Page 1

Operating Instructions

VEGAVIB

Page 2

Contents

Safety information .......................................................................... 2

Note Ex area .................................................................................. 2

1 Product description..................................................................... 3

1.1 Function and configuration .................................................... 3

1.2 Types and versions ................................................................ 3

1.3 Approvals .............................................................................. 4

1.4 Technical data ....................................................................... 5

1.5 Dimensions .......................................................................... 11

2 Mounting..................................................................................... 13

2.1 Mounting instructions .......................................................... 13

3 Electrical connection ................................................................ 16

3.1 Connection instructions VEGAVIB ....................................... 16

3.2 Wiring plan VEGAVIB .......................................................... 16

4 Set-up ......................................................................................... 18

4.1 VEGAVIB .............................................................................. 18

Contents

Safety information

Please read this manual carefully, and also take

note of country-specific installation standards

(e.g. the VDE regulations in Germany) as well as

all prevailing safety regulations and accident prevention rules.

For safety and warranty reasons, any internal

work in the instruments, apart from that involved

in normal installation and electrical connection,

must be carried out only by qualified VEGA personnel.

2 VEGAVIB

Note Ex area

Please note the attached safety instructions containing important information on installation and

operation in Ex areas.

These safety instructions are part of the operating instructions manual and come with the Ex

approved instruments.

Page 3

Product description

1 Product description

1.1 Function and configuration

VEGAVIB compact level switches are used for

level monitoring of powders and granules. The

vibrating level switches are energised

piezoelectrically and vibrate at their mechanical

frequency (VEGAVIB 31 approx. 210 Hz,

VEGAVIB 41 and 43 approx. 530 Hz, VEGAVIB

51, 52 and 53 approx. 350 Hz).

If the measured product reaches the sensor, the

vibrating amplitude is damped. An integrated

electronics detects this damping and triggers a

switching command.

VEGAVIB 31 is a tuning fork sensor and is suitable for unproblematic, fine-grained solids

> 100 g/l which do not cause buildup. Typical

products are gypsum, cement, chalk, fine granules, etc.

VEGAVIB series 40 and 50 vibrating level

switches can be used where levels of solids

with a density greater than approx. 20 g/l need

to be reliably detected. Due to the rod design, it

is almost impossible for material to build up or

get wedged in. This enables their use in foodstuffs and light solids such as e.g. packing

chips. Typical products are cement, gypsum,

chalk, flour, styrofoam, shredded paper, washing powder, plastic granules, down feathers,

packing chips etc. A pulsed actuating signal

causes the rod to begin vibrating again after

immersion and removes the measured product

from the vibrating rod.

Series 50 sensors are also suitable for the detection of solids in water.

1.2 Types and versions

VEGAVIB 31

Tuning fork compact level switch with fixed

installation length and mounting thread G 1 A.

The oscillator of VEGAVIB 31 has a floating

relay output.

VEGAVIB 41

Vibrating rod compact level switch with fixed

installation length and mounting thread G 1 A or

1 NPT. Three different oscillators are available

for different electrical outputs (contactless

electronic switch, relay or transistor). As an

option, a temperature adapter is available for

product temperatures exceeding 100°C.

VEGAVIB 43

Vibrating rod compact level switch with tube

extension up to max. 4 m. All other features are

the same as VEGAVIB 41. As an option, a lock

fitting is available for infinitely variable height

adjustment.

VEGAVIB 51

Vibrating rod compact level switch with fixed

installation length and mounting thread G 1½ A

or 1½ NPT. Four different oscillators are available for different electrical outputs (contactless

electronic switch, relay, transistor or two-wire

output). As an option, a temperature adapter is

available for product temperatures exceeding

100°C.

VEGAVIB 3

Page 4

Product description

VEGAVIB 52

Vibrating rod compact level switch with suspension cable extension up to max. 20 m. All other

features are the same as version VEGAVIB 51.

This version is suitable for temperatures up to

80°C.

VEGAVIB 53

Vibrating rod compact level switch with tube

extension up to max. 4 m. All other features are

the same as VEGAVIB 51. As an option, a lock

fitting is available for infinitely variable height

adjustment.

1.3 Approvals

VEGAVIB 51 Ex(S) and 53 Ex(S) are approved

for use in hazardous or dust-explosive areas of

zone 0, 20 and 2 in the scope of ATEX.

