Page 1

Operating Instructions

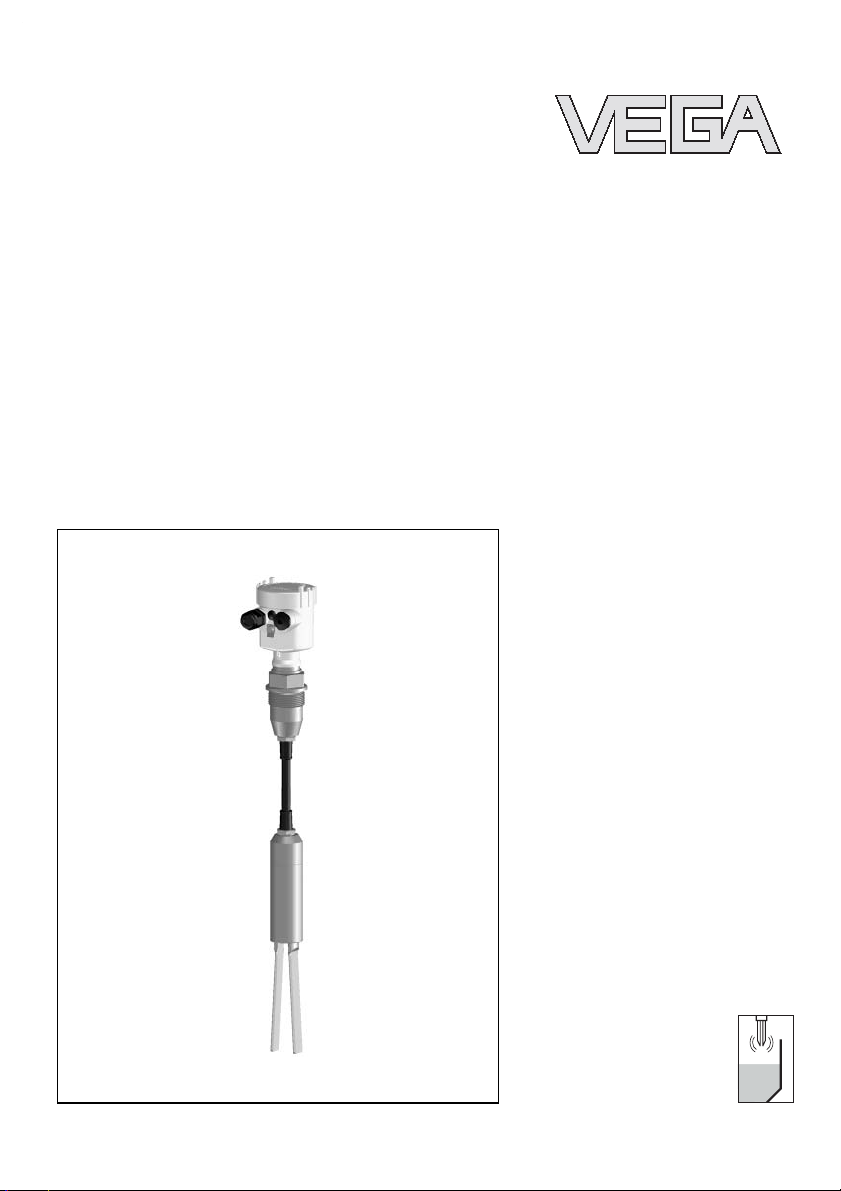

VEGAVIB 66

with relay output

Page 2

Contents

Contents

1 About this document

1.1 Function .............................

1.2 Target group ..........................

1.3 Symbolism used .......................

2 For your safety

2.1 Authorised personnel....................

2.2 Appropriate use........................

2.3 Warning about misuse ...................

2.4 CE conformity .........................

2.5 SIL conformity .........................

2.6 Safety information for Ex areas.............

2.7 Environmental instructions ................

3 Product description

3.1 Configuration..........................

3.2 Principle of operation ....................

3.3 Adjustment ...........................

3.4 Storage and transport ...................

4 Mounting

4.1 General..............................

4.2 Mounting information ....................

4

4

4

5

5

5

5

6

6

6

7

7

8

9

10

11

5 Connecting to power supply

5.1 Preparing the connection .................

5.2 Connection steps.......................

5.3 Wiring plans, single chamber housing ........

6 Set up

6.1 General..............................

6.2 Adjustment elements ....................

6.3 Function chart .........................

7 Maintenance and fault rectification

7.1 Maintenance ..........................

7.2 Fault rectification .......................

7.3 Exchange of the electronics ...............

7.4 Instrument repair .......................

8 Dismounting

8.1 Dismounting procedure ..................

8.2 Disposal .............................

2 VEGAVIB 66 - with relay output

15

15

16

19

19

20

22

22

23

25

26

26

29289-EN-060508

Page 3

Contents

9 Supplement

9.1 Technical data.........................

9.2 Dimensions ...........................

9.3 Industrial property rights..................

27

30

32

Supplementary operating instructions manuals

Information:

VEGAVIB 66 is available in different versions. Depending on

the selected version, supplementary operating instructions

manuals will also be included in the delivery. The supplementary operating instructions manuals are listed in section

"Product description".

Operating instructions manuals for accessories and

replacement parts

Tip:

To ensure reliable setup and operation of your VEGAVIB 66,

VEGA offers accessories and replacement parts. The asso-

ciated documents are:

l Operating instructions manual "Remote housing - VEGA-

VIB"

l Operating instructions manual "Oscillator VEGAVIB series

60"

l Operating instructions manual "Cable shortening set

VEGAVIB 62, 66"

29289-EN-060508

VEGAVIB 66 - with relay output 3

Page 4

About this document

1 About this document

1.1 Function

This operating instructions manual has all the information you

need for quick setup and safe operation. Please read this

manual before you start setup.

