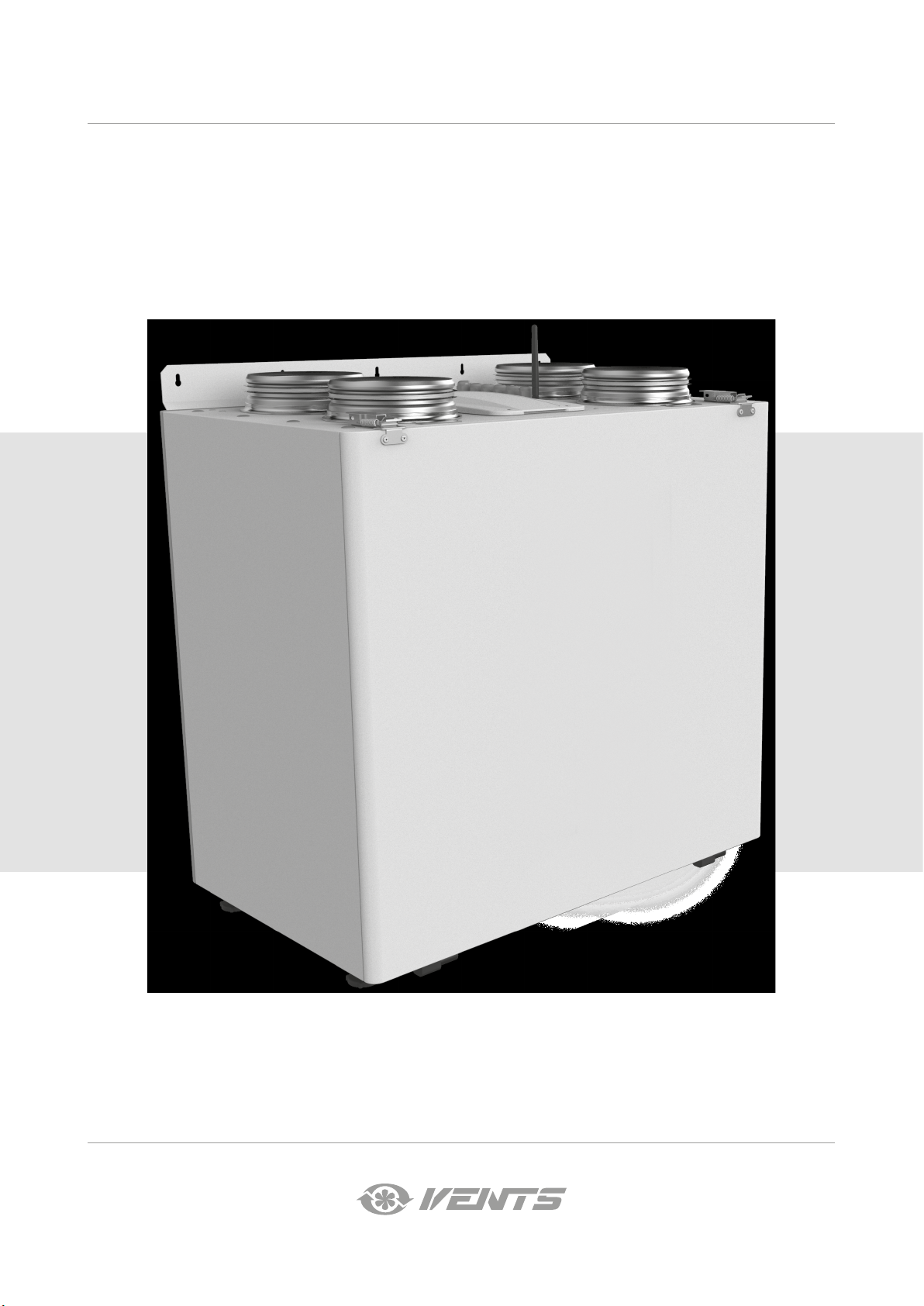

Vents VUT 550 VB EC, VUT 350 V1B EC, VUT 160 VB EC, VUT 160 V1B EC, VUT 160 V1 EC User Manual

...

