Page 1

VEGATROL 20 Ex

VEGATOR 526W Ex

on

TIB • Technical Information • Operating Instructions

Fail safe overfill

protection for

pressurized vessels

storing liquid gas

Approved acc. to the

VdTÜV-information

"Overfill protection" 100

no. TÜV.ÜS.94-35

liquid gas PN 25

Corresponds to the

requirements to

component tested overfill

protections of TRB 801,

no. 25

Corresponds to the

requirements of

DIN V 19250 AK 5

Conformity certificates

PTB-no. Ex-94.C.4035 X

BVS-no. 93.C.2015 X

VEGA Grieshaber KG

Electronic level measurement

Am Hohenstein 113

Postfach 11 42

D-77757 Schiltach/Schwarzwald

Phone 0 78 36 / 50 - 0

Fax 0 78 36 / 50 201

Page 2

Contents

1 Introduction

1.1 Contents of the instruction manual ..................................................................................................................... 3

1.2 Safety information ...............................................................................................................................................3

1.3 Approvals ............................................................................................................................................................3

2 Technical Information

2.1 Product description .............................................................................................................................................4

2.2 Configuration of an overfill protection ................................................................................................................. 5

2.3 Configuration of a measuring system .................................................................................................................6

2.3.1 Continuous level measurement ...............................................................................................................6

2.3.2 Additional switch point .............................................................................................................................6

2.4 Technical data ..................................................................................................................................................... 7

2.4.1 Signal conditioning instrument VEGATOR 526 W Ex ..............................................................................7

2.4.2 Sensor VEGASWING Ex with oscillator E86 Ex (overfill protection) .......................................................8

2.4.3 Capacitive measuring electrodes.............................................................................................................9

2.4.4 Housing of the system sensor ................................................................................................................. 9

2.5 Dimensional drawings ....................................................................................................................................... 10

2.5.1 VEGATROL 20 system sensor .............................................................................................................. 10

2.5.2 Flanges .................................................................................................................................................. 11

2.5.3 Signal conditioning instrument VEGATOR 526 W Ex ............................................................................ 11

2.6 Electrical connection ......................................................................................................................................... 12

2.6.1 Signal conditioning instrument VEGATOR 526 W Ex overfill protection ................................................ 12

2.6.2 VEGATROL 20 system sensor .............................................................................................................. 13

2.7 Mounting instructions and regulations .............................................................................................................. 14

2.8 Connection examples for overvoltage arresters ............................................................................................... 15

Contents

3 Mounting and set-up

3.1 Mounting ........................................................................................................................................................... 16

3.2 Set-up................................................................................................................................................................16

3.3 Operation .......................................................................................................................................................... 17

4 Supplement

4.1 Fault signals ...................................................................................................................................................... 17

4.2 Calculation information for sensor length..........................................................................................................18

4.3 General instructions for the use of overfill protections ...................................................................................... 19

2

VEGATROL 20 Ex

Page 3

1 Introduction

1 Introduction

1.1 Contents of the instruction manual

This Technical Information / Operating Instructions

(T.I.B.) contains information for correct

- installation

- connection

- set-up

for the fail-safe-protectionVEGATROL 20 Ex .

This TIB is supplied as part of the order. Knowledge of the

contents is important for correct operation of the

instrument. This TIB accompanies the product and is

addressed to technical staff which are trained or have

knowledge of the use of level measurement and control

equipment.

1.2 Safety information

The instrument must only be operated as described in this

TIB. Please note that other action can cause damage for

which VEGA does not take liability.

1.3 Approvals

VdTÜV

VEGATROL 20 is approved acc. to VdTÜV-information

"Overfill protection" 100 as overfill protection in stationary

storage vessels in liquid gas plants of groups A, B, C and

D (approval no. TÜV.ÜS.94-35).

This approval is also valid for storage vessels in

distribution plants.

DIN

The overfill protection of VEGATROL 20 corresponds to

the requirements of DIN V 19250, class 5.

TRB

VEGATROL 20 corresponds to the requirements on

component tested overfill protections acc. to TRB 801,

no. 25.

Overfill protection in vessels up from group C

Also in cases where TRB 801, no. 25, item 6.1.4.2

requires two independent overfill protections,

VEGATROL 20 is sufficient to meet with this requirement.

one

Ex-Zone 1

The system sensor of VEGATROL 20 is approved for the

use in hazardous areas zone 1. In such cases the

regulations and special conditions of the conformity

certificate PTB-no. Ex-94.C.4035 X and BVS-no.

93.C.2015 X must be observed.

If the capacitive measuring electrode of the system sensor

is used as part of a continuous level measurement or level

detection, the oscillator of the measuring electrode must

be supplied via a suitable intrinsically safe circuit of a

separate signal conditioning instrument.

These are the following possibilities:

- signal conditioning instrument VEGAMET in Ex-version

- signal conditioning instrument VEGAMET or evaluation

system VEGALOG with safety barrier

- signal conditioning instrument VEGATOR in Ex-version

- signal conditioning instrument VEGATOR with safety

barrier.

The regulations and special conditions of the conformity

certificates of the signal conditioning instruments or the

safety barrier must furthermore be observed.

Possible combinations of measuring systems are stated

on page 6.

VEGATROL 20 Ex

3

Page 4

2 Technical Information

2 T echnical Information

2.1 Product description

General

VEGATROL 20 for liquid gas consists of:

- VEGATROL 20 system sensor

- signal conditioning instrument VEGATOR 526 W Ex.

