Page 1

PROCESS AUTOMATION

MANUAL

WHA-GW-*

WIRELESSHART GATEWAY

®

Page 2

WHA-GW-*

With regard to the supply of products, the current issue of the following document is ap-

plicable: The General Terms of Delivery for Products and Services of the Electrical In-

dustry, published by the Central Association of the Electrical Industry (Zentralverband

Elektrotechnik und Elektroindustrie (ZVEI) e.V.) in its most recent version as well as the

supplementary clause: "Expanded reservation of proprietorship"

Page 3

WHA-GW-*

1 Safety................................................................................................. 6

1.1 Validity....................................................................................................................................6

1.2 Symbols used ........................................................................................................................6

1.3 Target Group/Staff.................................................................................................................7

1.4 Reference to further documentation....................................................................................7

1.5 Declaration of Conformity.....................................................................................................7

1.6 Marking ...................................................................................................................................7

1.7 Intended Use ..........................................................................................................................8

1.8 Mounting and Installation .....................................................................................................8

1.9 Operation, Maintenance, Repair...........................................................................................9

1.10 Delivery, Transport, Disposal................................................................................................9

2 Product Specifications .................................................................. 10

2.1 Introduction..........................................................................................................................10

2.2 Functional Overview............................................................................................................11

2.2.1 Network Management ...........................................................................................................12

2.2.2 Security Management............................................................................................................13

2.2.3 Virtual Remote I/O system..................................................................................................... 13

2.2.4 Gateway Cache Management ...............................................................................................15

2.3 Scope of Delivery.................................................................................................................16

2.4 Design...................................................................................................................................16

3 Installation ...................................................................................... 18

3.1 Mounting Considerations ...................................................................................................18

3.1.1 Positioning the Gateway........................................................................................................18

3.1.2 Antenna Characteristics......................................................................................................... 18

3.1.3 Examples for Good and Poor Positioning..............................................................................20

3.2 Mounting the Gateway.........................................................................................................22

3.3 Connecting to Ethernet.......................................................................................................23

3.4 Connecting to RS-485 .........................................................................................................28

3.5 Connecting the Antenna .....................................................................................................30

3.6 Connecting to Power Supply and Grounding ...................................................................31

4 Commissioning .............................................................................. 33

4.1 Important Steps to Getting Started ....................................................................................33

4.2 DTM Software.......................................................................................................................33

4.2.1 Downloading the required software .......................................................................................33

4.2.2 Installing the Required Software............................................................................................34

4.2.3 Updating the DTM catalog .....................................................................................................35

4.3 Connecting via RS485.........................................................................................................36

4.4 Connecting via Ethernet .....................................................................................................37

3

Page 4

WHA-GW-*

4.5 Creating a new PACTware Project ....................................................................................38

4.5.1 Creating a new project...........................................................................................................38

4.5.2 Adding the Communication DTM...........................................................................................38

4.5.3 Adding Device DTM...............................................................................................................43

5 Configuration ..................................................................................45

5.1 Configuration via DTM or Web Interface ...........................................................................45

5.2 Online and offline parameterization (DTM) .......................................................................46

5.3 Identification Parameters....................................................................................................48

5.4 Wireless Communication Parameters................................................................................49

5.4.1 Setup .....................................................................................................................................49

5.4.2 Instrument List .......................................................................................................................51

5.4.3 Burst Lists ..............................................................................................................................54

5.5 Wired Communication Parameters....................................................................................56

5.5.1 Interfaces > Serial..................................................................................................................56

5.5.2 Interfaces > Ethernet .............................................................................................................57

5.5.3 Protocols > HART ..................................................................................................................59

5.5.4 Protocols > Modbus...............................................................................................................60

5.6 Network Explorer Tables.....................................................................................................62

6 Operation .........................................................................................64

6.1 Controls and Indicators ......................................................................................................64

6.1.1 LEDs ......................................................................................................................................65

6.1.2 Buttons and DIP switches......................................................................................................66

6.2 Diagnosis..............................................................................................................................69

6.2.1 Identification...........................................................................................................................69

6.2.2 Wireless Communication .......................................................................................................70

6.2.3 Wired Communication ...........................................................................................................71

6.3 Additional DTM Functions ..................................................................................................74

6.3.1 Reset .....................................................................................................................................75

6.3.2 Self Test.................................................................................................................................75

6.3.3 Set DTM address...................................................................................................................76

6.3.4 Set device address ................................................................................................................77

6.3.5 List Editor...............................................................................................................................78

6.3.6 About .....................................................................................................................................79

6.3.7 Change Password .................................................................................................................79

6.3.8 Firmware Upgrade .................................................................................................................80

6.4 Network Enhancement ........................................................................................................81

6.5 Modbus Mapping .................................................................................................................83

6.5.1 Overview................................................................................................................................83

6.5.2 Modbus Mapping Description ................................................................................................84

7 Maintenance and repair..................................................................87

7.1 WHA-GW* .............................................................................................................................87

4

Page 5

WHA-GW-*

8 Troubleshooting ............................................................................. 88

8.1 Faults indicated by Gateway LEDs ....................................................................................88

8.2 Wired Communication Faults.............................................................................................88

8.3 Wireless Communication Faults.........................................................................................89

9 Technical specifications................................................................ 90

9.1 WHA-GW...............................................................................................................................90

9.2 Telecommunication Compliance........................................................................................92

10 Appendix A ..................................................................................... 93

10.1 Supported Commands ........................................................................................................93

10.1.1 Universal Commands ............................................................................................................93

10.1.2 Common Practice Commands ...............................................................................................94

10.1.3 Wireless Commands..............................................................................................................94

10.1.4 Device Commands ................................................................................................................95

10.2 Software License .................................................................................................................95

5

Page 6

WHA-GW-*

Safety

1Safety

1.1 Validity

The chapter “Safety” is valid as instruction manual.

Specific process and instructions in this document require special precautions to guarantee

the safety of personnel.

1.2 Symbols used

This document contains information that you must read for your own personal safety and to

avoid property damage. The warning signs are displayed in descending order depending

on the hazard category, as follows:

Safety-relevant symbols

Danger!

This symbol indicates a warning about a possible danger.

In case of ignoring the consequences may range from personal injury to death.

Warning!

This symbol indicates a warning about a possible fault or danger.

In case of ignoring the consequences may cause personal injury or heaviest property

damage.

Caution!

This symbol warns of a possible fault.

In case of ignoring the devices and any connected facilities or systems may be interrupted

or fail completely.

Informative symbols

Note!

This symbol brings important information to your attention.

Action

This symbol marks an acting paragraph.

221981 2011-07

6

Page 7

WHA-GW-*

Safety

1.3 Target Group/Staff

The plant owner is responsible for its planning, installation, commissioning, operation,

maintenance and disassembly.

Mounting, commissioning, operation, maintenance and dismounting of any devices may

only be carried out by trained, qualified personnel. The instruction manual must be read

and understood.

1.4 Reference to further documentation

Laws, standards, or directives applicable to the intended use must be observed. In relation

to hazardous areas, Directive 1999/92/EC must be observed.

The corresponding data sheets, declarations of conformity, EC Type-examination

certificates, certificates and Control Drawings if applicable (see data sheet) are an integral

part of this document. You can find this information under www.pepperl-fuchs.com.

Due to constant revisions, documentation is subject to permanent change. Please refer

only to the most up-to-date version, which can be found under www.pepperl-fuchs.com.

1.5 Declaration of Conformity

All products were developed and manufactured under observance of the applicable

European standards and guidelines.

Note!

A Declaration of Conformity can be requested from the manufacturer.

The product manufacturer, Pepperl+Fuchs GmbH, 68307 Mannheim, has a certified quality

assurance system that conforms to ISO 9001.

ISO9001

1. 6 M a r k i n g

WirelessHART® Gateway

Pepperl+Fuchs GmbH

Lilienthalstraße 200

68307 Mannheim, Germany

WHA-GW-*

PF 09 CERT 1469 X

II 3 G Ex nA II T4

221981 2011-07

7

Page 8

WHA-GW-*

Safety

1.7 Intended Use

The devices are only approved for appropriate and intended use. Ignoring these

instructions will void any warranty and absolve the manufacturer from any liability.

The approved usage of the connected device(s) and gateway can be taken from the

corresponding parts of their instruction manual.

The device is an intelligent WirelessHART device designed for the transmission of

measured values from connected C&I or HART devices.

The device must only be operated in the ambient temperature range and at the relative

humidity (non-condensing) specified.

Protection of the operating personnel and the overall system is not ensured if the product is

not being used according to its intended purpose.

1.8 Mounting and Installation

Prior to mounting, installation, and commissioning of the device you should make yourself

familiar with the device and carefully read the instruction manual.

The device must not be installed at locations where corrosive vapors may be present.

The devices are designed for use in pollution degree 2 and overvoltage category II as per

IEC/EN 60664-1.

If used in areas with higher pollution degree, the devices need to be protected accordingly.

Pay attention to avoid electrostatic discharges while operating the installed device. Avoid

electrostatic charge.

The usage of 2400 MHz equipment is bound to local restrictions. Ensure that restrictions

allow usage of this product before commissioning.

Country Guideline

Bulgaria General authorization required for outdoor use and public service.

Italy If used outside of own premises, general authorization is required.

Norway May be restricted in the geographical area within a radius of 20 km

from the center of Ny-Alesund.

Rumania Use on a secondary basis. Individual license required.

Latvia The outdoor usage of the 2.4 GHz band requires an authorization

from the Electronic Communications Office.

Only use antennas that are specified in the data sheet.

If devices have already been operated in general electrical systems, they may

subsequently no longer be installed in electrical systems used in combination with

hazardous areas.

221981 2011-07

8

Page 9

WHA-GW-*

Safety

The installation instructions in accordance with IEC/EN 60079-14 must be observed.

Connection or disconnection of energized non-intrinsically-safe circuits is only permitted in

the absence of a hazardous atmosphere.

The device must be disconnected from the power supply prior to installation and

maintenance. The power supply may be activated only after all the circuits required for

operation have been fully assembled and connected.

To ensure the IP degree of protection:

• all seals must be undamaged and correctly fitted

• all screws of the housing / housing cover must be tightened with the appropriate torque

• only cable of the appropriate size must be used in the cable glands

• all cable glands must be tightened with the appropriate torque

• all empty cable glands must be sealed with sealing plugs

The device must be mounted with at least a degree of protection of IP 54 according to

IEC/EN 60529.

1.9 Operation, Maintenance, Repair

Use switches only in the absence of a hazardous atmosphere.

When the device is in operation, a distance of at least 20 cm must be maintained at all

times between the device antenna and the body of the user or any other person within the

vicinity of the measuring point irrespective of application or use.

The devices must not be repaired, changed or manipulated. If there is a defect, the product

must always be replaced with an original device.

1.10 Delivery, Transport, Disposal

Check the packaging and contents for damage.

Check if you have received every item and if the items received are the ones you ordered.

Keep the original packaging. Always store and transport the device in the original

packaging.

Always store the device in a clean and dry environment. The permitted storage temperature

(see data sheet) must be considered.

Disposing of devices, packaging material, and possibly contained batteries must be in

compliance with the applicable laws and guidelines of the respective country.

221981 2011-07

9

Page 10

WHA-GW-*

1

2

3

4

5

Product Specifications

2 Product Specifications

2.1 Introduction

The HART® communication protocol (Highway Addressable Remote Transducer) is used

by many 4 ... 20 mA transmitters to enable digital communication for diagnosis and

maintenance purposes. Many device parameters, but also measurement values, can be

transmitted digitally to and from the device. Until now, HART

using the wired 4 ... 20 mA loop as physical layer.

®

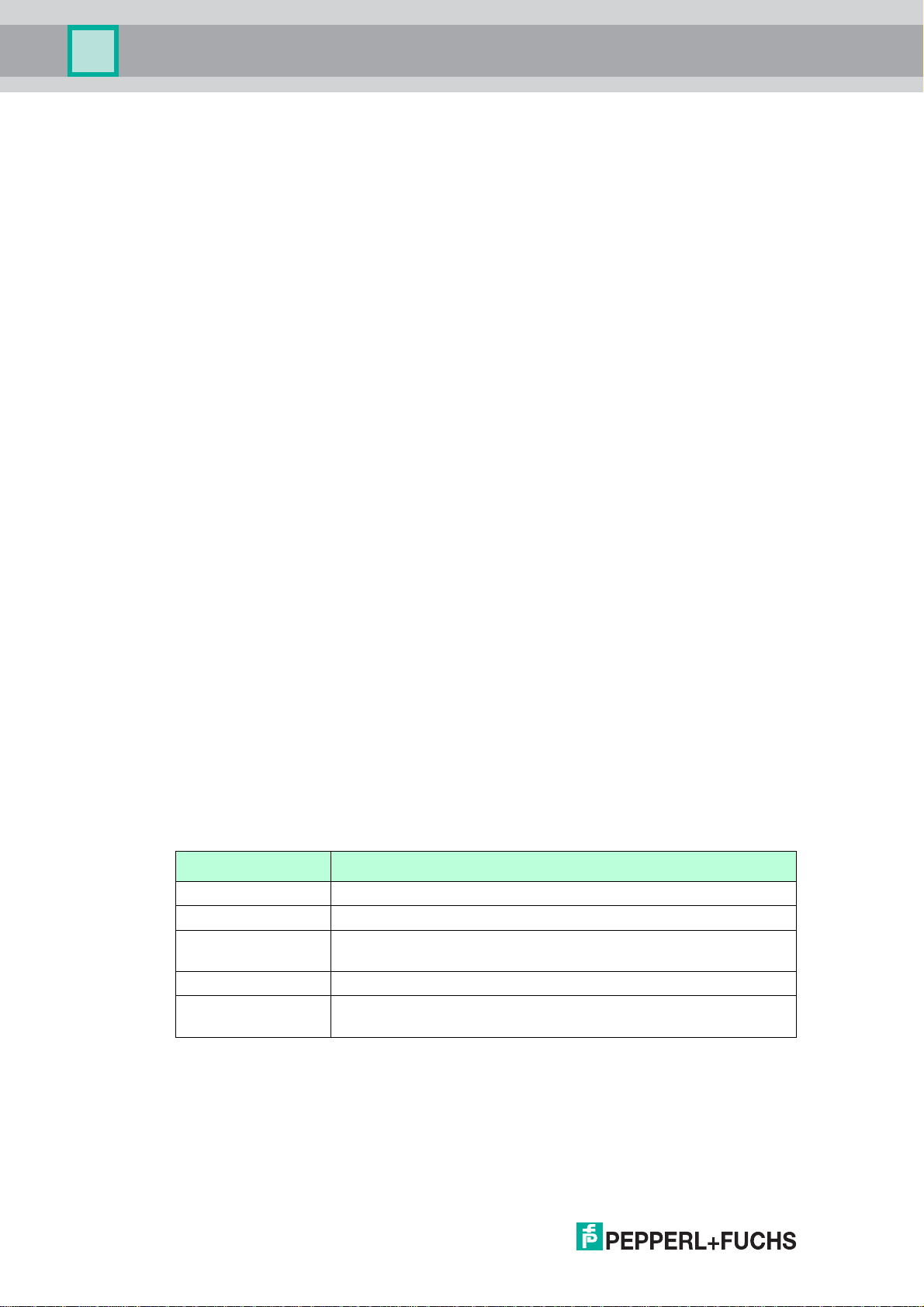

WirelessHART

employable worldwide, WirelessHART

802.15.4 wireless network) as physical layer. All WirelessHART devices form a mesh

network in which every device is not just a measurement point, but also a repeater. This

results in a bigger range of the whole network as well as an increased reliability through

redundant communication paths.

