VERDER Jec JRZL220, Jec JRZL105, Jec JRZL Series, Jec JRZL120, Jec JRZL225 Series Manual

...

ATEX Manual

Rotary pumps

in a Hazardous Environment (Acc. to 2014/34/EU)

1

CONTENTS

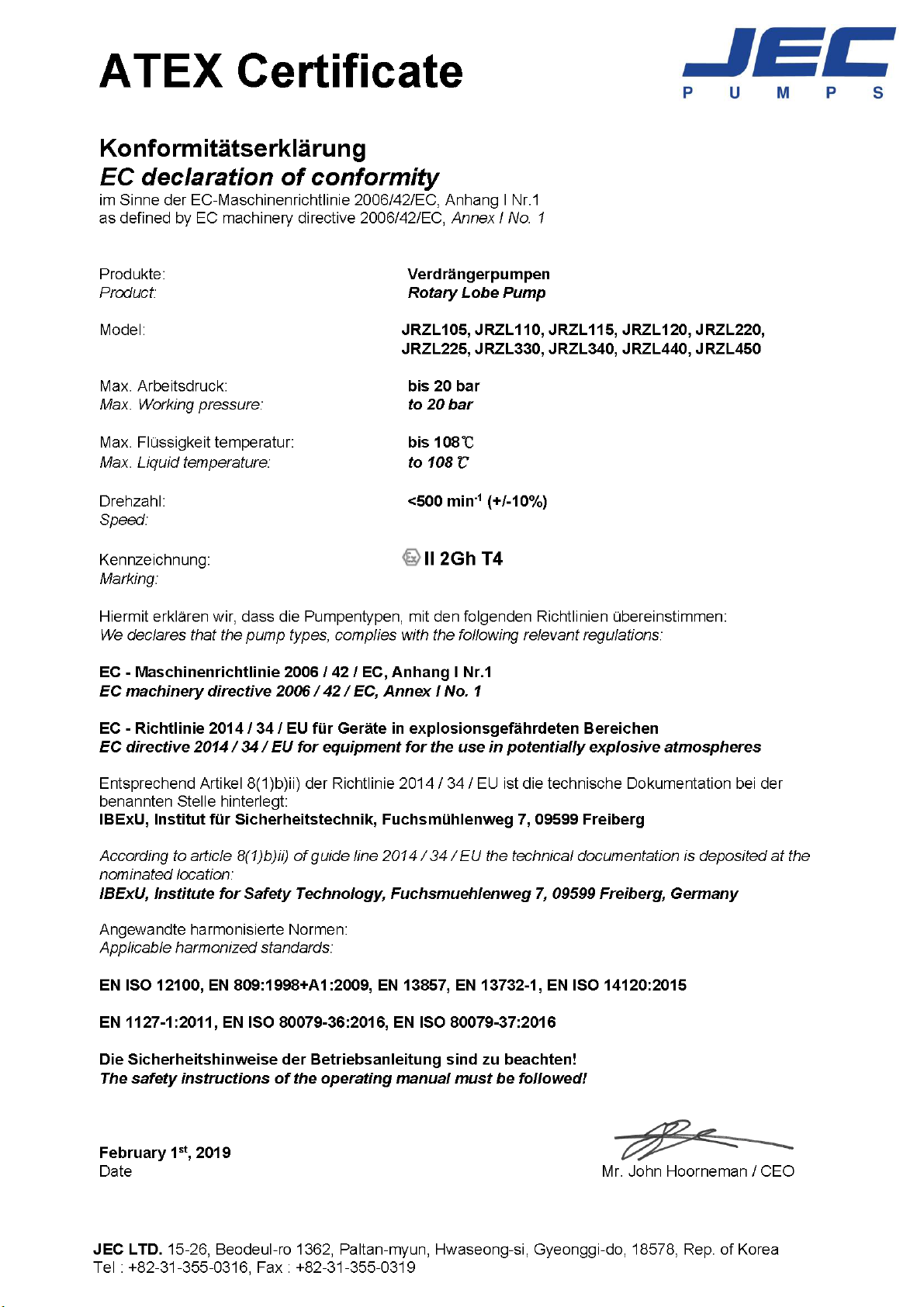

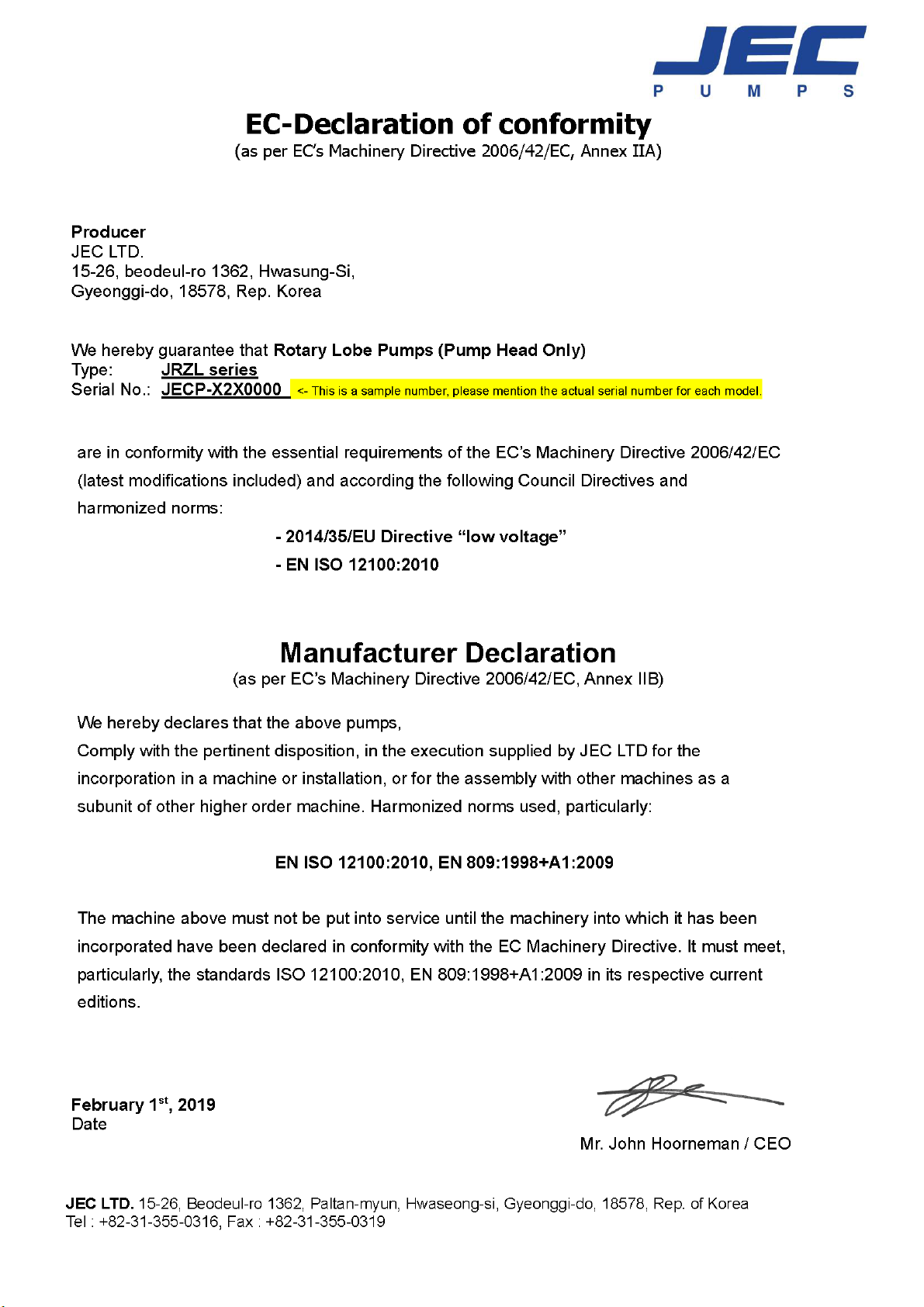

Certificates _JRZL series

ATEX (European Explosion proof certification) …………………………………………………………

CE(Declaration of conformity) …………………………………………………………………………………

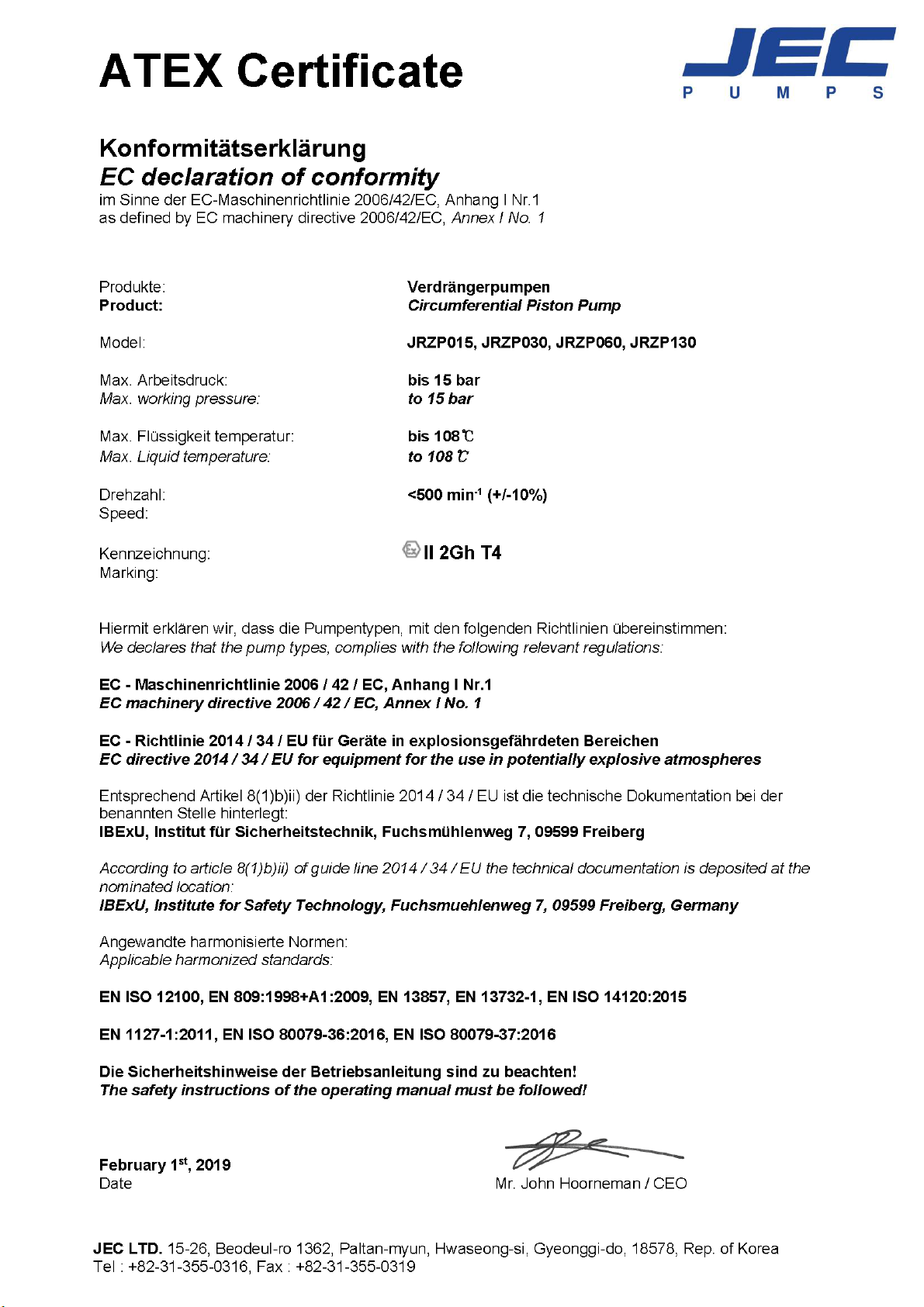

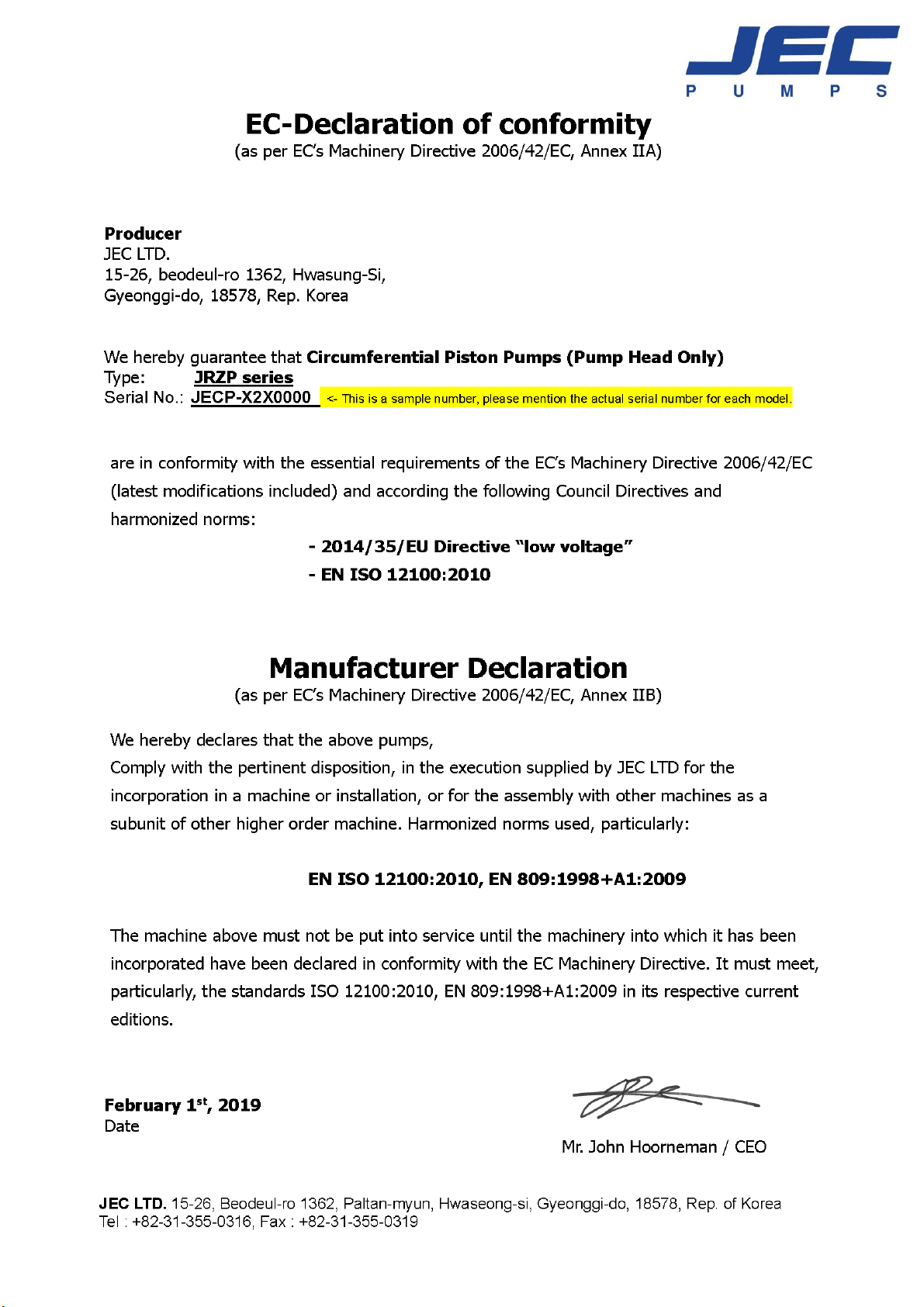

Certificates _JRZP series

ATEX (European Explosion proof certification) …………………………………………………………

CE(Declaration of conformity) …………………………………………………………………………………

