Page 1

SC-IW

(In-Wall)

Subwoofer

SubContractorTMSeries

INSTALLATION

MANUAL

Page 2

Caution!

.

www.velodyne.com

SC-IW Installation Manual

i

Page 3

Attention!

.

www.velodyne.com

SC-IW Installation Manual

ii

Page 4

Vorsicht!

.

www.velodyne.com

SC-IW Installation Manual

iii

Page 5

Attenzione!

.

www.velodyne.com

SC-IW Installation Manual

iv

Page 6

Table of Contents

P

roduct Overview.................................................................................................1

- Driver Technology ...........................................................................................1

- Cabinet Technology .........................................................................................1

Installation Overview .............................................................................................3

New Construction Installation - Standard Grille .........................................................4

New Construction Installation - Designer Grille .......................................................15

Retro-Fit Installation - Designer Grille ....................................................................25

Retro-Fit Installation - Standard Grille ....................................................................38

Other Velodyne Subwoofer Products .....................................................................53

.

www.velodyne.com

SC-IW Installation Manual

V

Page 7

Product Overview

T

he SC-IW (In-Wall) subwoofer can be installed in a variety of locations and positions in any given

installation. Although this product is extremely versatile and flexible in its uses, it has been

specifically designed for two major applications - New Construction Installations and Retro-Fit

Installations in structures made of traditional 2x4 studs with 16 inch spacing, on-center.

This document provides the detailed process for properly installing the SC-IW into a wall. The

SC-IW is designed to be powered by the SC-1250 subwoofer amplifier. For maxiumum

performance, it is strongly recommended that only the SC-1250 be used to power the SC-IW.

The user’s manual for the SC-1250 subwoofer amplifier provides the details on connectivity and

proper configuration of the SC-IW after installation.

Driver Technology

The SC-IW subwoofer utilizes new and innovative patent-pending driver technology that has been

created specifically for the custom installation market. The SC-IW driver was specially designed

to maximize in-wall subwoofer performance while significantly reducing wall vibration. The driver

uses "dual tandem spider design" along with a pr

an extremely long-throw driver capable of producing very high sound pressure levels. Below is

a cross section of the SC-IW driver.

opriety neodymium motor structure providing

Cabinet Technology

Complimenting the cutting edge technology in the SC-IW driver is the cabinet, again specially

designed for in-wall installations. The SC-IW cabinet wall utilizes a propriety multilayer "sandwich"

material consisting of two 1.0 mm aluminum plates sur

fiberboard (MDF) which is laminated under high pressure to create an extremely rigid cabinet

design that has the density and performance of traditional high end cabinets utilizing 3/4 or 1

inch MDF.

.

www.velodyne.com

rounding 2.5 mm of medium density

SC-IW Installation Manual

1

Page 8

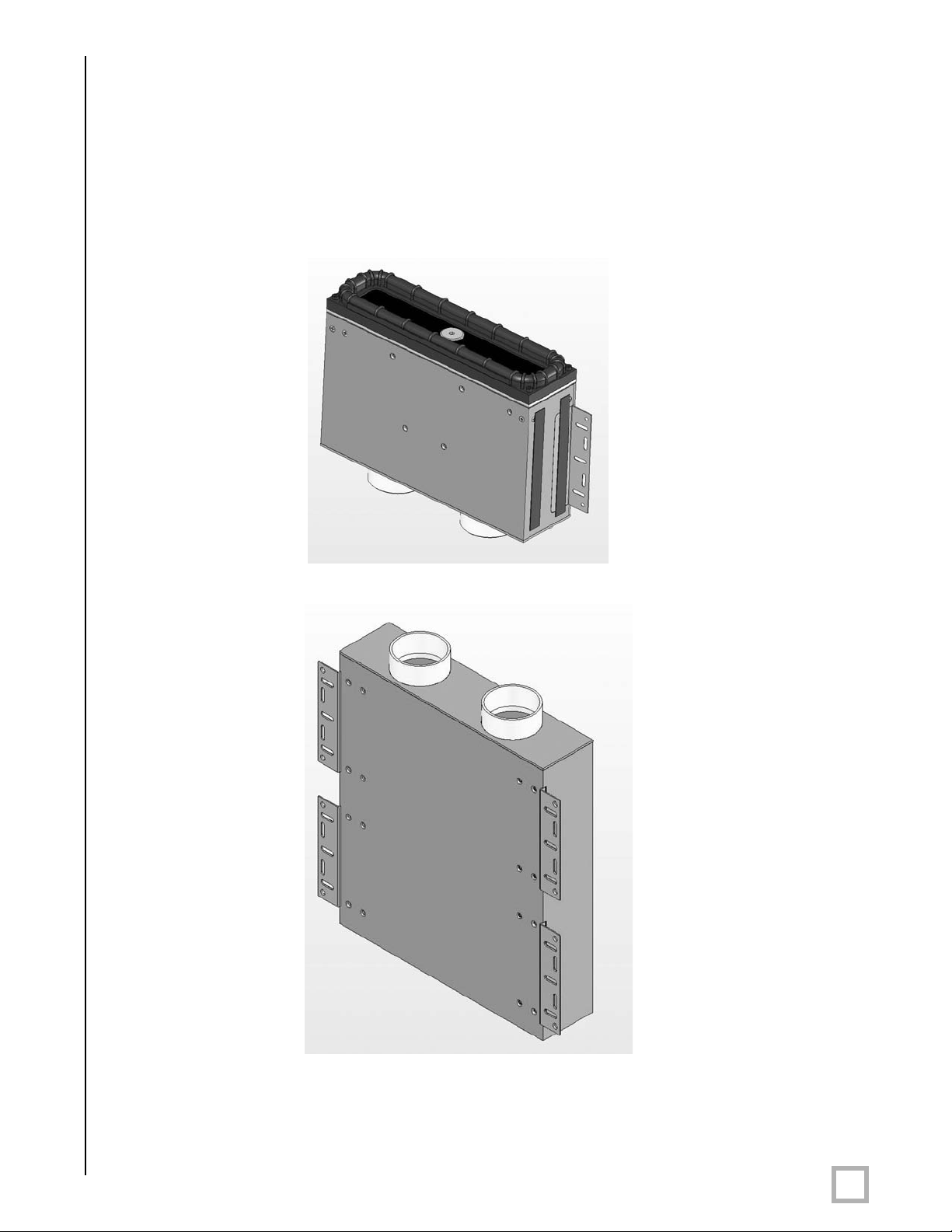

T

he SC-IW consists of two cabinets — the “driver module” and the “back box.” (a.k.a. the

“Enclosure”). Unlike other in-wall products where a back box may be optional, the SC-IW

r

equires both enclosures, unaltered, for every installation. In new construction situations, the

back box is in installed first (for example, at the framing or rough out stage), and the driver

module is installed later in the trim out stage. In retrofit situations both boxes are typically

installed together.

The driver module assembly is shown below. It uses a unique bracing system in that the driver

acts as the "internal bracing structure" for the speaker enclosure.

The in-wall back box contains internal bracing to minimize cabinet flex and wall vibration.

The driver module and the back box ar

supplied hose clamps. This linking system provides the installer the flexibility to either install the

two boxes together in the wall or separately prior to installation.

.

www.velodyne.com

e connected thr

ough two r

ubber conduits, sealed with

SC-IW Installation Manual

2

Page 9

T

he SC-IW comes in two completely separate cartons — the SC-IWBB (Back Box) and the

SC-IWDVR (Driver).

Parts included with the SC-IWBB rough install kit:

• In-wall back box - Qty 1

• Mudring for "retro fit" installation - Qty 1

• Installation manual - Qty 1

• Installation hardware

Parts included with the SC-IWDVR driver module:

• SC-IW driver module - Qty 1

• Clamp ring - Qty 2

• Standard grille - Qty 1

• Designer grille - Qty 1

• Hardware

• Installation manual - Qty 1

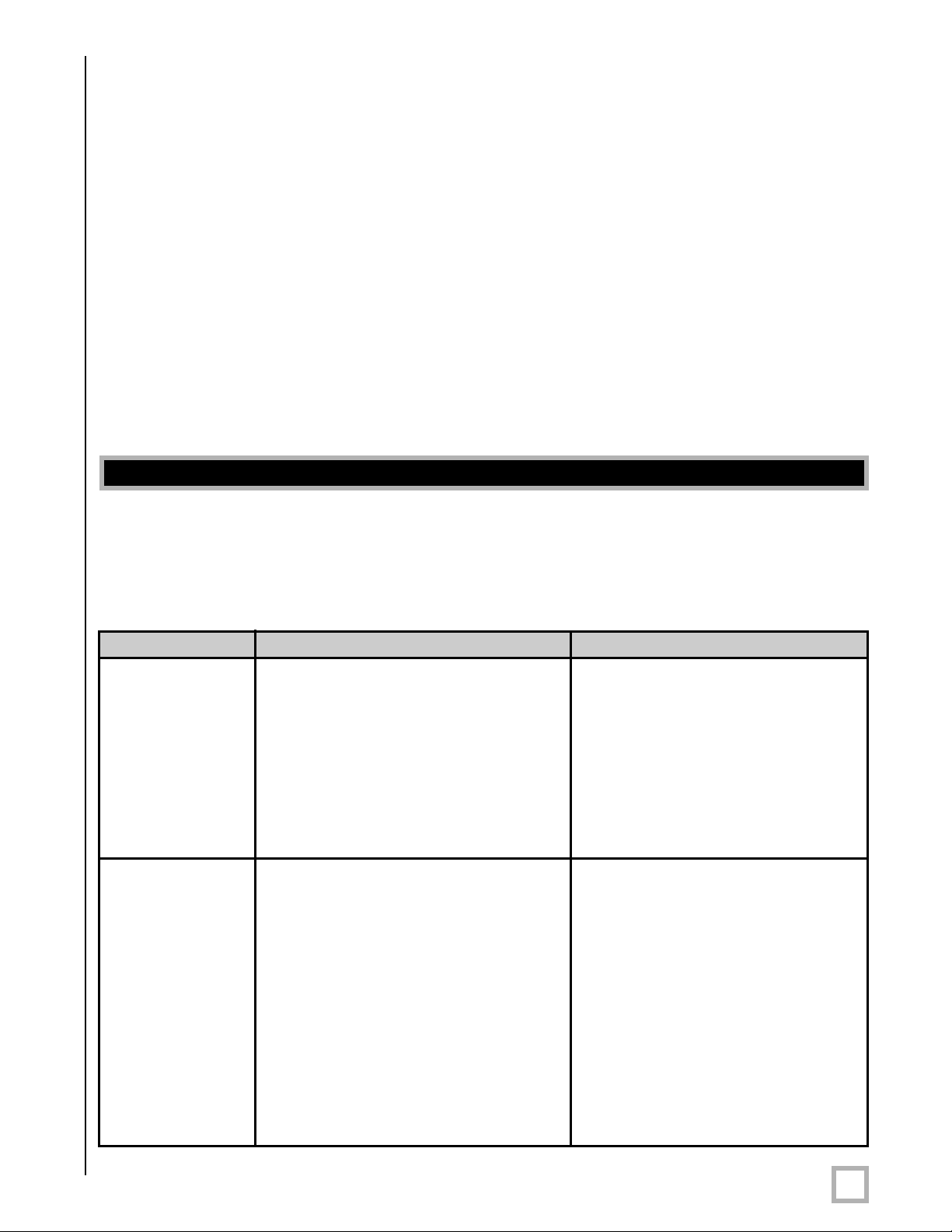

Installation Overview

You must first decide how the SC-IW is to be installed — whether new or retrofit installation,

and whether you are using the standard or designer grille. Remember that in all cases the grille

can be painted to match the room’s de´cor.

Consider the following information when deciding how the SC-IW will be installed.

CONSTRUCTION NEW RETROFIT

Standard Benefits: Benefits:

Grille

Designer Benefits: Benefits:

Grille

• Allows pre-installation of the back box Provides easiest servicing for the driver

at minimal risk and expense

• Provides easiest servicing for the driver

• No risk to the subwoofer during this installation

drywall/paint/finish processes

See page 4 for a description of

this installation

• Provides the smallest grille available Provides the smallest grille available

Considerations:

• Must install both back box and driver See page 25 for a description of

cabinet at frame out stage — higher risk this installation

of theft or damage to the subwoofer

• Difficult to service driver as drywall must

be removed to remove driver module

See page 38 for a description of

.

www.velodyne.com

See page 15 for a description of

this installation

SC-IW Installation Manual

3

Page 10

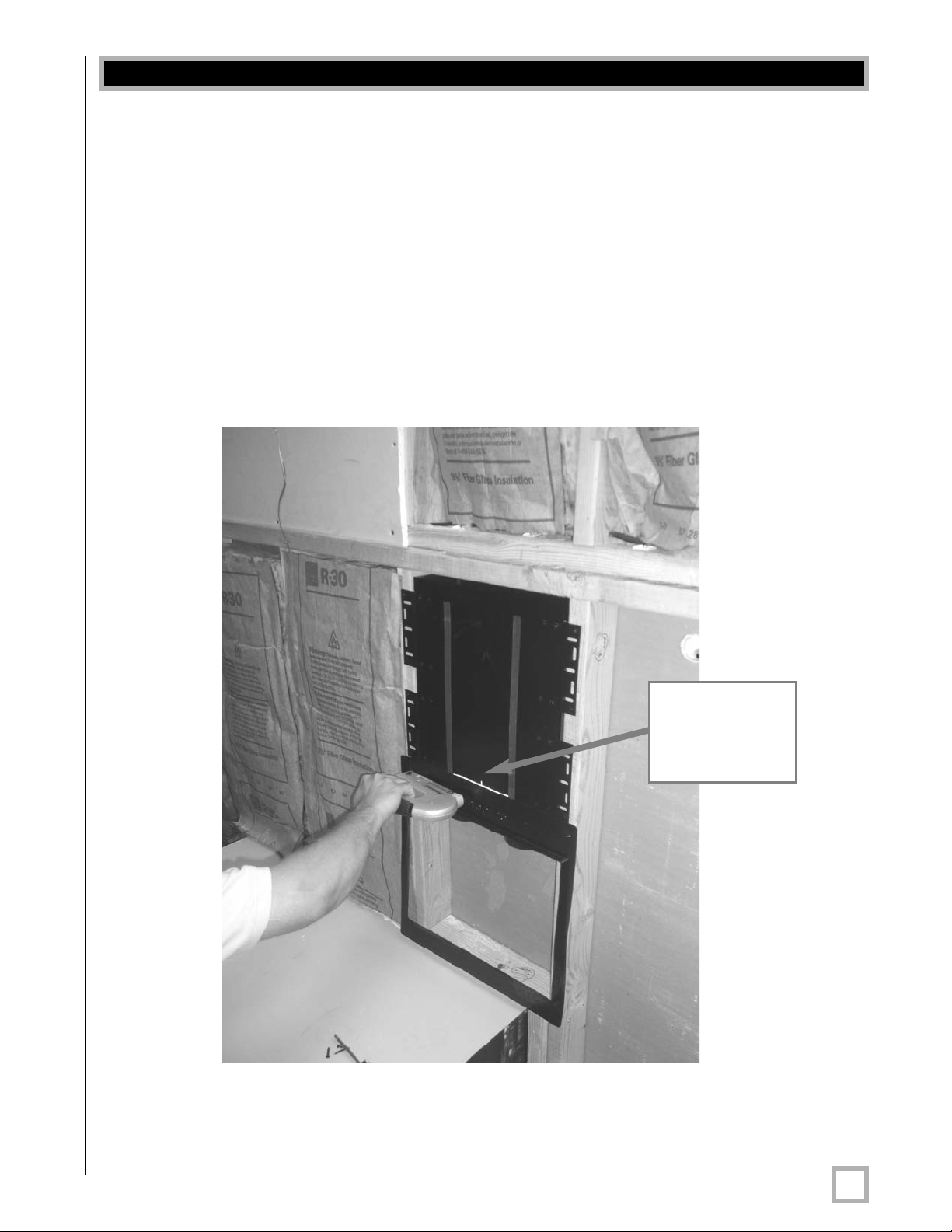

New Construction Installation — Standard Grille

N

ote:This installation process assumes that the installer has access to the open framed 2x4

studded wall with 16 inch spacing. In the event that the stud spacing is larger, an additional

2x4 or other spacer can be used to fill the space between the SC-IW back box and the

neighboring stud.

Step 1 - Install Mudring

Unpack the first carton (SC-IWBB) and place the contents on the floor. Remove the mudring

from the packaging. At this time the decision needs to be made about which direction the woofer

will fire (up or down) and therefore where the grille will be located on the wall. Typically the woofer

will fire downwards and the grille will be located near the floor. (Remember to consider

baseboards and other trim work that might be used on the house in this case.) Once you have

decided where to place the grille, staple the mudring to the studs as shown in figure 1.

Align mud

ring to line

on the

back box.

Figure 1: Install Mudring - The back box is used for reference position only — it is installed in the next step.

.

www.velodyne.com

SC-IW Installation Manual

4

Page 11

S

tep 2 - Install Back Box

O

nce the mudring is stapled into place, the back box should be installed using eight of the phillips

drive flat head screws included in the package. When installing the back box, the mudring

should be aligned to the white line on the cabinet. Once the mudring and the back box are

aligned, install the back box as shown.

