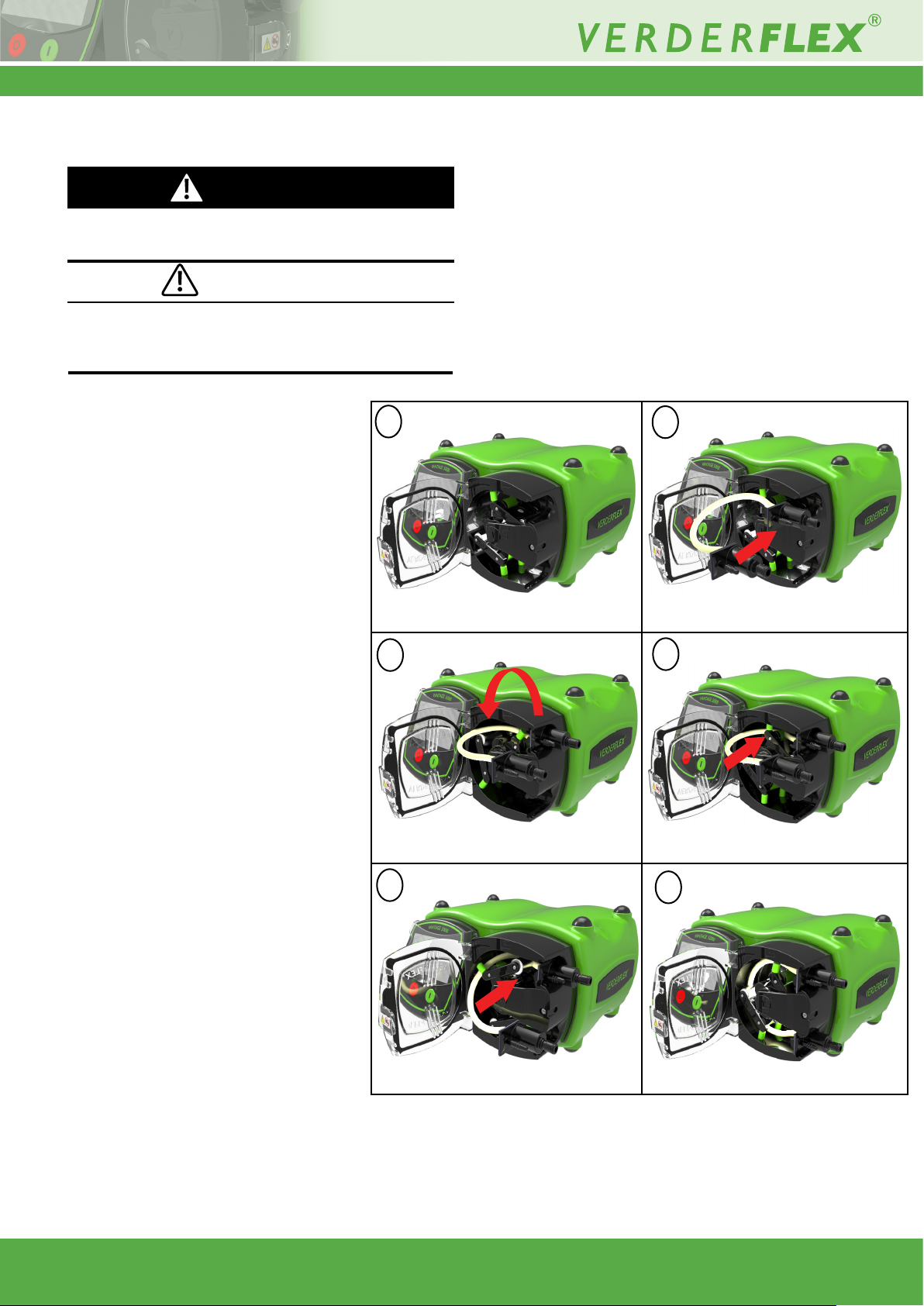

5.2.3 Installing the Tube Element

DANGER

u Isolate power supply from the pump before opening the

pump head.