technology now allows for the wireless transmission of HART® data. To be

®

technology has mostly been

®

technology utilizes the 2.4GHz Band (IEEE

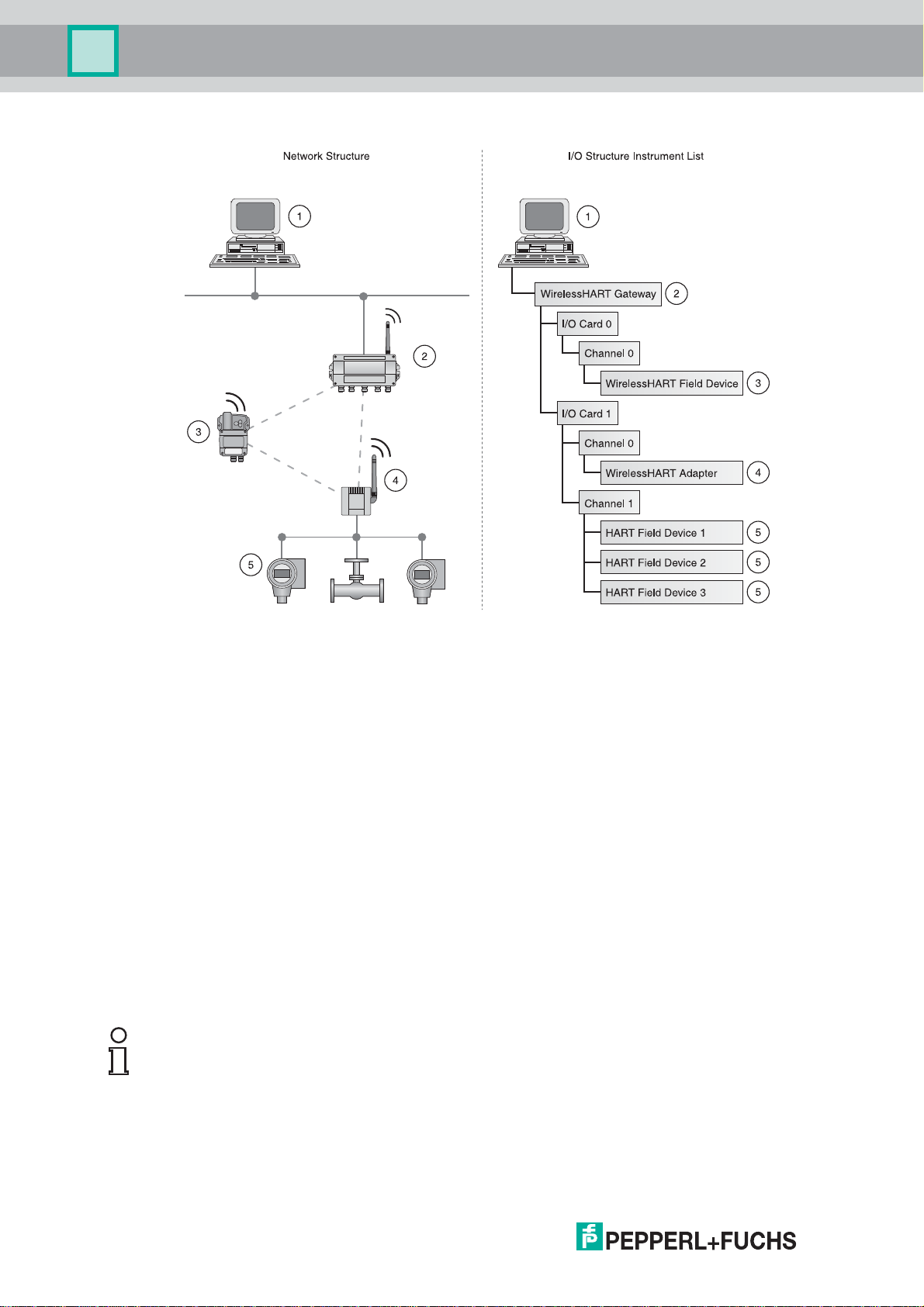

Figure 2.1WirelessHART mesh network

1 WirelessHART field device

2 WirelessHART adapter

3 WirelessHART Gateway

4 Fieldbus/Ethernet

5 Host applications

221981 2011-07

10

Page 11

WHA-GW-*

Product Specifications

The WirelessHART network is built up, organized and maintained by the WirelessHART

Gateway and is therefore self-organizing and self-healing. The Gateway also takes care for

connection to different host systems through different industrial protocol bus interfaces.

The WirelessHART Gateway supplies the WirelessHART field devices with the necessary

information for seamless network operation.

2.2 Functional Overview

The WirelessHART Gateway enables WirelessHART devices to communicate with each

other and manages network security and connectivity. The Gateway device converts

wireless device data to a format that is compatible with other systems.

Key features

• Gateway, Network Manager, and Network Access Point capabilities according to the

WirelessHART (HART 7.1) specification

• Interfaces: RS485 and Ethernet with support of HART communication protocol and

Modbus protocol on both interfaces

• Configuration, parameterization via FDT/DTM, EDDL or Web-Interface

• Fully galvanically isolated external interfaces; open-enclosure access to switches and

LEDs

• Intrinsically safe antenna port (planned)

• Local or Remote antenna options

• Redundant supply option

• Integrated web server for remote Gateway configuration and device variables

monitoring

Functionality

• Measurement

•Protocols:

• HART over RS-485, HART over UDP

• MODBUS RTU/TCP

• HTTP (Web Server) for configuration of the Gateway

• OPC Access via Host-resident HART OPC Server Software

• HOST integration: DTM, EDDL

The WirelessHART Gateway fulfills 4 different tasks in a WirelessHART network, which are

described shortly in the following.

221981 2011-07

11

Page 12

WHA-GW-*

4

1

5

2

3

Product Specifications

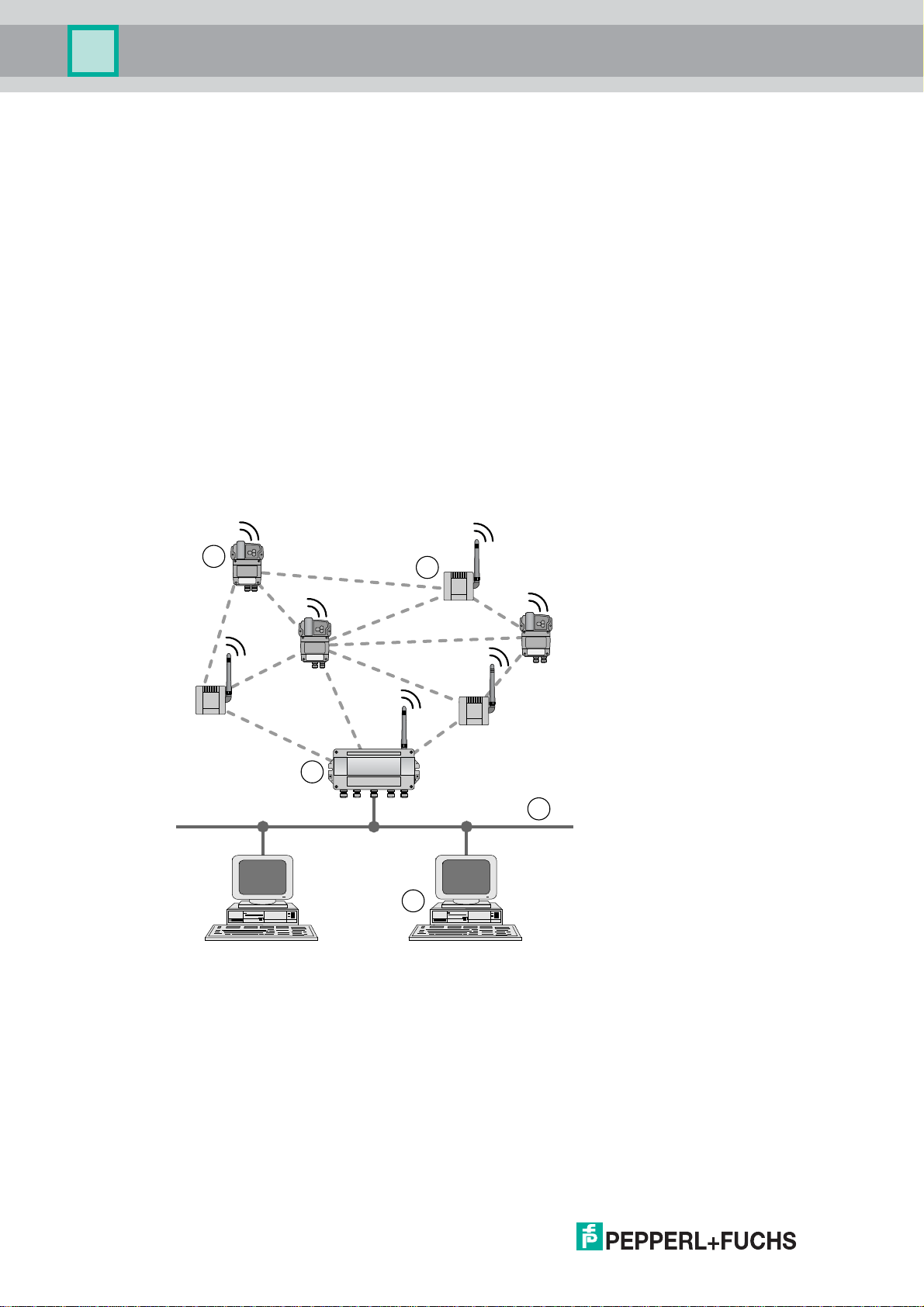

2.2.1 Network Management

The WirelessHART Gateway contains a network manager. The network manager takes

care of the wireless communication between the WirelessHART field devices. The network

manager takes care of the creation and maintenance of the wireless mesh network to

ensure proper communication between the WirelessHART field devices.

Figure 2.2Network management

1 Step 1: Advertising

2 Step 2: Joining

3 Step 3: Scheduling

4 WirelessHART Gateway

5 WirelessHART field device

First, the network manager sends advertising messages to announce the network’s

existence. When a WirelessHART field device receives such an advertising message, it

tries to join the network. If the WirelessHART field device can identify itself with the same

network ID and join key as stored in the WirelessHART Gateway, the field device is allowed

to join the network. Otherwise, the field device will be rejected.

The network manager can also instruct already joined devices to advertise on its behalf.

221981 2011-07

12

Page 13

WHA-GW-*

Product Specifications

In the next step, the network manager sends scheduling information to the field device. The

field device is told how to participate in the network and receives various information from

the WirelessHART Gateway:

• Number and identity of neighboring WirelessHART field devices,

• When to send messages and which channels to use,

• When to repeat messages for other WirelessHART field devices,

• The optimal communication path for messages as well as alternative communication

paths in case of failure.

During this process, the field device may also apply to send messages in certain intervals

and ask the network manager for the appropriate resources. The network manager then

takes care that these resources are available. For example, the network manager informs

other WirelessHART field devices when to repeat messages.

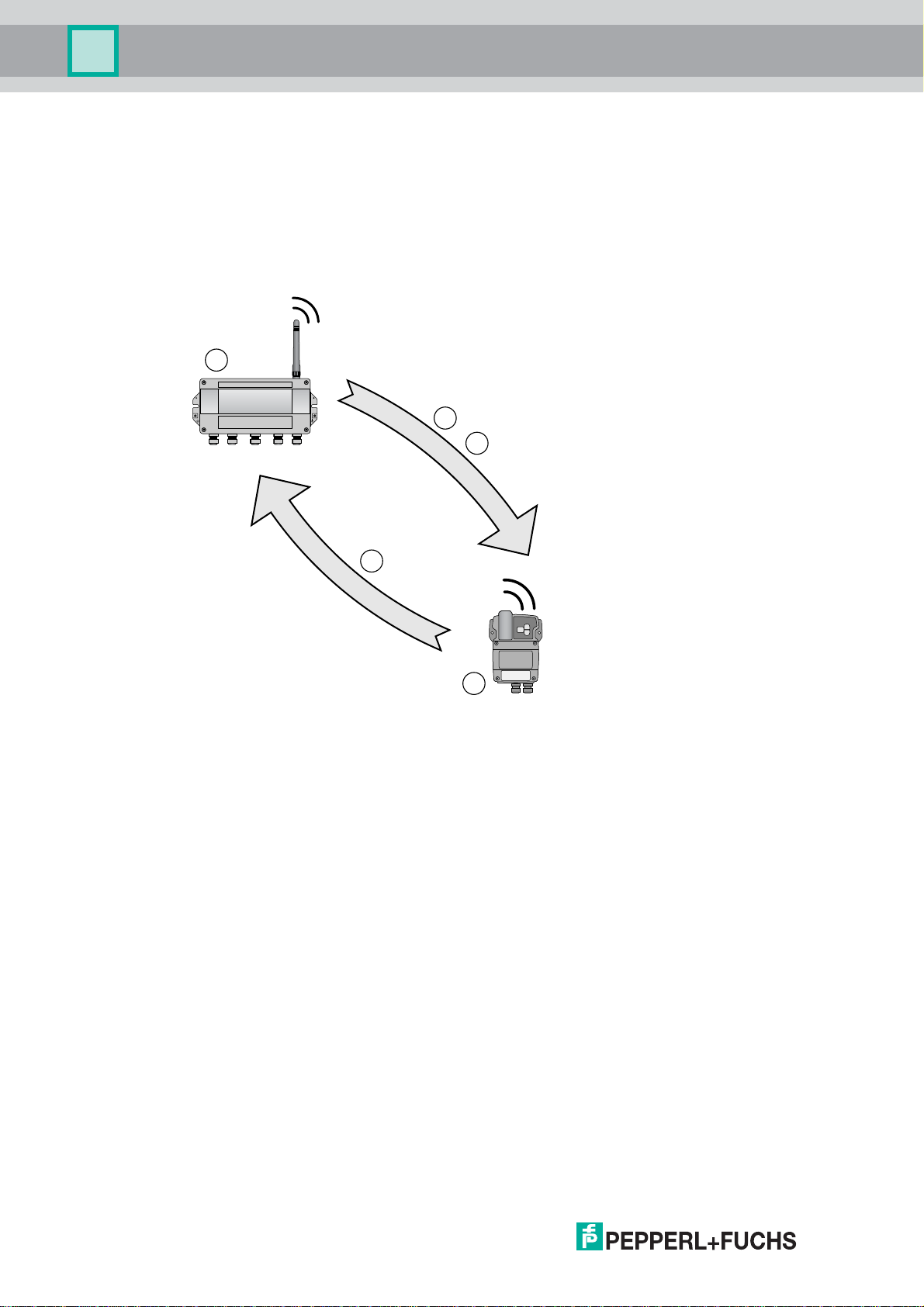

2.2.2 Security Management

The security manager is part of the WirelessHART Gateway. To make communication safe,

all messages are encrypted with industry-standard AES-128 block ciphers with symmetric

keys. Therefore, messages are unreadable for external listeners.