Figure 2: Install Back Box

.

www.velodyne.com

SC-IW Installation Manual

5

Page 12

S

tep 3 - Route Wire

R

oute the wire from the location where the electronics gear is located to where the SC-IW will

be. There is "extra space" between the studs and the back box in the event that the wire has

to pass along the side of the back box to the driver module.

Figure 3: Route Wire

Step 4 - Cover Rubber Couplings

If the installation is not going to be finished right away, Velodyne recommends "taping" or

otherwise “covering” the two connecting tubes to prevent paint, drywall and/or foreign objects

from entering the back box.

.

www.velodyne.com

SC-IW Installation Manual

6

Page 13

S

tep 5 - Finish Wall

T

he wall can now be finished in a traditional fashion utilizing the appropriate drywall thickness,

standard texturing and finishing methods. Be sure to advise the "finishing” contractors that they

are to drywall up to the edge of the mudring, as the mudring is the place holder for the

installation of the driver module and standard grille.

e 4: Finish Wall

Figur

Note: Steps 6 through 14 presume that you have obtained and are ready to install the

-IWDVR (In-W

SC

Step 6 - Verify Drywall was Properly Installed

Once the wall is finished, the installer must revisit the installation site and verify that the

contractors have properly used the mudring as their guide leaving an opening that is

oximately 16 1/2” x 13 1/4”.

appr

.

www.velodyne.com

all Driver Module).

SC-IW Installation Manual

7

Page 14

S

tep 7 - Remove Mudring

A

t this point, the mudring can be removed. It should be easily removed by "pulling it through"

the drywall opening. After it is removed, discard.

Figure 5: Remove Mudring

.

www.velodyne.com

SC-IW Installation Manual

8

Page 15

S

tep 8 - Place Clamp Rings on Driver Module

R

emove the two clamp rings from the packaging and place a clamp ring onto each of the

bottom edges of the tubes.

Note: The position of the clamp ring is critical. Make sure that the screw section of the ring

is on either side of the tube and not on the front or the back. Please see picture below.

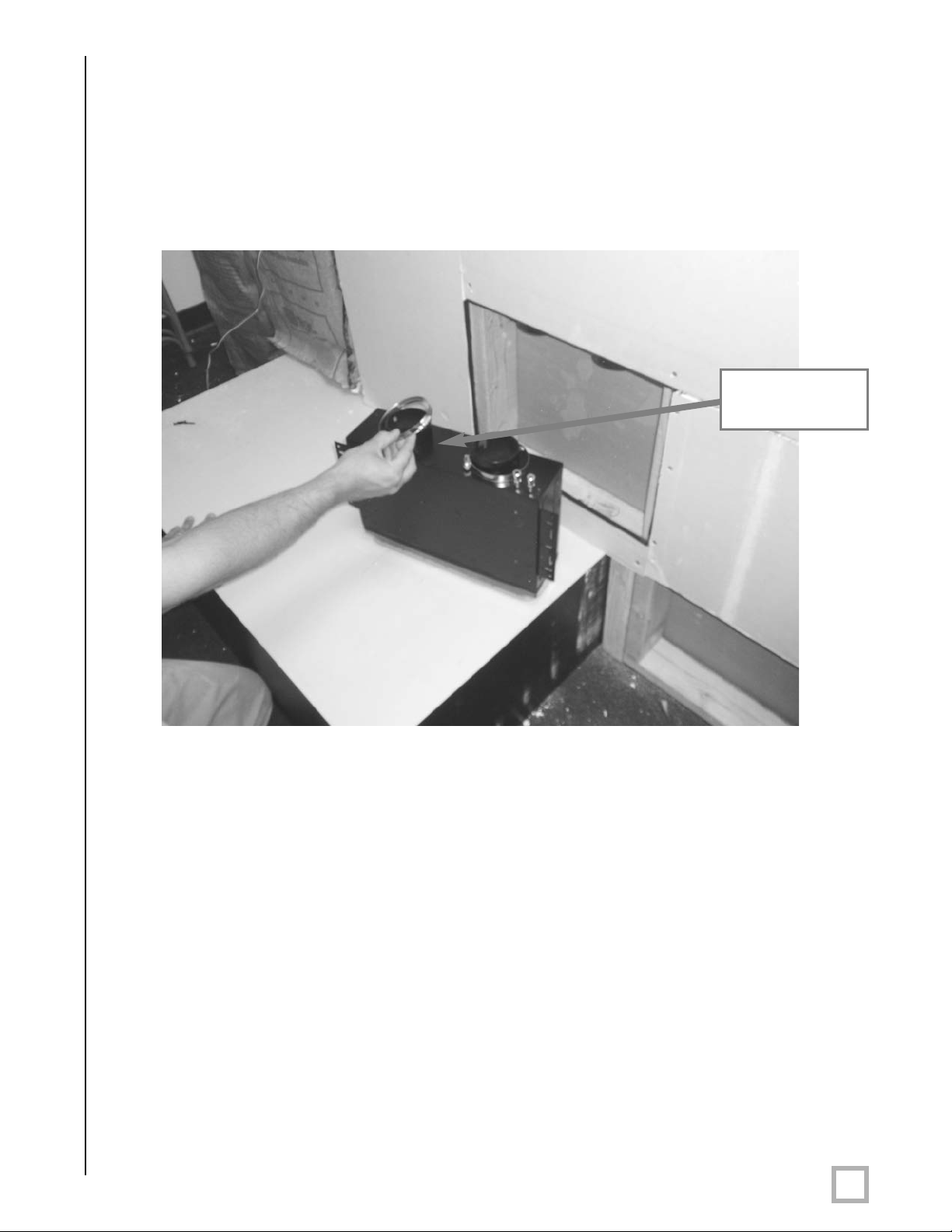

Screw must

face outward

Figure 6: Clamp Ring Placement

.

www.velodyne.com

SC-IW Installation Manual

9

Page 16

S

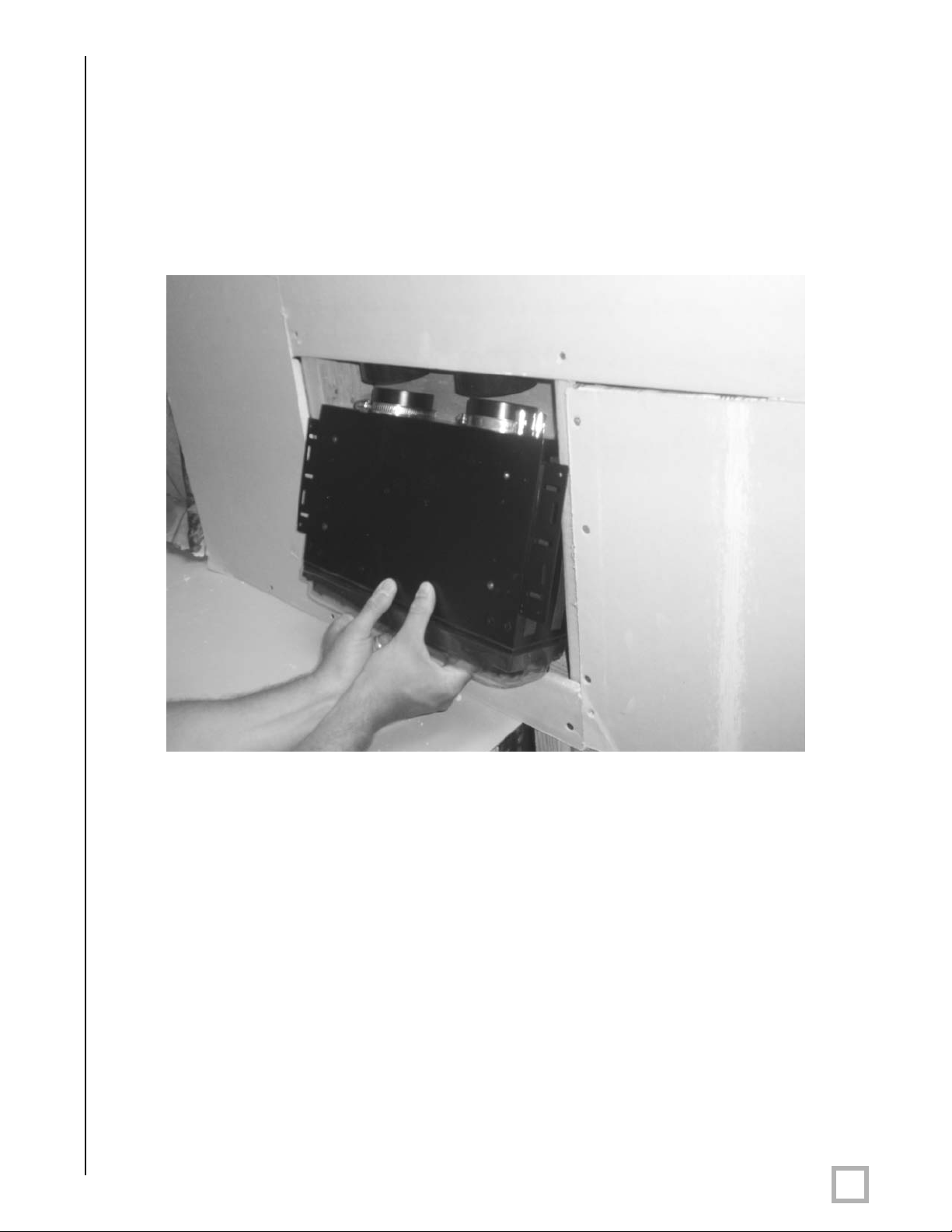

tep 9 - Install Driver Module

I

nsert the driver module assembly through the opening left in the wall by the mudring and slide

the plastic tubes onto the two connection tubes The connection tubes should slide all the way

down onto the surface of the driver module assembly. Once the tubes are flush with the driver

module, firmly tighten the two clamp rings to seal the rubber coupling to the plastic tube.

