Page 1

Operating Instructions

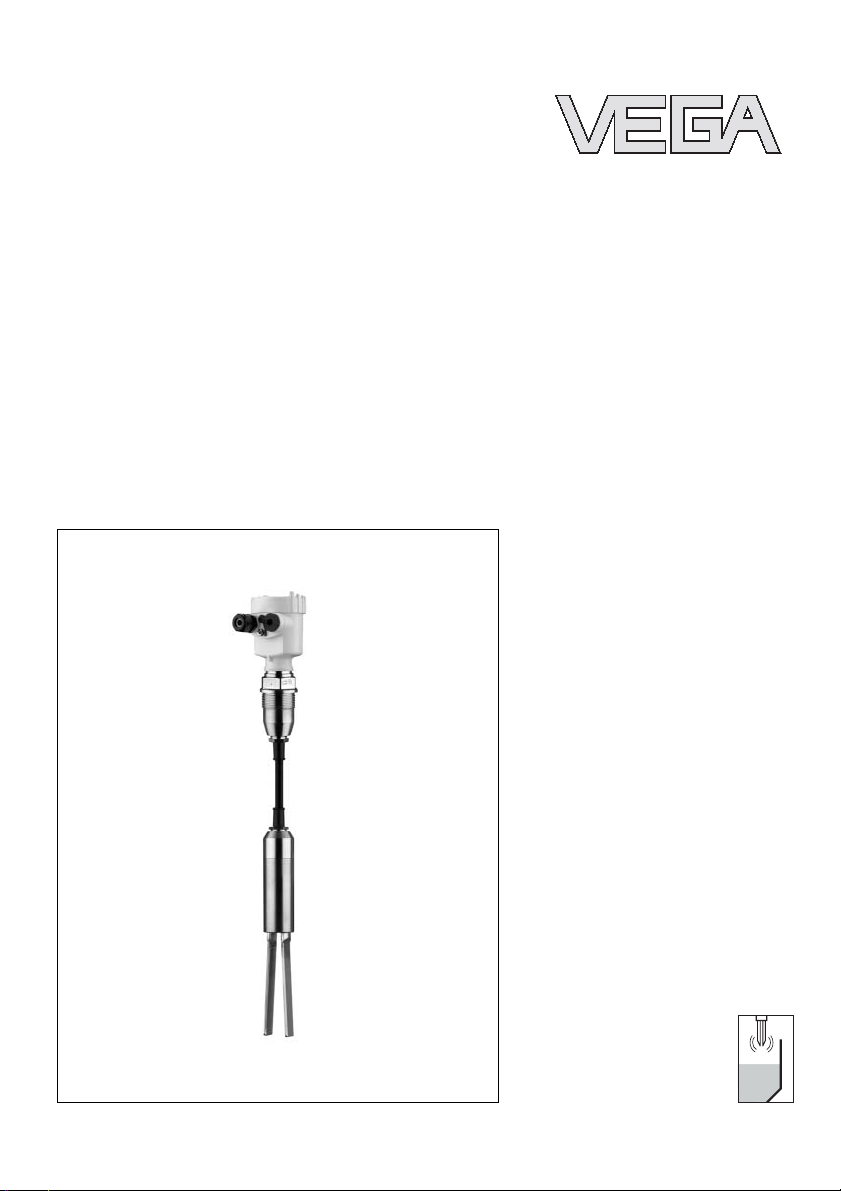

VEGAWAVE 62

Cable shortening set

Page 2

Contents

Contents

1 About this document

1.1 Function .............................

1.2 Target group ..........................

1.3 Symbolism used .......................

2 For your safety

2.1 Authorised personnel....................

2.2 Appropriate use........................

2.3 Warning about misuse ...................

2.4 Environmental instructions ................

3 Product description

3.1 Configuration..........................

3.2 Principle of operation ....................

3.3 Storage and transport ...................

4 Mounting

4.1 General instructions.....................

4.2 Mounting sequence .....................

5 Maintenance and fault rectification

5.1 Maintenance ..........................

5.2 Instrument repair .......................

3

3

3

4

4

4

4

5

5

5

6

7

17

17

6 Dismounting

6.1 Dismounting procedure ..................

6.2 Disposal .............................

7 Supplement

7.1 Technical data.........................

2 VEGAWAVE 62 - Cable shortening set

18

18

19

32361-EN-060822

Page 3

About this document

1 About this document

1.1 Function

This operating instructions manual has all the information you

need for quick mounting and setup of a replacement

component (cable shortening set). Please read this manual

before you start setup.

1.2 Target group

This operating instructions manual is directed to trained,

qualified personnel. The contents of this manual should be

made available to these personnel and put into practice by

them.