The security manager distributes the encryption keys and changes them in certain

(random) intervals, as an option.

2.2.3 Virtual Remote I/O system

The WirelessHART Gateway make wireless communication accessible to HOST systems

capable of HART technology through the following principles.

Instrument List

WirelessHART devices and wired devices connected to a WirelessHART adapter are made

available to HOST systems via a virtual HART I/O system. This I/O system contains one or

multiple I/O cards. Each I/O card has up to 2 channels. To each channel, up to 6 wired field

devices may be connected in multi-drop mode. (see Figure 2.3 on page 14).

The P+F WirelessHART Gateway assigns a virtual I/O card to each WirelessHART device

and stores card and channel values in the Instrument List. The I/O cards are assigned to

the WirelessHART devices in chronological order (0 ... 249). New WirelessHART devices in

the network are assigned to the next available I/O card.

WirelessHART devices are always assigned to Channel 0 of an I/O card. All wired devices

connected to a WirelessHART adapter are always assigned to channel 1 of the same I/O

card as the adapter (multi-drop mode).

221981 2011-07

13

Page 14

WHA-GW-*

Product Specifications

Figure 2.3Network structure and corresponding I/O structure

1 HOST application

2 WirelessHART Gateway

3 WirelessHART field device (joined first): I/O card 0, channel 0

4 WirelessHART adapter (joined second): I/O card 1, channel 0

5 Wired devices 1...3 connected to WirelessHART adapter: I/O card 1, channel 1

If a WirelessHART device loses communication to the Gateway, it keeps its position in the

Gateway's Instrument List and stays assigned to the respective I/O card. When

communication is established again, the device has the same channel/card values that it

had before.

The same principle applies to the field devices connected to the WirelessHART adapter:

After communication to the Gateway was lost, the field devices regain their previous

position in the Instrument List as soon as communication is established again.

Note!

The Instrument List is stored in a non-volatile memory. Card/channel number assignment

will remain the same after a Gateway power-up or software restart.

14

221981 2011-07

Page 15

WHA-GW-*

Product Specifications

Long Tag Emulation

The WirelessHART communication protocol uses the long tag to address devices.

However, long tags are only supported by HART 6 devices and newer devices

(HART 6 = version 6 of the HART communication protocol; current version: HART 7). Older

devices, for example HART 5 devices, have to be addressed by the "Message" field. If a

HART 5 device is connected to the WirelessHART network using a WirelessHART adapter,

the WirelessHART Gateway emulates the long tag with the "Message" field.

2.2.4 Gateway Cache Management

The WirelessHART Gateway caches parameters and dynamic values of the wireless and

wired subdevices and makes them available to the HOST. Some commands are cached by

the Gateway automatically (upon read). Other commands, for example dynamic values, are

only cached if the respective field device publishes them (upon publishing). For more

information on publishing of device values prease refer to the Burst lists section (see

chapter 5.4.3).

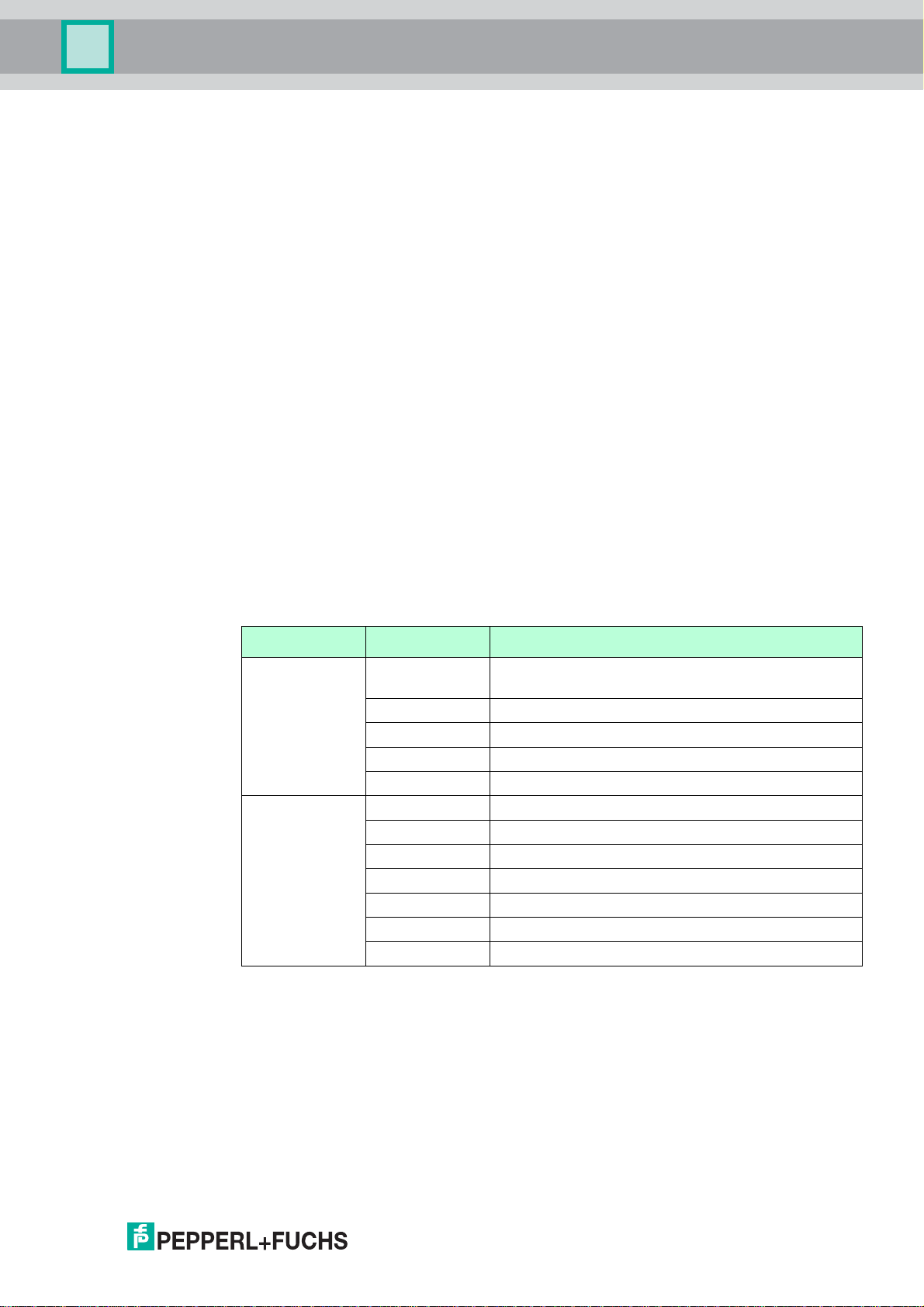

The responses to the command requests listed in the following table are cached in the

Gateway. Commands in the same row have an identical response frame and share the

same cache memory. The write commands (17, 18, 22, 51) will never get an immediate

answer, but their response will be cached (caching upon write-confirmation).

Information cached by the Gateway

Cache Command Description

Static

configuration

commands,

cached upon

read or upon

write

confirmation

Dynamic value

commands,

cached upon

publishing only

0, 11, 21 Read unique identifier (associated with tag or long

tag)

12, (17) Read (Write) Message

13, (18) Read (Write) Short Tag, Descriptor, Date

20, (22) Read (Write) Long Tag

50, (51) Read (Write) Dynamic Variable Assignments

1 Read Primary Variable

2 Read Current and Percentage

3 Read All Variables

9 Read Device Variables and Status

33 Read Device Variables

93 Read Trend

48 Read Additional Device Status

Status Information Caching

The Gateway chaches the device status byte separately for each wireless or wired device.

The device status will be cached from any type of received message, no matter if from a

wired or wireless device, or if it is a "published" or "normal" response.

The extended device status byte is cached in a similar way, but is available only for

wireless devices.

221981 2011-07

15

Page 16

WHA-GW-*

Product Specifications

2.3 Scope of Delivery

The scope of delivery of the WirelessHART Gateway includes:

•Device WHA-GW-*,

• Antenna W-ANT-2400-2DB-ROD,

• 3 sealing plugs for unused cable glands,

• Product documentation.

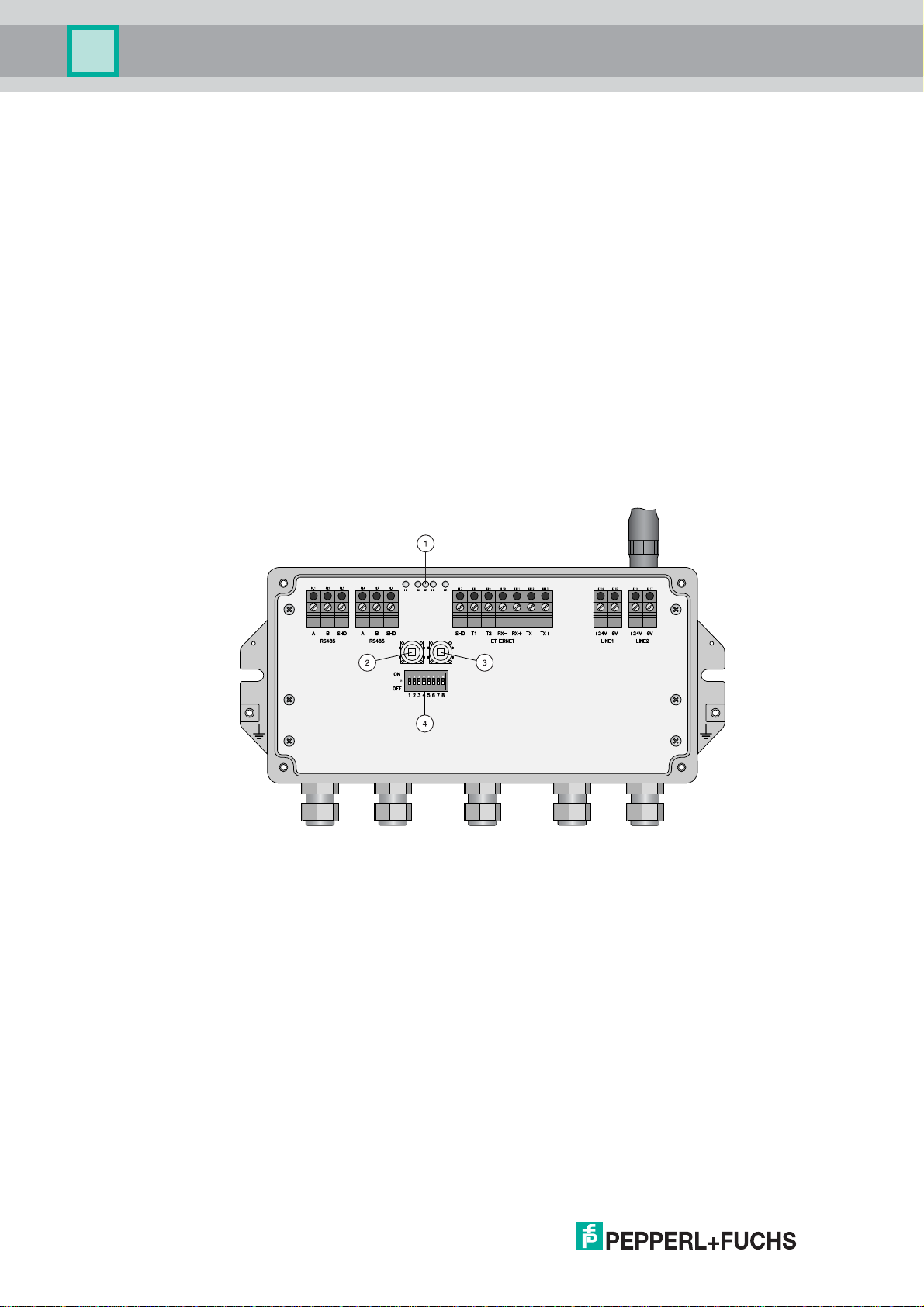

2.4 Design

The operating elements, connections and interfaces are accessible with open enclosure.

Controls and Indicators

Further information on the indications of the LEDs and the functions of the buttons and DIP

switches: see chapter 6.1.