1.2 Target group

This operating instructions manual is directed to trained,

qualified personnel. The contents of this manual should be

made available to these personnel and put into practice by

them.

1.3 Symbolism used

Information, tip, note

This symbol indicates helpful additional information.

Caution: If this warning is ignored, faults or

malfunctions can result.

Warning: If this warning is ignored, injury to persons and/or

serious damage to the instrument can result.

Danger: If this warning is ignored, serious injury to persons

and/or destruction of the instrument can result.

Ex applications

This symbol indicates special instructions for Ex applications.

l List

The dot set in front indicates a list with no implied sequence.

à Action

This arrow indicates a single action.

1 Sequence

Numbers set in front indicate successive steps in a procedure.

4 VEGAVIB 66 - with relay output

29289-EN-060508

Page 5

For your safety

2 For your safety

2.1 Authorised personnel

All operations described in this operating instructions manual

must be carried out only by trained specialist personnel

authorised by the operator. For safety and warranty reasons,

any internal work on the instruments must be carried out only

by personnel authorised by the manufacturer.

2.2 Appropriate use

VEGAVIB 66 is a sensor for level detection.

Detailed information on the application range of VEGAVIB 66

is available in chapter "Product description".

2.3 Warning about misuse

Inappropriate or incorrect use of the instrument can give rise to

application-specific hazards, e.g. vessel overfill or damage to

system components through incorrect mounting or adjustment.

2.4 General safety instructions

VEGAVIB 66 is a high-tech instrument requiring the strict

observance of standard regulations and guidelines. The user

must take note of the safety instructions in this operating

instructions manual, the country-specific installation standards

(e.g. the VDE regulations in Germany) as well as all prevailing

safety regulations and accident prevention rules.

2.5 CE conformity

VEGAVIB 66 is in CE conformity with EMC (89/336/EWG),

fulfils NAMUR recommendation NE 21 and is in CE conformity

with LVD (73/23/EWG).

Conformity has been judged according to the following

standards:

l EMC:

- Emission EN 61326: 1997 (class B)

- Susceptibility EN 61326: 1997/A1: 1998

l LVD: EN 61010-1: 2001

29289-EN-060508

VEGAVIB 66 - with relay output 5

Page 6

For your safety

2.6 SIL conformity

VEGAVIB 66 fulfills the requirements of functional safety

according to IEC 61508/IEC 61511. You can find further

information in the supplementary instructions manual "Safety

Manual - Functional safety (SIL) VEGAVIB series 60".

2.7 Safety information for Ex areas

Please note the Ex-specific safety information for installation

and operation in Ex areas. These safety instructions are part of

the operating instructions manual and come with the Exapproved instruments.

2.8 Environmental instructions

Protection of the environment is one of our most important

duties. That is why we have introduced an environment

management system with the goal of continuously improving

company environmental protection. The environment management system is certified according to DIN EN ISO 14001.

Please help us fulfil this obligation by observing the environmental instructions in this manual:

l Chapter "Storage and transport"

l Chapter "Disposal"