VEGAVIB 52 Ex is approved for use in hazardous areas of zone 0.

For such application, the corresponding official

documents (type approval certificate) must be

noted. They are delivered with the respective

instrument. Also note the relevant mounting and

operating instructions.

4 VEGAVIB

Page 5

Product description

1.4 Technical data

VEGAVIB 31

Housing

Housing material plastic PBT (Polyester)

Protection IP 66

Cable entry 2 x Pg 13.5

Terminals for max. 1.5 mm2 wire cross-section

Mechanical connection

Thread G 1 A of 1.4571

T uning fork

Material 1.4571 (StSt)

Lateral load max. 300 N perpendicular to the narrow fork side

Weight

VEGAVIB 31 approx. 0.8 kg

Ambient conditions

Ambient temperature on the housing -40°C … +70°C

Product temperature -40°C … +100°C (130°C for max. 30 minutes)

Storage and transport temperature -40°C … +70°C

Operating pressure

VEGAVIB 31 max. 25 bar

Product

Product density ≥0.1 g/cm³ (≥100 g/l)

Granulation size max. 6 mm

Oscillator - R (relay output)

Protection class I

Overvoltage category III

Immune to EMI > 10 V/m

Function

Integration time approx. 2 s

Frequency approx. 210 Hz

Signal lamp LED for switching point indication

Mode A/B switch

CE conformity

VEGAVIB 31 vibrating level switch meets the protective regulations of EMC (89/336/EWG) and

NSR (73/23/EWG). Conformity has been judged acc. to the following standards:

EMC Emission EN 50 081 - 1: 1992

Susceptibility EN 50 082 - 2: 1995

NSR EN 61 010 - 1: 1993

VEGAVIB 5

A - max. level detection

B - min. level detection

Page 6

Product description

VEGAVIB 41 and 43

Housing

Housing material plastic PBT (Polyester)

Protection IP 66

Cable entry 1 x Pg 13.5 (with oscillator R = 2 x Pg 13.5)

Terminals for max. 1.5 mm2 wire cross-section

Mechanical connection

Thread G 1 A or 1 NPT of 1.4571 (stst)

Lock fitting (VEGAVIB 43) G 1½ A of 1.4571 (stst)

Vibrating rod

Material 1.4571 (stst)

Lateral load 60 Nm or

Extension tube (VEGAVIB 43)

Materials 1.4571 (stst)

Length 350 mm … 4000 mm

Weight

VEGAVIB 41 approx. 0.8 kg

VEGAVIB 43 approx. 0.8 kg + extension tube (approx. 1 kg/m)