16

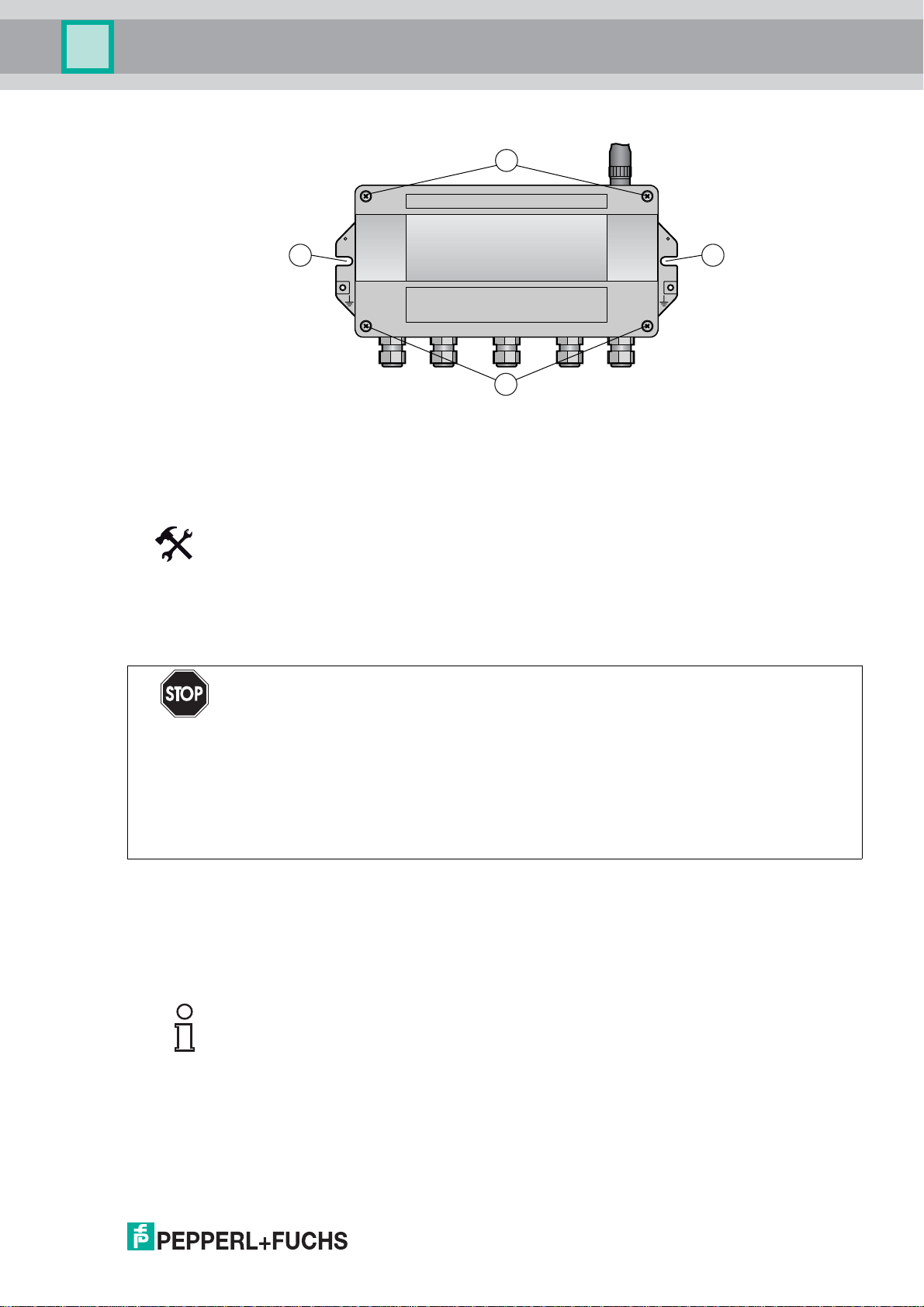

Figure 2.4WHA-GW with open enclosure

1 LEDs

2 Button A

3 Button B

4 DIP switches

221981 2011-07

Page 17

WHA-GW-*

Product Specifications

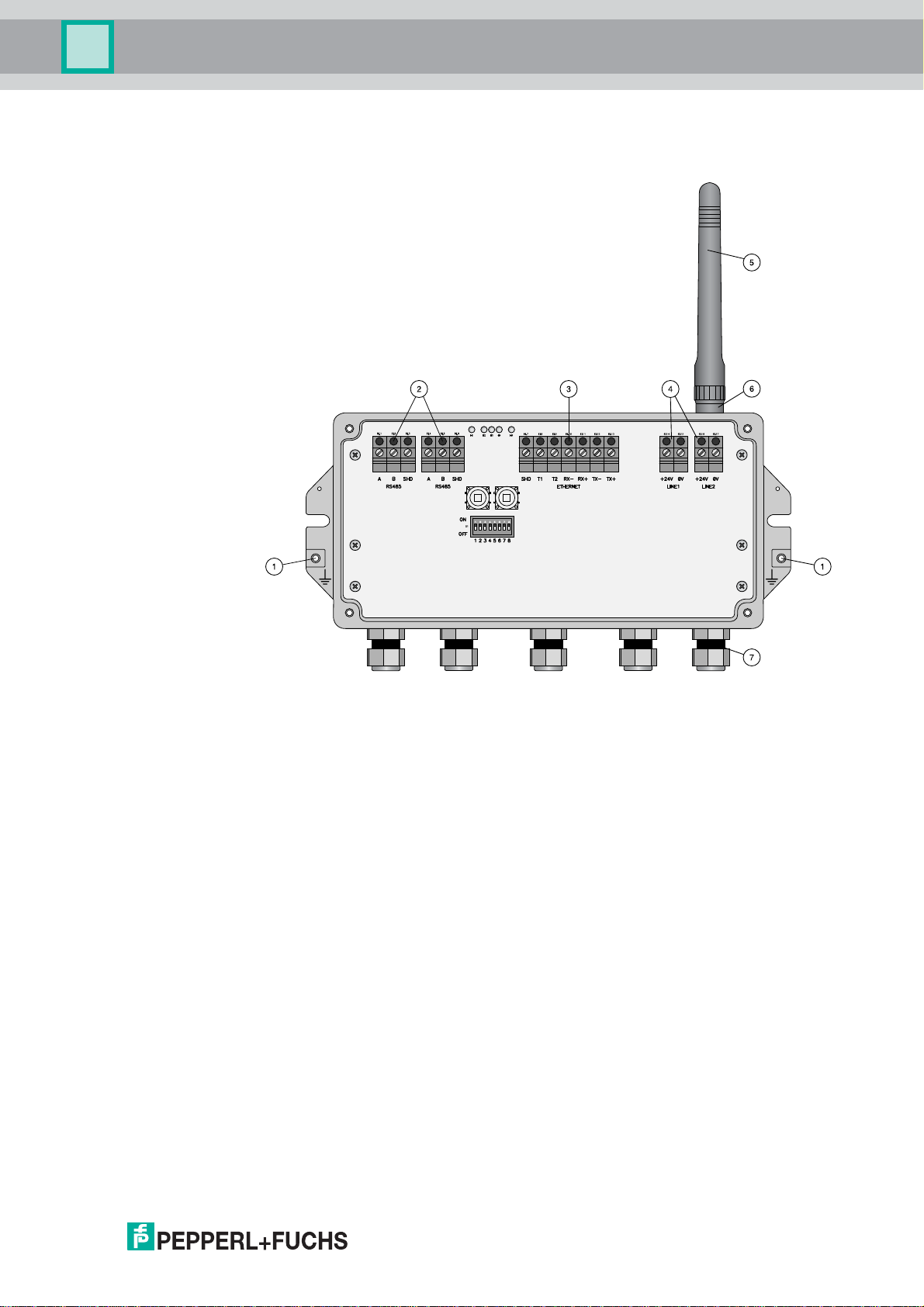

Connections and Interfaces

Figure 2.5Connections and Interfaces

1 Grounding terminal

2 RS-485 interfaces, duplicated terminal block for daisy-chain capability

3 Ethernet interface

4 Power supply connections (redundant)

5 Antenna

6 Antenna terminal

7 Cable glands

221981 2011-07

17

Page 18

WHA-GW-*

Installation

3Installation

3.1 Mounting Considerations

3.1.1 Positioning the Gateway

Install the Gateway first, before installing other WirelessHART devices. This way you can

check for proper operation of new devices as they are installed. Nevertheless, consider the

location of future WirelessHART devices that will be routed through the Gateway to ensure

good connectivity.

Guidelines for Planning a WirelessHART Network

• A line-of-sight between communication partners always is desirable. If a line-of-sight is

not possible, the obstacles should not be massive and the partners should be more to

the edge of an obstacle to allow the wave to "bend" around it (diffraction effect).

• Consider moving objects that could affect the device's antenna range.

• Install wireless devices at least 1 m above the ground or the floor.

• Make sure that the device's antenna is aligned vertically for best results.

• Make sure that a minimum of 2 other WirelessHART devices are well within the antenna

range of the device (see chapter 9). For more information on the antenna

characteristics please refer to the following section.

• Do not position WirelessHART devices directly below or above each other. They would

be outside each other's antenna range.

• Install WirelessHART devices at least 1 m away from each other.

• Antennas must be at least 6 cm away from any wall or any metallic material running

parallel to it.

• Position the device as far away as possible from metal surfaces or walls containing

metal. There should be as little metal close to the device as possible.

• Do not position other 2.4 GHz devices like cordless phone bases or WLAN routers near

WirelessHART devices. Keep in mind other wireless networks using the same

frequency spectrum (WLAN, Bluetooth, etc.). Wireless technologies used in an

industrial environment must be able to coexist without disrupting each other. If multiple

networks operate in one facility, a frequency management should be applied as part of

administration.

If it is not possible to mount the device outdoors, connect a remote antenna to the antenna

terminal and mount the remote antenna outdoors. The antenna cable should not be longer

than 15 m.

3.1.2 Antenna Characteristics

The antenna is an omni-directional dipole antenna. If you point the antenna upwards, the

signal radiates horizontally with an angle of approx. 45 degrees above and below the

horizontal (donut shaped). Allmost no signal will be radiated directly above and below the

antenna. Consider this when planning a WirelessHART network. The height differences

between wireless devices in a network should not be too big.

This is only valid for an antenna placed outdoors with no metal surfaces near. The radiation

pattern changes significantly when metal surfaces are close to the antenna.

18

221981 2011-07

Page 19

WHA-GW-*

Installation

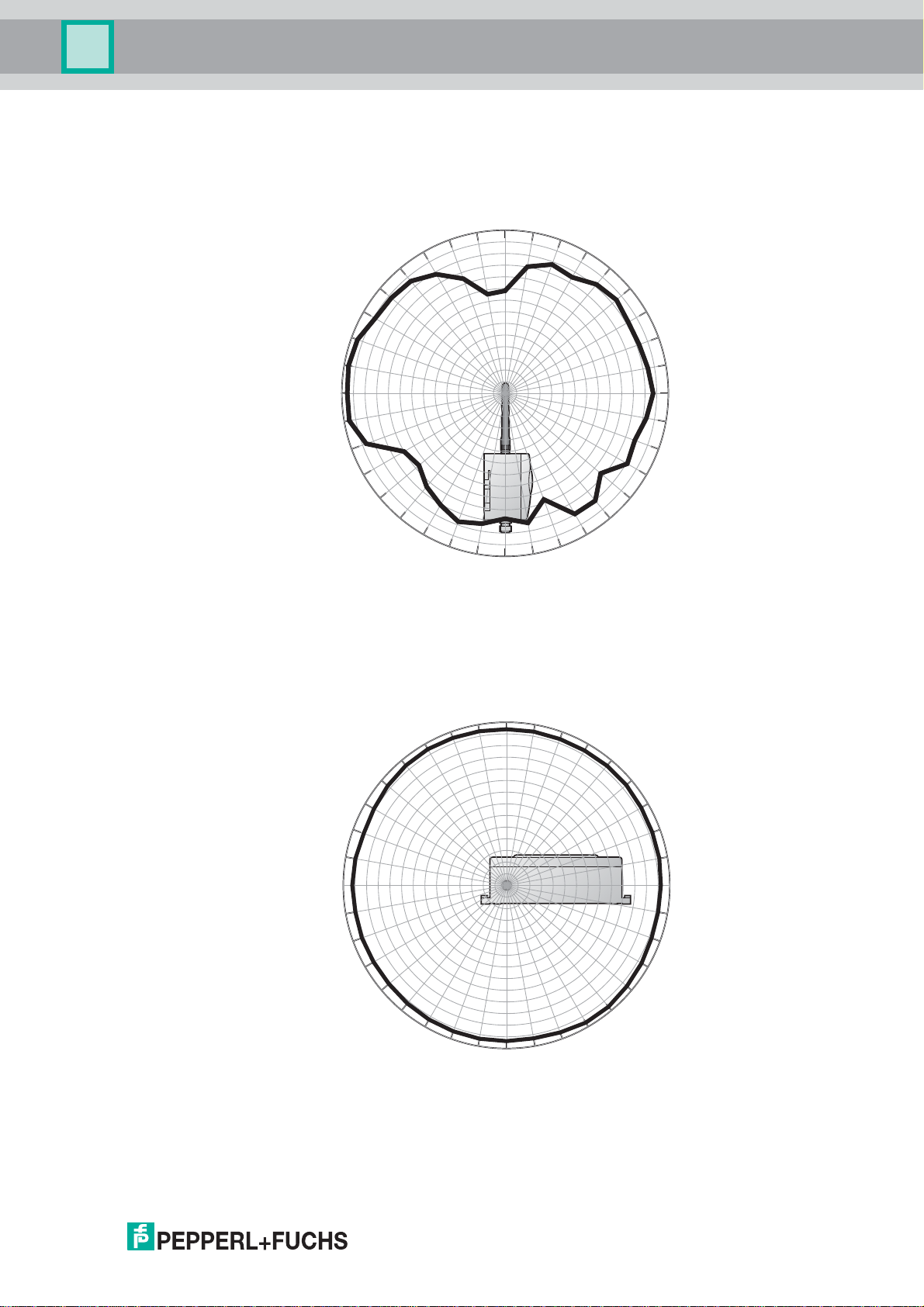

The following diagrams show the antenna gain in two different planes.

0°

280°

270°

290°

300°

310°

320°

330°

340°

350°

2

-1

-4

-7

-10

-13

-16

-19

-22

-25

-28

-31

-34

-37

10°

20°

30°

40°

50°

60°

70°

80°

90°

260°

250°

240°

230°

220°

210°

200°

190°

Figure 3.1Antenna gain (side view, 2450 MHz, dBi)

350°

340°

330°

320°

310°

300°

290°

280°

270°

180°

0°

2

-1

-4

-7

-10

-13

-16

-19

-22

-25

-28

-31

-34

-37

170°

10°

100°

110

120°

130°

140°

150°

160°

20°

30°

40°

50°

60°

70°

80°

90°

260°

250°

240°

230°

220°

210°

200°

190°

180°

Figure 3.2Antenna gain (top view, 2450 MHz, dBi)

221981 2011-07

170°

160°

140°

150°

100°

110

120°

130°

19

Page 20

WHA-GW-*

x

y

Installation

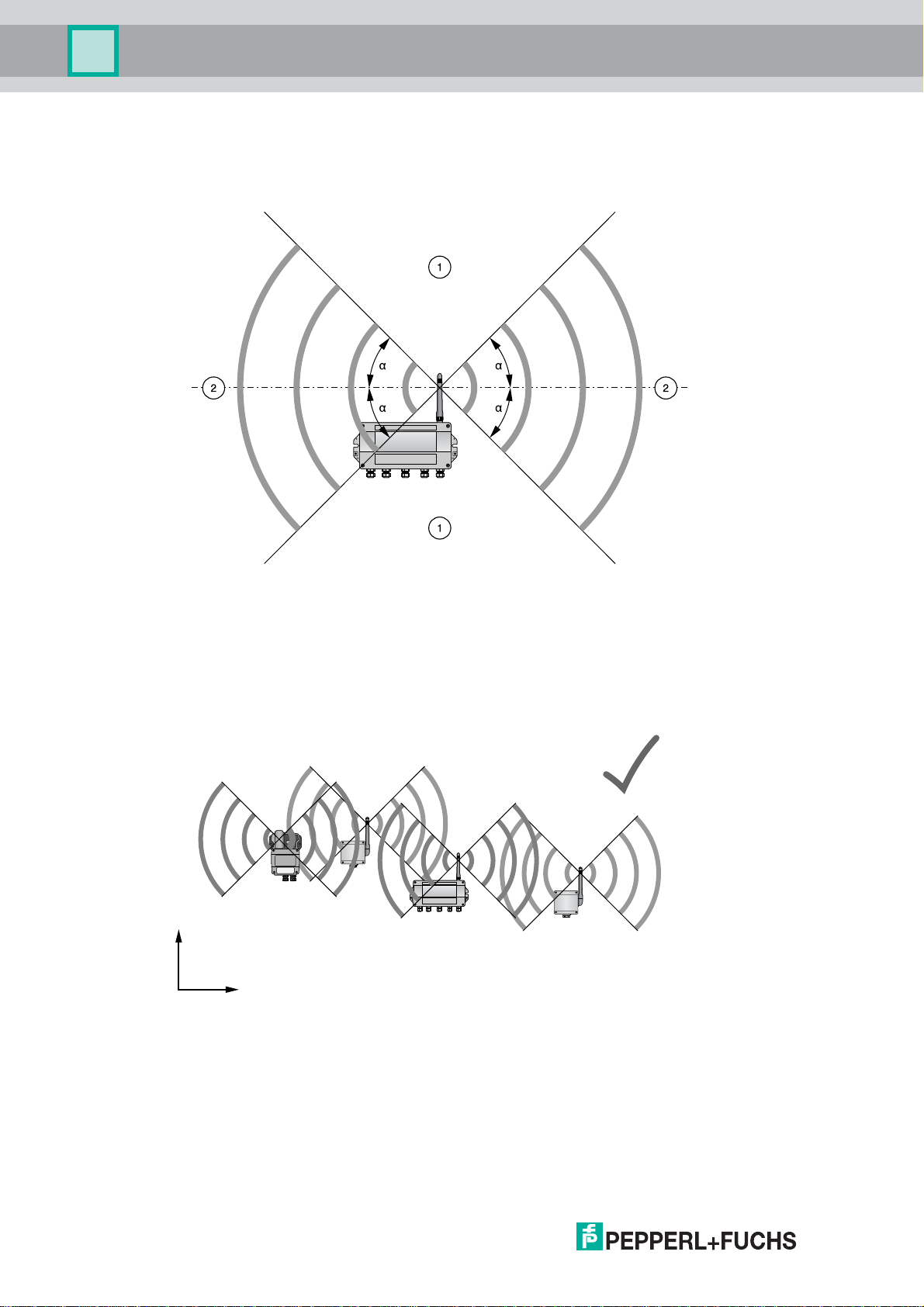

3.1.3 Examples for Good and Poor Positioning

Figure 3.3Wave propagation, schematic representation (alpha = approx. 45°, may vary considerably)