CAUTION

u Make sure the tube is compatible with the rotor assembly.

u Before using a new tube assembly, make sure the pump is

run in the counter-clockwise direction for 1 minute.

[ Ensure the Vantage 5000 pump is turned

off using the ON/OFF switch on the back

of the pump, if not, the rotor cannot be

turned by hand.

1. Open the pump door.

2. Slide the tube element into the pump

head.

3. Rotate the rotor assembly using the

vertical guide rollers in a counter-clockwise direction.

4. Place the tube behind the vertical guide

rollers and continue to turn the rotor

assembly in counter-clockwise direction.

5. When performed correctly the main

rollers will compress the tube element.

6. Slide the lower tube element housing into

the pump head.

1

3

2

4

7. Once the tube is in place, close the pump

door before switching on the power sup-

ply.

Vantage 5000 1.4v-09.2019 16 | Page

5

Figure 6.2 Installing the Tube Element

6

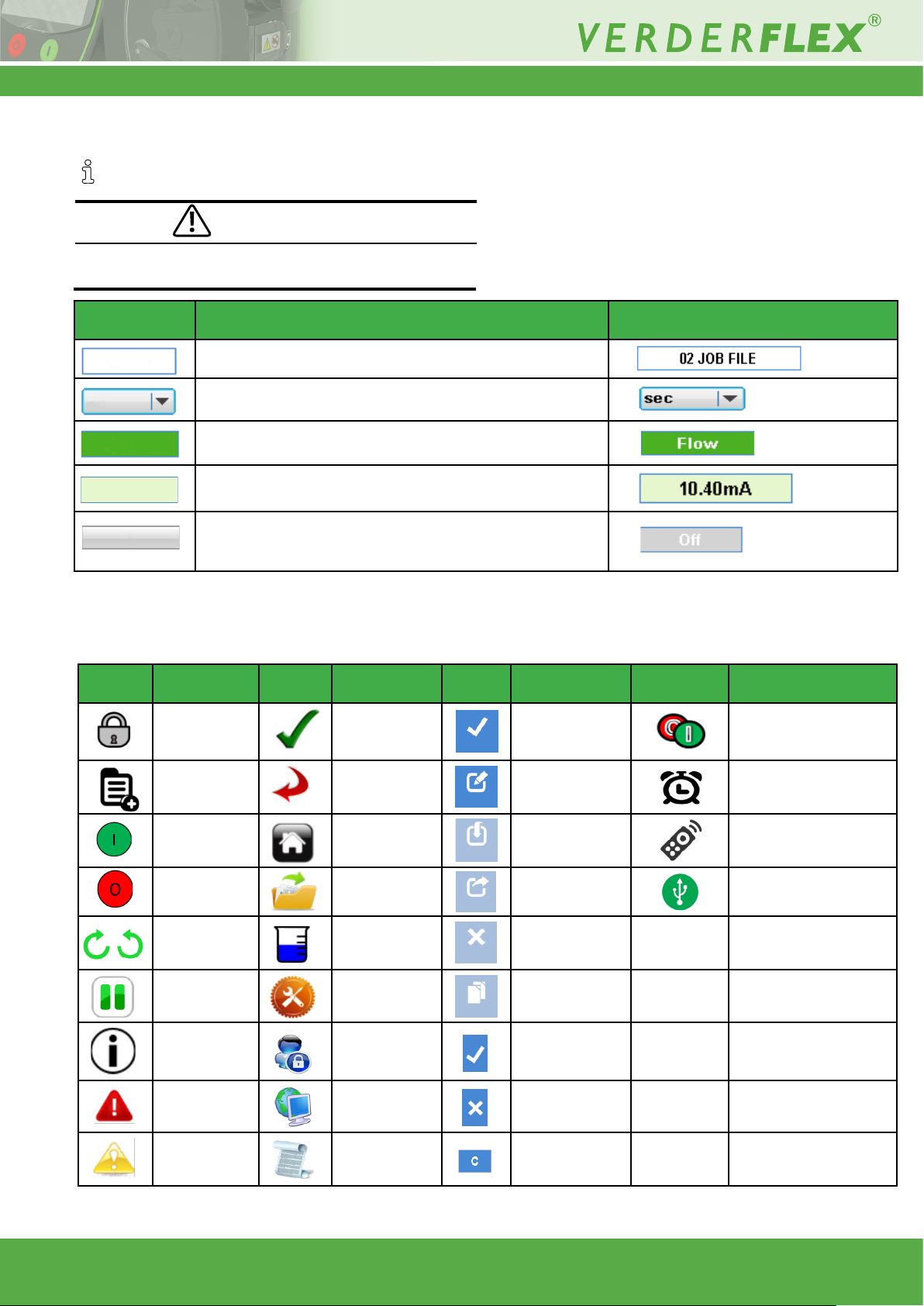

6 User Interface - overview

This manual is a representation of the features and functions

in the Vantage 5000.

CAUTION

u The user must use a suitable stylus or nger to operate the

touch screen.

Symbols Meaning Examples

A box with a BLUE outline indicates an editable value

A box with a BLUE outline and an arrow indicates a selection

from a list

A shape lled in DARK GREEN indicates a selectable button

A shape coloured LIGHT GREEN indicates read-only value and

is there for information

A shape coloured ‘GREYED OUT’ indicates a usually editable

eld which can no longer be edited due to the current conditions

of the pump setup.

Table 6 Symbols used for software

The following icons are used throughout this document:

Icons Denition Icons Denition Icons Denition Icons Denition

Lock / Unlock Accept Activate

Main Menu

Start Button Home Import

Stop Button Job Files Export

Pumping

Direction

Pump Paused Settings Copy

Information

Go Back /

Cancel

Calibration Clear Job

Users / Passcodes

Edit

YES / Accept

25Way Remote I/O Connector

Real Time Clock

Enabled

Remote

Control Enabled

Jobs File/Settings File

Backed to the USB Drive

Fault Remote Control NO / Cancel

Warning Logs / History

Table 7 Icons used for software

Vantage 5000 1.4v-09.2019 17 | Page

Delete Characters

7 Screen Layout

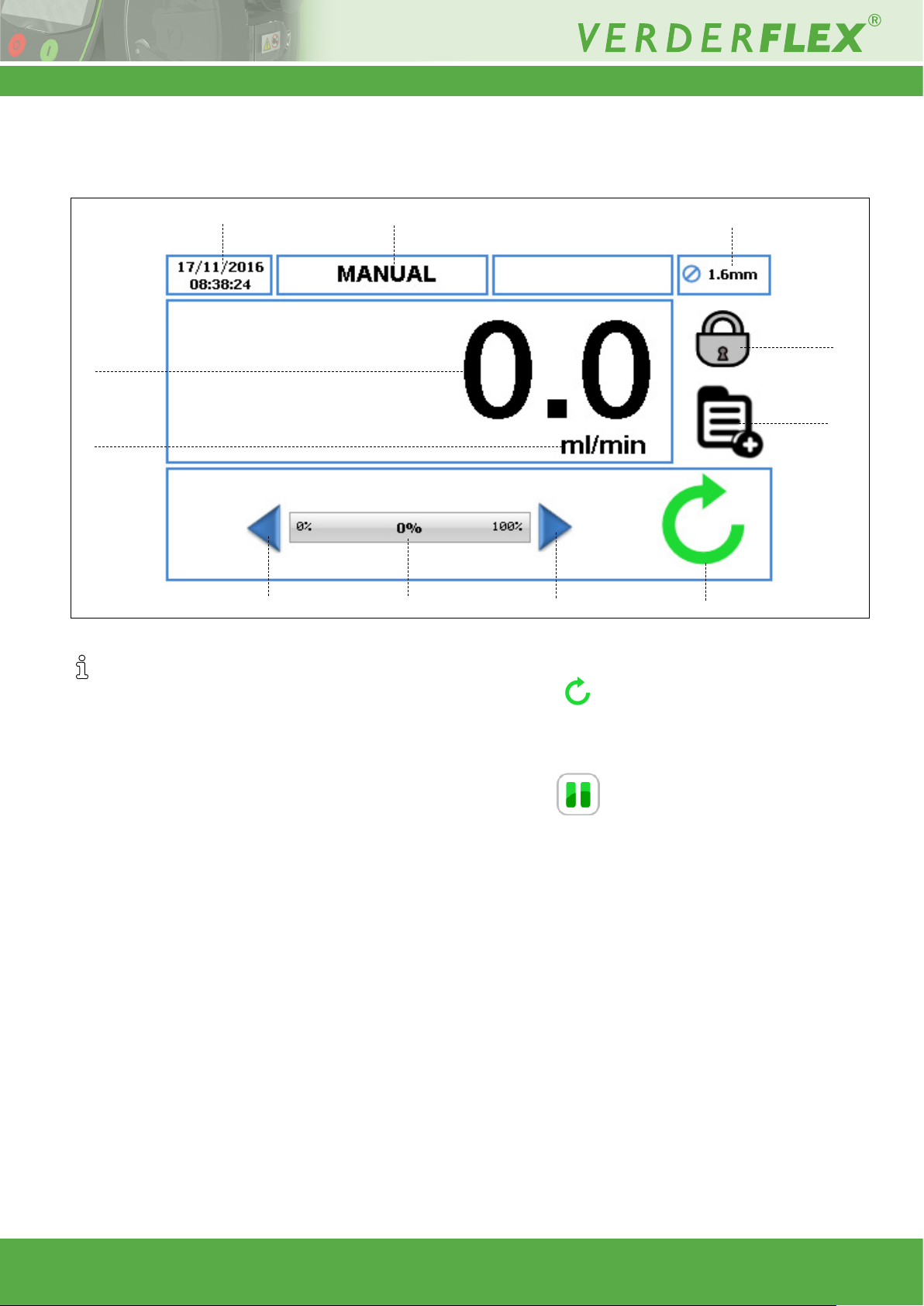

7.1 Home Screen

6

7

1

2

3

Figure 7 Home Screen

When you switch on the pump for the rst time the Home

Screen will be as per Figure 7. Layout of the Home Screen

will change depending on how you program and operate

the pump unit.

This screen layout is available when the pump is operated

using “MANUAL” Job File only.

4

8

3

5. Pump Status symbols:

a. Displays the direction of rotation and RPM (if

the pump is running). In ‘Manual’ Job File only, the

direction of rotation can be changed by touching the

symbol on the Home Screen.

5

9

10

1. Displays the ow rate of the pump. The user can change

the ow rate in (g 7.4 Edit Job Files).

2. Displays the unit of ow rate. The user can change the

units of ow rate in (g 7.4 Edit Job Files).

3. Increment/Decrement arrow will increase/decrease the ow

rate only in the ‘Manual’ Job File. It can either be pressed

once which will increment/decrement the ow rate in steps,

or held down, which will gradually increase/decrease the

ow rate. It is a temporary change on the Home Screen

and does not change the ow rate in the Job File Menu.

(g 7.4 Edit Job Files).

4. The ow rate indicator displays the current ow rate as

a percentage of the maximum available ow rate for the

selected tube size.

b. Indicates the pump is in pause mode, where

there is a program active but the pump is temporarily

paused.

6. Displays the current time and date as specied in the

(g 7.6 Settings). It is a read-only display.

7. Displays the current Activated Job File. The user can

change the name of the Job File in (g 7.4 Edit Job Files).

It is a read-only display and will be displayed on every

screen.

8. Displays the Tube Size, as dened in the currently activated

Job File.

9. LOCK/UNLOCK

a. LOCK touchscreen, when pressed the back-light

dims and the screen locks. This avoids accidental key

presses.

b. UNLOCK touchscreen.

10. This icon allows the user to access the main menu.

(g 7.2 Main Menu)

Vantage 5000 1.4v-09.2019 18 | Page

Loading...

Loading...