Ambient conditions

Ambient temperature on the housing -40°C … +70°C

Product temperature -40°C … +100°C

Storage and transport temperature -40°C … +70°C

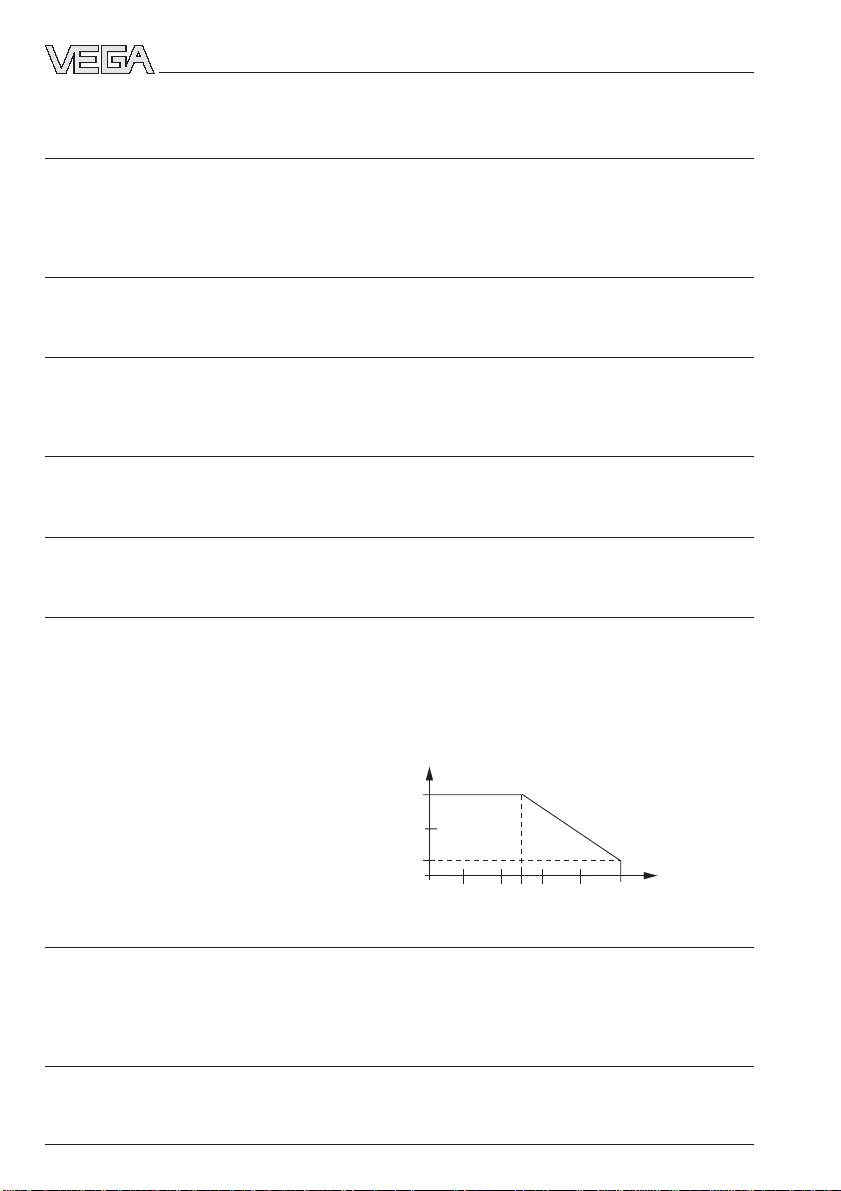

Product temperature with temperature

adapter of 1.4571 (option) -40°C … +150°C

max. 400 N on the rod end (VEGAVIB 41)

Permissible ambient

temperature

70˚C

60˚C

50˚C

100˚ 150˚C

110˚

120˚ 130˚

140˚

Product temperature with

temperature

adapter

Operating pressure

VEGAVIB 41, 43 max. 10 bar

VEGAVIB 43 with lock fitting

- version 1 unpressurised

- version 2 max. 4 bar

Product

Density ≥0.02 g/cm³ (≥ 20 g/l)

6 VEGAVIB

Page 7

Product description

Oscillators

Protection class

- oscillators C and R I

- oscillators T II

Overvoltage category III

Immune to EMI > 10 V/m

Function

Integration time approx. 2 s

Frequency approx. 530 Hz

Signal lamp LED for indication of the switching condition

Modes A/B switch

CE conformity

VEGAVIB 41 and 43 vibrating level switches meet the protective regulations of EMC

(89/336/EWG) and NSR (73/23/EWG). Conformity has been judged acc. to the following standards:

EMC Emission EN 50 081 - 1: 1992

Susceptibility EN 50 082 - 1: 1995

NSR EN 61 010 - 1: 1993

A - overfill or max. level detection

B - dry run protection or min. level detection

EN 50 082 - 2: 1995

version with relay output (R)

VEGAVIB 51, 52 and 53

Housing

Housing material plastic PBT (Polyester)

Protection IP 66

Cable entry 1 x Pg 13.5 (with oscillator R = 2 x Pg 13.5)

Terminals for max. 1.5 mm2 wire cross-section

Mechanical connection

Thread G 1½ A or 1½ NPT

Material

- VEGAVIB 51 and 52 plastic PBT, 1.4301 (StSt)

- VEGAVIB 53 1.4301 (StSt)

Lock fitting (VEGAVIB 53) G 2 A of 1.4301 (StSt)

Vibrating rod

Material 1.4301 (StSt)

Lateral load 60 Nm or

VEGAVIB 7

400 N on the rod end (VEGAVIB 51)

Page 8

Product description

Suspension cable (VEGA VIB 52)

Material PUR

Max. tensile load 6000 N

Length

- PBT mounting boss 600 mm … 10 m

- steel mounting boss 600 mm … 20 m

Extension tube (VEGAVIB 53)

Material 1.4301 (StSt)