1 Weaker signal above and below; almost no signal directly above and below

2 Stronger signal sideways

Figure 3.4Good positioning: Devices are within each others antenna range

221981 2011-07

20

Page 21

WHA-GW-*

x

y

Installation

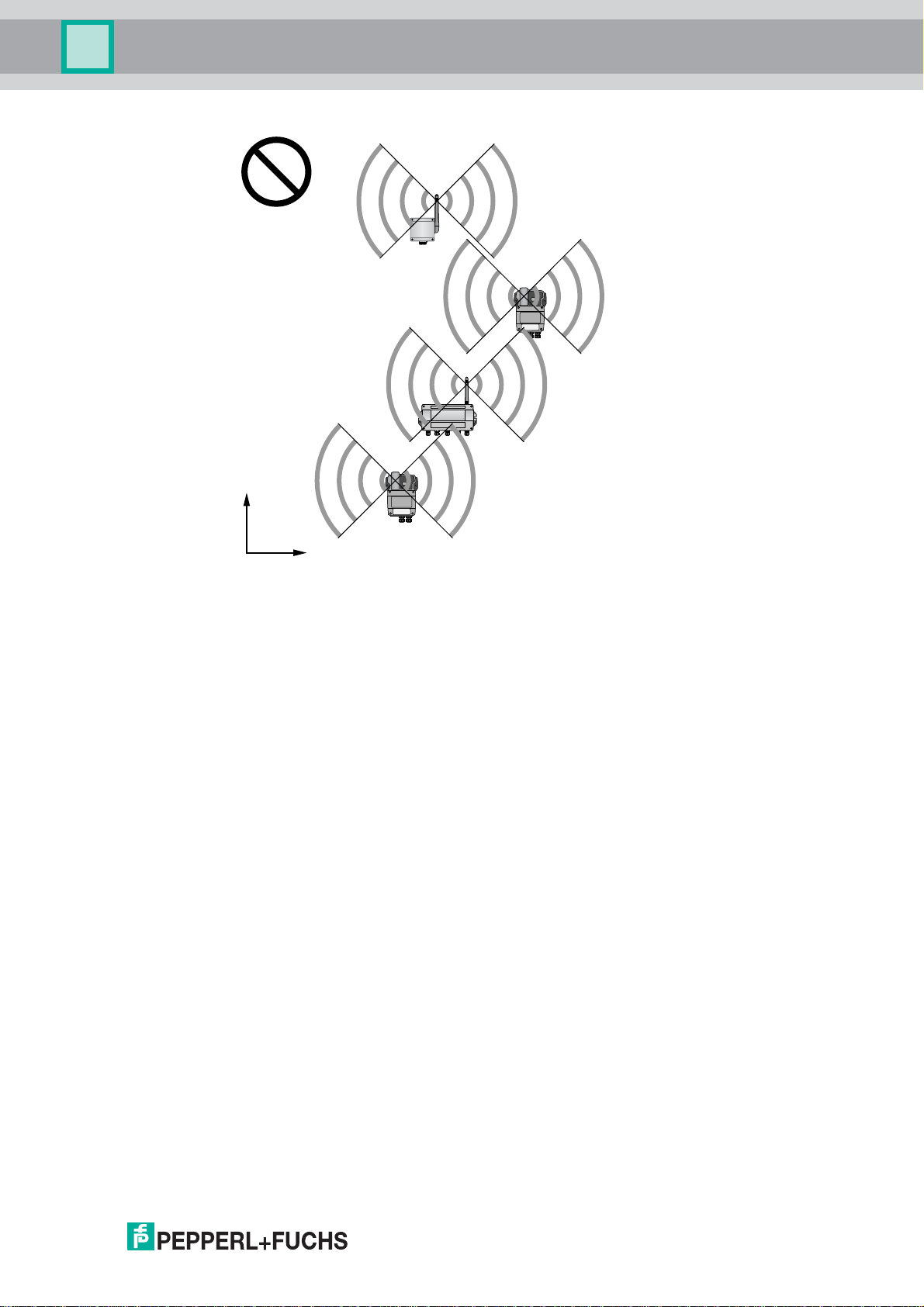

Figure 3.5Poor positioning: Devices are not within each others antenna range

221981 2011-07

21

Page 22

WHA-GW-*

Installation

3.2 Mounting the Gateway

Danger!

Electrostatic discharge hazard

The device contains non-conductive plastic parts. Care must be taken when operating the

installed device because of possible electrostatic charges. Electrostatic charged surfaces

may cause an ignition spark.

Electrostatic charges must be avoided. For example, do not rub the device and never clean

plastic surfaces with a dry cloth. Always use a damp cloth instead.

Danger!

Check cable glands

The IP degree of protection can not be ensured if the cables and cable glands are not fitted

correctly.

To ensure the IP degree of protection

• all screws of the housing / housing cover must have been tightened with the appropriate

torque,

• only cables of the appropriate size must be used in the cable glands,

• all cable glands must be tightened with the appropriate torque,

• all seals must be undamaged and fitted correctly,

• all empty cable glands must be sealed with appropriate plugs.

The mounting location should be well accessible for mounting and electrical installation.

Make sure that there is enough space to open the housing cover and to access the

terminals, switches, and cable glands. Choose a mounting location that meets the

requirements of the climatic limits specified in the technical data.

The housing has a degree of protection of IP65 and is designed for wall mounting

(mounting accessories and tools not included).

Required tools

22

• 2 screws (M6)

• Drill

•Screwdriver

Depending on the mounting surface, you may need additional mounting material.

221981 2011-07

Page 23

WHA-GW-*

2

1 1

2

Installation

Figure 3.6Mounting holes and housing screws

1 Mounting holes for M6 screws

2 Housing screws

Mounting the Gateway

1. Drill 2 holes into the mounting surface so that they match the holes of the housing.

2. Screw the device to the mounting surface using M6 screws.

3.3 Connecting to Ethernet

Danger!

Explosion hazard in Zone 2 when operating powered Gateway

If the Gateway is installed in Zone 2 and connected to power, there is an explosion hazard

when operating DIP switches, buttons or connecting/disconnecting cables.

The operation of DIP switches/buttons and the connection/disconnection of any cables in

Zone 2 is only permitted in the absence of a hazardous atmosphere or if the device is

disconnected from power!

The Gateway is equipped with a fully galvanic isolated 10 Base-T/100 Base-TX Ethernet

interface. You may connect the Gateway to an existing Ethernet hub, switch, router or

directly to a PC.

Open the housing cover to access the terminal blocks.

Note!

Keep in mind that an access point of the Ethernet network has to be available. The

maximum length of the cable running from the Gateway to the access point is 100 m,

depending on cable type and communication speed.

221981 2011-07

23

Page 24

WHA-GW-*

Installation

Note!

Tension relief and bending radii

Ensure sufficient relief of tension on the cables during installation and note the minimum

bending radii of the cables.

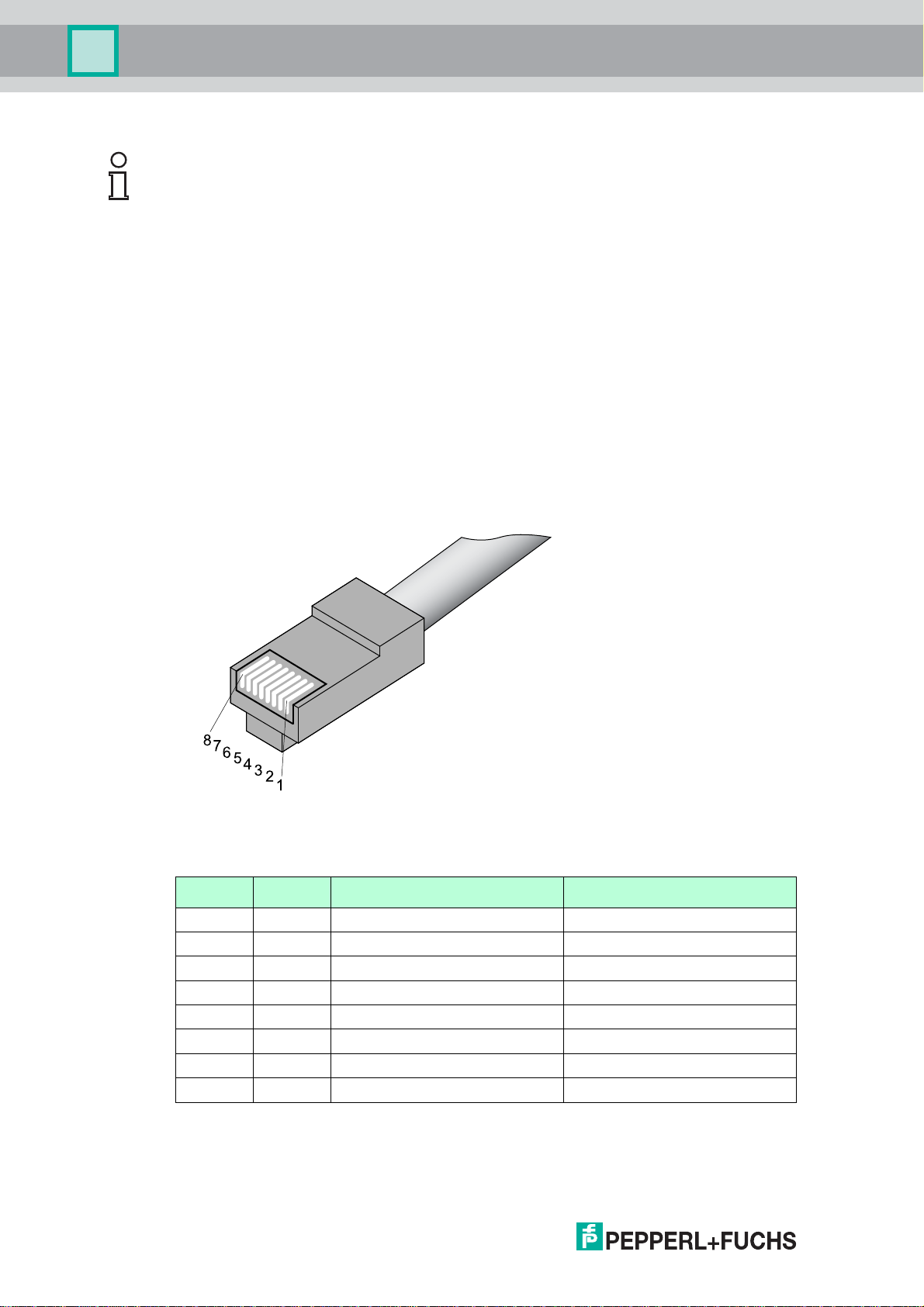

Pin assignment of the Ethernet plug

You do not need an Ethernet plug to connect the Ethernet cable to the Gateway. However,

you need an Ethernet plug at the other end of the cable to connect the cable to an Ethernet

hub, switch, router or PC.

There are different standards for Ethernet plugs: T568A and T568B (see following

figure/table). The only difference between these standards is that certain wires are

connected to different pins of the plug. It is not important which standard the plug uses.

But, depending on the plug standard, there are two different ways of connecting the other

end of the Ethernet cable to the Gateway.

24

Figure 3.7Pin assignment RJ45 plug

Pin assignment of a T568A/T568B plug

Signal RJ45 Pin Wire color T568A Wire color T568B

TX+ 1 white/green white/orange

TX- 2 green orange

RX+ 3 white/orange white/green

4 blue blue

5 white/blue white/blue

RX- 6 orange green

7 white/brown white/brown

8 brown brown

Table 3.1Pin assignment of a T568A and T568B plug

221981 2011-07

Page 25

WHA-GW-*

1

3

2

4

2

Installation

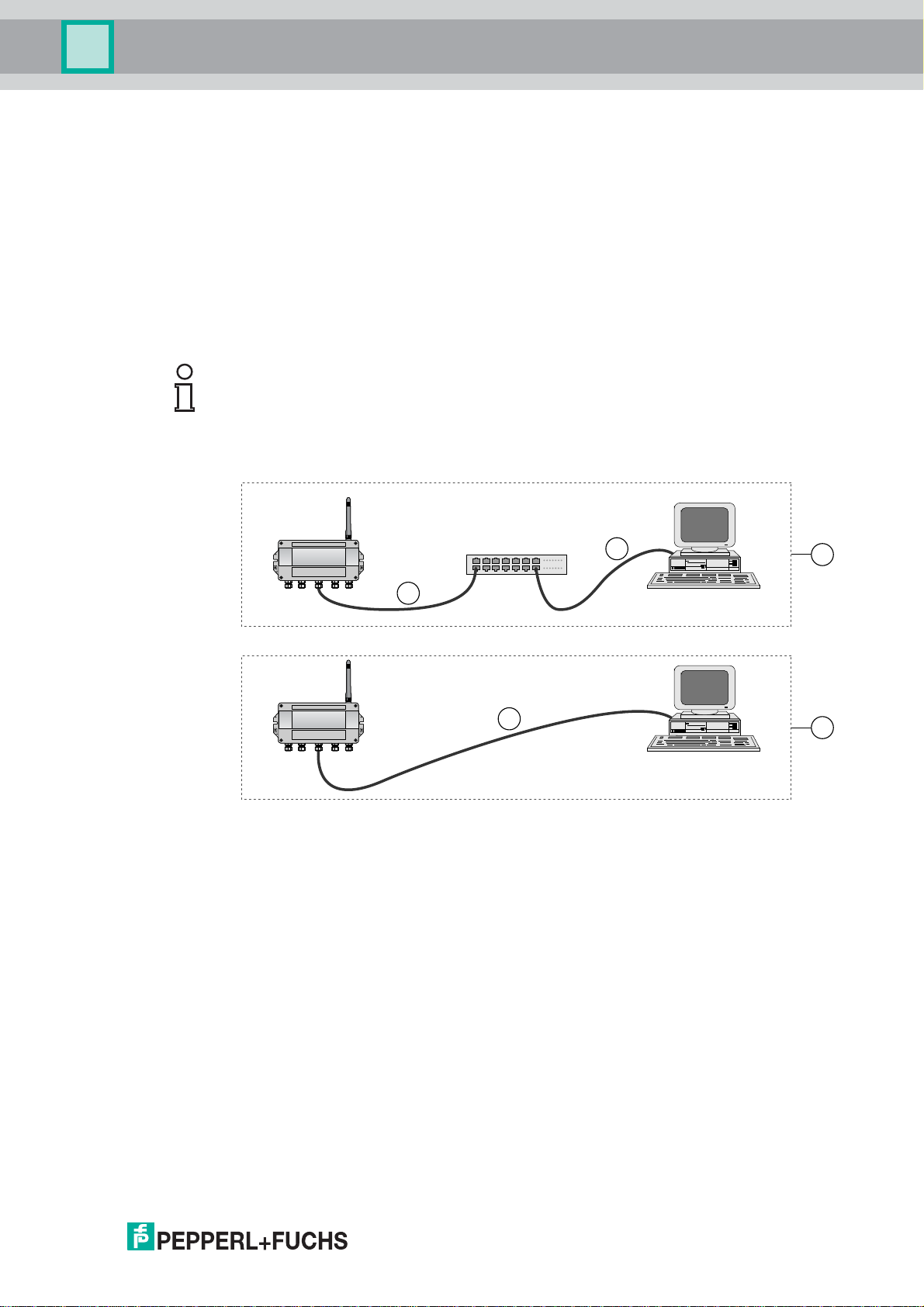

Crossover or straight through wiring

There are different types of Ethernet cables, depending on the application. In a straight

through cable, both cable ends have T568A plugs or both ends have T568B plugs. In a

crossover cable, one end has a T568A plug and the other end a T568B plug.

