VERDER AIR VA 8 810.6012 Instructions-parts List Manual

INSTRUCTIONS - PARTS LIST

Parts

This manual contains important

warnings and information.

READ AND RETAIN FOR REFERENCE

INSTRUCTIONS

819.6247

VERDERAIR VA 8 Air-Operated

Diaphragm Pumps

0.7 MPa, 7 bar Maximum Incoming Air Pressure

0.7 MPa, 7 bar Maximum Fluid Working Pressure

* NOTE: Refer to the pump listing on page to determine the Model No of your pump.

Patent Pending

Contents

Rev. R

Warnings 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Listing 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Kit Listing 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Lists 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Drawing 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Torque Sequence 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Data 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dimensions and Mounting Hole Layout 19. . . . . . . . . . . . . . . .

Performance Charts 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Customer/Guarantee 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

06176

Model 810.6012

shown

Warnings

Warning Symbol

Warning

This symbol alerts you to the possibility of serious injury or

death if you do not follow the instructions.

Warning

EQUIPMENT MISUSE HAZARD

Any misuse of the equipment or accessories, such as overpressurizing, modifying parts, using incompatible

INSTRUCTIONS

chemicals and fluids, or using worn or damaged parts, can cause them to rupture and result in splashing in the

eyes or on the skin, other serious injury, or fire, explosion or property damage.

This equipment is for professional use only. Observe all warnings. Read and understand all instruction manu-

als, warning labels, and tags before you operate this equipment. If you are not sure, or if you have questions

about installation or operation, call your VERDER distributor.

Never alter or modify any part of this equipment; doing so could cause it to malfunction.

Check all equipment regularly and repair or replace worn or damaged parts immediately.

Caution Symbol

Caution

This symbol alerts you to the possibility of damage to or destruction of equipment if you do not follow the instructions.

Never exceed the recommended working pressure or the maximum air inlet pressure stated on your pump or

in the Technical Data on page 19.

Do not exceed the maximum working pressure of the lowest rated component in your system. This equip-

ment has a 0.7 MPa (7 bar) maximum working pressure at 0.7 MPa (7 bar) maximum incoming air

pressure.

Be sure that all fluids and solvents used are chemically compatible with the wetted parts shown in the

Technical Data on page 19. Always read the manufacturer’s literature before you use fluid or solvent in the

pump.

Never move or lift a pump under pressure. If dropped, the fluid section may rupture. Always follow the

Pressure Relief Procedure on page 7 before you move or lift the pump.

2 819.6247

Warning

HAZARDOUS FLUIDS

Improper handling of hazardous fluids or inhaling toxic vapors can cause extremely serious injury or death from

splashing in the eyes, ingestion, or bodily contamination. Observe all the following precautions when you handle

hazardous or potentially hazardous fluids.

Know what fluid you are pumping and its specific hazards. Take precautions to avoid a toxic fluid spill.

Always wear appropriate clothing and equipment, such as eye protection and breathing apparatus, to protect

yourself.

Store hazardous fluid in an appropriate, approved container. Dispose of it according to all Local, State, and

Federal guidelines for hazardous fluids.

Secure the fluid outlet hose tightly into the receiving container to prevent it from coming loose and improperly

draining the fluid.

Pipe and dispose of the exhaust air safely, away from people, animals, and food handling areas. If the dia-

phragm fails, the fluid is exhausted along with the air. See Air Exhaust Ventilation on page 4.

FIRE AND EXPLOSION HAZARD

Static electricity is created by the flow of fluid through the pump and hose. If the equipment is not properly

grounded, sparking may occur. Sparks can ignite fumes from solvents and the fluid being pumped, dust particles, and other flammable substances, whether you are pumping indoors or outdoors, and can cause a fire or

explosion and serious injury and property damage.

To reduce the risk of static sparking, ground the pump and all other equipment used or located in the work

area. Check your local electrical code for detailed grounding instructions for your area and type of equipment. See Grounding on page 4.