Length 350 mm … 4000 m

Weight

VEGAVIB 51 approx. 1.7 kg

VEGAVIB 52 approx. 1.3 kg (with 2 m) + suspension cable

(approx. 0.15 kg/m)

VEGAVIB 53 approx. 2.0 kg + extension tube (approx. 2.2 kg/m)

Ambient conditions

Ambient temperature on the housing -40°C … +70°C

Product temperature

- VEGAVIB 51 and 53 -40°C … +100°C

- VEGAVIB 52 -40°C … +80°C

Storage and transport temperature -40°C … +70°C

Product temperature with temperature

adapter of 1.4571 (option)

(VEGAVIB 51 and 53 with

1.4301 mounting boss) -40°C … +150°C

Permissible

ambient temperature

70˚C

60˚C

50˚C

100˚ 150˚C

110˚

120˚ 130˚

140˚

Product temperature with

temperature

adapter

Operating pressure

VEGAVIB 51 and 53 max. 10 bar

VEGAVIB 52 max. 6 bar

VEGAVIB 53 with lock fitting unpressurised or vacuum

VEGAVIB 51 with PBT mounting boss max. 6 bar

Product

Density ≥ 20 g/l

8 VEGAVIB

Page 9

Product description

Oscillators

Protection class

- oscillators C and R I

- oscillators T and Z II

Overvoltage category III

Immune to EMI > 10 V/m

Function

Integration time approx. 2 s

Frequency approx. 350 Hz

Signal lamp

- oscillators C, R and T LED for indication of the switching condition

- oscillator Z LED lights when vibrating rod is immersed

Modes

- oscillators C, R and T A/B switch

A - overfill protection or max. level detection

B - dry run protection or min. level detection

- oscillator Z definition via signal conditioning instrument

Approvals

ATEX II 1G EEx ia IIC T6

ATEX II 1/2G EEx ia IIC T6

ATEX II 2G EEx ia IIC T6

ATEX II 1/2D IP 65 T

Note safety instructions for Ex applications

In hazardous areas you have to note the respective regulations, conformity and type approval

certificates of the sensors and power supply units. The sensors must only be operated on intrinsically safe circuits. The permissible electrical values are stated in the certificate.

CE conformity

VEGAVIB 51, 52 and 53 vibrating level switches meet the protective regulations of EMC

(89/336/EWG) and NSR (73/23/EWG). Conformity has been judged acc. to the following standards:

EMC Emission EN 50 081 - 1: 1992

Susceptibility EN 50 082 - 1: 1992

EN 50 082 - 2: 1995

version with relay output (R)

NSR EN 61 010 - 1: 1993

VEGAVIB 9

Page 10

Product description

Oscillators

C - Contactless (VIB E40 C, E50 C), VEGA VIB 41, 43, 51, 52, 53

Power supply 20 … 250 V AC, 50/60 Hz

Output contactless electronic switch

Domestic current requirement < 5 mA (via the load circuit)

Load current min. 10 mA, max. 400 mA (max. 4 A up to 40 ms)

The max. permissible ambient temperature is 60°C with a load current exceeding 300 mA.

R - Relay output (VIB E30 R, E40 R, E50 R), VEGAVIB 31, 41, 43, 51, 52, 53

Power supply 20 … 250 V AC, 50/60 Hz; 20 … 72 V DC

Power consumption approx. 1 … 8 VA, max. 1.5 W

Output relay output

Relay data:

- contact floating spdt

- contact material AgCdO and Au plated

- turn-on voltage min. 10 mV

- switching current min. 10 µA

- breaking capacitance max. 500 VA, 54 W

T - T ransistor output (VIB E40 T, E50 T), VEGA VIB 41, 43, 51, 52, 53

Power supply 10 … 55 V DC

Power consumption max. 0.5 W

Output floating transistor output

Load current max. 400 mA (output - overload resistant and

Voltage loss max. 1 V

Turn-on voltage max. 55 V DC

Blocking current < 10 µA

20 … 250 V DC

(the max. permissible ambient temperature decreases linearly from 70°C to 50°C between

60 V DC and 72 V DC)

max. 250 V AC, 250 V DC

max. 3 A AC, 1 A DC

NPN/PNP wirable

permanently short-circuit proof)