System sensor VEGATROL 20 includes in the concentric

tube the vibrating probe VEGASWING as well as

additionally a capacitive measuring electrode either as rod

or cable electrode.

The oscillators for VEGASWING as well as the measuring

electrode are also integrated in the housing of the system

sensor.

The vibrating level switch in conjunction with VEGATOR

526 W Ex is used as overfill protection.

The capacitive measuring electrode can be used as

follows:

- in conjunction with a signal conditioning instrument

VEGAMET for continuous level measurement

- in conjunction with a signal conditioning instrument

VEGATOR for an additional switch point (e.g.

operational switch-off acc. to VdTÜV).

These signal conditioning instruments are not part of

VEGATROL 20 and have to be ordered separately.

The continuous level measurement as well as the additional level detection are realized via the integral capacitive

measuring electrode. This electrode in conjunction with

the concentric tube or the metallic container wall forms a

capacitor. The liquid gas acts as dielectricum and changes

therefore the capacitance of this capacitor. The respective

oscillator converts the capacitance into a level proportional

direct current. The measuring range includes the total

length of the rod or cable electrode, measured from the

end of the VEGASWING.

The detected level can be used to realize an additional

switch point, e.g. an operational switch off point.

Fail-safe / Self-monitoring

A special feature of the overfill protection of VEGATROL

20 is the integral self-monitoring. It is based on a redundant microprocessor system in the signal conditioning

instrument and includes the whole measuring chain from

the tuning fork via the oscillator, the two-wire line as well

as the signal conditioning instrument.

The self-monitoring includes two routines:

- the permanent monitoring

- the cyclical self-test.

The application range comprises stationary vessels acc. to

the pressure vessel regulations for storing liquid gas acc.

to DIN 51 622:

- in individual vessel plants

- in liquid gas plants

- in distribution plants

- in plants with several vessels

each of group A, B, C and D.

When use in distribution plants up from group C min.

separate overfill protections must be installed acc. to the

requirement of TRB 801, no. 25. Even in these cases

VEGATROL 20 is sufficient due to the VdTÜV-approval to

meet with the TRB-requirement.

In plants with several vessels VEGATROL 20 can be used

as continuous monitoring and locking systems.

two

one

Function

The level is detected by a vibrating level switch

VEGASWING. Its tuning fork is piezoelectrically energized

and vibrates at its mechanical resonance frequency. A

second piezoelectric element measures this resonance

frequency. If the tuning fork is covered by the liquid gas,

the resonance frequency changes proportional to the

degree of covering. The oscillator in VEGASWING detects

continuously the resonance frequency and converts the

value into a current to the signal conditioning instrument.

When the switch point is reached an erratic increase of the

current signal is triggered. The level relay in the signal

conditioning instrument de-energizes.

During the permanent monitoring the signal conditioning

instrument causes the oscillator of the sensor to trigger a

test cycle in 960 msec. cycle. Defined test signals are

transmitted via the two-wire line to the signal conditioning

instrument. Possible failures in the sensor electronics as

well as line break, short-circuit and mechanical damage on

the tuning fork are signalled via these test signals.

During the cyclical selftest security relevant components

and procedures (e.g. level relay, CPU, memory, time

reaction) are checked in the signal conditioning instrument

in a very tough time pattern. The function test of the level

relays is made without interruption of the circuit of

connected systems.

If during the self-monitoring a failure is detected, the level

relays and the fail safe relay de-energize.

Due to the above mentioned measures a reliable and

correct function of the overfill protection is ensured without

any staff involved for control tasks.