If you experience any static sparking or even a slight shock while using this equipment, stop pumping

immediately. Check the entire system for proper grounding. Do not use the system again until you have

identified and corrected the problem.

Pipe and dispose of the exhaust air safely, away from all sources of ignition. If the diaphragm fails, the fluid is

exhausted along with the air. See Air Exhaust Ventilation on page 4.

Never use a polypropylene or Kynar pump with non-conductive flammable fluids as specified by your local

fire protection code. Refer to Grounding on page 4 for additional information. Consult your fluid supplier to

determine the conductivity or resistivity of your flui

Provide fresh air ventilation to avoid the buildup of flammable fumes from solvents or the fluid being pumped.

Do not smoke in the work area. Do not operate the equipment near a source of ignition or an open flame,

such as a pilot light.

Comply with all applicable local, state and national fire, electrical and safety regulations.

d.

819.6247 3

Installation

Tightening Threaded Fasteners Before First

Use

After unpacking the pump, and before using it for the first

time, check and retorque all external fasteners. See Service

for torque specifications. See Torque Sequence, page 17,

for torque sequence. After the first day of operation, retorque

the fasteners again. Although pump use varies, a general

guideline is to retorque fasteners every two months.

Use a compatible thread sealant on all male threads. Tighten

all connections firmly to avoid air or fluid leaks.

Caution

To avoid pump damage, do not overtighten the fittings to the

pump.