Note: The silicon rubber tubes should slide over the tubes protruding from the driver module

and the clamp rings should slide over the silicon rubber tubes.

Figure 7: Driver Module Installation

Note: It is critical that a good air seal be achieved between the back box and the driver module.

Be sure to properly tighten all clamps. Test the seal by listening to the connection with test

audio material after the install is complete.

.

www.velodyne.com

SC-IW Installation Manual

10

Page 17

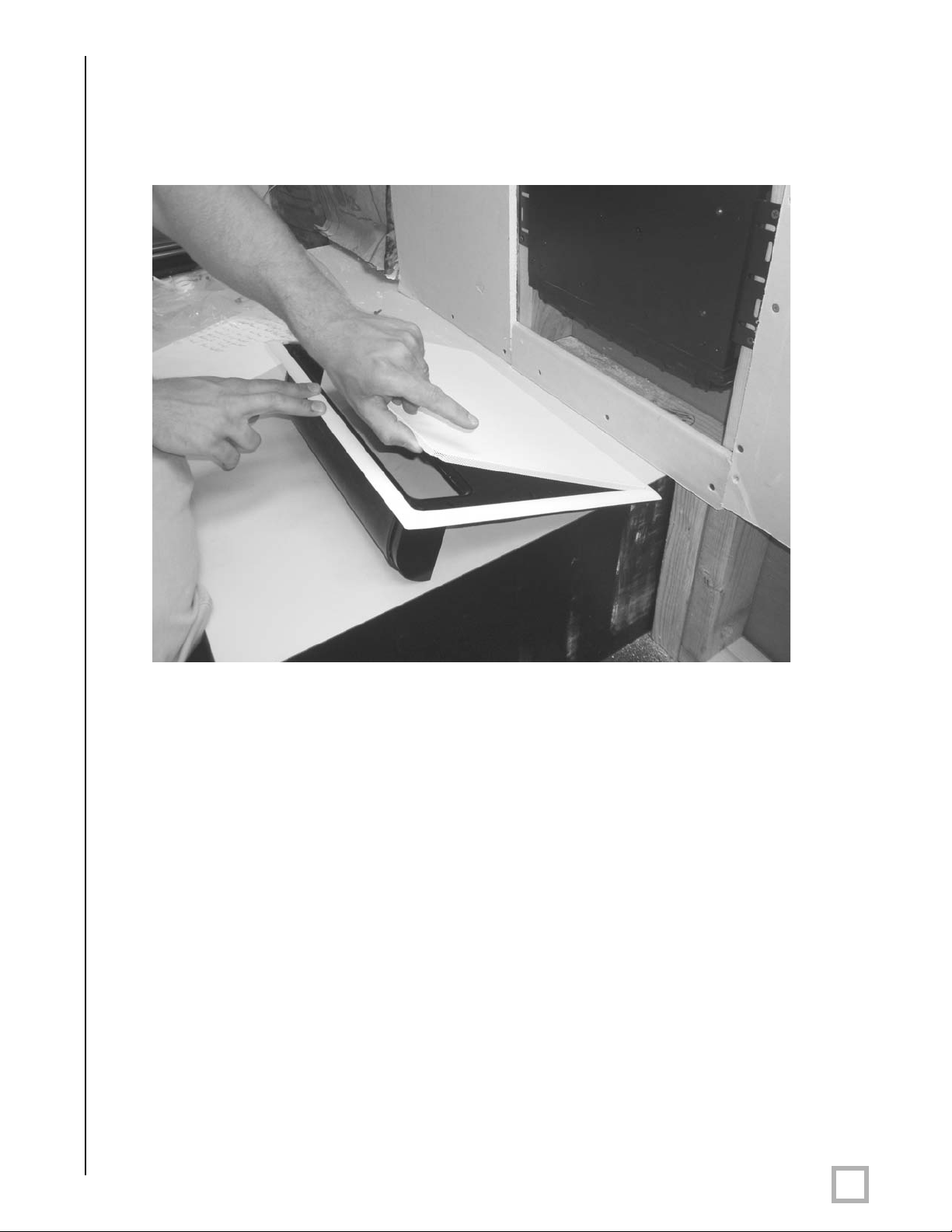

S

tep 10 - Remove Metal Grille

O

btain the standard grille with integrated scoop and remove the metal grille insert, as shown,

in the picture below.

Figure 8: Metal Grille Insert Removal

Note: The grille can be painted to match the de´cor. The supplied paint mask can be used to

paint the grille frame while the metal grille insert can be painted separately.

.

www.velodyne.com

SC-IW Installation Manual

11

Page 18

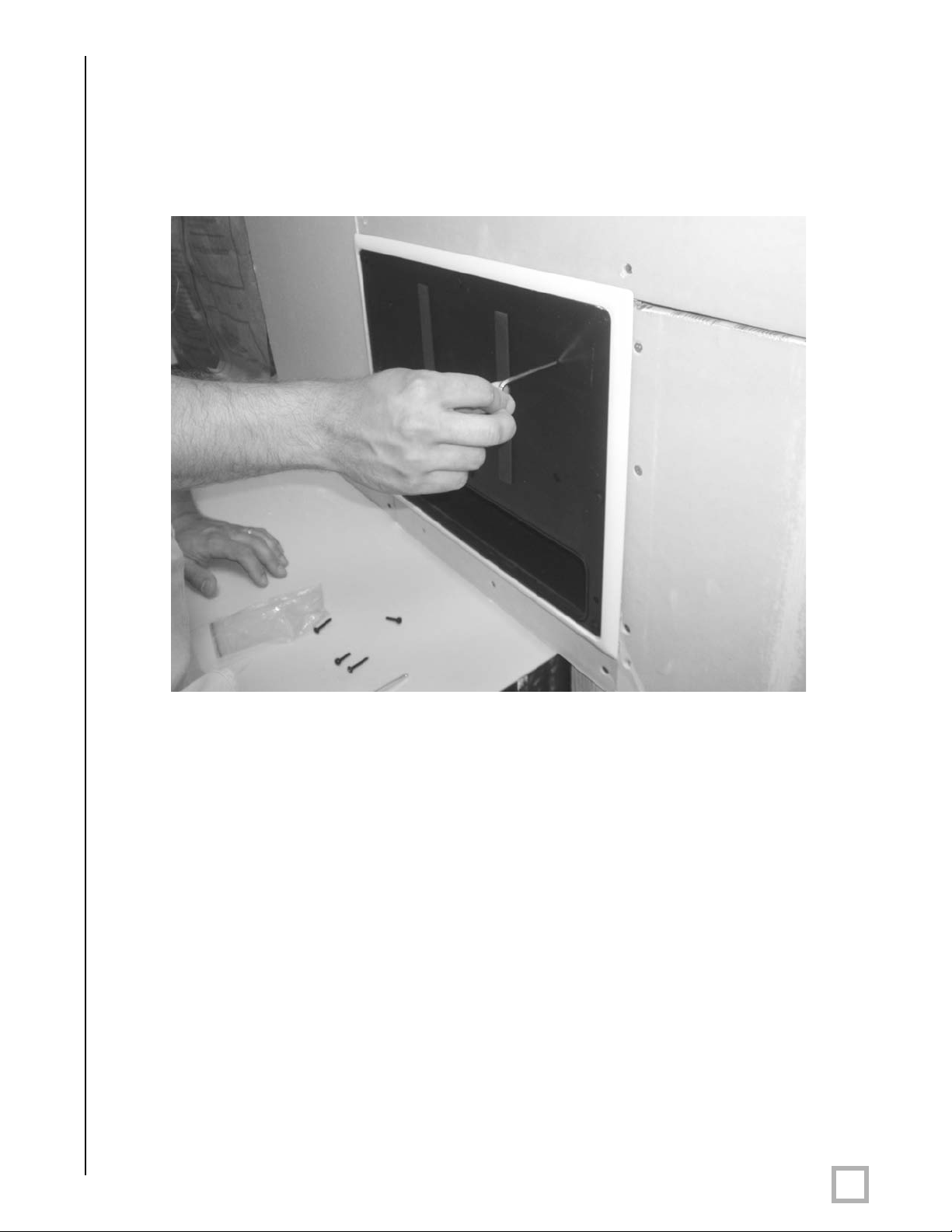

S

tep 11 - Install Grille Frame

I

nstall the plastic grille onto the driver module using the four included machine screws. The

grille hardware should easily be installed into the side of the cabinet. Tighten using the supplied

allen wrench.