6 VEGAVIB 66 - with relay output

29289-EN-060508

Page 7

3 Product description

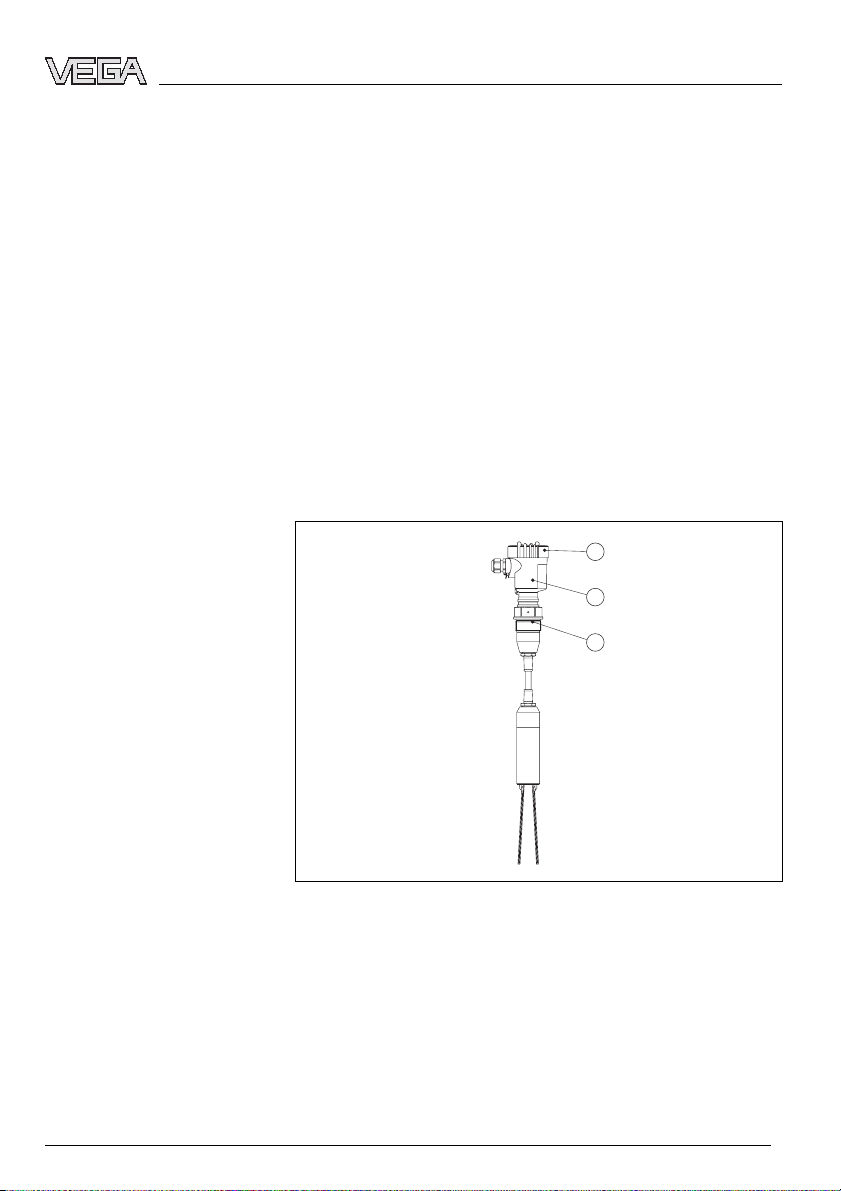

3.1 Configuration

Product description

Scope of delivery

Components

The scope of delivery encompasses:

l VEGAVIB 66 level sensor

l documentation

- this operating instructions manual

- Supplementary instructions manual "Plug connector for

level sensors" (optional)

- Ex specific safety instructions (with Ex versions), if

necessary further certificates

VEGAVIB 66 consists of the following components:

l Housing cover

l Housing with electronics

l process fitting with tuning fork

1

2

3

Fig. 1: VEGAVIB 66 with plastic housing

1 Housing cover

2 Housing with electronics

3 Process fitting

3.2 Principle of operation

Area of application

29289-EN-060508

VEGAVIB 66 - with relay output 7

VEGAVIB 66 is a level sensor with tuning fork for level

detection.

It is designed for industrial use in all areas of process

technology and is preferably used for bulk solids.

Page 8

Product description

Typical applications are overfill and dry run protection. Thanks

to its simple and robust measuring system, VEGAVIB 66 is

virtually unaffected by the chemical and physical properties of

the solid.

It functions even when exposed to strong external vibration or

changing products.

Solid detection in water

If VEGAVIB 66 was ordered for solid detection in water, the

tuning fork is to the density of water. In air or if covered by

water (density: 1 g/cm³/0.036 lbs/in) VEGAVIB 66 signals

uncovered. Only if the vibrating element is also covered with

solids (e.g. sand, sludge, gravel etc.) will the sensor signal

covered.

Fault monitoring

The electronics of VEGAVIB 66 continuously monitors the

following criteria:

l Correct vibrating frequency

l Line break to the piezo drive

If one of the stated malfunction is detected or in case of power

failure, the electronics takes on a defined switching condition,

i.e. the relay deenergises (safe condition).

Physical principle

The tuning fork is piezoelectrically energised and vibrates at its

mechanical resonance frequency of approx. 150 Hz. When the

tuning fork is submerged in the product, the vibration

amplitude changes. This change is detected by the integrated

oscillator and converted into a switching command.

Power supply

VEGAVIB 66 is a compact instrument, i.e. it can be operated

without external evaluation system. The integrated electronics

evaluates the level signal and outputs a switching signal. With

this switching signal, a connected device can be operated

directly (e.g. a warning system, a PLC, a pump etc.).

The exact range of the supply voltage is specified in the

"Technical data" in the "Supplement".

3.3 Adjustment

With the factory setting, products with a density of >0.02 g/cm³

(>0.0008 lbs/in³) can be measured. It is possible to adapt the

instrument for products with lower density >0.008 g/cm³

(>0.0003 lbs/in³).

8 VEGAVIB 66 - with relay output

29289-EN-060508

Page 9

Product description

On the electronics module you will find the following indicating

and adjustment elements:

l signal lamp for indication of the switching condition (green/

red)

l potentiometer for adaptation to the product density

l Mode switch for selecting the switching condition (min./

max.)

3.4 Storage and transport

Packaging

Storage and transport tem-

perature

Your instrument was protected by packaging during transport.

Its capacity to handle normals loads during transport is

assured by a test acc. to DIN 55439.

The packaging of standard instruments consists of environ-

ment-friendly, recyclable cardboard. In addition, the sensor is

provided with a protective cover of cardboard. For special

versions PE foam or PE foil is also used. Dispose of the

packaging material via specialised recycling companies.

l Storage and transport temperature see "Supplement -

Technical data - Ambient conditions"