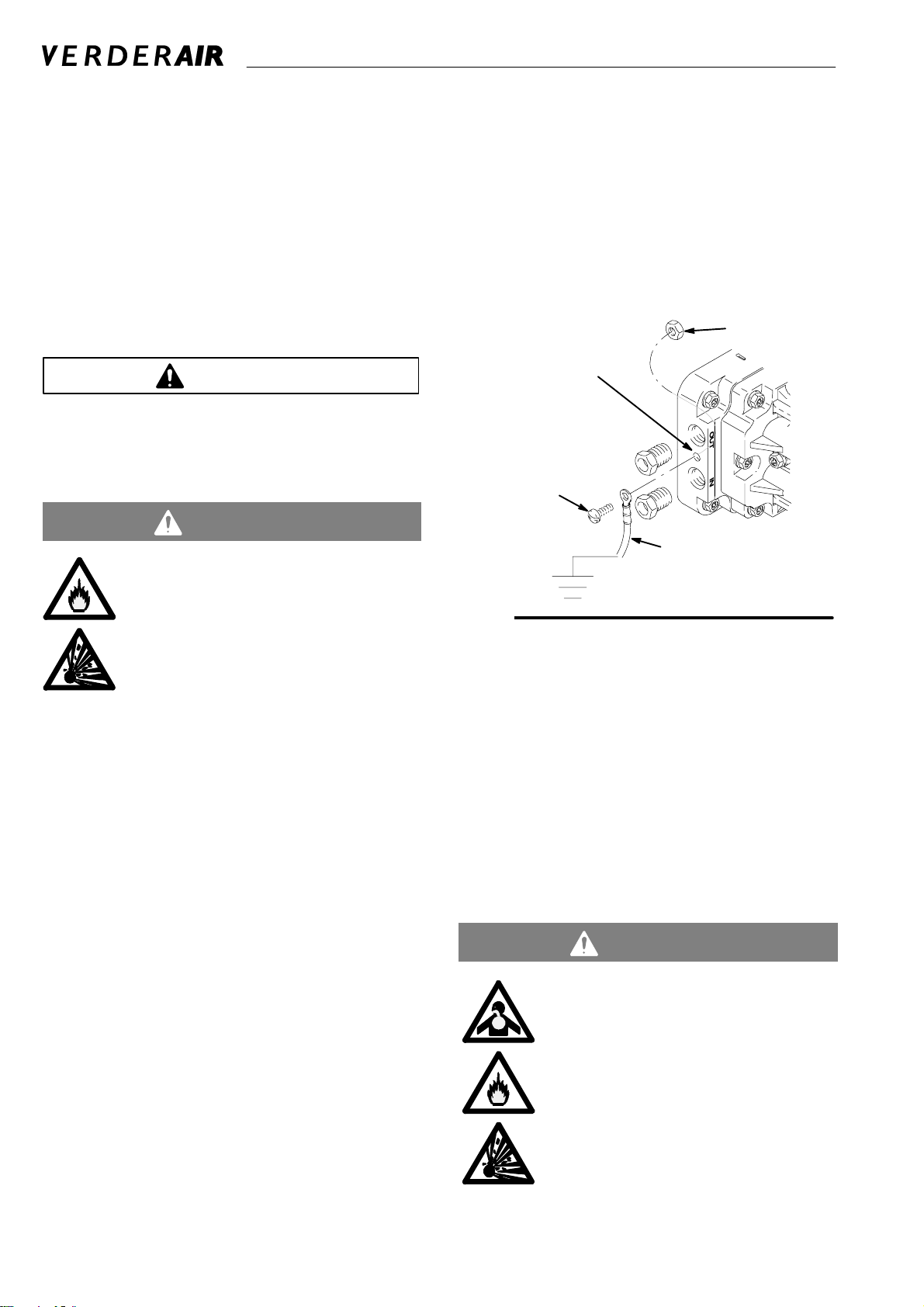

Grounding

Warning

This pump must be grounded. Before you

operate the pump, ground the system as

explained below. Also read the section FIRE

AND EXPLOSION HAZARD on page 3.