Figure 9: Grille Frame Installation

.

www.velodyne.com

SC-IW Installation Manual

12

Page 19

S

tep 12 - Secure Grille

I

nstall two pan head phillips screws (provided) into standard grille into bottom left and bottom

right holes.

Figure 10: Secure Grille

.

www.velodyne.com

SC-IW Installation Manual

13

Page 20

S

tep 13 - Install Metal Grille Insert

Figure 11: Metal Grille Insert Installation

Step 14 - Installation Complete

The installation is complete. Test the

installation with bass audio material

and check for buzzes, rattles, and air

leaks and address accordingly.

.

www.velodyne.com

Figure 12: Completed Installation

SC-IW Installation Manual

14

Page 21

New Construction Installation — Designer Grille

N

ote:This installation process assumes that the installer has access to the open framed 2x4

studded wall with 16 inch spacing. (In the event that the stud spacing is larger, an additional

2x4 or other spacer can be used to fill the space between the SC-IW back box and the

neighboring stud.)

Step 1 - Assemble Cabinet and Driver Modules Together

Remove both the back box and driver modules from the packaging and place them on a clean

surface. Place the back box with the two silicon rubber tubes facing upward. Remove the two

clamp rings from the packaging and place them over the tubes.

Figures 13a and 13b: Cabinet and Driver

Module Assembly

Note: Leave the paint cover on the driver to pr

and finishing process.

.

www.velodyne.com

event damage during the installation, painting

SC-IW Installation Manual

15

Page 22

S

tep 2 - Mark Installation Location

M

easure from the bottom (or top if the SC-IW is to fire upwards) of the designer grille’s lowest

(or highest) position 6 3/8” up along the stud and mark the stud in this location. This location

will determine the bottom edge of the bracket on the driver module.

6 3/8”

e 14: Mark Installation Location

Figur

.

www.velodyne.com

SC-IW Installation Manual

16

Page 23

S

tep 3 - Route Wire

R

oute the wire from the location where the electronics gear is located to where the SC-IW will

be. There is "extra space" between the studs and the back box in the event that the wire has

to pass along the side of the back box to the driver module.

e 15: Route Wire

Figur

.

www.velodyne.com

SC-IW Installation Manual

17

Page 24

S

tep 4 - Secure Subwoofer to Wall

A

fter the location has been determined, securely fasten the subwoofer to the studs. Velodyne

provides 12 screws for this purpose.

Figure 16: Secure Subwoofer

.

www.velodyne.com

SC-IW Installation Manual

18

Page 25

S

tep 5 - Connect Speaker Wire to Subwoofer

C

onnect the previously routed speaker wire to the subwoofer taking care to match the positive

wire to the red terminal and the negative wire to the black terminal. The spring loaded binding

post will hold and secure the wire in place.

Figure 17: Speaker Wire Installation

.

www.velodyne.com

SC-IW Installation Manual

19

Page 26

S

tep 6 - Install Filler Panel

V

elodyne provides an MDF filler panel to fill the distance between the driver module and the

drywall. This filler panel also acts as a guide for the standard grille. The filler panel easily

installs using the four flat head screws and included allen wrench. Be sure to orientate the filler

panel as shown such that the tapered edge faces way from the driver.

Tapered

Edge

Tapered

Tapered

Edge

Edge

Figure 18: Filler Panel Installation

.

www.velodyne.com

Straight

Edge

SC-IW Installation Manual

20

Page 27

S

tep 7 - Install Template Place Holder

C

ut out the part of the installation template that outlines the designer grille. Affix the template

to the studs at the bottom of the filler panel as shown.

e 19: Template Place Holder Installation

Figur

.

www.velodyne.com

SC-IW Installation Manual

21

Page 28

S

tep 8 - Finish Wall

T

he wall can now be finished in a traditional fashion utilizing the appropriate drywall thickness,

standard texturing and finishing methods. Be sure to advise the "finishing” contractors that they

are to drywall up to the edge of the template, as the template is the place holder for the

installation of the designer template grille.

Figure 20: Finish Wall

Step 9 - Verify Drywall was Properly Installed

Once the wall is finished, the installer must revisit the installation site and verify that the

contractors have properly used the mudring as their a guide leaving an opening that is

oximately 17 1/2” x 4 1/2”.

appr

.

www.velodyne.com

SC-IW Installation Manual

22

Page 29

S

tep 10 - Install Designer Grille

R

emove metal grille insert from the plastic grille and insert into opening into the wall. The grille

should then be affixed to the studs using the four included phillips drive pan head screws.

Figures 21a and 21b: Designer Grille Installation

.

www.velodyne.com

SC-IW Installation Manual

23

Page 30

S

tep 11 - Install Metal Insert into Plastic Grille Frame

Figure 22: Metal Insert Installation

Step 12 - Finished Grille

Figur

e 23: Finished Grille Installation

.

www.velodyne.com

SC-IW Installation Manual

24

Page 31

Retro-Fit Installation with Designer Grille

S

tep 1 - Decide on Subwoofer Orientation and Grille Location

The first decision for a retrofit installation is which way the subwoofer will face (up or down),

and therefore where the designer grille will be located on the wall (near the floor or ceiling).

Once the location is decided, locate the 2x4 studs, spaced 16 inches on center. After the

general area of the studs is located, determine the exact location of the studs as detailed in

the picture below. There are many methods to do this. Shown is the use of a “drywall saw”

used horizontally to find the edge of each stud.

.

Figure 24: Subwoofer Orientation and Grille Location

.

www.velodyne.com

SC-IW Installation Manual

25

Page 32

S

tep 2 - Cut Out Drywall Per Template

O

nce the studs have been located, place the supplied designer grille template on the wall. After

the template is secured to the wall with either staples or tape, score the drywall along the lines

as detailed on the template.

Figure 25: Cut Out Drywall Per Template

Note: Two templates are provided, one for the designer grille and one for the standard grille.

Be sure to use the correct template!

.

www.velodyne.com

SC-IW Installation Manual

26

Page 33

S

tep 3 - Remove Drywall After it is Scored

A

fter the drywall is scored, remove the template and the drywall as indicated. The cutout after

removal is shown in figures 26a and 26b.

Figures 26a and 26b: Drywall Removal

.

www.velodyne.com

SC-IW Installation Manual

27

Page 34

S

tep 4 - Run Speaker Wire from Amplifier Location to In-Wall Subwoofer

R

oute the wire from the location where the electronics gear is located to where the SC-IW will

be. There is extra space between the studs and the box in the event that the wire has to pass

along the side of the back box to the driver module.

Figure 27: Speaker Wire Installation

Note: 14 A

.

www.velodyne.com

WG or lar

ger wire is recommended.

SC-IW Installation Manual

28

Page 35

S

tep 5 - Assemble Cabinet and Driver Modules Together

R

emove both the back box and driver modules from the packaging and place them on a clean

surface. Place the back box with the two silicon rubber tubes facing upward. Remove the two

clamp rings from the packaging and place them over the tubes.

Figures 28a and 28b: Cabinet and Driver Module Assembly

Note: Leave the paint cover on the driver to pr

and finishing process.

.

www.velodyne.com

event damage during the installation, painting

SC-IW Installation Manual

29

Page 36

S

tep 6 - Mark Installation Location

M

easure from the bottom of the cutout 6 3/8” up along the stud and mark the stud in this

location. This location will determine the bottom edge of the bracket on the driver module.

6 3/8”

e 29: Mark Installation Location

Figur

.

www.velodyne.com

SC-IW Installation Manual

30

Page 37

S

tep 7 - Install Subwoofer into Opening

A

fter the in-wall subwoofer assembly is complete, and the mounting position marked, orient the

assembly inside the wall. In this installation example we have decided to face the unit downward.

It is critical at this point that the top of the cabinet module is aligned with the top of the cutout

and that the brackets are 6 3/8” from the bottom of the cutout.