• Use straight through wiring if you connect the Gateway to a switch, hub or router (see

Figure 3.8 on page 25).

• Use crossover wiring if you connect the Gateway directly to another ethernet device

(e.g. a PC) without a switch, hub or router (see Figure 3.8 on page 25).

Note!

Latest network interface cards and hub/switch/router versions can be able to automatically

adjust to the cable version used, also if this is not the applicable one according to the

guidelines given in this manual.

Figure 3.8Straight Through or Crossover connection

1 Gateway connected to PC via hub/switch/router

2 Straight Through cable

3 Gateway connected directly to PC

4 Crossover cable

221981 2011-07

25

Page 26

WHA-GW-*

Installation

Connecting to Ethernet Network

1. Unscrew the 4 screws of the housing cover (see Figure 3.6 on page 23).

2. Remove the housing cover.

3. Route the Ethernet cable through the cable gland in the middle of the Gateway housing.

The permissible cable diameter lies between 6 ... 10 mm.

4. Connect the Ethernet cable to the terminal block labelled "Ethernet" (see Figure 3.9 on

page 26) according to the following figure/tables.

5. Screw the housing cover to the housing again.

6. Tighten the cable gland with appropriate torque (see table "Installation torque cable

glands" on page 32).

The Gateway is now connected to the Ethernet network. The yellow Ethernet

communication status LED starts flashing when a correct HART or Modbus protocol

message is received (see chapter 6.1).

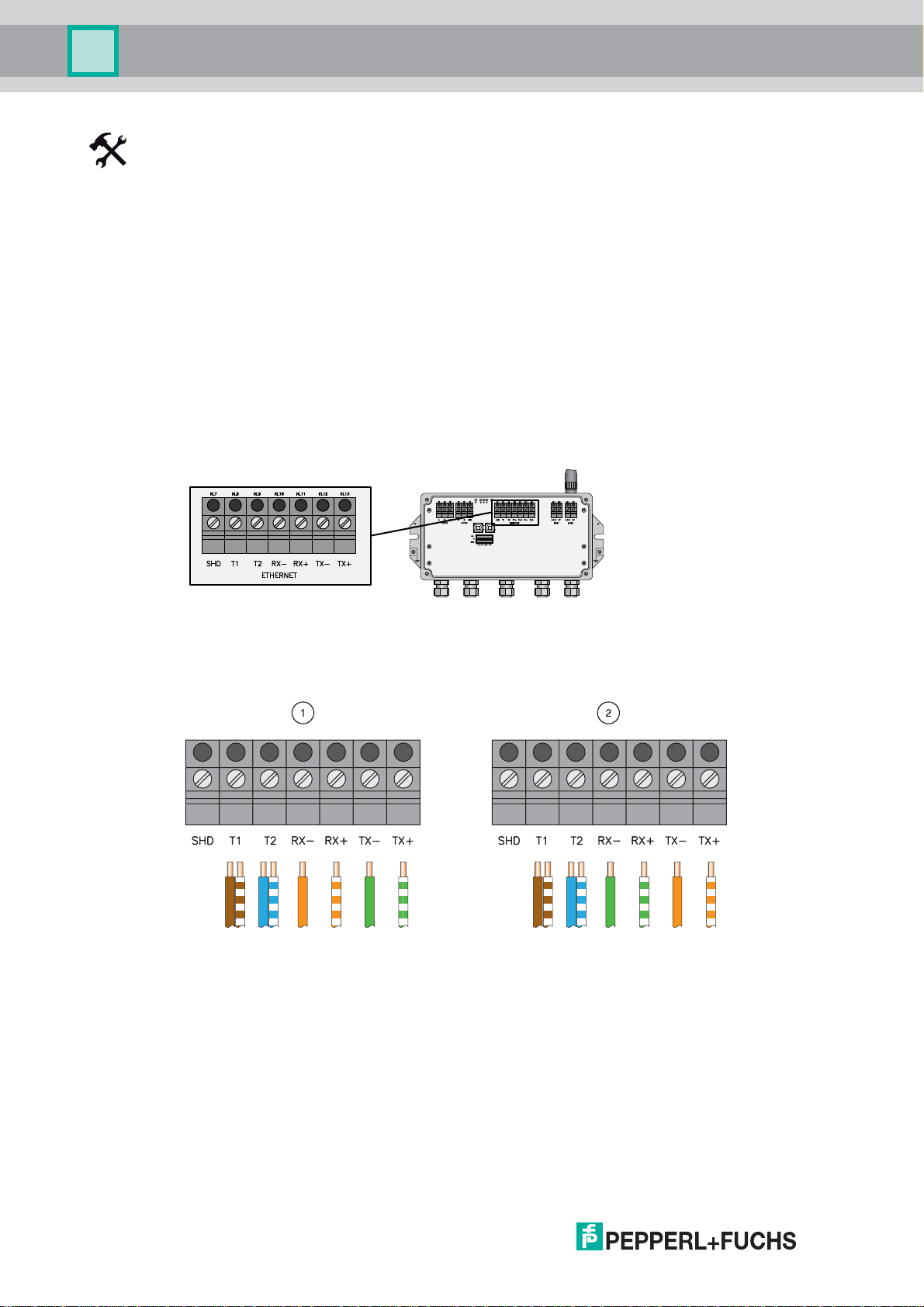

Figure 3.9Ethernet interface

Figure 3.10Gateway Ethernet wiring

1 Straight through connection with an T568A plug

or

Crossover connection with a T568B plug

26

2 Crossover connection with an T568A plug

or

Straight Through connection with a T568B plug

221981 2011-07

Page 27

WHA-GW-*

Installation

Wiring with a T568A plug

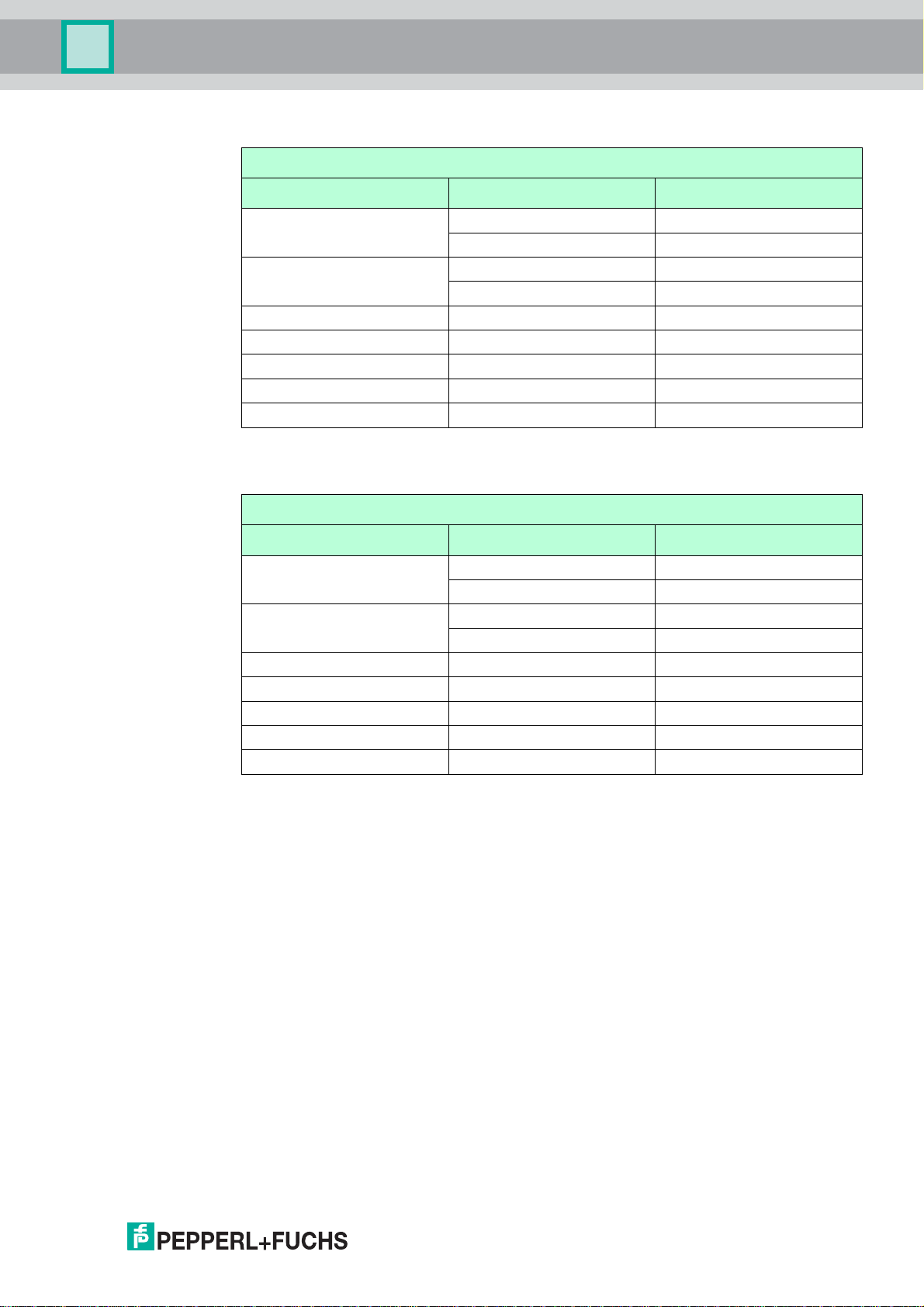

Gateway wiring with a T568A plug

Gateway Terminal Crossover wiring Straight through wiring

T1 brown brown

white/brown white/brown

T2 blue blue

white/blue white/blue

RX- green orange

RX+ white/green white/orange

TX- orange green

TX+ white/orange white/green

SHD Cable shield Cable shield

Table 3.2Wiring with a T568A plug

Wiring with a T568B plug

Gateway wiring with a T568B plug

Gateway Terminal Crossover wiring Straight through wiring

T1 brown brown

white/brown white/brown

T2 blue blue

white/blue white/blue

RX- orange green

RX+ white/orange white/green

TX- green orange

TX+ white/green white/orange

SHD Cable shield Cable shield

Table 3.3Wiring with a T568B plug

221981 2011-07

27

Page 28

WHA-GW-*

Installation

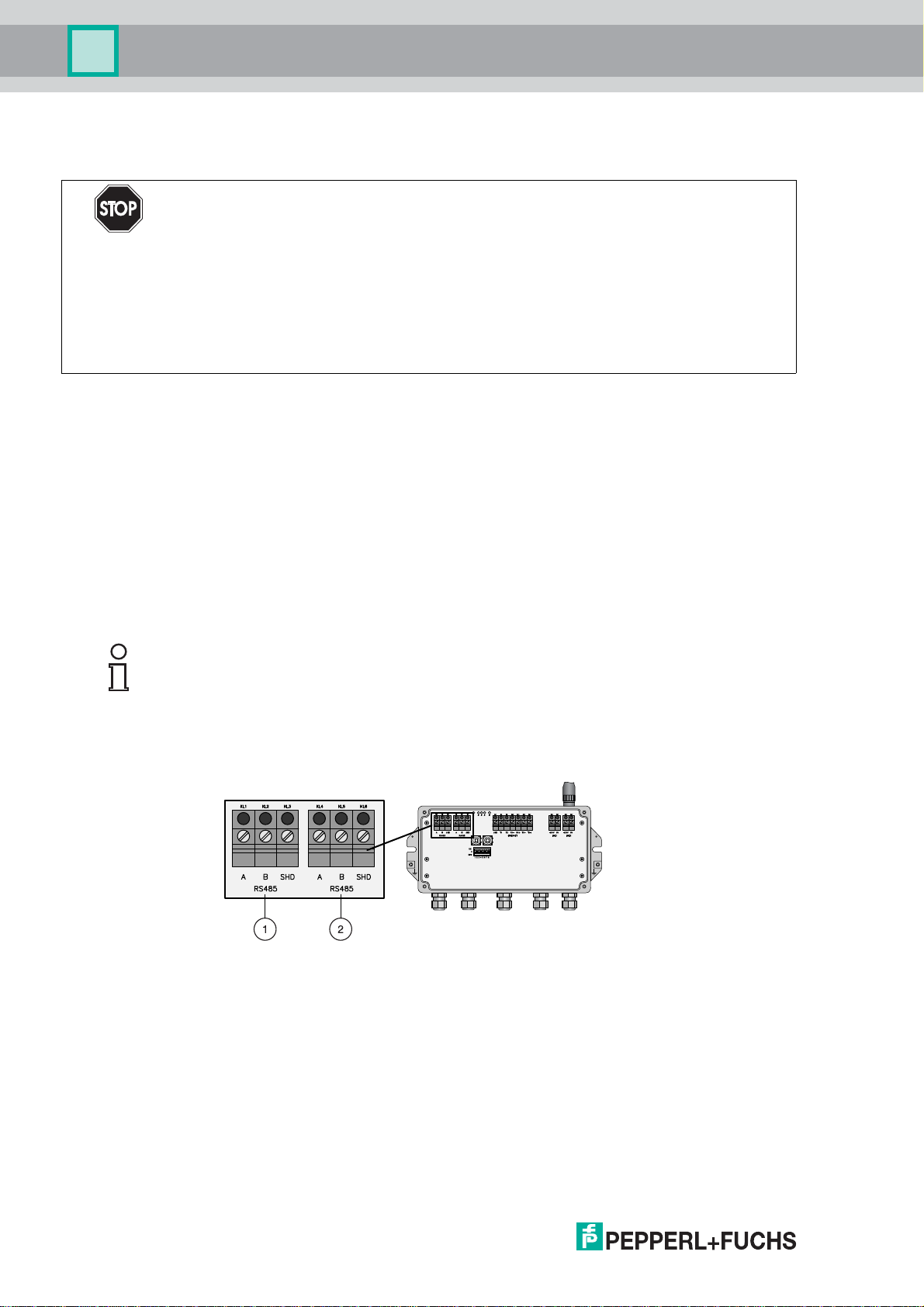

3.4 Connecting to RS-485

Danger!