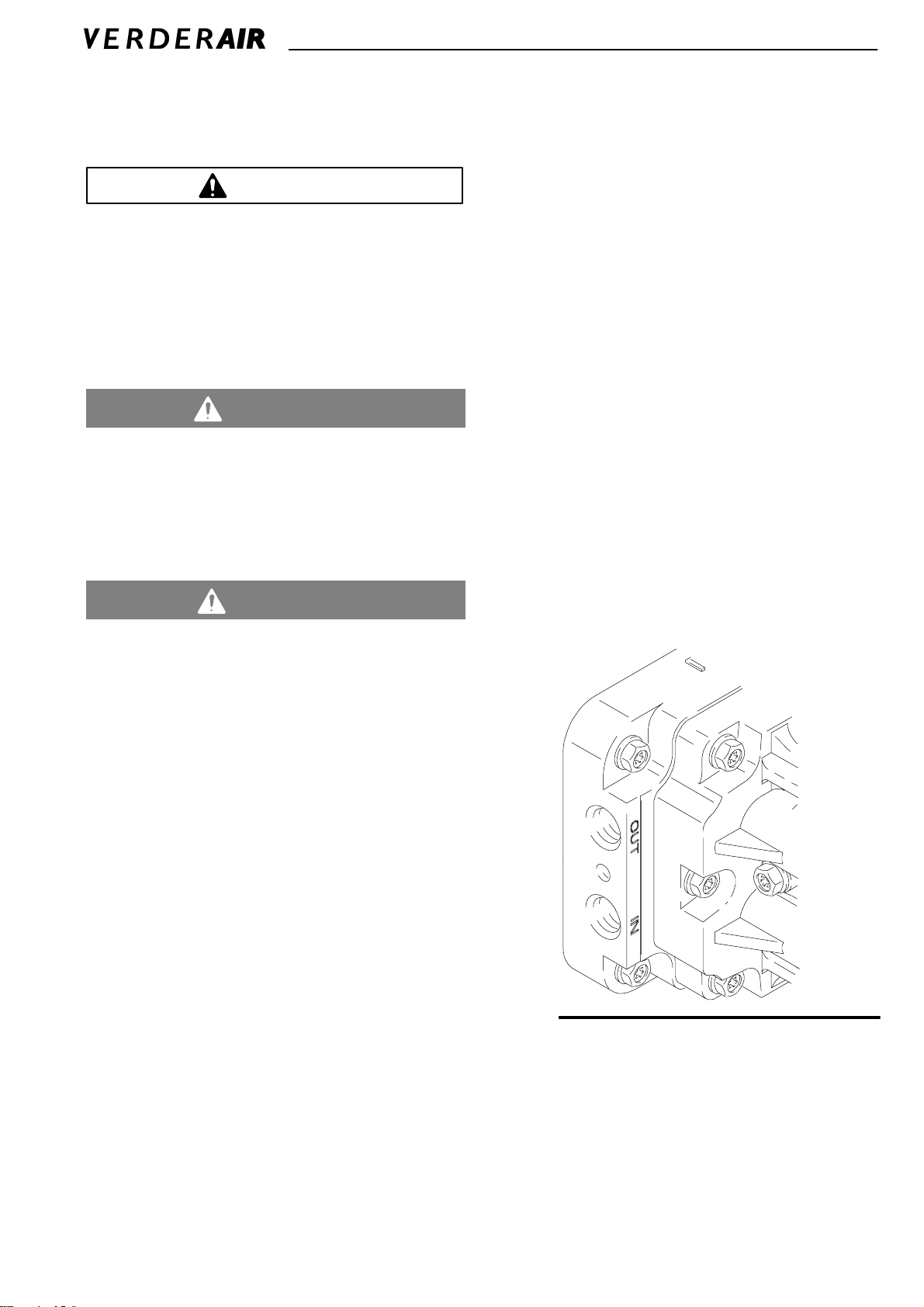

1. Place the nut in the nut catcher on the underside of the

manifold.

2. Insert the bolt through the loop end of the ground wire.

3. Insert the bolt through the hole on the pump manifold

and tighten it into the nut that you positioned in step 1.

4. Connect the clamp end of the ground wire to a true earth

ground.

B

grounding hole

C

A

Fig. 1

06179A

The acetal pump contains stainless steel

fibers which make the wetted parts conductive. Attaching the ground wire to one of the

grounding locations grounds the wetted

parts.

The polypropylene and Kynar pumps are not conduc-

tive. When you pump conductive flammable fluids, al-

ways ground the entire fluid system. Make sure the fluid

has an electrical path to a true earth ground, see Fig 1.

Never use a polypropylene or Kynar pump with non-con-

ductive flammable fluids as specified by your local fire

protection code.

US Code (NFPA 77 Static Electricity) recommends a conductivity greater than 50 x 10

meter) over your operating temperature range to reduce

the hazard of fire. Consult your fluid supplier to determine

the conductivity or resistivity of your fluid. The resistivity

must be less than 2 x 10

To reduce the risk of static sparking, ground the pump and all

other equipment used or located in the pumping area. Check

your local electrical code for detailed grounding instructions

for your area and type of equipment.

Acetal Pump Grounding Instructions

For polypropylene and Kynar pumps, see the warning

above.

Ground all of this equipment.

Pump: Connect a ground wire (A) and clamp, Part No.

819.0157. See Fig. 1. The pump grounding locations are on

the manifold between the inlet and outlet ports. Use the nut

(B) and bolt (C) that are provided with the pump, and install

as follows:

–12

Siemans/meter (mhos/

12

ohm-centimeters.

4 819.6247

Air and fluid hoses: Use only grounded hoses with a maximum of 500 ft (150 m) combined hose length to ensure

grounding continuity.

Air compressor: Follow the manufacturer’s recommendations.

All solvent pails used when flushing: Follow the local code.

Use only grounded metal pails, which are conductive. Do not

place the pail on a non-conductive surface, such as paper or

cardboard, which interrupts the grounding continuity.

Fluid supply container: Follow the local code.

Air Exhaust Ventilation

Warning

TOXIC FLUID HAZARD

Read the USING HAZARDOUS FLUIDS and

FIRE AND EXPLOSION HAZARD sections

on page 3 before you operate this pump.