Figure 30: Subwoofer Installation

6 3/8”

.

www.velodyne.com

SC-IW Installation Manual

31

Page 38

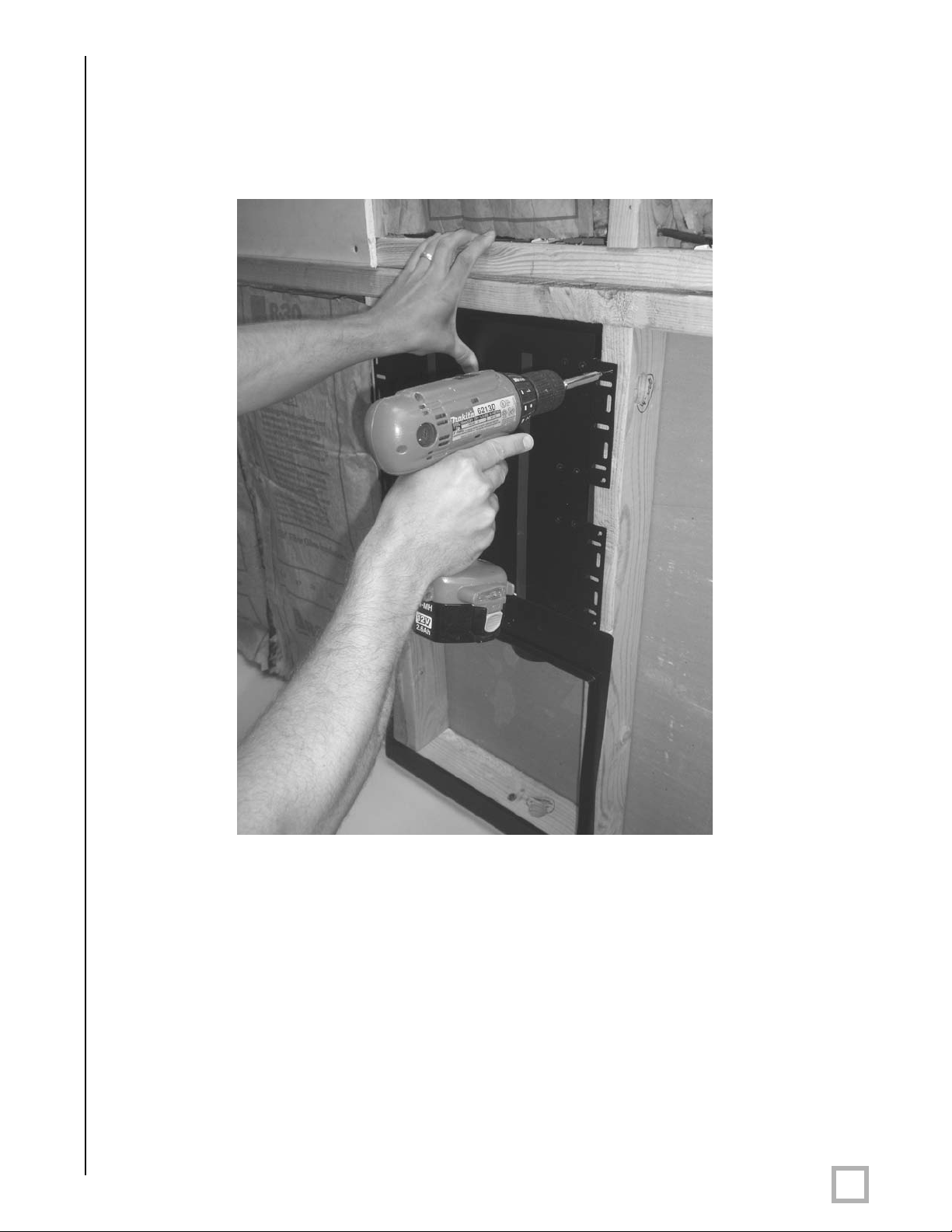

S

tep 8 - Secure Subwoofer to Wall

A

fter the location has been determined, securely fasten the subwoofer to the studs. Velodyne

provides 12 screws for this purpose.

Figure 31: Secure Subwoofer

.

www.velodyne.com

SC-IW Installation Manual

32

Page 39

S

tep 9 - Connect Speaker Wire to Subwoofer

C

onnect the previously routed speaker wire to the subwoofer taking care to match the positive

wire to the red terminal and the negative wire to the black terminal. The spring loaded binding

post will hold and secure the wire in place.

e 32: Connect Speaker Wire

Figur

.

www.velodyne.com

SC-IW Installation Manual

33

Page 40

S

tep 10 - Install Filler Panel

V

elodyne provides an MDF filler panel to fill the distance between the driver module and the

drywall. This filler panel also acts as a guide for the designer grille. The filler panel easily installs

using the four flat head screws and included allen wrench. Be sure to orientate the filler panel

as shown such that the tapered edge faces way from the driver.

Tapered

Edge

Tapered

Edge

Figure 33: Filler Panel Installation

Straight

Edge

Taper

Edge

ed

.

www.velodyne.com

SC-IW Installation Manual

34

Page 41

S

tep 11 - Install Drywall Above Filler Plate

A

fter the filler plate is secured to the driver module, install a replacement piece of drywall above

the filler plate in the opening. This drywall should be securely fastened to the studs using

drywall screws.

Figure 34: Drywall Installation

Step 12 - T

After the SC--IW is installed into the wall, the wall should be taped, textured, blended and then

painted to match the existing wall. Note the grille can also be painted to match the de´cor.

Note: The paint cover should be remain on the driver until this step is complete.

.

www.velodyne.com

ape, Mud, T

exture and Paint Wall

SC-IW Installation Manual

35

Page 42

S

tep 13 - Install Designer Grille

R

emove metal grille insert from the plastic grille and insert into opening into the wall. The grille

should then be affixed to the studs using the four included phillips drive pan head screws.

Figures 35a and 35b: Designer Grille Installation

.

www.velodyne.com

SC-IW Installation Manual

36

Page 43

S

tep 14 - Install Metal Insert into Plastic Grille Frame

Figure 36: Metal Insert Installation

Step 15 - Finished Grille

Figure 37: Finished Grille Installation

.

www.velodyne.com

SC-IW Installation Manual

37

Page 44

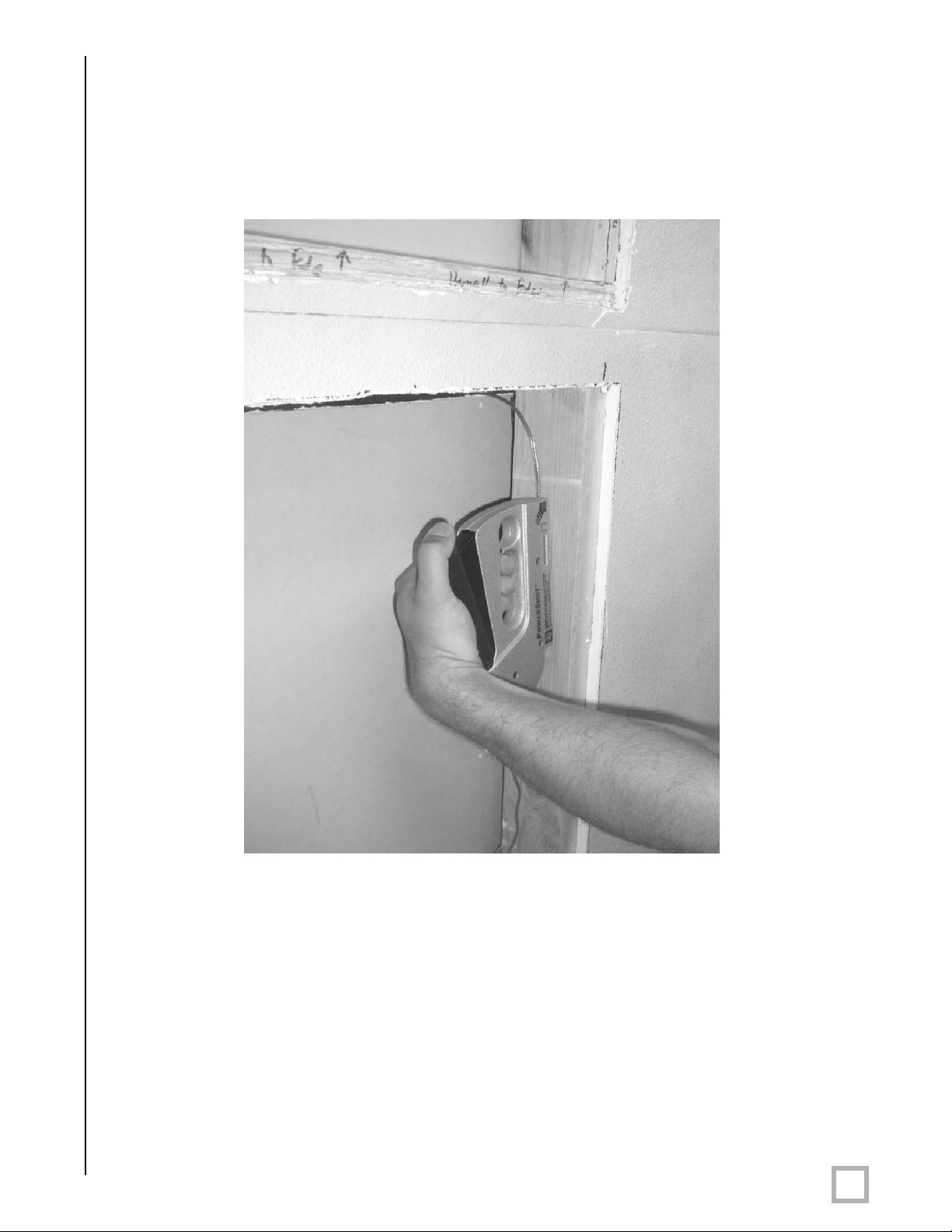

Retro-Fit Installation with Standard Grille

S

tep 1 - Decide on Subwoofer Orientation and Grille Location

The first decision for a retrofit installation is which way the subwoofer will face (up or down),

and therefore where the standard grille will be located on the wall (near the floor or ceiling).

