VERDER Carbolite TZF Series, TZF 12/75/700, TZF 12/38/400, TZF 12/65/550, TZF 12/100/900 Installation, Operation & Maintenance Instructions Manual

CONTENTS

Section page

Installation, Operation &

Maintenance Instructions

1200°C Tube furnaces (3-zone)

types TZF

This manual is for the guidance of operators of the above Carbolite products

and should be read before the furnace is connected to the electricity supply.

Manuals are supplied separately for the furnace controllers

(and overtemperature controller when fitted).

Please read the controller manuals before operating the furnace.

1.0 INTRODUCTION

Instrument switch: when the instrument switch is operated the temperature

control circuit is energised.

Heat Light: the adjacent light glows or flashes to indicate that power is

being supplied to the elements

DANGER of electrical shock– read any warning printed by this symbol.

DANGER – hot surface. Read any warning printed by this symbol.

WARNING: all surfaces of a furnace may be hot.

DANGER – read any warning printed by this symbol.

Heat Switch: the switch disconnects power to the heating elements; unless

this switch is off there is a danger of electric shock when inserting objects

into the furnace

1.1 Switches and Lights

1.2 Warning Symbols

2 MF12 3.12

2.0 INSTALLATION

2.1 Unpacking & Handling

When unpacking or moving the furnace always lift it by its base or by both ends of the main body.

Never lift it by its work tube or the surrounding insulation. For the larger models, or where the

furnace and control box are not fixed together, use two people to carry the furnace.

Remove any packing material from inside the furnace before use.

NOTE: This product contains Refractory Ceramic Fibre (better described as Alumino Silicate

Wool) for precautions and advice in handling this material see the ‘Repairs and Replacements’

section.

2.2 Siting

Place the furnace in a well ventilated room, away from other sources of heat, and on a surface

which is resistant to accidental spillage of hot materials. Do not mount the furnace on an

inflammable surface.

Ensure that there is free space around the furnace. Do not obstruct any of the vents in the control

section: they are needed to keep the controls cool.

Ensure that the furnace is placed in such a way that it can be quickly switched off or disconnected

from the electrical supply - see below.

2.3 Setting Up

A furnace ordered for vertical use has a small clip or plate at one end to prevent a wound tube

element or a work tube from slipping downwards. Mount the furnace so that this clip is at the

bottom. In models with one thermocouple the thermocouple should be near the top rather than the

bottom.

If the furnace is supplied with a separate work tube or any accessories fit these into position.