1.3 Symbolism used

Information, tip, note

This symbol indicates helpful additional information.

Caution: If this warning is ignored, faults or

malfunctions can result.

Warning: If this warning is ignored, injury to persons and/or

serious damage to the instrument can result.

Danger: If this warning is ignored, serious injury to persons

and/or destruction of the instrument can result.

Ex applications

This symbol indicates special instructions for Ex applications.

l List

The dot set in front indicates a list with no implied sequence.

à Action

This arrow indicates a single action.

1 Sequence

Numbers set in front indicate successive steps in a procedure.

32361-EN-060822

VEGAWAVE 62 - Cable shortening set 3

Page 4

For your safety

2 For your safety

2.1 Authorised personnel

All operations described in this operating instructions manual

must be carried out only by trained specialist personnel

authorised by the operator. For safety and warranty reasons,

any internal work on the instruments must be carried out only

by personnel authorised by the manufacturer.

2.2 Appropriate use

The cable shortening set is used to shorten VEGAWAVE

sensors in cable version (VEGAWAVE 62).

2.3 Warning about misuse

Inappropriate or incorrect use of the instrument can give rise to

application-specific hazards, e.g. vessel overfill or damage to

system components through incorrect mounting or adjustment.

2.4 Environmental instructions

Protection of the environment is one of our most important

duties. That is why we have introduced an environment

management system with the goal of continuously improving

company environmental protection. The environment management system is certified according to DIN EN ISO 14001.

Please help us fulfil this obligation by observing the environmental instructions in this manual:

l Chapter "Storage and transport"

l Chapter "Disposal"

4 VEGAWAVE 62 - Cable shortening set

32361-EN-060822

Page 5

3 Product description

3.1 Configuration

Product description

Scope of delivery

Area of application

Physical principle

Packaging

The scope of delivery encompasses:

l Cable shortening set

l Documentation

- this operating instructions manual

3.2 Principle of operation

The cable shortening set is a set of parts required to shorten a

VEGAWAVE 62.

The cable shortening set can be also used e.g. if the sensors

must be led through a narrow tube.

The cable shortening set must not be used if the concerned

sensor is used for solid detection in water.

The cable of the sensor consists of a suspension cable, the

electrical wires and an outer insulation.

3.3 Storage and transport

Your instrument was protected by packaging during transport.

Its capacity to handle normal loads during transport is assured

by a test according to DIN EN 24180.

The packaging of standard instruments consists of environ-

ment-friendly, recyclable cardboard. For special versions, PE

foam or PE foil is also used. Dispose of the packaging material

via specialised recycling companies.

Storage and transport temperature

32361-EN-060822

VEGAWAVE 62 - Cable shortening set 5

l Storage and transport temperature see "Supplement -

Technical data - Ambient conditions"

l Relative humidity 20 … 85 %

Page 6

Mounting

4 Mounting

4.1 General instructions

Necessary tools:

l Tape measure/Yardstick

l Cloth

l Marker (permanent)

l Bolt cutter

l Flat wrench SW 24

l Gaspipe pliers

l Skinning tools

l Cable cutter

l Wire cutter

l Crimping tool

l Allen wrench 2 mm

l Hot air blow-dryer

l Talcum/Mounting grease

Additionally:

l Bench vice with Aluminium or plastic braces

6 VEGAWAVE 62 - Cable shortening set

32361-EN-060822

Page 7

4.2 Mounting sequence

Mounting

1 2

7 6

Fig. 1: Cable shortening set for VEGAWAVE 62

1 Crimp connector yellow, 2 pcs., article no. 2.11444

2 Crimp connector red, 3 pcs., article no. 2.18710

3 Crimping sleeve blue 8 x 30 mm, 1 pce., article no. 1.243

4 Crimping sleeve black 3 x 55 mm, 1 pce., article no. 1.1207

5 O-rings 37 x 2 mm, 2 pcs., article no. 2.28878

6 Pins M4 x 6, 4 pcs., article no. 2.28894

7 Cable

clamp 12 x 20 mm, 1 pce., article

The numbers refer to the figures on the following pages.

no. 2.28876

3 4

5

Mounting

1 Interrupt the voltage supply of the sensor and remove

connection cable.

2 Dismount the sensor.

3 Clean the cable (9) of the sensor.

4 Determine new sensor length (L) with a tape measure

according to the illustration and mark with the marker.

You find information on the sensor length (L) in the

operating instructions manual of the sensor.