Be sure the system is properly ventilated for

your type of installation. You must vent the

exhaust to a safe place, away from people,

animals or food handling areas when pumping flammable or hazardous fluids

If the diaphragm ruptures, the fluid being

pumped is exhausted with the air. Place a

container at the end of the air exhaust line to

catch fluid in case the diaphragm ruptures,

and disconnect the pump.

Installation

Mountings

Caution

The pump exhaust air may contain contaminants. If needed,

ventilate to a remote area to reduce possible fluid contamination. See Air Exhaust Ventilation on page 4.

Be sure the mounting can support the weight of the

pump, hoses, and accessories, as well as the stress

caused during operation.

For all mountings, be sure the pump is secured with

screws and nuts.

Warning

To reduce the risk of serious injury, splashing in the eyes

or on the skin, and toxic fluid spills, never move or lift a

pump under pressure. If dropped, the fluid section may

rupture. Always follow the Pressure Relief Procedure on

page 7 before you move or lift the pump.

Air Lines

Warning

Bleed-Type Master Air Valve and Fluid Drain Valve

A bleed-type master air valve and a fluid drain valve are

required on your system.

The bleed-type master air valve relieves air trapped between itself and the pump. Trapped air can cause the

pump to cycle unexpectedly, which could result in serious

bodily injury, including splashing in the eyes, injury from

moving parts, or contamination from hazardous fluids.

The fluid drain valve reduces the risk of serious bodily

injury, including splashing in the eyes or on the skin, or

contamination from hazardous fluids. Install the fluid drain

valve close to the pump’s fluid outlet to relieve pressure in

the hose if the hose becomes plugged.

b. Install a bleed-type master air valve downstream

from the air regulator, and use it to relieve trapped

air. See the Bleed-Type Master Air Valve and

Fluid Drain Valve warning at left. Locate another

bleed-type master air valve upstream from all air line

accessories, and use it to isolate the accessories

during cleaning and repair.

c. The air line filter removes harmful dirt and moisture

from the compressed air supply.

2. Install a flexible air hose between the accessories and

the pump air inlet. Screw the air line fitting into the air

inlet.

3. Do not restrict the exhaust port. Excessive exhaust

restriction can cause erratic pump operation.

Fluid Lines

Fig. 2. On each end of the fluid manifold are a fluid IN port

and a fluid OUT port. NOTE: Make sure the fluid OUT port

on the fluid manifold is mounted up. This will insure proper

pump priming. Fluid-in and fluid-out lines can be connected

on the same end, or opposite ends of the manifold. Plug

ports that are not used (plugs provided).

1. Mount the air line accessories on the wall or on a

bracket. Be sure the air line supplying the accessories

is grounded.

a. The pump speed can be controlled in one of two

ways: To control it on the air side, install an air

regulator. To control it on the fluid side, install a

fluid valve near the outlet.