l Relative humidity 20 … 85 %

29289-EN-060508

VEGAVIB 66 - with relay output 9

Page 10

Mounting

4 Mounting

4.1 General

Switching point

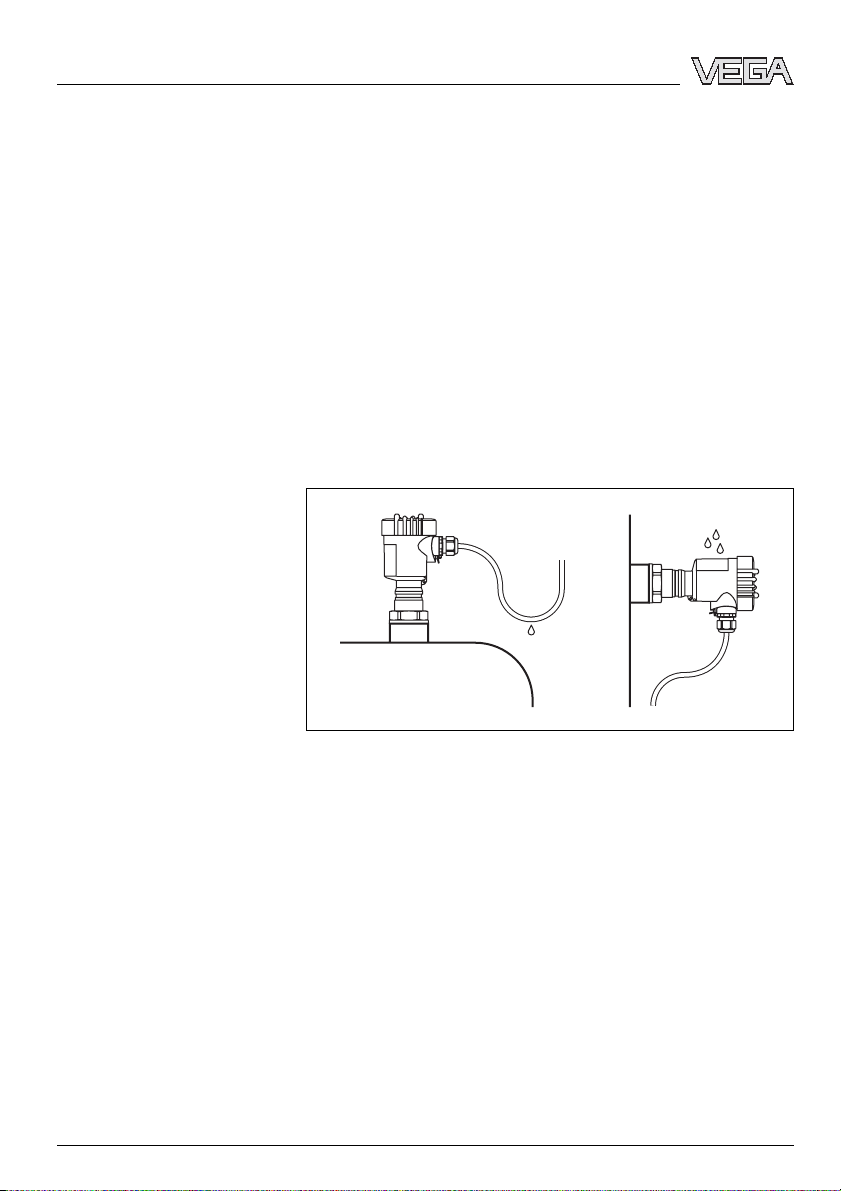

Moisture

Transport

In general, VEGAVIB 66 can be mounted in any position. The

instrument must be mounted in such a way that the vibrating

element is at the height of the requested switching point.

Use the recommended cables (see chapter "Connecting to

power supply") and tighten the cable gland.

You can give your VEGAVIB 66 additional protection against

moisture penetration by leading the connection cable downward in front of the cable entry. Rain and condensation water

can thus drain off. This applies mainly to mounting outdoors, in

areas where moisture is expected (e.g. by cleaning processes)

or on cooled or heated vessels.

Fig. 2: Measures against moisture penetration

Do not hold VEGAVIB 66 on the vibrating element. E specially

with flange and tube versions, the sensor can be damaged by

the weight of the instrument.

Remove the protective cover just before mounting.

Pressure/Vacuum

The process fitting must be sealed if there is gauge or low

pressure in the vessel. Before use, check if the seal material is

resistant against the measured product and the process

temperature.

The max. permissible pressure is stated in the "Technical

data" in the "Supplement" or on the type label of the sensor.

Handling

The vibrating level switch is a measuring instrument and must

be treated accordingly. Bending the vibrating element will

destroy the instrument.

10 VEGAVIB 66 - with relay output

29289-EN-060508

Page 11

Mounting

Warning:

The housing must not be used to screw in the instrument!

Applying tightening force on the housing can damage its

internal mechanical parts.

To screw in, use the hexagon above the thread.

4.2 Mounting information

Tensile load

Material cone

Make sure that the max. permissible tensile load of the

suspension cable is not exceeded. The danger of this

happening exists particularly with very heavy solids and large

meas. lengths. The max. permissible load is stated under

"Technical data" in the "Supplement".