Once the location is decided, locate the 2x4 studs, spaced 16 inches on center. After the

general area of the studs is located, the installer needs to determine the exact location of the

studs as detailed in the picture below. There are many methods to do this. Shown is the use of

a drywall saw used horizontally to find the edge of each stud.

Figure 38: Subwoofer Orientation and Grille Location

.

www.velodyne.com

SC-IW Installation Manual

38

Page 45

S

tep 2 - Cut Out Drywall Per Template

O

nce the studs have been located, place the supplied standard grille template on the wall. After

the template is secured to the wall with either staples or tape, score the drywall along the lines

as detailed on the template.

Figure 39: Cut Out Drywall

Note: Two templates are provided, one for the designer grille and one for the standard grille.

Be sure to use the correct template!

.

www.velodyne.com

SC-IW Installation Manual

39

Page 46

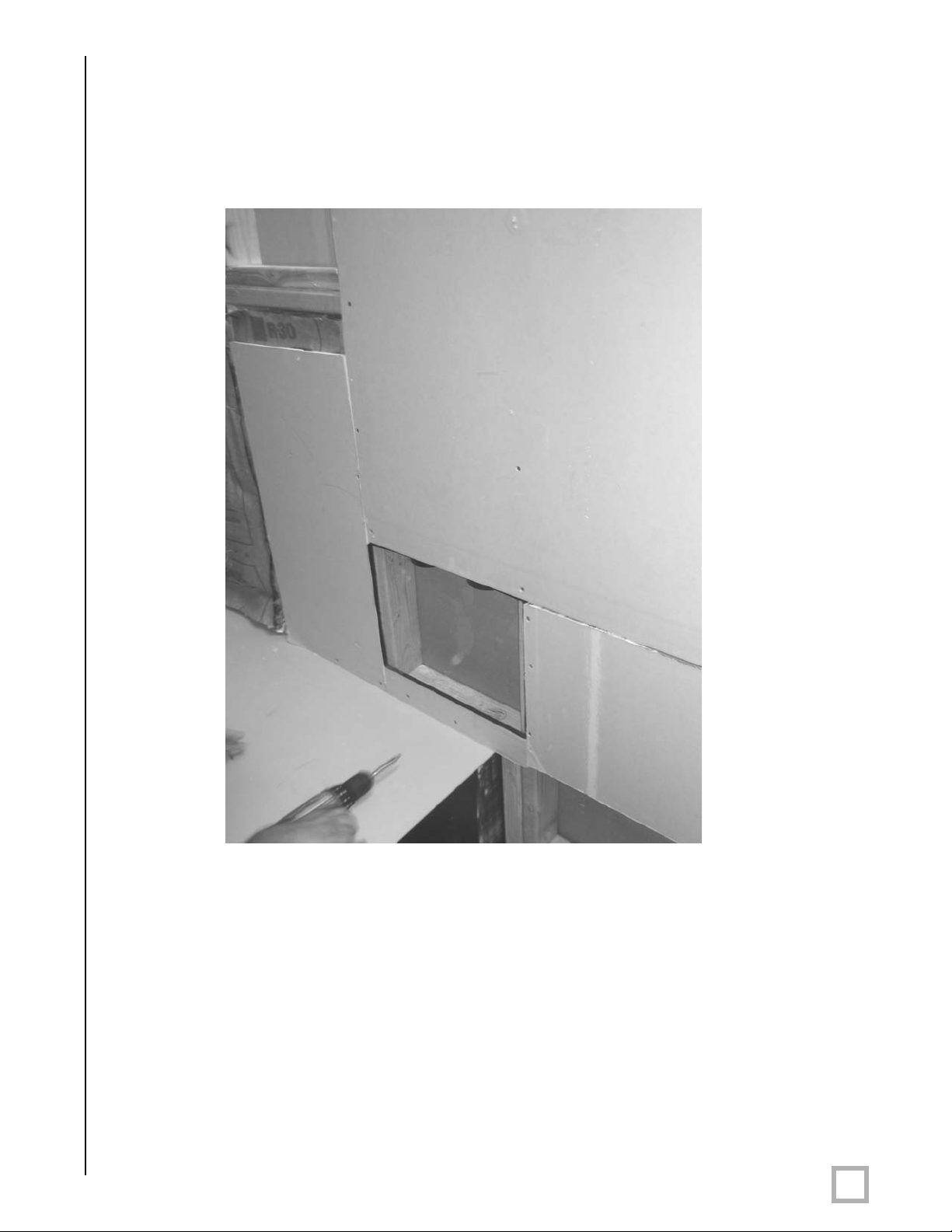

S

tep 3 - Remove Drywall After it is Scored

A

fter the drywall is scored, remove the template and the drywall as indicated. The cutout after

removal is shown in figures 40a and 40b.

Figures 40a and 40b: Drywall Removal

.

www.velodyne.com

SC-IW Installation Manual

40

Page 47

S

tep 4 - Run Speaker Wire from Amplifier Location to In-Wall Subwoofer

R

oute the wire from the location where the electronics gear is located to where the SC-IW will

be. There is extra space between the studs and the box in the event that the wire has to pass

along the side of the back box to the driver module.

Figure 41: Speaker Wire Installation

.

www.velodyne.com

SC-IW Installation Manual

41

Page 48

S

tep 5 - Assemble Cabinet and Driver Modules Together

R

emove both the back box and driver modules from the packaging and place them on a clean

surface. Place the back box with the two silicon rubber tubes facing upward. Remove the two

clamp rings from the packaging and place them over the tubes.

Figures 42a and 42b: Cabinet and Driver Module Assembly

Note: Leave the paint cover on the driver to pr

and finishing process.

.

www.velodyne.com

event damage during the installation, painting

SC-IW Installation Manual

42

Page 49

S

tep 6 - Mark Installation Location

M

easure from the bottom of the cutout 5 3/8” up along the stud and mark the stud in this

location. This location will determine the bottom edge of the bracket on the driver module.

5 3/8”

e 43: Mark Installation Location

Figur

.

www.velodyne.com

SC-IW Installation Manual

43

Page 50

S

tep 7 - Install Subwoofer into Opening

A

fter the in-wall subwoofer assembly is complete, orientate the assembly inside the wall. In this

installation example we have decided to face the unit downward. It is critical at this point that

the top of the cabinet module is aligned with the top of the cutout and that the brackets are

5 3/8” from the bottom of the cutout.

Figure 44: Subwoofer Installation

5 3/8”

.

www.velodyne.com

SC-IW Installation Manual

44

Page 51

S

tep 8 - Secure Subwoofer to Wall

A

fter the location has been determined, securely fasten the subwoofer to the studs. Velodyne

provides 12 screws for this purpose.

Figure 45: Secure Subwoofer

.

www.velodyne.com

SC-IW Installation Manual

45

Page 52

S

tep 9 - Connect Speaker Wire to Subwoofer

C

onnect the previously routed speaker wire to the subwoofer taking care to match the positive

wire to the red terminal and the negative wire to the black terminal. The spring loaded binding

post will hold and secure the wire in place.

e 46: Speaker Wir

Figur

.

www.velodyne.com

e Installation

SC-IW Installation Manual

46

Page 53

S

tep 10 - Install Filler Panel

V

elodyne provides an MDF filler panel to fill the distance between the driver module and the

drywall. This filler panel also acts as a guide for the standard grille. The filler panel easily

installs using the four flat head screws and included allen wrench. Be sure to orientate the filler

panel as shown such that the tapered edge faces way from the driver.