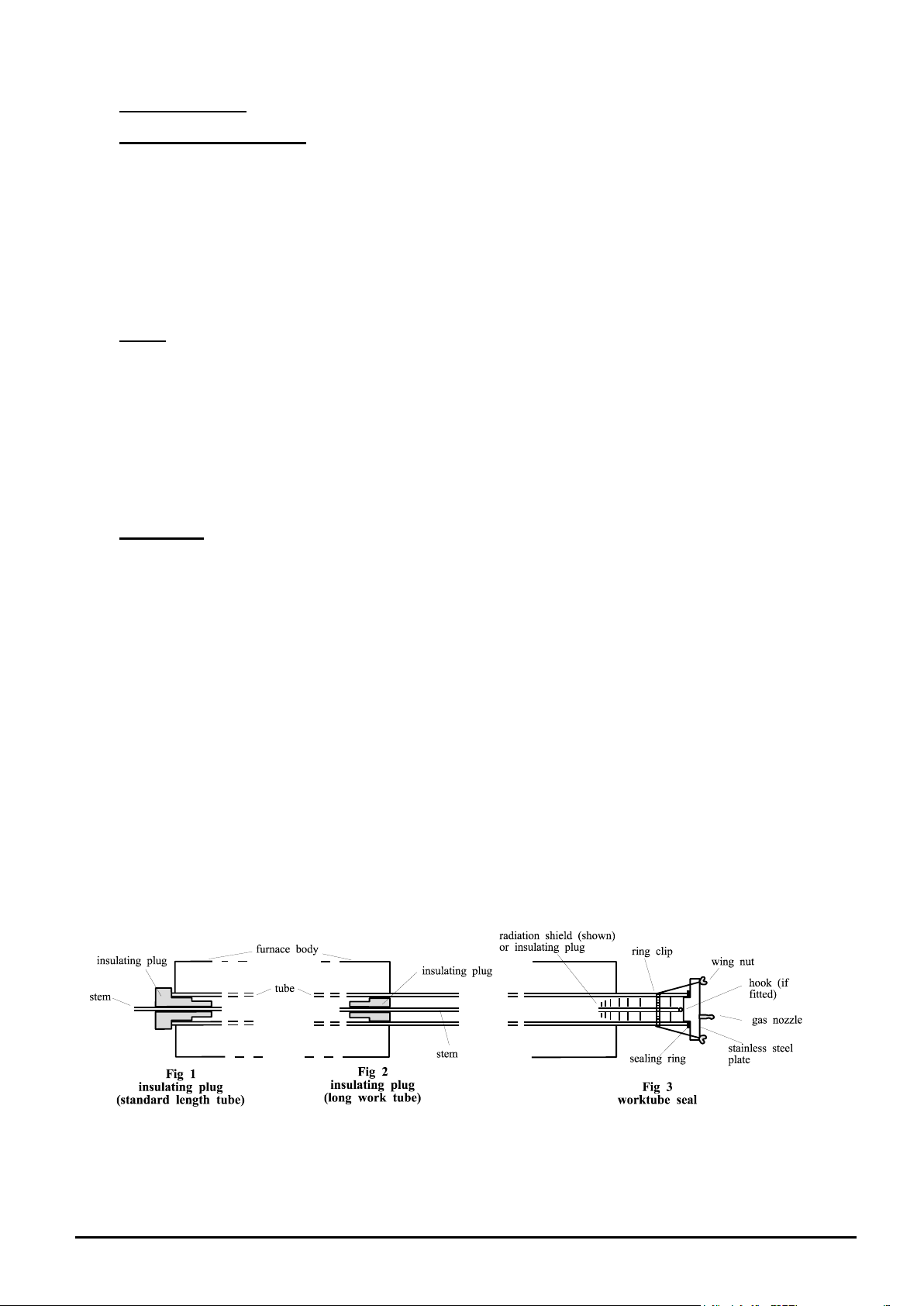

For optimum temperature uniformity, insulating plugs should be placed in the tube ends as shown

in fig.1. With a long work tube, the stem of the plug assembly should line up with the end of the

tube as in fig.2. Alignment of radiation shields is similar to that of plugs.

If stainless steel seals with gas inlets are supplied they are to be fitted as shown in fig.3; the stem

of any insulating plug should touch the seal. Stainless steel seals for vertical use: a hook and eye

arrangement holds the upper insulating plug assembly; alternatively a gland nut.

Horizontal models: if heavy fittings are to be clamped to the end of an extended work tube they

can increase the bending stress at the centre of the tube. Support such fittings in such a way that

expansion of the tube is allowed.

If a metal work tube is being used in the furnace, ensure that it is earthed. In the case of wound-

tube models (TZF) it should be mounted so as not to touch the furnace ceramic tube. See the safety

warning in section 3.4.