Z - T wo-wire output (VIB E50 Z, E50 Z Ex), VEGA VIB 51, 52, 53

Power supply 12 … 36 V DC

Output two-wire output

Current consumption

- vibrating rod free 8 mA

- vibrating rod immersed 16 mA

Suitable signal conditioning instruments VEGALOG 571

10 VEGAVIB

(power supply via VEGATOR signal conditioning

instrument)

VEGATOR 425 Ex F, 525 F, 534 Ex, 536 Ex,

537 Ex, 636 Ex, 825 Ex

Page 11

Product description

1.5 Dimensions

VEGAVIB 31

VEGAVIB 41

VEGAVIB 43

80x110

95

20

148

100

G 1 A

Ø 29

~30

SW 41

95

140

20

100

80x110

~30

SW 41

G 1 A

Ø 14

Housing Lock fitting unpressurised

60

15

330°

rotable

20

20

SW 41

SW 60

G 1½ A

80x110

95

20

L (min. 300, max. 4.000 mm)

100

~30

SW 41

G 1 A

Ø 29

Ø 14

PG 13,5

Temperature adapter (1.4571)

57

VEGAVIB 11

41

Page 12

Product description

VEGAVIB 51 VEGAVIB 52 VEGAVIB 53

95

22

253 (Kunststoff), 238 (V2A)

160

80x110

Ø 18

~30

G 1½ A

Ø 43

SW 60

PG 13,5

80x110

95

22

L (min. 600, max. 20.000)

332

160

Ø 18

~30

G 1½ A

Ø 43

SW 60

PG 13,5

80x110

95

22

G 1½ A

Ø 43

L (min. 300, max. 4.000)

160

Ø 18

~30

PG 13,5

SW 60

Housing Temperature adapter (1.4301) Lock fitting

SW 60

60

15

330°

rotable

104

∅57

80

105

12 VEGAVIB

SW 75

G 2 A

Page 13

Mounting

2 Mounting

2.1 Mounting instructions

VEGAVIB

Generally, the instruments can be mounted in

any position. The instrument must be mounted

so that the measuring system (vibrating rod) is

at the height of the requested switching point.

VEGAVIB 31, however, from below the vessel

bottom. Installation will vary depending on the

various measured products and the requirements on the measurement. You should give

consideration to the following points.

Lateral load

Make sure that the vibrating element is not

subjected to lateral forces. Mount the instrument

at a location in the vessel where no adverse

conditions, e.g. caused by stirrers, filling openings etc. can occur. This applies mainly to

instrument types with cable or extension tube

(see fig. 2.1). The surfaces of the tuning fork of

VEGAVIB 31 should be parallel to the product

movement.

Stirrers

Through the action of stirrers or similar devices,

the level switches can be subjected to strong

lateral forces. For this reason, do not use an

overly long extension tube for VEGAVIB 43 and

VEGAVIB 53, but check if it is possible to mount

instead a VEGAVIB 41 or VEGAVIB 51 level

switch on the side of the vessel in horizontal

position.

Filling opening

Mount the instrument in such a way that the

vibrating element does not protrude directly into

the filling stream. If such a mounting location is

necessary, install a suitable protective sheet

above or in front of the vibrating element, e.g.

L80 x 8 DIN 1028 (see fig. 2.2 a). Mounting acc.

to Fig. 2.2 has proven successful for measuring

abrasive solids. A product cornice grows on the

concave protective sheet and keeps it from

being abraded.

Horizontal installation

To achieve a very precise switching point,

VEGAVIB can be mounted horizontally. However

if the switching point can have a tolerance of a

few centimetres, we recommend mounting the

instruments downwardly inclined (approx. 20°)

to avoid buildup (see fig. 2.2). Mount VEGAVIB

31 in such a way that the surfaces of the tuning

fork are vertical.

a.

Fig. 2.1

Dimensions

b.

20%

The dimensions of the vibrating rod or the tuning fork should not be modified. Any change will

destroy the instrument.

Fig. 2.2

VEGAVIB 13

Page 14

Mounting

Handling

The vibrating level switch is a measuring instrument and must be treated accordingly. Bending

the vibrating element will destroy the instrument.