4

VEGATROL 20 Ex

Page 5

2 Technical Information

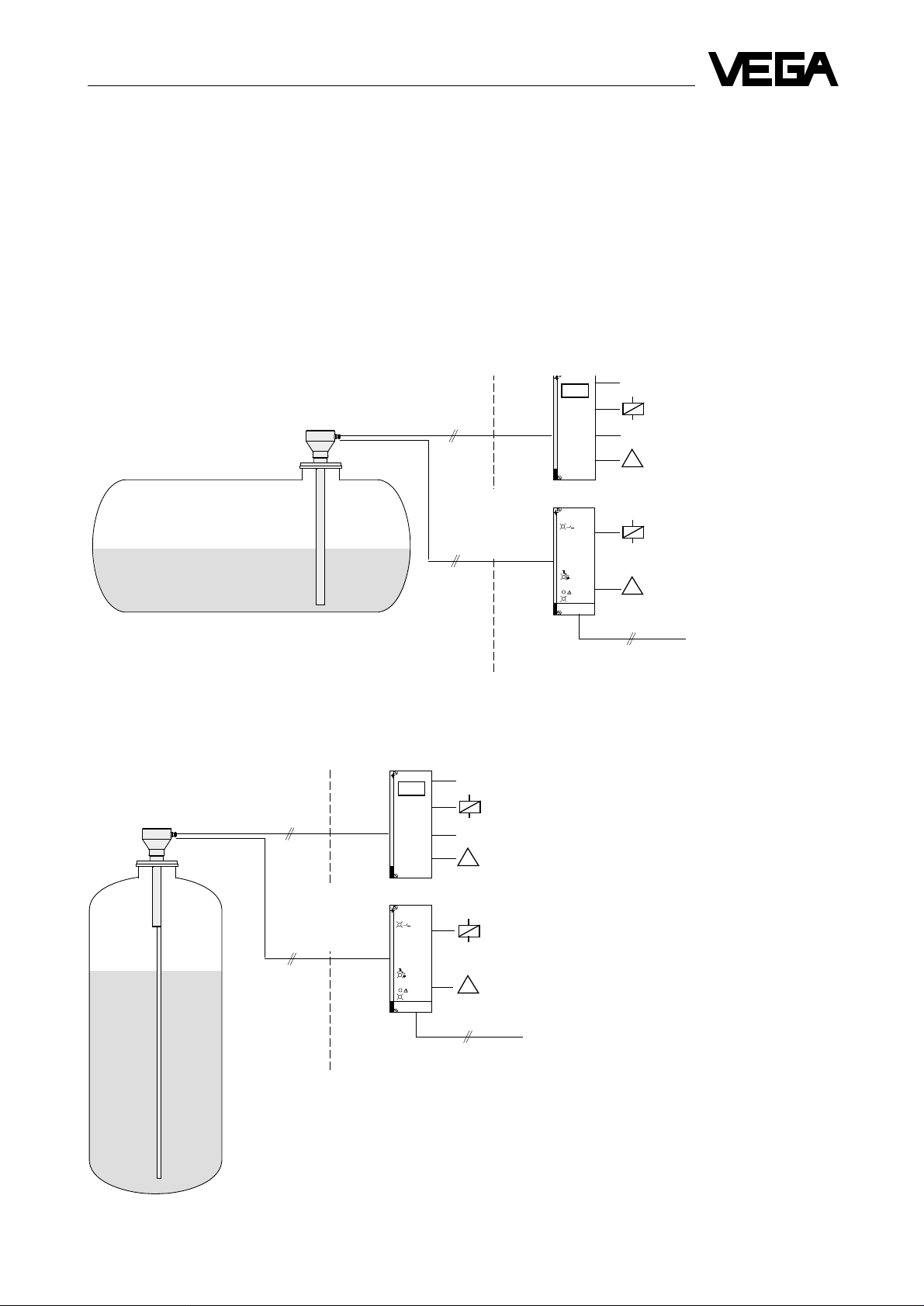

2.2 Configuration of an overfill protection

Storage vessels in liquid gas plants of group A, B, C and D

The overfill protection VEGATROL 20 for a storage vessel consists of:

- VEGATROL 20 system sensor with rod and cable electrode

- signal conditioning instrument VEGATOR 526 W Ex.

Additional instruments:

- signal conditioning instrument VEGAMET for continuous level measurement or for additional switch point

- overvoltage arresters etc. acc. to the requirements of the system.

Version I: cylindrical tank

Ex-Zone 1

e.g. rod electrode

Version II: spherical tank

VEGATROL 20

System sensor

Ex-Zone 1

e.g. cable

z.B. Seil-

electrode

elektrode

VEGATROL 20

System sensor

two-wire

line each

(intrinsically safe

circuit)

two-wire

line each

(intrinsically safe

VEGAMET Ex

0/4 … 20 mA

VEGATOR 526 W Ex

•

•

•

•

•

VEGATOR 526 W Ex

VEGATOR 526 W Ex

on

DISBUS

!

!

circuit)

Not-Ex-area

VEGAMET Ex

0/4 … 20 mA

VEGATOR 526 W Ex

•

•

•

•

•

VEGATOR 526 W Ex

VEGATOR 526 W Ex

on

Continuous level

measurement

Overfill

protection

DISBUS

!

!