MF12 3.12 3

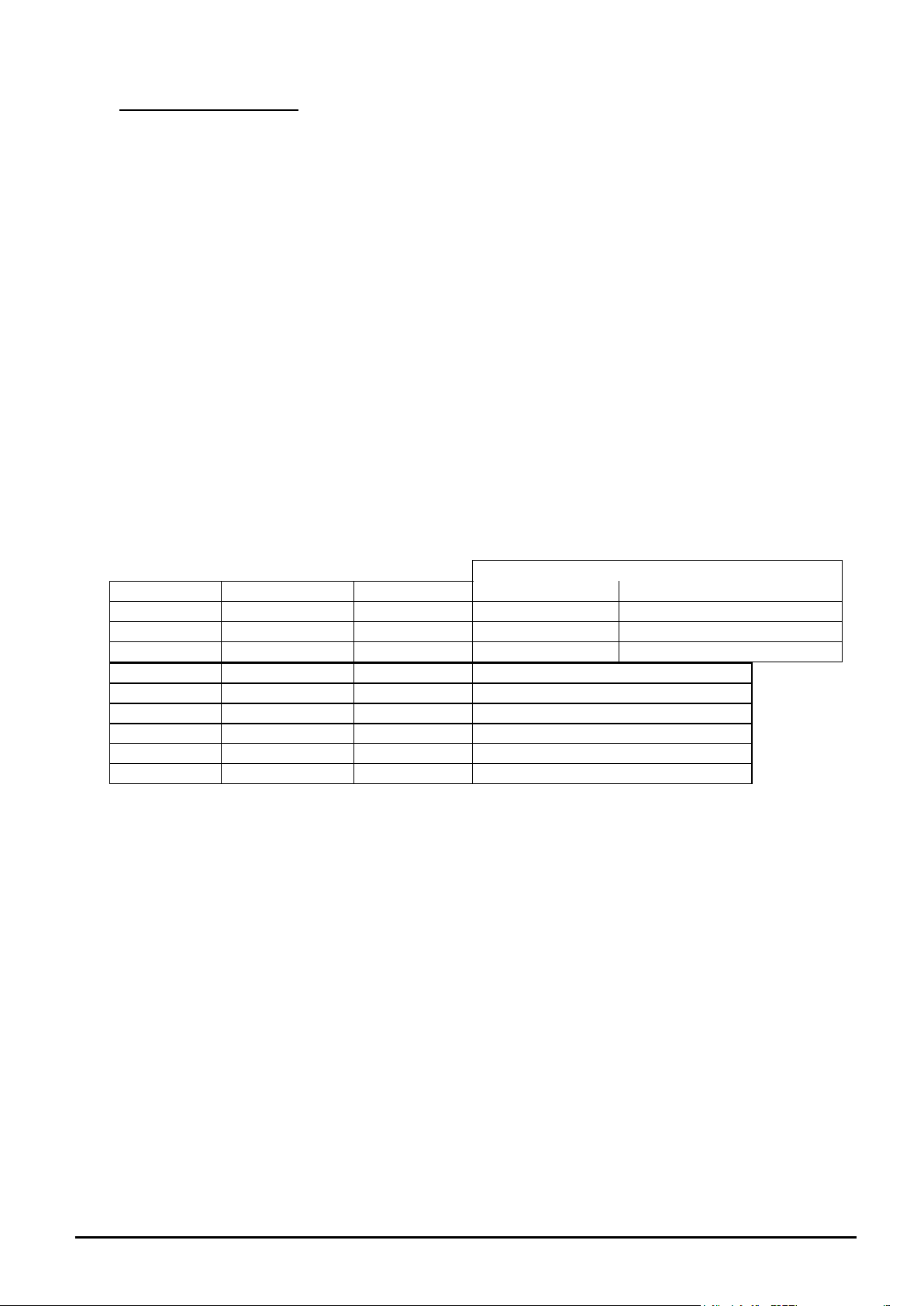

2.4 Electrical Connections

CONNECTION DETAILS

supply type

Supply

Terminal label

Cable colour

Live-Neutral

Reversible or Live-Live

1-phase

L

Brown

To live

to either power conductor

N

Blue

To neutral

to the other power conductor

PE

Green/Yellow

To earth (ground)

to earth (ground)

supply

Terminal label

Cable colour

2- or 3-phase

L1

Black

to phase 1

L2

Black

to phase 2

L3

Black

to phase 3 except 2-phase

N

Light Blue

to neutral except delta

PE

Green/Yellow

to earth (ground)

Connection by a qualified electrician is recommended.