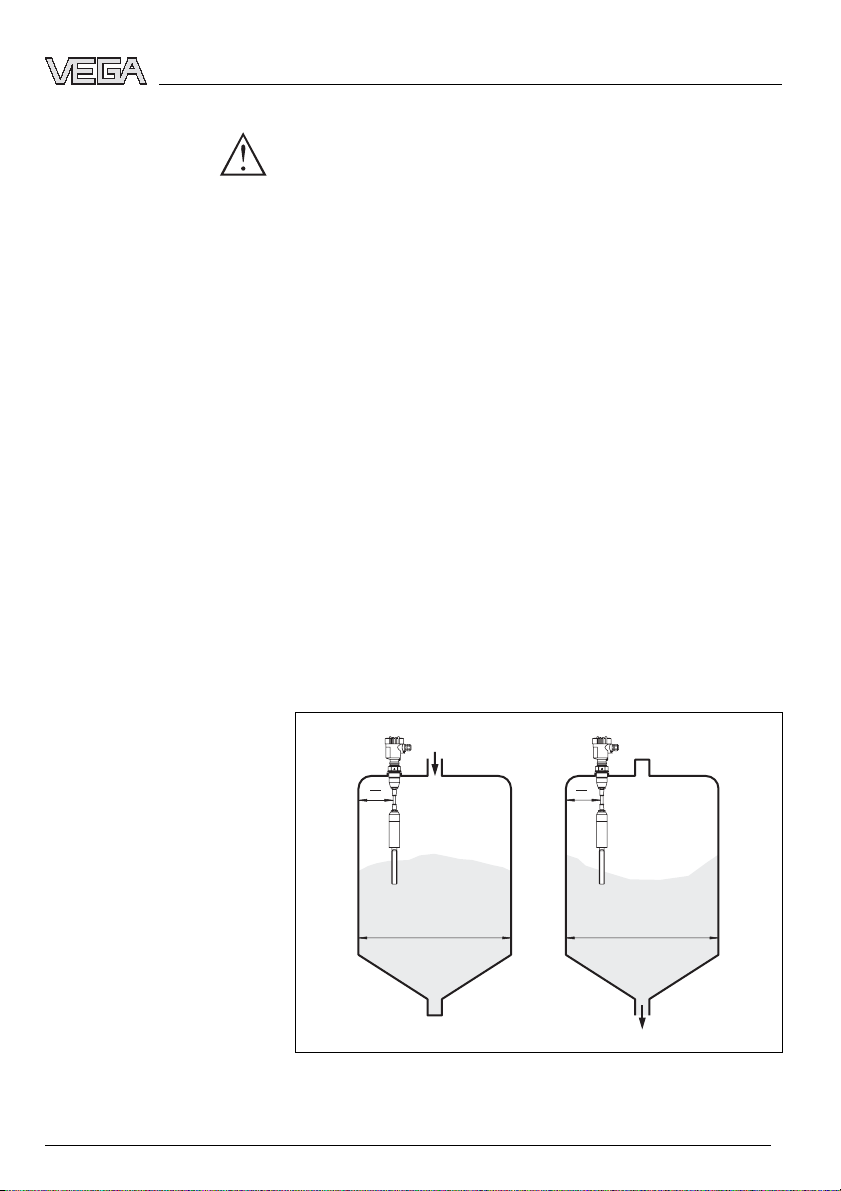

In silos with bulk solids, material cones can form which change

the switching point. Please keep this in mind when installing

the sensor in the vessel. We recommend selecting an

installation location where the sensor detects the average

value of the material cone.

The tuning fork must be mounted at a location that takes the

arrangement of the filling and emptying apertures into account.

To compensate measurement errors caused by the material

cone in cylindrical vessels, the sensor must be mounted at a

distance of d/6 from the vessel wall.

d

6

d

6

d d

Fig. 3: Filling and emptying centered

29289-EN-060508

VEGAVIB 66 - with relay output 11

Page 12

Mounting

Socket

Inflowing material

6

d

1

2

d

3

Fig. 4: Filling in the center, emptying laterally

1 VEGAVIB 66

2 Emptying opening

3 Filling opening

The vibrating element should protrude into the vessel to avoid

buildup. For that reason, avoid using mounting bosses for

flanges and screwed fittings. This is mainly applicable for

adhesive products.

If VEGAVIB 66 is mounted in the filling stream, unwanted

switching signals may be generated. Mount VEGAVIB 66 at a

location in the vessel where no disturbing influence from e.g.

filling openings, agitators etc. can occur.

29289-EN-060508

12 VEGAVIB 66 - with relay output

Page 13

Fig. 5: Inflowing material

Mounting

Flows

Baffle protection against fall-

ing rocks

To minimise flow resistance caused by the tuning fork,

VEGAVIB 66 should be mounted in such a way that the

surfaces of the fork are parallel to the product movement.

1

2

Fig. 6: Orientation of the tuning fork in case of flow

1 Marking with screwed version

2 Direction of flow

In applications such as grit chambers or settling basins for

coarse sediments, the vibrating element must be protected

against damage with a suitable baffle.

29289-EN-060508

VEGAVIB 66 - with relay output 13

Page 14

Mounting

This baffle must be manufactured by you.

>125

Fig. 7: Baffle protection against damages

14 VEGAVIB 66 - with relay output

29289-EN-060508

Page 15

Connecting to power supply

5 Connecting to power supply

5.1 Preparing the connection

Note safety instructions

Take note of safety

instructions for Ex

applications

Select power supply

Select connection cable

Always observe the following safety instructions:

l Connect only in the complete absence of line voltage

In hazardous areas you should take note of the appropriate

regulations, conformity and type approval certificates of the

sensors and power supply units.

Connect the power supply according to the following diagrams.

Oscillator VB60R is designed in protection class 1. To maintain

this protection class, it is absolutely necessary that the ground

conductor be connected to the internal ground terminal. Take

note of the general installation regulations. As a rule, connect

VEGAVIB 66 to vessel ground (PA), or in case of plastic

vessels, to the next ground potential. On the side of the

housing there is a ground terminal between the cable entries.

This connection serves to drain off electrostatic charges. In Ex

applications, the installation regulations for hazardous areas

must be given priority.

The data for power supply are stated in the "Technical data" in

the "Supplement".

VEGAVIB 66 is connected with standard cable with round

cross-section. An outer cable diameter of 5 … 9 mm

(0.2 … 0.35 in) ensures the seal effect

If

cable with a different diameter or wire cross section is used,

of the cable entry.

exchange the seal or use an appropriate cable connection.

In hazardous areas, only use approved cable connections for

VEGAVIB 66.

Select connection

cable for Ex applica-

tions

Take note of the corresponding installation regulations for Ex

applications.

5.2 Connection steps

With Ex instruments, the housing cover may only be opened if

there is no explosive atmosphere present.