Tapered

Edge

Tapered

Tapered

Edge

Edge

Figure 47: Filler Panel Installation

.

www.velodyne.com

Straight

Edge

SC-IW Installation Manual

47

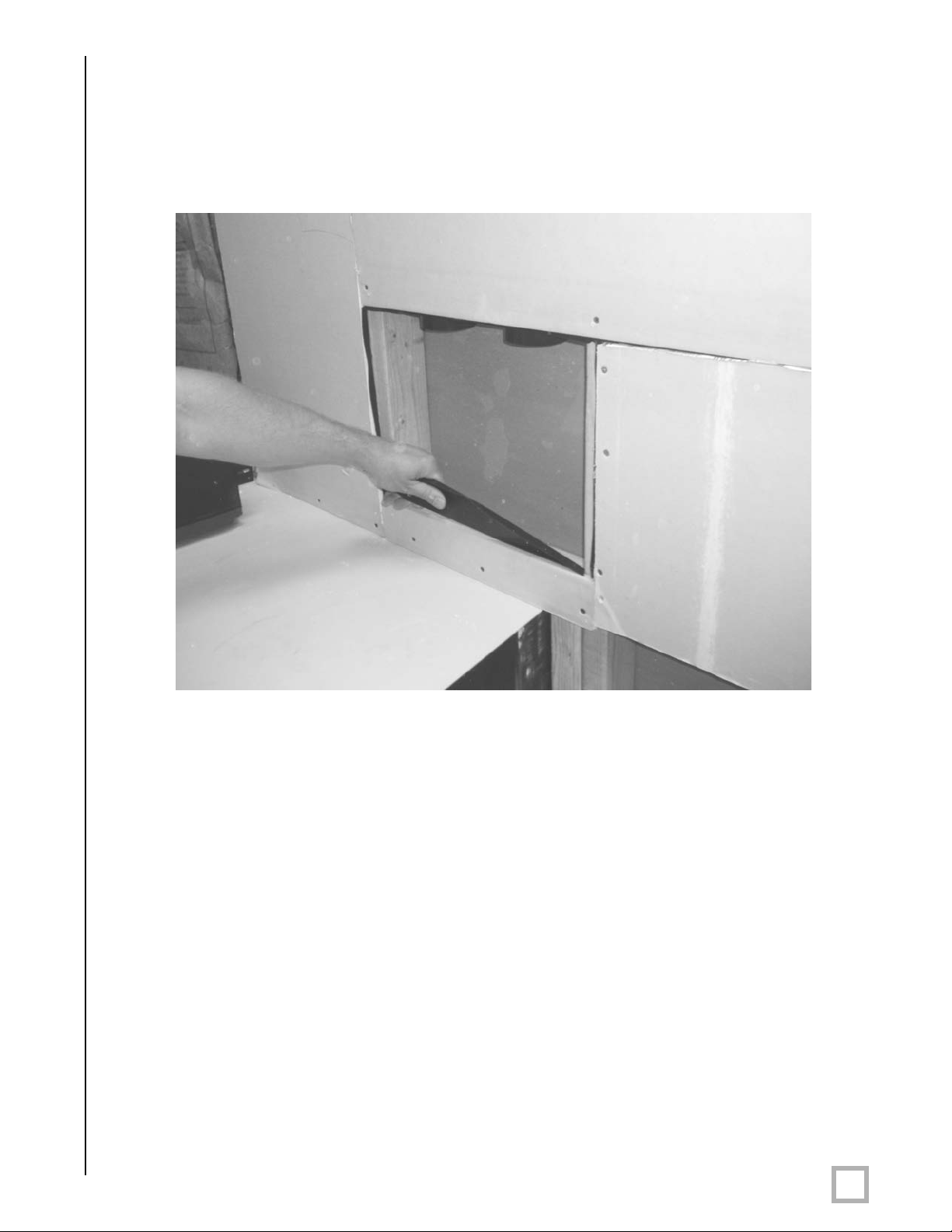

Page 54

S

tep 11 - Install Drywall Above Filler Plate

A

fter the filler plate is secured to the driver module, install a replacement piece of drywall above

the filler plate in the opening. This drywall should be securely fastened to the studs using

drywall screws.

Figure 48: Drywall Installation

Step 12 - Tape, Mud, Texture and Paint Wall

After the V

blended and then painted to match the existing wall. It is not required to finish the filler plate

as it will be removed in the next step.

Note the grille can also be painted to match the de´cor. The supplied paint masks can be used

to paint the grille frame while the metal grille insert can be painted separately.

Note: The paint cover should be remain on the driver until this step is complete.

.

www.velodyne.com

elodyne subwoofer is installed into the wall, the wall should be taped, textured,

SC-IW Installation Manual

48

Page 55

S

tep 13 - Remove Metal Grille

R

emove the filler plate. Obtain the standard grille with integrated scoop and remove metal grille

insert, as shown, in the picture below.

Figure 49: Metal Grille Insert Removal

.

www.velodyne.com

SC-IW Installation Manual

49

Page 56

S

tep 14 - Install Grille Frame

I

nstall the plastic grille onto the driver module using the four included machine screws. The

grille hardware should easily be installed into the side of the cabinet. Tighten using the supplied

allen wrench.

Figure 50: Grille Frame Installation

.

www.velodyne.com

SC-IW Installation Manual

50

Page 57

S

tep 15 - Secure Grille

I

nstall two pan head phillips screws (provided) into standard grille into bottom left and bottom

right holes.

Figure 51: Secure Grille

.

www.velodyne.com

SC-IW Installation Manual

51

Page 58

S

tep 16 - Install Metal Grille Insert

Figure 52: Metal Grille Insert Installation

Step 17 - Installation Complete

The installation is complete. Test the

installation with bass audio material and

check for buzzes, rattles, and air leaks

and address accordingly.

The grille can also be painted to match

the de´cor if desired.

.

www.velodyne.com

Figure 53: Completed Installation

SC-IW Installation Manual

52

Page 59

Other Velodyne Subwoofer Products

110V

DD Series

DD-10

DD-12

DD-15

DD-18

Digital Drive 1812

Signature Edition

DLS-R Series

DLS-3500R

DLS-3750R

DLS-4000R

DLS-5000R

DPS Series

DPS-10

MiniVee™

SMS™-1

SPL-R Series

SPL-800R

SPL-1000R

SPL-1200R

-1500R

SPL

VRP Series

VRP-1000

VRP-1200

VX Series

VX-10

230V

DD Series

DD-10

DD-12

DD-15

DD-18

Digital Drive 1812

Signature Edition

CHT-R Series

CHT-8R

CHT-10R

CHT-12R

CHT-15R

SMS™ -1

SPL-800i

SPL-R Series

SPL-800R

SPL-1000R

SPL-1200R

-1500R

SPL

DPS-12

.

www.velodyne.com

SC-IW Installation Manual

53

Page 60

LIMITED WARRANTY

VELODYNE ACOUSTICS, Inc. (“VELODYNE”) warrants all electronics and powered subwoofers for a period of two

years and full range speakers for a period of five years. All VELODYNE products have a warranty from the date of

purchase against defects in materials and workmanship subject to the following conditions:

1. VELODYNE is not responsible for defects which result from the use of an amplifier or controller other than

the one originally supplied with the unit (subwoofer) or defects which result from modifications or repairs

made by any component of the system by anyone other than a VELODYNE factory authorized

service representative.

2. This warranty is void if any repairs or service covered by the terms of this warranty are made to any

component of the system by anyone other than a VELODYNE factory authorized service representative.

3. VELODYNE is not responsible for damage caused by accidents, abuse, misuse, natural or personal disaster

or unauthorized modification. The VELODYNE products are not intended for professional or commercial use

and VELODYNE is not responsible for damage resulting from such use.

4. The VELODYNE product warranty is limited to units that are purchased from authorized VELODYNE dealers

and finalized within authorized dealer locations.

5. This warranty is nontransferable under any condition.

TO OBTAIN SERVICE

Information regarding service may be obtained from the dealer from whom you purchased the unit, or by contacting

VELODYNE customer service. Warranty service must be performed by a VELODYNE factory authorized service

representative within the warranty period set forth above. If VELODYNE determines the unit is defective, VELODYNE

will, at VELODYNE’s option, repair or replace the product at no charge if the product is forwarded prepaid to a factory

authorized service representative. Products forwarded to the factory authorized service representative should be

shipped securely and properly packaged, insured and freight prepaid.

63-SCIWBB REV B SEP06

.

www.velodyne.com

Velodyne Acoustics, Inc.

Morgan Hill, CA 95037

408.465.2800 voice

408.779.9208 service fax

Service E

Product E

Technical E

345 Digital Drive

408.779.9227 fax

.velodyne.com

www

-mail: service@velodyne.com

-mail: help@velodyne.com

-mail: techhelp@velodyne.com

SC-IW Installation Manual

54

Loading...

Loading...