Explosion hazard in Zone 2 when operating powered Gateway

If the Gateway is installed in Zone 2 and connected to power, there is an explosion hazard

when operating DIP switches, buttons or connecting/disconnecting cables.

The operation of DIP switches/buttons and the connection/disconnection of any cables in

Zone 2 is only permitted in the absence of a hazardous atmosphere or if the device is

disconnected from power!

The Gateway is equipped with a fully galvanic isolated RS-485 interface. The interface is

daisy-chain capable through its duplicated RS-485 terminal block.

A terminating resistor is integrated and may be switched on/off by using the corresponding

DIP switch inside the Gateway housing (see chapter 6.1) . It is also possible to switch on/off

the terminating resistor via software (see chapter 5.5.1).

If the RS-485 cable ends at the WirelessHART Gateway and is not routed to other devices

(no daisy-chain connection), activate the terminating resistor to ensure reliable RS-485

communication.

Note!

Keep in mind the location of the Modbus PLC or DCS. The maximum length of the cable

running from the Gateway to the PLC/DCS is 1200 m (at reduced communication speed).

Use shielded twisted pair (STP) cables only.

Figure 3.11RS-485 interfaces

28

1 First RS-485 interface

2 Second RS-485 interface

221981 2011-07

Page 29

WHA-GW-*

Installation

Note!

Tension relief and bending radii

Ensure sufficient relief of tension on the cables during installation and note the minimum

bending radii of the cables.

Note!

If the cable shield is grounded, the grounding should only be connected to one end of the

cable, in order to avoid equipotential bonding currents.

Connecting to RS-485

1. Unscrew the 4 screws of the housing cover (see Figure 3.6 on page 23).

2. Remove the housing cover.

3. Route the STP cable through the first cable gland from left at the bottom of the Gateway

housing (see Figure 2.5 on page 17). The permissible cable diameter lies between

6...10mm.

4. Connect the STP cable to the first terminal block labelled "RS485" (see Figure 3.11 on

page 28) according to the following table.

5. For a daisy-chain connection, route the second STP cable through the second cable

gland from left at the bottom of the Gateway housing. Connect the second STP cable to

the second terminal block labelled "RS485" according to the following table.

6. To activate the RS-485 termination, set DIP switch number 7 to "ON" (see Figure 6.4 on

page 67).

7. Screw the housing cover to the housing again.

8. Tighten the cable gland with appropriate torque (see table "Installation torque cable

glands" on page 32).

The Gateway is now connected to the RS-485 network. The yellow RS-485

communication status LED starts flashing when a correct HART or Modbus protocol

message is received (see chapter 6.1).

Gateway wiring (RS-485 connection)

Wire RS-485 cable Terminal WHA-GW Meaning

RxD/TxD - (RS-485 A) A RS-485 differential signal

RxD/TxD + (RS-485 B) B

Shield SHD Cable shielding

221981 2011-07

29

Page 30

WHA-GW-*

Installation

3.5 Connecting the Antenna

Danger!

Loss of the device's certification

Only use antennas that are specified in the data sheet.

Danger!

Explosion hazard in Zone 2 when operating powered Gateway

If the Gateway is installed in Zone 2 and connected to power, there is an explosion hazard

when operating DIP switches, buttons or connecting/disconnecting cables.

The operation of DIP switches/buttons and the connection/disconnection of any cables in

Zone 2 is only permitted in the absence of a hazardous atmosphere or if the device is

disconnected from power!

An antenna is supplied with the device. However, if the device is mounted indoors, or if

there are many metal obstacles near the device, it is better to use a suitable remote

antenna instead.

The remote antenna should be installed outdoors in a position where it is within the

antenna range of other WirelessHART devices. To minimize signal loss, the cable

connecting the remote antenna to the Gateway should not be longer than 10 m.

The guidelines for positioning a WirelessHART device also apply to the positioning of a

remote antenna (see chapter 3.1.1).

Note!

Only antennas of the type W-ANT-2400-2DB-ROD or remote antennas with an antenna

gain 2 dBi may be connected to the device.

Connecting the antenna

Firmly screw the antenna or a a remote antenna to the device's antenna terminal (see

Figure 2.5 on page 17).

30

221981 2011-07

Page 31

WHA-GW-*

Installation

3.6 Connecting to Power Supply and Grounding

Danger!

Explosion hazard in Zone 2 when operating powered Gateway

If the Gateway is installed in Zone 2 and connected to power, there is an explosion hazard

when operating DIP switches, buttons or connecting/disconnecting cables.

The operation of DIP switches/buttons and the connection/disconnection of any cables in

Zone 2 is only permitted in the absence of a hazardous atmosphere or if the device is

disconnected from power!

There are two 24 V dc power supply terminal blocks located inside the Gateway, allowing

for redundant power supply. Open the housing cover to access the terminal blocks.

Note!

Tension relief and bending radii

Ensure sufficient relief of tension on the cables during installation and note the minimum

bending radii of the cables.

Figure 3.12Power supply

1 First power supply connection

2 Second (redundant) power supply connection

3 Grounding terminals

Connecting to Power Supply and Grounding

1. Connect one of the grounding terminals to a ground wire (see Figure 3.12 on page 31).

2. Unscrew the 4 screws of the housing cover (see Figure 3.6 on page 23).

3. Remove the housing cover.

4. Ensure that appropriate power is supplied.

5. Draw the power cable through the second cable gland from right (see Figure 2.5 on

page 17). The permissible cable diameter lies between 6 ... 10 mm.

6. Connect the power cable to the first power supply connection "Line 1" observing polarity

(see Figure 3.12 on page 31).

221981 2011-07

31

Page 32

WHA-GW-*

Installation

7. If you want to connect a redundant power supply (optional), draw the second power

cable through the cable gland on the far right of the housing.

8. Connect the second power cable to the second power supply connection "Line 2"

observing polarity.

The Gateway is connected to power supply. The green power LED may remain off for

up to 40 seconds after connection to power (system boot-up).

9. Tighten the cable glands with appropriate torque (see table "Installation torque cable

glands" on page 32).

10.Seal empty cable glands with the provided plugs.

Note!

The tightening torques of cable glands depend on what type of cable is used and must

therefore be determined by the user. The cap nuts must be securely tightened. Tightening

the cap nuts too tight can have a negative effect on the protection class. The following

figures should be taken as rough guides only.

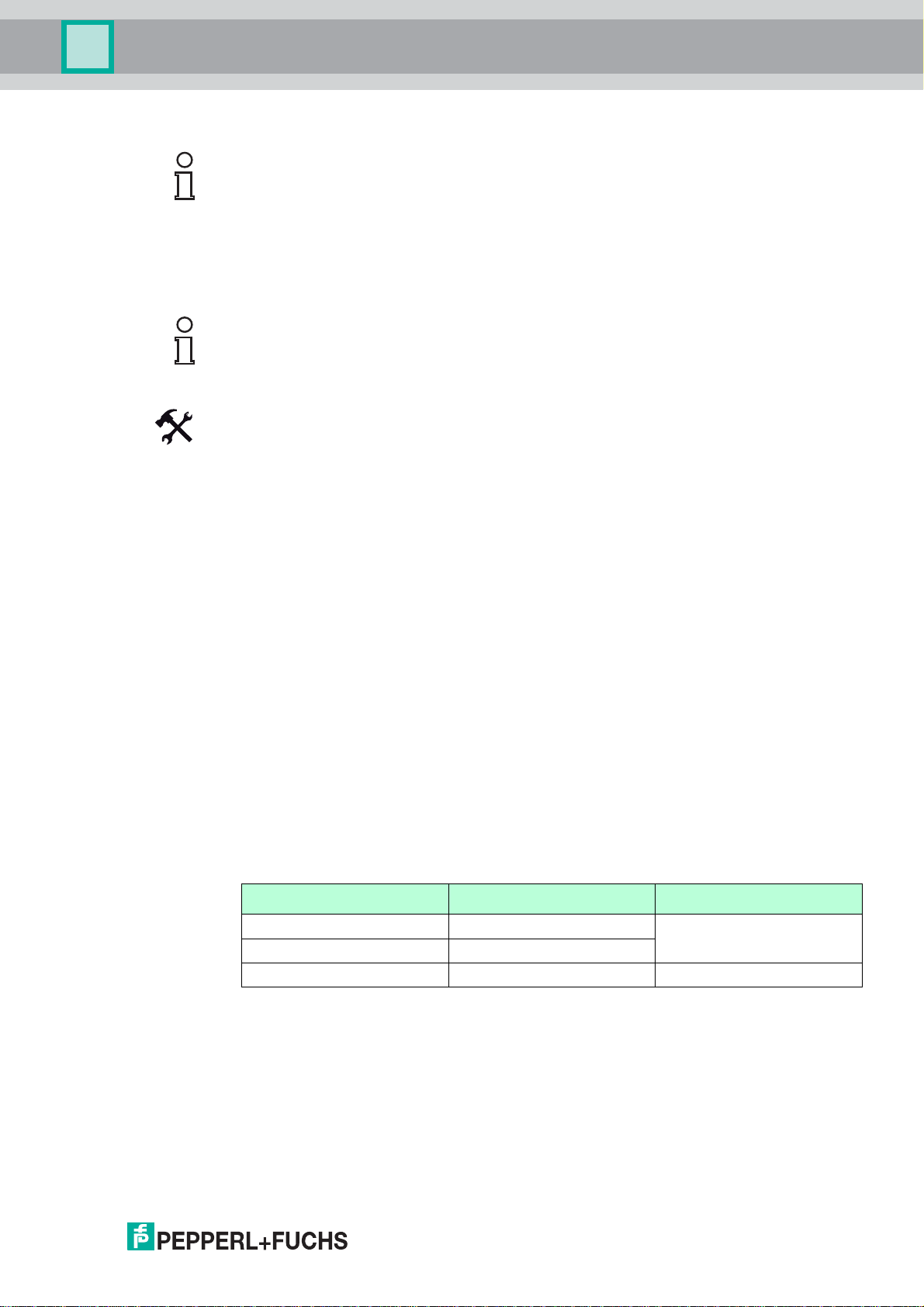

Installation torque cable glands

Type of cable glands Installation torque cable glands

Plastic 2.5 Nm

Nickel plated brass 4.11 Nm

Stainless steel 4.11 Nm

Table 3.4Installation torque cable glands

Danger!

Check cable glands

The IP degree of protection can not be ensured if the cables and cable glands are not fitted

correctly.

To ensure the IP degree of protection

• all screws of the housing / housing cover must have been tightened with the appropriate

torque,

• only cables of the appropriate size must be used in the cable glands,

• all cable glands must be tightened with the appropriate torque,

32

• all seals must be undamaged and fitted correctly,

• all empty cable glands must be sealed with appropriate plugs.

221981 2011-07

Page 33

WHA-GW-*

Commissioning

4 Commissioning

4.1 Important Steps to Getting Started

There are different possibilities how to connect to the gateway and how to configure the

gateway. The following overview tells you which steps to take. But first, please answer the

following question.

Are you going to configure the gateway via DTM software or via the browser-based web

interface?

• DTM software: Please follow the instructions given in "Configuring via DTM software"

below.

• Web interface: Please follow the instructions given in "Configuring via browser-based

web interface" below.

Configuring via DTM software

1. Download and install the following software components, if not already installed: Mi-

crosoft

(see chapter 4.2).

®

.NET Framework, PACTware® Framework, DTM Collection, HART CommDTM

2. Connect to the gateway via the RS-485 interface (see chapter 4.4) or the Ethernet

interface (see chapter 4.5).

3. Create a new PACTware project (see chapter 4.6).

4. Configure the gateway via DTM (see chapter 5.1).

Configuring via browser-based web interface

1. Download and install a web browser, if not already installed (Microsoft® Internet Explorer

v7 or higher, Mozilla Firefox v3 or higher).

2. Connect to the gateway via the Ethernet interface (see chapter 4.5).

3. Configure the gateway via your web browser (see chapter 5.1).

4.2 DTM Software

4.2.1 Downloading the required software

Required software:

®

•Microsoft

• PACTware

• WirelessHART DTM

The DTM collection including WirelessHART device DTMs and Ethernet communication

DTM.

.NET Framework

TM

Framework

• HART CommDTM

The HART CommDTM has to be installed separately if serial HART communication via

the Gateway's RS-485 interface is required. The HART CommDTM supports both

FSK (i.e. HART modem) and RS-485 interfaces.

221981 2011-07

33

Page 34

WHA-GW-*

Commissioning

Note!

If one of the software components is already installed on your system, the installation may

be omitted.

Where to download the required software?

1. Visit www.pepperl-fuchs.com and scroll down to the bottom of the page until you see the

2. Click on the Process Automation link.

3. In the Process Automation Products menu, click on the Software link.

4. Now download the software components Microsoft

area Pepperl+Fuchs International site links.

The Process Automation main page is loaded.

The Software main page is loaded.

®

.NET Framework, PACTware®,

WirelessHART DTM and, if required, the HART CommDTM. You might need to scroll

down the page to find the required component.

5. Unzip the downloaded files and store the data to your local hard drive.

4.3 Installing the Required Software

Hardware requirements for PACTware® and the device DTM:

®

•IBM

• Processor Intel/AMD min. 500 Mhz,

• min. 256 MB RAM,

• min. 200MB free disk space,

• Graphics resolution 1024 x 768.

Software requirements for PACTware

• Windows 2000 Service Pack 4, Windows XP Service Pack 1/2/3 or Windows Vista,

•Microsoft

• unzip software.

Note!

You need to be logged on to Windows with administrator privileges during installation.

or compatible PC,

®

and the device DTM:

®

.NET Framework Release 1.1 Service Pack 1,

221981 2011-07

34

Page 35

WHA-GW-*

Commissioning

Installing the required Software

1. Install the Microsoft® .NET Framework by starting the corresponding setup.exe file and

following the installation instructions given on the screen.

2. Install PACTware

installation instructions given on the screen.

3. Install the WirelessHART DTM collection by starting the corresponding setup.exe file

and following the installation instructions given on the screen.

4. Install the HART CommDTM by starting the corresponding setup.exe file and following

the installation instructions given on the screen.

You have installed the required software.

4.3.1 Updating the DTM catalog

After you have installed the FDT base application and the new DTMs onto the computer, it

may be necessary to update the DTM catalog. In PACTware, the DTM catalog is called the

"device catalog" and is usually updated automatically when PACTware starts up.