32361-EN-060822

VEGAWAVE 62 - Cable shortening set 7

Page 8

Mounting

145 mm

45

(5

/64")

L

neu

Fig. 2: Cut the cable with a bolt cutter

9 Cable

9

L

5 Cut the cable (9) with a bolt cutter approx. 145 mm

(approx. 5.7 in) above the new sensor length (L).

6 Clamp the upper part of the oscillator (19) in to the bench

vice.

149

Fig. 3: Unscrew pressure screw

9 Cable

14 Pressure screw

7 Remove pressure screw (14) with the flat spanner SW 24

so that the cable does not turn with the following

dismounting.

8 Clamp the lower part of the oscillator (below the screwed

separating position) into the bench vice.

Do not clamp on the fork tines

8 VEGAWAVE 62 - Cable shortening set

32361-EN-060822

Page 9

149 19

Fig. 4: Turn the vibrating element

9 Cable

14 Pressure screw

19 Upper part of the oscillator

Mounting

9 Loosen the upper part of the oscillator (19) with gaspipe

pliers and unscrew it. Both threaded connections are

secured with soluable screw retention lacquer.

Make sure that the cable (9) does not turn.

A B

Fig. 5: Uncompress the vibrating element carefully - cut the leads

AUpper part of the oscillator

BLower part of the oscillator

10 Uncompress the two parts (A and B) carefully.

Cut the leads directly on the clead pressing (see arrows)

with wire cutting pliers.

32361-EN-060822

VEGAWAVE 62 - Cable shortening set 9

Page 10

Mounting

Fig. 6: Pull the cable out the of upper part of the oscillator

9 Cable

10 Breaker plate

19 Upper part of the oscillator

11 Pull the cut cable (9) out of the upper part of the oscillator

(19).

Keep all parts for mounting.

9 1019

79 12 10

Fig. 7: Cut the suspension cable (12) with a bolt cutter

7 Cable clamp

9 Cable

10 Breaker plate

12 Suspension cable

12 Cut the suspension cable (12) with a bolt cutter and keep

the breaker plate (10) for mounting.

13 Clean the remaining sensor cable (9) from oil and grease

and rub it off with talcum.

The old cable crimping can be no longer used and must be

disposed accordingly.

10 VEGAWAVE 62 - Cable shortening set

32361-EN-060822

Page 11

Fig. 8: Shift the parts to the cable

6 Pins (4 pcs.)

7 Cable clamp

8 Mounting boss

9 Cable

10 Breaker plate

14 Pressure screw

15 Pressure ring

16 Rubber cover

17 Washer

18 Rubber rings (4 pcs.)

19 Upper part of the oscillator

Mounting

100 mm

15

(3

/16")

6181798 14 15 16 19 10 7

14 Shift the individual parts (14, 15, 16, 17, 18, 19) to the

cable according to drawing.

Make sure that the shoulder of the washer (17) points in the

direction of the pressure ring (15).

15 Remove the outer isolation of the cable on 100 mm (4 in)

length.

16 Shorten the suspension cable (12) with a bolt cutter by

70 mm (2.8 in)(remaining length: 30 mm/1.2 in).

32361-EN-060822

VEGAWAVE 62 - Cable shortening set 11

Page 12

Mounting

30mm

3

(1

/16")

Fig. 9: Shorten suspension cable - shift cable clamp

6 Pins

7 Cable clamp

10 Breaker plate

12 Suspension cable

17 Plug the breaker plate (10) on the bare suspension cable

(12) and lead the 4 wires (green, yellow, red, green-yellow)

separately through the outer holes of the breaker plate

(10).

Do not lead the fawn plastic cords (11) through the breaker

plate.

18 Shift the cable clamp (7) flush to the suspension cable (12).

When shifting, turn the cable clamp in the direction of the

cable drilling to avoid splicing the wire. The chamfered side

facilitates inserting the suspension cable.

19 Tighten the pins (6) constantly on all sides with an Allen

wrench 2 mm. The pins should be screwed in with the

same depth into the cable clamp (approx. 3 Nm / 2.2 lbf ft).

20 Cut the fawn plastic cords (11) as short as possible with a

wire cutter.

21 Remove the insulation of the screened green (GN) and

yellow (YE) wire

back the screen braiding and open it with a sharp object in

the rear section.

Make sure that the wires are not damaged.

100 mm

15

(3

/16")

on

a length of 60 mm (2.4 in). Slightly push

69 1210 7

12 VEGAWAVE 62 - Cable shortening set

32361-EN-060822

Page 13

RD

11

Fig. 10: Pull the wires out of the braiding

11 Plastic cords

GN Green

YE Yellow

Mounting

60mm

23

(2

/64")

GN

BK

YE

GN/YE

22 Pull the yellow and green wire backwards out of the screen

braiding.