USER’S MANUAL

VUT 160 V EC

VUE 160 V EC

VUT 160 V1 EC

VUE 160 V1 EC

VUT 160 VB EC

VUE 160 VB EC

VUT 160 V1B EC

VUE 160 V1B EC

VUT 350 V1B EC

VUE 350 V1B EC

VUT 350 VB EC

VUE 350 VB EC

VUT 550 VB EC

VUE 550 VB EC

Heat and energy recovery air handling unit

VUT/VUE 160/350/550 V(1)(B) EC

CONTENTS

Safety requirements .....................................................................................................................................................................2

Purpose ................................................................................................................................................................................................ 4

Delivery set ........................................................................................................................................................................................ 4

Designation key .............................................................................................................................................................................. 4

Technical data .................................................................................................................................................................................. 5

Design and operating principle ........................................................................................................................................... 7

Installation and set-up................................................................................................................................................................ 9

Connection to power mains .................................................................................................................................................. 13

Technical maintenance .............................................................................................................................................................. 16

Storage and transportation regulations .......................................................................................................................... 17

Manufacturer’s warranty ........................................................................................................................................................... 18

Certificate of acceptance .......................................................................................................................................................... 19

Seller information .......................................................................................................................................................................... 19

Installation certificate .................................................................................................................................................................. 19

Warranty card ...................................................................................................................................................................................19

This user’s manual is a main operating document intended for technical, maintenance, and operating staff.

The manual contains information about purpose, technical details, operating principle, design, and installation of the

VUT/VUE 160/350/550 V(1)(B) EC unit and all its modifications.

Technical and maintenance staff must have theoretical and practical training in the field of ventilation systems and should be able to

perform works in accordance with workplace safety rules as well as construction norms and standards applicable in the territory of the

country.

The information in this user’s manual is correct at the time of the document’s preparation.

The Company reserves the right to modify the technical characteristics, design, or configuration of its products at any time in order to

incorporate the latest technological developments.

No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form or by any means in any information

search system or translated into any language in any form without the prior written permission of the Company.

SAFETY REQUIREMENTS

• Please read the user’s manual carefully prior to installing and operating the unit.

• All user’s manual requirements as well as the provisions of all the applicable local and national construction, electrical, and technical

norms and standards must be observed when installing and operating the unit.

• The warnings contained in the user’s manual must be considered most seriously since they contain vital personal safety information.

• Failure to follow the rules and safety precautions noted in this user’s manual may result in an injury or unit damage.

• After a careful reading of the manual, keep it for the entire service life of the unit.

• While transferring the unit control, the user’s manual must be turned over to the receiving operator.

UNIT INSTALLATION AND OPERATION SAFETY PRECAUTIONS

• Disconnect the unit from power mains prior

to any installation operations.

• The unit must be grounded!

• Unpack the unit with care.

• While installing the unit, follow the safety

regulations specific to the use of electric

tools.

2

www.ventilation-system.com

VUT/VUE 160/350/550 V(1)(B) EC

• Do not change the power cable length

at your own discretion. Do not bend the

power cable. Avoid damaging the power

cable. Do not put any foreign objects on the

power cable.

• Do not use damaged equipment or cables

when connecting the unit to power mains.

• Do not lay the power cable of the unit in

close proximity to heating equipment.

• Do not operate the unit outside the

temperature range stated in the user’s

manual. Do not operate the unit in

aggressive or explosive environments.

• Do not touch the unit controls with wet

hands. Do not carry out the installation and

maintenance operations with wet hands.

• Do not allow children to operate the unit.

• Do not store any explosive or highly

flammable substances in close proximity to

the unit.

• Do not open the unit during operation.

• Do not block the air duct when the unit is

switched on.

• Do not wash the unit with water. Protect

the electric parts of the unit against ingress

of water.

• Disconnect the unit from power mains prior

to any technical maintenance.

• When the unit generates unusual sounds,

odour, or emits smoke, disconnect it from

power supply and contact the Seller.

• Do not direct the air flow produced by the

unit towards open flame or ignition sources.

• In case of continuous operation of the unit,

periodically check the security of mounting.

• Do not sit on the unit and avoid placing

foreign objects on it.

THE PRODUCT MUST BE DISPOSED SEPARATELY AT THE END OF ITS SERVICE LIFE.

www.ventilation-system.com

• Use the unit only for its intended purpose.

DO NOT DISPOSE THE UNIT AS UNSORTED MUNICIPAL WASTE.

3

VUT/VUE 160/350/550 V(1)(B) EC

PURPOSE

The unit is designed to ensure continuous mechanical air exchange in houses, offices, hotels, cafés, conference halls, and other utility

and public spaces as well as to recover the heat energy contained in the air extracted from the premises to warm up the filtered stream

of supply air.