If PACTware does not automatically update the device catalog, proceed as follows.

®

by starting the corresponding setup.exe file and following the

Updating the device catalog

1. Start PACTware.

2. Select View > Device catalog or press the F3 key or click the Device catalog icon on

the toolbar.

The Device catalog window opens.

3. Click the Update device catalog button to update the device catalog (see on page 35).

Device catalog in PACTware

4. Click Yes to confirm the next prompt.

The program then searches for recently installed DTMs (see on page 35). The updated

device catalog appears once the search has finished.

221981 2011-07

Search for DTMs in PACTware

35

Page 36

WHA-GW-*

Commissioning

4.4 Connecting via RS485

Once the Gateway has been connected to the RS485 bus (see chapter 3.4), you may

connect the RS485 bus to your PC. This can be done by using a RS485–RS232 converter

or a RS485–USB converter.

Note!

The usage of an approved RS-485 converter is recommended for faster configuration and

more reliable high-speed operation. In addition, the usage of a galvanically isolated RS485 converter is strongly recommended for permanent installations.

Connecting via RS485

1. Connect the RS485–RS232 converter or the RS485–USB converter to your PC.

2. To find out to which COM port the converter is connected, open the Windows

manager (Windows XP: Start > Settings > Control Panel > System > Hardware > Device

Manager).

®

device

3. Under "Ports (COM & LPT)" you should see the converter and the COM port assigned

to it (see on page 36). You will need the COM port number later on.

View of the USB converter in the Windows

®

device manager

221981 2011-07

36

Page 37

WHA-GW-*

Commissioning

4.5 Connecting via Ethernet

Once the gateway has been connected to the Ethernet (see chapter 3.3), you are ready to

connect your PC.

Connecting to the gateway via Ethernet

1. Connect the Ethernet cable to the Ethernet jack of your PC.

2. To communicate with the gateway, you need to configure the IP address and subnet

mask of your PC. To do this, launch the Network Connections window (Windows

Start > Settings > Control Panel > Network Connections).

3. Right-click on the icon Local Area Connection and choose Properties from the

context menu.

The Local Area Connection Properties window opens.

®

XP:

Local Area Connection Properties window

4. Select the list entry Internet Protocol (TCP/IP).

5. Press Properties.

The Internet Protocol (TCP/IP) Properties window opens.

221981 2011-07

37

Page 38

WHA-GW-*

Commissioning

Entering IP address and subnet mask

6. Choose Use the following IP address and type 192.168.1.100 into the field IP

address.

7. T y p e 255.255.255.0 into the field Subnet mask.

8. Press OK.

Your PC is now ready to communicate with the gateway.

4.6 Creating a new PACTware Project

4.6.1 Creating a new project

Creating a new project in PACTware

Select File > New or click the Create new project icon on the toolbar.

A new, unnamed project appears in the main window. The project initially consists of the

entry Host PC.

4.6.2 Adding the Communication DTM

®

A communication DTM is an interface between the FDT frame application and the device

DTM. The communication DTM enables communication between the device DTM and the

device connected to the PC.

Depending on how your PC is connected to the Gateway (via RS485 or Ethernet), you

need to add a corresponding communication DTM to your PACTware project. The RS485

communication DTM is the HART Communication DTM, and the Ethernet communication

DTM is called HART IP Communication.

221981 2011-07

38

Page 39

WHA-GW-*

Commissioning

Adding RS485 Communication DTM

Note!

The HART CommDTM is not included in the WirelessHART DTM Collection. It can be

downloaded separately from www.pepperl-fuchs.com. For further information on

downloading and installing the DTM, see chapter 4.2.

1. Select the entry HOST PC in the project view of your PACTware project.

2. Choose or click the Add device icon on the toolbar.

Device > Add device

The Device for window appears (see on page 39).

Selection of HART communication DTM

3. Select the entry HART Communication.

4. Click OK.

The HART communication DTM is added to the project.

HART communication DTM in PACTware project

5. To edit the parameters, double-click on the HART communication DTM.

The parameter window appears.

221981 2011-07

39

Page 40

WHA-GW-*

Commissioning

Parameter window of HART communication DTM

6. Set the parameters according to the following table.

7. Click OK to save the changes and to close the parameter window.

Parameter Description Default

Communication

interface

Port Set this parameter to the COM port your

Baudrate Set the baudrate according to the settings of the

RTS Control Depending on the RS485–RS232 converter used, it may

Master Specify if you want the Gateway to be the primary or the

Preamble Number of preambles for HART communication. 5

Number of

communication

retries

Start address Here the address range is set, in which the HART

End address 15

Set this parameter to HART multiplexer. HART

modem

COM1

RS485–RS232 converter or your RS485–USB converter

is connected to (see chapter 4.4).

19200

Gateway's baud rate. The Gateway's baud rate can be

adjusted via the DIP switches inside the Gateway housing

(see chapter 6.1) or via software (see chapter 5.5.3, see

chapter 5.5.4).

Toggle

be necessary to switch on or off the request-to-send

control in order to be able to switch over correctly between

reception and transmitting mode

Primary

secondary master. If, for example, there already is a

primary master connected, you have to choose

Secondary master.

The number of retries for HART communication in case of

an error.

Communication DTM is to search for HART Multiplexers

connected to the RS 485 bus.

Master

3

0

221981 2011-07

40

Page 41

WHA-GW-*

Commissioning

Adding Ethernet Communication DTM

1. Select the entry HOST PC in the project view.

2. Choose Device > Add device or click the Add device icon on the toolbar.

A device selection window opens (see on page 41).

Selection of the communication DTM

3. Select the entry HART IP Communication.

4. Click OK.

The Ethernet communication DTM is added to the project.

Ethernet communication DTM in PACTware project

5. To edit the parameters, double-click on the HART IP Communication DTM.

The parameter window appears.

221981 2011-07

41

Page 42

WHA-GW-*

Commissioning

Parameter window of Ethernet communication DTM

6. Set the parameters according to your preferences. In most cases, the default values

7. In some cases you might have to edit the Additional Functions > Set DTM addresses

8. Click OK to save the changes and to close the parameter window.

Editing Additional Functions > Set DTM addresses of the HART IP

Communication DTM

The Additional Functions > Set DTM addresses menu contains settings which are

important for establishing a connection between the communication DTM and the

Gateway. The IP address, bus address and UDP port set in this menu must match the

corresponding parameters set in the gateway. When using a new Gateway, there is no

need to change the following parameters, because the default settings of the gateway

match the default settings of the HART IP Communication DTM.

should be fine.

menu. Please read the following instructions for further information.

1. Right-click on the entry HART IP Communication.

Ethernet communication DTM in PACTware project

A context menu is displayed.

2. Choose Additional Functions > Set DTM addresses.

The Set DTM addresses window is displayed.

HART IP Communication > Additional Functions > Set DTM addresses

3. Change the parameters as required (see following table).

4. Press Update changed data to apply the new settings.

5. Disconnect and reconnect the communication and the Gateway DTM to activate the

221981 2011-07

new settings.

42

Page 43

WHA-GW-*

Commissioning

HART IP communication DTM parameters Corresponding Gateway parameters

Parameter Explanation Default Parameter Default

Tag Gateway name in the

Project view of

PACTware. Any name

may be entered (not

relevant for

connection to

gateway)

Bus

Address

UDP

Address

UDP Port Gateway port number

Gateway polling

address; must match

the settings of the

Gateway.

IP address of the

Gateway; must match

the settings of the

Gateway.

(HART over UDP);

must match the

settings of the

Gateway.

4.6.3 Adding Device DTM

Adding the Device DTM

WHA-GW – –

1 Parameterization

> Wired Communication

> Protocols > HART

> Bus Address

192.168.1.1 Parameterization

> Wired Communication

> Interfaces > Ethernet

> IP Address

5094 Parameterization

> Wired Communication

> Protocols > HART

> Port Number

1

192.168.1.1

5094

1. In the project view, right-click on the entry of the communication DTM you have added in

the previous step.

2. To add the device DTM, choose Add device.

The Device for window opens (see on page 43).

Device for window with Gateway DTM

3. Select the entry WHA-GW.

221981 2011-07

43

Page 44

WHA-GW-*

Commissioning

4. Click OK.

Gateway DTM in the PACTware project view

5. Remember to save your PACTware project from time to time (File > Save).

The Gateway DTM is added to the project (see on page 44). You may continue with

parameterizing the Gateway as described in the following (see chapter 5).

221981 2011-07

44

Page 45

WHA-GW-*

Configuration

5 Configuration

5.1 Configuration via DTM or Web Interface

There are two possible ways of configuring the device:

• Configuration via the device DTM within an FDT frame application, e.g. PACTware

• Configuration via a browser-based web interface.

The main difference is the concept of offline/online parameterization when configuring with

DTM/FDT (see chapter 5.2). This concept does not apply to browser-based configuration,

because browser-based parameterization is always an online parameterization.

Note!

In the following sections, only the configuration via DTM and PACTware

However, because both approaches are similar, you may also use the given information as

a guideline for browser-based configuration.

®

is described.

®

.

Diagnosis > Wired Communication and Diagnosis > Health Status are only available

via the web interface (see chapter 6.2). In comparison to the DTM, the web interface only

has the additional functions Reset and About (see chapter 6.3).

Configuring via DTM/FDT

1. Make sure that your PC is connected to the Gateway via RS485 (see chapter 4.4) or via

Ethernet (see chapter 4.5).

2. Start PACTware and load your project file (see chapter 4.6).

3. Make sure that you have added the appropriate communication DTM (see chapter

4.6.2) and the device DTM (see chapter 4.6.3) to your PACTware project.

4. Parameterize the Gateway online or offline as described in the following sections.

Configuring via web interface

Note!

The connection to the web interface is made using a secure connection (HTTPS) which

requires a user name and a password. The factory default settings are:

User name: admin

Password: admin

You can change both user name and password in the web interface (Additional functions >

Change Password, see chapter 6.3.7)

1. Make sure that your PC is connected to the Gateway via Ethernet (see chapter 4.5).

2. Start your web browser.

3. If your web browser uses a proxy, then deactivate the proxy. The proxy setting

normally can be found in the connection properties of your browser (where exactly

depends on your type of browser).

221981 2011-07

45

Page 46

WHA-GW-*

Configuration

4. Type the IP address of the Gateway into the browser's address field. The factory default

is 192.168 .1.1. If you have already changed the Gateway's IP address, type in the new

IP address. NOTE: In some browsers, you might have to clear the address history first

or add "/index.html" after the IP address.

Depending on the browser you use, some messages might pop up informing you about

the secure connection and the security certificate. In this case, click "OK", "Proceed", or

similar options. Do not cancel the procedure.

A window is displayed asking you for your user name and password (see on page 46).

Entering login data for secure connection

5. Enter your user name and password.

6. Click OK.

You are directed to the Gateway's web interface.

7. Change the parameters as needed. Press Enter to accept a new value. The DTM

parameters described in the following sections also apply to browser-based

configuration.

5.2 Online and offline parameterization (DTM)

Note!

This section only applies to parameterization via FDT/DTM.

The device DTM provides dialogs for offline and online parameterization.

• Offline parameterization (not connected to device): If there is no active connection to

the device, only the device data stored in the PACTware project can be edited and

saved to the PACTware project again. You may write the offline data record into the

device as soon as a connection has been established.

To ensure that the data you are editing is up to date, first load the data from the device

when its online and then edit the data offline.

• Online parameterization (connected to device): If there is an active connection to the

device, the device data stored in the device can be edited directly (online). Parameter

changes are stored to the device immediately.

The online and offline data are updated using the commands Store to device and Load

from device.

221981 2011-07

46

Page 47

WHA-GW-*

Configuration

Note!

The data edited and stored in the device during online parameterization is not automatically

synchronized with the offline data record in the PACTware project. If you only change

device parameters online, the device data stored in the project differs from the data stored

in the device!

To ensure that the device data stored in the PACTware project always matches the data

stored in the device, load the device data into the project after parameterizing online.

Parameterizing offline

1. Right-click the device entry in the PACTware project.

A context menu opens.

2. Choose Parameter > Offline Parameterization.

The window containing the offline data record appears.

3. Modify a parameter by typing in a new value or choosing a new value from the dropdown list.

4. To accept the new value, press Enter.

5. After all parameter changes have been made, save your project by choosing File >

Save.

6. To store the new offline configuration to the device, right-click on the device entry in the

project view and choose Connect.

A connection to the device is established.

7. Right-click on the device entry again and choose Store to device.

The new configuration is stored to the device.

Parameterizing online

1. Right-click the device entry in the PACTware project.

A context menu opens.

2. Select Connect.

A connection to the device is established.

3. Right-click the device entry in the PACTware project.

4. Select Parameter > Online Parameterization.

The window containing the online data record opens (data is read from the device).

5. Modify a parameter by typing in a new value or choosing a new value from the dropdown list.

6. To accept the new value, press Enter.

The new value is stored to the device immediately.

7. After all parameter changes have been made, you may store the online configuration

into the PACTware project. To do this, right-click on the device entry in the project view

and choose Load from device.

The device date is stored into the PACTware project.

8. Save your project by choosing File > Save.

221981 2011-07

47

Page 48

WHA-GW-*

Configuration

Note!

Many device parameters can be edited both online and offline. The parameters that can

only be edited online are especially pointed out in the following sections.

5.3 Identification Parameters

The identification parameters provide various information about the device and identify the

device within the network.

Figure 5.1Identification parameters

Identification Parameters

Parameter Description Default

Device Long Tag Identifies the device in a WirelessHART network. Enter up

to 32 characters.

Device Tag Identifies the field device within the process plant. Enter up

to 8 characters.

Descriptor Further description of the device. Enter up to 16

characters.

Date User-defined date (e.g. last parameter change). Format:

DD.MM.YYYY

The Date parameter is not modified by the Gateway itself.

Instead is has to be set by the user or Host application.

Message User-defined message. Enter up to 32 characters. –

Country Code Select the country code of the country in which the device

is operated from this drop-down list.

Table 5.1Identification Parameters

221981 2011-07

–

–

–

–

–

48

Page 49

WHA-GW-*

Configuration

5.4 Wireless Communication Parameters

5.4.1 Setup

The setup parameters contain the necessary information for establishing and maintaining a

WirelessHART network.

Figure 5.2Wireless Communication Parameters > Setup

Note!

Parameter Join Key

The parameter Join Key can only be edited when the security mode is activated by means

of a DIP switch inside the gateway housing. To activate the security mode, set DIP switch 8

to ON (see Figure 6.4 on page 67). In the security mode it is possible to use CMD 768

HART command to set the gateway join key as required.

Caution!

Network security risk

For security reasons do not to use the security mode connection as a normal

communication channel. After having changed the join key, disable the security mode again

using the DIP switch (DIP switch 8 = OFF).

221981 2011-07

49

Page 50

WHA-GW-*

Configuration

Caution!

Possible loss of connection when changing Network ID

If you change the Network ID parameter of an already operating WirelessHART network,

be aware that the Gateway will store the new network ID. However, the new network ID will

only be applied the next time the network is reformed (please note that reforming the