Lock fitting

Lock fittings are available for VEGAVIB 43 and

VEGAVIB 53 for infinitely variable height adjustment. Be aware that VEGAVIB 53 level switches

in conjunction with a lock fitting must not be

used in pressurized vessels. VEGAVIB 43 can

be used in vessels with up to 4 bar pressure.

Tensile load

When using the cable version, make sure that

the max. permissible tensile load of 6000 N is

not exceeded. This can occur mainly with very

heavy solids and large measuring lengths.

Buildup

With VEGAVIB 31, the surfaces of the tuning

fork should be vertical in order to reduce

buildup. The orientation of a tuning fork is

marked on the hexagon of VEGAVIB. With it you

can check the position of the tuning fork. When

the hexagon touches the seal, the thread can

still be turned by approx. half a turn. This is

sufficient to reach the recommended installation

position.

If the granulation size of the solid is larger than

the min. distance between the tuning fork

blades (8 mm), product particles can wedge

themselves in the tuning fork and trigger a

malfunction. In this case, series 40 or 50 vibrating level switches should be used.

Pressure

When there is gauge pressure or underpressure

in the vessel, the mounting boss must be sealed

on the thread. Cover the thread with teflon tape,

hemp or a similar material or use a sufficiently

resistant seal ring.

Fig. 2.3

Material cone

When planning the location of the vibrating rod

in the vessel, be aware that in solids, material

cones can form which can change the switching point. We recommend selecting an installation location where the vibrating rod detects an

average value of the material cone. The mounting location of the vibrating rod must take the

location of the filling and emptying apertures of

the vessel into account. To compensate measurement errors caused by the material cone in

cylindrical tanks, the vibrating rod must be

mounted at a distance of d/6 from the vessel

wall. Here, a min. distance of approx. 40 cm

must be maintained (see fig. 2.4).

Moisture

Turn the cable entry of the instrument downwards (after installation) to avoid moisture ingress. For this purpose, the housing can be

rotated by approx. 330°. With vertically installed

instruments, loop the cable to the instrument

housing downwards so that rain or condensation water can drain off (see fig. 2.3).

14 VEGAVIB

Page 15

Mounting

Filling and emptying centered

Filling

d

6

d

Filling centered, emptying lateral

Filling

Emptying

d

6

d

Emptying

3

6

d

d

1

1 Emptying aperture

2 Filling aperture

2

3 VEGAVIB

Fig. 2.4

VEGAVIB 15

Page 16

3 Electrical connection

Electrical connection

3.1 Connection instructions VEGAVIB

Note

Switch off power supply before starting connection work.

The electrical connection must be carried out

according to the installed oscillator. Connect

supply voltage according to the wiring diagrams

on the following pages.

As a rule, connect VEGAVIB to vessel ground

(PA) or in plastic vessels, to nearest ground

potential. For this purpose, a thread (screw M4 x

5) is provided on the side on the hexagon of the

mounting boss. This connection serves to drain

off electrostatic charges.

In dust-Ex applications or applications acc. to

CENELEC, the PA terminal (on the hexagon of

the mounting boss) must be connected to the

potential equalisation line.

1

9

8

3.2 Wiring plan VEGAVIB

Non-contact electronic switch

(VIB E40 C, E50 C)

123

AC L1 N Vessel ground

DC + –

or

DC – +

Power supply:

20 … 250 V AC, 50/60 Hz; 20 … 250 V DC (for

further information see Technical data)

For direct control of relays, contactors, magnet

valves, warning lights, horns, etc. Instrument

must not be operated without connected load

(switching in series), as the oscillator can be

destroyed when connected directly to mains.

Not suitable for connection to low voltage PLC

inputs.

2

The domestic current is temporarily lowered

3

below 1 mA after switching off the load so that

the contactors, whose load current is less than

4

the permanently flowing domestic current of the

electronics, are reliably switched off.

5

6

7

1 Housing cover

2 Signal lamp (LED)

3 Terminals

4 A/B switch

5 Potentiometer

6 Instrument housing

7 Cable entry (Pg 13.5)

8 Oscillator

9 Type label oscillator

16 VEGAVIB

Page 17

Electrical connection

Floating relay output (VIB E30 R, E40 R,

E50 R)

+

-

L1

N

2

1

3 4

5

6

Relay output

Power supply

Power supply:

20 … 250 V AC, 50/60 Hz; 20 … 72 V DC (for

further information see Technical data)

For direct switching of external voltage sources

to relays, contactors, magnet valves, warning

lights, horns, etc.