Proceed as follows:

29289-EN-060508

VEGAVIB 66 - with relay output 15

Page 16

Connecting to power supply

1 Unscrew the housing cover

2 Loosen compression nut of the cable entry

3 Remove approx. 10 cm (4 in) of the cable mantle, strip

approx. 1 cm (0.4 in) insulation from the ends of the

individual wires

4 Insert the cable into the sensor through the cable entry

5 Lift the opening levers of the terminals with a screwdriver

(see following illustration)

6 Insert the wire ends into the open terminals according to

the wiring plan

7 Press the opening lever of the terminals downward, you will

hear the terminal spring closing

8 Check the hold of the wires in the terminals by lightly

pulling on them

9 Tighten the compression nut of the cable entry, the seal

ring must completely encircle the cable

10 If necessary, carry out a fresh adjustment

11 Screw the housing cover back on

The electrical connection is finished.

Fig. 8: Connection steps 5 and 6

5.3 Wiring plans, single chamber housing

The following illustrations apply to the non-Ex as well as to the

EEx d version.

16 VEGAVIB 66 - with relay output

29289-EN-060508

Page 17

Housing overview

Connecting to power supply

Electronics and connection

compartment

44

1

Fig. 9: Material versions, single chamber housing

1 Plastic (not with EExd)

2 Aluminium

3 Stainless steel (not with EExd)

4 Filter element for pressure compensation (not with EExd)

2 3

4

5

4

1

2

3

Fig. 10: Electronics and connection compartment

1 Potentiometer for switching point adaptation (covered)

2 DIL switch for mode adjustment

3 Ground terminal

4 Screwed terminals

5 Control lamp

Wiring plan

We recommend connecting VEGAVIB 66 in such a way that

the switching circuit is open when there is a level signal, line

break or failure (safe condition).

The relays are always shown in non-operative condition.

29289-EN-060508

VEGAVIB 66 - with relay output 17

Page 18

Connecting to power supply

Fig. 11: Wiring plan

1 Relay output

2 Relay output

3 Voltage supply

3

2 1

18 VEGAVIB 66 - with relay output

29289-EN-060508

Page 19

Set up

6 Set up

6.1 General

The numbers in brackets refer to the following illustrations.

Function/Configuration

On the electronics module you will find the following indicating

and adjustment elements:

l Potentiometer for switching point adaptation (1)

l DIL switch for mode adjustment - min./max.(2)

l Signal lamp (5)

Note:

As a rule, always set the mode with mode switch (2) before

starting the setup of VEGAVIB 66 . The switching output will

change if you set the mode switch (2) afterwards. This could

possibly trigger other connected instruments or devices.

6.2 Adjustment elements

1

5

2

4

3

Fig. 12: Oscillator VB60R - Relay output

1 Potentiometer for switching point adaptation

2 DIL switch for mode adjustment

3 Ground terminal

4 Screwed terminals

5 Control lamp

29289-EN-060508

VEGAVIB 66 - with relay output 19

Page 20

Set up

Switching point adaptation (1)

Mode adjustment (2)

Signal lamp (5)

With the potentiometer you can adapt the switching point to the

solid. It is already preset and must only be modified in special

cases.

By default, the potentiometer of VEGAVIB 66 is set to

complete right position (>0.02 g/cm³ or >0.0008 lbs/in³). In

case of very light-weight solids, you have to turn the

potentiometer to the complete left position (>0.008 g/cm³ or

>0.0003 lbs/in³). Hence the VEGAVIB 66 will be more

sensitive and can detect light-weight solids more reliably.

For instruments detecting solids in water, these values are not

applicable. The potentiometer is preset and must not be

changed.

With the mode adjustment (min./max.) you can change the

switching condition of the relay. You can set the required mode

acc. to the "Function chart" (max.-max. detection

or

overfill

protection, min.-min. detection or dry run protection).

We recommend connecting acc. to the quiescent current

principle (replay contact deenergizes when reaching the

switching point), because the relay takes on the same (safe)

condition if a failure is detected.

Control lamp for indication of the switching condition.

l green = relay energized

l red = relay deenergized

l red (flashing) = failure

6.3 Function chart

The following chart provides an overview of the switching

conditions depending on the adjusted mode and level.

Level Switching sta-

tus

Mode max.

Overfill protection

Relay energized Green

Mode max.

Overfill protection

Relay deener-

gized

20 VEGAVIB 66 - with relay output

53 4

(8)(6) (7)

53 4

(8)(6) (7)

Control lamp

red

29289-EN-060508

Page 21

Set up

Level Switching sta-

Mode min.

Dry run protection

Mode min.

Dry run protection

Failure of the

supply voltage

any

(min./max. mode)

Failure any

tus

Control lamp

53 4

(8)(6) (7)

Relay energized Green

53 4

(8)(6) (7)

Relay deener-

red

gized

53 4

(8)(6) (7)

Relay deener-

gized

53 4

(8)(6) (7)

Relay deener-

flashes red

gized

29289-EN-060508

VEGAVIB 66 - with relay output 21

Page 22

Maintenance and fault rectification

7 Maintenance and fault rectification

7.1 Maintenance

When used as directed in normal operation, VEGAVIB 66 is

completely maintenance-free.

7.2 Fault rectification

Checking the switching signal

Causes of malfunction

Fault rectification

24 hour service hotline

VEGAVIB 66 offers maximum reliability. Nevertheless faults

can occur during operation. These may be caused by the

following, e.g.:

l Sensor

l Process

l Power supply

l Signal processing

The first measure to be taken is checking the output signal. In

many cases, the causes can such be determined and failures

can be rectified.

If the following measures are not successful, please call in

urgent cases the VEGA service hotline at +49 1805 858550.

The hotline is available to you 7 days a week round-the-clock.

Since we offer this service world-wide, the support is only

available in the English language. The service is free of

charge, only the standard telephone costs will be charged.