Introduction

Preliminary information ……………………………………………………………………………………………

Validity ……………………………………………………………………………………………………………………

Safety notes

Symbols ……………………………………………………………………………………………………………………

ATEX certificates and pump markings ………………………………………………………………………

Personnel …………………………………………………………………………………………………………………

Unauthorized modifications ………………………………………………………………………………………

Installation and start up

Location and surroundings ………………………………………………………………………………………

Electrical connections ………………………………………………………………………………………………

Grounding ………………………………………………………………………………………………………………

Filling procedure ………………………………………………………………………………………………………

Operation and maintenance

Operation …………………………………………………………………………………………………………………

Maintenance and service …………………………………………………………………………………………

Dismantling / Re-assembly ………………………………………………………………………………………

2

3

4

5

6

6

7

7

7

8

8

8

9

9

9

10

11

2

3

4

5

6

Introduction

Preliminary Information

Applications in sites with potentially explosive atmosphere require particular attention

concerning installation, operation, maintenance and supervision. The main information about

the pumps is contained in the general manual.

All safety regulations, standards and procedures must be followed to avoid personal injury,

damage to the equipment and environmental contamination. Personnel involved with the

installation, start-up, operation, maintenance or service must review and follow these

instructions.

Our warranty does not apply to any device which has been subject to improper use and

negligence.

Validity

This document refers to JEC rotary pumps. The serial number is indicated on the label.

Safety Notes

The operating range should never be exceeded. See specification for limits.

Provisional repair and improper spare parts are inconsistent with the ATEX regulations. To

maintain the explosion protection, the use of original JEC spare parts is mandatory.

Tubes and protective devices should not be impaired, bended etc. (never climb onto any

component).