23 Exchange O-rings (5), slightly grease thread and O-rings.

19 3 414

Fig. 11: Exchange O-ringe - prepare wires

3 Shrinking sleeve - blue

4 Crimping sleeve - black

5 O-rings

14 Pressure screw

19 Upper part of the oscillator

5 5

32361-EN-060822

VEGAWAVE 62 - Cable shortening set 13

Page 14

Mounting

24 Merge the screening of the wires (yellow) and (green) and

twist ist. Insulate the twisted screening with the black

crimping sleeve (4) according to the drawing. Shrink the

transition green-black-yellow in the isolated wire with the

blue crimping sleeve (3).

6

712

Fig. 12: Connect wires

6 Pins

7 Clamp terminal

12 Suspension cable

GN Green

BK Black

YE Yellow

RD red

GN/YE

Green-yellow

Fig. 13: Connect wires with crimping pliers

1 Crimp connection - yellow (2 pcs.)

2 Crimp connection - red (3 pcs.)

3 Shrinking sleeve - blue

14 Pressure screw

19 Upper part of the oscillator

GN/YE

GN

BK

YE

RD

GN/YE

GN

BK

YE

RD

25 Dismantle the wires on 5 mm (0.2 in) and connect with the

crimp connectors and crimping pliers according to drawing.

1 2314 19

26 Merge the parts of the vibrating element (A + B). Provide

the thread with screw retention lacquer. Make sure that you

do not squeeze any wires.

The cable must not turn.

32361-EN-060822

14 VEGAWAVE 62 - Cable shortening set

Page 15

14 A B

Fig. 14: Mount the vibrating element

14 Pressure screw

AUpper part of the oscillator

BLower part of the oscillator

Mounting

27 Mount the parts of the vibrating element. Clamp the lower

part of the oscillator (B) into the bench vice and turn only

the upper part of the oscillator (A). The cable must not turn.

28 Pull the cable (9) to the top and push the seal rings (18)

and the washer (17) in the upper part of the oscillator (19).

29 Shift the pressure screw (14) and the pressure ring (15) on

the rubber jacket (16).

181714 15 16 19

Fig. 15: Cable seal

14 Pressure screw

15 Pressure ring

16 Rubber jacket

17 Washer

18 Rubber rings

19 Upper part of the oscillator

30 Provide the pressure screw (14) with screw retention

lacquer and screw it into the upper part of the oscillator

(19).

31 Tighten the pressure screw (14) with the flat wrench SW 24

(approx. 6 Nm/4.4 lbf ft).

32 Check length of the sensor.

32361-EN-060822

VEGAWAVE 62 - Cable shortening set 15

Page 16

Mounting

33 Install the sensor.

34 Connect the sensor according to the operating instructions

manual of the sensor.

35 Check the correct switching function of the sensor.

16 VEGAWAVE 62 - Cable shortening set

32361-EN-060822

Page 17

Maintenance and fault rectification

5 Maintenance and fault rectification

5.1 Maintenance

If mounted correctly to the sensor, the cable shortening set is

maintenance-free. There are no restrictions of the specifications in the sensor documentation.

5.2 Instrument repair

Take note of the specifications in the sensor documentation.

32361-EN-060822

VEGAWAVE 62 - Cable shortening set 17

Page 18

Dismounting

6 Dismounting

6.1 Dismounting procedure

Note chapter "Mounting" and carry out the stated steps in

reverse order.

6.2 Disposal

The cable shortening set consists of materials which can be

recycled by specialised recycling companies.

Materials: see "Technical data"

Take note of the specifications in the sensor documentation.

18 VEGAWAVE 62 - Cable shortening set

32361-EN-060822

Page 19

Supplement

7 Supplement

7.1 Technical data

General data

Materials, wetted parts The resistance of the sensor does not change

by using the cable shortening set.

The materials used are stated in the operating

instructions manual of the sensor.

Sensor length 0.3 ... 80 m (1 ... 262 ft)

Approvals

The respective approvals of the sensor are not restricted by the correct use of the cable

shortening set.

32361-EN-060822

VEGAWAVE 62 - Cable shortening set 19

Page 20

VEGA Grieshaber KG

Am Hohenstein 113

77761 Schiltach

Germany

Phone +49 7836 50-0

Fax +49 7836 50-201

E-mail: info@de.vega.com

www.vega.com

ISO 9001

All statements concerning scope of delivery, application,

practical use and operating conditions of the sensors and

processing systems correspond to the information avail-

able at the time of printing.

© VEGA Grieshaber KG, Schiltach/Germany 2006

Subject to change without prior notice 32361-EN-060822

Loading...

Loading...