? VEGAVIB 66 signals "covered" when the vibrating element

is not submerged (overfill protection)

? VEGAVIB 66 signals "uncovered" when the vibrating

element is submerged (dry run protection)

l Supply voltage too low

à Check the power supply

l Electronics defective

à Press the mode switch (min./max.). If the instrument

then changes the mode, the instrument may be

mechanically damaged. Should the switching function

in the correct mode still be faulty, return the instrument

for repair.

à Push the mode switch. If the instrument then does not

change the mode, the oscillator may be defective.

Exchange the oscillator.

29289-EN-060508

22 VEGAVIB 66 - with relay output

Page 23

Maintenance and fault rectification

à Check if there is buildup on the vibrating element, and if

so, remove it.

l Unfavourable installation location

à Mount the instrument at a location in the vessel where

no dead zones or mounds can form.

à Check if the vibrating element is covered by buildup on

the socket.

l Wrong mode selected

à Set the correct mode on the mode switch (max.: overfill

protection; min.: dry run protection). Wiring should be

carried out acc. to the quiescent current principle.

? Signal lamp flashes red

l Electronics has detected a failure

à Exchange instrument or return it for repair

7.3 Exchange of the electronics

In general, all oscillators of series VB60 can be interchanged. If

you want to use an oscillator with a different signal output, you

can download the corresponding operating instructions manual from our homepage under Downloads.

With EEx d instruments, the housing cover must only be

opened if there is no explosive atmosphere.

Proceed as follows:

1 Switch off power supply

2 Unscrew the housing cover

3 Lift the opening levers of the terminals with a screwdriver

4 Pull the connection cables out of the terminals

5 Loosen the two screws with a screw driver (Torx size T10

or slot 4)

29289-EN-060508

VEGAVIB 66 - with relay output 23

Page 24

Maintenance and fault rectification

1

2

Fig. 13: Loosen the screws

1 Electronics module

2 Screws (2 pcs.)

6 Remove the old oscillator

7 Compare the new oscillator with the old one. The type label

of the oscillator must correspond to that of the old

oscillator. This applies particularly to instruments used in

hazardous areas.

8 Compare the settings of the two oscillators. Set the

adjustment elements of the new oscillator to the settings of

the old oscillator.

Information:

Make sure that the housing is not rotated during the electronics

exchange. Otherwise the plug may be in a different position

later.

9 Insert the oscillator carefully. Make sure that the plug is in

the correct position.

10 Tighten the two screws with a screwdriver (Torx size T10

or slot 4).

11 Insert the wire ends into the open terminals according to

the wiring plan

12 Press the opening lever of the terminals downward, you will

hear the terminal spring closing

13 Check the hold of the wires in the terminals by lightly

pulling on them

14 Check the tightness of the cable entry. The seal ring must

completely encircle the cable.

15 Screw the housing cover back on

The electronics exchange is finished.

24 VEGAVIB 66 - with relay output

29289-EN-060508

Page 25

Maintenance and fault rectification

7.4 Instrument repair

If a repair is necessary, please proceed as follows:

You can download a return form (23 KB) from our homepage

www.vega.com under: "Services – Downloads – Forms and

Certificates – Repair form".

By doing this you help us carry out the repair quickly and

without having to call for additional information.

l Print and fill out one form per instrument

l Clean the instrument and pack it damage-proof

l Attach the completed form and possibly also a safety data

sheet to the instrument

l Please request the address for the return shipment from

the VEGA agency serving you.

29289-EN-060508

VEGAVIB 66 - with relay output 25

Page 26

Dismounting

8 Dismounting

8.1 Dismounting procedure

Warning:

Before dismounting, be aware of dangerous process conditions such as e.g. pressure in the vessel, high temperatures,

corrosive or toxic products etc.

Take note of chapters "Mounting" and "Connecting to power

supply" and carry out the listed steps in reverse order.

With Ex instruments, the housing cover may only be opened if

there is no explosive atmosphere present.

8.2 Disposal

The instrument consists of materials which can be recycled by

specialised recycling companies. We use recyclable materials

and have designed the electronic modules to be easily

separable.

WEEE directive 2002/96/EG

This instrument is not subject to the WEEE directive 2002/96/

EG and the respective national laws (in Germany, e.g.

ElektroG). Pass the instrument directly on to a specialised

recycling company and do not use the municipal collecting

points. These may only be used for privately used products

according to the WEEE directive.

Correct disposal avoids negative effects to persons and

environment and ensures recycling of useful raw materials.

Materials: see "Technical data"

If you cannot dispose of the instrument properly, please

contact us about disposal methods or return.

26 VEGAVIB 66 - with relay output

29289-EN-060508

Page 27

Supplement

9 Supplement

9.1 Technical data

General data

Material 316L corresponds to 1.4404 or 1.4435

Materials, wetted parts

- Process fitting - Thread 316L

- Process fitting - Flange 316L

- Process seal Klingersil C-4400

- Seal (vibrating element) CR, CSM

- Tuning fork 316L

- Suspension cable PUR

Materials, non-wetted parts

- Housing Plastic PBT (Polyester), Alu die-casting pow-

der-coated, 316L

- Seal ring between housing and

housing cover

- Ground

Weights

- with plastic housing 1500 g (53 oz)

- with Aluminium housing 1950 g (69 oz)

- with stainless steel housing 2300 g (81 oz)

- Suspension cable 165 g/m (1.8 oz/ft)

terminal 316L

NBR (stainless steel housing), silicone (Alu/

housing)

plastic

Max. permissible tensile load 3000 N (675 lbs)

Sensor length 0.3 … 80 m (1 … 262 ft)

Output variable

Output relay output (DPDT), 2 floating spdts

Turn-on voltage

- min. 10 mV

- max. 253 VAC, 253 VD

Switching

- min. 10 µA

- max. 3 AAC, 1 ADC

29289-EN-060508

VEGAVIB 66 - with relay output 27

current

C

Page 28

Supplement

Breaking capacity

- min. 50 mW

- max.