Continuous level

measurement

Overfill

protection

VEGATROL 20 Ex

Not-Ex-area

5

Page 6

2 T echnical Information

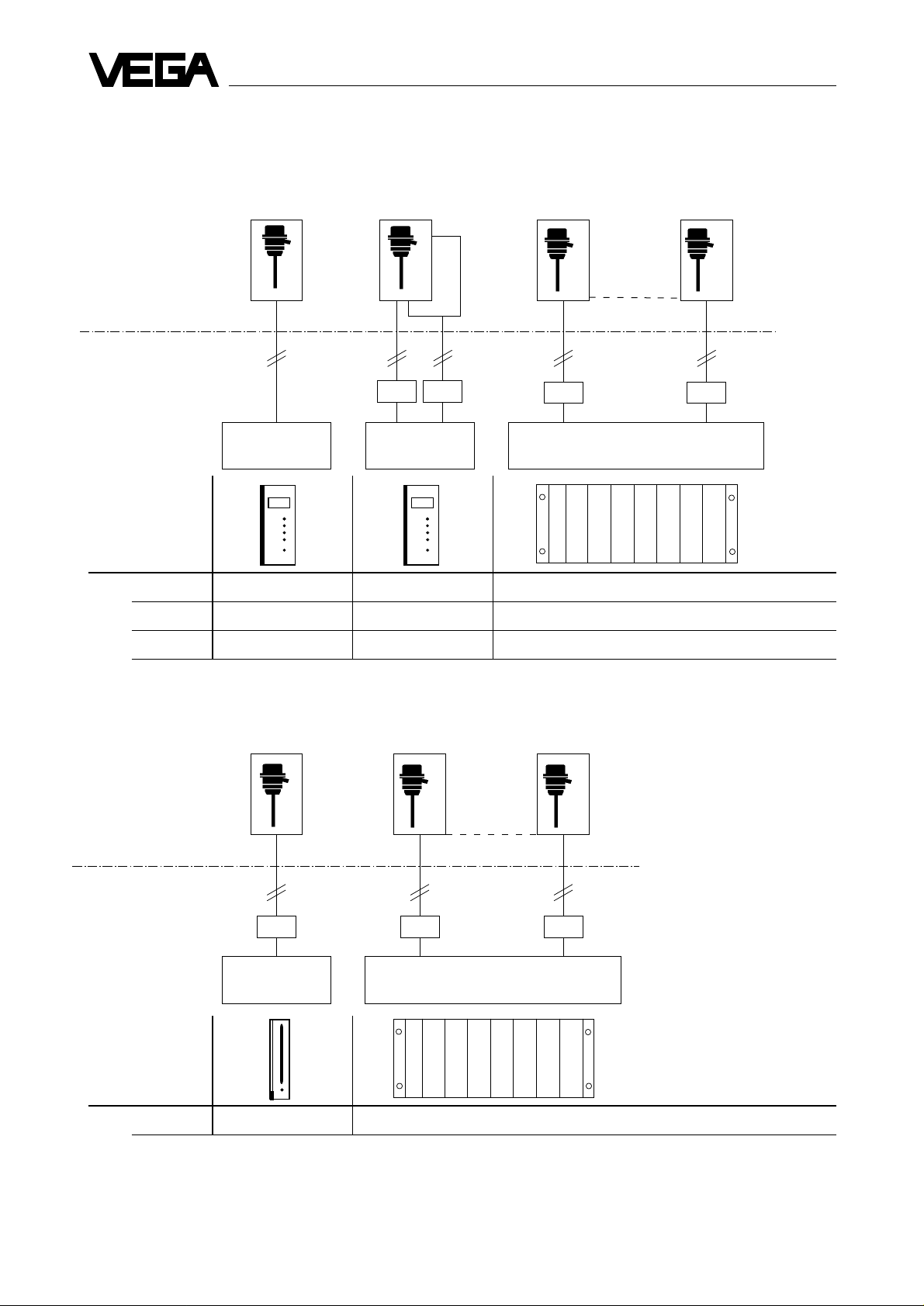

2.3 Configuration of a measuring system

2.3.1 Continuous level measurement

Sensor VEGATROL 20 VEGATROL 20 VEGATROL 20

1

2

Ex-area

Not Ex-area

Safety barrier 145 145 145 145

Signal conditioning VEGAMET VEGAMET VEGALOG 571

instrument 509 Z Ex 512 Z EA-card (input analog)

1

10

Outputs

Relay 3 x 3 x 10 x per AR-card (output relay)

Current 1 x 3 x 10 x per AA-card (output analog)

DISBUS 1 x 1 x for max. 30 VEGADIS per AD-card (output DISBUS)

2.3.2 Additional switch point

Sensor VEGATROL 20 VEGATROL 20

1

Ex-area

Not Ex-area

Safety barrier 145 145 145

Signal conditioning VEGATOR VEGALOG 571

instrument 525 F EA-card (input analog)

10

Outputs

Relay 1 x 10 x per AR-card (output relay)

Additional instruments for measuring systems - Overvoltage arresters

- Indicators VEGADIS 171 A / 172 (0 … 20 mA)

- VEGADIS 173 (DISBUS)

- Interface converters VEGACOM 557

6

VEGATROL 20 Ex

Page 7

2 Technical Information

2.4 Technical data

2.4.1 Signal conditioning instrument VEGATOR 526 W Ex

Power supply

Operating voltage U

Power consumption approx. 11 VA or approx. 8 W

Fuse (intern) Plug fuse 800 mA, moderately slow blow

Measuring data input - Operating data

Data transmission analog, 4 … 20 mA

Power supply 14 … 18,9 V DC

Current limitation at 45 mA, short-circuit proof

Connection line 2-wire

Resistance per conductor max. 35 Ohm

Measuring data input - Ex-technical data

Max. values: Voltage U ≤ 18,9 V DC

Current I ≤ 95 mA

Efficiency P ≤ 647 mW

Characteristics trapezoidal

Internal effective inductance L

Internal effective capacitance C

int

int

= 24 V AC (20 … 28 V), 50 / 60 Hz or

nenn

= 24 V DC (16 … 60 V)

unimportant

≤ 10 nF

Flame proofing EEx … IIC EEx … IIB

Max. permissible outer inductance L

ext

… ia… 0,5 mH 1 mH 1,5 mH 2 mH 0,5 mH 1 mH 1,5 mH 2 mH

… ib… 4 mH 15 mH

Max. permissible external capacitance C

… ia… 52 nF 40 nF 27 nF 15 nF 200 nF 190 nF 177 nF 160 nF

ext

… ib… 240 nF 1,1 F

The intrinsically safe circuit is reliably galvanically separated from the not-intrinsically safe circuits up to a peak value of

375 V of the nominal voltage.

Level relay

Contact 1 floating spdt, AgCdO and gold flashed

Min. turn-on voltrage 12 V DC

switching current 10 mA DC

Max. turn-on voltage 250 V AC, 48 V DC

switching current 2,5 A at 250 V AC; 1 A at 48 V DC

breaking capacity 125 VA AC

Required external fuse

for relay contacts 2 A, slow

Fail safe relay

Contact 1 floating spdt, AgCdO and Au platted

Min. turn-on voltage 10 mV

switching current 10 µA

Max. turn-on voltage 250 V AC, 60 V DC

switching current 2 A AC, 1 A DC

breaking capacity 125 VA AC, 60 W DC

Ambient conditions

Permissible operating temperature -20°C … +70°C

Storage and transport temperature -25°C … +80°C

Electrical connection

Connection Plug connection acc. to DIN 41 612, series F, 32-pole, d, z

Carrier 596 Ex Connection to the respective module

Housing 589 - 10 Ex Connection to terminal (max. 1,5 mm

VEGATROL 20 Ex

2

)