All other components connected to the pump (driving elements, couplings, valves, fittings,

measuring instruments etc.) must meet at least the same safety requirements acc. to

2014/34/EU.

7

Symbols

An operating procedure, which, if not strictly observed, can result in personal injury

or environmental contamination

A procedure, essential to avoid damage to the equipment.

Important information that should not be overlooked, otherwise the functionality of

the pump is reduced.

ATEX Certificates and Pump Markings

II 2 G h T4

Marking and JEC certificate are valid only for pump resp. pump head, not for the

motor! The pump complies with the requirements of the Council Directive

2014/34/EU, in a hazardous atmosphere (group II), consisting in a mixture of gas

and air (G). The safety category is 2, and the temperature class T4. This determines

an upper limit of 135°C for the delivered liquid.

The motor requires its own declaration of conformity, issued by the corresponding

manufacturer. The temperatures resulting from the pump operation should not be

in excess of the admissible values at the motor shaft and the motor flange,

otherwise the safety cannot be guaranteed. In case of doubt, consult the

manufacturer.

For motors with flameproof enclosure Eexde II CT4: Frequency 5 to

87Hz

Personnel

The installation, operation and maintenance of the pump must be in accordance with all of the

user and local regulatory standards and procedures. Refer installation to qualified and trained

personnel with an adequate knowledge about safety measures in a potentially explosive

atmosphere.

8

Unauthorized Modifications

Unauthorized modifications, changes of design etc. are strictly forbidden.

Negligence during the installation work should be avoided. Consequential damages

are not covered by the warranty.

Installation and Start-Up

Location and Surroundings

Mount the pump in a suitable, accessible location. To protect the motor from

overheating, provide sufficient room for ventilation. A minimum clearance to

adjacent parts and walls should be maintained.

A further potential danger source are distorted tubes. As the pump tolerances are

quite narrow, a tube spoiled by bending may introduce friction to the system,

entailing the generation of inadmissible heat.

RPM max. <500 min

Electrical Connections

All electrical connections must be made according to local wiring regulations and electrical code.

These tasks are reserved to a qualified electrician. Maximum power values, issued by the motor

manufacturer, must be observed. A protective motor switch is strongly recommended.

If during the installation procedure the explosive atmosphere is already present, never verify

the direction of rotation by switching off and restarting the dry pump. A temperature rise with

frictional heat at the mechanical seals may cause an explosion hazard.

-1

(+/- 10%)

9

Grounding

Between pump and base plate or foundation, a potential equalization line must be

provided.

Filling Procedure

During operation, the inside is usually completely filled, so an explosive atmosphere

is absent. By this reason, filling/De-aerating the pump and the suction line before

starting-up is mandatory.

A dry run can be dangerous, particularly in the zone of the rotating mechanical seal.

If the formation of gas bubbles and pockets in the area of the mechanical seal

cannot be excluded during operation, special monitoring methods must be applied.

For a vertically mounted pump, this is always the case.

One more time: Dry running is dangerous and could result in serious

injury or death, or damage to the equipment!

Operation and Maintenance

Operation

It is obvious, that a safe operation in a hazardous location is only possible with a careful respect

of the specification – or there will be the risk of an uncontrollable temperature rise. It is also

forbidden to lock the suction line for a longer time, because this will create friction energy and

an accumulation of heat.

When working with a locked pressure line, pump or tubes may burst.

During starting-up, the suction valve should be totally opened, and the valve of the pressure

side partially. Thus the operating range of the pump will be observed.