The unit is not intended for organizing ventilation in swimming pools, saunas, greenhouses, summer gardens and other spaces with high

humidity.

Due to the ability to save heating energy by means of energy recovery, the unit is an important element of energy-efficient premises.

The unit is a component part and is not designed for stand-alone operation.

It is rated for continuous operation.

Transported air must not contain any flammable or explosive mixtures, evaporation of chemicals, sticky substances, fibrous materials,

coarse dust, soot and oil particles or environments favourable for the formation of hazardous substances (toxic substances, dust,

pathogenic germs).

Relative humidity of transported air must not exceed +20 °C at an ambient humidity of 80 %.

THE UNIT SHOULD NOT BE OPERATED BY CHILDREN OR PERSONS WITH REDUCED

PHYSICAL, MENTAL, OR SENSORY CAPACITIES, OR THOSE WITHOUT

THE APPROPRIATE TRAINING.

THE UNIT MUST BE INSTALLED AND CONNECTED ONLY BY PROPERLY QUALIFIED

PERSONNEL AFTER THE APPROPRIATE BRIEFING.

THE CHOICE OF UNIT INSTALLATION LOCATION MUST PREVENT UNAUTHORIZED

ACCESS BY UNATTENDED CHILDREN.

DELIVERY SET

Name Number

Air handling unit 1 pc.

User's manual 1 pc.

Packing box 1 pc.