7

Page 8

2 T echnical Information

Electrical protective measures

Protection unassembled IP 00

installed in Carrier Type 596 Ex with Ex-module

front completely equipped .........................IP30

Upper and lower side ................................IP20

Wiring side rear .........................................IP00

installed in Housing Type 589 - 10 Ex ......................... IP30

(in both cases observe the respective TIB)

Protection class II (in housing 589)

Overvoltage category II

Mechanical data

Series Module unit for carrier type 596 Ex or

housing 589 - 10 Ex

Dimensions unassembled W = 50,8 mm (10 TE), H = 128,4 mm, D = 162 mm

Dimensions in plastic housing 589 W = 62,5 mm, H = 136 mm, D = 222 mm

Weight approx. 400 g

VEGATOR 526 W Ex must only be connected to instruments in which no higher voltages than AC 250 V (50 Hz) occur.

Potential stages and galvanic separation

Sensor

Ex-area

Meas. data input Power sup. unit

P1

Microcomputer control and output Relay contacts Relay contacts

P3 P4 P5

Fail safe relay Level relay

Voltage supply

P2

2.4.2 Sensor VEGASWING Ex with oscillator E86 Ex (overfill protection)

Supply and signal circuit

Power supply 12 … 18,9 V DC

(from signal conditioning instrument VEGATOR 526 W Ex)

Data transmission analog, 4 … 20 mA

Flame proofing EEx ia IIC, T4

Internal effective capacitance C

Internal effective inductance L

Power consumption Tuning fork uncovered ca. 7 mA

Tuning fork covered 10 … 20 mA

Fault signal approx. 25 mA

Reference value approx. 15 mA

Connection line 2-wire

unimportant

int

unimportant

int

P1 … P5

Potential stages

Ambient conditions

Permissible operating temperature -30°C … +70°C

Storage and transport temperature -40°C … +80°C

Operating pressure max. 25 bar

however observe max. permissible pressure of the flange

Electrical connections

Terminals in plastic housing for connection of max. 1,5 mm

Cable entry Pg 13,5

Electrical protective measures

Protection class II

8

2

VEGATROL 20 Ex

Page 9

2 Technical Information

Mechanical data

Material Mounting parts Stainless steel1.4571 (V4A)

Extension tube Stainless steel 1.4571 (V4A)

Tuning fork Stainless steel 1.4581 (V4A)

Resonance frequency of the tuning fork in air approx. 380 Hz

Dimensions see dimensional drawing

2.4.3 Capacitive measuring electrodes

Supply and signal circuit

Oscillator 117/4 A Ex, continuous level measurement

Power supply approx. 17,8 V at 4 mA, approx. 14 V at 25 mA

(data of VEGAMET 509 Z Ex)

ca. 12 … 16 V (via ia-safety barrier 145)

Data transmission analog, 4 … 20 mA

Flame proofing EEx ia IIC, T6

Internal effective capacitance C

Internal effective inductance L

Oscillator 115 A Ex, additional switch point (only with rod electrode)

Power supply ca. 12 … 16 V (via ia-safety barrier 145)

Data transmission analog, 4 … 20 mA

Flame proofing EEx ia IIC, T6

Internal effective capacitance C

Internal effective inductance L

Ambient conditions

Permissible operating temperature -30°C … +70°C

Storage and transport temperature -40°C … +80°C

Operating pressure max. 25 bar

unimportant

int

unimportant

int

unimportant

int

≤ 0,2 mH

int

Electrical connection

Terminals for max. 2,5 mm

2

Cable entry Pg 13,5

Electrical protective measures

Protection class III

Mechanical data

Material Mounting parts Stainless steel 1.4571 (V4A)

Isolation PTFE partly insulated

Electrode rod Stainless steel 1.4571 (V4A)

Electrode cable Stainless steel 1.4571 (V4A)

Fixing insulator Porcelain

max. tensile strength cable electrode 3 KN

Dimensions see dimensional frawing

(max. rod length 4000 mm, max. cable length 12000 mm)

2.4.4 Housing of the system sensor

Mechanical data

Material Housing Stainless steel 1.4571 (V4A)

Flange Stainless steel 1.4571 (V4A)

Concentric tube Stainless steel 1.4571 (V4A)

Pg-cable entry brass nickle plated

Fixing pieces in the concentric tube PTFE

Dimensions see dimensional drawing (concentric tube length 4000 mm)

Weight basic weight approx. 4 kg

per metre concentric tube additional approx. 1 kg

Electrical protective measures

Protection IP 67

VEGATROL 20 Ex

9

Page 10

2.5 Dimensional drawings

2.5.1 VEGATROL 20 system sensor

(approx. dimensions in mm)

with rod electrode with cable electrode

32

ø170

32

2 T echnical Information

ø170

Pg 13,5

195

b

L1

L2

25

100

Switch point

Rod electrode

195

b

L1

Pg 13,5

L2

25

ø48,3

ø2,5

Switch point

100

40

Cable electrode

ø48,3

L1: length of the concentric tube and

the rod electrode

L2: length of the tuning fork sensor

(concentric tube and rod electrode

have the same length)

An additional switch point can be realized with the

capacitive measuring electrode. In this case the rod

electrode must be selected min. 300 mm longer than the

distance of the lower flange edge to the requested switch

point.