10

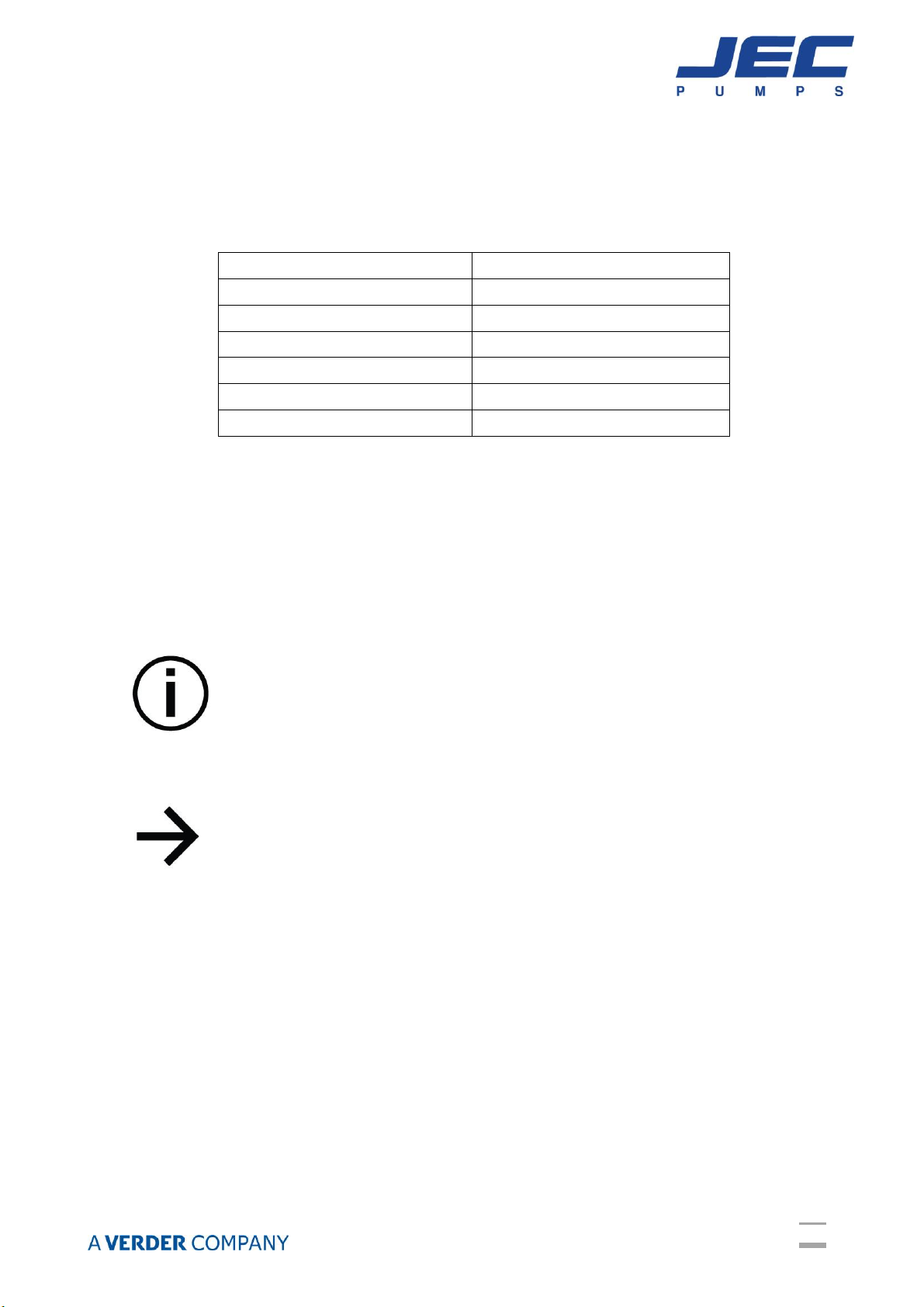

Class

Temperature

T1

450°C

T2

300°C

T3

200°C

T4

135°C

T5

100°C

T6

85°C

The maximum surface temperature has to be controlled weekly. If the values listed below are

exceeded, the pump has to be set out of action at once.

Admissible Temperatures

Admissible temperatures for transported liquid and pump

surface, depending on the ATEX temperature class.

Maintenance and Service

To reduce the occurrence of problems with the pump, the preventive maintenance

schedule must be followed, otherwise a safe operation in a hazardous location is

not guaranteed.

This is particularly important for wearing parts like mechanical seals, O-rings and

bearings. A regular visual inspection of static seals is mandatory.

Personnel should be sufficiently qualified and thoroughly familiar with the operation

of the pump, before starting any maintenance procedure. The same holds for

inspection and cleaning in the case of a possible dismantling and reassembling of

the pump. During this kind of work, an explosive atmosphere should not be

present.

Inspection and Maintenance Intervals:

Daily:

Oil level in the pump gearing, visual leakage control

Monthly / after 720 hours:

Oil level (viewing lass at the side of the gear case)

Yearly:

During the exchange of the mechanical seal, inspect and, if necessary, replace the

rolling bearing. O-rings and rotary seals sometimes have to be exchanged as well.

11

Dismantling / Re-assembly

Follow the steps listed in the general manual. Gap distances between rotating and

static parts are crucial, otherwise dangerous friction phenomena are possible. The

same holds for screw torques. Loose parts cannot be tolerated.

Another important parameter, by the reason mentioned above, is the correct

distance between rotating parts and covers.

Loading...

Loading...