Fig. 2

06179A

819.6247 5

Installation

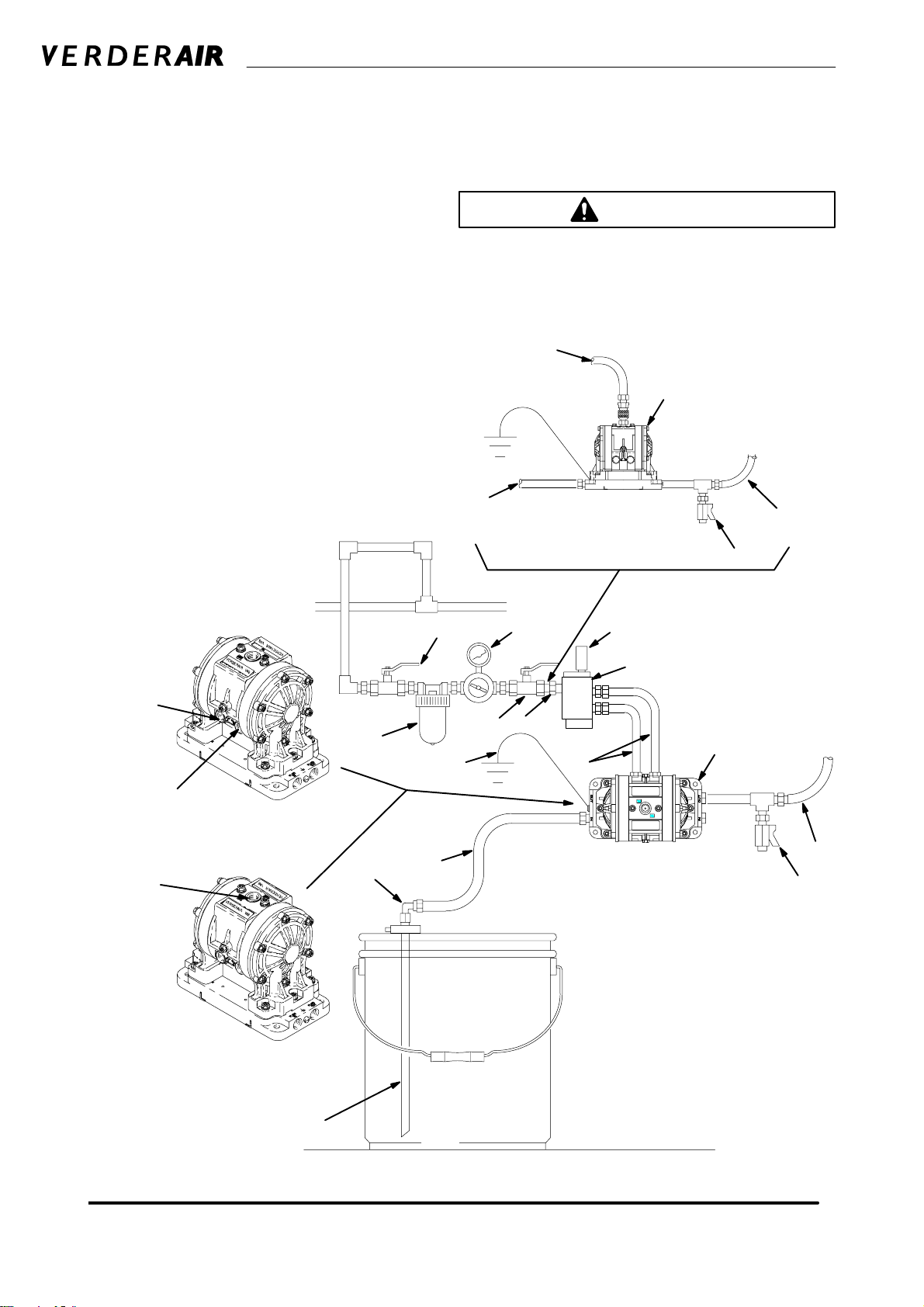

Typical Installation

The installation shown in Fig. 3 is only a guide to help select

and install a pump; they are not actual system designs.

Typical installation includes (not supplied by VERDER):

For solenoid operation: four-way, 5-port, 2-position sole-

noid valve with 1/4-in. ports. Schrader Bellows Part

No. C511ABB5 or equivalent.

KEY

A VERDERAIR VA 8 pump

B Bleed-type master air valve

(required for pump)

C Air line(s)

E Master air valve (for accessories)

F Air line filter

G Muffler

H Pump air regulator

J Fluid drain valve

(required on fluid outlet side of pump)

L Fluid suction line

N Fluid supply hose

T Bung adapter

U 4-way solenoid

Y Ground wire (required)

See page 4 for installation instructions.

PLC or timer. Consult your local industrial controls

distributor.

Caution

For solenoid operation, the pump must exhaust through the

solenoid. Failure to exhaust through solenoid could cause the

diaphragms to fail.