L3

L1: length of the cable electrode

L2: length of the tuning fork sensor

L3: length of the fixing facility

(min. 200 mm, max. 250 mm)

Note:

- the cable electrode inside the concentric tube is

designed as rod electrode

- the dimension "L2" is mentioned on the type plate as

length of the overfill protection

- flange thickness "b" see next page

10

VEGATROL 20 Ex

Page 11

2 Technical Information

2.5.2 Flanges

The welded flanges for system sensor VEGATROL 20 are made of stainless steel (material no. 1.4571, V4A) acc. to

DIN 2527 or ANSI - ASA - B 16,5.

Flange acc. to DIN (Dimensions in mm)

90°

45°

Flange Dimensions Holes

DN PN D b k Number Screws d

50 25 / 40 165 20 125 4 M16 18

65 25 / 40 185 22 145 8 M16 18

80 25 / 40 200 24 160 8 M16 18

100 25 / 40 235 24 190 8 M20 22

150 25 / 40 300 28 250 8 M24 26

d

2

b

ø k

ø D

D = outer flange diameter

b = flange thickness

k = hole circle

d

= diameter of holes

2

Flange acc. to ANSI (Dimensions in mm)

Flange Dimensions Holes

ANSI psi D b k Number Screws d

2" 600 165,1 25,4 127,0 8 M16 19,1

1

2

/2" 600 190,5 28,4 149,4 8 M20 22,4

3" 600 209,6 31,8 168,1 8 M20 22,4

4" 600 273,1 38,1 215,9 8 M24 25,4

2.5.3 Signal conditioning instrument VEGATOR 526 W Ex

(approx. dimensions in mm)

2

2

12

Circuit board 100 x 160 x 1,5 Multipoint connector

European size

100

162

4

10 TE

128,4

50,8

VEGATROL 20 Ex

11

Page 12

2.6 Electrical connection

2.6.1 Signal conditioning instrument VEGATOR 526 W Ex overfill protection

Coordination of the Terminal socket with multipoint Module with multipoint

terminal socket or the connector (part of the housing connector acc. to DIN

multipoint connector Type 589 - 10 Ex) 41 612 for carrier

d b z

2 L1 (+)

18

20

30

32

N (-)

2

4

8

8

10

Power

supply

Fail safe relay

Level relay

(overfill

protection)

+

Measuring

-

data input

(intrinsically

safe signal

circuit)

10

12

14

16

18

20

22

24

28

30

32

d

2

4

6

8

z

2

4

6

8

10

12

14

16

18

Coded

key

20

22

24

E Ex i

28

30

32

d

z

2 T echnical Information

(rear view)

d b z

2

4

6

8

10

12

14

16

18

Separation

20

22

24

26

28

30

32

Not Ex-area

Ex-area

Note:

- the relay contacts are shown in currentless condition

Sensor 1

2 3

1

Ex-separation

Overvoltage arrester

Connection when using

overvoltage arresters, see

page 15

Overvoltage arrester

Oscillator E86 Ex of

VEGASWING in the housing

of the system sensor

12

VEGATROL 20 Ex

Page 13

2 Technical Information

2.6.2 VEGATROL 20 system sensor

Inner view after removing the cover

Oscillator E86 Ex of the

overfill protection

123

Earth connection

Pg 13,5

Plastic cover (visible after

removing the oscillator)

Overfill protection

Connection

1

2

3

Continuous level measurement

Blind stopper or Pg 13,5

(attached to consignment)

Oscillator 117/4 A Ex or 115 A Ex

of the capacitive measuring

electrode

d32

-

+

d30

Signal conditioning

instrument

VEGATOR 526 W Ex

Terminals

(visible after removing the plastic cover)

2

1

VEGATROL 20 Ex

3

4

Connection

2

3

1

4

d32

-

+

d30

Signal conditioning

instrument, e.g.

VEGAMET 509 Z Ex

13

Page 14

2 T echnical Information

2.7 Mounting instructions and

regulations

General instruction for electrical connection

The electrical connection is made acc. to the wiring diagram on page 12 and 13 or acc. to the type plates on the

instruments. The voltage stated on the type plate of the

signal conditioning instrument must correspond with the

value of the power supply.

Coding

A mechanical coding in form of a pin in the multipoint

connector and a hole in the multiple plug ensures that only

one Ex-instrument can be plated in one Ex-module (carrier

or housing).

In case of connection of a sensor installed in the Ex-area it

must be ensured that VEGATOR 526 W Ex (see figure) is

provided with a coded key in the respective position.

Ex-modules of Messrs. VEGA are supplied with plugged in

coded key.

2

4

6

8

10

12

14

16

18

20

Coded key here

Coding on the multipoint connector

(view)

22

24

26

28

30

32

- If strong electromagnetic interferences have to be

expected, screened cable is recommended.

- If there is a danger of overvoltages, overvoltage

arresters are recommended. Observe the respective

TIB for connection.

- Connected systems must correspond to VDE 0100

part 725 (auxiliary circuits).

- If screened cable is used, the screening should be

earthed at one end. The earth must be realized on the

sensor.

- The respectively valid Ex-regulations as well as the

special conditions in the conformity certificate must be

observed.

Ex-mounting regulations

The signal conditioning instrument VEGATOR 526 W Ex

and the signal conditioning instrument for the capacitive

measuring electrode must be installed generally outside

hazardous areas (or special Ex-protective measures must

be taken).

Installation into carrier (DIN 41 494 part 5)

VEGATOR 526 W Ex must be installed such that a

protection of min. IP 20 (acc. to IEC 144 (529)) is reached.