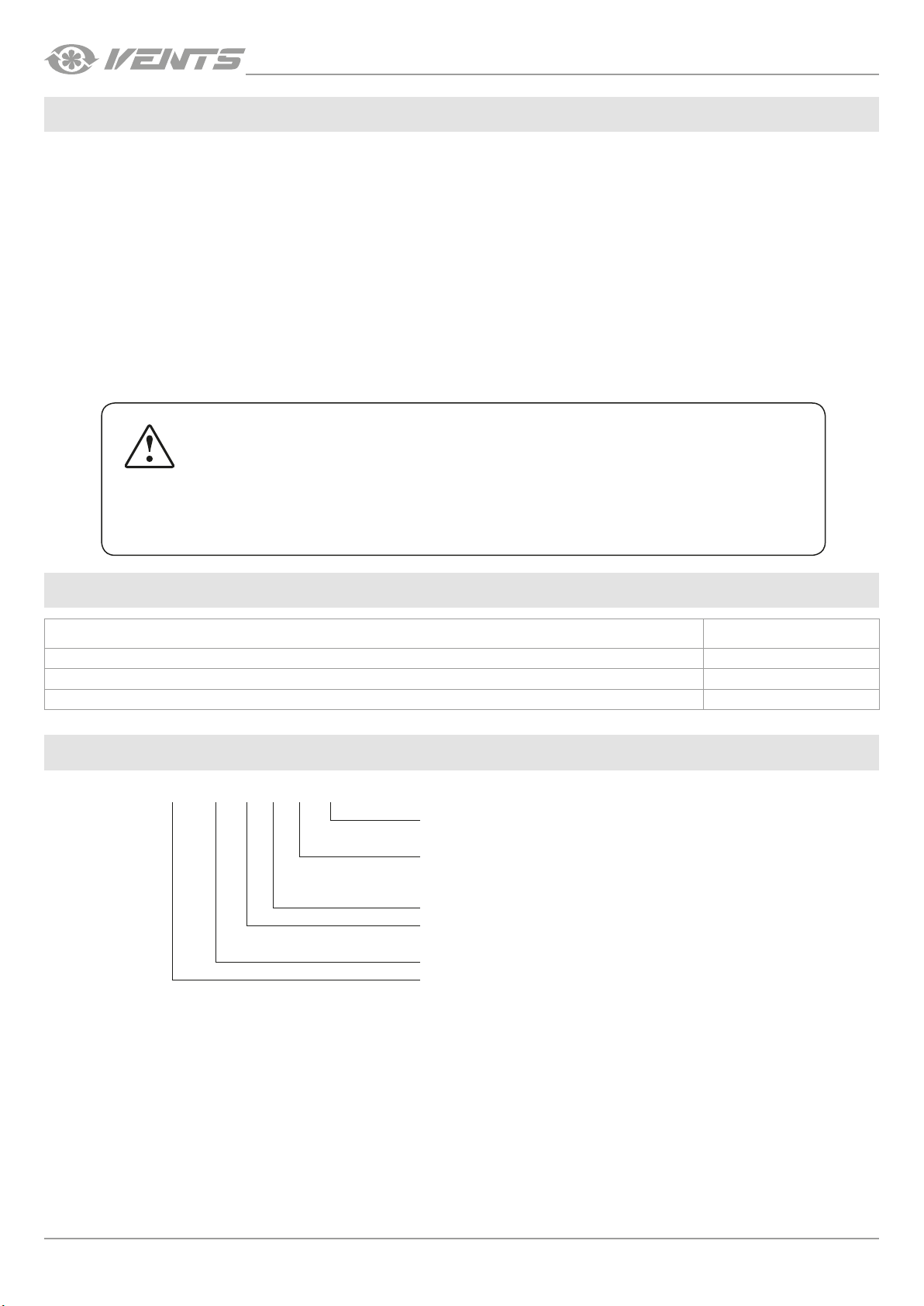

DESIGNATION KEY

VUT 350 V 1 B EC

Motor type

EC — electronically commutated

Additional components

_ — no

B – bypass

Casing design

Spigot orientation

V — vertical

Rated air ow [m

Series of units

VUT — heat recovery air handling unit

VUE — energy recovery air handling unit

3

/h]

4

www.ventilation-system.com

VUT/VUE 160/350/550 V(1)(B) EC

TECHNICAL DATA

The unit is designed for indoor application with the ambient temperature ranging from +1 °C up to +40 °C and relative humidity up to

80 %.

In order to prevent condensation on the internal walls of the units, it is necessary that the surface temperature of the casing is 2-3 °C

higher than the dew point temperature of the transported air.

The unit is rated as a Class I electrical appliance.

Hazardous parts access and water ingress protection rating:

• IP22 for the unit connected to the air ducts

• IP44 for the unit motors

The unit design is constantly being improved, thus some models may be slightly different from those described in this manual.