750 VA AC, 54 WDC

If inductive loads or stronger currents are

switched through, the gold plating on the relay

contact surface will be permanently damaged.

The contact is then no longer suitable for

switching low-level signal circuits.

Contact material (relay contacts) AgNiorAgSnO and Au plated

Modes (adjustable) min./max.

Integration time

- when immersed approx. 0.5 s

- when laid bare approx. 1 s

Ambient conditions

Ambient temperature on the housing -40 … +80 °C (-40 … +176 °F)

Storage and transport temperature -40 … +80 °C (-40 … +176 °F)

Process

conditio

ns

Parameter Limit level of solids

Process pressure -1 … 6 bar/-100 … 600 kPa (-14.5 … 87 psi)

VEGAVIB 66 of 316L -20 … +80 °C (-4 … + 176 °F)

Density

- Standard >0.02 g/cm³ (>0.0007 lbs/in³)

- adjustable >0.008 g/cm³ (>0.0003 lbs/in³)

Electromechanical data

Cable entry/plug (dependent on

- Single chamber housing

the version)

l 1x cable entry M20x1.5 (cable-ø 5 … 9 mm),

1x blind stopper M20x1.5, attached 1x

cable entry M20x1.5

or:

l 1x cable entry ½ NPT, 1x blind stopper

½ NPT, 1x cable entry ½ NPT

or:

l 1x plug M12x1, 1x blind stopper M20x1.5

Spring-loaded terminals for wire cross-section up to 1.5 mm²

(0.0023 in²)

28 VEGAVIB 66 - with relay output

29289-EN-060508

Page 29

Supplement

Adjustment elements

Mode switch

- min. min. detection or dry run protection

- max. max. detection or overfill protection

Voltage supply

Supply voltage 20 … 253 VAC, 50/60 Hz, 20 … 72 VDC(at

U >60 VDC, the ambient temperature can be

max. 50 °C/122 °F)

Power consumption 1 … 8 VA (AC), approx. 1.3 W (DC)

Electrical protective measures

Protection IP 66/IP 67

Overvoltage category III

Protection class I

Approvals

1)

ATEX II 1/2G, 2GEExd d IIC T6

ATEX II 1/2 DIP66 T

1)

Deviating data in Ex applications: see separate safety instructions.

29289-EN-060508

VEGAVIB 66 - with relay output 29

Page 30

Supplement

9.2 Dimensions

VEGAVIB 66

69mm (2 23/32")

ø77mm (3 1/32")

M20x1,5/

½ NPT

1 2 3

Fig. 14: Housing versions

1 Plastic housing

2 Stainless steel housing

3 Aluminium housing

")

32

/

13

112mm (4

69mm (2

M20x1,5/

½ NPT

23

/32")

ø77mm (3

M20x1,5/

½ NPT

116mm (4 9/16")

ø84mm (3

5

/16")

")

16

/

9

116mm (4

M20x1,5

1

/32")

")

64

/

39

117mm (4

30 VEGAVIB 66 - with relay output

29289-EN-060508

Page 31

L

19

")

64

/

55

22mm

(

")

64

/

37

40mm

(1

")

64

/

160mm (6

G1½A

ø 43mm (1

ø 11mm (

ø 43mm (1

33mm

7

/16")

")

64

/

19

(1

11

/16")

11

/16")

Supplement

")

32

/

29

150mm (5

Fig. 15: VEGAVIB 66, threaded version G1½ A

L = Sensor length, see "Technical data"

29289-EN-060508

VEGAVIB 66 - with relay output 31

Page 32

Supplement

9.3 Industrial property rights

VEGA product lines are global protected by industrial property rights.

Further information see http://www.vega.com.

Only in U.S.A.: Further information see patent label at the sensor housing.

VEGA Produktfamilien sind weltweit geschützt durch gewerbliche Schutzrechte.

Further information under http://www.vega.com.

Les lignes de produits VEGA sont globalement protégées par des droits de

propriété intellectuelle.

Pour plus d'informations, on pourra se référer au site http://www.vega.com.

VEGA lineas de productos están protegidas por los derechos en el campo de la

propiedad industrial.

Para mayor información revise la pagina web http://www.vega.com.

Линии продукции фирмы ВЕГА защищаются повсему миру правами на

интеллектуальную собственность.

Дальнейшую информациюсмотрите на сайте http://www.vega.com.

德(VEGA)系列品在全球享有知保。

一步信息网站<http://www.vega.com>。

32 VEGAVIB 66 - with relay output

29289-EN-060508

Page 33

Supplement

29289-EN-060508

VEGAVIB 66 - with relay output 33

Page 34

Supplement

34 VEGAVIB 66 - with relay output

29289-EN-060508

Page 35

Supplement

29289-EN-060508

VEGAVIB 66 - with relay output 35

Page 36

VEGA Grieshaber KG

Am Hohenstein 113

77761 Schiltach

Germany

Phone +49 7836 50-0

Fax +49 7836 50-201

E-mail: info@de.vega.com

www.vega.com

ISO 9001

All statements concerning scope of delivery, application,

practical use and operating conditions of the sensors and

processing systems correspond to the information avail-

able at the time of printing.

© VEGA Grieshaber KG, Schiltach/Germany 2006

Technical data subject to alterations 29289-EN-060508

Loading...

Loading...