C

A

L

Internal Air Valve View

(shown upright for clarity)

N

J

Air line to Port A

Air line to Port B

Air line to inlet

Remote Solenoid Operated

Internal Air Valve Operated

E H

G

U

C

F

L

T

B

A

Y

C

Remote Solenoid View

N

J

Fig. 3

6 819.6247

L

06504

Operation

Pressure Relief Procedure

Warning

To reduce the risk of serious injury, including splashing fluid

in the eyes or on the skin, follow this procedure whenever

you are instructed to relieve pressure, when you shut off

the pump, and before you check, adjust, clean, move, or

repair any system equipment.

1. Shut off air and reserve air to the pump.

2. Open the dispensing valve if the system has one.

3. Open the fluid drain valve to relieve all system pressure,

and have a container ready to catch the drainage.

Flushing the Pump Before First Use

The pump was tested in water. If water could contaminate the

fluid you are pumping, flush it thoroughly with a compatible

solvent. Follow the procedure in Starting and Adjusting the

Pump.

Starting and Adjusting the Pump

Warning

To reduce the risk of serious injury, splashing in the eyes or

on the skin, and toxic fluid spills, never move or lift a pump

under pressure. If the pump is dropped, the fluid section

could rupture. Always follow the Pressure Relief Proce-

dure above before you move or lift the pump.

3. Place the suction tube (if used) in the fluid to be pumped.

4. Place the end of the outlet hose into an appropriate container.

5. Close the fluid drain valve.

6. With the air regulator closed, open all bleed-type master

air valves.

7. If the outlet hose has a dispensing device, hold it open

while continuing with step 8.

8. Slowly open the air regulator until the pump starts to

cycle. Allow the pump to cycle until all air is pushed out

of the lines and the pump is primed.

NOTE: To prime a remote solenoid-operated air

valve, operate the pump at a minimum 60 cpm

rate until the pump is fully primed.

Pump Shutdown

At the end of the work shift, and before you check, adjust,

clean, or repair the system, relieve air and fluid pressure.

Warning

To reduce the risk of serious injury whenever you are

instructed to relieve pressure, always follow the Pressure

Relief Procedure at left.

1. Be sure the pump is properly grounded. Read and follow

the instructions in Grounding on page 4.

2. Check all fittings to be sure they are tight. Be sure to use

a compatible liquid thread sealant on all male threads.

Tighten the fluid inlet and outlet fittings and plugs securely. Retorque all fasteners before start-up.

819.6247 7

Maintenance

Lubrication

The air valve is lubricated at the factory and designed to operate without additional lubrication.

If added lubrication is desired, every 500 hours of operation

(or monthly), remove the hose from the pump air inlet and

add two drops of machine oil to the air inlet.

Caution

Do not over-lubricate the pump. Excess oil is exhausted

through the muffler, which could contaminate your fluid supply or other equipment.

Tightening Threaded Connections

Before each use, check all hoses for wear or damage, and

replace as necessary. Be sure all threaded connections are

tight and free of leaks.

Check fasteners. Tighten or retorque as necessary. Although

pump use varies, a general guideline is to retorque fasteners

every two months. See Service for torque specifications. See

Torque Sequence, page 17, for torque sequence.

Flushing and Storage

Flush the pump to prevent the fluid from drying or freezing in

the pump and damaging it. Always flush the pump and re-

lieve the pressure before storing for any length of time. Use

a compatible solvent.

Warning

To reduce the risk of serious injury whenever you are

instructed to relieve pressure, always follow the Pressure

Relief Procedure on page 7.

If you are flushing, run the pump long enough to thoroughly

clean the pump and hoses, close the air regulator, and remove the suction hose from the solvent and place it in the

fluid to be pumped.

If you are shutting down the pump, remove the suction hose

from the fluid container, run the pump until the fluid is forced

out of the system, and shut off the air supply immediately.

8 819.6247

Loading...

Loading...