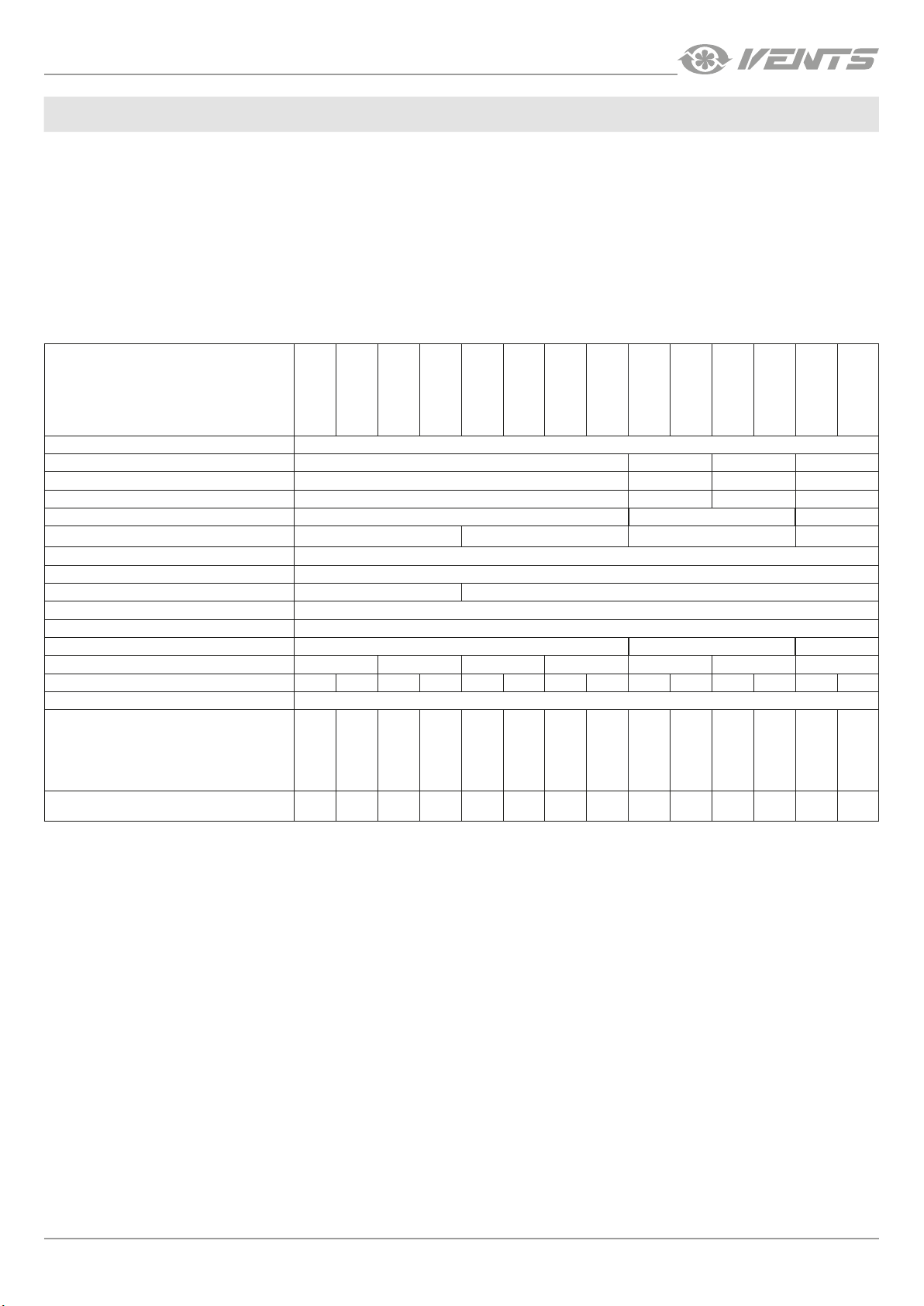

TECHNICAL DATA

MODEL

VUT 160 V EC

VUE 160 V EC

VUT 160 VB EC

VUE 160 VB EC

VUT 160 V1 EC

VUE 160 V1 EC

VUT 160 V1B EC

VUE 160 V1B EC

VUT 350 V1B EC

VUE 350 V1B EC

VUT 350 VB EC

VUE 350 VB EC

VUT 550 VB EC

Supply voltage [V/50 (60) Hz] 1~ 220-240

Maximum fan power [W ] 57 169 178 337

Maximum unit current (without a heater) [A] 0.5 1.3 1.4 2.4

Maximum air flow [m

RPM [min

Sound pressure level at 3 m distance [dBA] 24 22 28 26

Transported air temperature [°С] -25...+40

Casing material Painted steel

Insulation, mineral wool [mm] 20 40

Filtering class of the extract filter G4

Filtering class of the supply filter F7 (optionally G4)

Connected air duct diameter [mm] 125 160 200

Weight [kg] 34 36 42 44 57 64 82

Heat recovery efficiency [%] 85-93 76-92 85-93 76-92 85-93 76-92 85-93 76-92 85-92 73-91 85-92 73-91 84-92 73-91

Heat exchanger type Counter-flow

-1

] 3770 3200 2860

3

/h] 200 420 450 690

VUE 550 VB EC

Heat exchanger material

Polystyrene

Enthalpy

membrane

Polystyrene

Enthalpy

membrane

Polystyrene

Enthalpy

membrane

Polystyrene

Enthalpy

membrane

Polystyrene

Enthalpy

membrane

Polystyrene

Enthalpy

membrane

Polystyrene

SEC class A+ A A+ A A+ A A+ A A+ A A+ A A+ A

The VUE units are equipped with an enthalpy heat exchanger and do not require condensate drainage.

Enthalpy

membrane

www.ventilation-system.com

5

B

B1

L2

VUT/VUE 160/350/550 V(1)(B) EC

ØD

L1

Model

VUT/VUE 160 V EC

VUT/VUE 160 V1 EC

VUT/VUE 160 VB EC

VUT/VUE 160 V1B EC

VUT/VUE 350 VB EC

VUT/VUE 350 V1B EC

VUT/VUE 550 VB EC

H1

ØD1

H

L

Dimensions [mm]

Ø D Ø D1 B B1 H H1 L L1 L2

125 18 340 330 665 550 600 388 143

125 18 380 370 690 590 640 388 143

125 18 340 330 665 580 600 388 143

125 18 380 370 710 620 640 388 143

160 18 600 583 760 675 730 426 230

160 18 480 470 760 675 730 426 200

200 18 730 720 76 0 675 823 498 288

6

www.ventilation-system.com

Loading...

Loading...