The furnaces covered by this manual may be ordered for single phase A.C. supply, which may be

Live to Neutral non-reversible, Live to Neutral reversible or Live to Live. Some models can be

supplied for three phase use; some for use on two phases of a three phase with neutral supply (one

phase unused).

Check the furnace rating label before connection. The supply voltage should agree with the voltage

on the label, and the supply capacity should be sufficient for the amperage on the label.

The supply should be fused at the next size equal to or higher than the amperage on the label. A

table of the most common fuse ratings is also given in section 8.1 of this manual. Where a supply

cable is present there are internal supply fuses; customer fusing is preferred but not essential.

Furnace with supply cable: either wire directly to an isolator or fit with a line plug.

Furnace without supply cable: a permanent connection to a fused and isolated supply should be

made to the internal terminals after temporary removal of the furnace back panel.

Connection by line plug: the plug should be within reach of the operator, and should be quickly

removable.

Connection to isolating switch: this should operate on both conductors (single phase) or on all live

conductors (three phase), and should be within reach of the operator.

The supply MUST incorporate an earth (ground).

4 MF12 3.12

3.0 OPERATION

Home

List

Access

List

°C/F/k

ACCS

°C/F/k

codE

0.0

Zone temperature

difference; use /

to access offset

home list

for factory access to lists

and parameters not

available to the operator

OP.Hi

Output

oP

power limit

setting, if

present

The instructions for operating the temperature controller are given in a separate manual.

If the furnace is fitted with a time switch, see also the supplementary manual MS03.

If cascade control is fitted, see the supplementary manual MS07.

3.1 3-zone Control Methods

The models in this manual are typically designed to achieve an extended uniform temperature zone

by the use of three control zones. The control zones are typically linked so that they are all follow

the central controller in a master-slave approach; there are two ways of doing this. Alternatively

independent control zones may be ordered. There are thus three control methods (A, B & C).

A. Back-to-Back Thermocouples

This is the most commonly supplied option.

The central zone of the work tube is controlled directly by the central temperature controller. Each

end zone thermocouple is wired in opposition to a central reference thermocouple, and the small

voltage resulting when the zones are at different temperatures is used by the end zone controller.

The circuit diagram in section 7.1 shown the thermocouple arrangement.

Set the "setpoint" of the end zone controllers to zero. Alternatively, a small temperature difference

(offset) can be created by setting a non-zero value, but the sum of the main controller set-point and

the slave controller offset MUST NOT exceed the furnace maximum temperature. The "measured

temperature" display shows the actual offset.

To alter the setpoint (with the display at “home”), press Down or Up once to display the

setpoint; press again or hold down to adjust it. The display returns to the measured temperature

offset when no key is pressed for 0.5 seconds.

Sometimes a furnace using this type of control does not cool down: the end controllers try to

remain at the central temperature. Should this occur, contact Carbolite’s technical department.

2132 Slave Controller Navigation Diagram

B. Retransmission of Setpoint using Broadcast comms

When this is ordered there are three independent thermocouples connected to the three

controllers. The controllers are linked together, the central controller communicating the desired

setpoint to the end controllers.

Additional communication modules are fitted in the controllers, rather than an additional

thermocouple as in A. The communication between the controllers of the Eurotherm 3000 series is

known as Broadcast comms.

It is possible to switch off the linked control and allow the controllers to work independently. In

level 2 of the end zone controllers (see controller operating instruction), scroll to L-r. Where the

end zone controller is a 3216 use the up down and select NO. Where the end zone controller

is a 3508 use the up down to select SP1, (SP1 = Local, and SP2 = Remote). There is no

need to alter the centre controller.

It is possible to use local trim in the end zone controllers to enter a positive or negative adjustment

from the centre zone temperature. Once entered this trim will always be added or subtracted from

MF12 3.12 5

Loading...

Loading...