This is ensured with carrier type 596 Ex. It must be

furthermore observed that a min. distance of 50 mm is

kept between intrinsically and not-intrinsically safe circuits.

This can be realized by adding a separation (included in

"VEGA-module"). The requred air gaps and creeping

distances between the instruments in the carrier must be

maintained. Observe therefore EN 50 020, especially

schedule 2, modification 2. The following instructions are

valid with e.g. a voltage of 250 V AC, 50 Hz (corresponds

to a peak value of 375 V) in neighbouring instruments:

- Between the left carrier wall and VEGATOR 526 W Ex

a distance of 2 TE must be maintained.

- If a power supply unit VEGASTAB 592 or 593 is used,

observe the mounting instructions in the TIB of the

carrier.

- If VEGATOR 526 W Ex is mounted together with notEx-instruments or instruments of other manufacturers in

a carrier, a min. distance of 2 TE must be maintained to

these instruments.

- This min. distance is not required if the VEGAinstrument (10 TE width) on the left of VEGATOR 526

W Ex is provided with a black cover on its right side.

Installation into housing type 589 - 10 Ex

In case of installation of VEGATOR 526 W Ex into housing

type 589 - 10 Ex the distances between intrinsically and

not intrinsically safe circuits must be maintained.

General mounting and installation regulations

- The wiring between signal conditioning instrument and

sensor can be made with standard cable suitable and

marked for intrinsically safe circuits.

- Line resistance, max. permissible outer inductance and

capacitance, see technical data, page 7 and 9.

14

VEGATROL 20 Ex

Page 15

2 Technical Information

2.8 Connection examples for overvoltage arresters

Vessel without cathodic tank protection

Ex-area Not Ex-area

VEGATROL 20

System sensor

117/4 A Ex

or

115 A Ex

E86 Ex

External earth terminal

Overvoltage arrester

Type B 62 - 27 Ex 0-2

or B 62 - 27 Ex-2

Overvoltage arrester

Outer isolation

1

2

1

2

Line length

≤ 50 m

A1

B62-27

A2

A1

B62-27

A2

Screen

min. 4 mm2 Cu

Metal housing isolated or

plastic housing

E1

Typ

E2

E1

Typ

E2

Earth- / PAconnection terminal

Outer isolation

Screen

either

overvoltage arrester

E1

Typ

B62-27G

E2

Typ

E1

B62-27G

E2

intrinsically safe

A1

A2

A1

A2

circuit to signal

conditioning

instrument

VEGATOR

526 W Ex

d30

d32

Note:

- Suitable cable must be used, either with metal cover (or screen). If a

(control room)

to potential

equalization line

cable with metal cover or screen is used (as on above figure), a potential

equalization along the entire length of the intrinsically safe circuit is not

necessary. Screen or metal cover must only be connected to the

overvoltage arrester.

- The current load capacity of the screen must correspond at least to that

of a 1,5 mm

2

Cu-line.

Vessel with cathodic tank protection

Ex-area Not Ex-area

Overvoltage arrester

Type B 62 - 27 Ex 0 - 2

or B 62 - 27 Ex - 2

VEGATROL 20

System sensor

117/4 A Ex

or

115 A Ex

E86 Ex

External earth

terminal

1

2

1

2

Cathodic tank protection

2 … 24 V

(object voltage)

Outer isolation

Line length

≤ 50 m

Screen

min. 4 mm

(control room)

either

overvoltage arrester

E1

Typ

B62-27G

E2

Typ

E1

B62-27G

E2

intrinsically safe

A1

A2

A1

A2

circuit to signal

conditioning

instrument

d30

d32

Overvoltage arrester

A1

Typ

B62-27

A2

A1

Typ

B62-27

A2

2

Cu

Metal housing isolated or

plastic housing

E1

E2

E1

E2

Outer isolation

Screen

Earth- / PA

connection terminal

Note:

- Suitable cable must be used with metal cover (or screen). Screen or

metal cover must only be connected to the overvoltage arrester.

Screen or metal cover must not be earthed.

- The cable must have an outer isolation.

- The current load capacity of the screen must correspond at least to that

of a 1,5 mm

2

Cu-line.

VEGATOR

526 W Ex

VEGATROL 20 Ex

15

Page 16

3 Mounting and set-up

3 Mounting and set-up

3.1 Mounting

The tuning fork of system sensor VEGATROL 20 is within

the concentric tube. The length from the flange lower edge

to the end of the tuning fork is stated on the type plate

(corresponds to the dimension L2, page 10).

The switch point must be generally at 85 % of the vessel

volume.

The adaption to the respective vessel dimensions is

realized via dimensioning of the concentric tube.

Calculation help see supplement.

A sealing must be used between flange and system

sensor which is suitable for the use in liquid gas plants.

In case of installation lengths of the system sensor

exceeding 1,5 m the extension tube in the vessel must be

protected against bending (e.g. vibrations by fluctuating

product). If there is danger of mechanical damage, the

extension tube in the vessel must be protected against

bending.

The system sensor with cable electrode is supplied with

fixing insulator and fixing spring. The cable electrode must

be fixed via the fixing spring and the fixing insulator to the

bottom of the vessel (the spring is used to tighten the

cable electrode).

Pre-requirements for set-up

- the sensor VEGATROL is installed in its final position

and the tuning fork is not covered

- the failure LED is dark

The set-up is carried out by pushing the set-up key for

approx. 4 sec.

During set-up, VEGATOR is adapted to VEGASWING.