Tw o-wire output (VIB E50 Z)

For connection to a VEGATOR signal conditional instrument (only with VEGAVIB 51, 52 and

53)

Power supply via the connected VEGATOR

signal conditioning instrument (12 … 36 V DC)

(for further information see Technical data)

Floating transistor output

(VIB E40 T, E50 T)

-

2

1

3 4+5

Power supply : 10 … 55 V DC

(for further information see the following connection examples as well as Technical data)

Connection examples

+- +

1

+

NPN action PNP action

-

2

3 4 5 1

-

2

3 4 5

+

-

As a rule, the signal lamp in the housing lights

when the vibrating rod is immersed, independent of the mode set in the signal conditioning

instrument.

Note the operating instructions manual of the

The transistor switches the supply voltage of the

oscillator to the binary input of a PLC or to an

electrical load. By connecting the consumer

(load) in different ways, PNP or NPN action can

be preset.

signal conditioning instrument. Suitable signal

conditioning instruments under Technical data.

-

+

123

VEGATOR

signal conditioning

instrument

VEGAVIB 17

Page 18

4 Set-up

Set-up

4.1 VEGAVIB

Adjustment elements

The diode (2) can be checked with closed

housing. To adjust VEGAVIB, loosen the four

screws on the upper side of the housing with a

screwdriver and remove the housing cover.

The oscillators allow the following settings:

• A/B mode, only with oscillators C, R and T;

with oscillator Z: switch over via the signal

conditioning instrument

• sensitivity setting with potentiometer (not with

VEGAVIB 31)

With the A/B switch (4) you can change the

switching condition of the contactless electronic

switch (C), the relay output (R) or the transistor

output (T) . You can set the required mode acc.

to the "Function chart". A - max. level detection

or overfill protection, B - min. level detection or

dry run protection.

With oscillator Z the A/B mode can be switched

via the signal conditioning instrument. Note the

setup of the signal conditioning instrument.

With the potentiometer (5) you can change the

switching sensitivity and adapt it to the density

of the product. This is necessary for detection of

extremely light or heavy products. Turn the

potentiometer anticlockwise to make the vibrating probe more sensitive. Normally, a modification of the default setting will only be necessary

with extremely light products.

For most products, it is not necessary to change

the setting of the preset potentiometer (default

setting of the potentiometer = 5).

To modify the integration time, you have to use

oscillator Z in conjunction with a suitable signal

conditioning instrument (VEGATOR 534, 536,

537 and 636).

The instrument version for detection of solids in

water is adapted for use in water and cannot be

used for normal level detection. Adjustment of

the settings of the instrument is identical.

2

1

1 Type label

2 Signal lamp (LED)

3 Terminals

4 A/B switch

5 Potentiometer (not with VEGAVIB 31)

3

4

5

With adhesive products, it might be necessary

to turn the potentiometer clockwise to achieve a

better oscillation.

18 VEGAVIB

Page 19

Set-up

Function chart

The following chart provides an overview of the switching conditions depending on the adjusted

mode and level.

Level Switching condition Signal Current Signal

Mode A

Mode B

Failure of the supply voltage

Mode

A / B any Transistor

VIB E40 / VIB E30 / VIB E40 / lamp consumpt. lamp

50 C 40 / 50 R 50 T VEGAVIB E50 Z VEGAVIB

21

Switch Relay

closed energised

21

Switch Relay deopen energised

21

Switch Relay

closed energised

21

Switch Relay deopen energised

21

Switch Relay deopen energised

Transistor

64 5

conducts appr. 8 mA

Transistor

64 5

blocks appr. 16 mA

Transistor

64 5

conducts appr. 16 mA

Transistor

64 5

blocks appr. 8 mA

64 5

blocks 0 mA

VEGAVIB 19

Page 20

VEGA Grieshaber KG

Am Hohenstein 113

77761 Schiltach

Germany

Phone (07836) 50-0

Fax (07836) 50-201

E-Mail info@de.vega.com

www.vega.com

ISO 9001

All statements concerning scope of delivery, practical use and operating

conditions of the sensors and processing systems correspond to the

latest information at the time of printing.

Technical data subject to alterations

17496-EN-030718

Loading...

Loading...