The actual resonance frequency is detected as current by

VEGATOR and stored as reference value.

Condition up to approx. 4 secs. after set-up:

Yellow LED lights

VEGATOR 526 W Ex

Green LED in set-up key lights

on

Green LED lights

Condition up from approx. 4 secs. after set-up:

The system sensor must be generally mounted vertically.

3.2 Set-up

After electrical connection of VEGASWING Ex to

VEGATOR 526 W Ex the overfill protection goes to

operating status.

Operating status before set-up:

Yellow LED lights

VEGATOR 526 W Ex

on

(= level relay de-energized)

Green LED in set-up key flashes

(= set-up not yet carried out)

Green LED lights

(= supply voltage in)

VEGATOR 526 W Ex

on

Green LED lights

Note:

- If the signal conditioning instrument VEGATOR

526 W Ex is exchanged by a new instrument of the

same type, the set-up must be repeated.

- The set-up of the continuous level measurement or

level detection is made acc. to the description in the TIB

of the signal conditioning instrument used.

16

VEGATROL 20 Ex

Page 17

4 Supplement

3.3 Operation

If in case of overfilling, the tuning fork is covered up to the

switch point with the liquid gas, the level relay de-energizes with a delay of approx. 500 msec. and the respective

LED lights.

This remains as long as the fork is covered.

If the level reduces below the switch point, the relay

energizes with a delay of approx. 1 sec. and the

respective LED extinguishes.

4 Supplement

4.1 Fault signals

There are two error classes concerning the condition of

the LED in the front panel:

- error during set-up

- error detected during the self-monitoring.

Level and fail safe relays de-energize in both cases.

In case of failures during set-up, start again (switch off the

voltage and switch on again) and repeat the set-up acc. to

section 3.2.

If an error is detected, the voltage must be switched off

first, the failure (e.g. line break) removed and then the

voltage switched on again. It is not necessary to repeat

the set-up.

Failure reason Failure treatment

External failure Remove the fault and

(line break, short-circuit, start again

fault SWING-electronic)

Set-up was carried out Start again and repeat

when tuning fork was set-up with uncovered

covered tuning fork

Set-up key was pushed Start again and repeat

too long (> 6 secs.) set-up correctly

Error during self-monitoring

lights

VEGATOR 526 W Ex

on

Failure reason Failure treatment

Line break, Remove failure and start

short-circuit again

Component failure Inform VEGA-service or

lights

return the instrument for

invertigation

Error during set-up

VEGATOR 526 W Ex

on

lights

lights for approx. 2 sec.

lights

VEGATROL 20 Ex

17

Page 18

4.2 Calculation information for sensor length

The determination of the sensor length must be generally made with the respective expert.

Example: cylindrical tank

3000 mm

L

Volume 85 %

corresponds to 2400 mm

0 mm

4 Supplement

600 mm distance from

flange lower edge to the

determined swicht point

Procedure

- calculate the level of the max. permissible volume

85 %, e.g. 2400 mm

- determine the distance from the flange lower edge up

to the calculated level

- determine the total length of VEGASWING

L = distance + 25 mm

(25 mm = submerging depth up to the switch point)

in this example

L = 600 m + 25 mm = 625 mm

A VEGASWING with a total length of 625 mm must be

ordered.

Note:

An increase of the total length of VEGASWING will cause

the instrument to respond even at low levels, a reduction

causes a response at higher levels.

If the required total length cannot be exactly determined,

the calculated value must be rounded up (determination to

the safe side).

18

VEGATROL 20 Ex

Page 19

4 Supplement

4.3 General instructions for the use of

overfill protections

Application of a liquid gas overfill protection (ÜFS) is to

monitor the level of the liquid gas stage and to interrupt

the filling procedure when the permitted level in the vessel

is reached and to trigger an acoustic or optic alarm.

The configuration as well as the operation of such an

overfill protection must always meet with the requirements

of an overfill protection as well as the special conditions of

the VdTÜV-regulation "overfill protection 100".

This furthermore requires that the filling of a pressurized

vessel for liquid gas is only possible if it is ensured that the

overfill protection works interferencefree and correctly. At

least before each filling procedure the whole measuring

system of the overfill protection must be checked.

Normally this test of overfill protections is triggered by a

manually triggered test key. In case of failure the filling

must be suppressed by a locking circuit.

Due to the self-monitoring, this test is not necessary with

VEGATROL.

The overfill protection always operates discontinuously

and can be planned and operated independent from the

function of the continuous level measurement. The

continuous level measurement is not subjected to the

special requirements to the functional reliability of the

overfill protection.

However both have to be included in an alarm system as

follows:

- the continuous measurement generates the pre-alarm

signal and controls an acoustic or optic warning system

or interrupts the filling procedure

- the overfill protection triggers a main alarm signal and

stops the system

Criteria for dimensioning:

- triggering pre-alarm, e.g. at 83 % to filling (dependent

on the vessel geometry)

- triggering main alarm, generally at 85 % filling

- tolerance of the switch point of the overfill protection:

± 1 %

The pre-alarm is adjusted such that there is sufficient time

to avoid response of the overfill protection.

VEGATROL 20 Ex

19

Page 20

VEGA Grieshaber KG

Electronic level measurement

Am Hohenstein 113

Postfach 11 42

D-77757 Schiltach/Schwarzwald

Phone 0 78 36 / 50 - 0

Fax 0 78 36 / 50 201

Technical data subject to alterations 2.17 749 / Sept. '94

Loading...

Loading...